Patents

Literature

62results about How to "Achieve feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

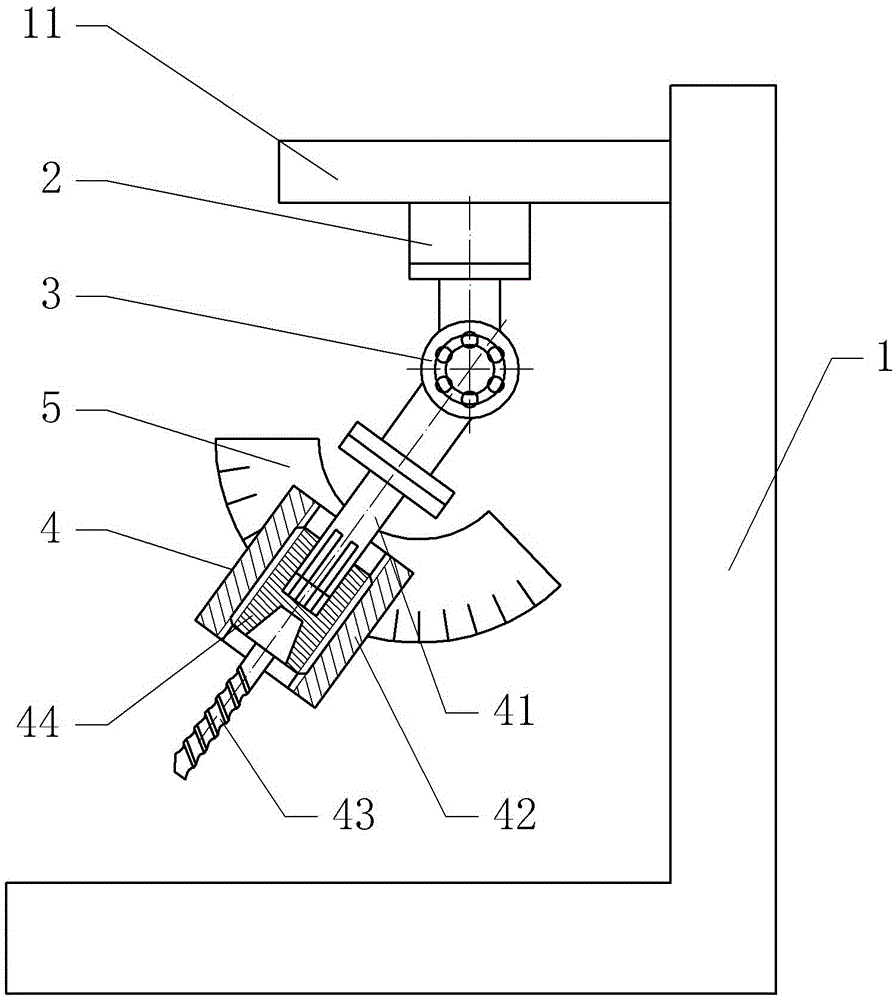

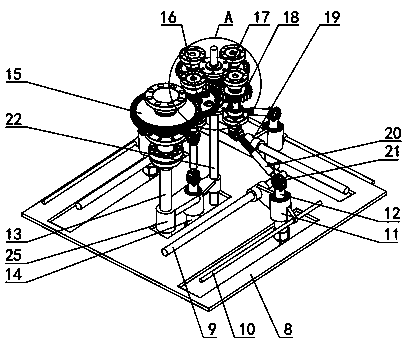

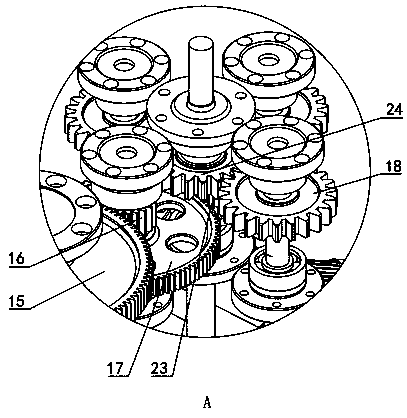

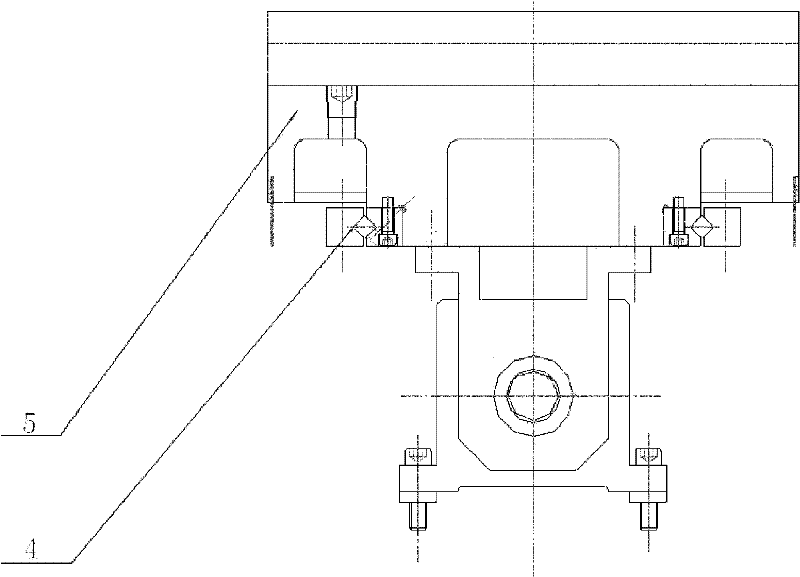

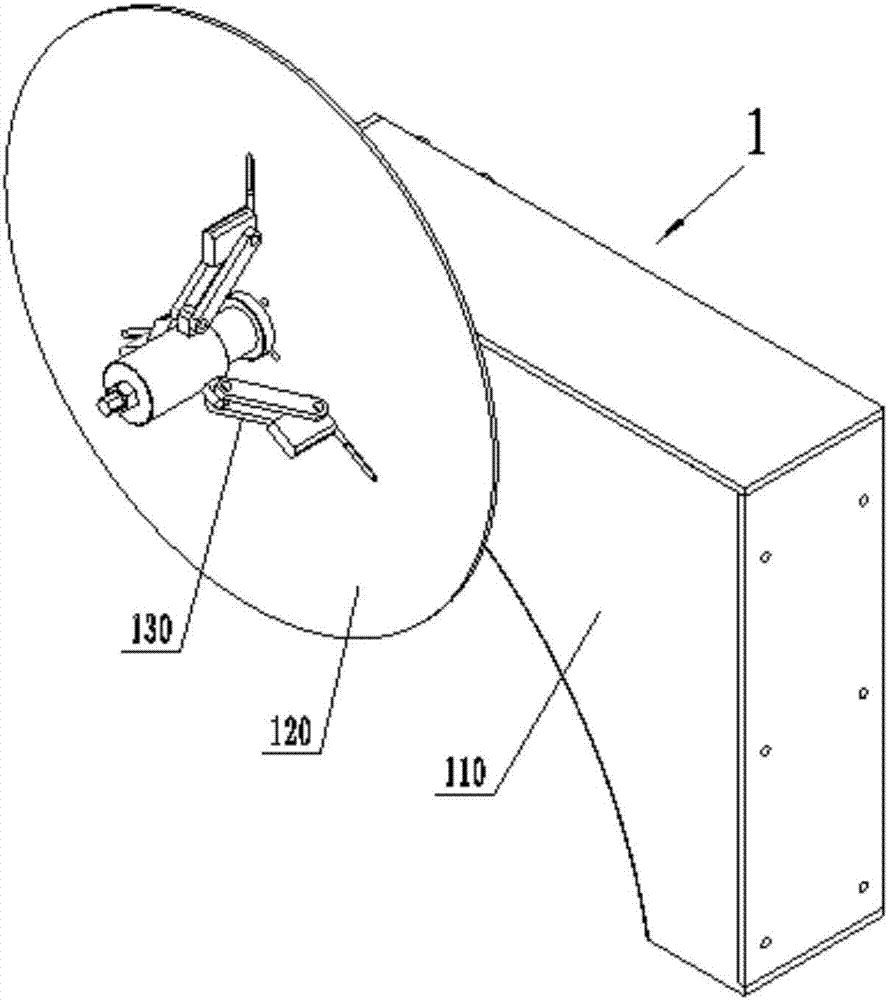

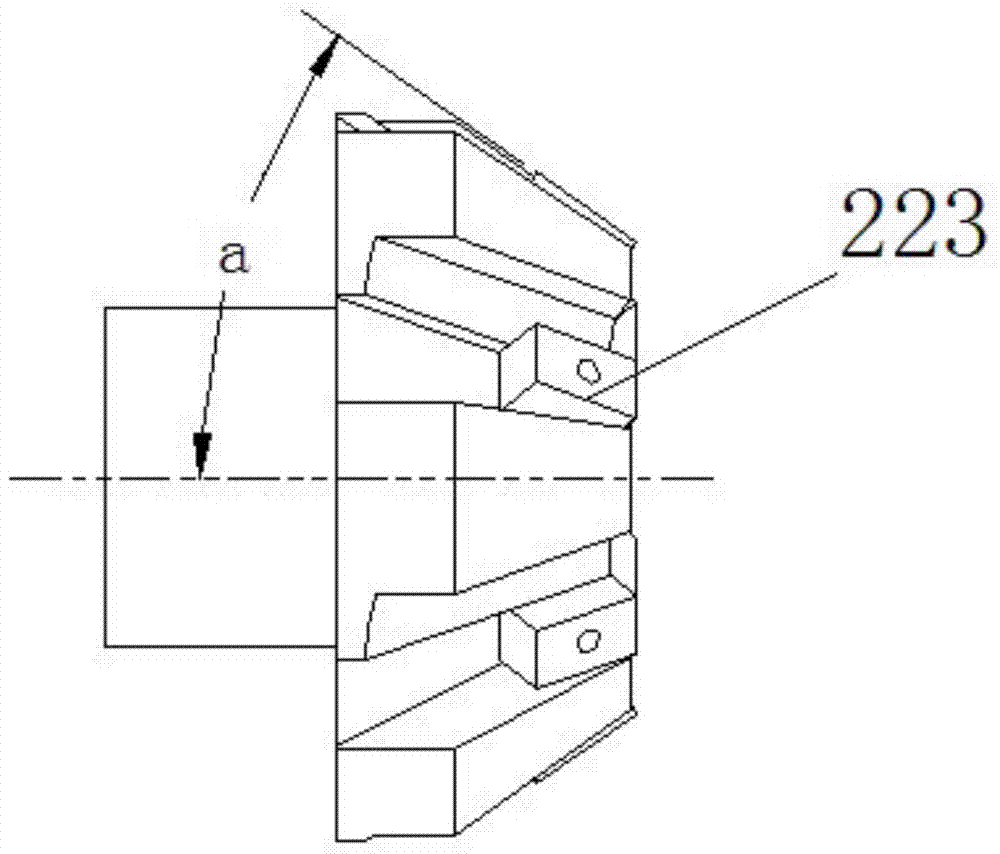

Drilling machine with variable-angle drill bit

InactiveCN105458321AAchieve rotationAchieve feedFeeding apparatusDriving apparatusDrive shaftUniversal joint

The invention discloses a drilling machine with a variable-angle drill bit and relates to a drilling device. The drilling machine with the variable-angle drill bit comprises a rack, a rotary seat, a drive portion and a drilling portion. The rotary seat is rotationally connected to the rack. The drilling portion comprises a transmission shaft, a sleeve, a feeding block and the drill bit. The sleeve is rotationally connected to the rack. An internal thread is arranged in the sleeve. An external thread is arranged on the feeding block. The feeding block is arranged in the sleeve and matched with the sleeve in a threaded manner. One end of the feeding block is provided with an internal spline. The drill bit is fixedly connected to the other end of the feeding block. The angle of the drill bit can be changed by rotating the sleeve. One end of the transmission shaft is connected with the spline in sliding fit with the feeding block. The transmission shaft is connected with the rotary seat through a universal joint so that variable-angle power transmission can be achieved. A fastening screw is arranged between the sleeve and the rack so that the sleeve can be fastened to the rack.

Owner:徐州致诚会计服务有限公司

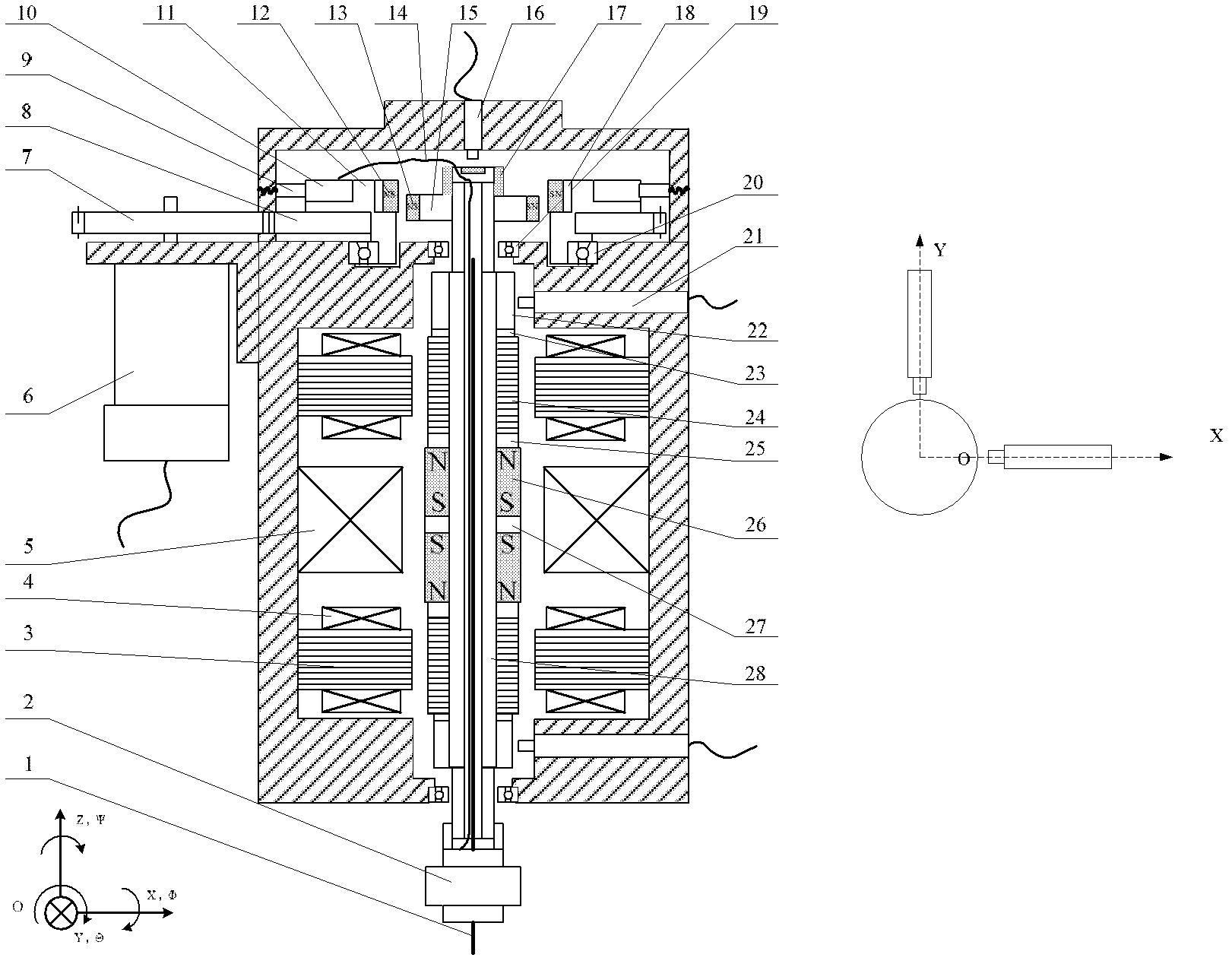

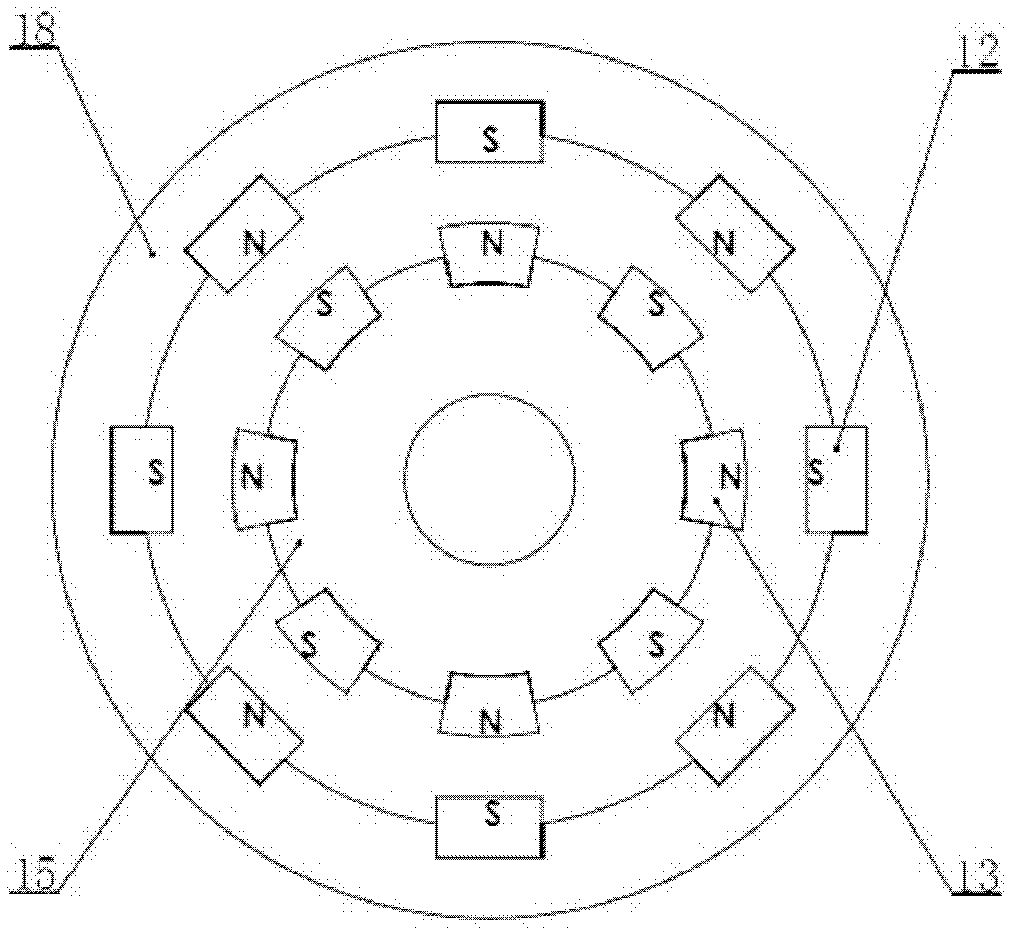

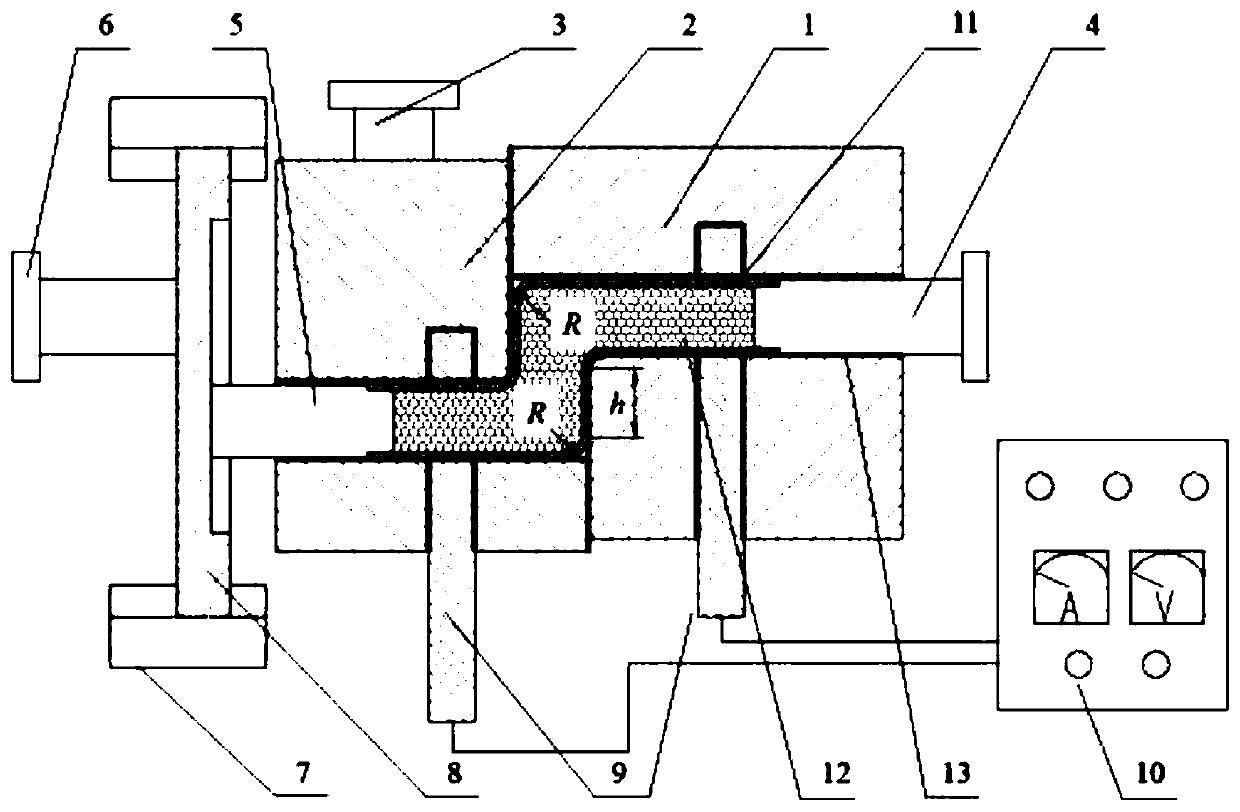

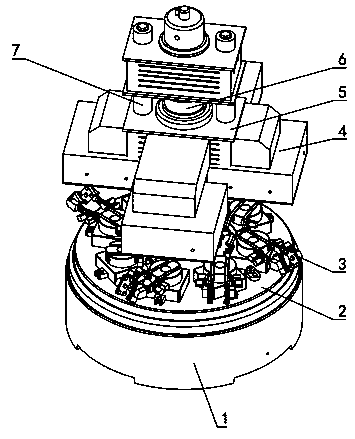

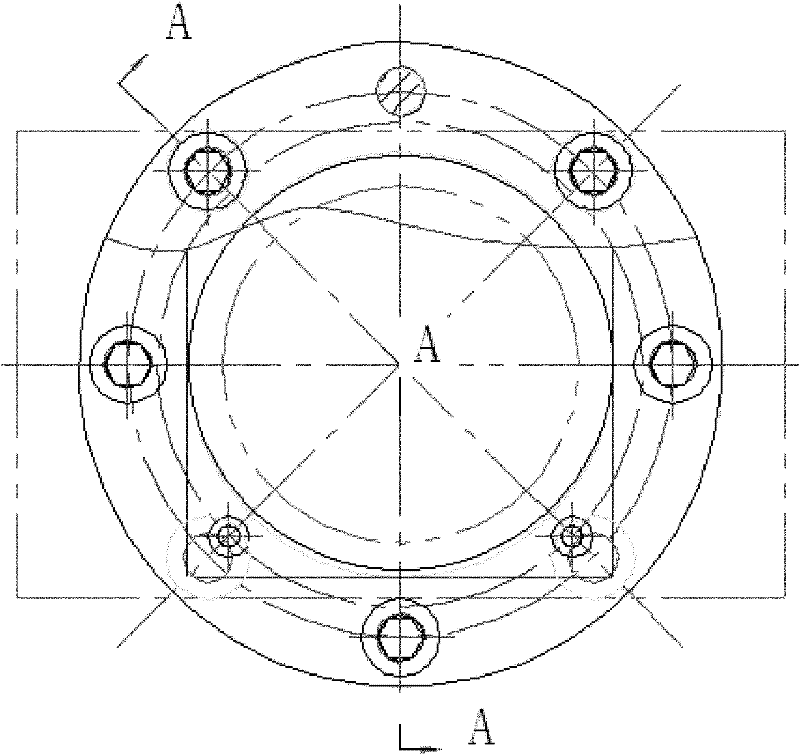

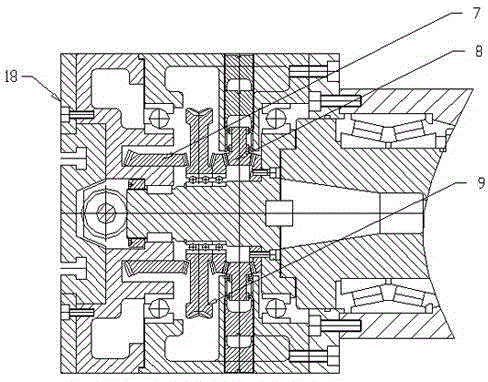

Spindle device for processing micro-hole electric spark based on magnetic levitation servo drive

ActiveCN102601473AIncrease servo tracking speedEasy to adjustMagnetic holding devicesElectrical-based auxillary apparatusBall bearingCoupling

The invention relates to a spindle device for processing a micro-hole electric spark based on a magnetic levitation servo drive. A magnetic coupling inner rotor is fixedly connected with an upper part of a hollow mandrel; a rotor end cover is arranged on the hollow mandrel at an upper part of the magnetic coupling inner rotor; a flexible lead enters in a cavity of the hollow mandrel through the rotor end cover; an inner rotor permanent magnet is arranged on the magnetic coupling inner rotor; a radical eddy current displacement sensor is fixed inside an upper shell; a lower end of an insulatedturntable is arranged on the upper shell at an inner side of an angular contact ball bearing; a magnetic coupling outer rotor is fixed on an upper part of the insulated turntable; and an outer rotor permanent magnet is fixed on the magnetic coupling outer rotor. According to the invention, the spindle device provided by the invention is helpful for discharging an electrolytic corrosion product intime and improving discharge condition of a discharge gap; and is helpful for improving the quality and efficiency of electric spark micro-hole processing. The spindle device can realize processing of micro-straight holes, taper holes and stepped holes of hole diameters phi ranging from 100mum to 300mum according to different processing requirements.

