Patents

Literature

40results about How to "Meet dust removal requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

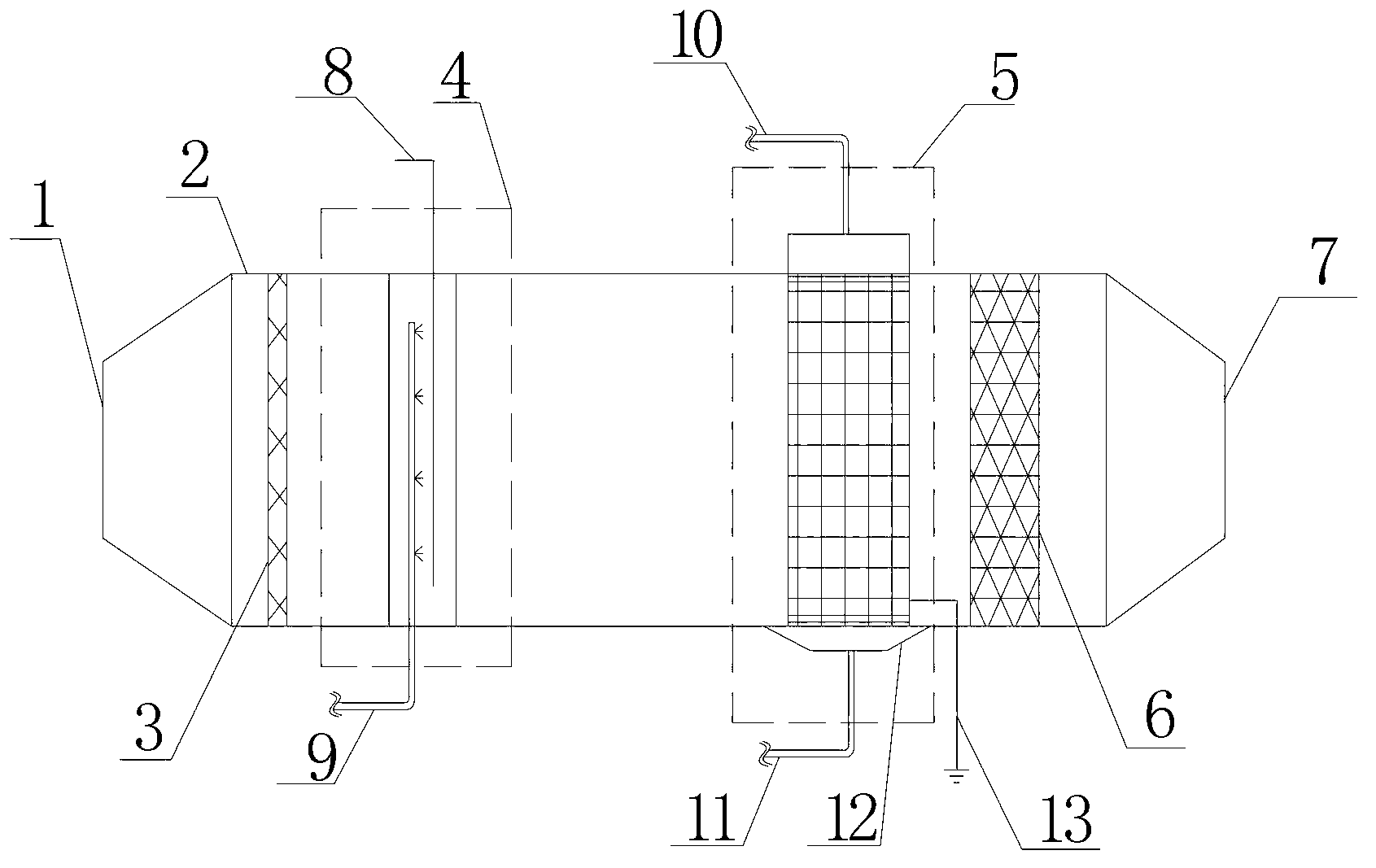

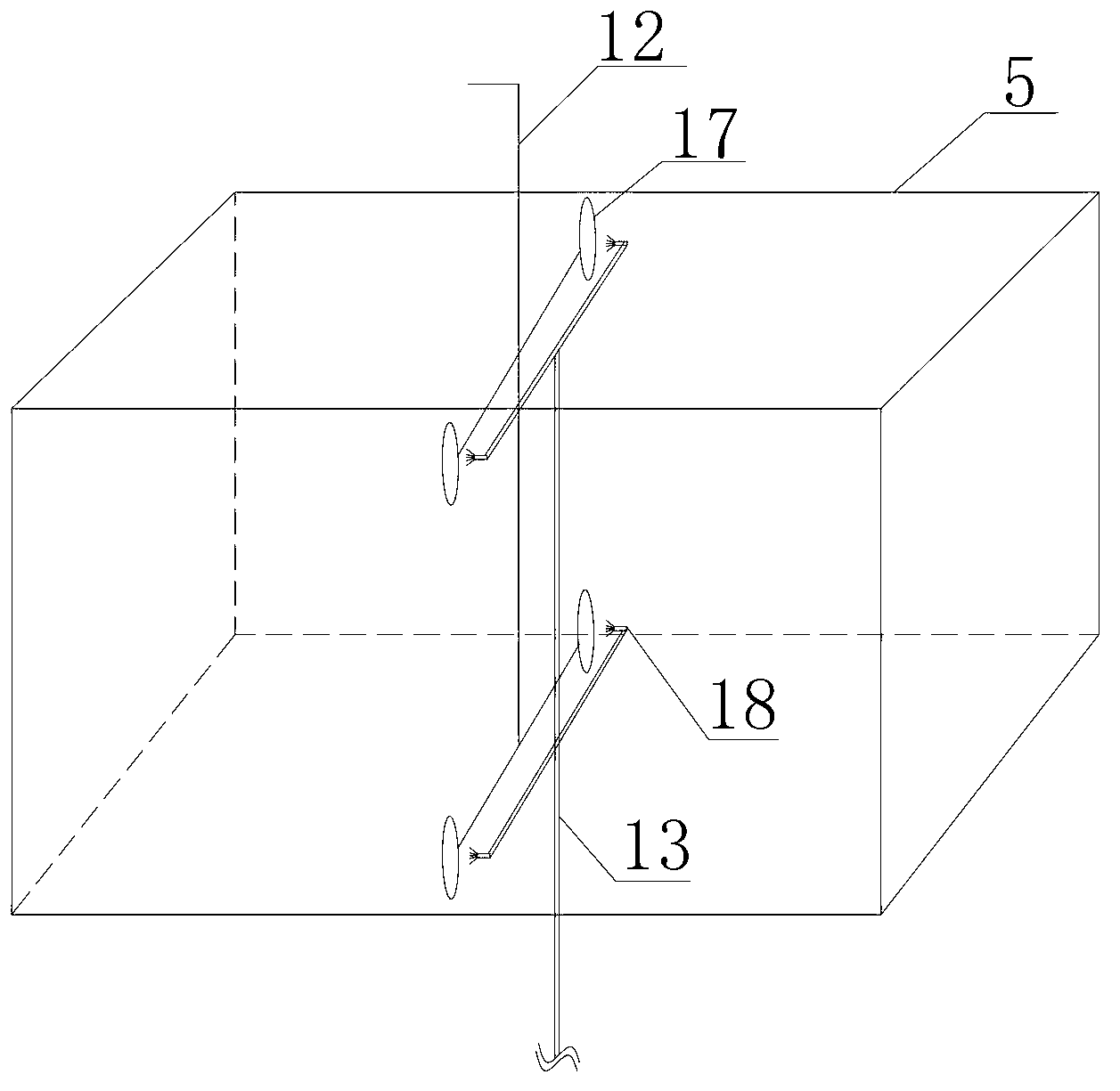

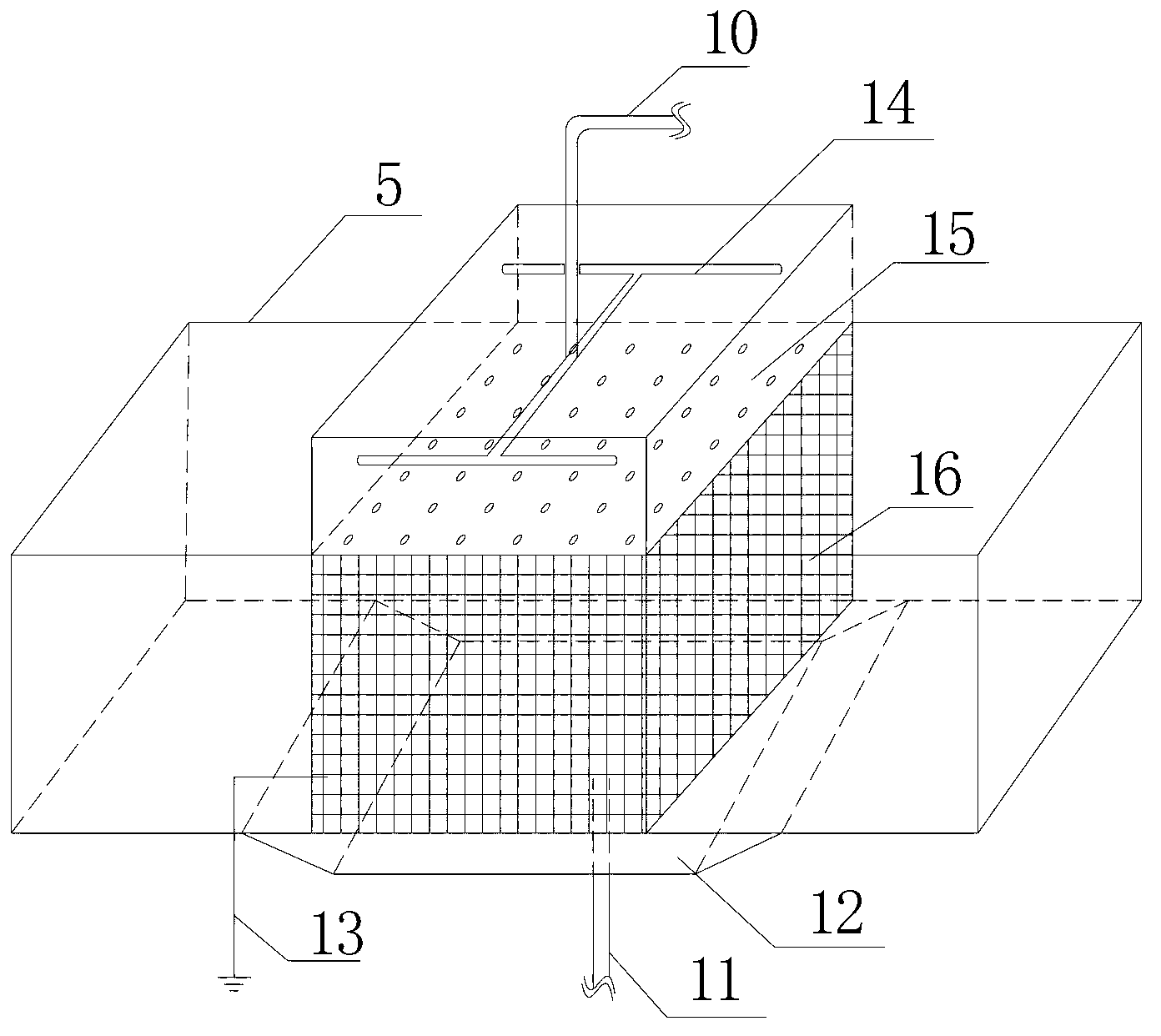

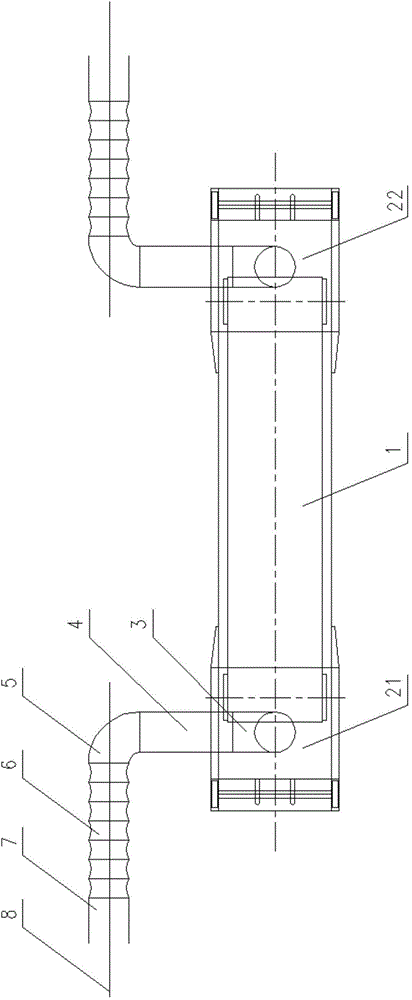

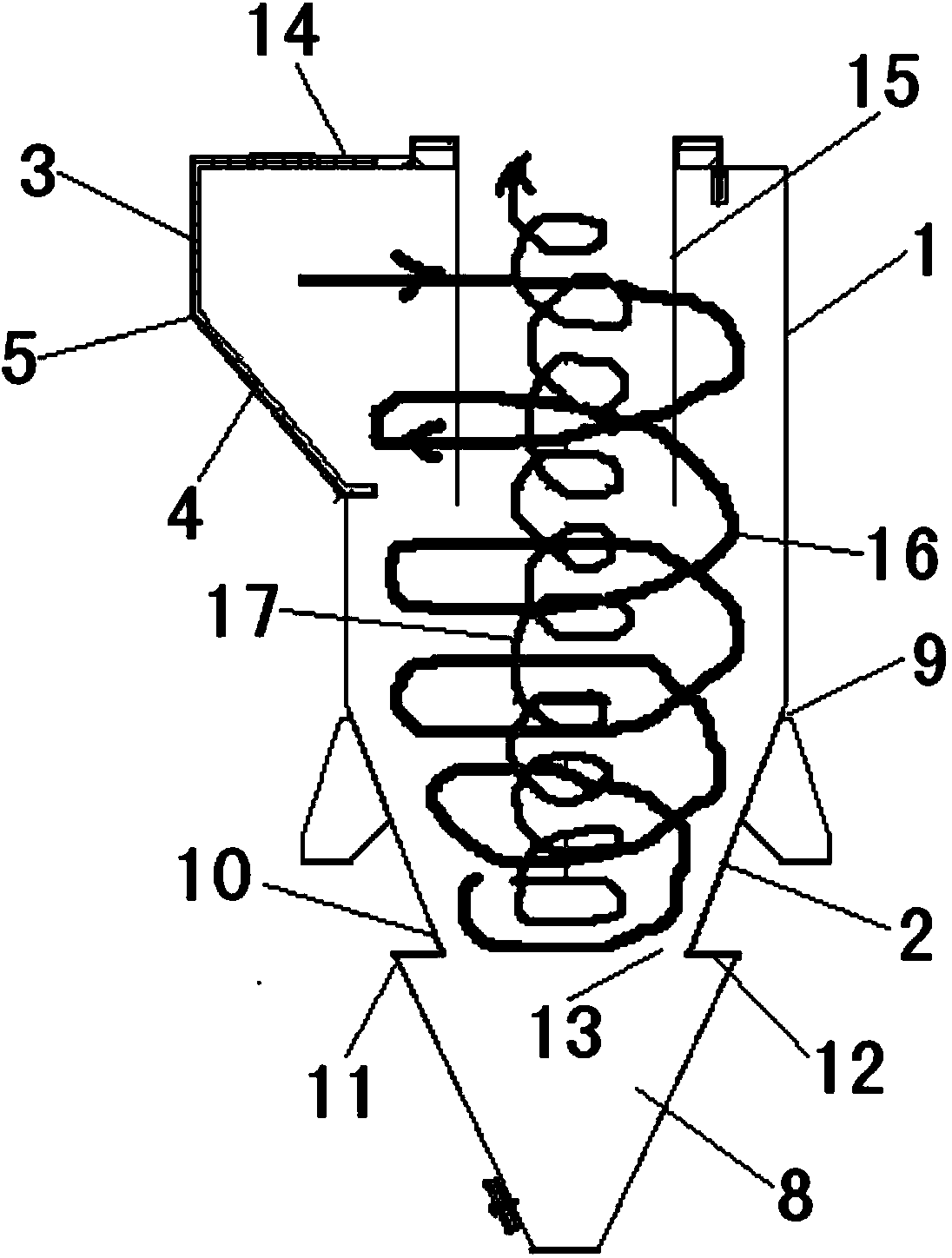

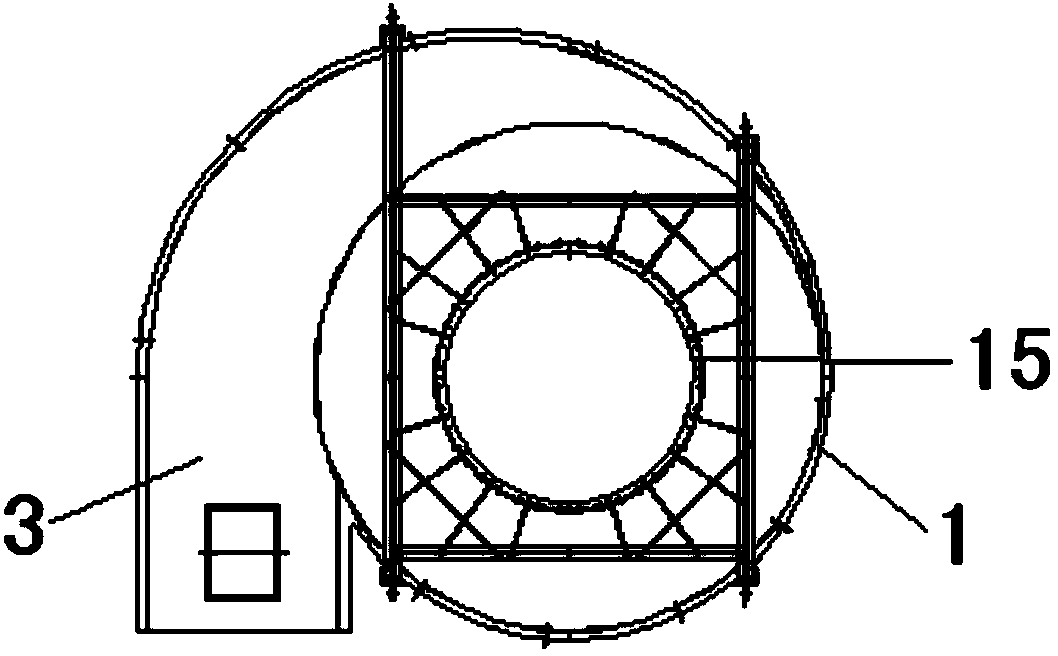

Electrostatic spraying and dust-removing system

InactiveCN102698557AImprove filtration efficiencyMeet dust removal requirementsCombination devicesHigh pressureDistributor

