Worm helical gearing mechanism

A transmission mechanism and helical gear technology, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of inability to carry out surface heat treatment, difficult assembly, difficult processing of worm gear, etc., to shorten the production cycle, The effect of reducing the difficulty of assembly and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

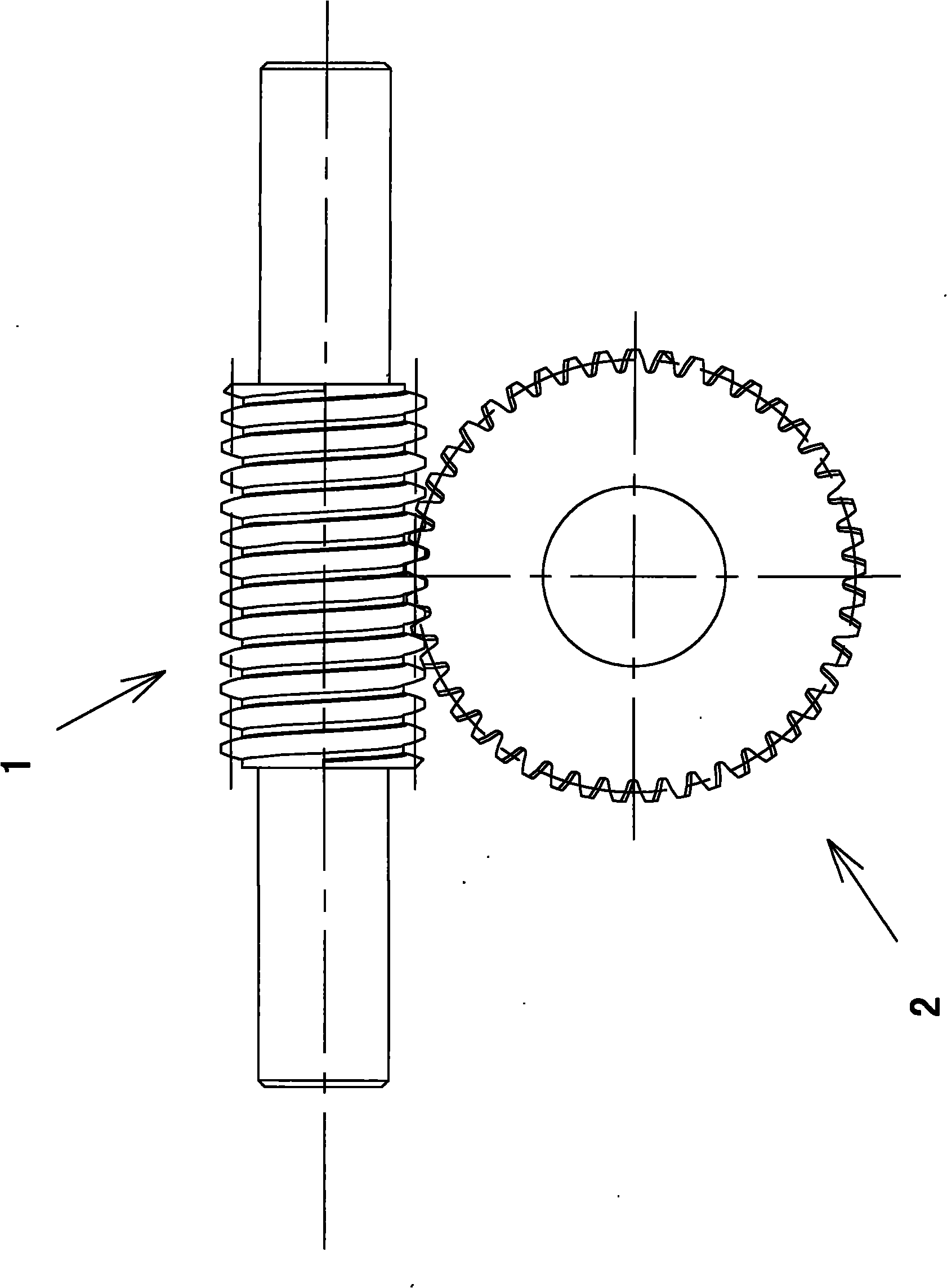

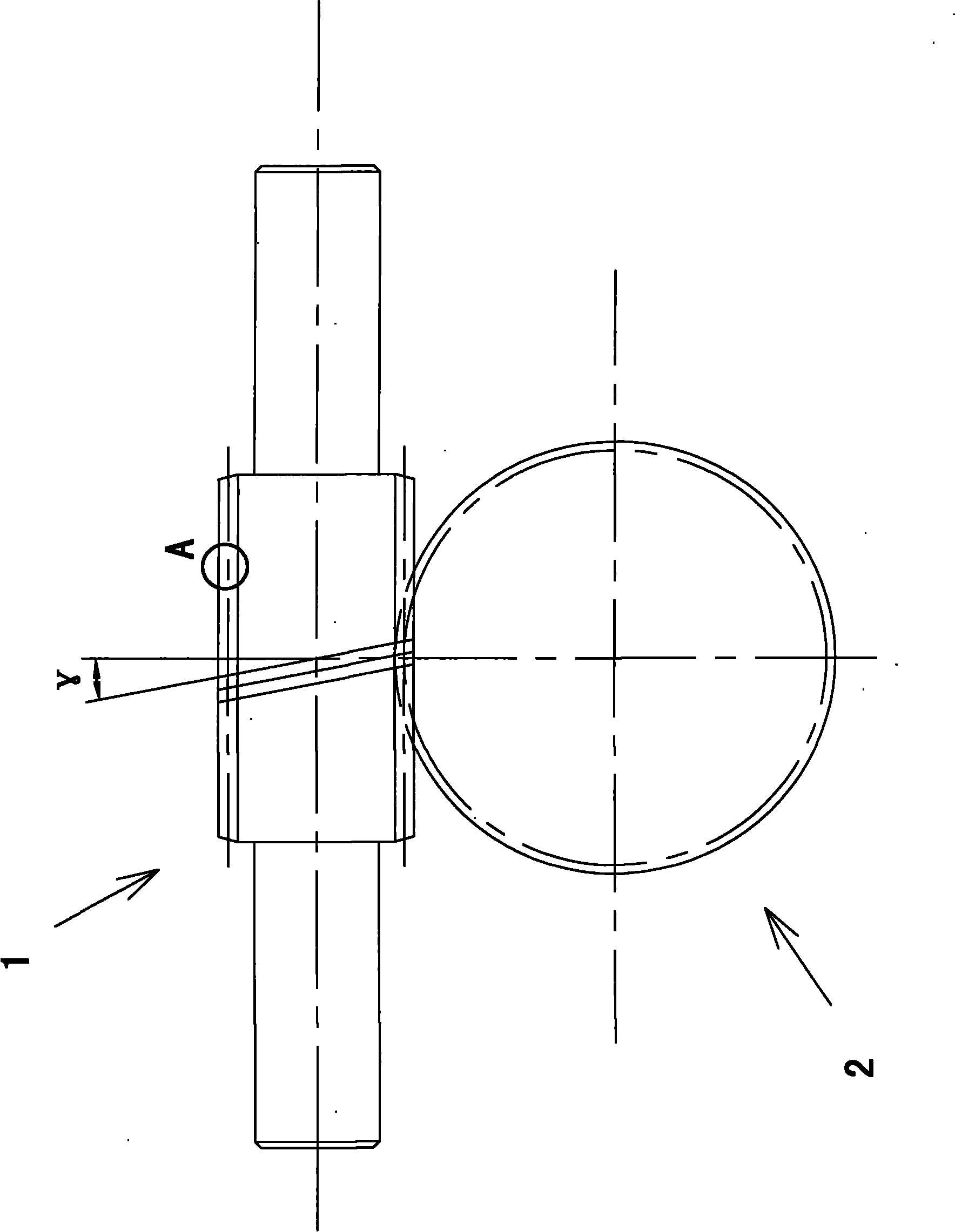

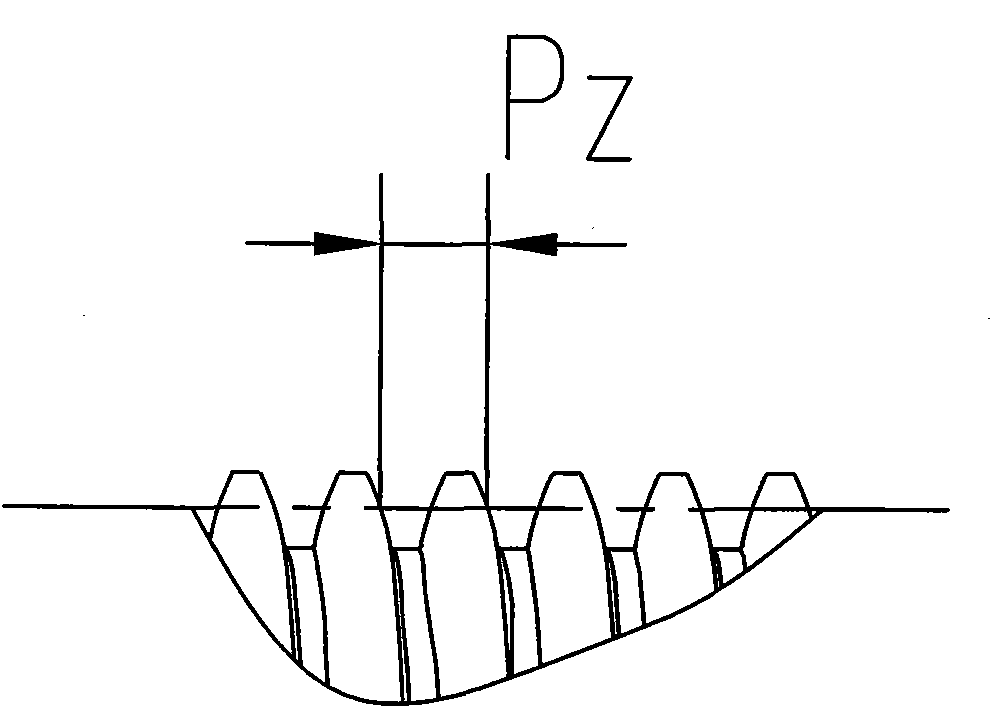

[0010] Such as figure 1 , 2 , Shown in 3, 4: 1 is worm screw, and 2 is the helical gear that meshes with worm screw 1, and the axle center lines of worm screw 1 and helical gear 2 are vertically arranged mutually, and worm screw 1 and helical gear 2 are involute type. The lead Pz of the worm 1, the lead angle γ of the worm 1 is equal to the helical angle β of the helical gear 2, and the normal modulus of the worm 1 is equal to the normal modulus of the helical gear 2. After ensuring the above conditions, the worm and the helical gear can mesh well to achieve the purpose of power transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com