Owner:HARBIN INST OF TECH

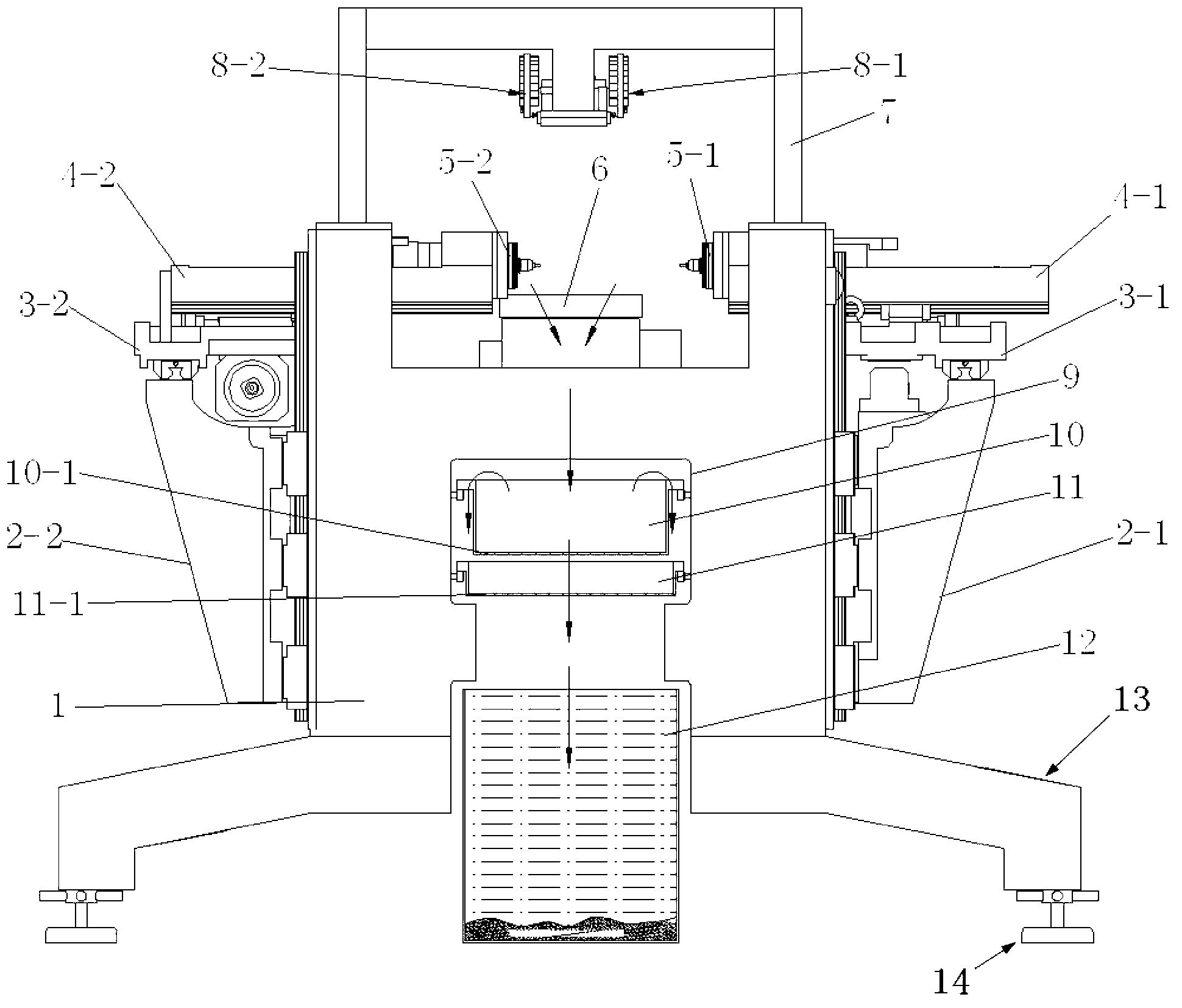

Automatic abrasive wheel cutting machine

InactiveCN101797712AAchieve feedRealize automatic cuttingGrinding machinesGrinding/polishing safety devicesHydraulic cylinderEngineering

The invention discloses an automatic abrasive wheel cutting machine. In the technical scheme, one end of a beam is connected with a working table through a fixed hinge pair, the other end of the beam is provided with an abrasive wheel shaft assembly and an abrasive wheel, a motor is fixed on the end of the beam connected with the working table through the fixed hinge pair and drives the abrasive wheel to rotate, the middle part of the beam is connected with a hydraulic cylinder or a pneumatic cylinder through a fixed hinge, and a throttle valve used for regulating a feeding speed is arranged at the outlet of the hydraulic cylinder or the pneumatic cylinder through a hose. Since the hydraulic cylinder or the pneumatic cylinder is used as the kinetic damping of the abrasive wheel, the uniform and automatic cutting can be realized. A cooling pump is arranged on a water tank, and part cooling and dedusting can be realized through the cooling pump and spray of a water pipe. During cutting, the abrasive wheel can move downwards under the effect of gravity, and the cutting speed can be regulated through adjusting the opening of the throttle valve. After cutting, the beam can be lifted to reset the abrasive wheel, thereby completing the cutting. The invention has the advantages of simple structure, energy conservation, economical and practical use, low pollution and controllable cutting speed, and can realize the automatic cutting of different metal parts.

Owner:HEBEI AGRICULTURAL UNIV.

Novel self-chip-removal machine tool

InactiveCN104889445ASmooth chip removalFast Chip EvacuationFeeding apparatusDriving apparatusEngineeringCam

The invention provides a novel self-chip-removal machine tool. The cutting efficiency is effectively improved through vibrating drilling, and the novel self-chip-removal machine tool is smooth in chip removal and high in chip removal speed. A guide rod is arranged on the machine frame. An upper supporting plate is connected to the periphery of the guide rod in a vertical sliding and sleeving mode. The two ends of each spring are fixedly connected to the upper supporting plate and a machine frame respectively. A first drive device is arranged on the machine frame. A cam mechanism comprises a cam and a driven rod. The cam is connected to the periphery of an output shaft of the first drive device in a sleeving mode and is driven by the first drive device to rotate. One end of the driven rod is arranged on the upper supporting plate, and the other end of the driven rod abuts against the cam. A second drive device is arranged on the upper supporting plate and can drive a lower supporting plate to move in the axial direction of the guide rod. A third drive device is arranged on the lower supporting plate and can drive a drilling assembly to rotate. A drill stem is connected with an output shaft of the third drive device. A drill bit is arranged on the side, away from the third drive device, of the drill stem. The novel self-chip-removal machine tool is used for arranging a clamping piece on the machine frame, wherein the clamping piece is used for clamping workpieces.

Owner:蚌埠市金林数控机床制造有限公司

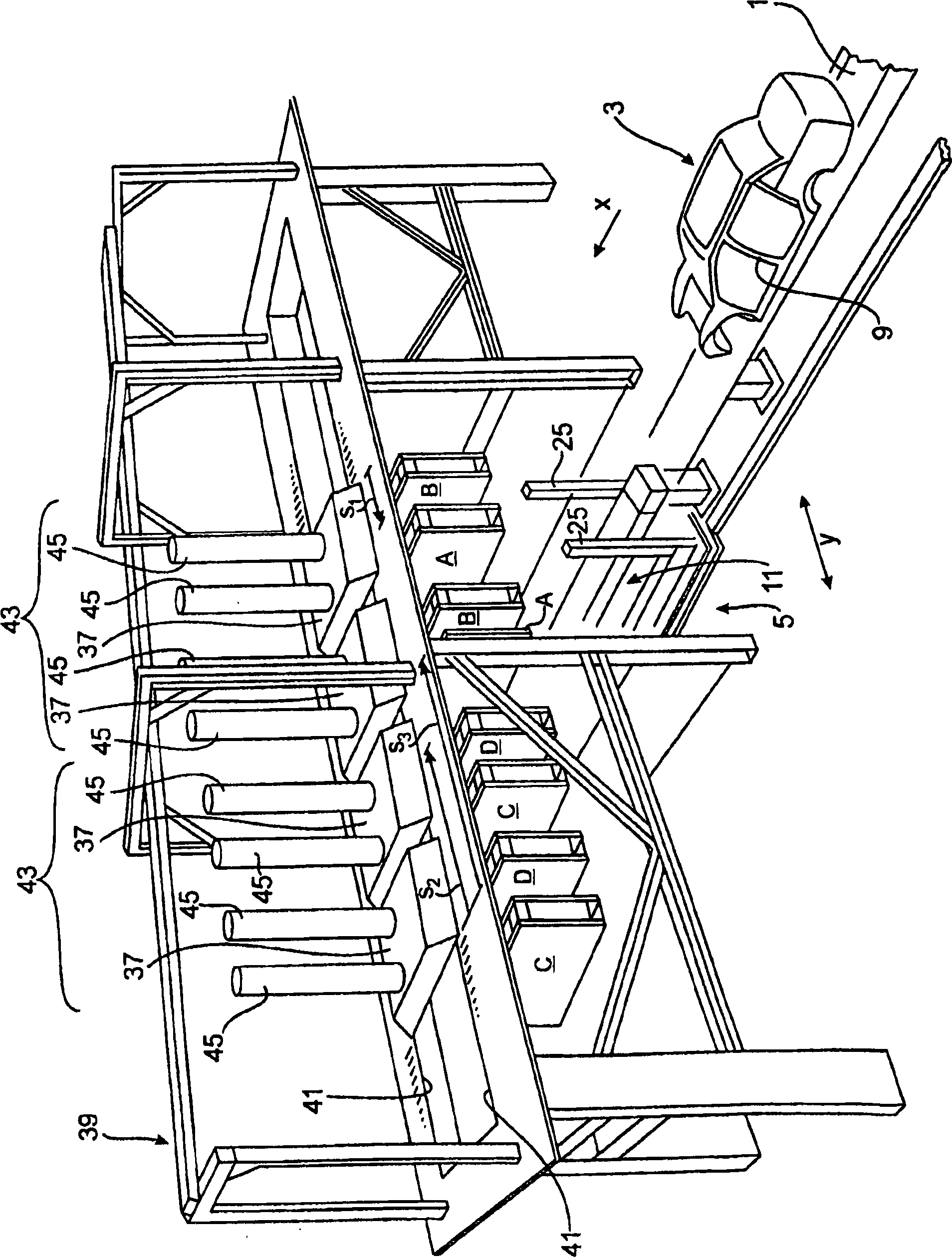

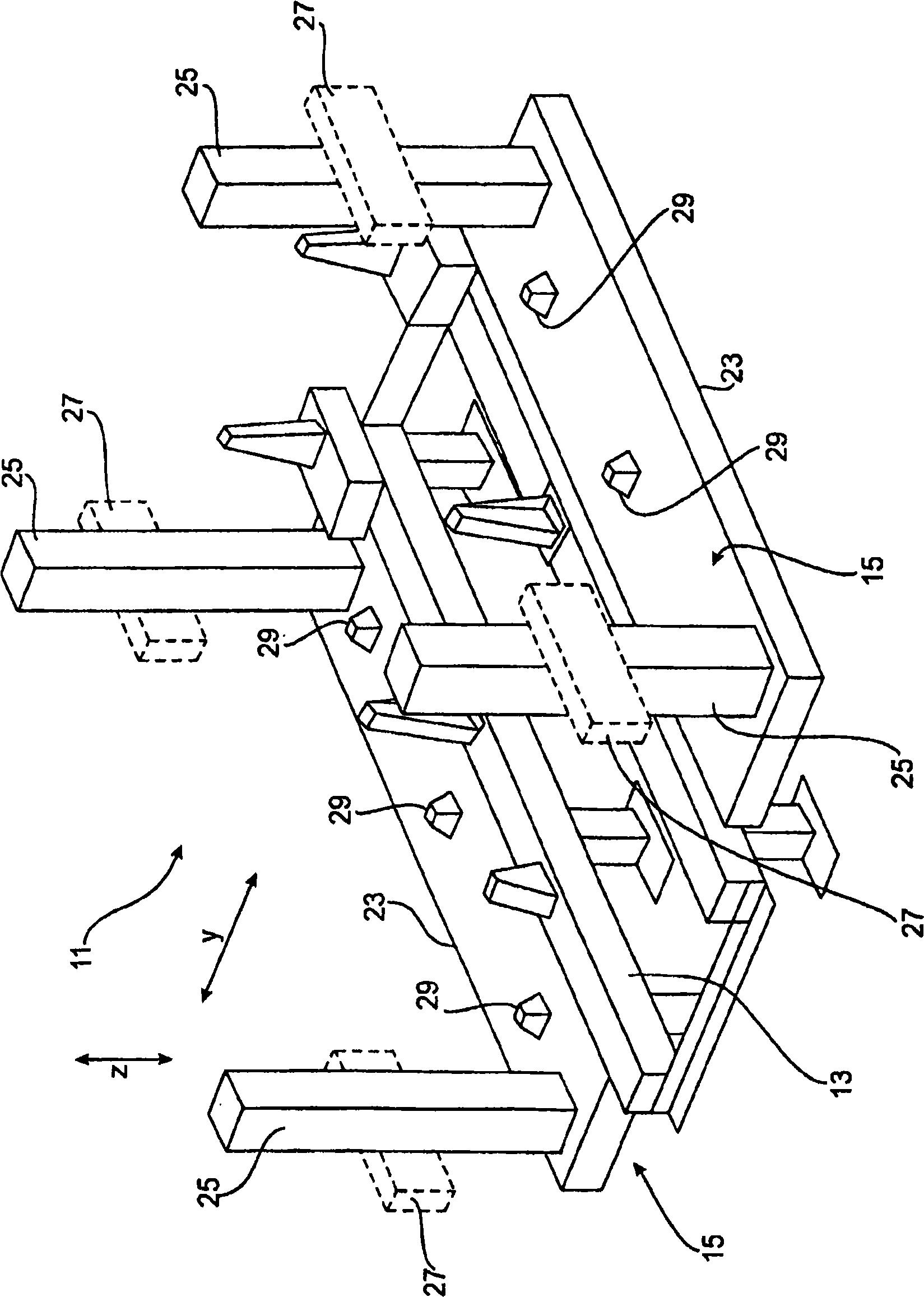

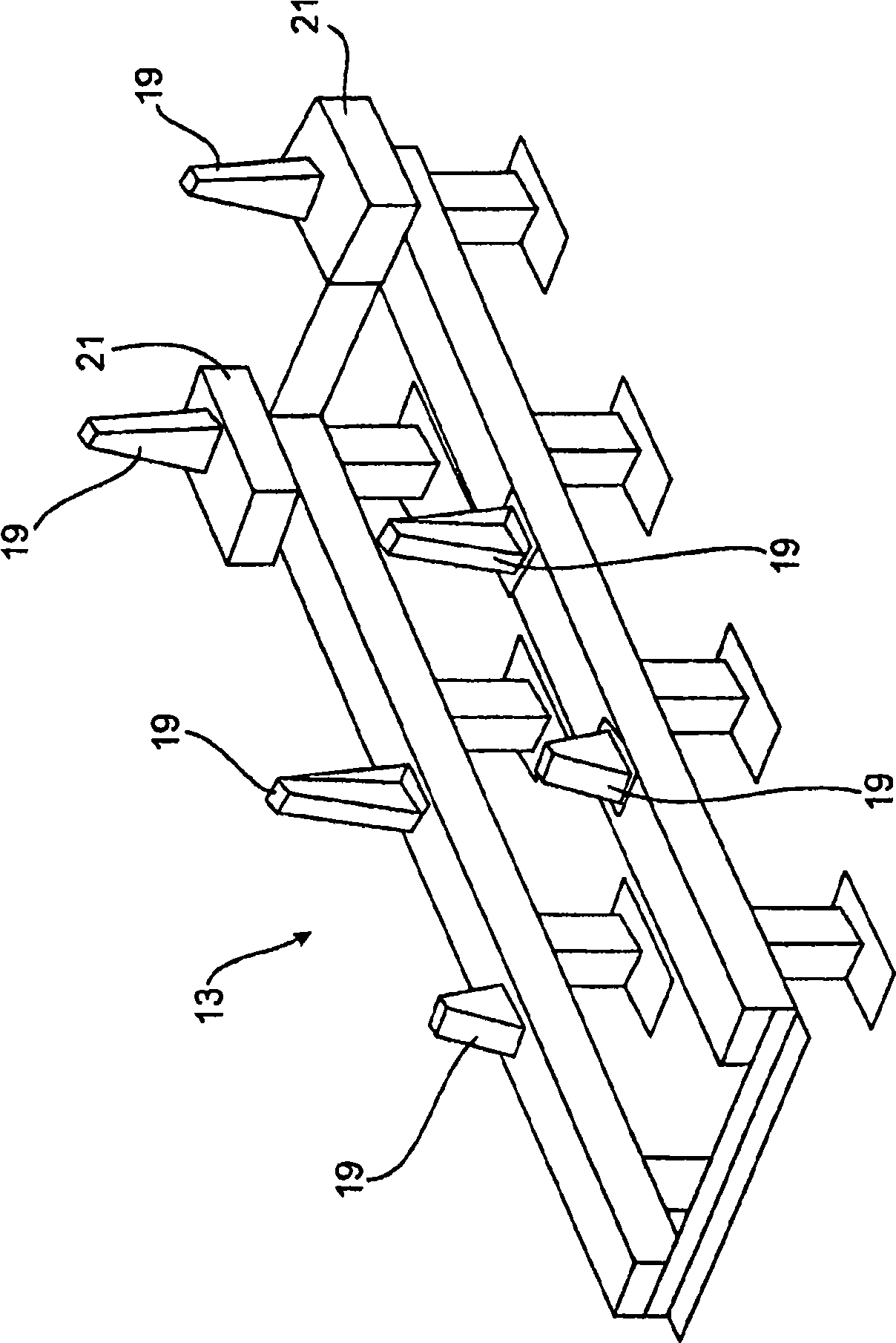

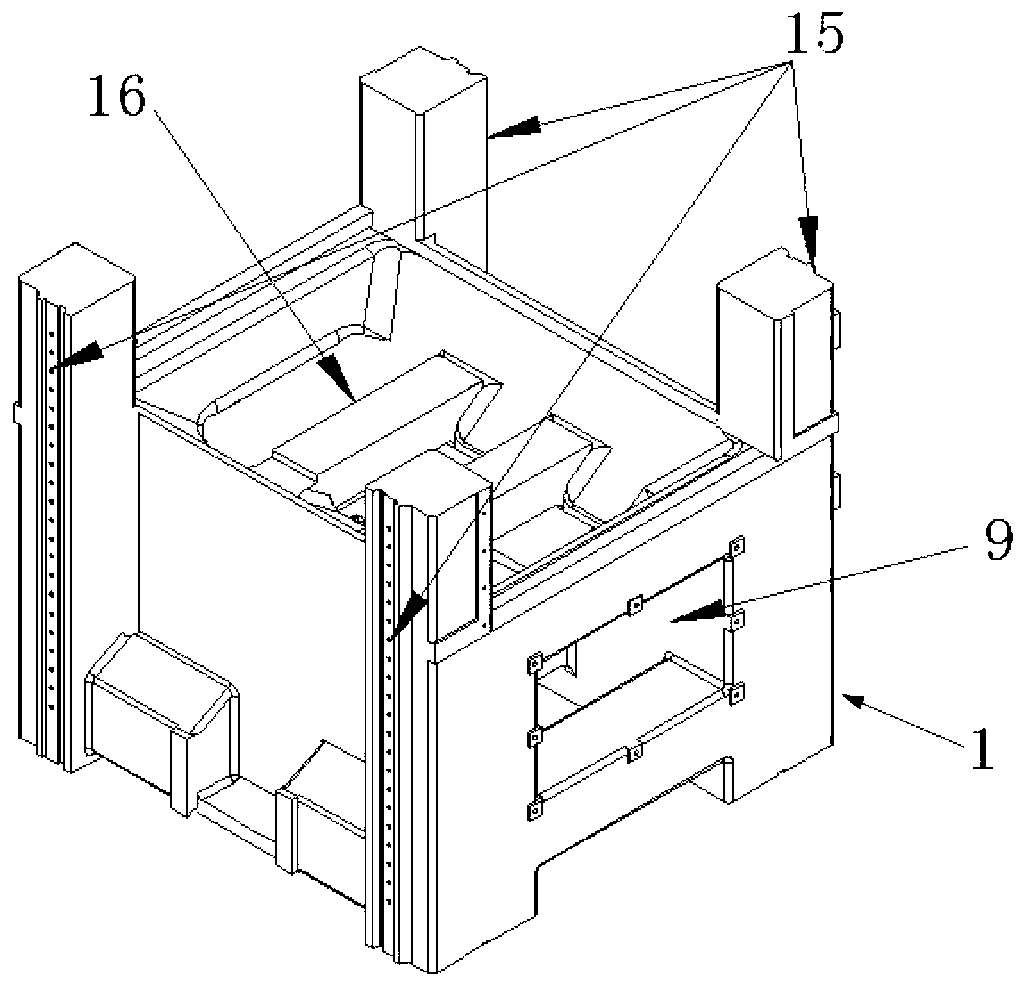

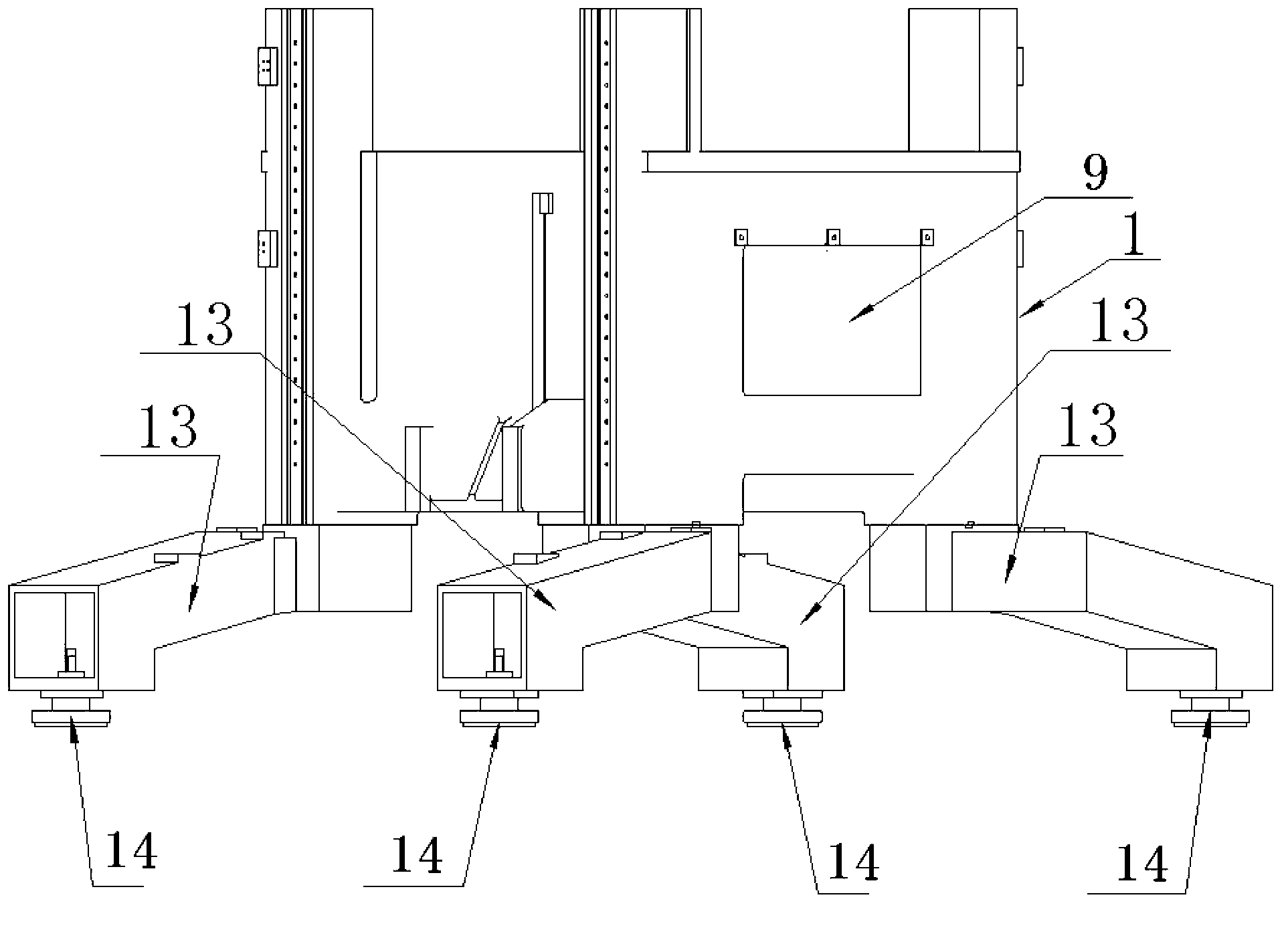

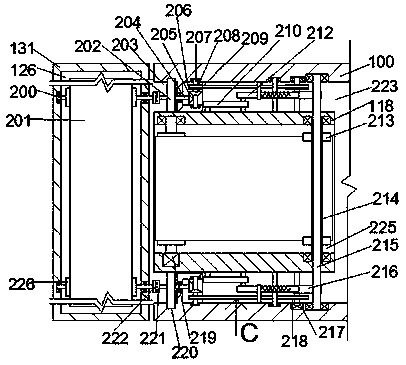

Work station for joining body parts of a motor vehicle, assembly line comprising such a work station, and method for delivering/replacing clamping frames in a work station

The invention relates to a work station of an assembly line for joining body parts (3, 9) of a motor vehicle, especially for joining at least one lateral part (9) to a body structure (3, 51). Said work station has a clamping frame storage area (39) used to provide clamping frames (A, B, C, D) and comprising at least one carriage (37) for moving at least one clamping frame (A, B, C, D) in the clamping frame storage area (39), and a lifting device (35) for moving the clamping frames (A, B, C, D) between the clamping frame storage area (39) and the work station (5). According to the invention, the carriage (37) and the lifting device (35) form a movably-coupled structural unit (47) containing the clamping frames (A, B, C, D).