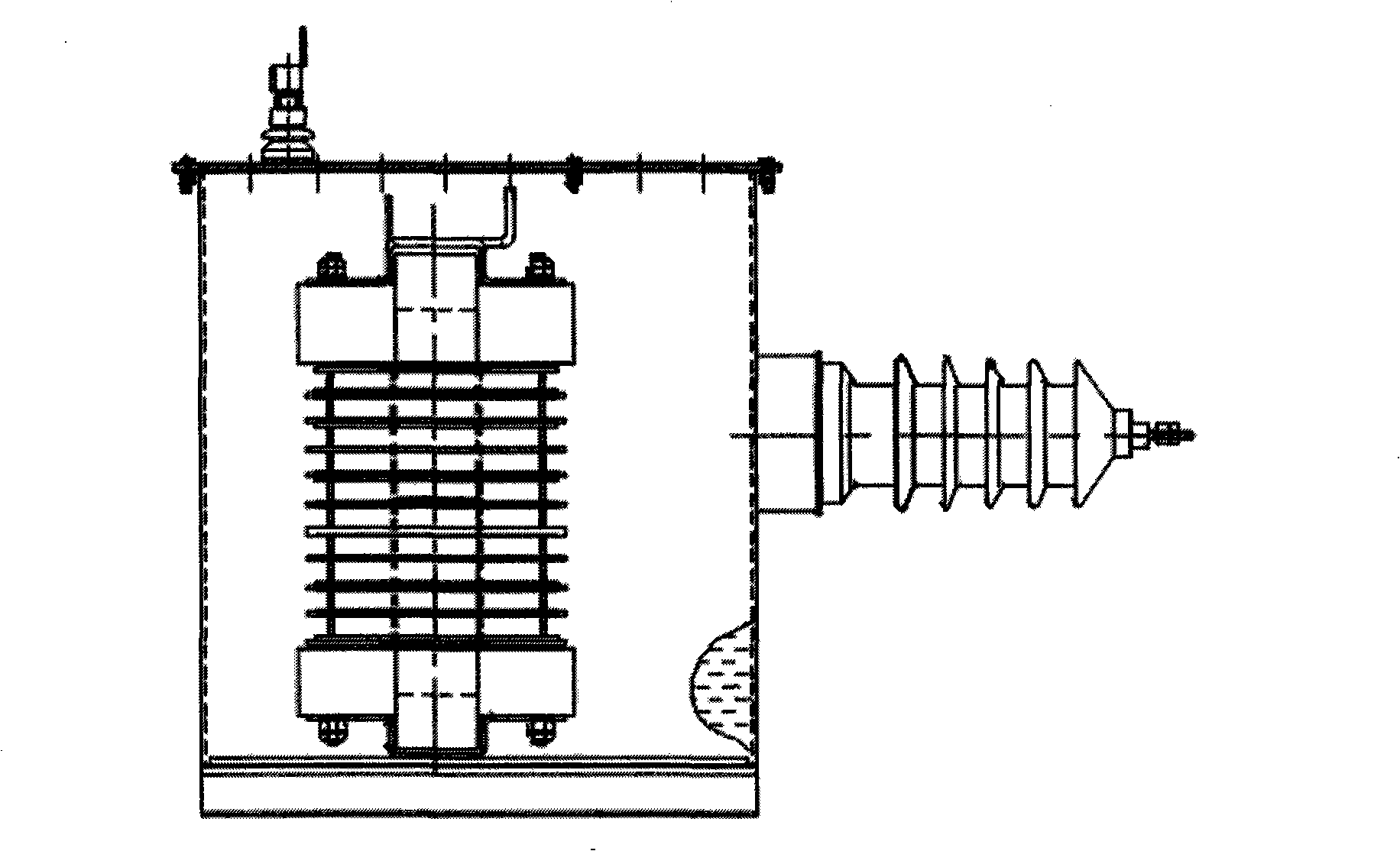

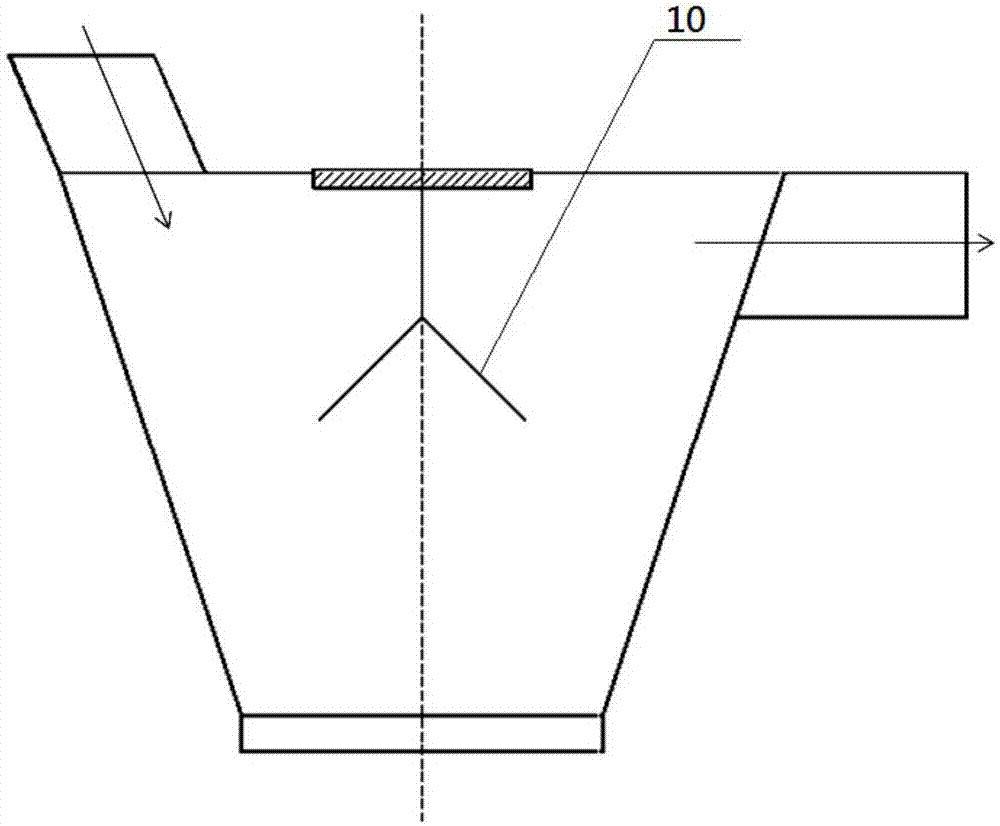

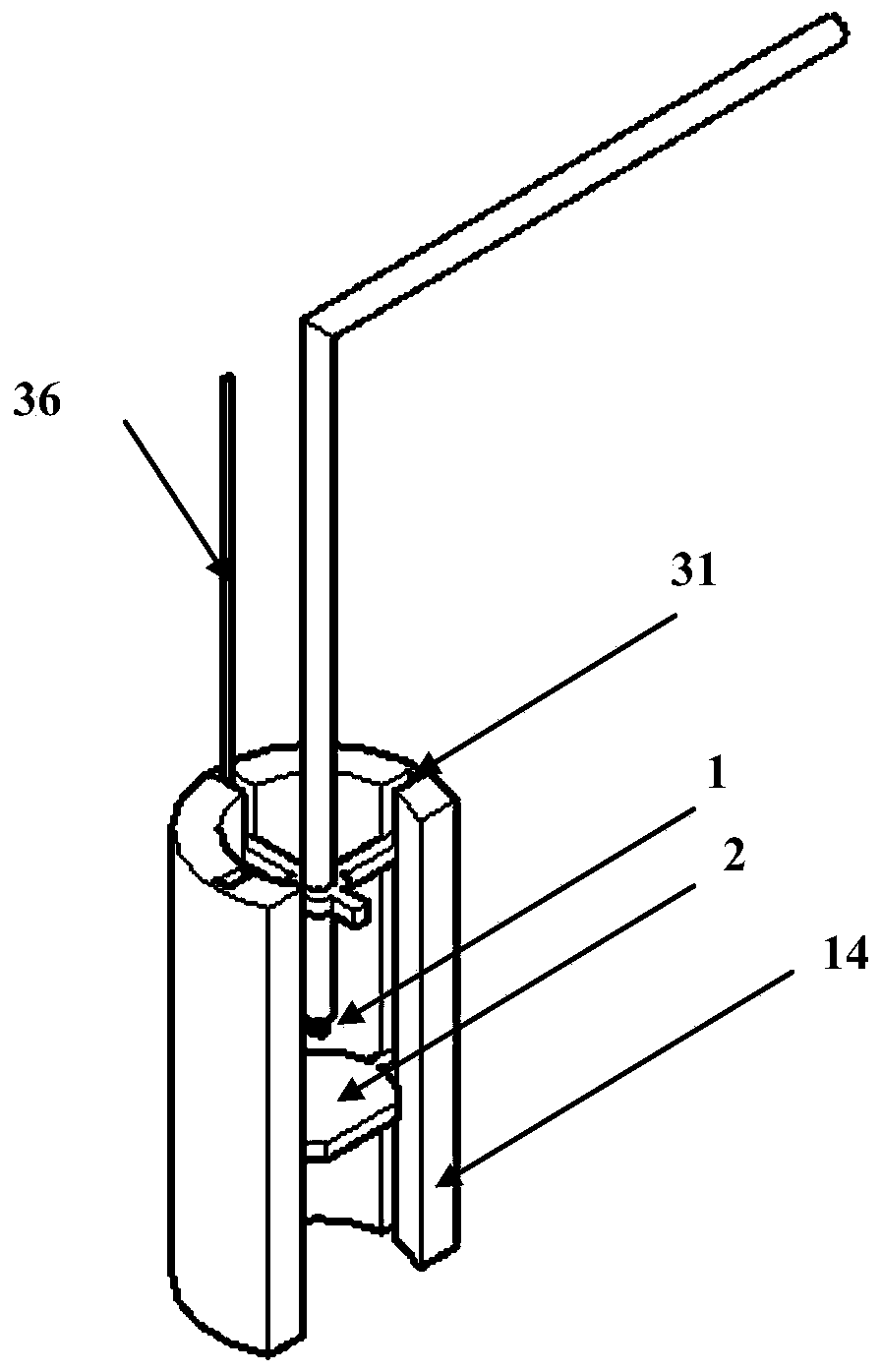

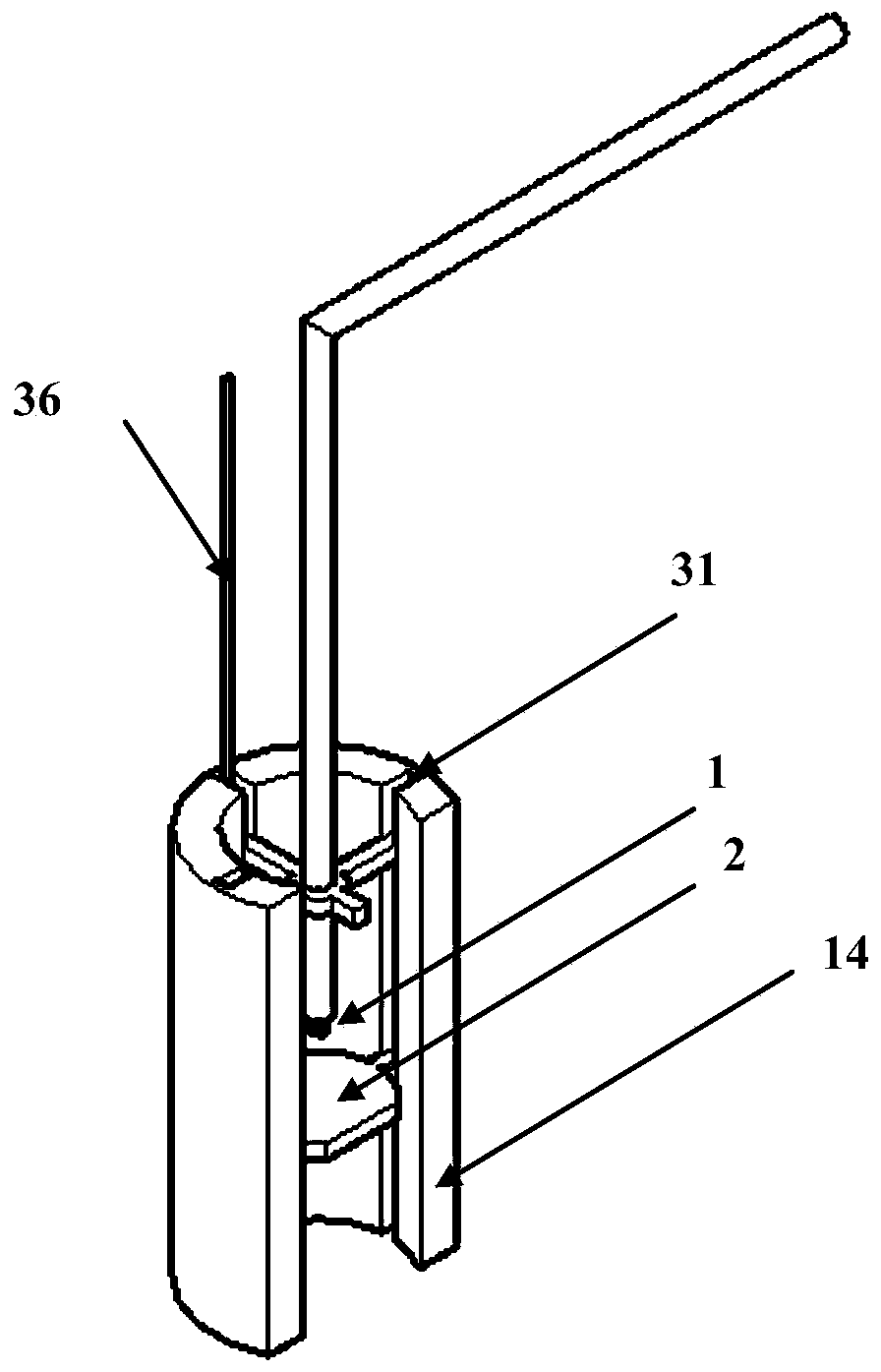

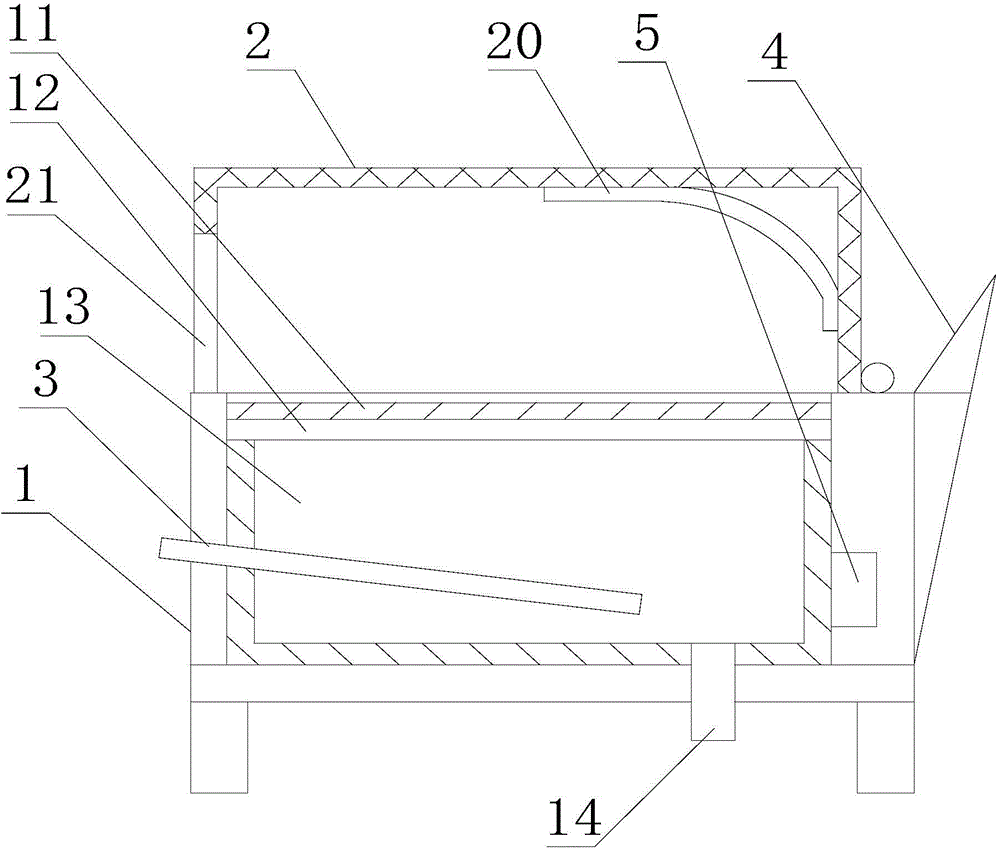

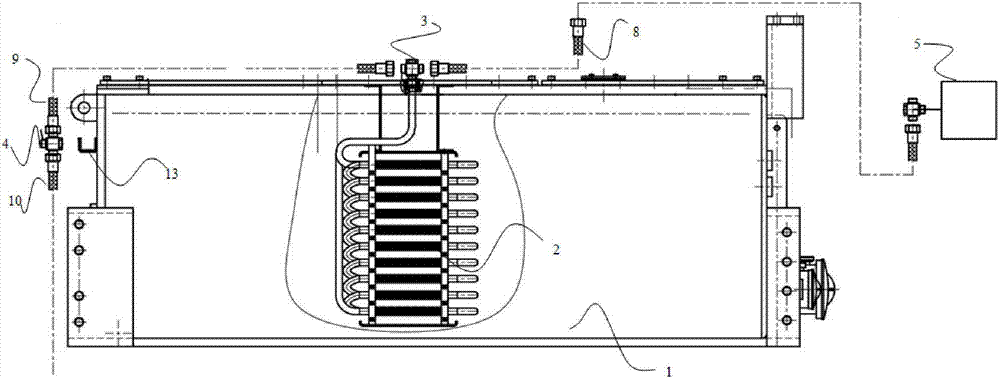

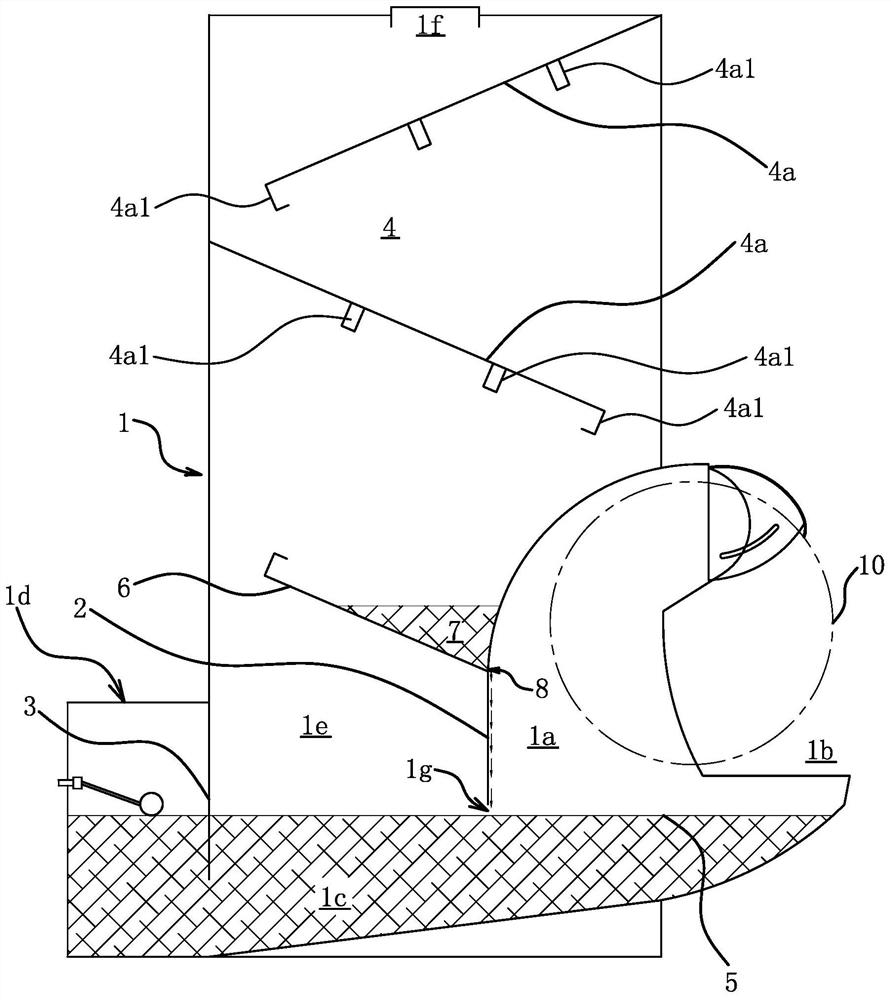

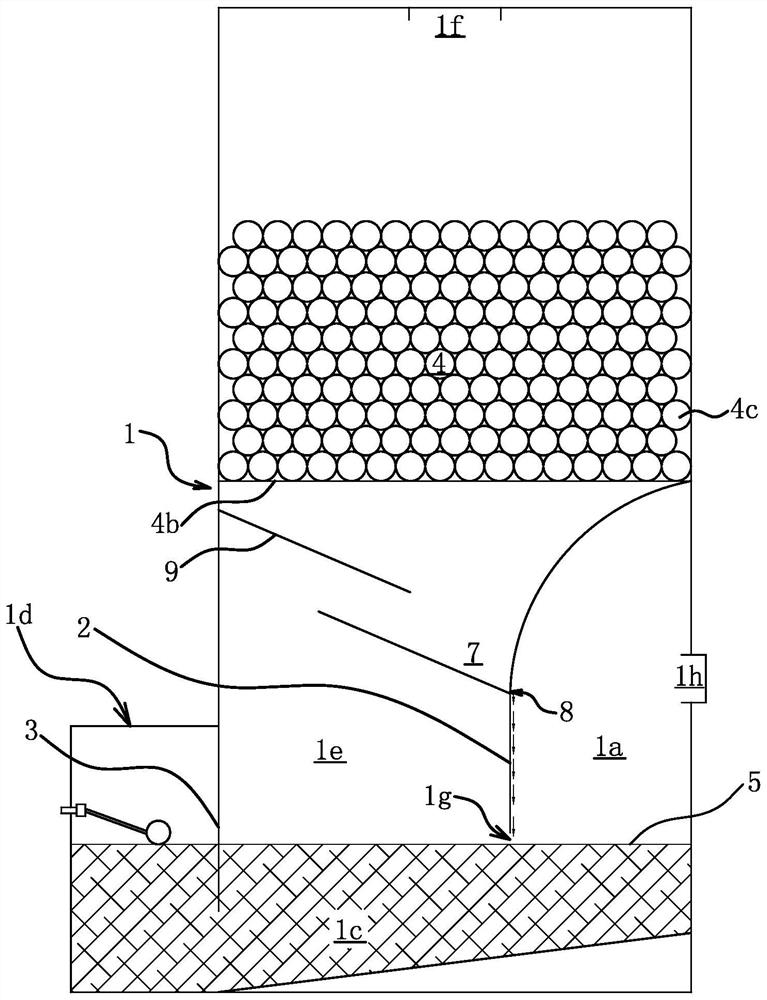

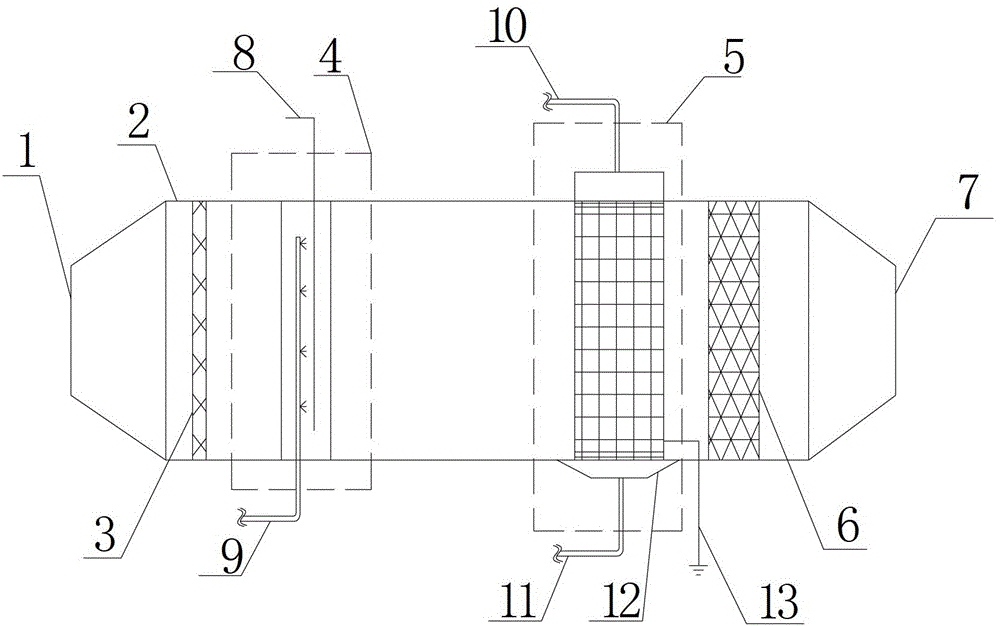

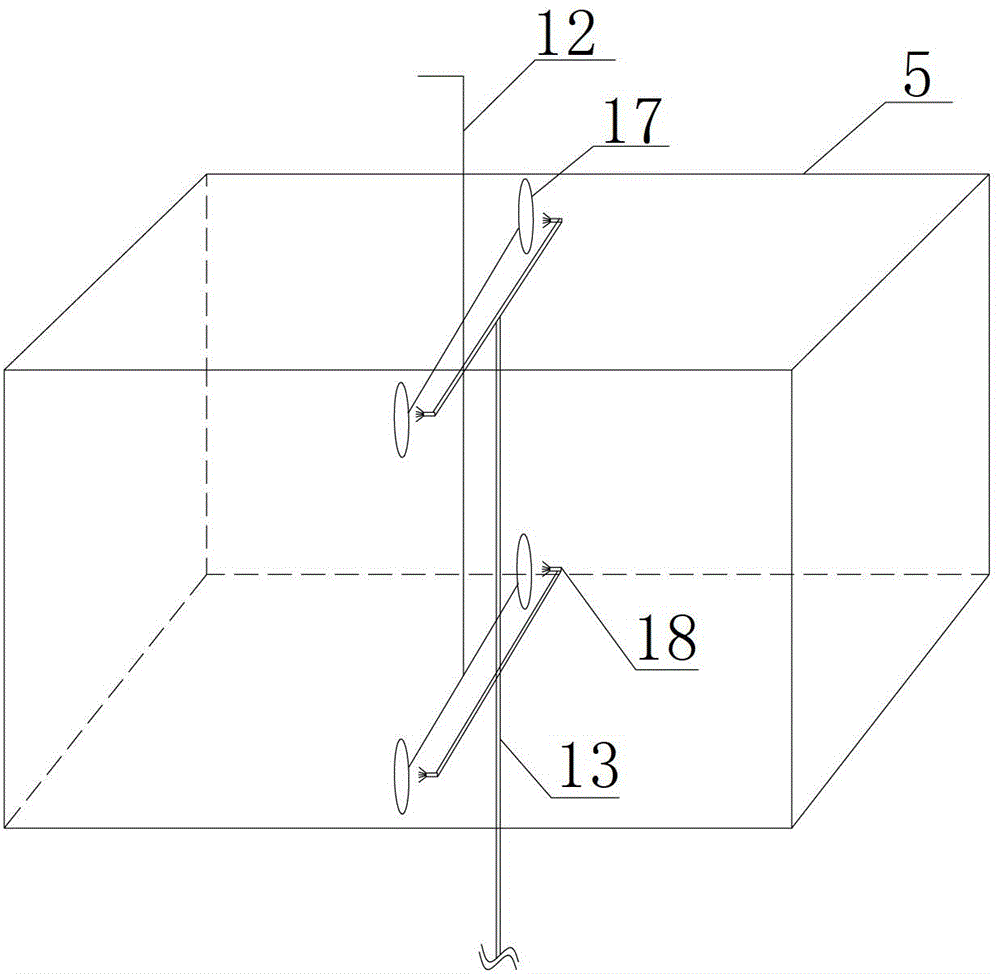

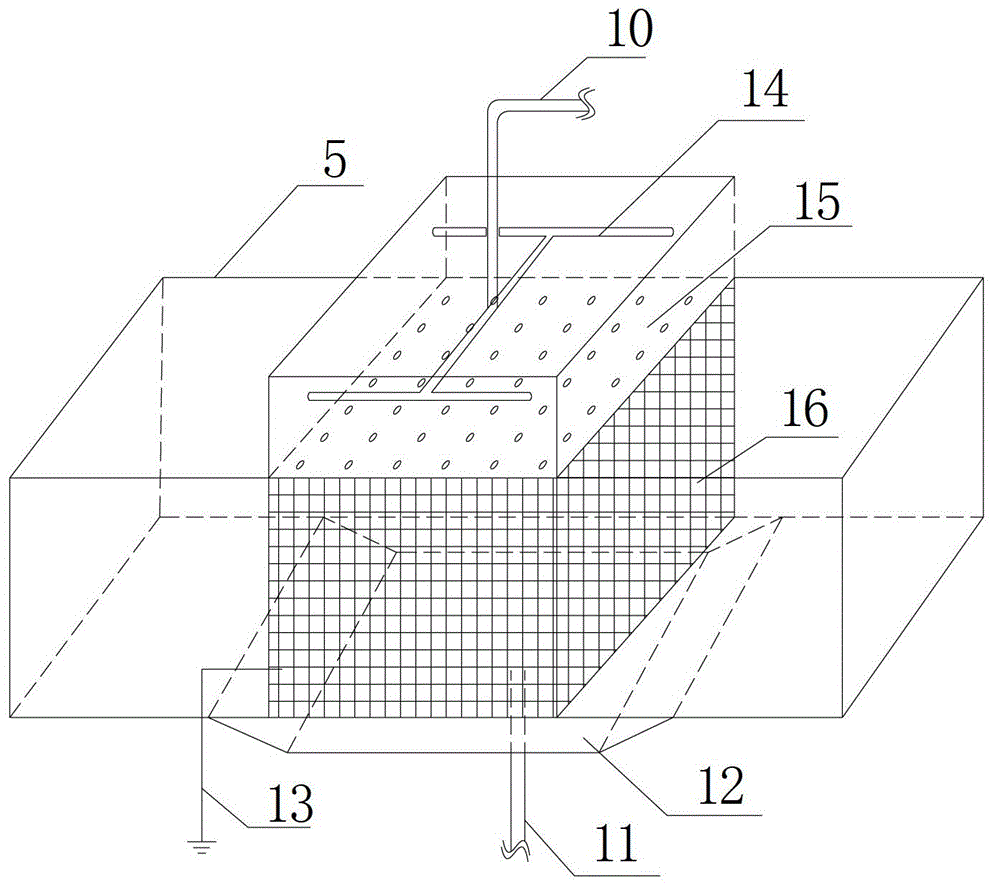

The invention relates to an electrostatic spraying and dust-removing system. One end of a shell is an inlet of a dust-removing system while the other end of the shell is an outlet of the dust-removing system; an air flow distributor, an electrostatic spraying device, a filtering dust-collecting and washing device and a water separator are arranged in the shell orderly from the inlet to the outlet; at least one atomizing nozzle is connected to a water supply pipe in the electrostatic spraying device, a high pressure static ring is arranged in front of each atomizing nozzle; the high pressure static ring is connected with a high pressure static generator at the outer part of the system through a lead; a filler is arranged in the filtering dust-collecting and washing device, and the upper part of the filler is provided with a water pouring distributor; the water pouring distributor is connected with a system external water supply pipe through a water pipe; and the bottom part of the filler is provided with a water collecting disk, and the water collecting disk is provided with a water draining pipe. The system can satisfy the dust removing requirement of grains in different sizes in air, and has a relatively good effect to filter the powder dust with the grain diameter being more than 0.1 micro meters.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

