Bar material drill

A technology of drilling machine and drilling mechanism, which is applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., which can solve the problems of easy deviation of bars and drill bit breakage, etc., and achieve Prevent the drill bit from breaking, control the drilling depth, and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

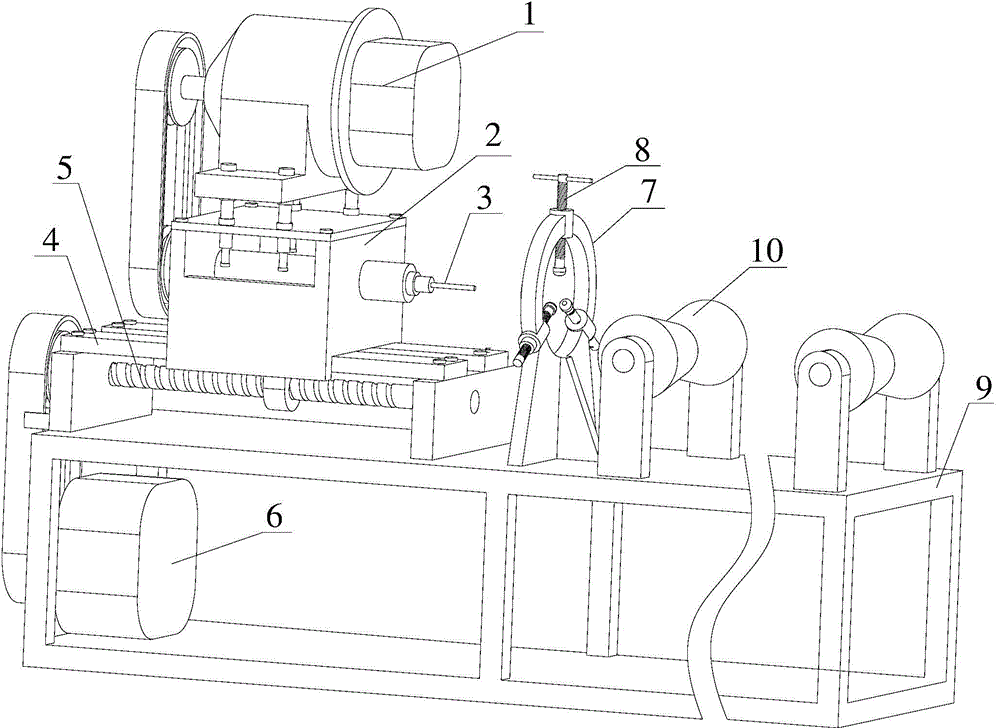

[0016] Such as figure 1 As shown, a bar drilling machine includes a drilling mechanism, a propulsion mechanism that pushes the drilling mechanism forward, a support mechanism for supporting the bar, and a positioning device for bar positioning;

[0017] The drilling mechanism includes a motor one 1, a gear box 2 connected to the motor one 1 and a drill bit 3 fixedly connected to the output end of the gear box 2, and the propulsion mechanism can push the drilling mechanism to move toward the positioning device.

[0018] Further, the propulsion mechanism includes a guide rail 4, a lead screw 5 arranged along the length direction of the guide rail 4, and a motor 2 6 that drives the lead screw 5 to rotate. The drilling mechanism is slidably connected with the guide rail 4, and the drilling mechanism passes through The threaded hole is threadedly connected with the leading screw 5 .

[0019] The support mechanism includes a support frame 9 and a guide roller 10 installed on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com