Owner:AUDI AG

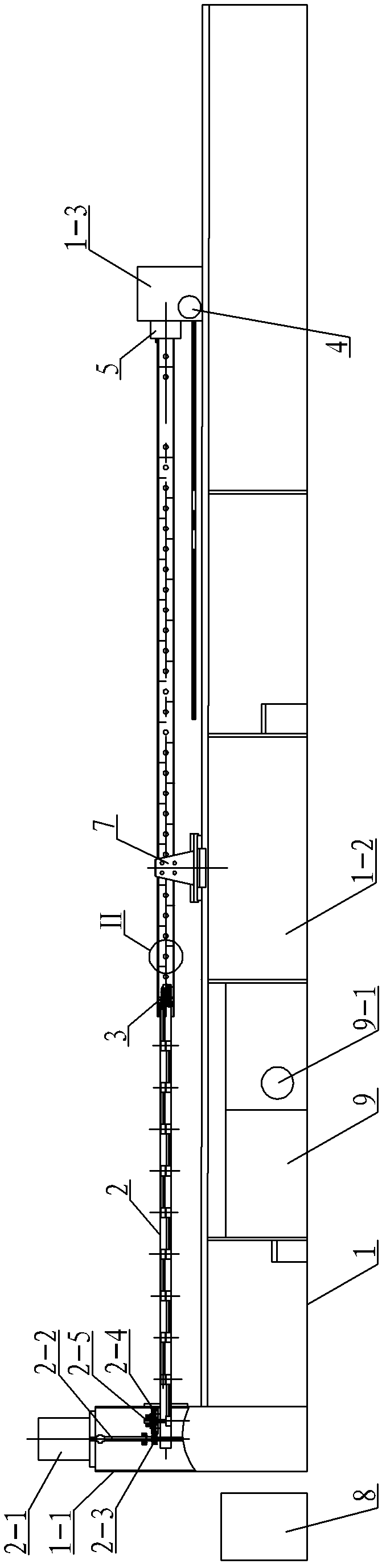

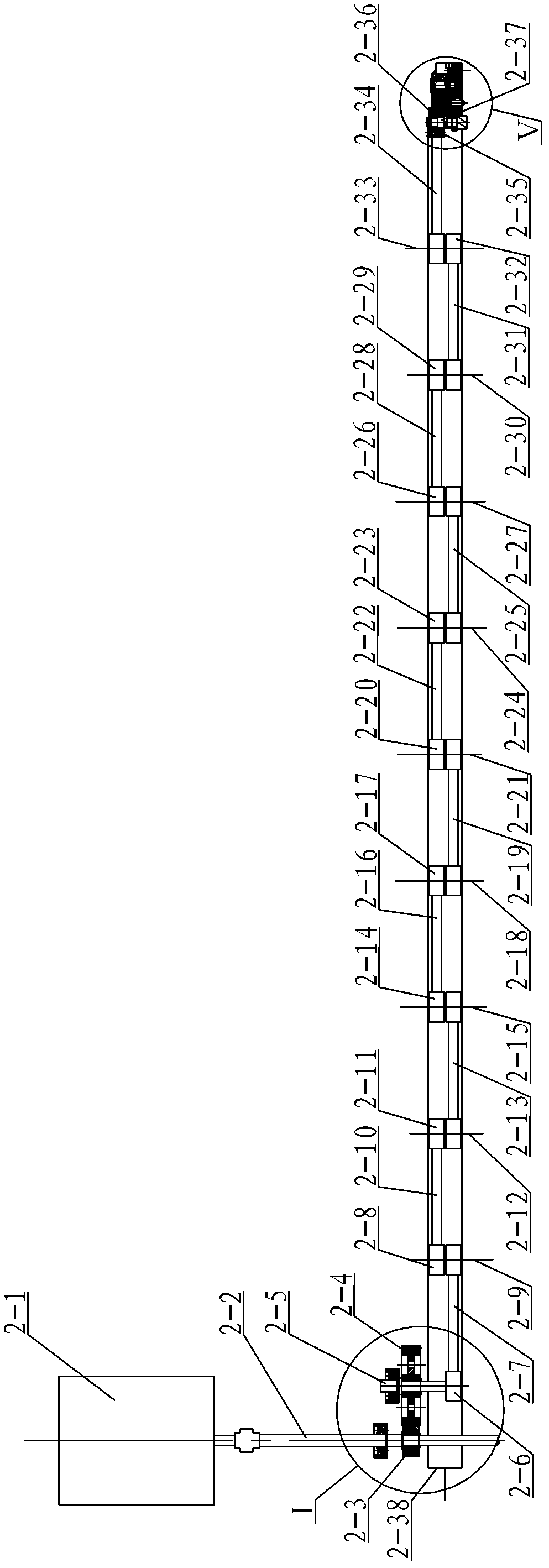

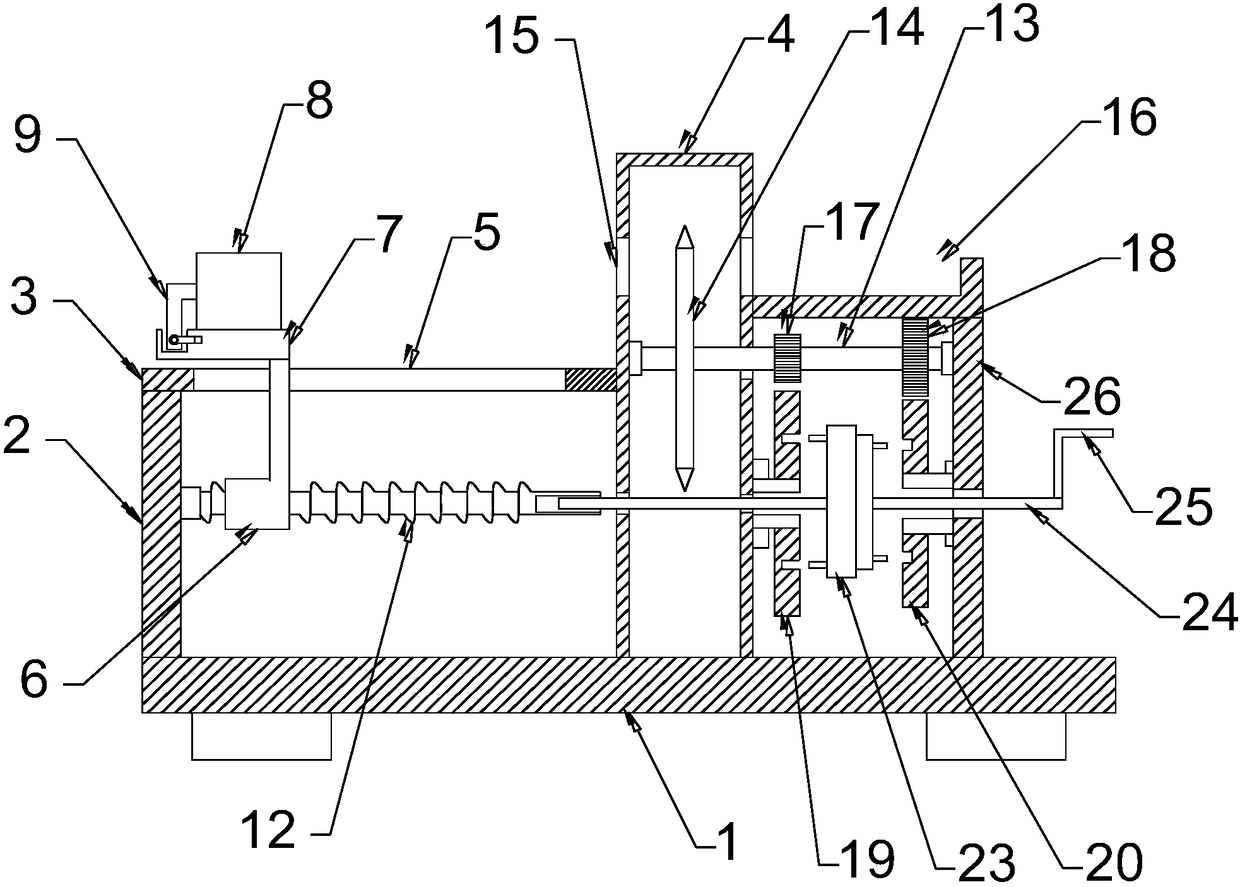

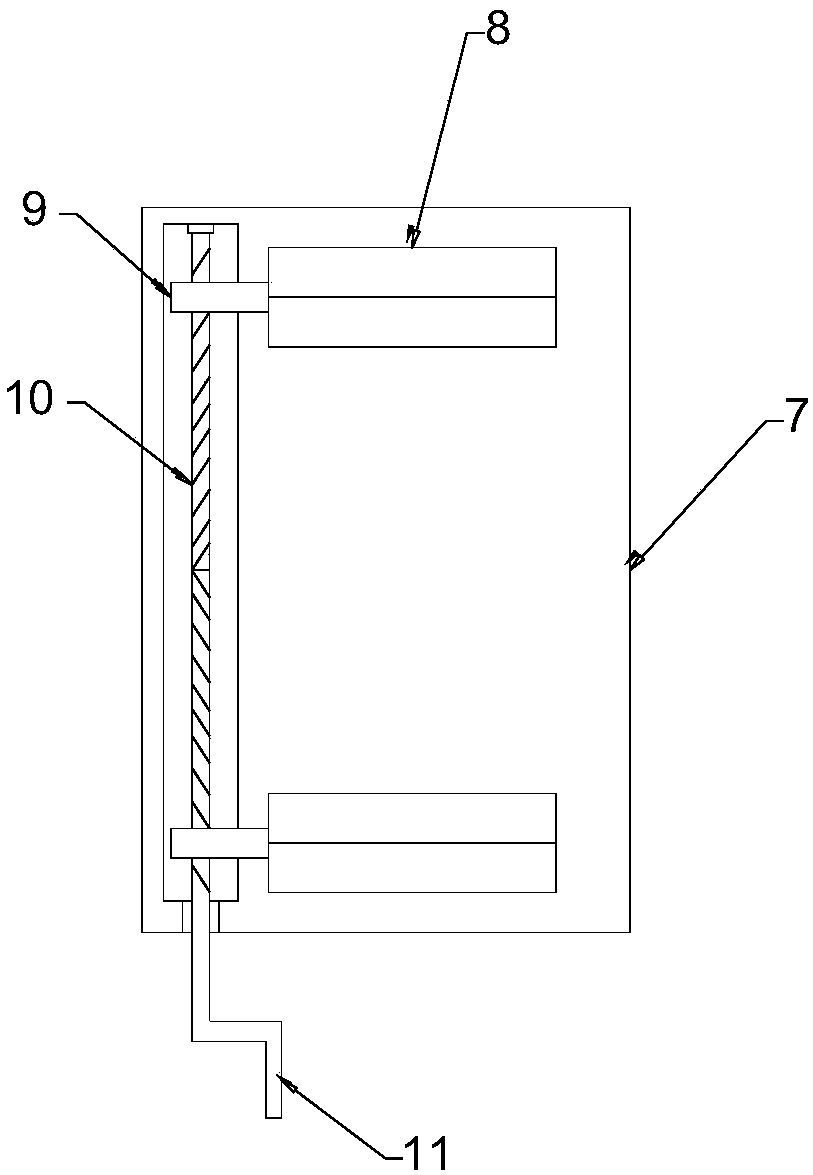

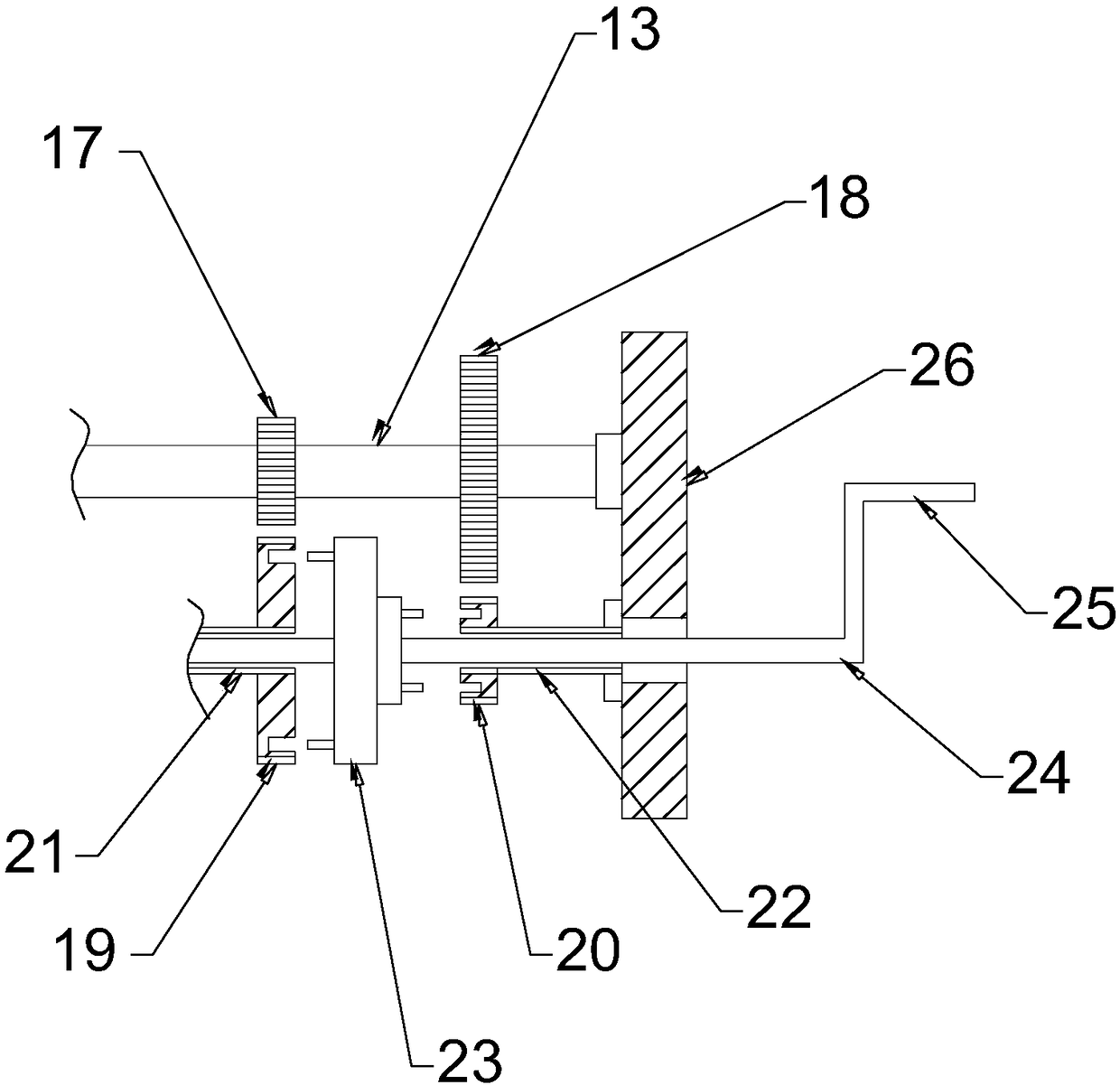

Numerical-control drilling machine for machining inner blind hole of oil-production perforation gun tube body

ActiveCN102248197AFully burstAchieve positioningPrecision positioning equipmentChucksNumerical controlGear wheel

The invention relates to a drilling machine for machining inner blind holes and in particular relates to a numerical-control drilling machine for machining an inner blind hole of an oil-production perforation gun tube body, and the drilling machine provided by the invention is used for solving the problem in the prior art fails that the inner blind hole of a perforation gun tube with a small inside diameter can not be directly machined. The rotation of a drill bit which is arranged on a cutter head mechanism is achieved by the transmission of a chain which is driven by a drive motor which is arranged on a chain transmission mechanism. The longitudinal feeding operation is achieved by the engagement of a feeding gear and a toothed rack which are driven by a feeding motor which is arranged on a longitudinal feeding mechanism through a feeding worm and a feeding worm wheel. The division of a chuck is achieved by the transmission of a division worm wheel and a division worm which are driven by a division motor which is arranged on a chuck division mechanism. The clamping of the chuck is achieved by driving a chuck clamping sleeve on a chuck clamping mechanism through a chuck clamping motor which is arranged on the chuck clamping mechanism. A numerical control device controls the transmission motor, the feeding motor, the division motor, the chuck clamping motor and a hydraulic control motor which is arranged on a hydraulic control system respectively. An oil inlet is connected with an oil supply pipe which is arranged on the hydraulic control system through an oil pipe. The numerical-control drilling machine provided by the invention is applied to machining the inner blind holes.

Owner:哈尔滨市东方刃具厂有限公司

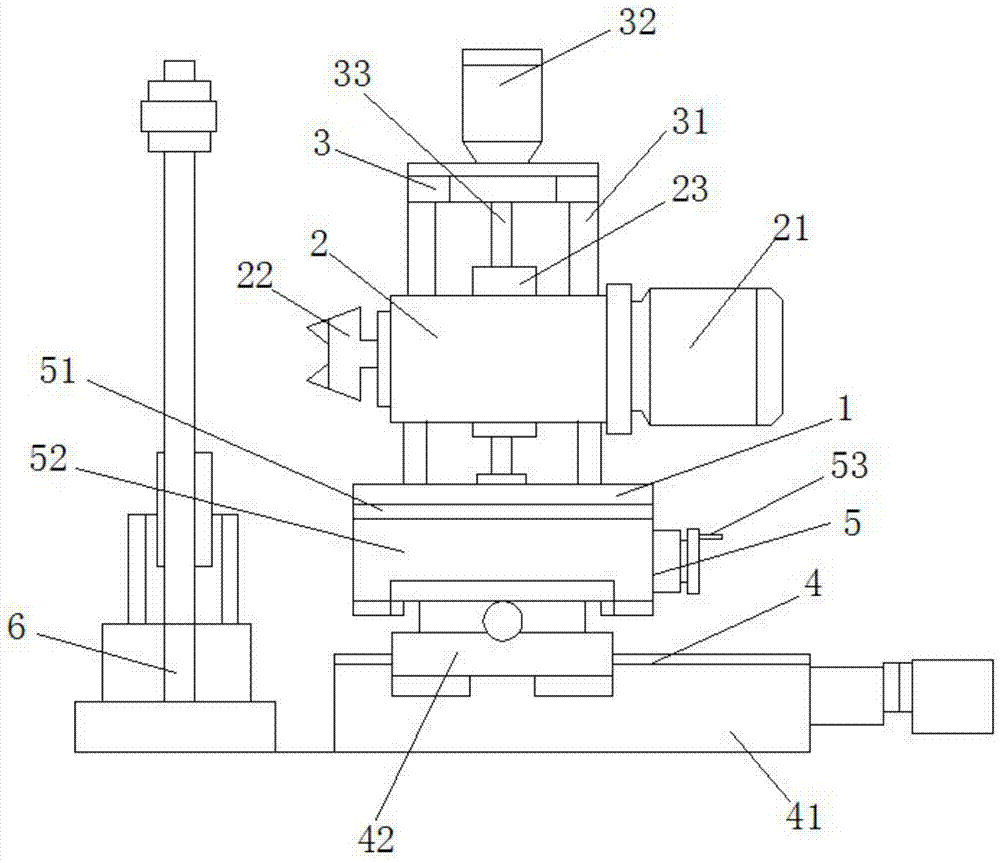

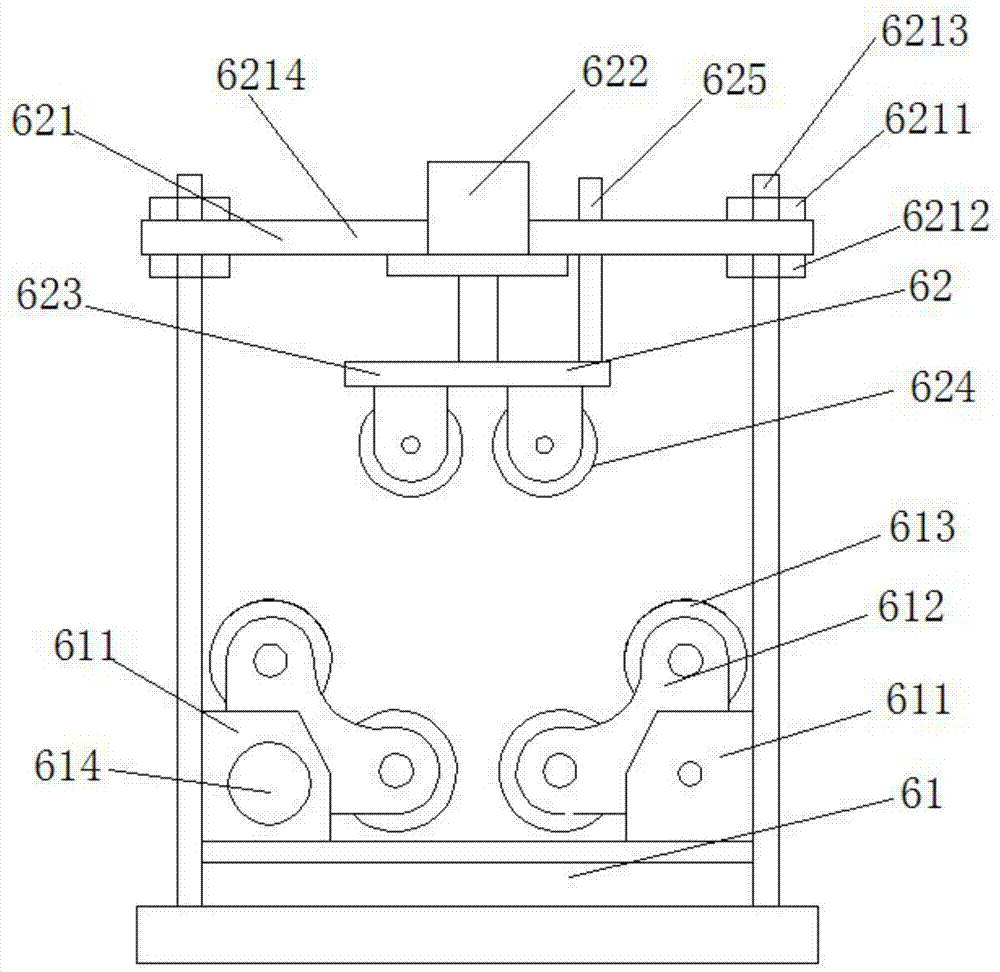

Bar material drill

InactiveCN104439394AAchieve feedAvoid breakingFeeding apparatusPositioning apparatusEngineeringDrilling machines

The invention provides a bar material drill and adopts the technical scheme that the bar material drill comprises a drilling mechanism, a propelling mechanism for pushing the drilling mechanism to advance, a support mechanism for supporting a bar material, and a positioning device for positioning the bar material, wherein the drilling mechanism comprises a motor I, a reduction gearbox and a drill bit, the reduction gearbox is in transmission connection with the motor I, the drill bit is fixedly connected with the output end of the reduction gearbox, the positioning device is positioned at one end of the drill bit, and the drilling mechanism can be pushed by the propelling mechanism to move towards the positioning device. The bar material drill has the benefits that the motor I is fixedly mounted on the reduction gearbox, so that the drilling mechanism can move forwards and backwards without affecting the transmission of the motor; besides, a screw is driven by the motor to push the drilling mechanism to advance, the feeding of the drill bit is realized, the drilling depth is effectively controlled, deviating phenomena cannot occur in the feeding process, drill bit breaking problems are effectively avoided, the structure is simple, and the operation is convenient.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

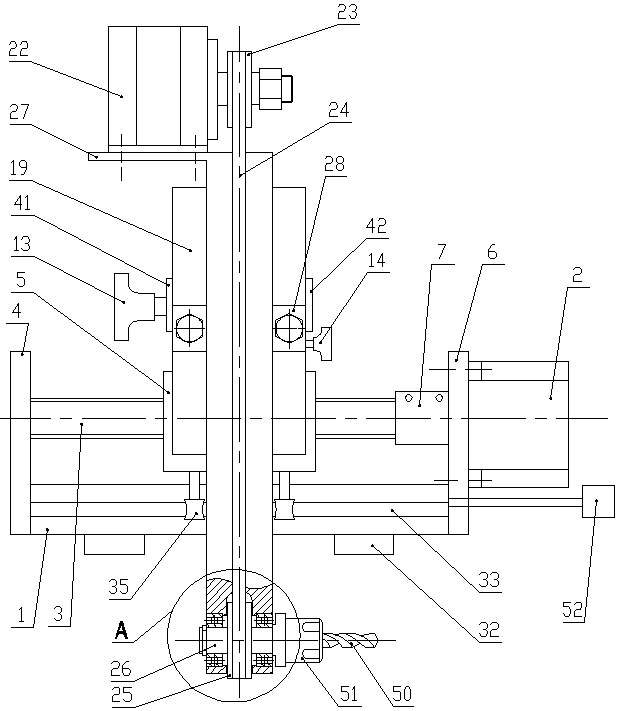

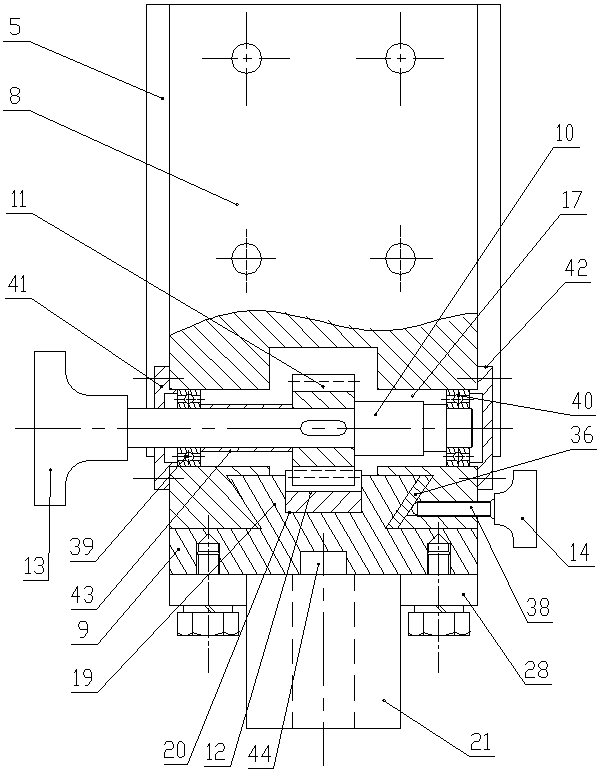

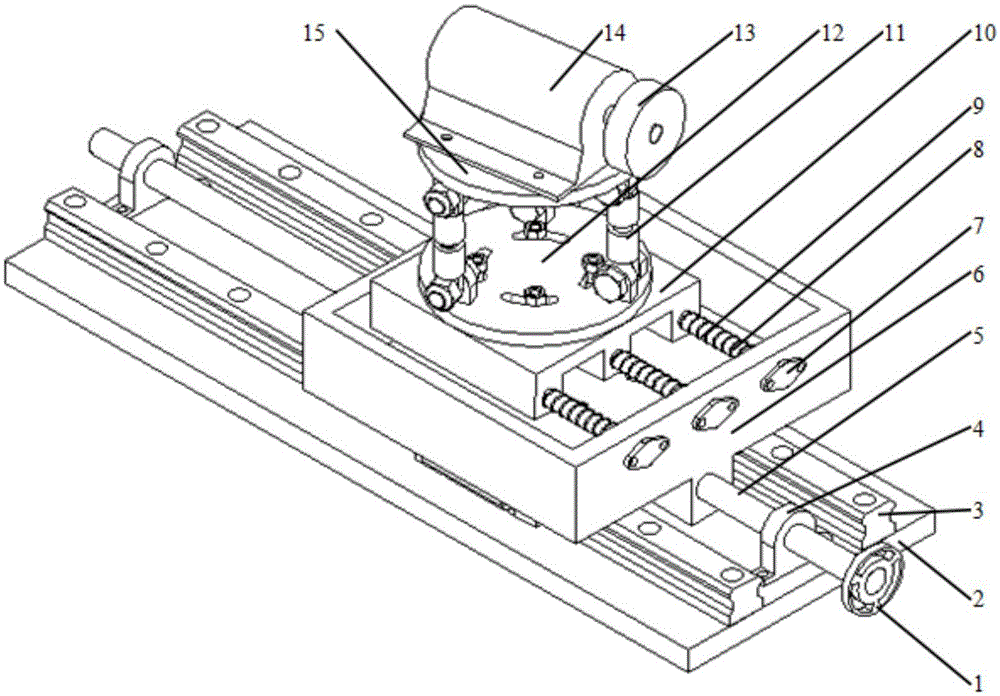

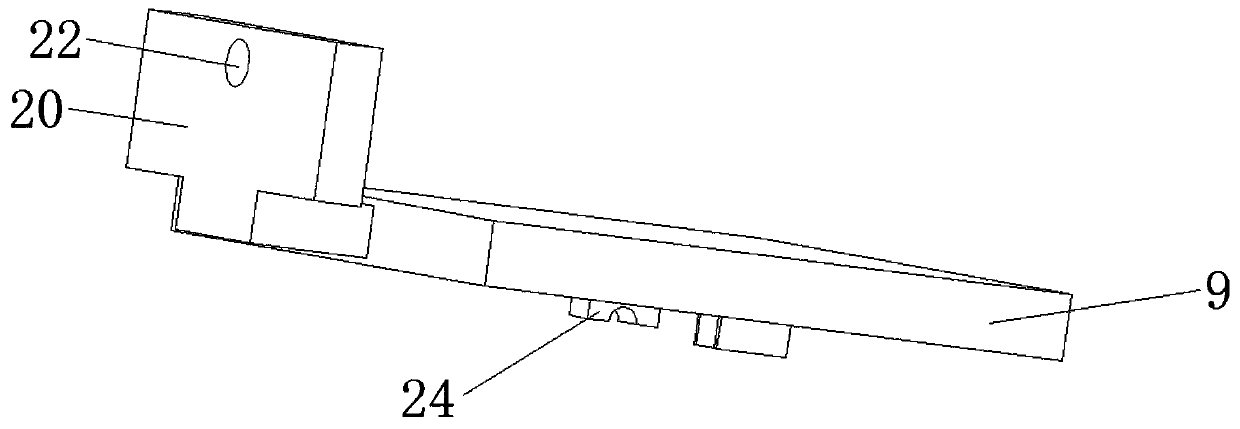

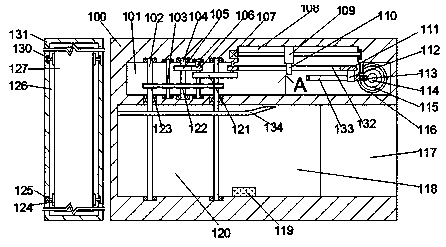

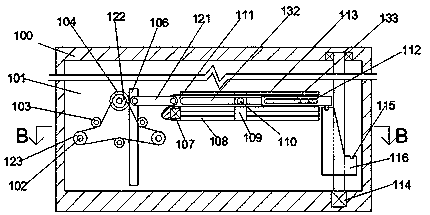

Portable inner cavity micro-hole drilling machining device

ActiveCN107900413ARelieve pressureGuaranteed straightnessPositioning apparatusMetal-working holdersBall screwDrive shaft

The invention discloses a portable inner cavity micro-hole drilling machining device. The device comprises a fixing base, a feeding mechanism, a lifting mechanism, a cutter transmission mechanism anda detachable cutter structure; the fixing base is horizontally arranged; the feeding mechanism comprises a first motor, a ball screw and nut pair, a nut seat, a bearing block and a flange plate; the lifting mechanism comprises a sliding table base, a sliding table, a lifting transmission shaft, a gear, a rack, an adjusting handle and a locking assembly; a dovetail groove is formed in the front endsurface of a sliding groove part in the upward direction; a dovetail table is arranged on the rear end surface of the sliding table and is arranged in the dovetail groove; the cutter transmission mechanism comprises a connecting rod, a second motor, a driving pulley, a belt, a driven pulley and a main shaft; the driving pulley is in transmission connection with an output shaft of the second motor; the driven pulley is in transmission connection with the main shaft; and the detachable cutter structure is arranged on a cutter mounting section of the main shaft. The device has the advantages ofbeing capable of solving the problems of the machining difficulty and the machining cost effectively, high in machining precision, convenient to operate, small in size, easy to carry and the like.