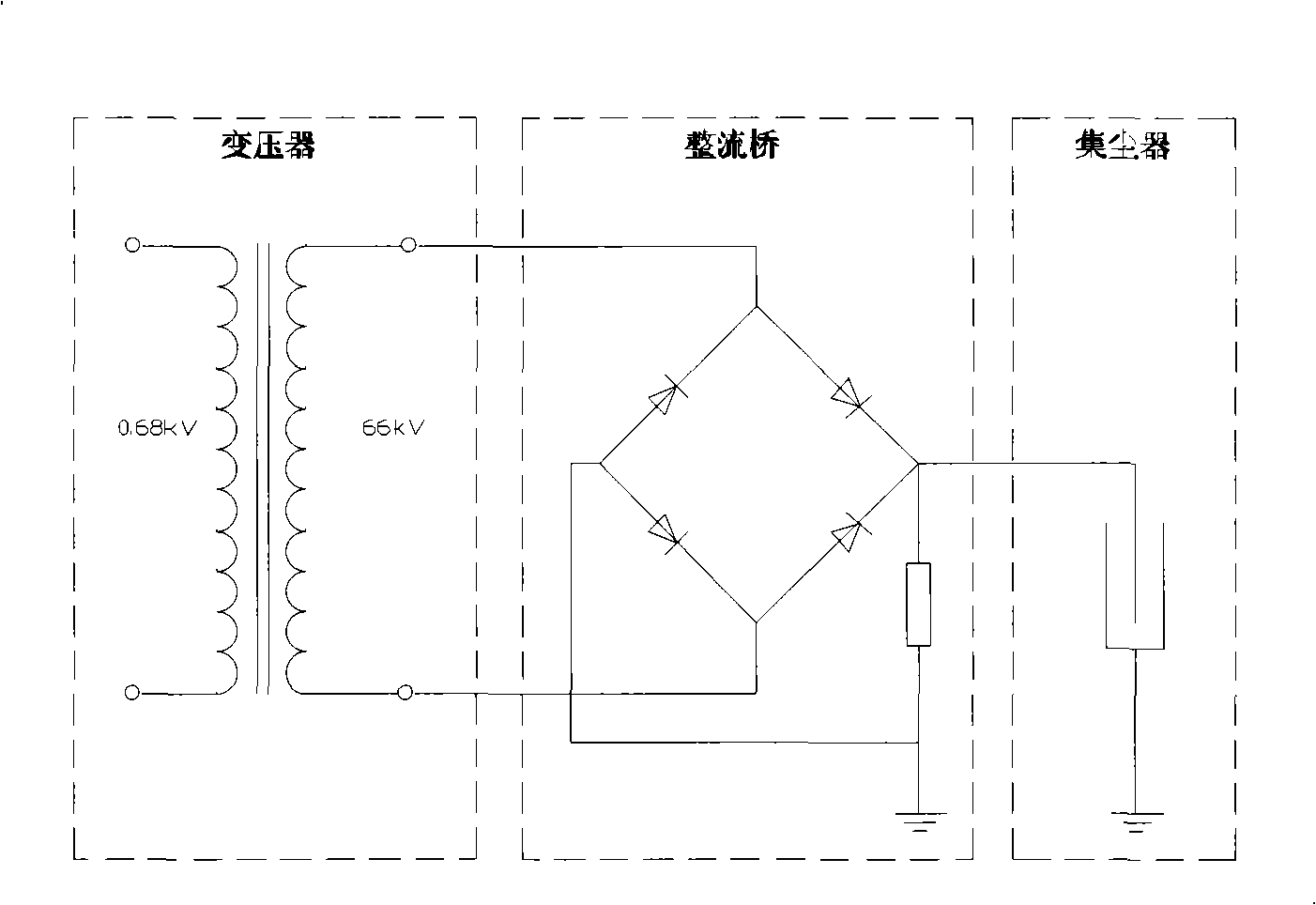

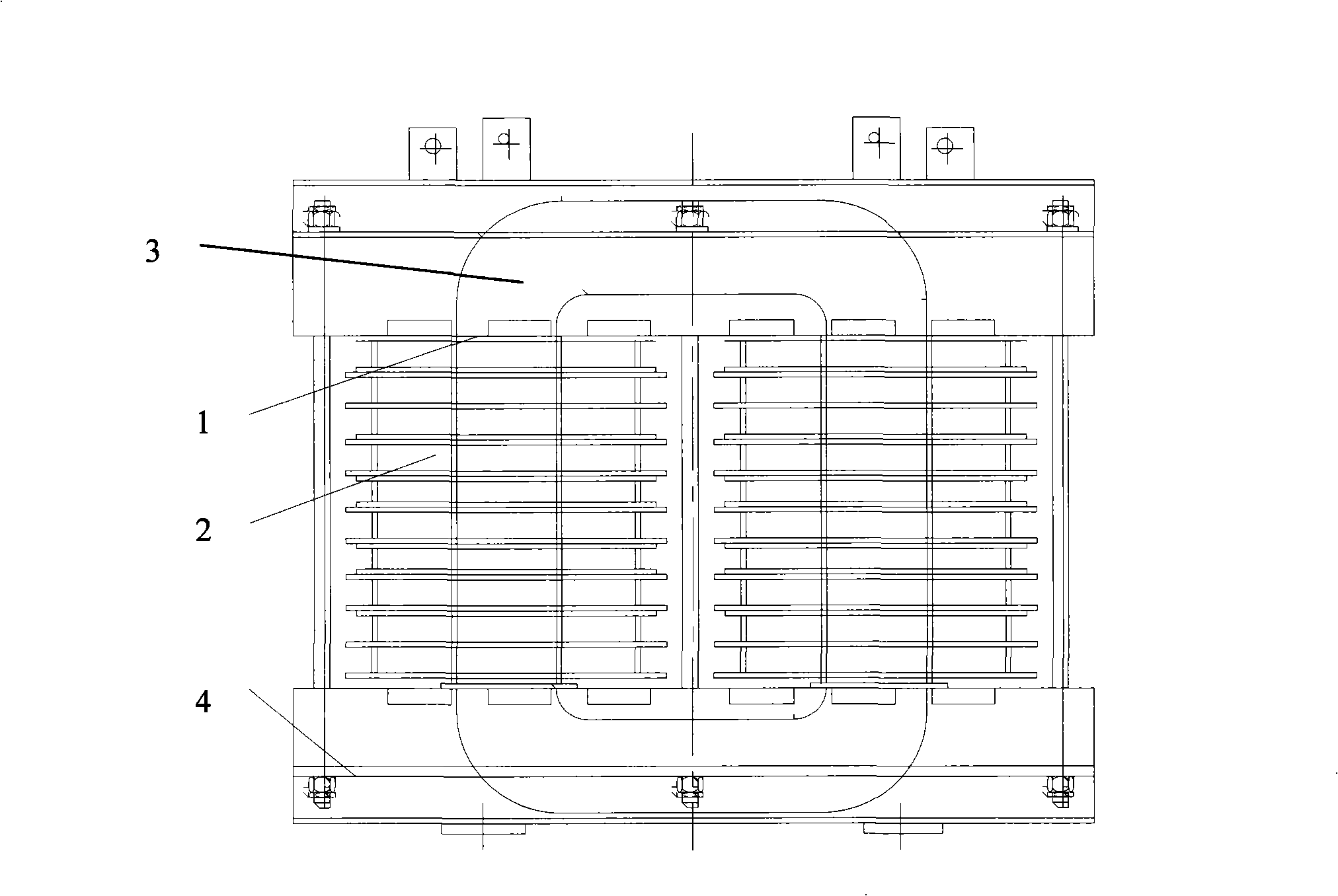

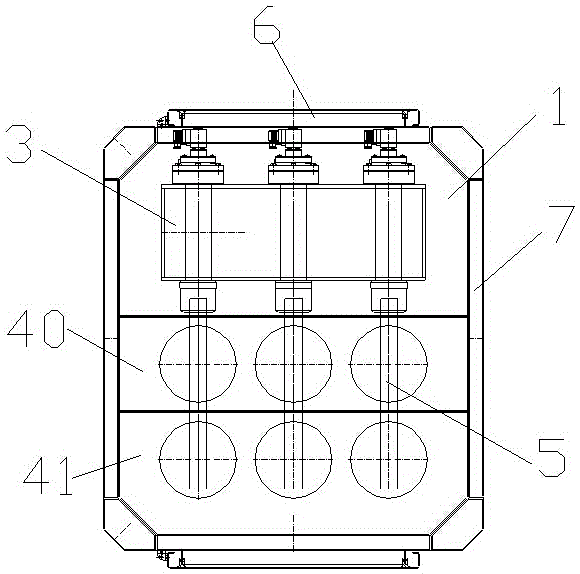

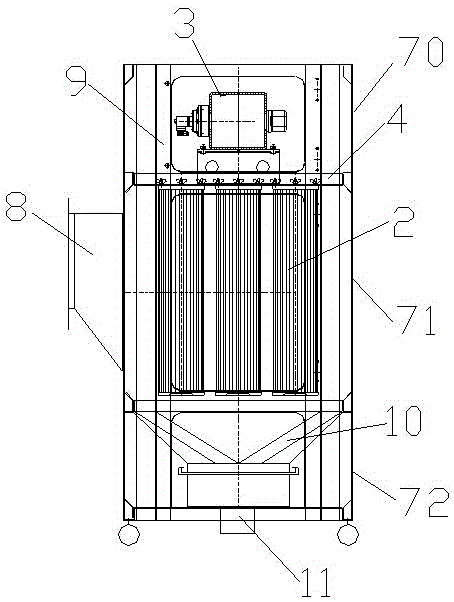

High-frequency dust removing transformer

InactiveCN101339839ASolve the problems existing in the dust removal processReduce output efficiencyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLow voltageButt joint

The invention discloses a high-frequency dedusting transformer which comprises a low voltage winding, a high voltage winding and an iron core; the iron core takes a 'Square' shape which consists of two half-'Square' shapes in butt joint, and the iron core is made from ferrite material; the output voltage of the low voltage winding is 0.68kV, the output voltage of the high voltage winding is 66kV, and the working frequency of the transformer is 7-8kHz. The low voltage winding is wound by copper foil, the high voltage winding is of multi-pancake continuous type, and insulation and cooling are realized by transformer oil. Compared with the prior art, the high-frequency dedusting transformer has the advantages that the operation is stable, the dedusting efficiency is increased by about 20% relative to that of a power frequency transformer, the volume of the transformer is decreased by about 10%, which facilitates the installation of the whole set of equipment, and the high-frequency dedusting transformer is applicable to environment-friendly dedusting equipment.

