Numerical control woodworking inner arc surface milling machine

An internal arc surface and milling machine technology, applied in wood processing appliances, manufacturing tools, forming/shaping machines, etc., can solve the problems of unsuitable for mass production of standardized products, low production efficiency, high labor intensity, etc., and achieve low cost and operation. Convenience and small production area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

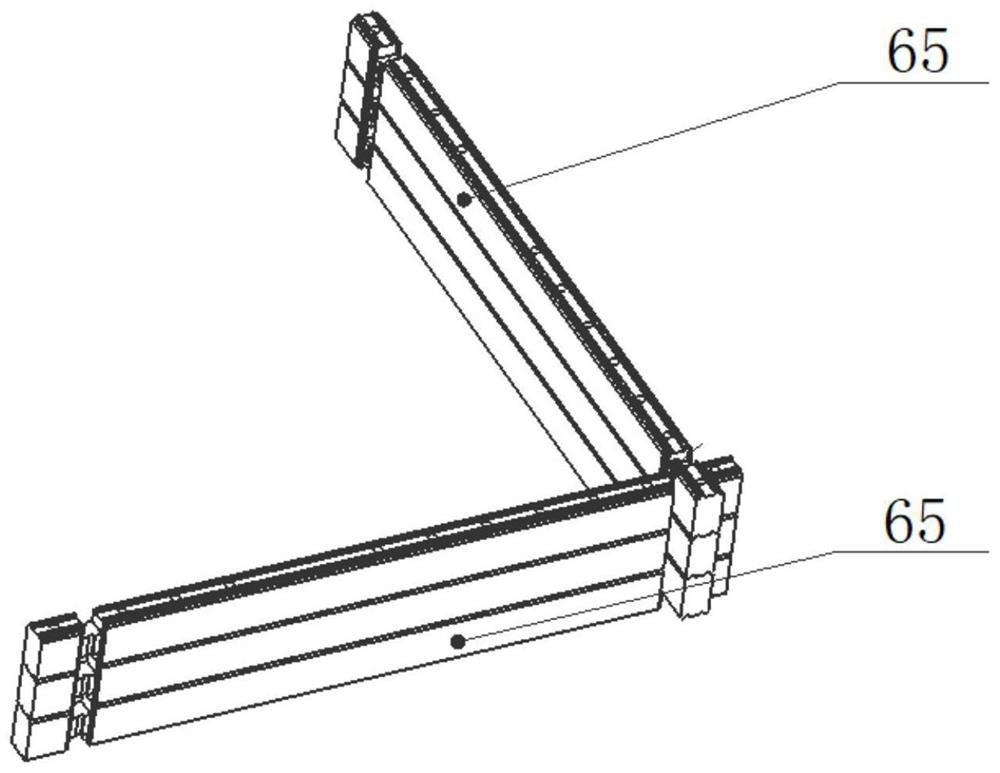

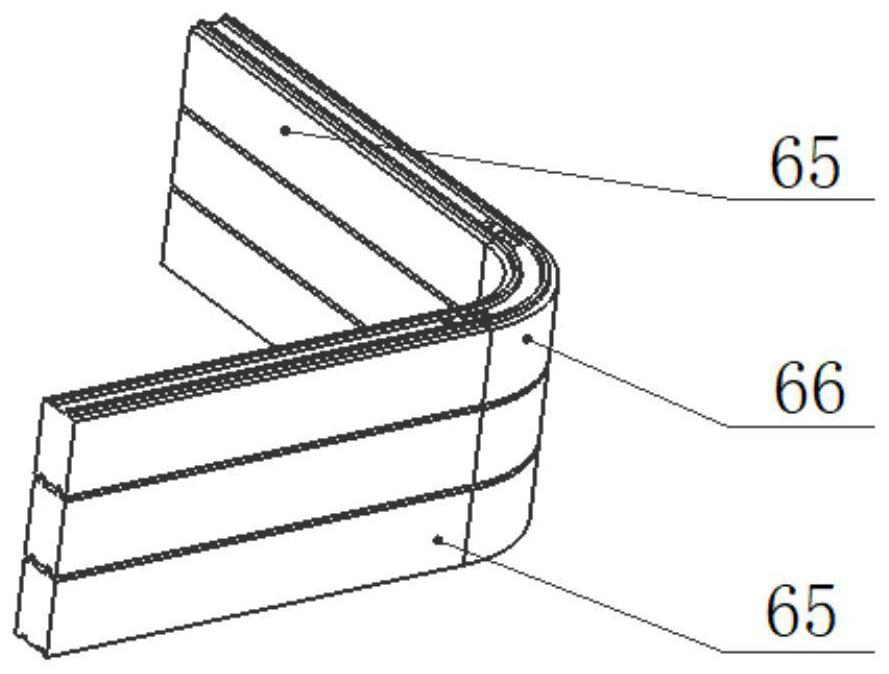

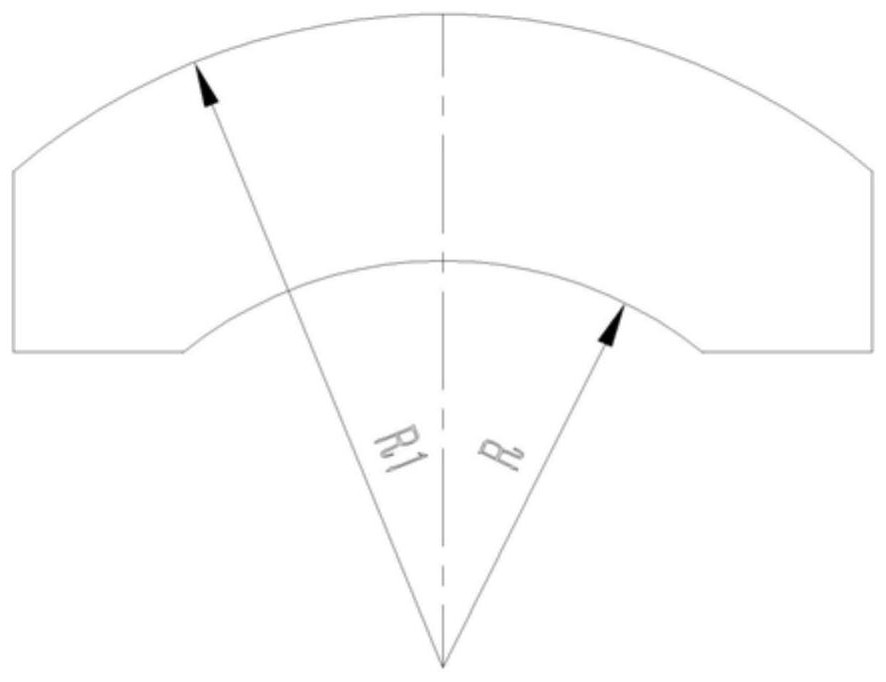

[0042] This embodiment discloses a CNC woodworking inner arc milling machine, such as Figure 7-11 As shown, it includes a cutting device, a feeding device, a positioning device, a dust removal device, a rotary table 32, a bed and an automatic control system;

[0043] A rotary table 32 is arranged horizontally above the bed; the lower part of the cutting device is arranged on the underside of the bed, and the upper part is installed in the rotary table 32; the feeding device is arranged under the bed for driving the cutting device and rotary table 32; the positioning device is arranged on the rotary table 32, and the dust removal device is arranged above the cutting device (cutter 4) and below the workpiece to be cut; the automatic control setting and the feeding device (cutter shaft motor 49 and workbench motor 22) are electrically connected.

[0044] The bottom of the bed is provided with a base frame 51, the base frame 51 is fixed with a dovetail lower guide rail 57, the d...

Embodiment 2

[0062] This embodiment discloses a

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com