Owner:HENAN POLYTECHNIC UNIV

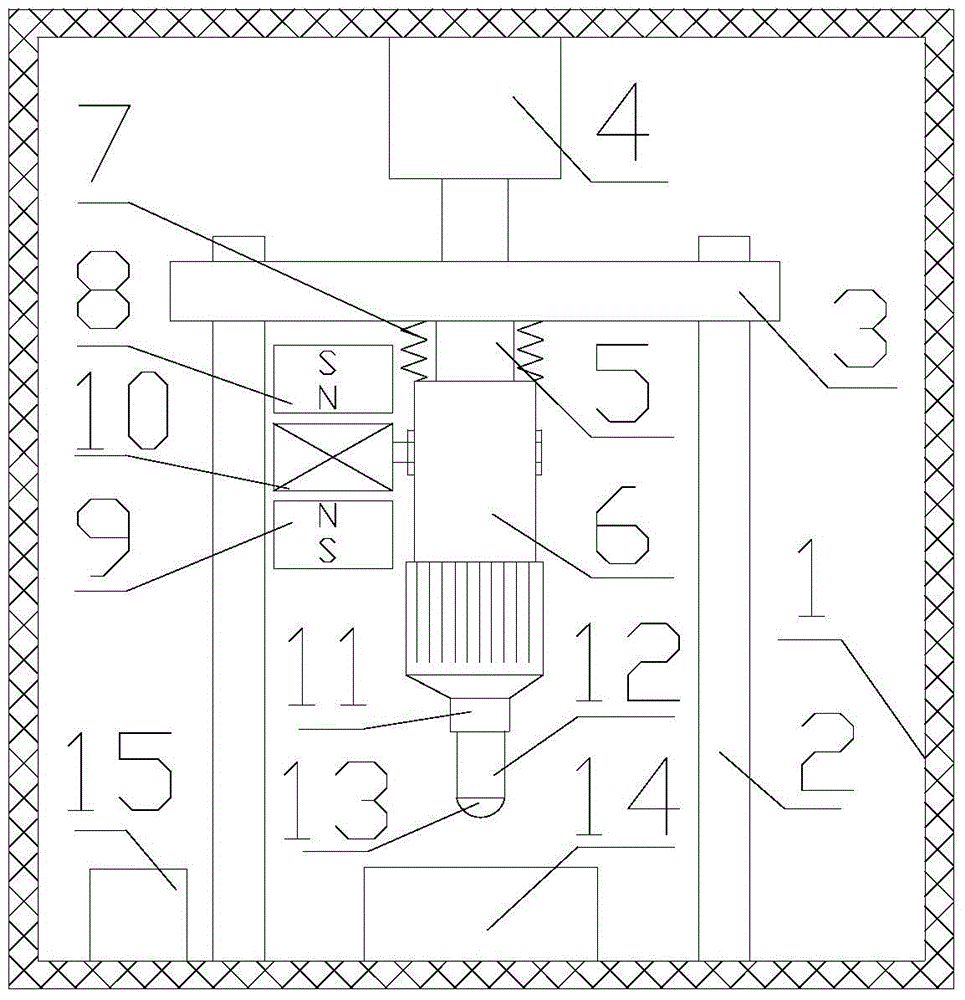

Machine tool capable of removing chip quickly

InactiveCN104907597AFast Chip EvacuationSmooth chip removalFeeding apparatusMetal working apparatusMagnetic polesEngineering

The invention provides a machine tool capable of removing chip quickly. A guide rod is arranged in a rack. A support board is connected to the periphery of the guide rod in a sleeving mode. A first drive device is arranged on the rack. An output shaft of the first driving device is connected with the support board. A suspender is arranged on the support board. A sliding rod is arranged on the periphery of the suspender in a sliding mode and is connected with the support rod through a spring. A second permanent magnet is located under a first permanent magnet. The like poles of the first permanent magnet and the second permanent magnet are opposite. An electric magnet with magnetic poles vary alternately is arranged at the periphery of the sliding rod through a clamping nut and is located between the first permanent magnet and the second permanent magnet. A second driving device is arranged on the sliding rod. The second driving device can drive a drilling component to rotate. The drilling component comprises a drill rod and a drill bit. A clamping element used for clamping a workpiece is arranged on the rack and is located under the drilling component. The drilling component comprises the drill head and the drill bit. According to the machine tool capable of removing the chip quickly has the advantages that chip removing is smooth, chip removing is fast, and processing is stable.

Owner:蚌埠市金林数控机床制造有限公司

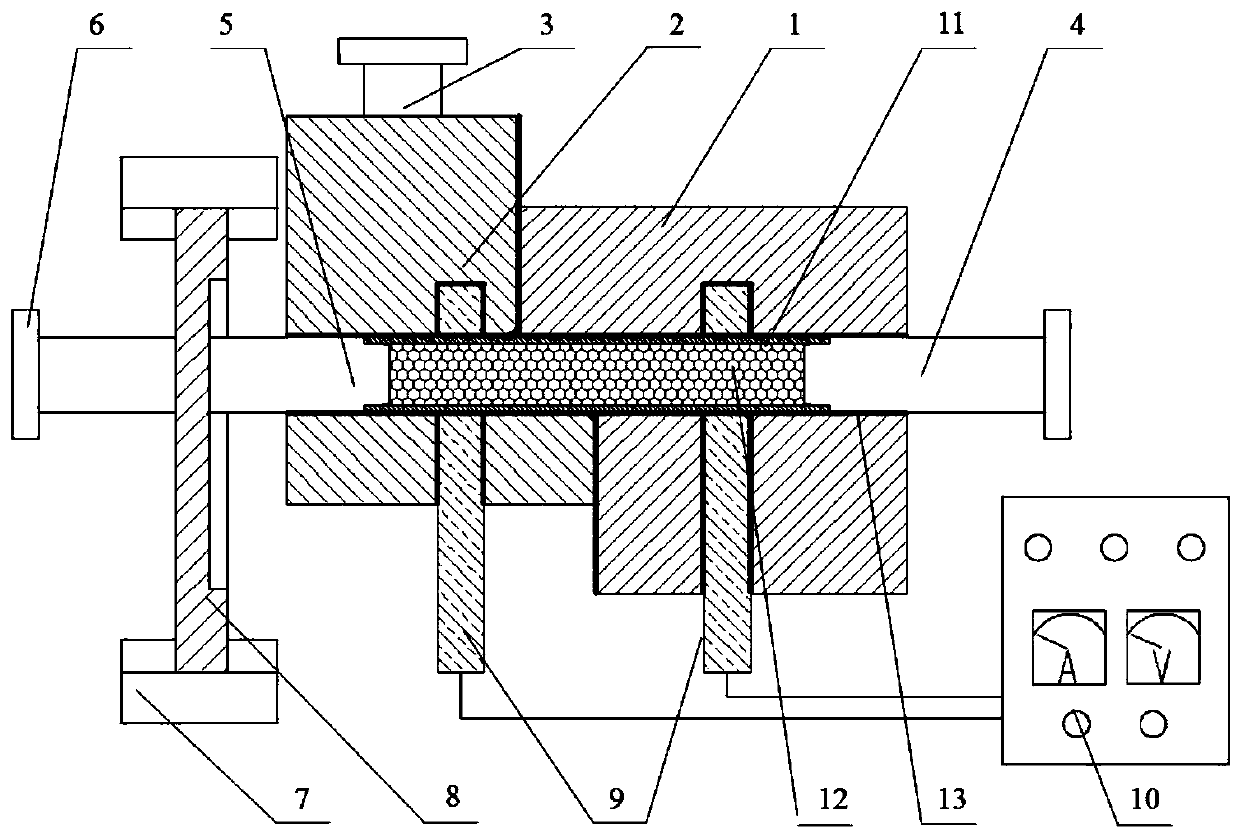

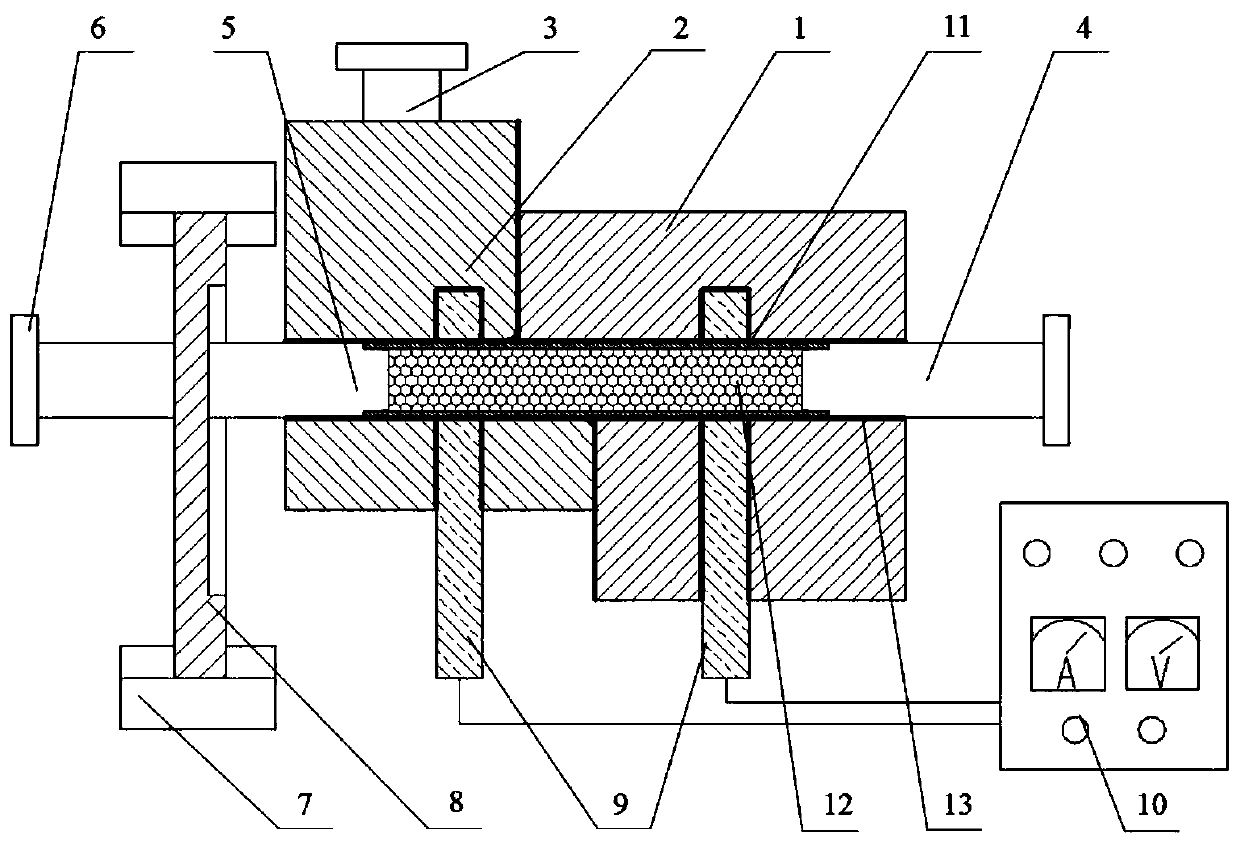

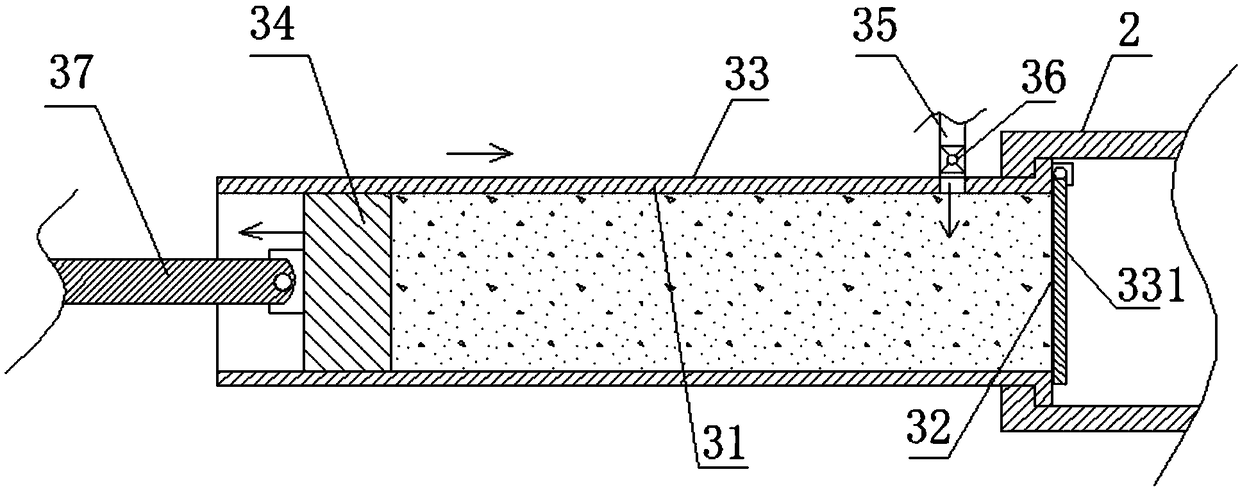

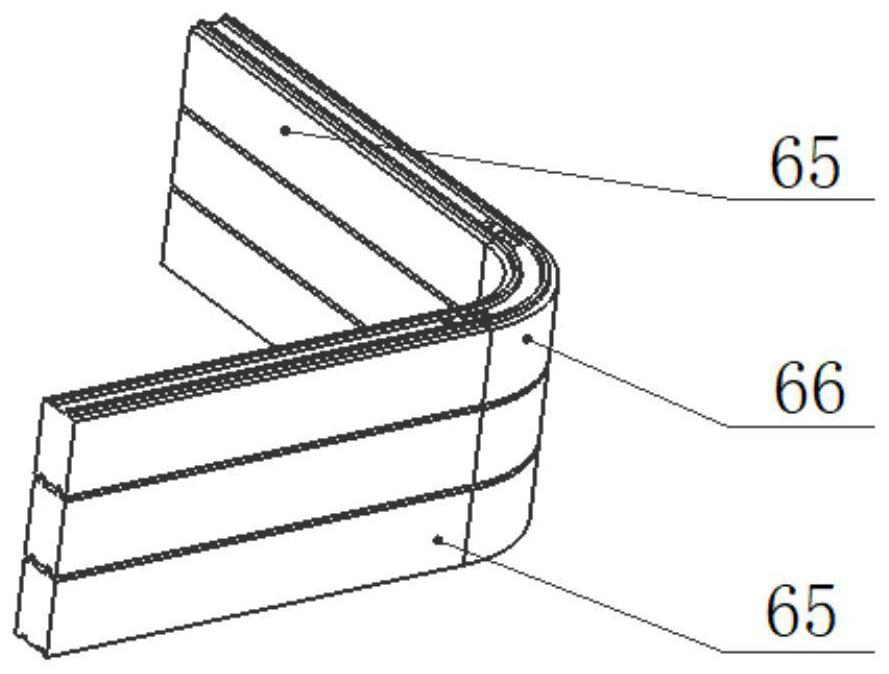

Bending forming method for small bending radius tube

ActiveCN110064689ASolve the problem of low forming limitRaise the forming limitPower flowSolid particle

The invention discloses a bending forming method for a small bending radius tube. The method comprises the following steps that S1, a tube blank is filled with a solid particle medium; S2, the tube blank is put into a forming die and sealed; S3, current is applied to the tube blank, and electrifying is stopped after the temperature of the tube blank reaches an experiment required temperature; S4,the right end of the tube blank is driven to move inwards in the axial direction, the left side of the tube blank is driven to move in a tangential direction, shear-bending deformation of the tube blank occurs, and the left end of the tube blank is driven to move inwards in the axial direction; S5, when the forming size of the tube blank reaches a set value, feeding is stopped, and a formed tube is obtained; and S6, a punch is reset, the forming die is opened, the formed tube is taken out, the solid particle medium in the tube blank is removed, and the small bending radius tube is obtained. The problem of low forming limit in existing tube bending forming technologies at normal temperature can be solved, and the obtained formed tube has the characteristics such as small bending radius, high forming precision and excellent shaping performance.

Owner:HARBIN INST OF TECH

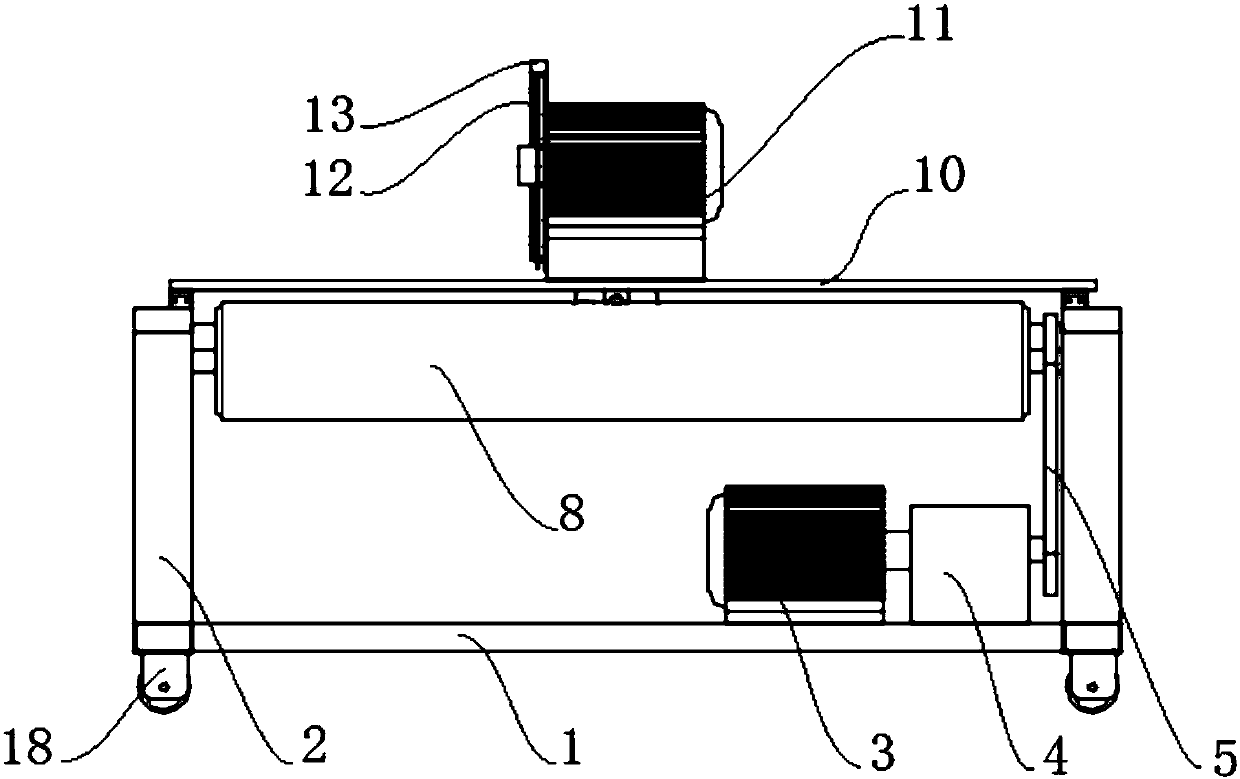

Strip steel burr polishing device applied to finishing unit, debugging method of strip steel burr polishing device

ActiveCN106392810AAvoid defectsQuality improvementEdge grinding machinesGrinding machine componentsLocking mechanismEngineering

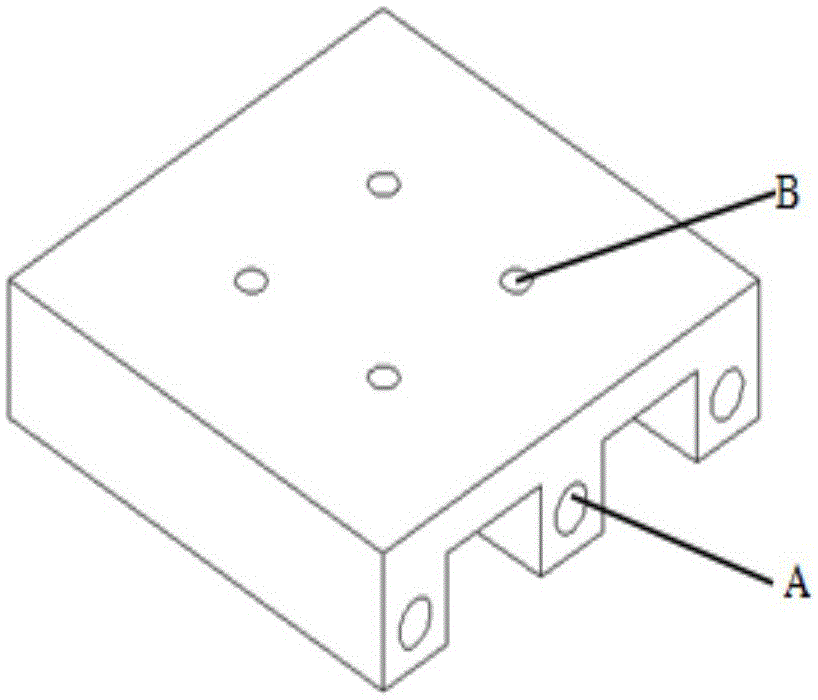

The invention discloses a strip steel burr polishing device applied to a finishing unit. The strip steel burr polishing device comprises a horizontal feeding mechanism, a horizontal angle adjusting and locking mechanism and a vertical angle adjusting mechanism, wherein the horizontal feeding mechanism is used for allowing the strip steel burr polishing device to run along a track so as to adapt to changes of specification of strip steel; the horizontal angle adjusting and locking mechanism is arranged on the horizontal feeding mechanism and comprises a motor lower base (10) and a motor middle base (12), wherein the motor lower base (10) and the motor middle base (12) are connected by a bolt; the motor lower base (10) and the motor middle base (12) are provided with waist-shaped hole sliding chutes and a bolt structure, wherein the waist-shaped sliding chutes are used for relative horizontal rotation of the motor lower base (10) and the motor middle base (12), and the bolt structure is used for fixation, and thus adjustment of horizontal angle of the device is implemented; the vertical angle adjusting mechanism is arranged on the motor middle base (12) of the horizontal angle adjusting and locking mechanism and is used for adjusting the height and the vertical angle of the burr polishing device. The burr polishing device disclosed by the invention is ingeniously adjustable in feeding, adjustable in horizontal angle, adjustable in vertical angle, adjustable in height, adjustable in burr polishing pressure and capable of adapting to different burr polishing requirements of different specifications and different steel types.

Owner:BAOSHAN IRON & STEEL CO LTD

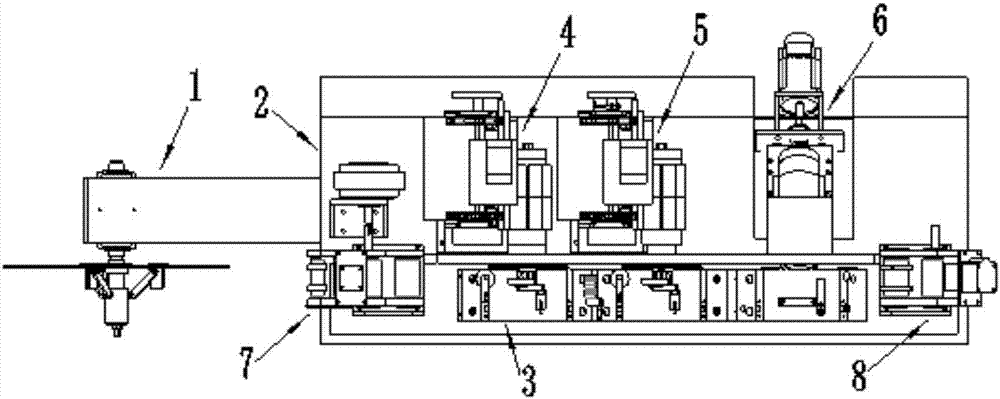

Special machine tool for machining small-sized precise component of computer, communication and consumer electronic (3C) products

InactiveCN103223630ARealize the function of walking up and downRealize the function of walking back and forthLarge fixed membersMetal working apparatusEnvironmental resistanceEngineering

The invention discloses a special machine tool for machining a small-sized precise component of computer, communication and consumer electronic (3C) products. The special machine tool comprises a base, wherein the base is provided with two sets of independent X-Y-Z-axis systems and two sets of independent tool magazines, one side surface of the base is provided with a square groove, a drawer-type chipping accumulation mechanism is installed in the square groove, the drawer-type chipping accumulation mechanism consists of a chipping accumulation drawer and an overflow drawer which are arranged from top to bottom, the bottoms of the chipping accumulation drawer and the overflow drawer are respectively provided with a filter net, a water tank is arranged below the overflow drawer, a turntable on the upper top surface of the overflow drawer is provided with a through hole, and the through hole corresponds to the overflow drawer. Due to the adoption of the machine tool, the working efficiency can be further improved on the basis of the existing device, the cost is reduced, and the machining precision and the product quality can be improved. The drawer-type chipping accumulation mechanism can effectively collect all chippings produced in the machining process, so that the peripheral environment and the application performance of the machine tool can be guaranteed, and through the collection and the reliable recovery of the chippings, not only can the peripheral environment be free from being polluted, but also an environmental protection effect can be realized.