Owner:ZHENJIANG TIANLI TRANSFORMER

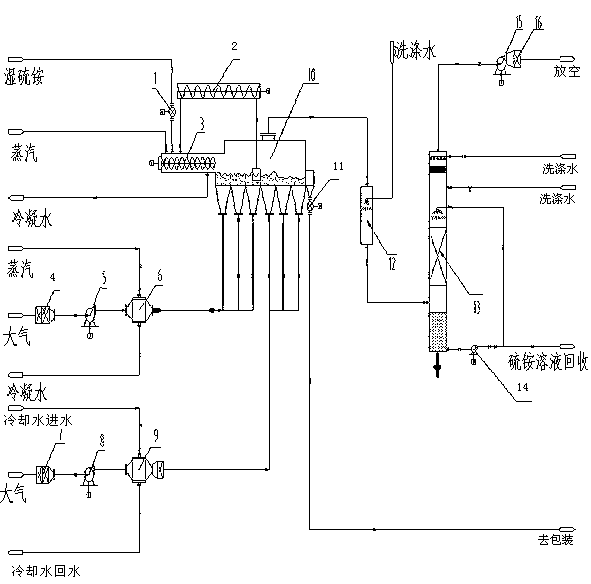

Fluidized bed drying process for ammonium sulfate

InactiveCN103277983AFeed performance is stableAvoid cakingDrying solid materials with heatDrying gas arrangementsFluidized bed dryingCold air

Owner:NANJING TIANHUA CHEM ENG

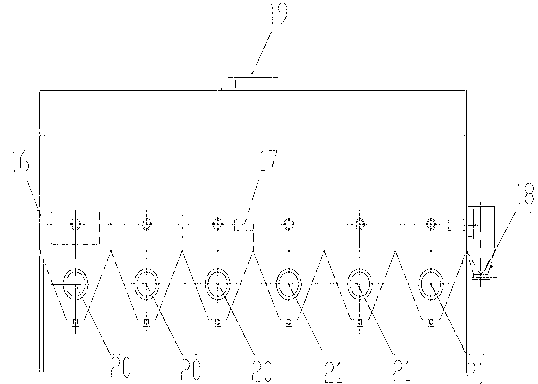

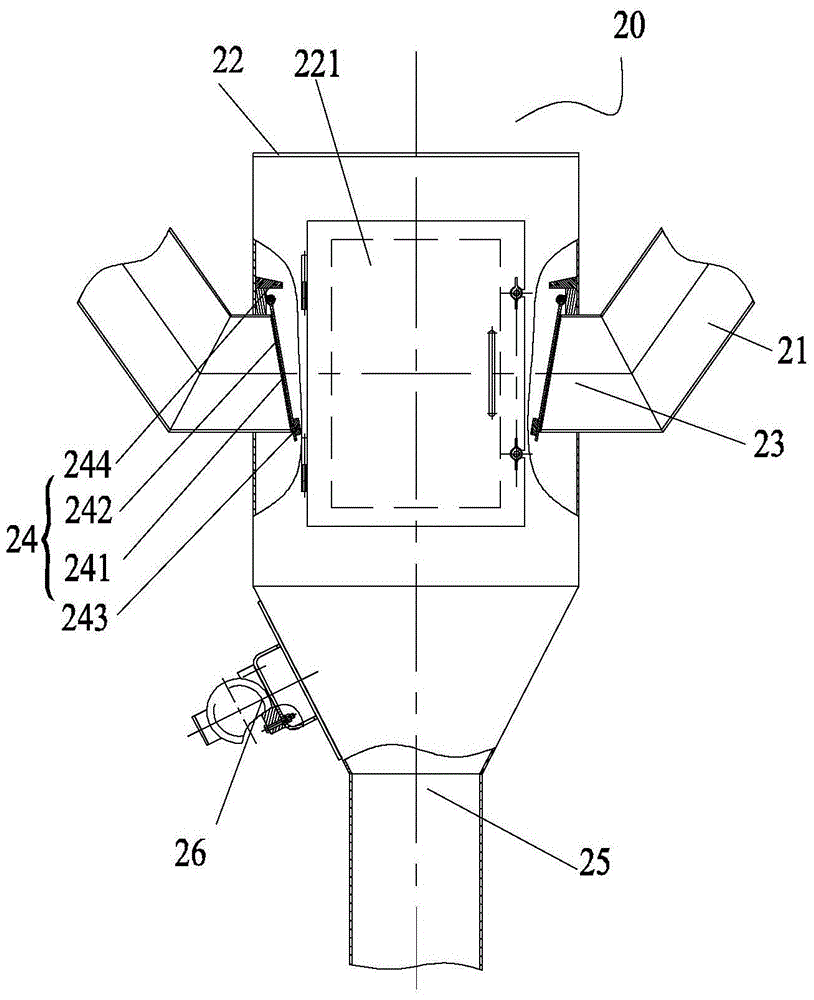

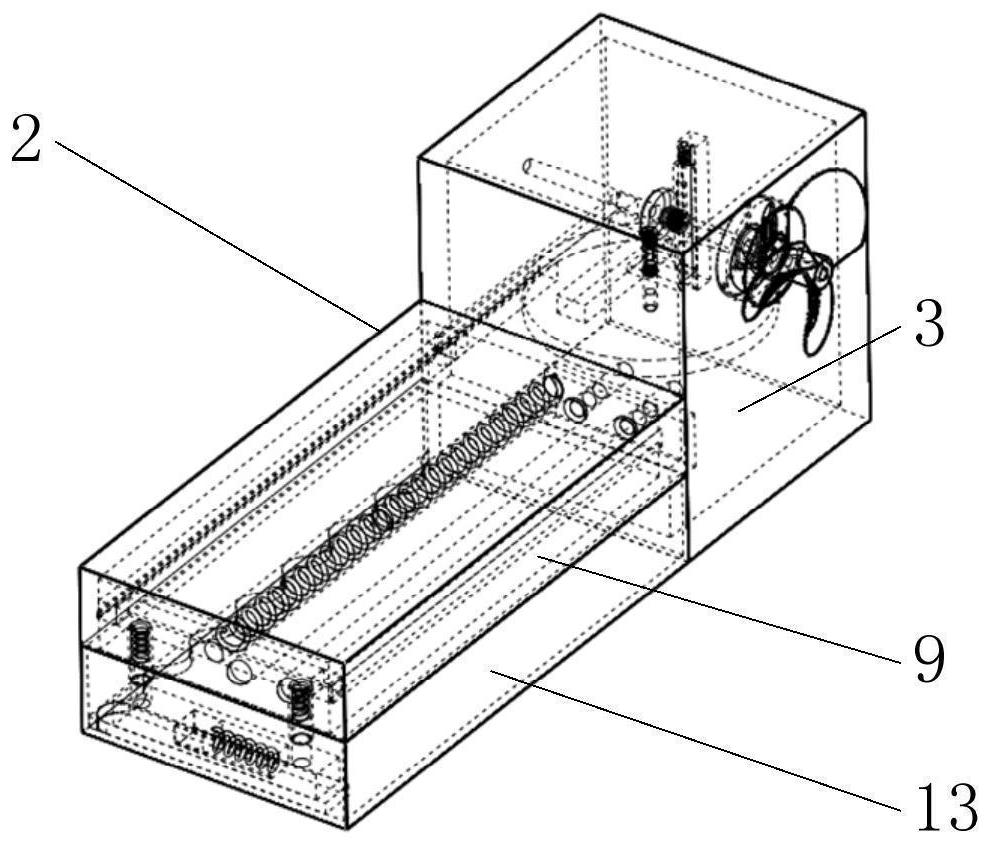

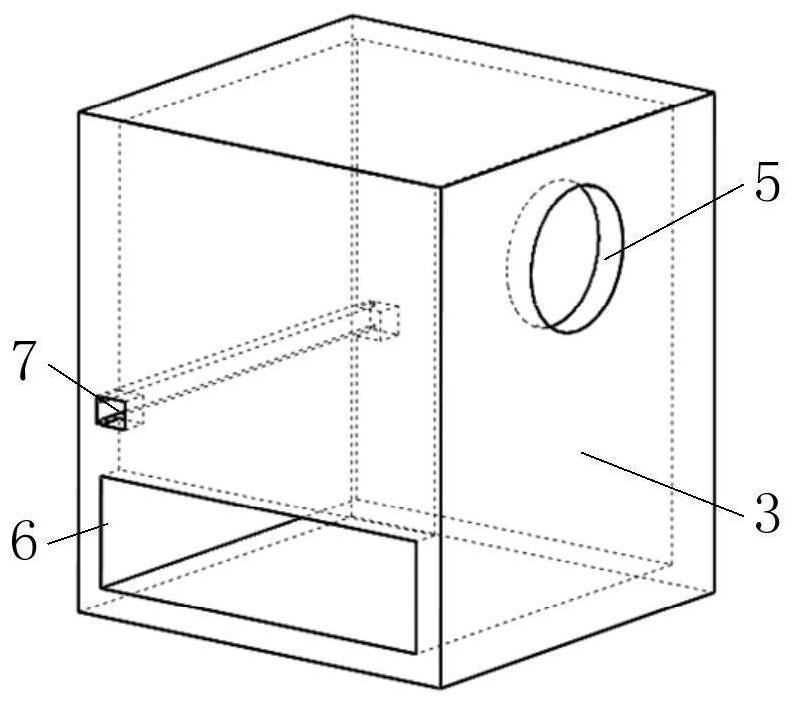

Gravity dust removal apparatus and asphalt stirring device

PendingCN107288012AAchieving AdaptivenessOvercome limitationsDispersed particle separationRoads maintainenceFlue gasAsphalt

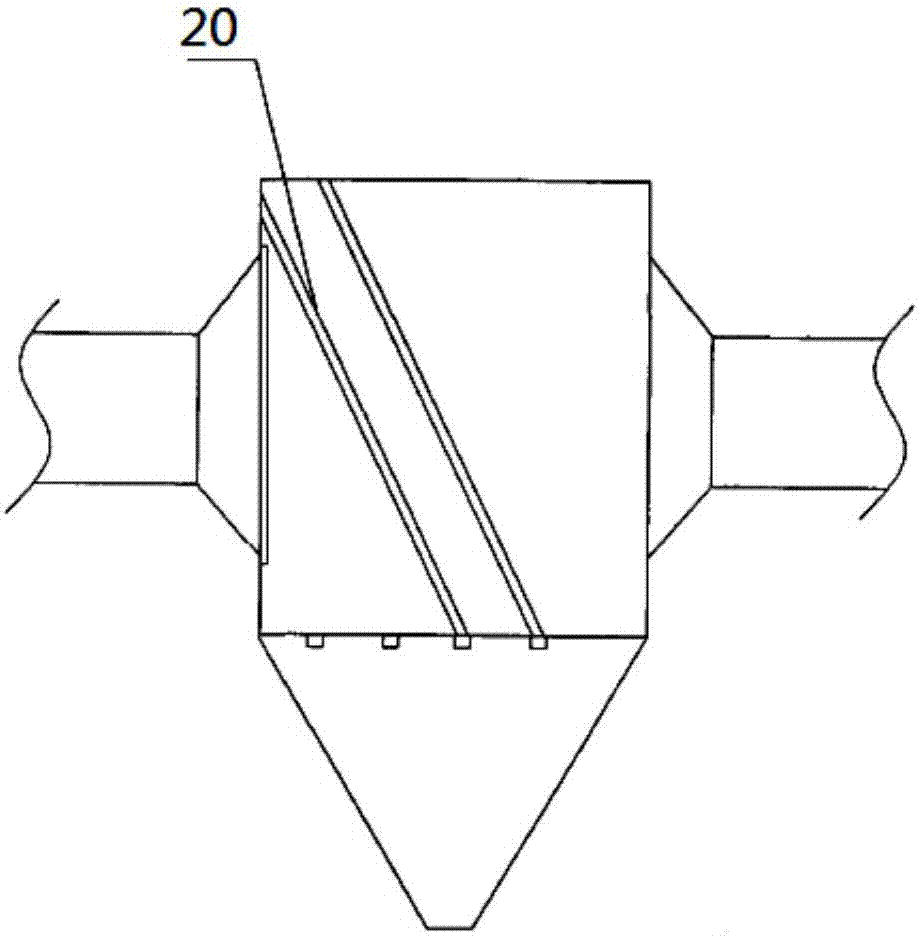

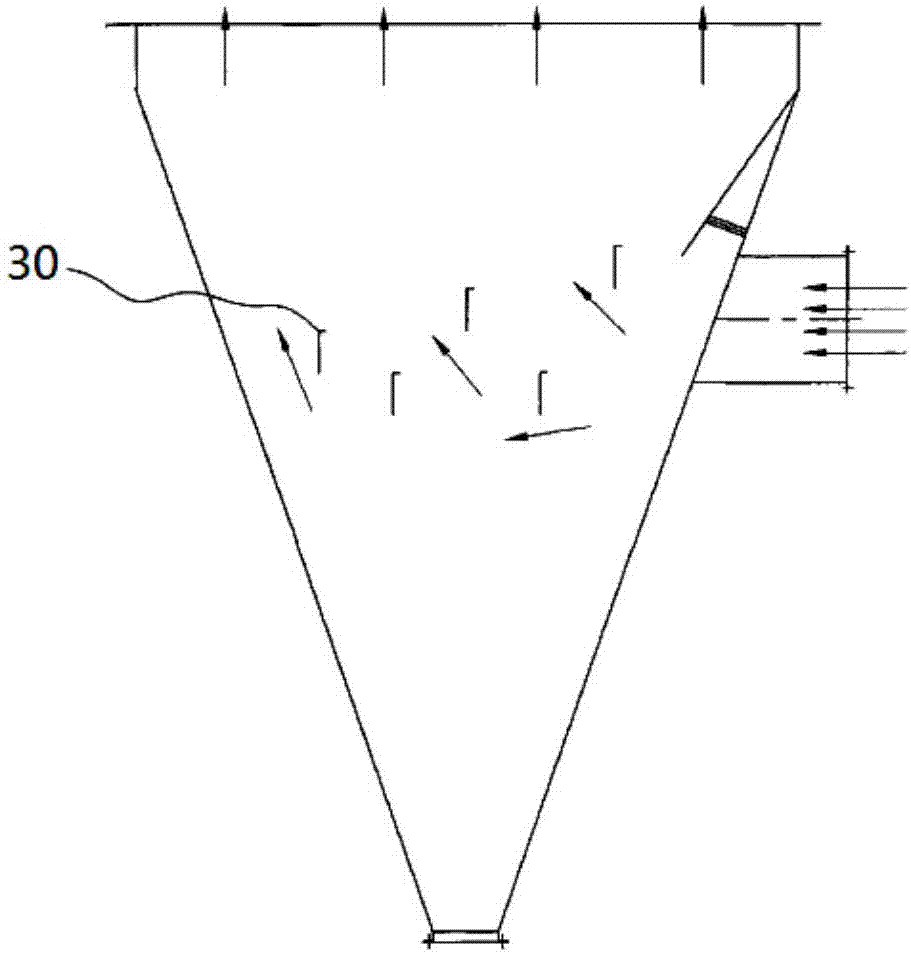

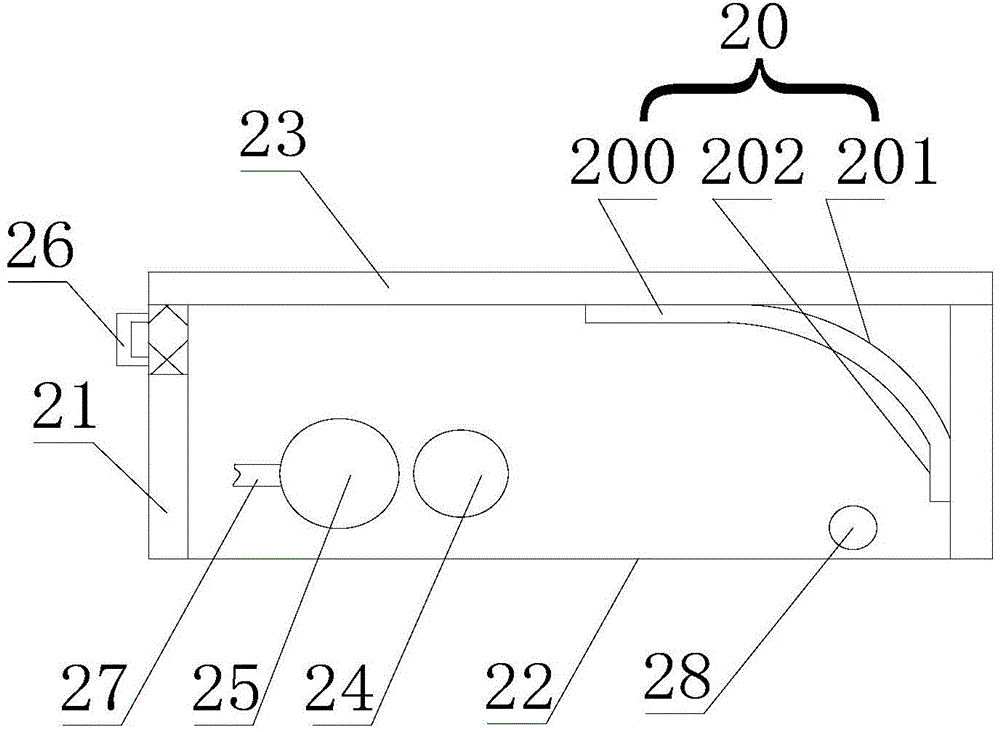

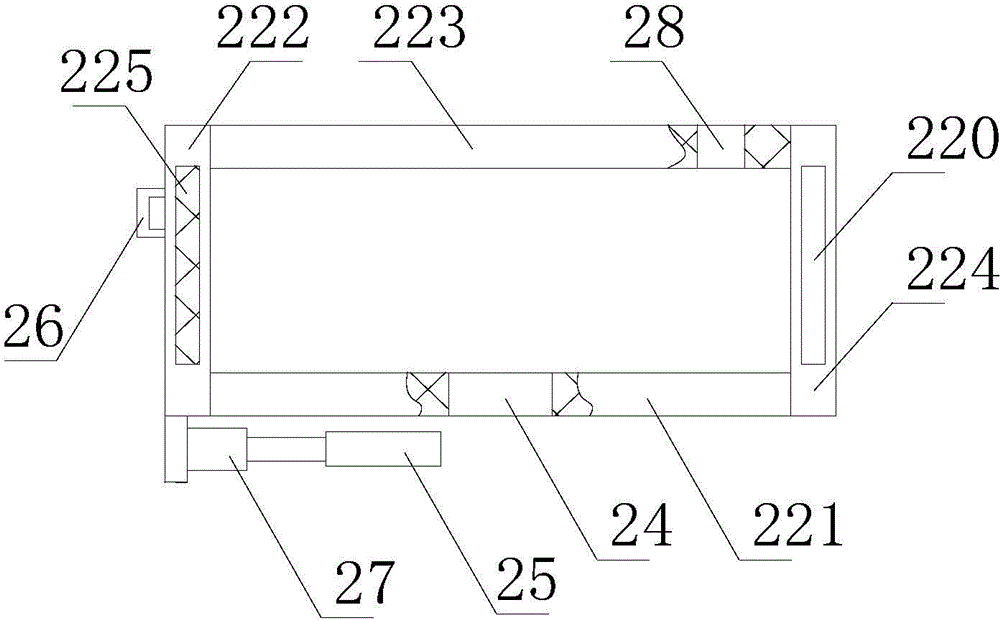

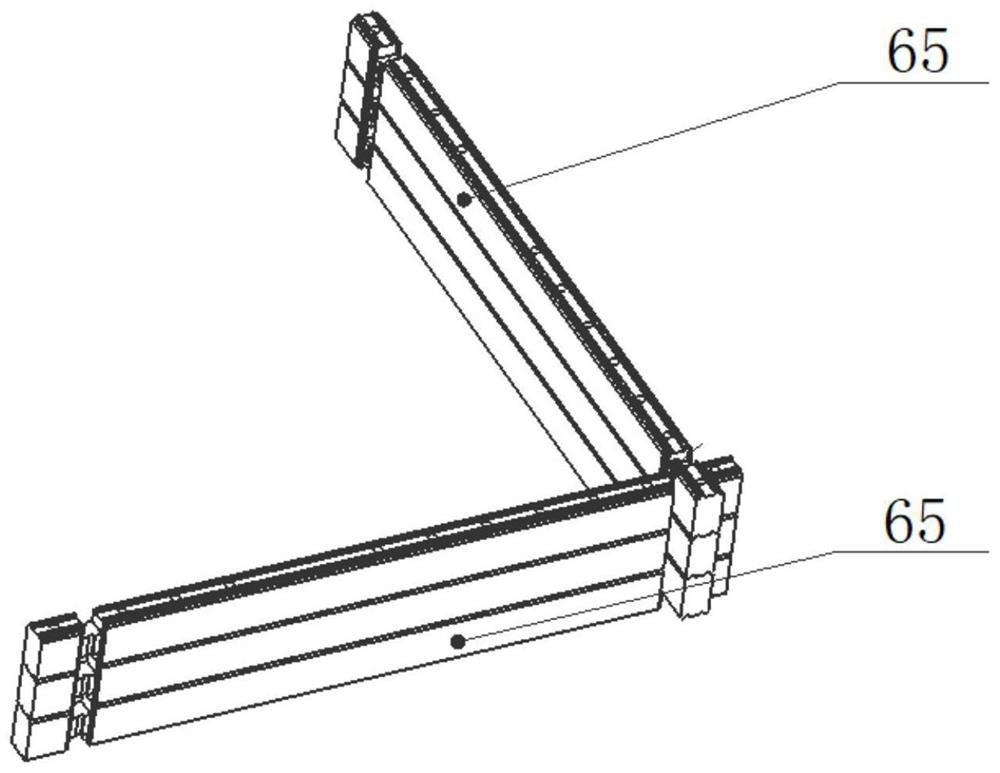

The invention relates to a gravity dust removal apparatus and an asphalt stirring device. The gravity dust removal apparatus includes an air inlet bin (1), a gravity dust removal bin (2) and an air outlet bin (3). The air inlet bin is used for feeding dust-containing flue gas. The gravity dust removal bin is located at the downstream of the air inlet bin and is used for removing at least a part of dust in the dust-containing flue gas through gravity, wherein the purified flue gas is discharged through the air outlet bin. Flow-guide blades (51) are located in the gravity dust removal bin and are used for performing dust removal and guidance to the flue gas passing through the gravity dust removal bin, flow-guide angle of the flow-guide blades being adjustable. By arranging the flow-guide blades with adjustable flow-guide angle, limitation of a gravity dust removal apparatus in the prior art is overcome; in the gravity dust removal apparatus, the flow-guide angle of the flow-guide blades can be adjusted at any time according to actual operation status of the asphalt stirring device, so that self-adaption of the flow-guide angle is achieved. The gravity dust removal apparatus guarantees dust removal efficiency and satisfies dust removal demand.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