Owner:YIXING LINGREN MACHINERY

Fish oil pumping device and pumping method

InactiveCN109296516AAvoid adverse effects on qualityReduce heatPositive displacement pump componentsPump installationsFish oilEngineering

The invention relates to a fish oil pumping device and pumping method. The fish oil pumping device comprises a fish oil temporary storage container, an oil pumping conveying pipeline and two pumping device bodies, wherein the two pumping device bodies are connected in parallel between the fish oil temporary storage container and the oil pumping conveying pipeline and are provided with the same structure; the oil inlets of the pumping device bodies communicate with the fish oil temporary storage container; the oil outlets of the pumping device bodies communicate with the oil pumping conveying pipeline; the bottom height of the fish oil temporary storage container is higher than the oil inlets; each of the two pumping device bodies comprises a cylinder and a piston arranged in the cylinder in a sealing, sliding and sleeving manner; the oil outlets are formed in the opening end parts of the cylinders; an opening-closing plate opens or closes the communicating part between each of the oiloutlets and the oil pumping conveying pipeline; and the upper ends of the opening-closing plates are hinged to the upper end parts of the cylinders. The fish oil pumping device and pumping method canovercome the adverse factor of the existing oil pump to fish oil, generate less heat and can avoid adverse effect of the heat to the fish oil quality.

Owner:FUZHOU ZHONGJILIAN ELECTROMECHANICAL TECH

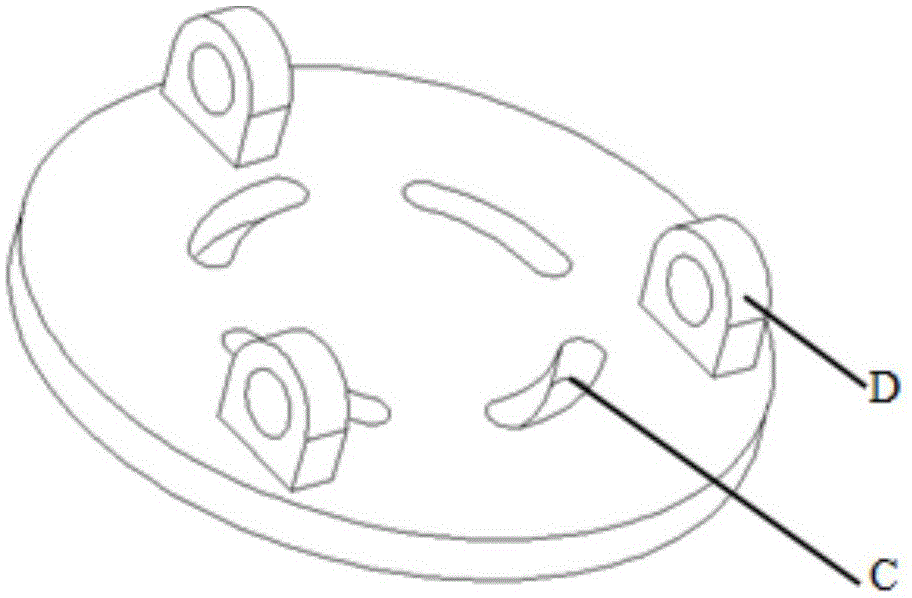

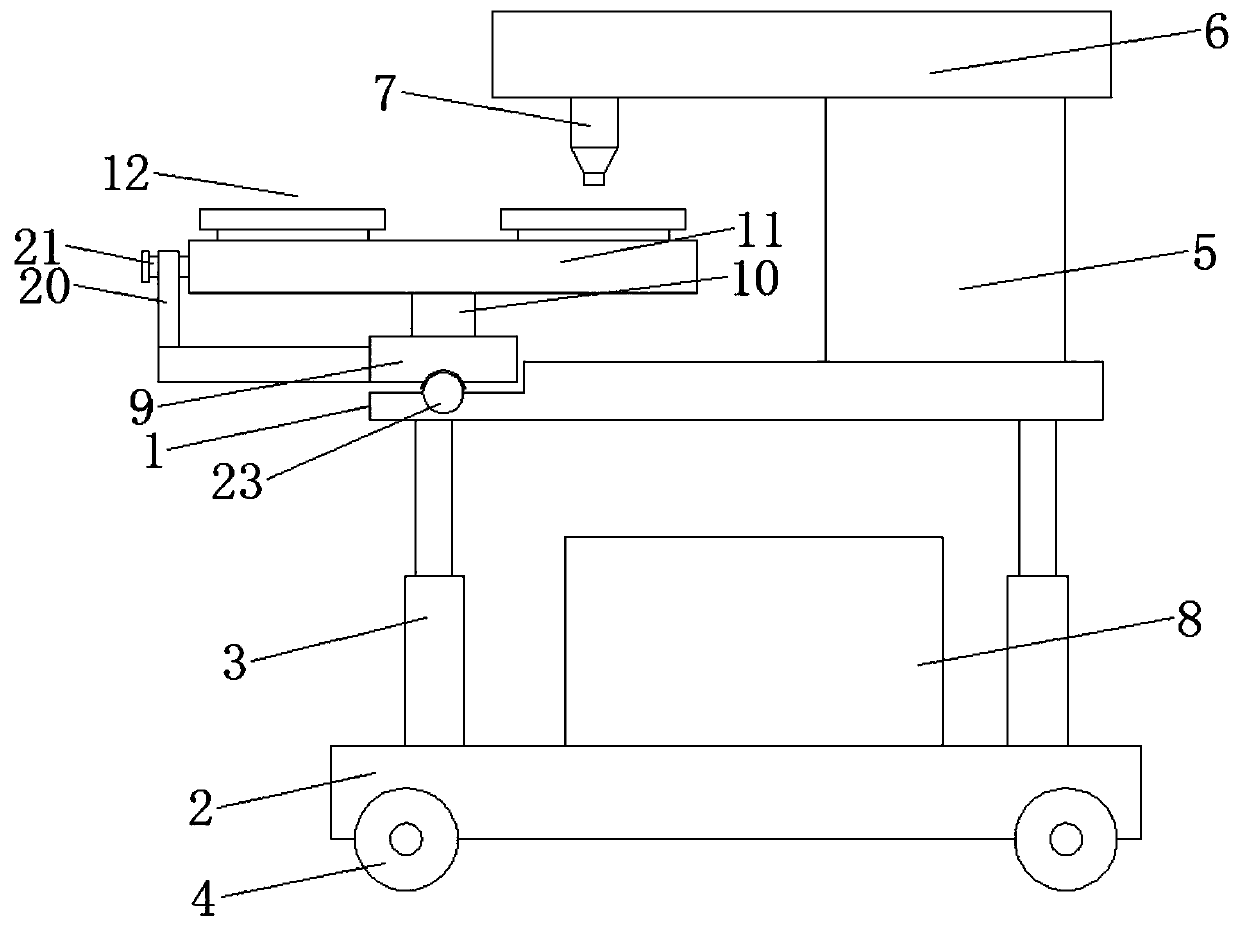

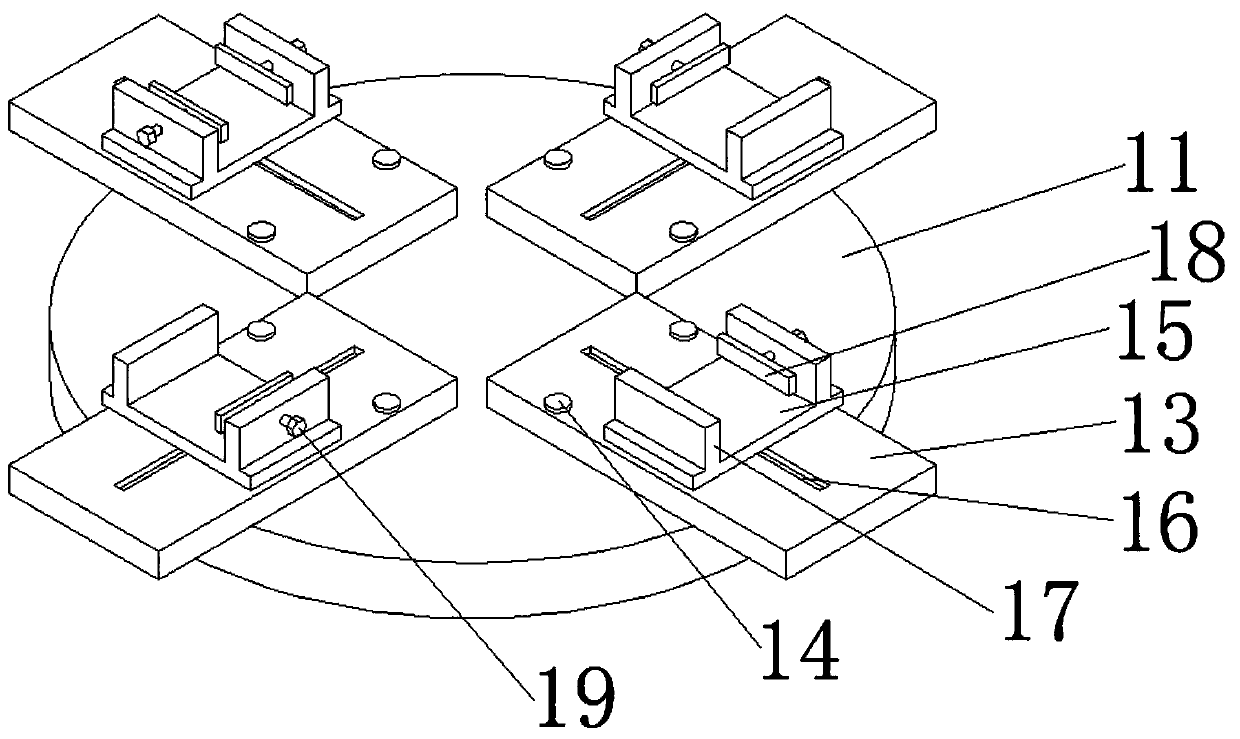

Welding equipment for copper processing

ActiveCN110842402AAchieve feedRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

The invention relates to the field of copper processing and specifically discloses welding equipment for copper processing. The welding equipment for copper processing comprises a platform, a base, lifting supporting legs, rolling wheels, a supporting base, a cross beam, an electric welding spray head and a control cabinet. An adjusting seat swinging around the midpoint is arranged at the left endof the platform. A rotary shaft perpendicular to the surface of the adjusting seat is rotatably connected to the upper surface of the adjusting seat. A rotary disk parallel to the adjustment seat iscoaxially fixed to the upper end of the rotary shaft. A plurality of detachable clamping and moving mechanisms are mounted on the upper surface of the rotary disk. Each clamping and moving mechanism comprises a mounting plate, fixing bolts, a movable seat and a sliding groove. The inclination angle of the electric welding spray head can be changed through the adjusting seat capable of swinging. The welding equipment for copper processing can conduct welding on different positions, especially weld seams in the vertical direction, can conduct continuous welding on workpieces mounted on the clamping and moving mechanisms, has no influence on the welding process during discharging and feeding and can save time and improve the production efficiency.

Owner:苏州铜盟电气有限公司

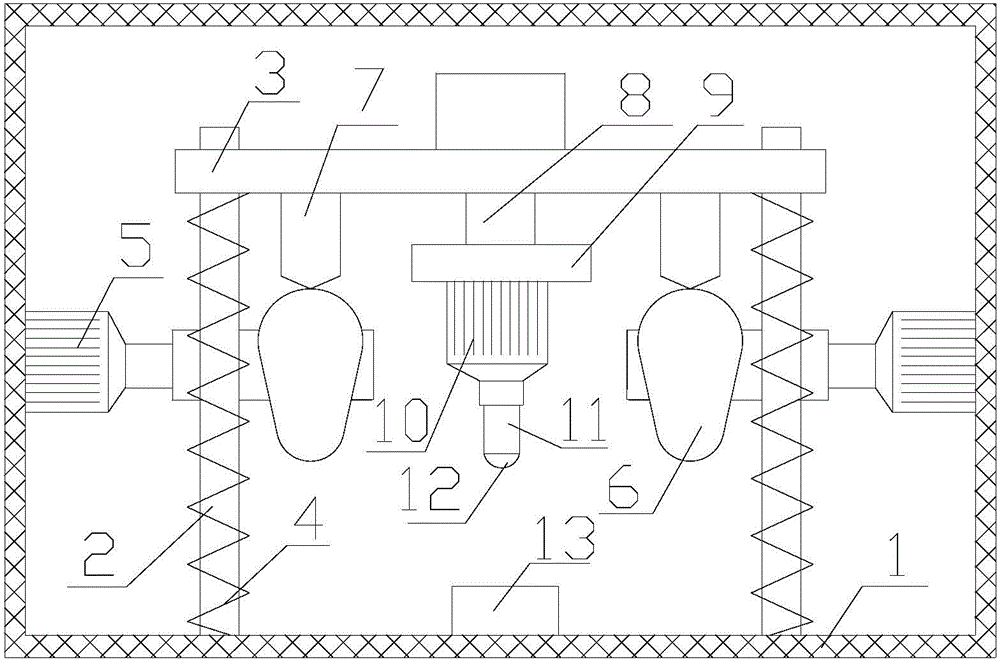

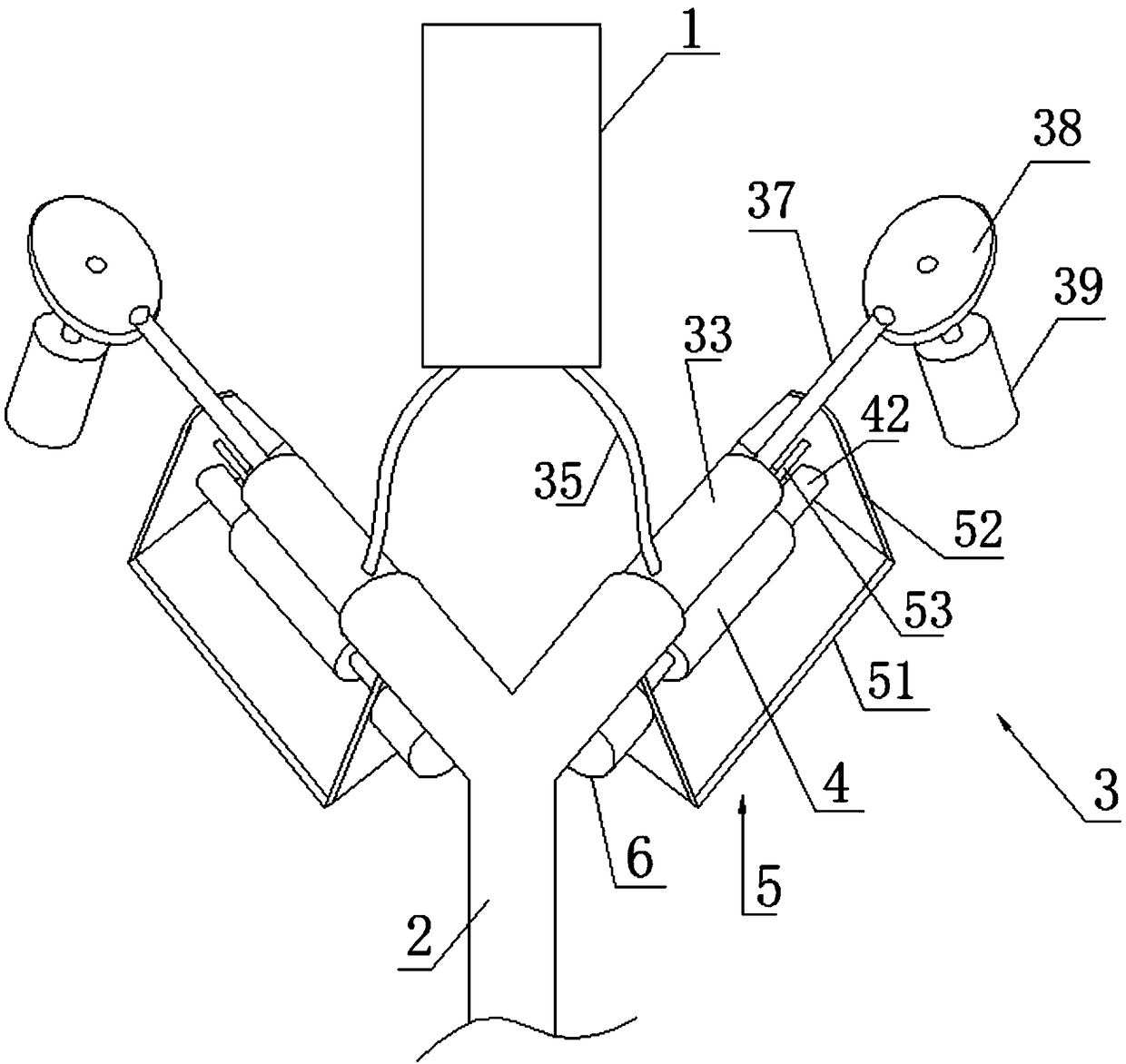

Threaded through hole detection device

InactiveCN110153511AStable positionAchieve regulationThread cutting machinesMeasurement/indication equipmentsElectric machineEngineering

The invention relates to a threaded through hole detection device, and belongs to the technical field of threaded hole detection equipment. The threaded through hole detection device is characterizedby comprising a lifting mechanism, a plurality of mounting frames (8) arranged around the lifting mechanism and clamps (3) arranged on the lower sides of the mounting frames (8), a plurality of translation mechanisms are arranged on each mounting frame (8), each translation mechanism is connected with a drill rod in a sliding manner, and the lower end of each drill rod is connected with a screw tap through a power device; a rotary disc (33) is rotationally arranged on a rotary mechanism, the rotary disc (33) is connected with a clamp motor for driving the rotary disc (33) to rotate, two swingarms are symmetrically arranged on the two sides of the rotary disc (33), a jaw vice (37) is arranged between the two swing arms, a first swing arm motor is further arranged on the rotary disc (33), and an output shaft of the first swing arm motor is connected with the two swing arms at the same time. According to the threaded through hole detection device, the relative positions of threaded through holes can be detected, threads of the threaded through holes can also be detected, so that the detection of the threaded holes in multiple surfaces can be completed through one-time clamping.

Owner:SHANDONG UNIV OF TECH +1

Multifunctional woodworking drilling machine

InactiveCN108000643AEasy to operateImprove practicalityStationary drilling machinesPulp and paper industryWoodworking

The invention discloses a multifunctional woodworking drilling machine. The multifunctional woodworking drilling machine comprises a working frame, two sliding blocks are further fixed to the two sidesurfaces of the working frame in a sliding mode, short shafts are fixedly arranged on the two sliding blocks, sliding frames are rotationally connected to the short shafts, a first positioning hole and a second positioning hole are formed in each sliding block, and the distance between the first positioning hole and the corresponding short shaft is equal to the distance between the second positioning hole and the corresponding short shaft; and positioning pins are arranged at the lower ends of the sliding frames, a rotating beam is further arranged on the sliding frames, and the rotating beamis provided with drilling machines. According to the multifunctional woodworking drilling machine, the sliding blocks are fixed to the working frame in a sliding mode, so that the sliding frames which are rotationally connected to the sliding blocks can move linearly relative to the working frame; the positioning pin is inserted into the corresponding first positioning hole, so that the sliding frames can be fixed to a perpendicular position relative to the working frame; and the positioning pin is inserted into the corresponding second positioning hole, so that the drilling machines can be horizontally placed, a vertical drilling machine can be converted into a horizontal drilling machine, moreover, the operation is convenient, and the practicability is high.

Owner:深圳市安东尼奥家具有限公司

Traverse feeding device of external groove plungecut grinder

InactiveCN102172890AReduce frictional resistanceImprove stabilityGrinding drivesReduction driveReducer

The invention provides a traverse feeding device of an external groove plungecut grinder. The traverse feeding device comprises a roller cross guide rail pair, a traverse feed table and a drive unit, wherein the roller cross guide rail pair comprises guide rails, a roller retainer and a cylindrical roller, and the cylindrical roller is arranged on the guide rails through the roller retainer; the drive unit comprises a stepping motor, a harmonic speed reducer and a ballscrew, wherein the stepping motor drives the harmonic speed reducer to connect the ballscrew, an output shaft of the harmonic speed reducer is fixedly connected with a shaft end of a screw of the ballscrew, a nut of the ballscrew is connected with the transverse feed table, and the nut of the ballscrew can move forth and back on the screw of the ballscrew. By means of the transverse feeding device, the deceleration with large rotation ratio can be carried out through the harmonic speed reducer so that the transverse feeding is more stable, and the transverse feeding precision is improved by controlling the stepping motor through electric programs, thus accurate feeding and reversing are realized, and the machining precision of a bearing ring is accurate; and simultaneously, the stroke of the transverse feeding is also enlarged, the purchase cost of new equipment is reduced, and the purpose of a machine tool is widened.