Dust removing device for electric automation equipment

ActiveCN110756519AChange the blowing rangeDust blowing range can be changed flexiblyDirt cleaningCleaning using toolsCircular discThermodynamics

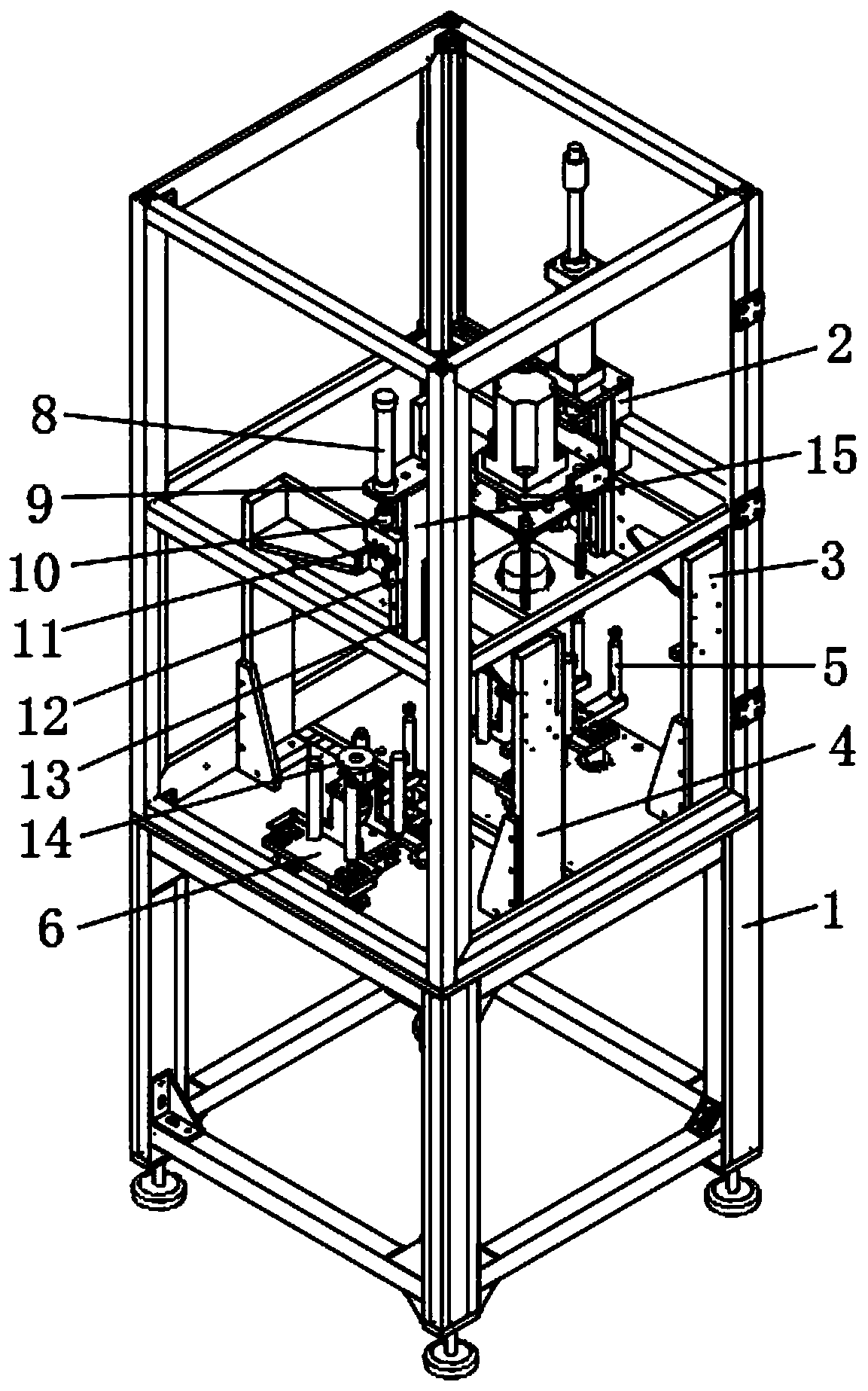

The invention discloses a dust removing device for electric automation equipment. A rotating rod is driven to rotate by a second motor, and a supporting disc is driven to move in the length directionof a screw rod, so that guide pipes move in the vertical direction to perform dust blowing treatment on different areas of the electric automation equipment, and the dust removing efficiency is improved; and when a third cylinder is started, and the third cylinder pushes a third push rod to move, so that the guide pipes move back and forth in a movable groove and are contracted or extended in thediameter direction of a supporting plate, and then the dust blowing range of the guide pipes is changed; and the working positions of the guide pipes can be flexibly changed according to different shapes of the electric automation equipment, so that the guide pipes carry out comprehensive dust removing treatment on the electric automation equipment, and the conditions that heat dissipation holes distributed on a heat dissipation plate are prone to be blocked caused by accumulation of a large amount of dust for a long time, then blockage is not favorable for timely heat dissipation of electricelements, and therefore, the internal part of the electric automation equipment is prone to overheating to influence the service life of the equipment are avoided.

Owner:ZHUHAI HENGQIN KUNPENG NEW ENERGY ENVIRONMENTAL PROTECTION TECH CO LTD

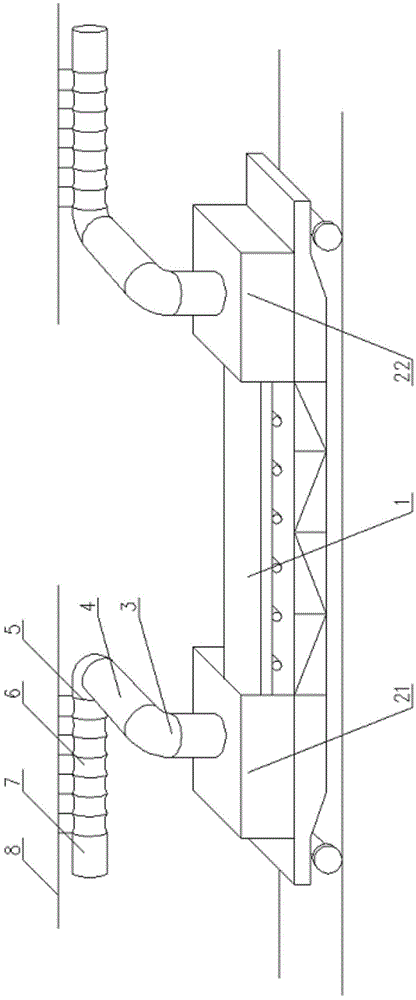

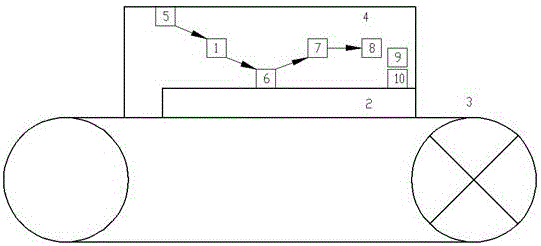

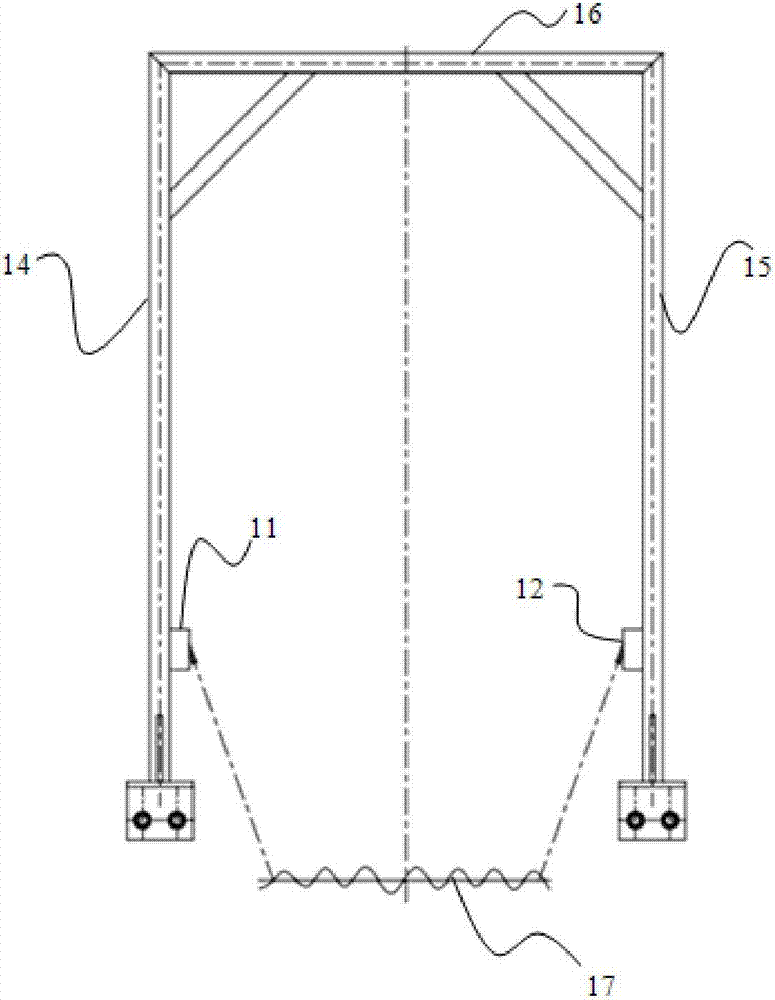

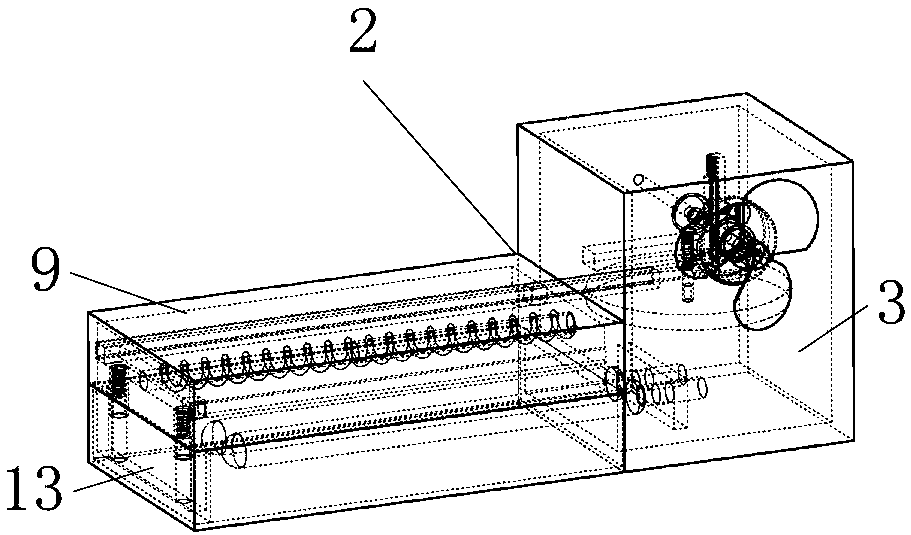

Reversible mobile belt conveyer

The invention provides a reversible mobile belt conveyer. According to the reversible mobile belt conveyer, a first dust collection device and a second dust collection device are arranged at the machine head discharging end and the machine tail discharging end respectively, the first duct collection device comprises a first hopper which is arranged outside the machine head discharging end in a covering mode, a first dust collection pipeline which can be used for supplying negative pressure is connected to the outside of the first hopper in a sealed mode, the first dust collection pipeline can move along with the first hopper, the second dust collection device comprises a second hopper which is arranged outside the machine tail discharging end in a covering mode, a second dust collection pipeline which can be used for supplying negative pressure is connected to the outside of the second hopper in a sealed mode, and the second air collection pipeline can move along with the second hopper. According to the reversible mobile belt conveyer, the dust collection devices are arranged at the machine heat discharging end and the machine tail discharging end respectively, and thus the dust collection requirement can be met when discharging is conducted at any end; in the whole airtight operating process aiming at raise dust and air carriers of the raise dust, tracking type dust collection can be achieved under different working conditions and in different working states, the air volume is small, and the dust collection effect is good.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Non-secondary-pollution elimination method of dedusting fluid during dedusting process

InactiveCN106693583AAdaptableReduce manufacturing costCombination devicesGas treatmentPetrochemicalAbsorption effect

The invention relates to a non-secondary-pollution elimination method of a dedusting fluid during a dedusting process. The non-secondary-pollution elimination method belongs to the technical field of dedusting during a mine production process, and is characterized being a method that after the dedusting fluid is used in a main dedusting process and an auxiliary dedusting process, the dedusting fluid and controlled dust are eliminated without pollution; an elimination process is uninterruptedly carried out in the dedusting fluid, is a rapid energy change process, can be completed in picosecond, provides better traction and absorption effects to enable the dedusting process to be carried out continuously and orderly, and is used for circularly and continuously absorbing the dedusting fluid without secondary pollution, so that the method achieves the aim of dedusting at a dust source part without secondary pollution, and meets the crying needs of protecting environment and treating haze. The method provided by the invention can be widely applicable in various dust or particle pollution treatment processes in the systems and fields of mines, agriculture, petrochemical engineering, metallurgy, electric power, pharmacy, environmental protection and the like.

Owner:TAIYUAN UNIV OF TECH

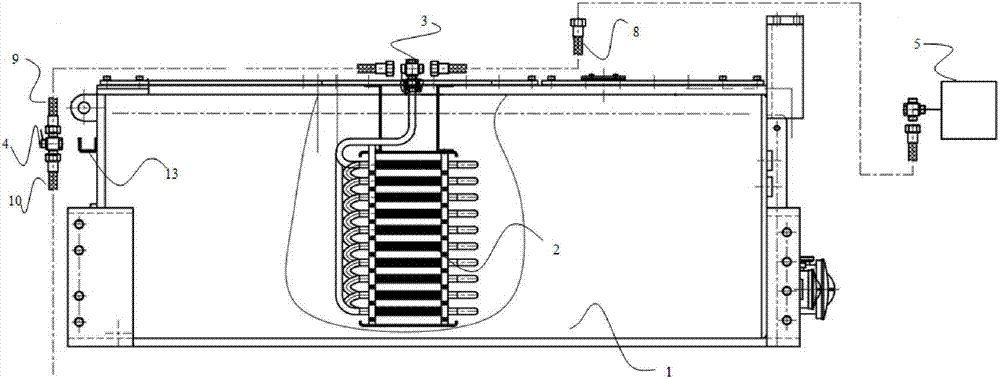

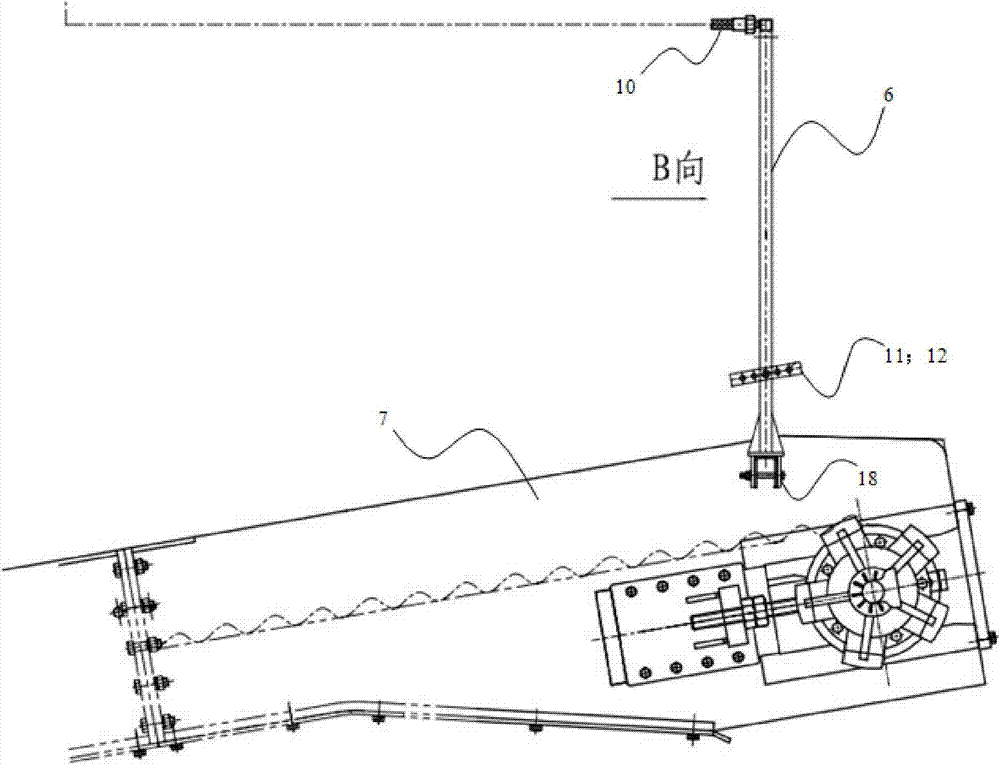

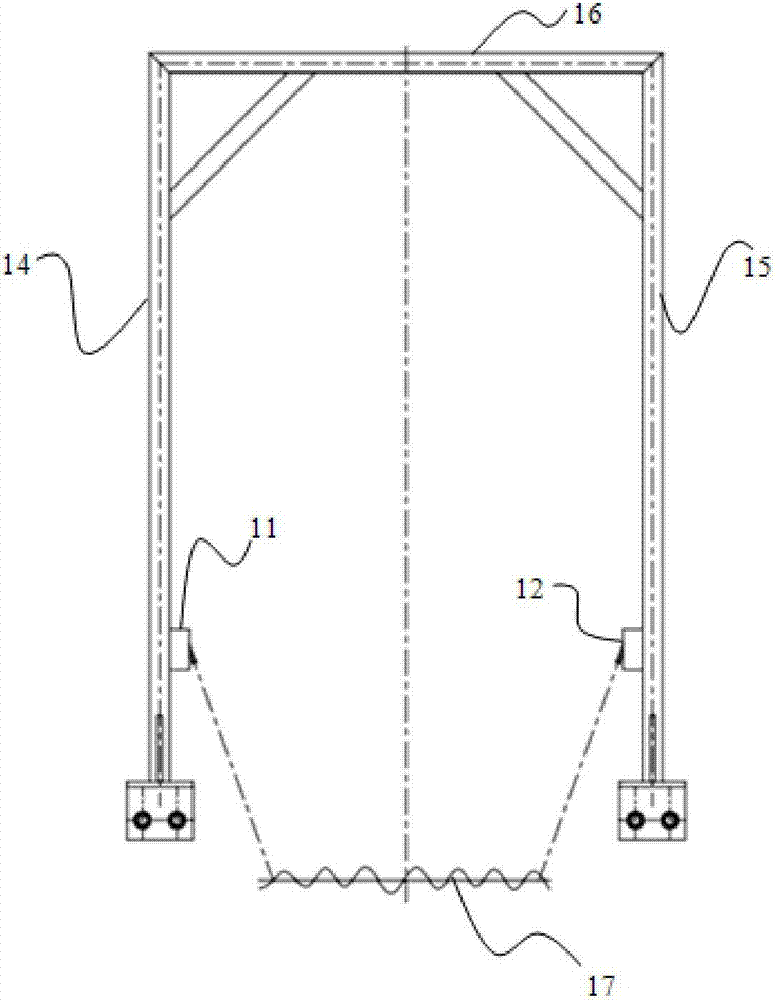

Built-in water-cooling and dust-removing device for fuel tank of road-header

ActiveCN103032420AImprove cooling effectMake up for the shortcomingsFluid-pressure actuator componentsFuel tankInlet pressure

The invention discloses a built-in water-cooling and dust-removing device for a fuel tank of a road-header, wherein a snakelike copper tube cooler is internally installed in the fuel tank to cool hydraulic oil; a water inlet of the snakelike copper tube cooler is connected with a water pressure safety valve through a high-pressure hinge joint and a rubber tube to adjust the water inlet pressure; a water outlet of the snakelike copper tube cooler is connected with a first connector of a ball valve through another high-pressure hinge joint and another rubber tube; a second connector of the ball valve is connected with a water spray bracket through another rubber tube; and water orifice of the water spray bracket sprays water to the tail part of a scraper conveyor. According to the built-in water-cooling and dust-removing device for the fuel tank of the road-header, the snakelike copper tube cooler is internally installed in the fuel tank, so that the hydraulic oil is directly and efficiently cooled, defects of the cooling method of a traditional external plate-fin type cooler are effectively overcame, and the cooling is rapid; and the used cooling water is used for removing dust when the road-header is in the cutting process, and the cooling water is fed into a roof bolter when the road-header is free from the cutting process, so that the hydraulic oil can be continuously cooled during two time periods of cutting work and cutting-free work, and the cooling water is also recycled effectively.

Owner:AEROSUN CORP

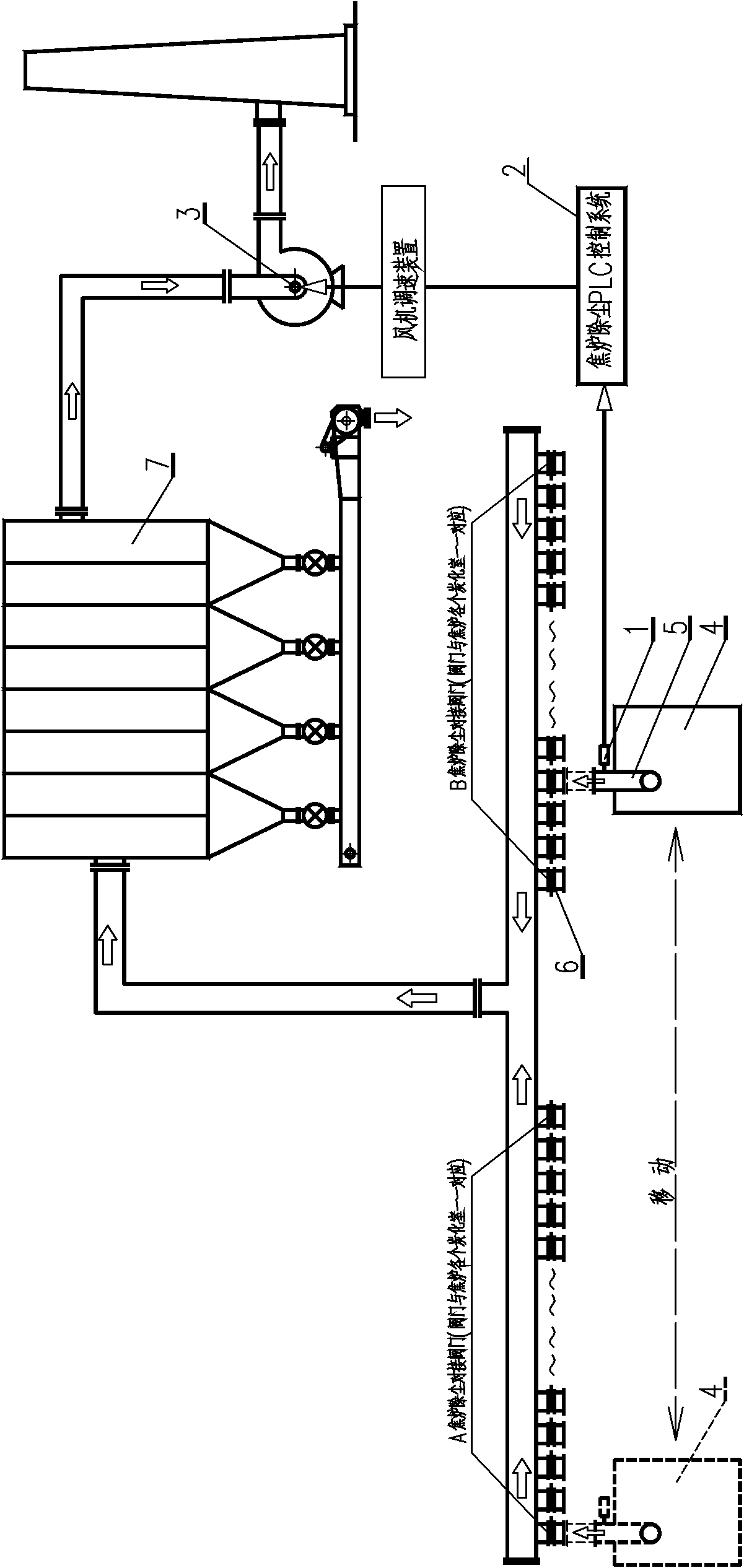

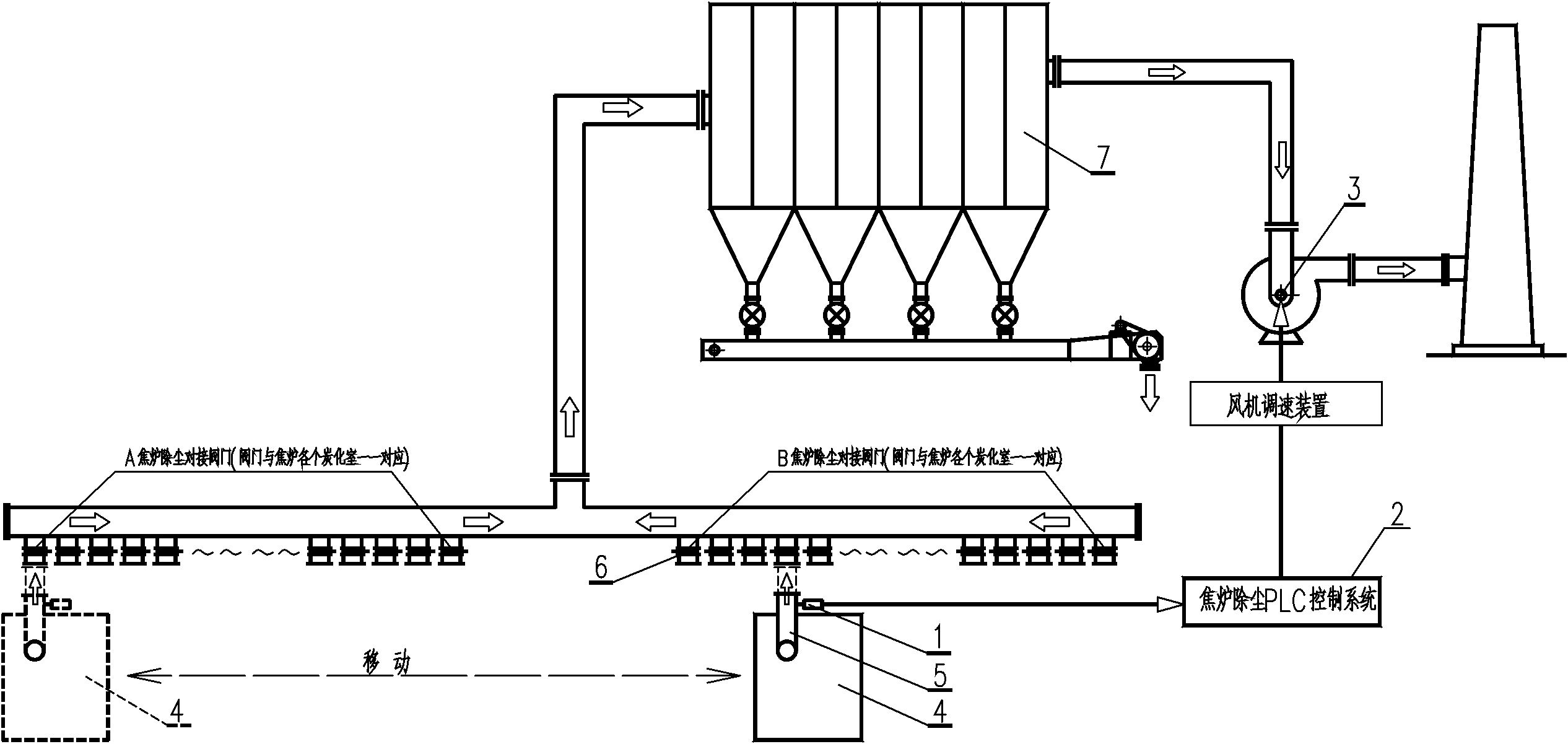

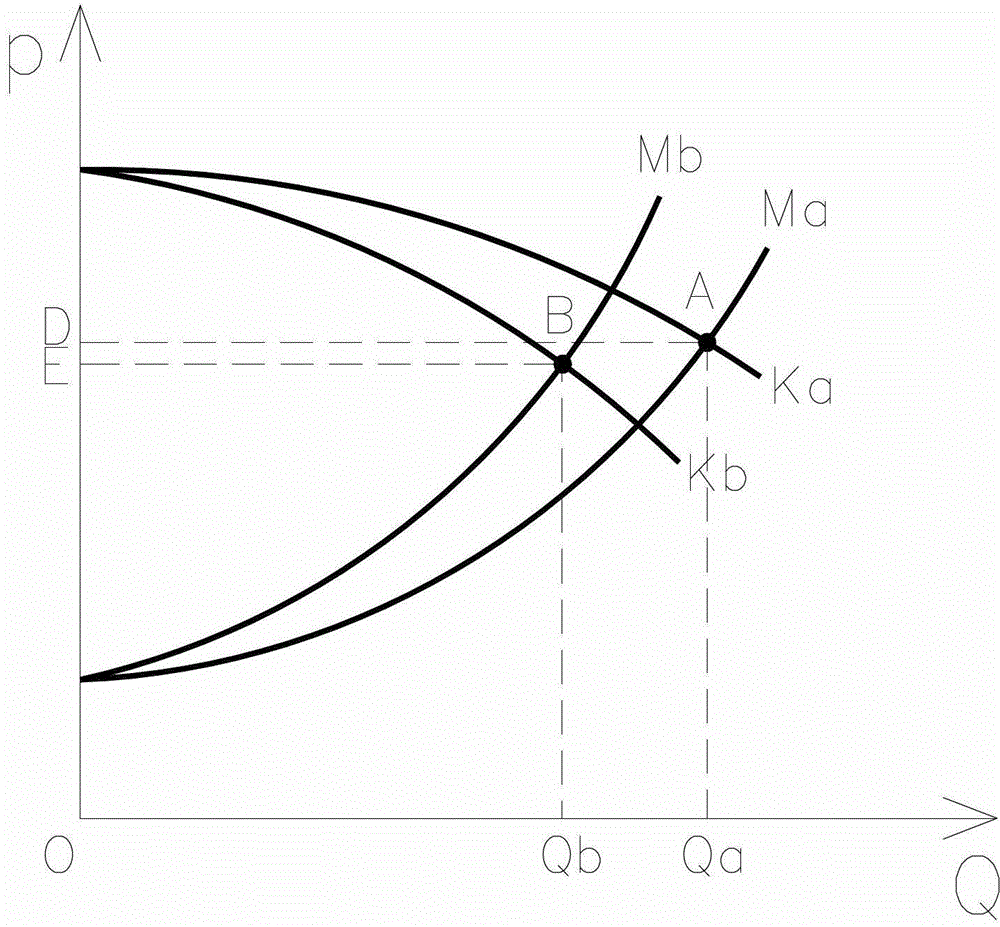

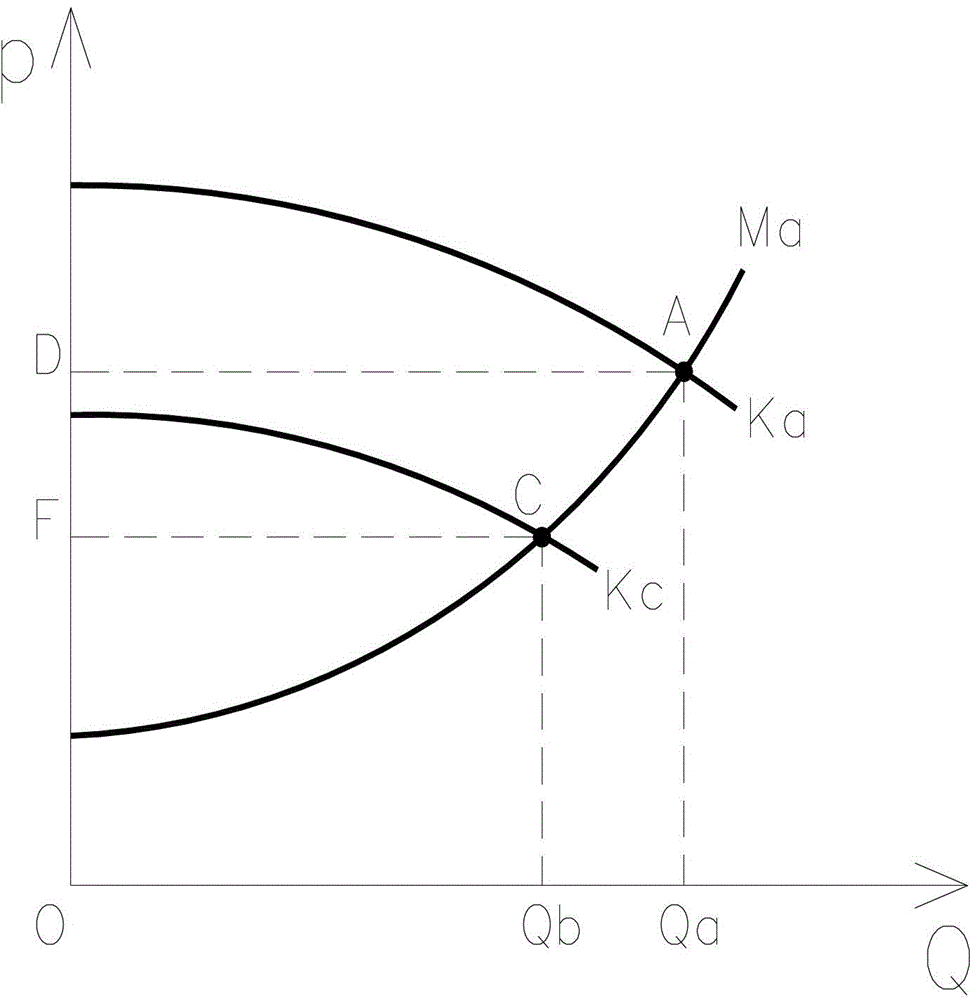

Energy-saving control method and device of dust removal blower of coke oven

InactiveCN101975184AMeet dust removal requirementsControl energy-saving operationOven incrustations prevention/removalPump controlControl signalProgrammable logic controller

The invention relates to an energy-saving control method and device of a dust removal blower of a coke oven, which is characterized in that a dust removal conducting pipeline of a coke oven vehicle is internally provided with a pressure signal collecting device for continuously collecting pressure numerical values in the conducting pipeline during dust removal; the collected pressure numerical values are outputted into a dust removal PLC (Programmable Logic Controller) system of the coke oven; the dust removal PLC system of the coke oven is used for carrying out comparative operation on the received pressure numerical values and a set numerical value and transmitting a control signal to a speed regulating device of the blower; the speed regulating device of the blower is used for regulating the rotating speed of the blower according to the control signal; and the dust removal PLC system of the coke oven is used for outputting the control signal for controlling the dust removal blower to run at the current rotating speed until the measured pressure value in the dust removal conducting pipeline on the coke oven vehicle is equal to the set numerical value. The invention has the advantages that for coking chambers in different positions of the coke oven, the rotating speed of the blower in high-speed running can be respectively regulated and controlled; and thereby, when the dust of any coking chamber of the coke oven is removed, the actual wind quantity for the dust removal is equal to the wind quantity required by the dust removal so as to achieve the purpose of controlling the blower to run under an energy-saving condition.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

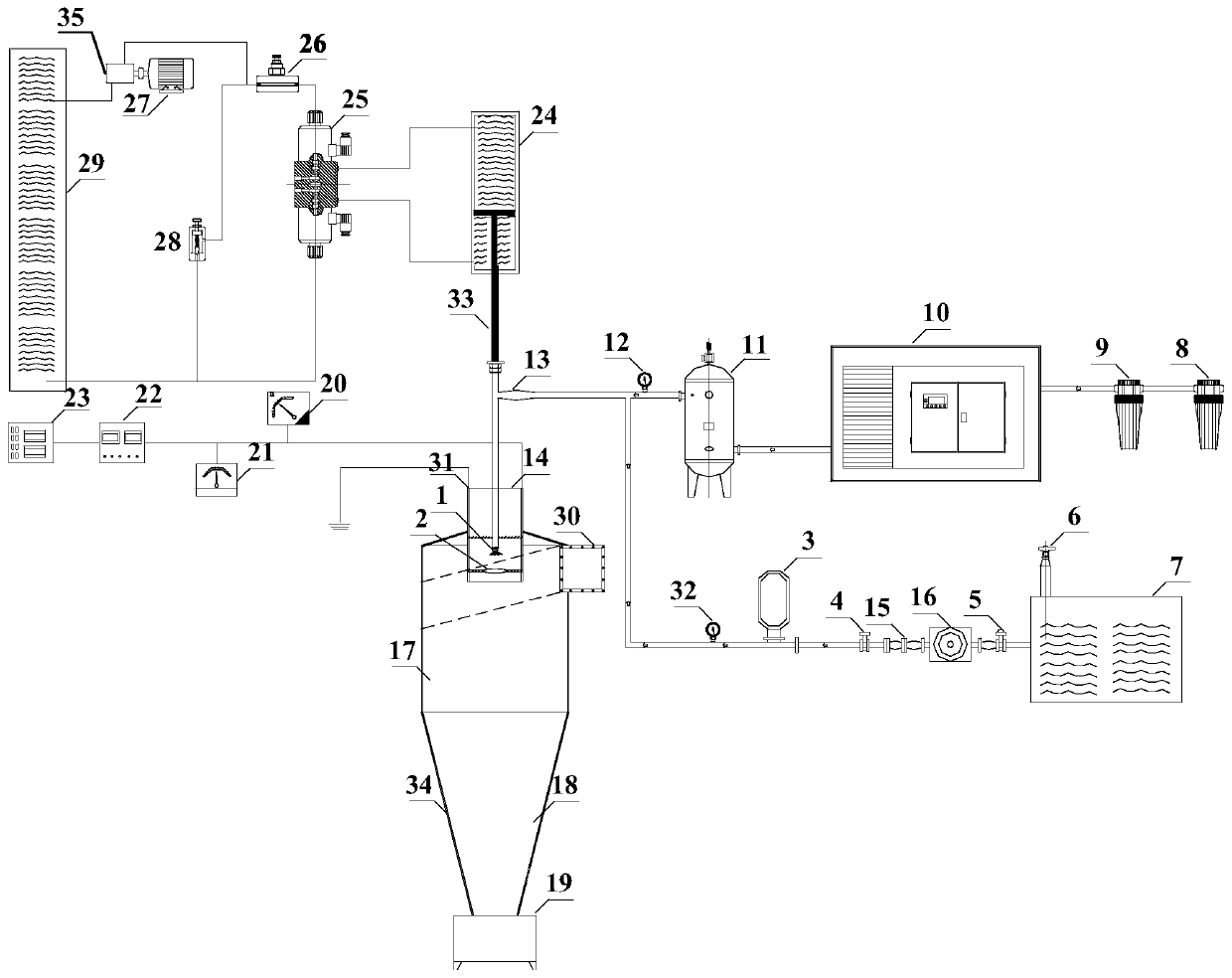

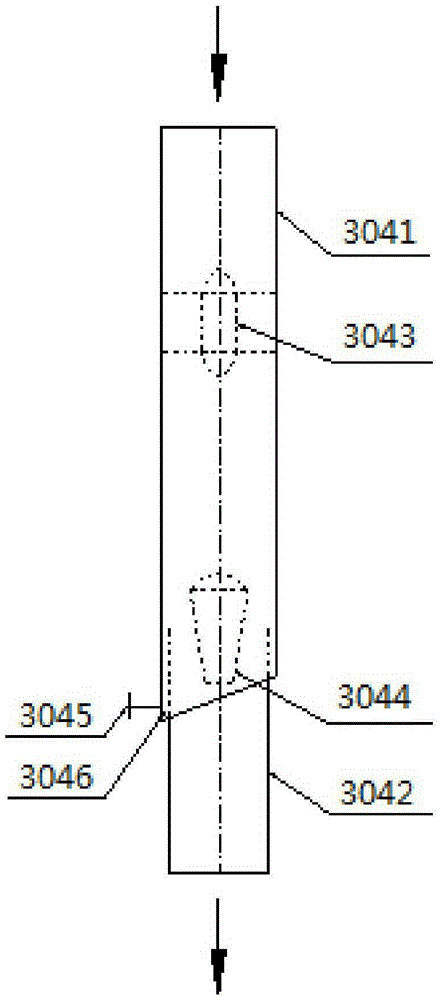

Charged micro-fog cyclone dust removal system for fine particles, and dust removal method thereof

InactiveCN111167249AOvercoming low dust removal rateOvercome the shortcomings of wet dust removal such as large water consumptionCombination devicesParticulatesCyclonic separation

The invention discloses a charged micro-fog cyclone dust removal system for fine particles and a dust removal method thereof, and belongs to the field of dust removal operation. Thecharged micro-fog cyclone dust removal system comprises a micro-fog system gas path, a micro-fog system water path, a charge generation system, an atomizing nozzle, an annular electrode, an exhaust cylinder, a hydraulicsubsystem and a cyclone separation subsystem; an outlet of the micro-fog system gas path and an outlet of the micro-fog system water path are both communicated with the atomizing nozzle; theannular electrode is arranged below the atomizing nozzle; the annular electrode is connected with the charge generation system; wherein the atomizing nozzle and the annular electrode are both arranged in the exhaust cylinder, the exhaust cylinder is provided with an exhaust cylinder slideway, the atomizing nozzle is provided and connected with an atomizing nozzle sliding block, the atomizing nozzle slidingblock is matched with the exhaust cylinder slideway, thecyclone separation subsystem is connected below the exhaust cylinder, and the atomizing nozzle is connected with thehydraulic subsystem. The charged micro-fog cyclone dust removal system can effectively overcomethe problems of low dust removal rate of fine-particle dust and high water consumption of wet dust removal in anexisting cyclone dust removal system, and improvethe dust removal rate of fine-particle dust below 2.5 <mu>m.