Owner:HARBIN BEARING GROUP CORP

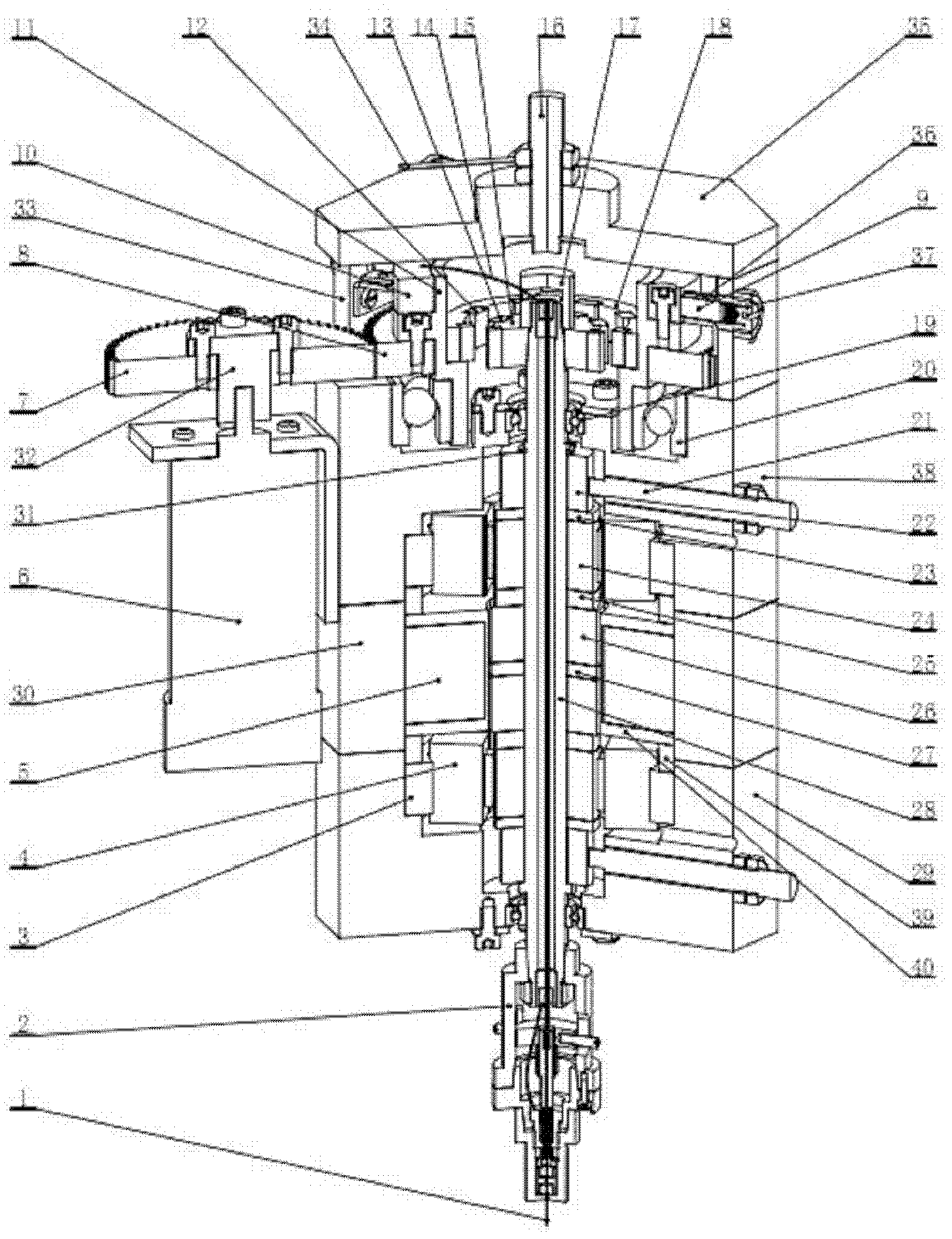

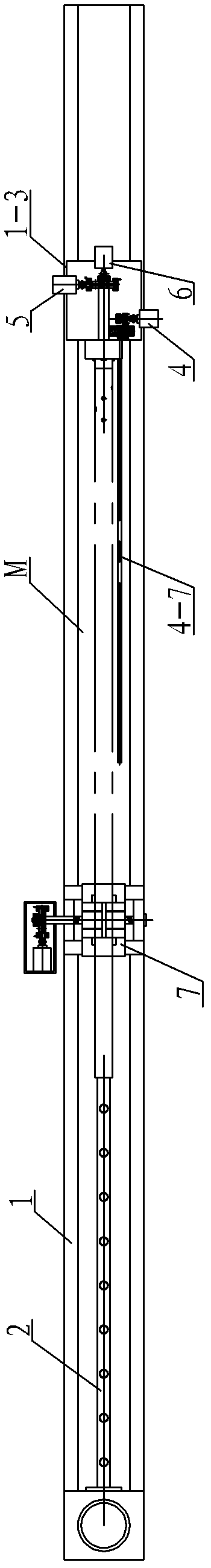

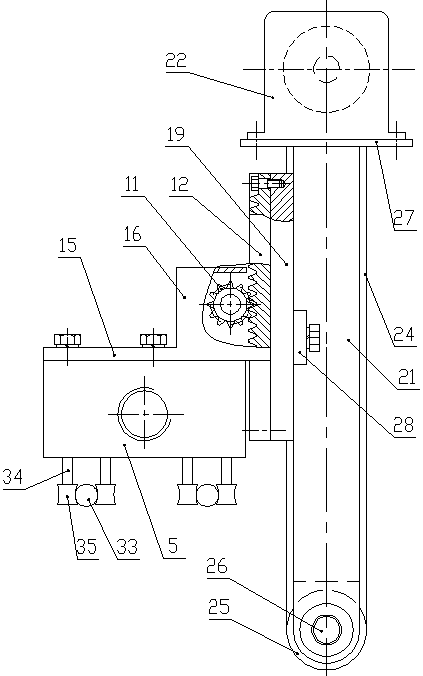

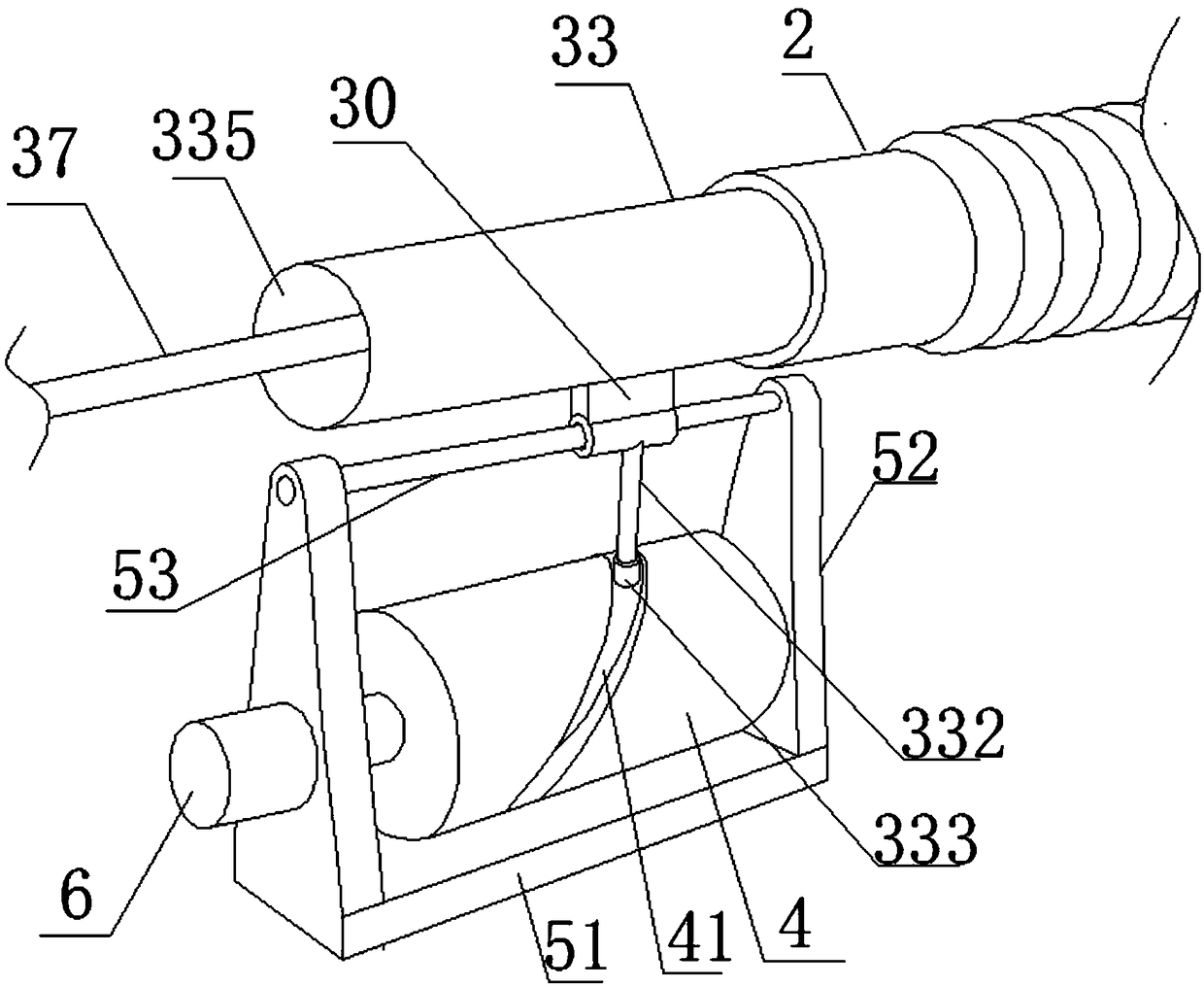

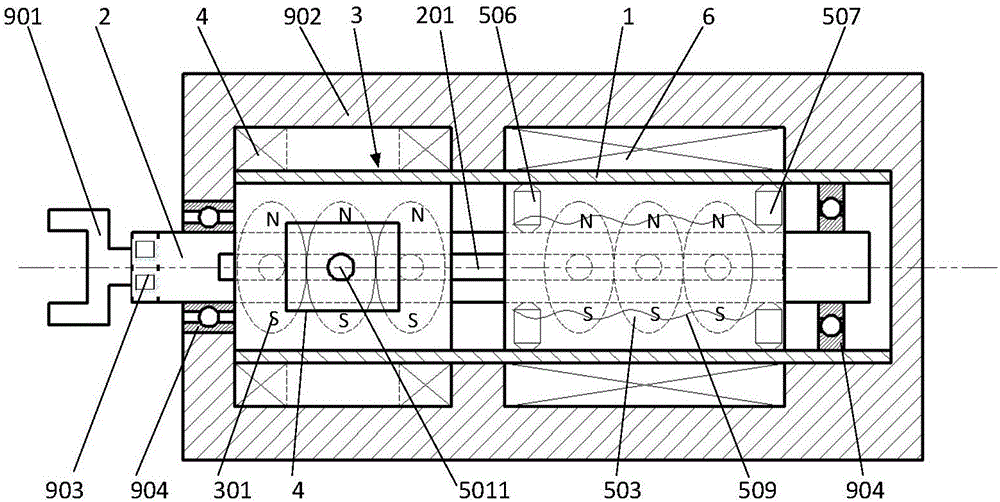

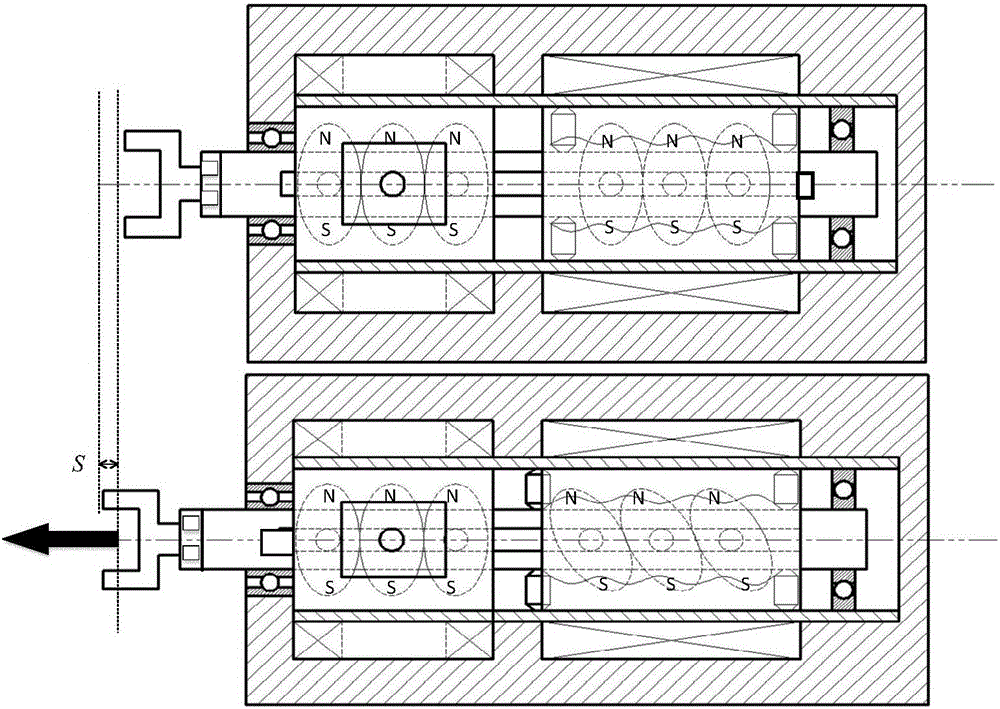

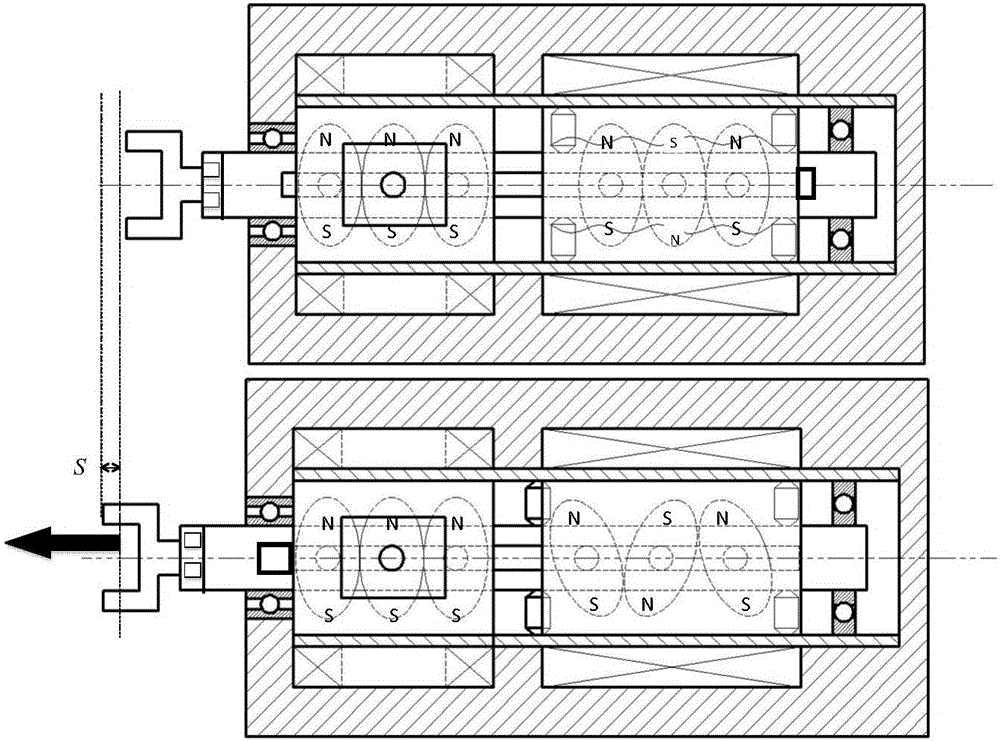

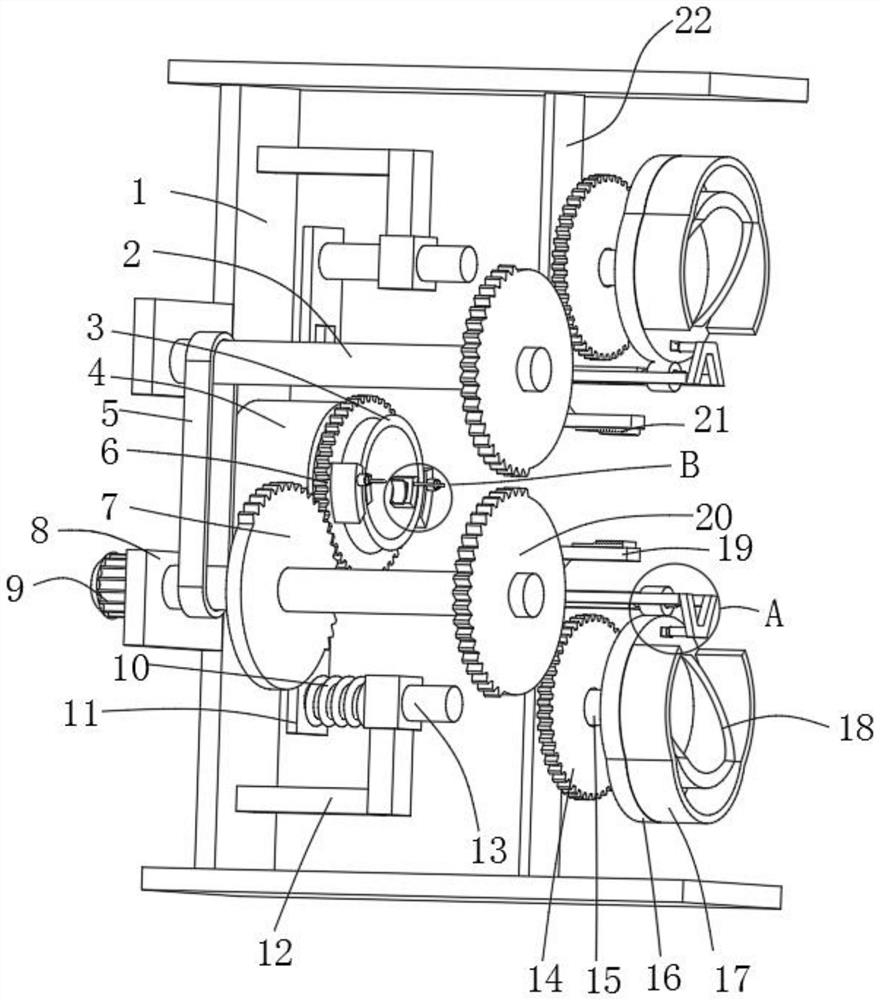

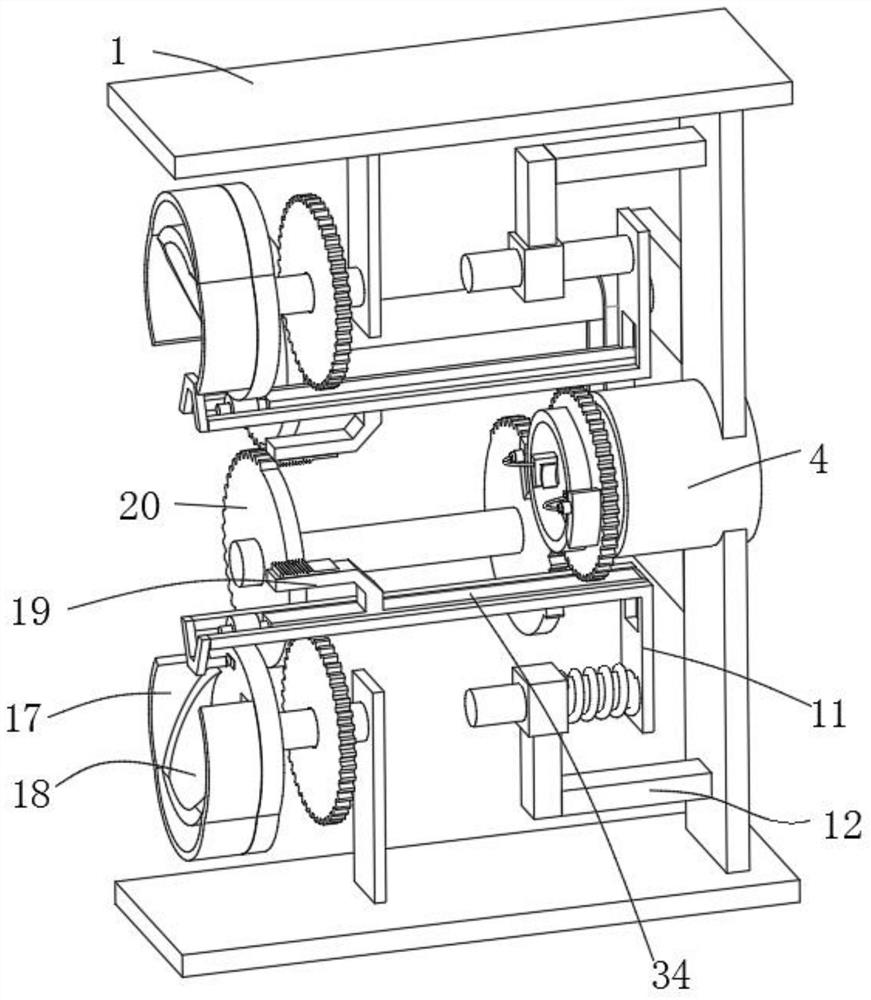

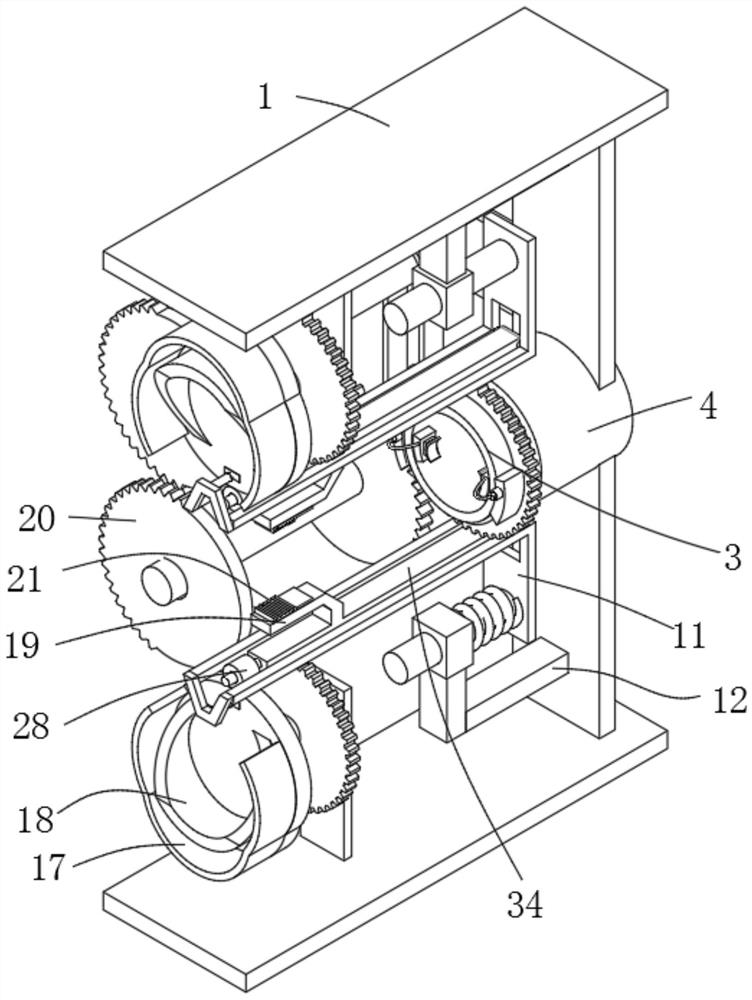

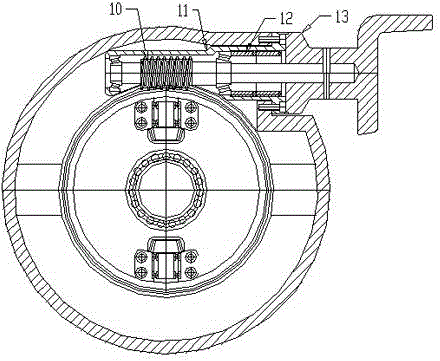

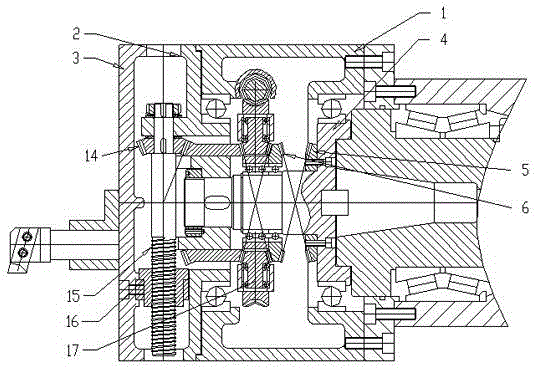

Controllable rotary feed system and control method

PendingCN106849568AAchieve rotationAchieve feedGrinding drivesDynamo-electric machinesFeed driveControl theory

The invention provides a controllable rotary feed system and a control method. The controllable rotary feed system comprises a sleeve (1), a main shaft (2), a rotary drive mechanism (3), a rotary drive coil (4), a feed drive mechanism (5) , and a feed drive coil (6). A rotary drive rotor (301) is driven by the rotary drive coil (4) to drive the main shaft (2) to rotate relative to the sleeve. A feed drive rotor (601) is driven by the feed drive coil (6) to drive the main shaft (2) through a positioning device to perform feed motion relative to the sleeve (1). The controllable rotary feed system is a precisely controllable rotary and direct drive device capable of separately rotating and feeding and simultaneously rotating and feeding, and can be applied to the fields such as grinding.

Owner:SHANGHAI JIAO TONG UNIV

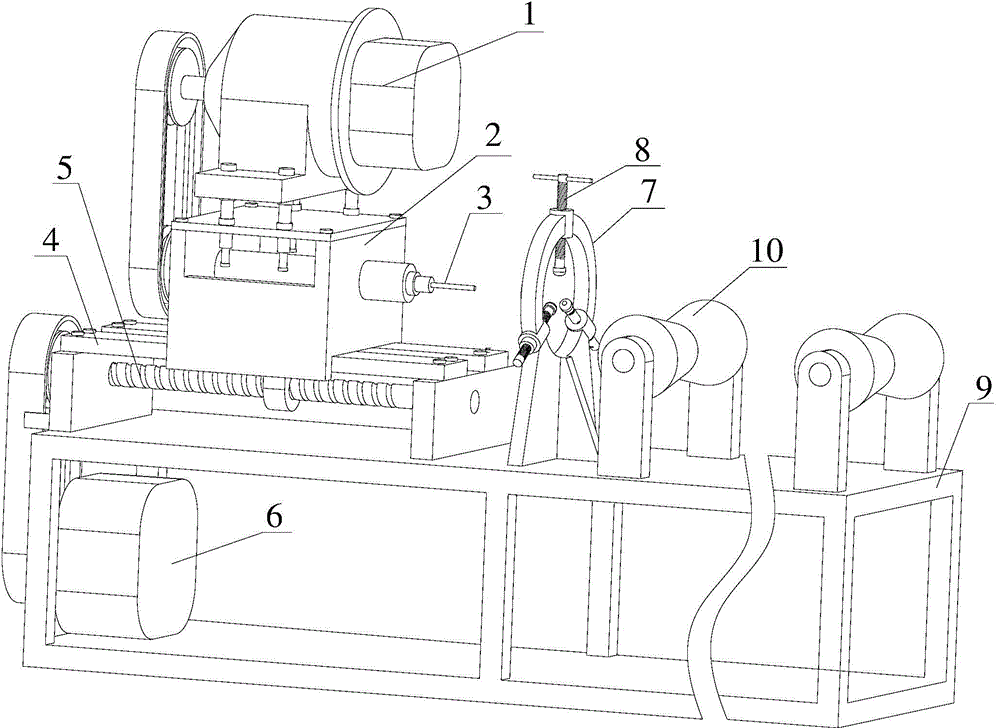

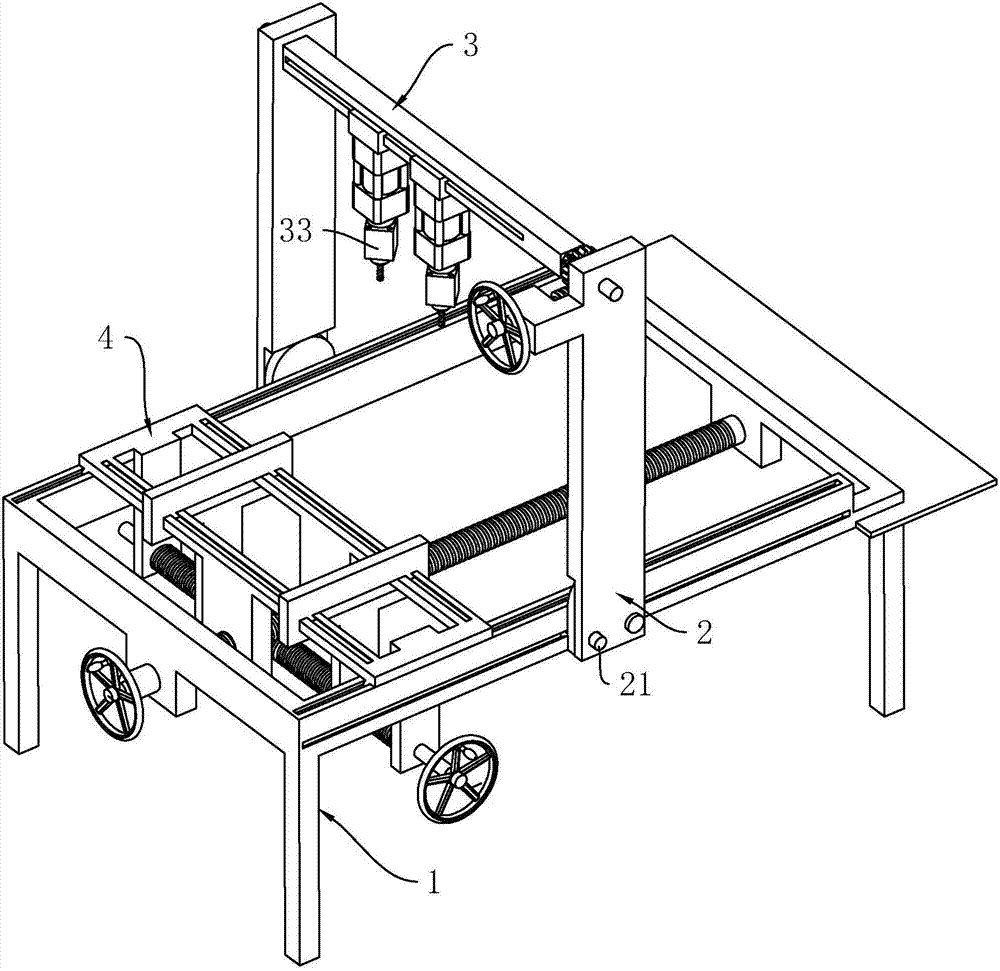

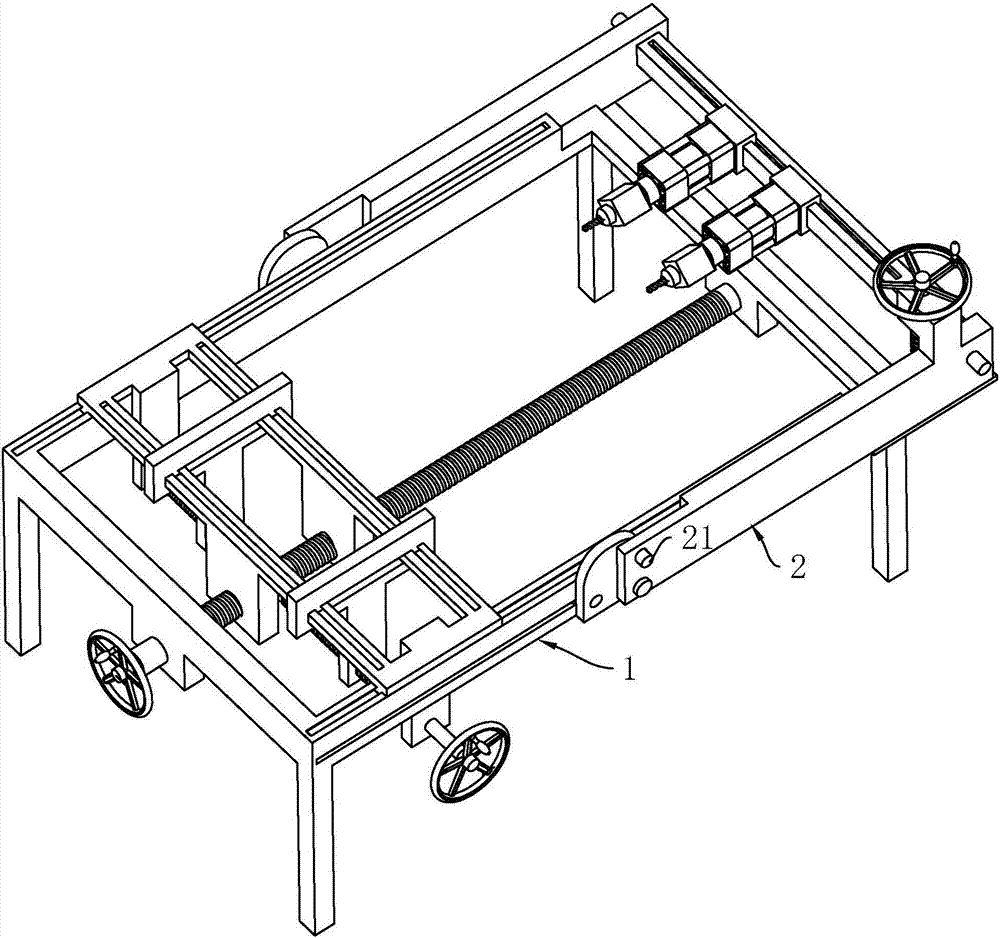

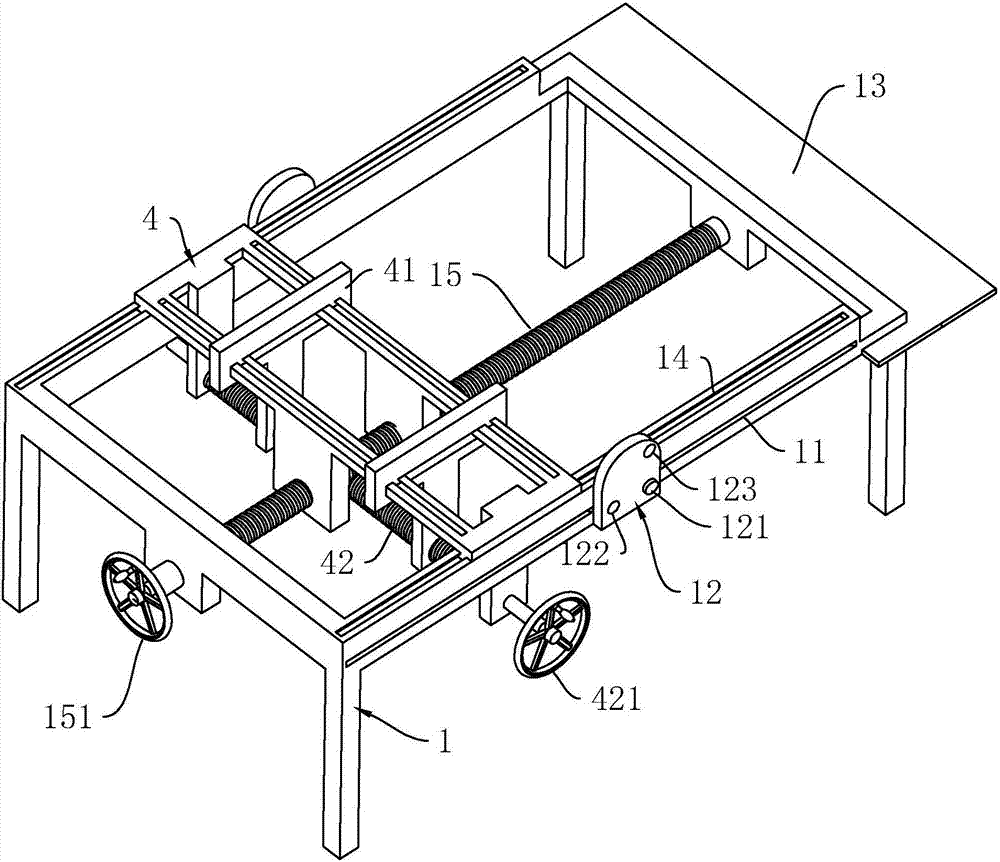

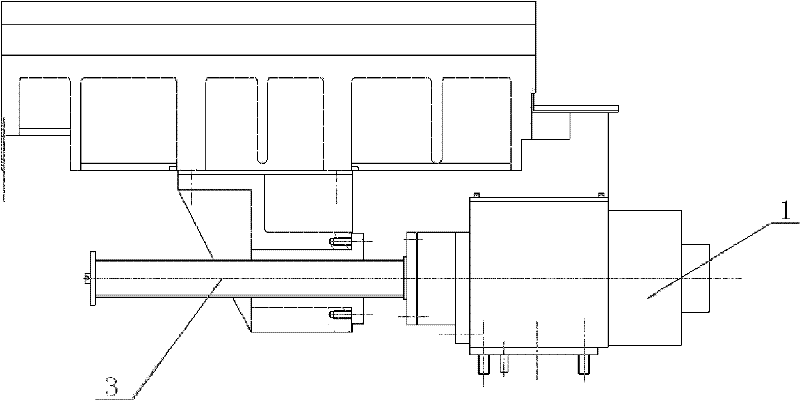

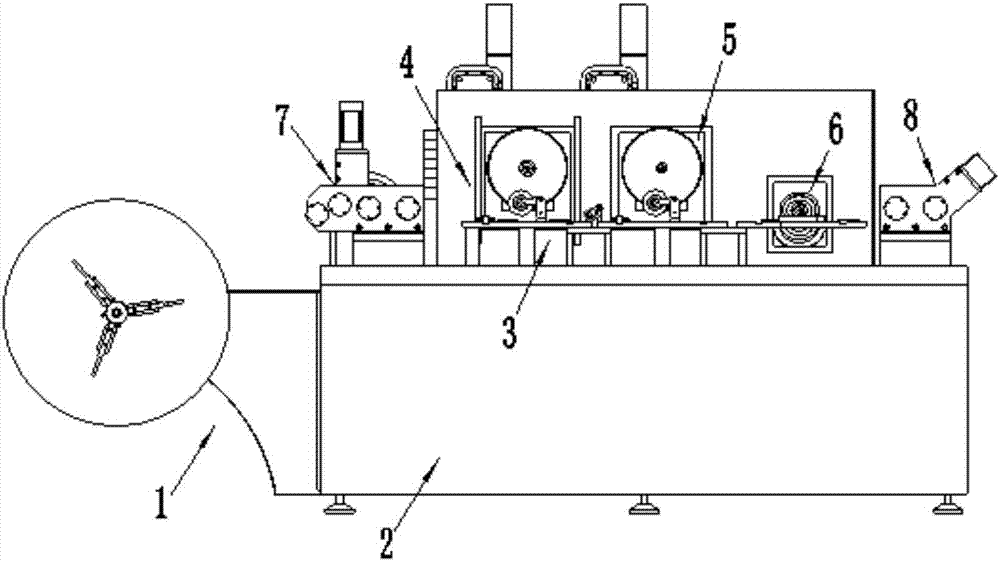

Ink scraper grinding machine and using method thereof

ActiveCN107378705AImprove grinding efficiency andImprove grinding accuracyOther manufacturing equipments/toolsGrinding machinesGrinding millSteel belt

The invention discloses an ink scraper grinding machine and a using method thereof and belongs to the field of grinding machines. A workbench assembly of the grinding machine is arranged on a machine frame and used for supporting an ink scraper. A plane grinding assembly is used for grinding the surface of the ink scraper. A cutting edge grinding assembly is used for grinding a cutting edge of the ink scraper. A steel strip coiling device is used for clamping a to-be-machined steel coil. A brake assembly is used for controlling the ink scraper for braking and correcting the smoothness of the ink scraper while the ink scraper is delivered. A drive assembly is used for driving the ink scraper to be fed. The brake assembly, the plane grinding assembly, the cutting edge grinding assembly and the drive assembly are sequentially arranged on the machine frame in the machining direction. The ink scraper grinding machine can complete grinding of the surface and the cutting edge of a flexible steel strip, and straighten the steel strip before grinding of the steel strip so as to ensure the surface smoothness. By means of the method, the surface and the cutting edge of the steel coil of the oil scraper can be ground quickly and efficiently.

Owner:马鞍山俊强精密机械设备有限公司

Variable-speed manual pseudo-ginseng medicinal material slicing device

The invention discloses a variable-speed manual pseudo-ginseng medicinal material slicing device. The device comprises a bottom plate and a blade, wherein a left side plate is fixedly connected abovethe left side of the bottom plate, a transverse plate is fixedly connected to the top of the left side plate, and a protective cover is fixedly connected to the right side of the transverse plate; theblade is arranged in the protective cover, and the blade is rotationally connected with the inner wall of the protective cover through a driven shaft; and material holes are formed in the two sides of the protective cover, and a material discharging groove is fixedly connected in the right side of the protective cover and is located below the corresponding material hole. According to the variable-speed manual pseudo-ginseng medicinal material slicing device, the blade and a movable clamping device are arranged, so that manual rotation is achieved, meanwhile, feeding and cutting of pseudo-ginseng materials are achieved, and manual slicing efficiency of the pseudo-ginseng materials is improved; and transmission gears and a clutch wheel are arranged, so that different rotating speeds of theblade at the same feeding speed can be achieved, the width of slices is controlled, and the effects of being simple and efficient are achieved.

Owner:苏州高新区鼎正精密机电有限公司

Surface treatment equipment for metal corrugated pipe machining

InactiveCN113478342AImprove sanding qualityAvoid local deformationGrinding carriagesGrinding drivesClassical mechanicsCam

The invention discloses surface treatment equipment for metal corrugated pipe machining. The surface treatment equipment comprises a supporting frame, wherein a fixing ring is fixed to the position, close to the middle, of the supporting frame; a rotating sleeve used for grinding is rotationally installed inside the fixing ring; grinding mechanisms used for grinding the surface of an annular corrugated pipe are symmetrically arranged inside the rotating sleeve; a transmission mechanism used for intermittent feeding and clamping of the annular corrugated pipe is connected to the supporting frame; a driving mechanism used for driving the rotating sleeve to rotate and enabling the transmission mechanism to operate is further connected to the supporting frame; and a double-cam mechanism used for left-right movement of a mounting frame and up-down movement of a clamping plate is connected to the supporting frame. According to the surface treatment equipment, the fitting effect of water pressure is utilized, on one hand, the grinding quality is improved, and meanwhile, local deformation caused by too large stress can be avoided; and meanwhile, a grinding head is contracted under the action of the water pressure, and feeding type grinding of the metal corrugated pipe is facilitated.

Owner:李升来

Sheet feeding device

InactiveCN108928612AImprove work coordinationGuaranteed normal transmissionConveyorsControl devices for conveyorsScreening effectElectric machinery

Owner:绍兴西恒科技有限公司

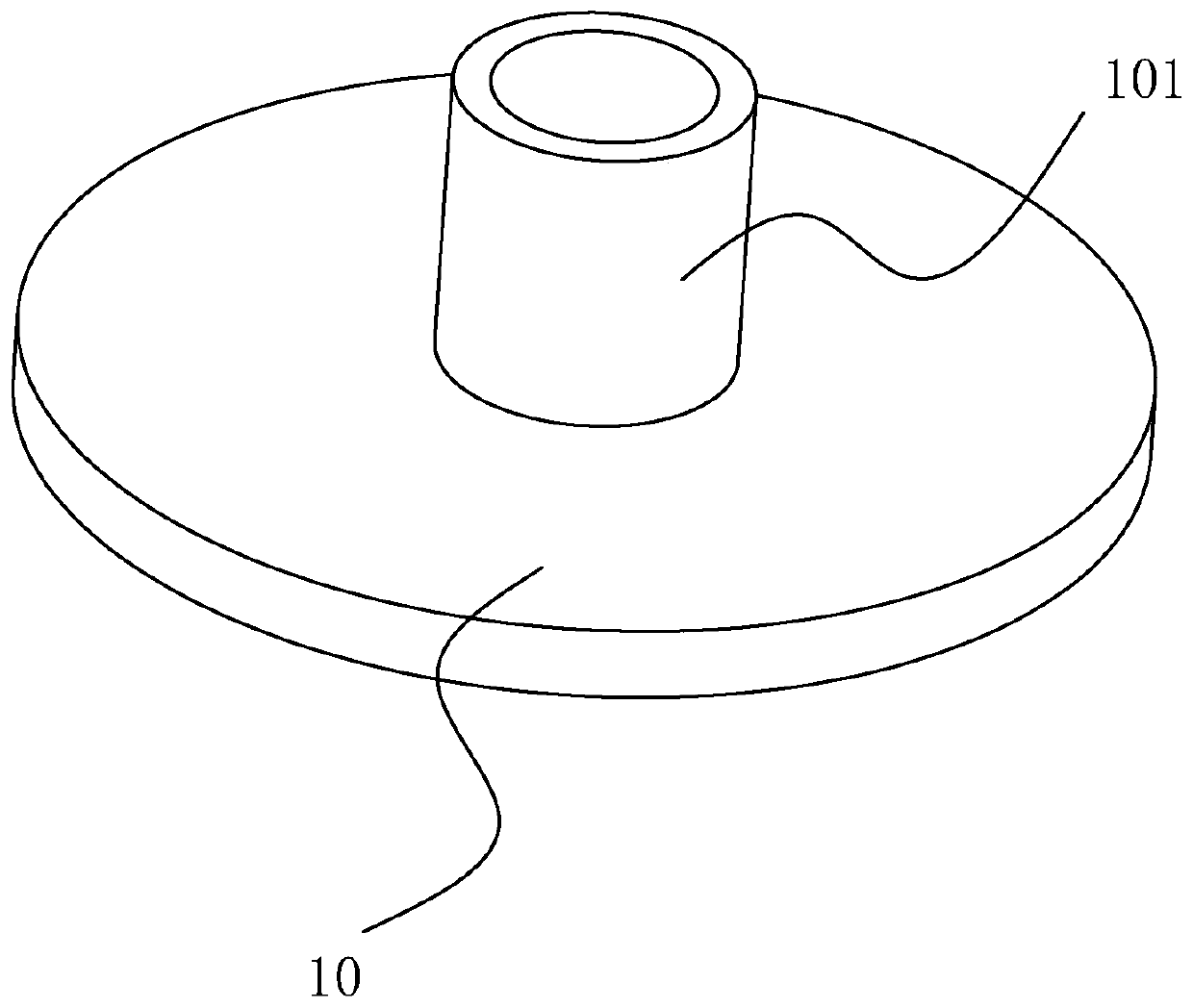

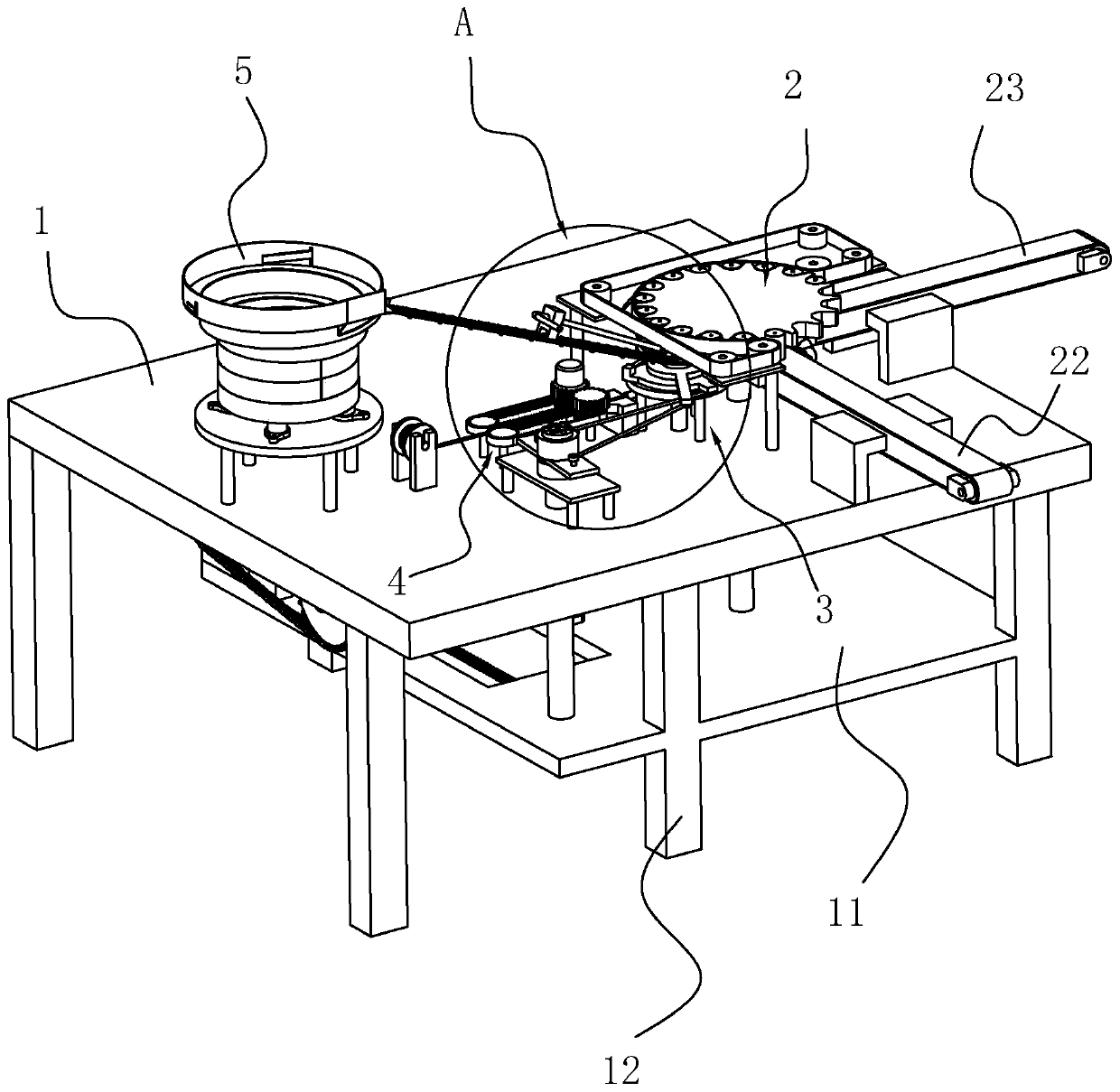

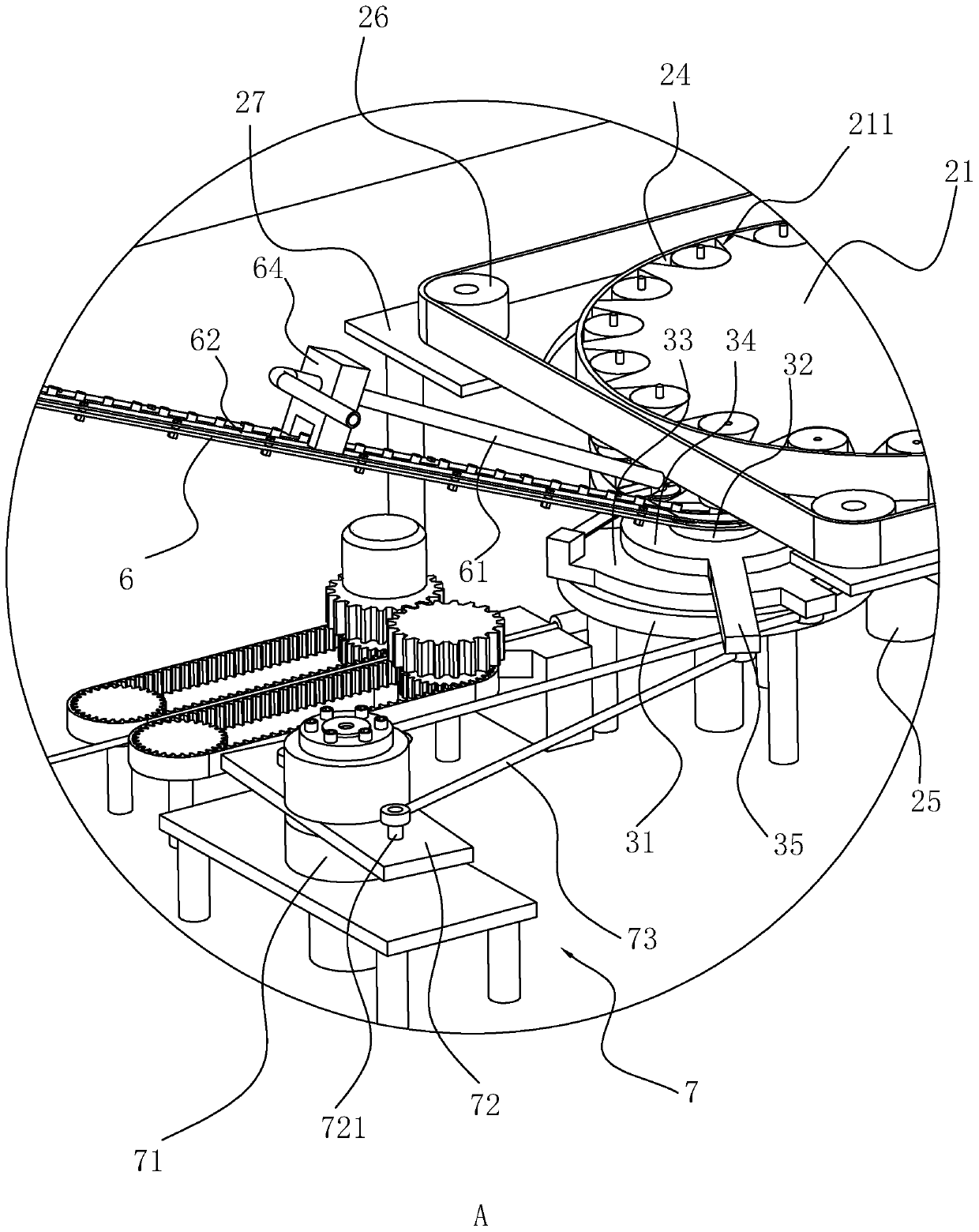

Wax block core penetrating equipment

ActiveCN110699188AOperation saves time and effortAchieve feedCandle preparation apparatusEngineeringWorkbench

The invention discloses wax block core penetrating equipment. The invention relates to the technical field of wax cup processing. The problem that a wax core is inconvenient to insert into a wax blockbase is solved; according to the technical scheme, the wax block core penetrating equipment is characterized by comprising a workbench, a supporting table, a fixed shaft, a rotating block, an extrusion disc, a threading table, a vibration disc, a guide plate, a horizontal plate, a limiting plate, a supporting plate, a material stirring block, an extrusion block fixedly connected to the top of theextrusion disc, a cutter fixedly connected to the top of the rotating block and a rotating mechanism; the vibration disc and the guide plate are used for conveying the wax block base; the wax block base is shifted to the top of the threading table under the action of the material stirring block; the wax core is inserted into a round piece and a limiting pipe from the bottom of the threading table, then the limiting pipe is extruded through the extrusion block and the material stirring block to clamp the wax core, then the wax core is cut off from the bottom of the round piece through the cutter, then the wax block base obtained after threading is completed is manually taken down, and threading of the next wax block base continues to be conducted.

Owner:青岛欧亚自动化设备有限公司

A steel pipe beveling machine

The invention provides a facing machine for a steel tube. A common lathe cannot clamp the large-caliber steel tube. The facing machine comprises a supporting frame, a milling device, a lifting device, a moving device and a rotating device. The milling device comprises a driving motor and a machine head, and is provided with a sliding block. The lifting device comprises a guiding rod, a lifting motor and a screw rod, wherein the guiding rod penetrates the milling device, the screw rod is connected with the lifting motor, and the screw rod is in threaded fit with the sliding block of the milling device. The rotating device is fixed to the supporting frame. The moving device is connected with the rotating device. The machine head comprises an installation seat and cutters. The installation seat is provided with a plurality of installation grooves annularly arranged along the surface of the installation seat, the cutters are installed in the installation grooves, and chip grooves are formed in the installation seat. The steel tube facing machine is simple in structure, reasonable in design, wide in application range, high in working efficiency and convenient to operate.