Owner:LIAONING TECHNICAL UNIVERSITY

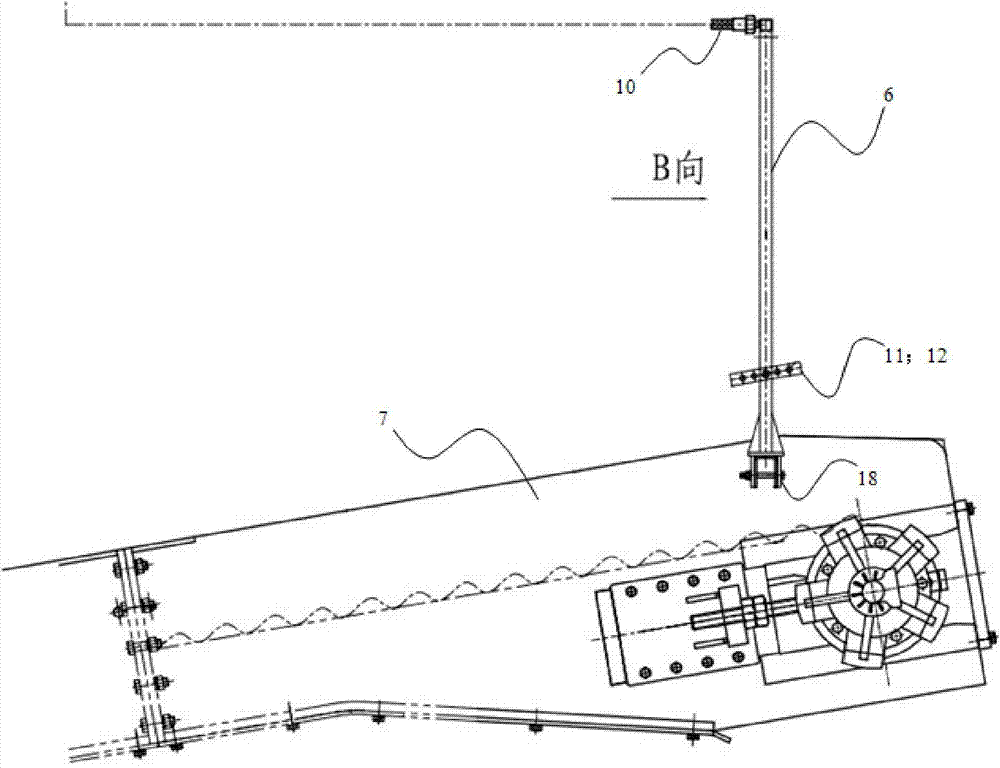

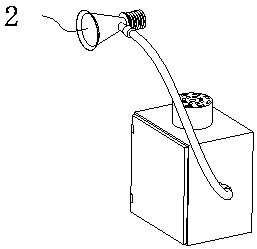

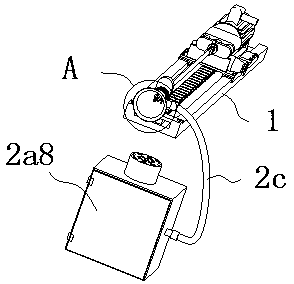

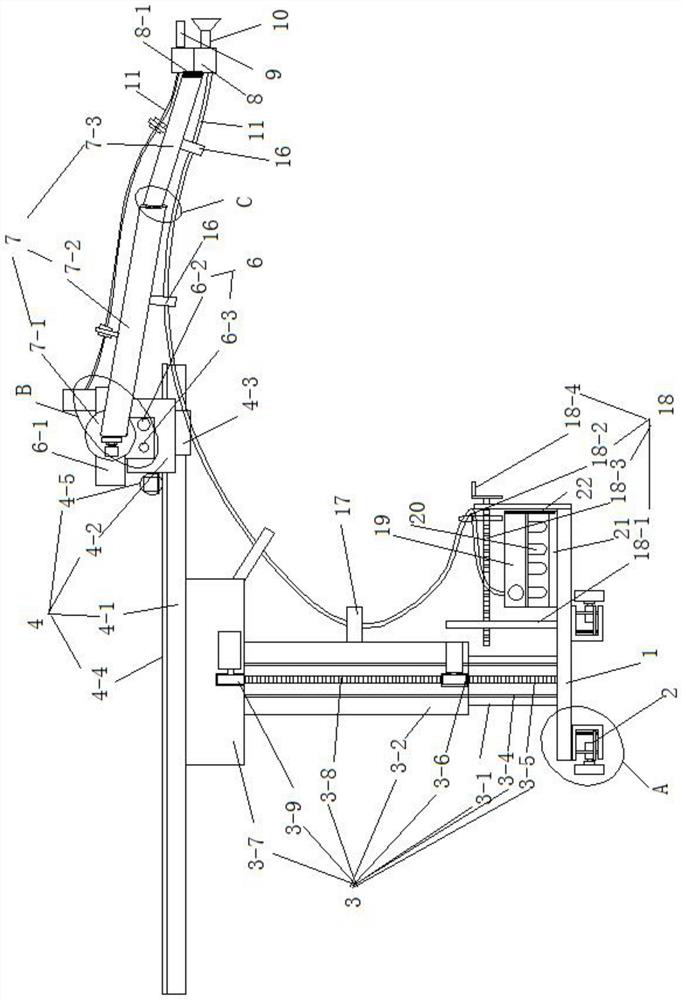

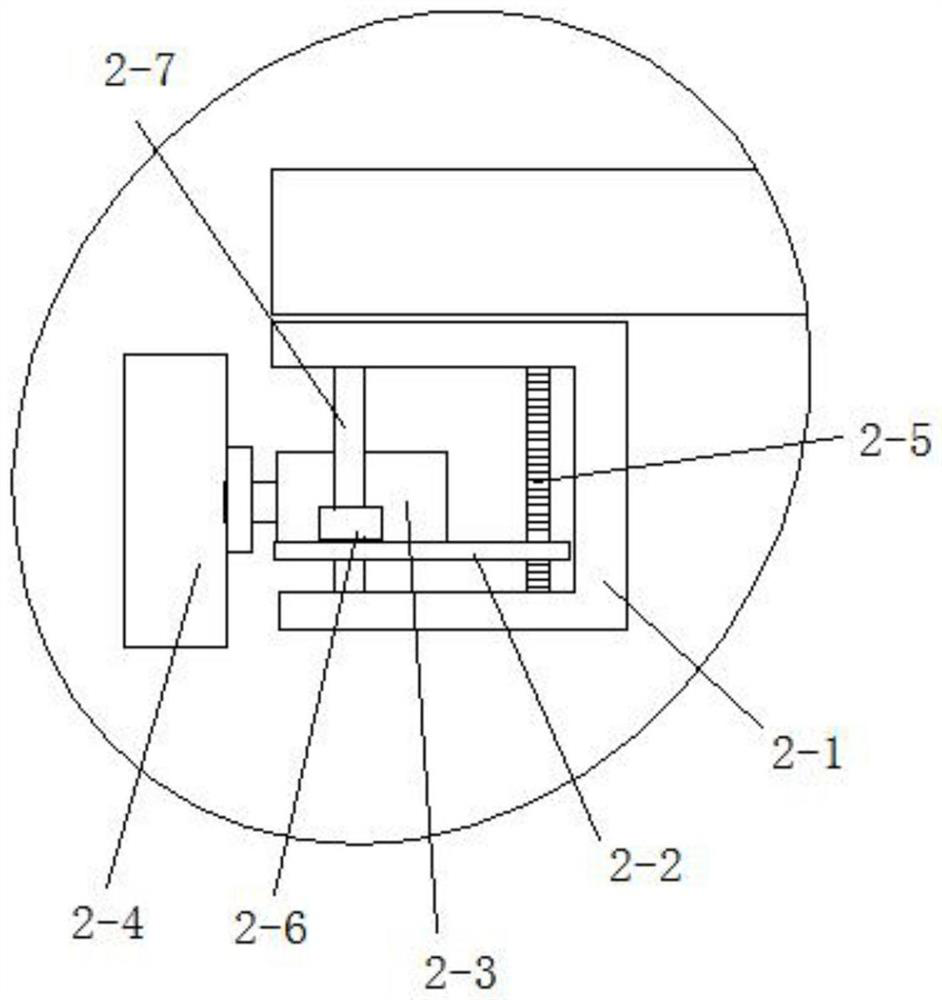

Dust-free rock electric drill for rock and soil exploration

InactiveCN110617020AEasy to assemble and disassembleImprove convenienceConstructionsDerricks/mastsDrill bitCoal dust

The invention relates to the field of rock electric drills, in particular to a dust-free rock electric drill for rock and soil exploration. The dust-free rock electric drill comprises a rock electricdrill and a dust removal mechanism, wherein the dust removal mechanism is arranged on the side of the rock electric drill and comprises a dust removal box and a dust catching hood; the dust catching hood is arranged on one surface, far away from an electric drill driving device, of a drill rod support frame, and is arranged outside a drill rod and a drill bit in a sleeving manner; the dust removalbox is arranged on a guide rail support; the dust removal box and the dust catching hood are connected through a dust removal pipeline; the dust removal box comprises a collecting box, a draught faninstalling box, a baffle plate and a filter; the draught fan installing box is arranged on the top end of the collecting box; the baffle plate is arranged inside the collecting box; a certain gap is formed between one end of the baffle plate and the collecting box; and the filter is arranged at the gap. By arranging the dust removal mechanism, the dust-free rock electric drill effectively reducesthe splashing of dust on the working surface, improves the environments of the working surface and the working environment of workers, reduces the potential safety hazards of the working surface, andeliminates the hidden danger of coal dust in wells.

Owner:赵健

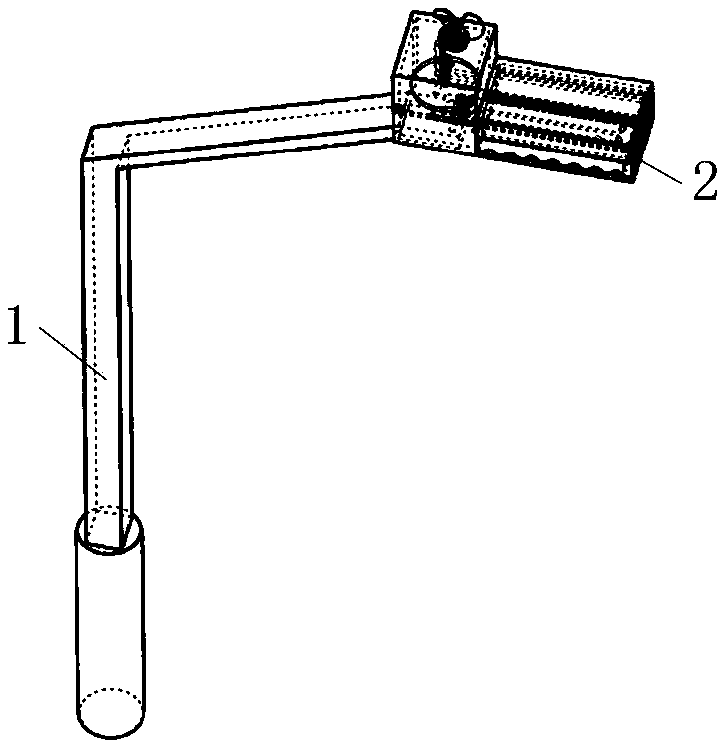

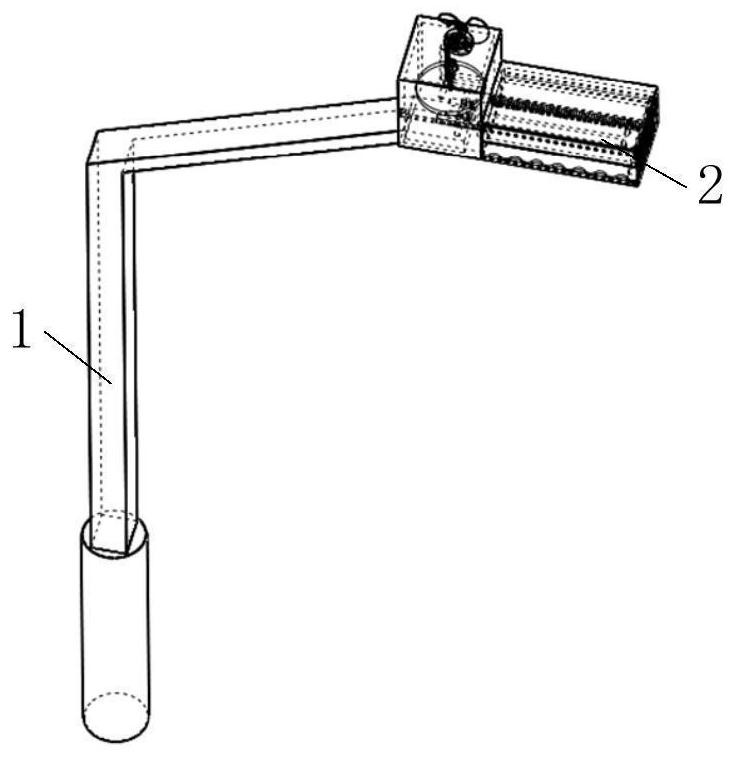

Streetlamp capable of removing dust on inner wall

ActiveCN109140337AImprove lighting effectsLow costMechanical apparatusLighting elementsWind speedReciprocating motion

The invention belongs to the field of streetlamps and particularly relates to a streetlamp capable of removing dust on the inner wall. The streetlamp comprises a lamp pole and a streetlamp mechanism,wherein the streetlamp mechanism is mounted at the top of the lamp pole. The streetlamp utilizes wind energy to automatically remove the dust, and thus the maintenance cost of the streetlamp is greatly lowered; a worker does not need to climb to the top of the lamp pole for maintenance, and thus the possible danger caused by climbing of maintenance personnel is avoided; a centrifugal wheel can identify the magnitude of the wind speed, if the wind speed is small, the centrifugal wheel does not interact with a first rack, a dust removing strip does not play a role of dust removing, and if the wind speed is large, the centrifugal wheel interacts with the first rack, so that the dust removing strip conducts four-time reciprocating motion in a lampshade to complete clearing of the inner wall ofthe lampshade; and the dust removing strip swings leftwards and rightwards while sliding along the bottom of the inner wall of the lampshade under driving of a second rack, so that the stubborn dustin the lampshade is cleared, the dust removing effect in the lampshade meets the dust removing requirement to the maximum extent, and the using effect of the lampshade after dust removing is better.

Owner:余燕秀

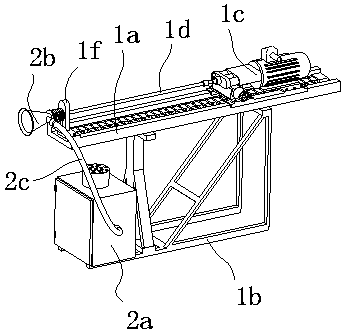

Portable mobile protection device for abrasive wheel cutting machine

The invention relates to a portable mobile protection device for an abrasive wheel cutting machine. The portable mobile protection device comprises a machine frame and a protection cover. The machine frame is provided with a guide rail, a filtering net, a water tank, a limiting assembly and a grounding device. The water tank is movably connected with a poking assembly and a drainage pipe. A fireproof plate is arranged in the protection cover which is provided with a control groove. The portable mobile protection device has the advantages that the abrasive wheel cutting machine is installed on the guide rail of the machine frame and is effectively prevented from generating smoke, smog and dust through the protection cover during operation, so that the requirement for dust removal is met; noise is remarkably lowered when the abrasive wheel cutting machine operates, so that the requirement for noise reduction is met; electric spark splashing generated in the cutting process is effectively reduced and even avoided, so that the fire risk is completely eradicated; threats to safety of operators from blade breaking, alloy tool bit breaking and splashing and the like possibly occurring when the abrasive wheel cutting machine operates are effectively reduced; by the arrangement of the machine frame, the working condition of operators is improved, and labor of operators is saved.