Owner:浙江德威不锈钢管业股份有限公司

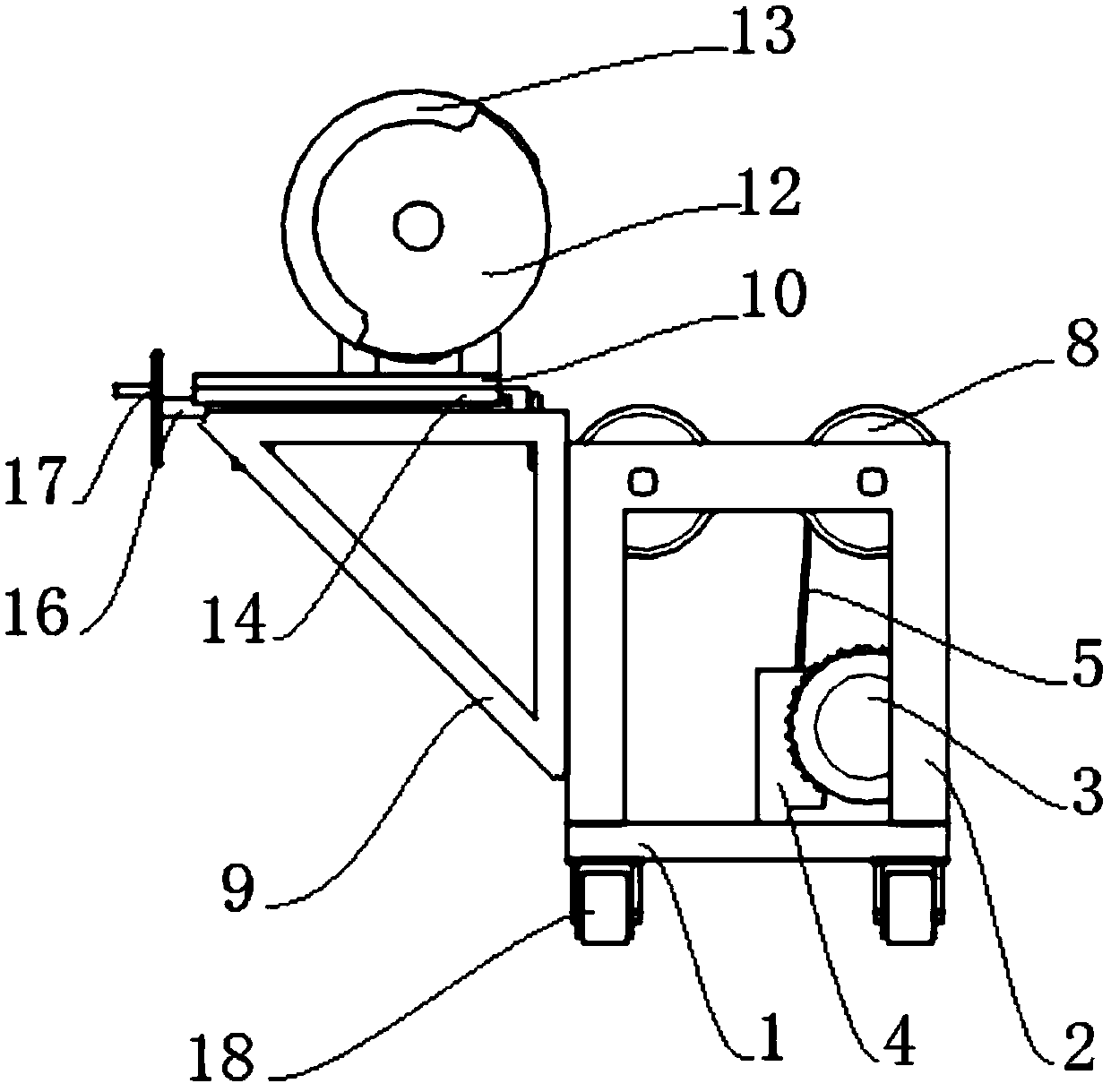

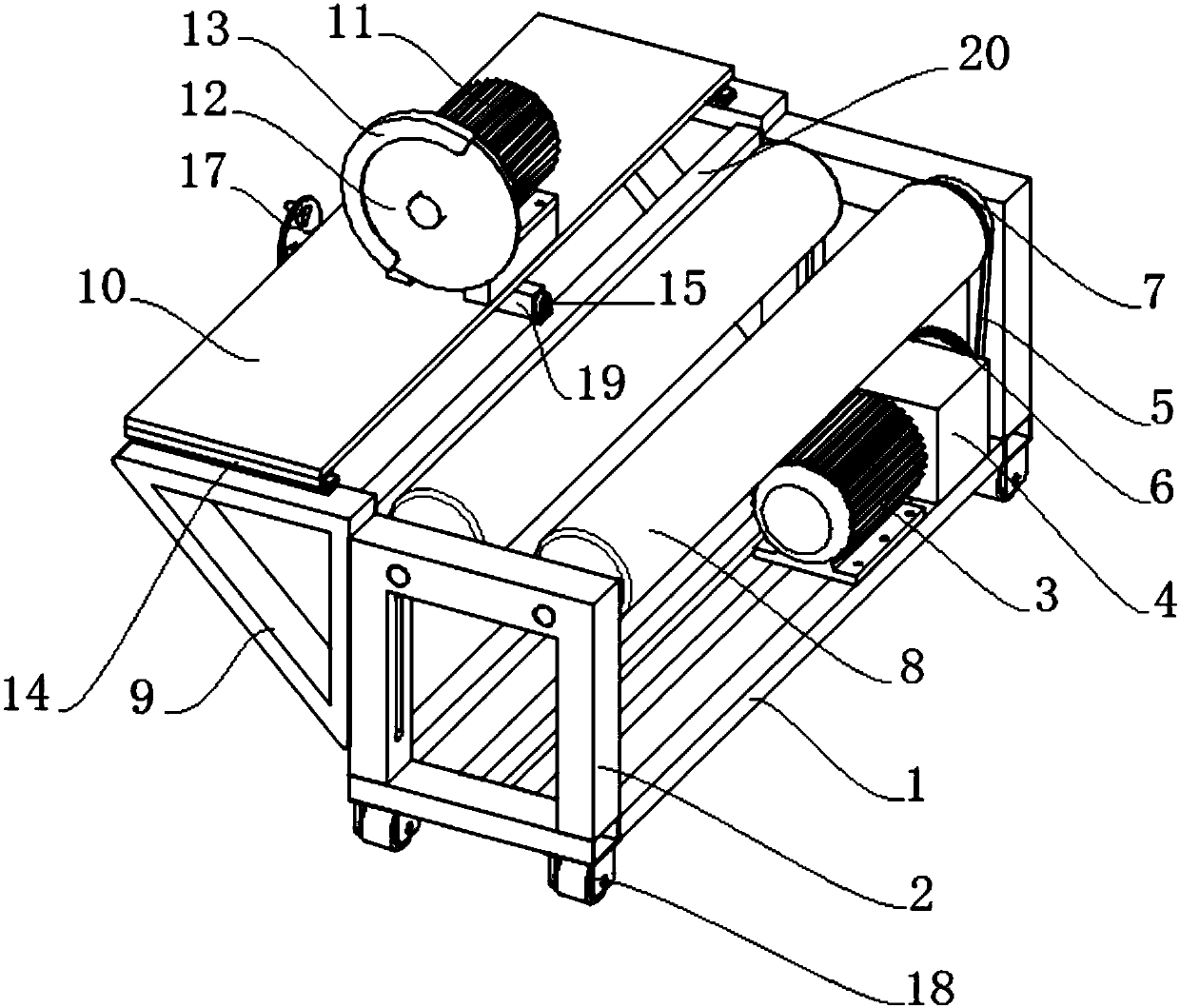

Cutting device special for petroleum pipelines

InactiveCN108044169AAchieve feedAchieve exitFeeding apparatusTube shearing machinesCouplingEngineering

The invention discloses a cutting device special for petroleum pipelines. The cutting device comprises a cutting device body and a transmission unit. The transmission unit comprises a base, supports,a first electromotor, a reduction gearbox, a transmission belt, a first transmission belt wheel, a second transmission belt wheel and transmission rollers. The two supports are fixedly mounted at theleft end and the right end of the base correspondingly. The two transmission rollers are mounted at the two ends of the tops of the supports correspondingly. The second transmission belt wheel is fixedly mounted on a shaft rod of one transmission roller. The first electromotor is connected with the reduction gearbox through a coupling. An output shaft of the reduction gearbox is fixedly connectedwith the first transmission belt wheel. The first transmission belt wheel and the second transmission belt wheel are connected through a transmission belt. The first electromotor and the reduction gearbox are fixedly mounted on the base. A triangular frame is mounted on each support. An operation plate is mounted on the triangular frames. The cutting device body is fixedly mounted on the operationplate. According to the device, the petroleum pipelines of different pipe diameters can be cut, cutting is uniform, adopted manpower is reduced, the cutting quality is guaranteed, and the cutting efficiency is improved.

Owner:CHENGDU DAMO PETROLEUM TECH CO LTD

Independent horizontal disc

InactiveCN104551822AGuaranteed uptimeBalanced forceFeeding apparatusLarge fixed membersEngineeringMachining process

The invention discloses an independent horizontal disc and belongs to machine tools. The disc comprises a cutter head, a cutter seat, a slider and a press plate and is composed of a cylindrical fixing member, a rotating member and a central shaft; the fixing member is movably connected to the central shaft and the rotating member through a bearing, and the central shaft penetrates the center of the fixing member and is tightly connected to the central hole of the rotating member; a differential mechanism which is located between the fixing member and the central shaft and which is composed of a bevel gear pair, a bevel gear ring and a worm gear is connected to a feed screw of the internal of the rotating member to drive the slider to feed radially. The transmission of the bevel gear pair and bevel gear ring is adopted to form the differential mechanism with the worm gear and a worm, the radial feeding is implemented ingeniously, the independent horizontal disc is widely applied to the machining process, such as grooving, for a boring-milling machine, and the operating efficiency can be improved greatly.

Owner:EZHOU WEIDA MACHINE LIMITED BY SHARE

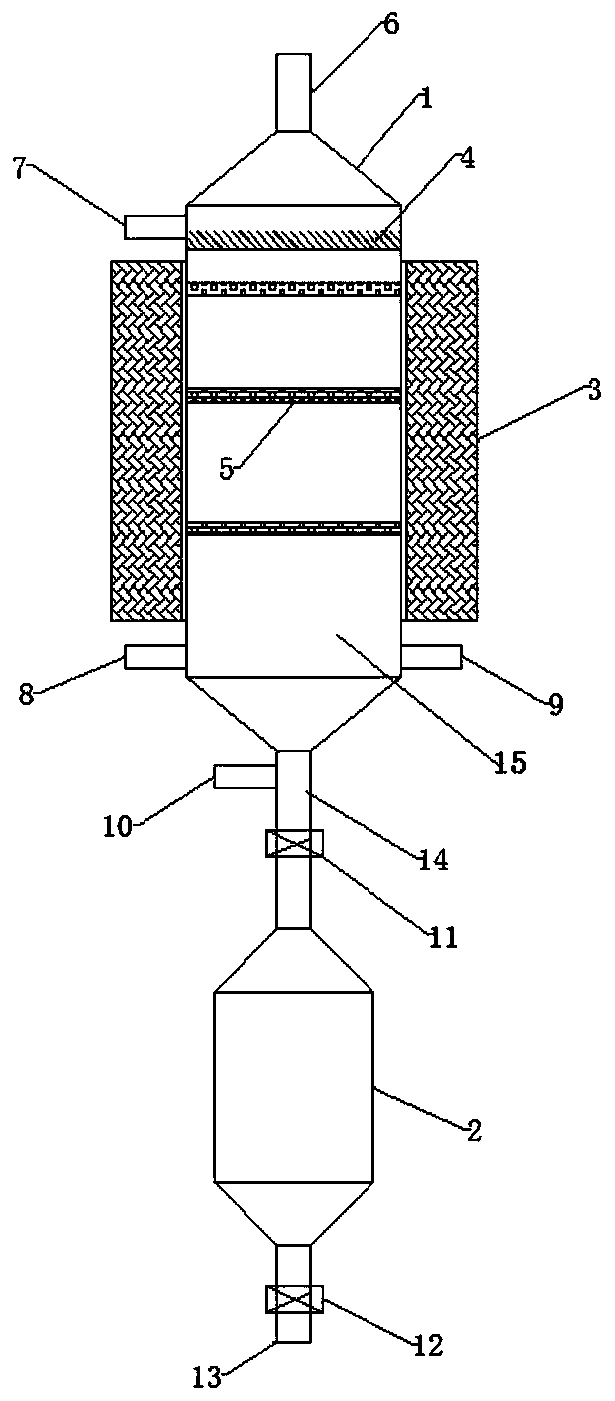

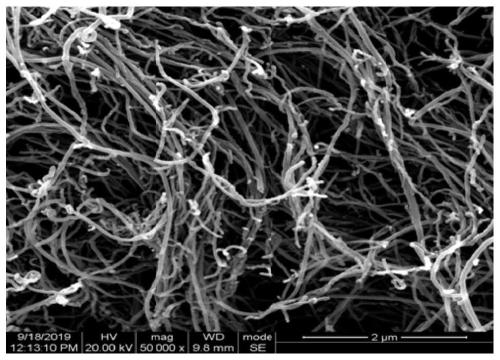

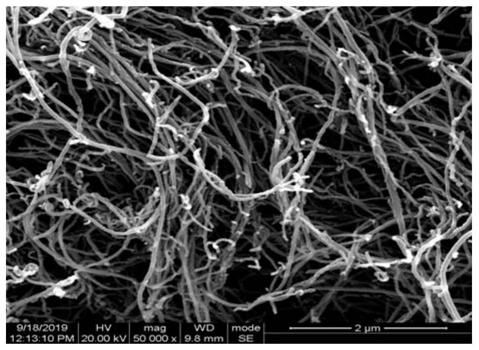

Carbon nanotubes purified by gas phase damping method, device and purification method

The invention relates to the technical field of carbon nanotube purification, and in particular, relates to a carbon nanotubes purified by a gas phase damping method, a device and a purification method. The method disclosed by the invention comprises three steps of feeding the carbon nanotubes, purifying, cooling and collecting. According to the invention, a high-temperature corrosion-resistant ultrasonic vibrating screen is used for feeding carbon nanotubes, so that quantitative feeding can be realized, and the screen can be prevented from being blocked; a gas-phase damping ring is utilized to increase the resistance of the carbon nanotubes in the descending process of a purification chamber and prolong the contact time of the carbon nanotubes and chlorine, and a residual metal catalyst in the carbon nanotubes reacts under the heating condition to generate chloride, the metal catalyst and the carbon nanotubes are separated, and the purpose of purifying the carbon nanotubes is achieved. The method disclosed by the invention is simple, easy to amplify in productivity, small in pollution, easy to engineer, good in purification effect and suitable for removing various residual metalsin various carbon nanotubes. The purity of the carbon nanotubes is high, and the content of single metal impurities in the carbon nanotubes is less than 20 ppm.

Owner:成都莱尔纳米科技有限公司

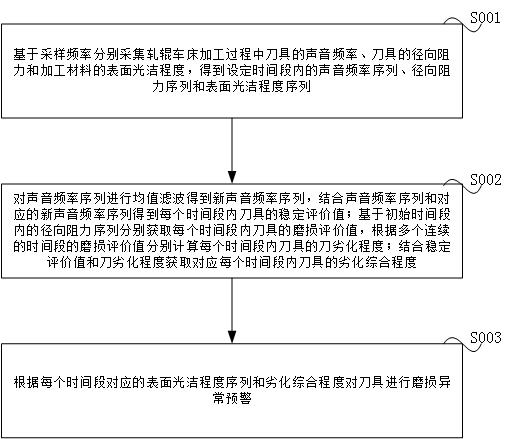

Roller modification auxiliary optimization method based on big data

The invention relates to the technical field of machine tool part machining, in particular to a big data-based roller remanufacturing auxiliary optimization method, which can be applied to the intelligent manufacturing equipment industry, and particularly can be applied to manufacturing of industrial automatic control system devices, machine tool field bus control systems, machine tool programmable control systems and other metal machining machines. The sound frequency generated by tool friction in the roller lathe machining process, the radial resistance of a tool cutting machining material and the surface smoothness of the machining material are analyzed in a combined mode, the tool deterioration degree is obtained, real-time early warning is conducted on tool abrasion abnormity on the basis of the deterioration degree, and therefore abnormal tool use is avoided, and the machining efficiency is improved. The machining quality is improved, the probability of machining accidents is reduced, and feeding of a part for supporting a cutter or a workpiece is achieved.

Owner:南通恒强轧辊有限公司

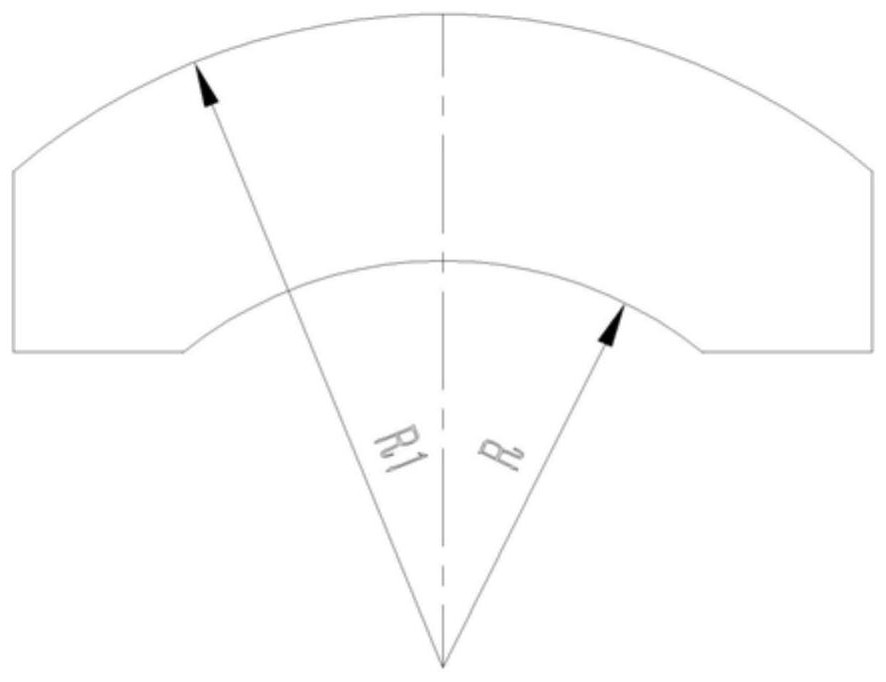

Numerical control woodworking inner arc surface milling machine

PendingCN111941552ARealize the function of continuous processingEasy to assemble and disassembleProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlAutomatic control

The invention provides a numerical control woodworking inner arc surface milling machine. The milling machine comprises a cutting device, a feeding device, a positioning device, a dust removal device,a rotary workbench, a lathe bed and an automatic control system, wherein the rotary workbench is horizontally arranged above the lathe bed, the lower portion of the cutting device is arranged on thelower side of the lathe bed, the upper portion penetrates through the rotary workbench, the feeding device is arranged below the lathe bed and used for driving the cutting device and the rotary workbench, the positioning device is arranged on the rotary workbench, the dust removal device is arranged above the cutting device and below a to-be-cut workpiece, and the automatic control system is electrically connected with the feeding device. The milling machine is suitable for machining the inner arc-shaped surfaces of connecting elbows with different radiuses for wood structure buildings produced in batches, equipment is easy to operate, continuous production can be achieved, clamping and dismounting of products are convenient and rapid, other products can be mounted and dismounted while equipment cutting machining is conducted, the production efficiency is greatly improved, and the equipment is low in manufacturing cost, small in occupied area, reliable in operation and high in productmachining precision.

Owner:YINGKOU XINBAIYUN MACHINERY CO LTD

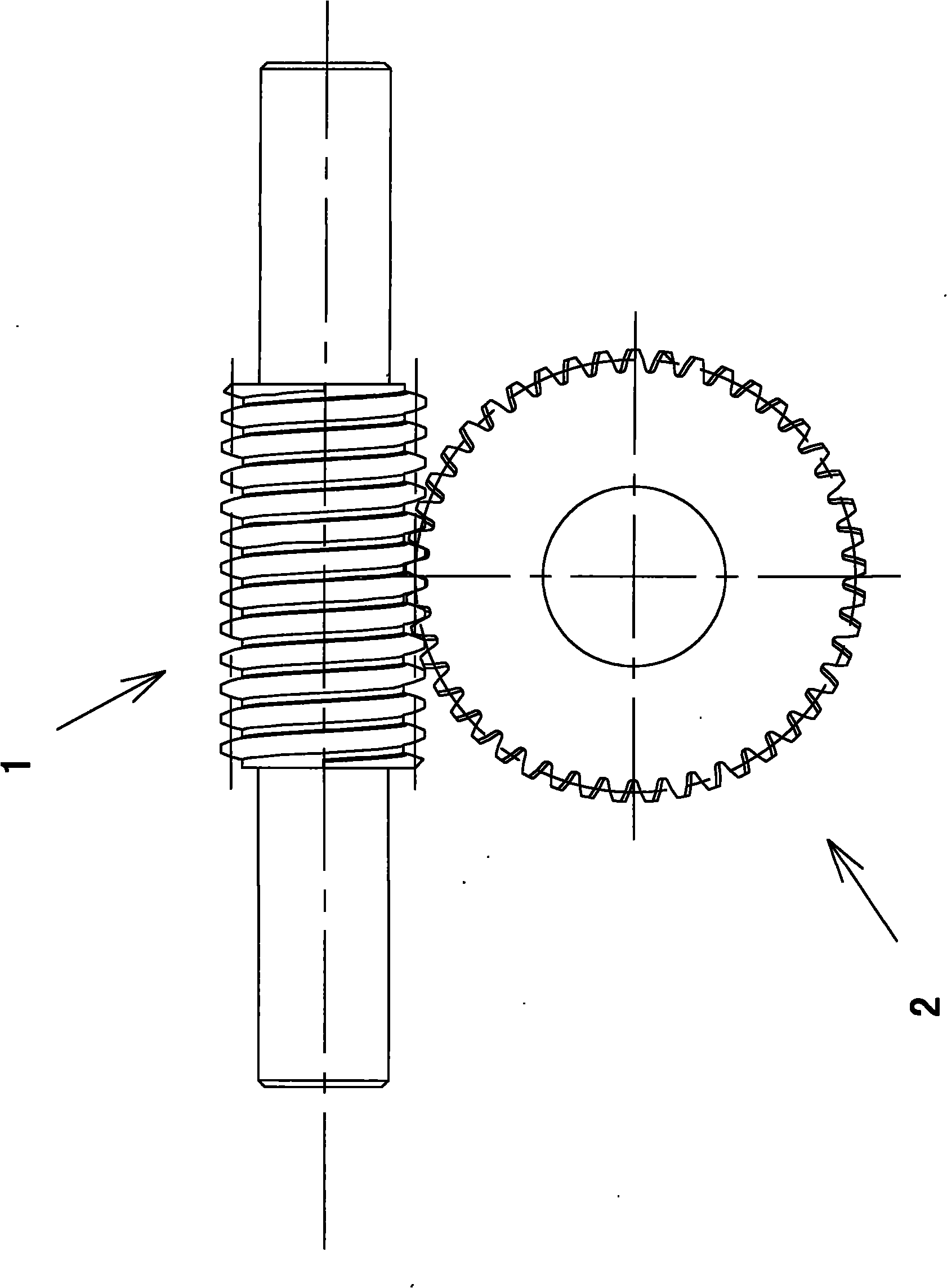

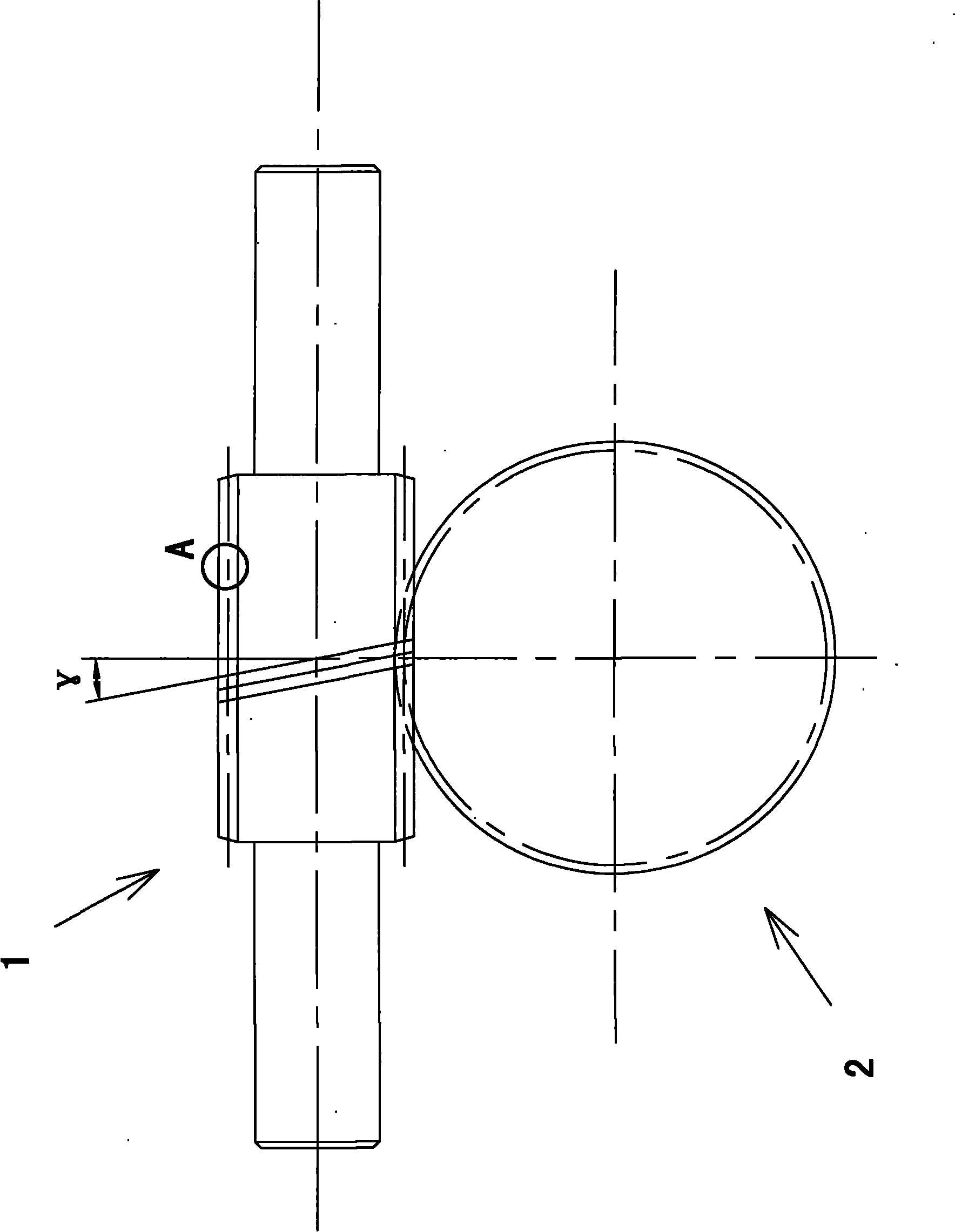

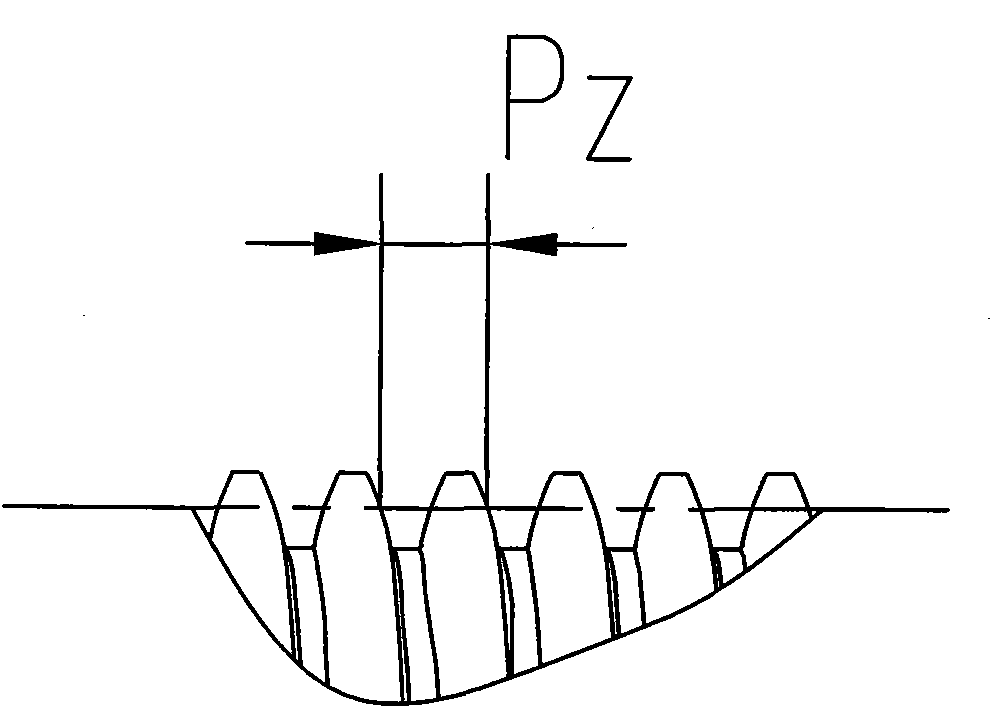

Worm helical gearing mechanism

The invention discloses a worm helical gearing mechanism which comprises a worm (1) and a helical gear (2). The invention is characterized in that the worm (1) and the helical gear (2) are engaged with each other, the axial line of the worm (1) is perpendicular to the axial line of the helical gear (2), the worm (1) is an involute worm with a leading angle equal to the helix angle of the helical gear (2) and a normal modulus equal to the normal modulus of the helical gear (2). The invention has advantages of large transmission ratio, stable transmission, compact structure, small noise and self-locking. In most cases, the invention can substitute for worm wheel transmission and can be widely applied on transmission structures such as feeding cases, slide carriage cases and gearboxes of machine tools as well as feeding cases of quenching cars, which realizes motions of feeding and speed change.

Owner:大连机床(数控)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com