Owner:ZHEJIANG HUADIAN EQUIP TESTING INST +1

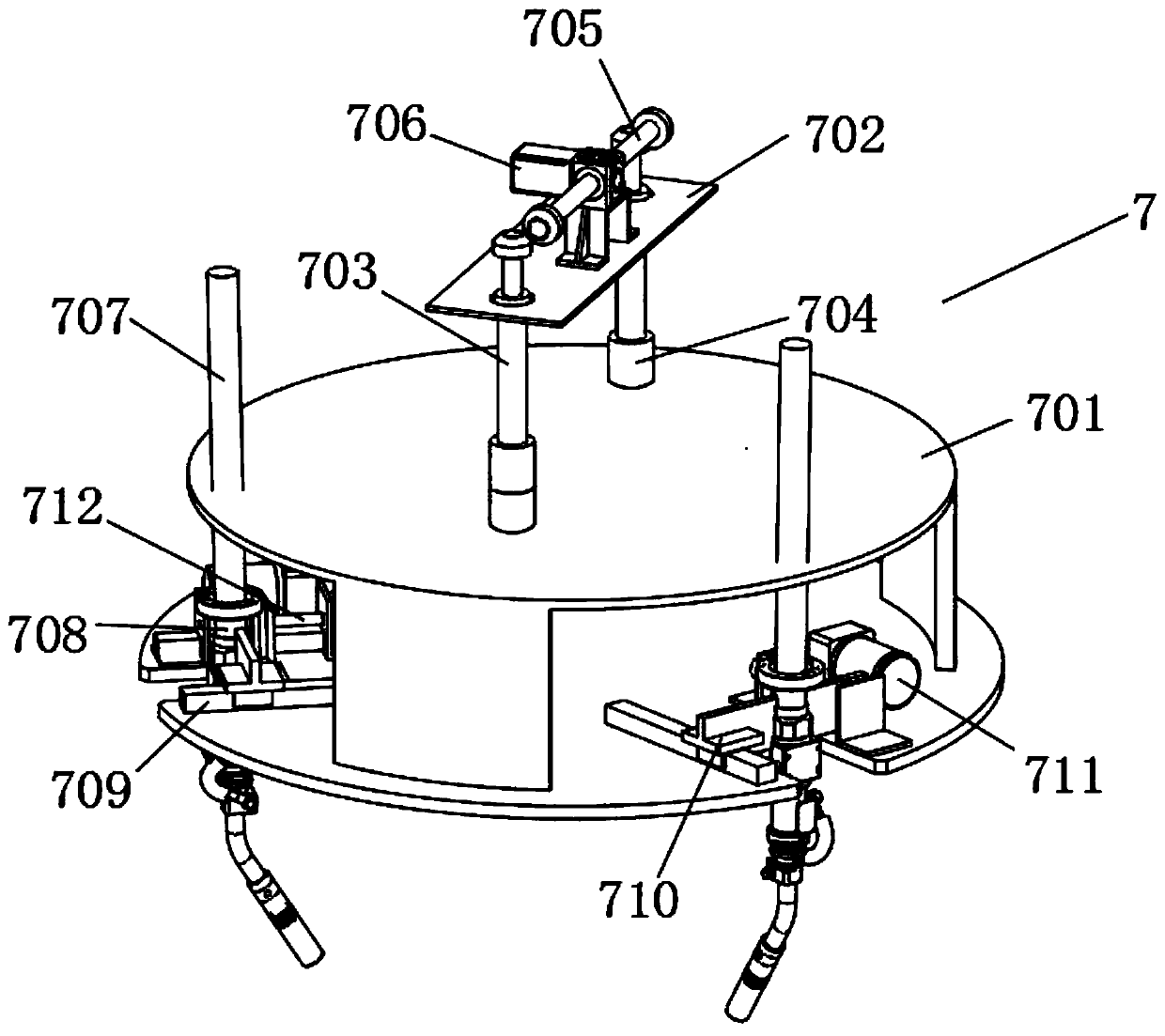

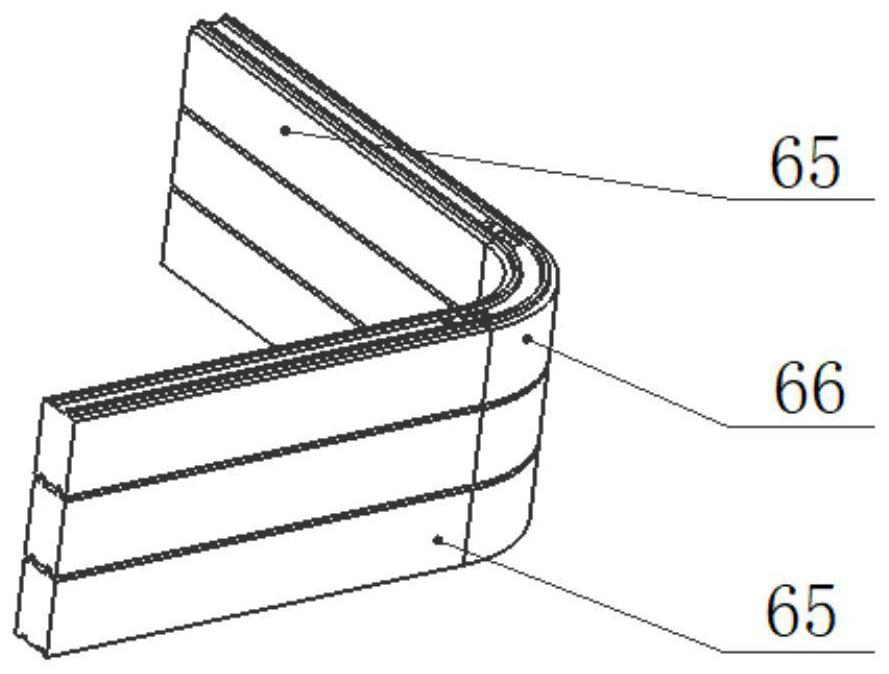

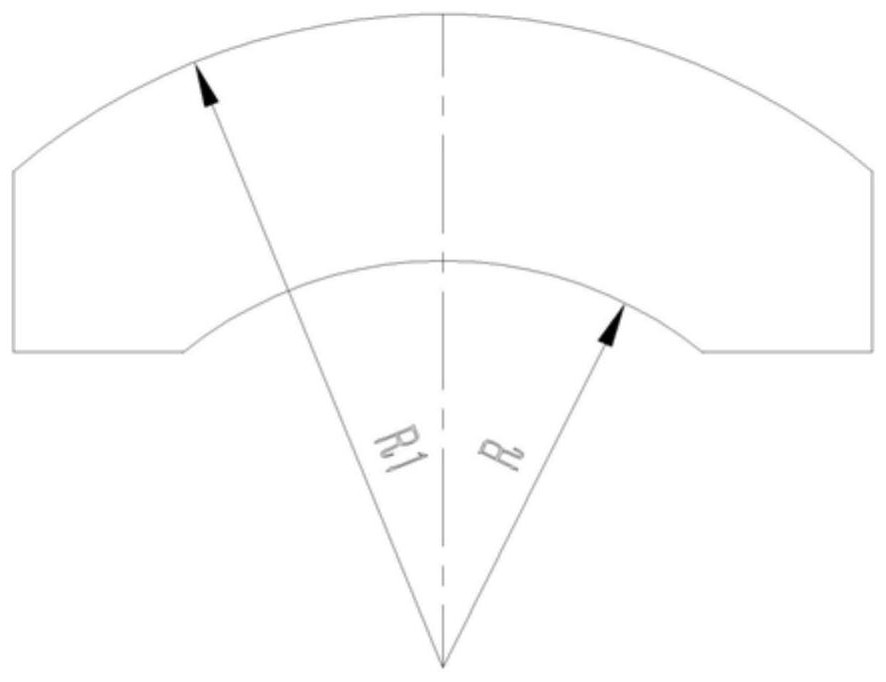

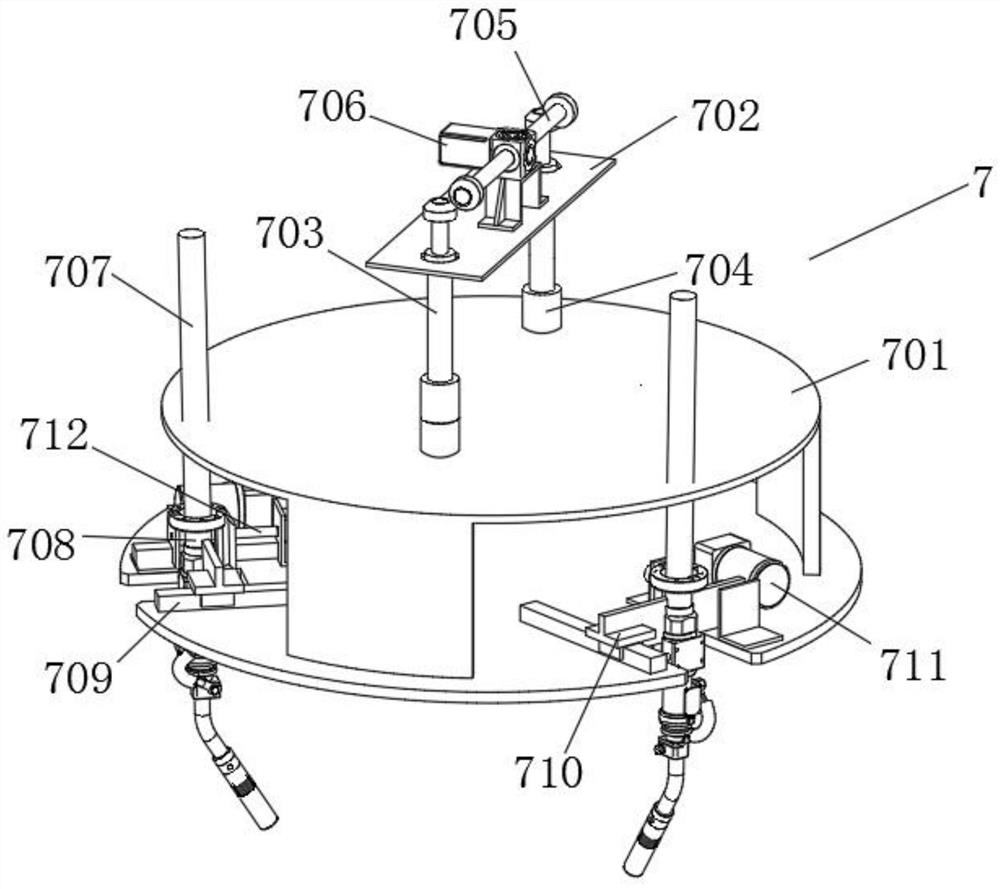

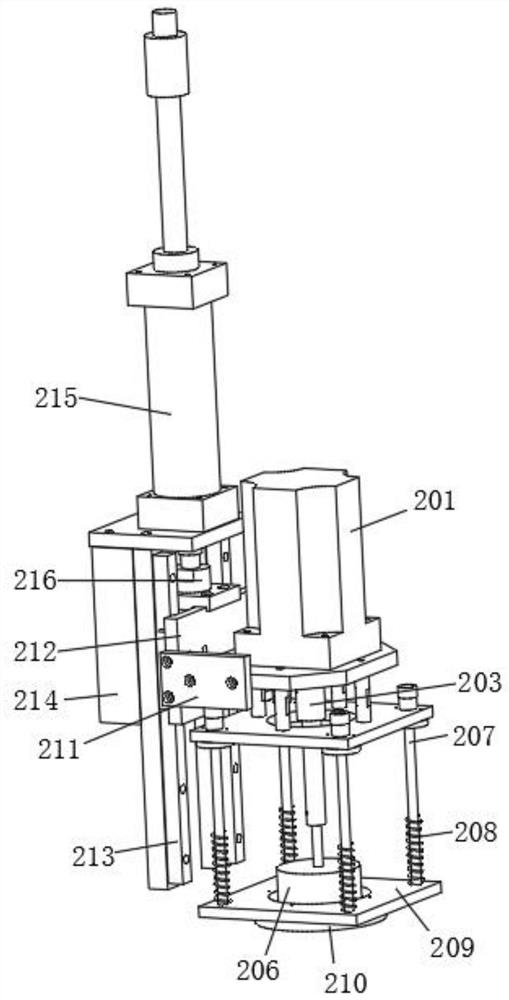

Numerical control woodworking inner arc surface milling machine

PendingCN111941552ARealize the function of continuous processingEasy to assemble and disassembleProfiling/shaping machinesBark-zones/chip/dust/waste removalNumerical controlAutomatic control

The invention provides a numerical control woodworking inner arc surface milling machine. The milling machine comprises a cutting device, a feeding device, a positioning device, a dust removal device,a rotary workbench, a lathe bed and an automatic control system, wherein the rotary workbench is horizontally arranged above the lathe bed, the lower portion of the cutting device is arranged on thelower side of the lathe bed, the upper portion penetrates through the rotary workbench, the feeding device is arranged below the lathe bed and used for driving the cutting device and the rotary workbench, the positioning device is arranged on the rotary workbench, the dust removal device is arranged above the cutting device and below a to-be-cut workpiece, and the automatic control system is electrically connected with the feeding device. The milling machine is suitable for machining the inner arc-shaped surfaces of connecting elbows with different radiuses for wood structure buildings produced in batches, equipment is easy to operate, continuous production can be achieved, clamping and dismounting of products are convenient and rapid, other products can be mounted and dismounted while equipment cutting machining is conducted, the production efficiency is greatly improved, and the equipment is low in manufacturing cost, small in occupied area, reliable in operation and high in productmachining precision.

Owner:YINGKOU XINBAIYUN MACHINERY CO LTD

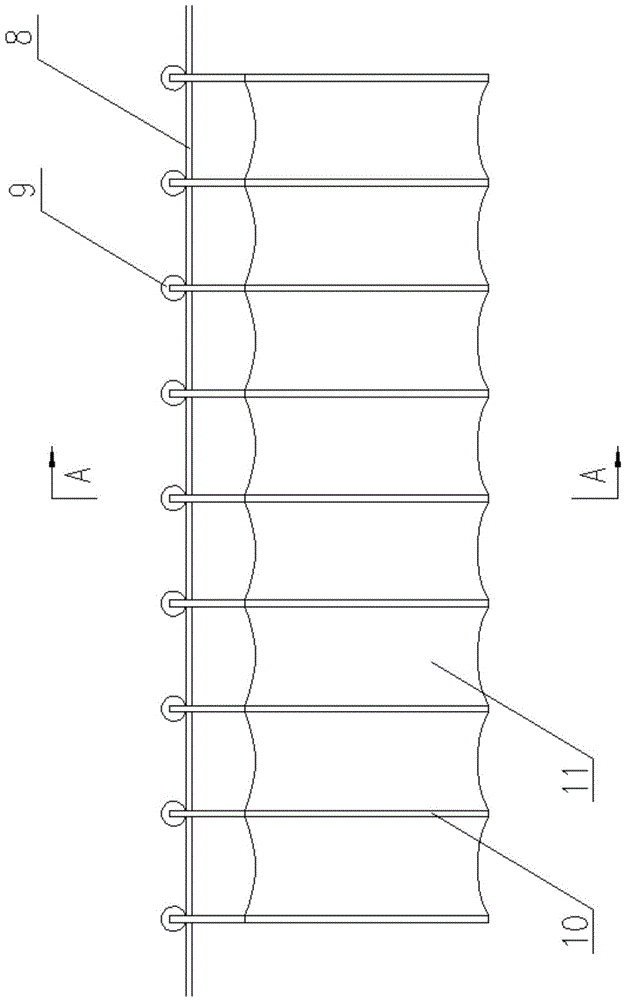

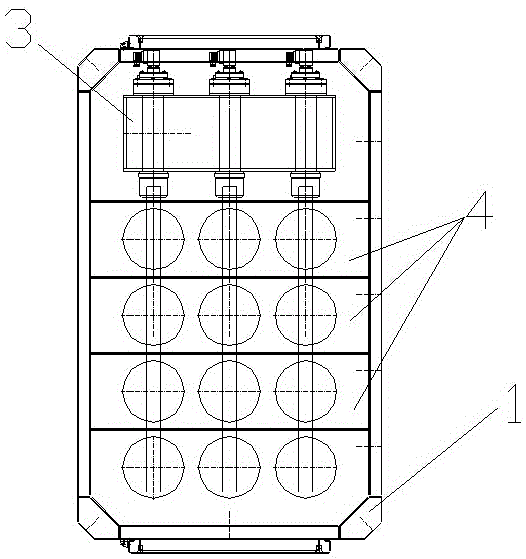

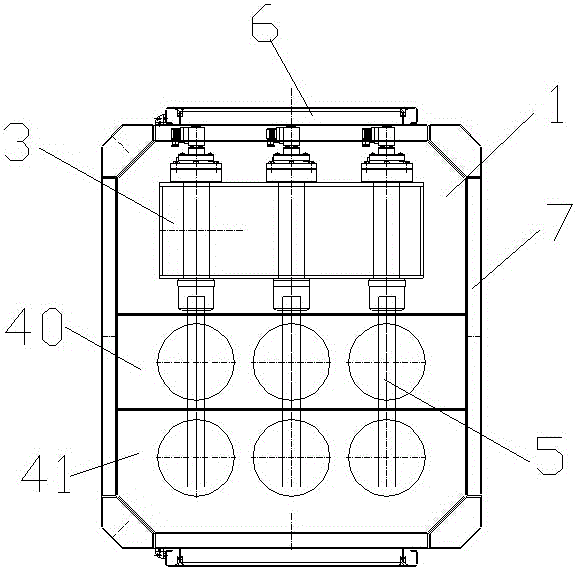

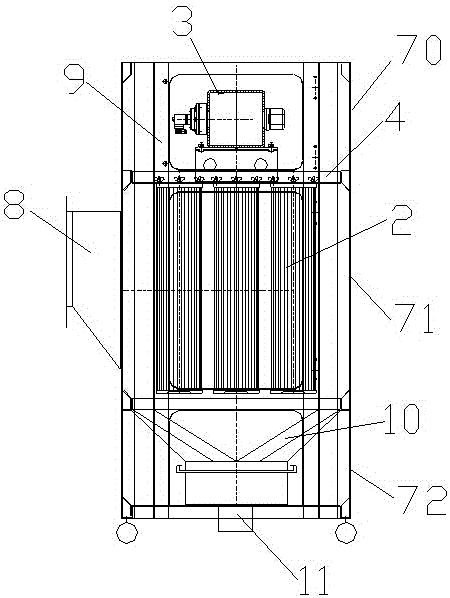

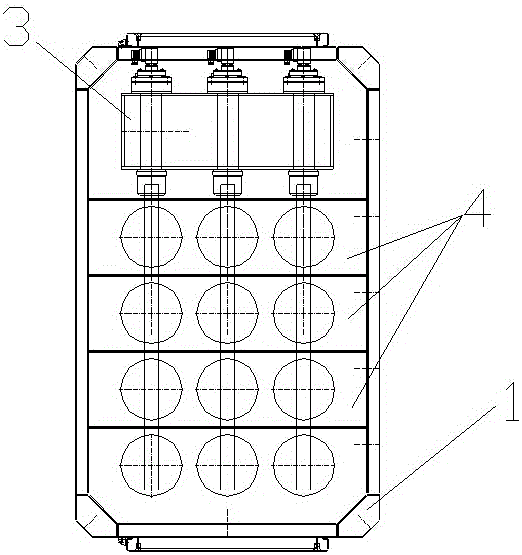

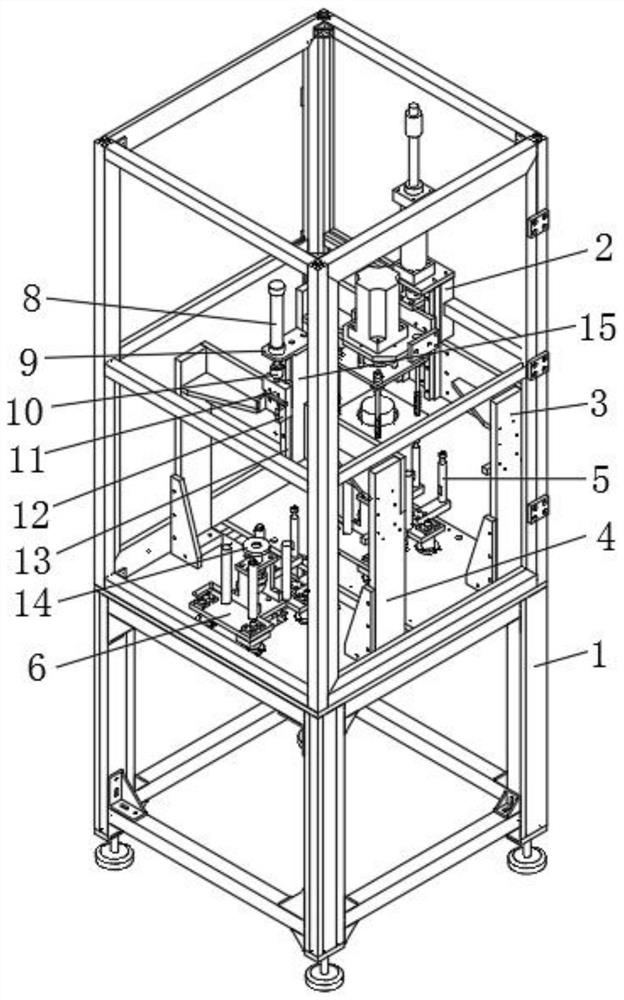

Modular single dust collector and assembly method thereof

ActiveCN105056659AMeet dust removal requirementsSimple structureDispersed particle filtrationFiltrationGas supply

The present invention relates to a modular single dust collector and an assembly method thereof. The modular single dust collector comprises a plurality of unit dust removal devices and a plurality of porous plates, wherein the side plates on the periphery of the unit dust removal devices are respectively provided with a screw hole and are connected with the peripheral unit dust removal devices through bolts in the screw holes, the top portions of the unit dust removal devices are provided with a plurality of gas bags communicated with a gas supply system, each gas bag is connected with a blowing pipe, the gas blowing nozzles on the blowing pipes are opposite to each filtration cylinder, the porous plate is arranged between the blowing pipe and the filtration cylinder, the porous plates are provided with through holes opposite to the filtration cylinders, and the porous plates and the unit dust removal devices are assembled according to the dust removal scale and the like. According to the modular single dust collector of the present invention, with the unit dust removal device and the porous plate, the ash clearing and gas supply of all filtration cylinders in the X direction and the Y direction is respectively achieved, and the ash clearing and dust removal requirements of various dust removal scales and dust collectors with various sizes are achieved; and the modular single dust collector has characteristics of simple structure, substantial cost reducing, easy assembly combination, and effective work efficiency improving.

Owner:NANFANG ENVIRONMENT PURIFYING EQUIP HANGZHOU

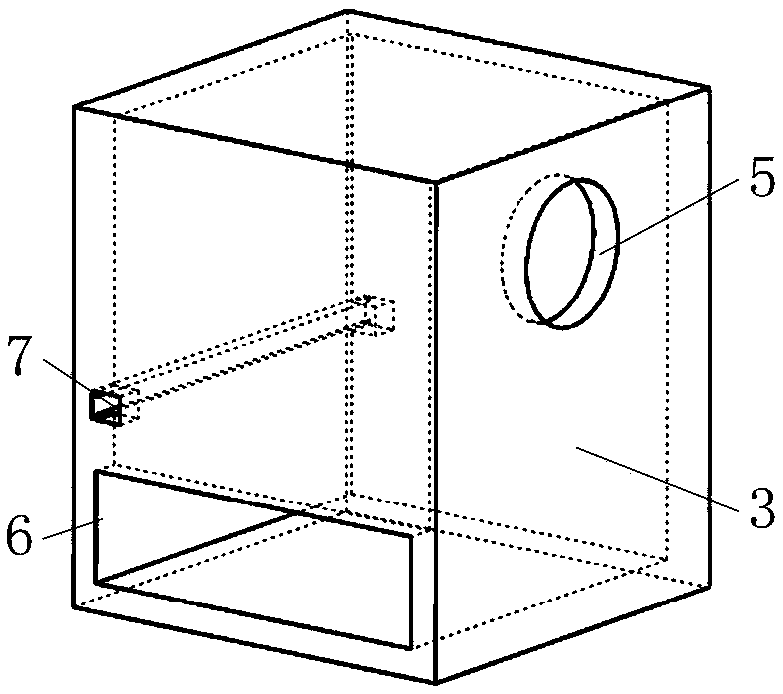

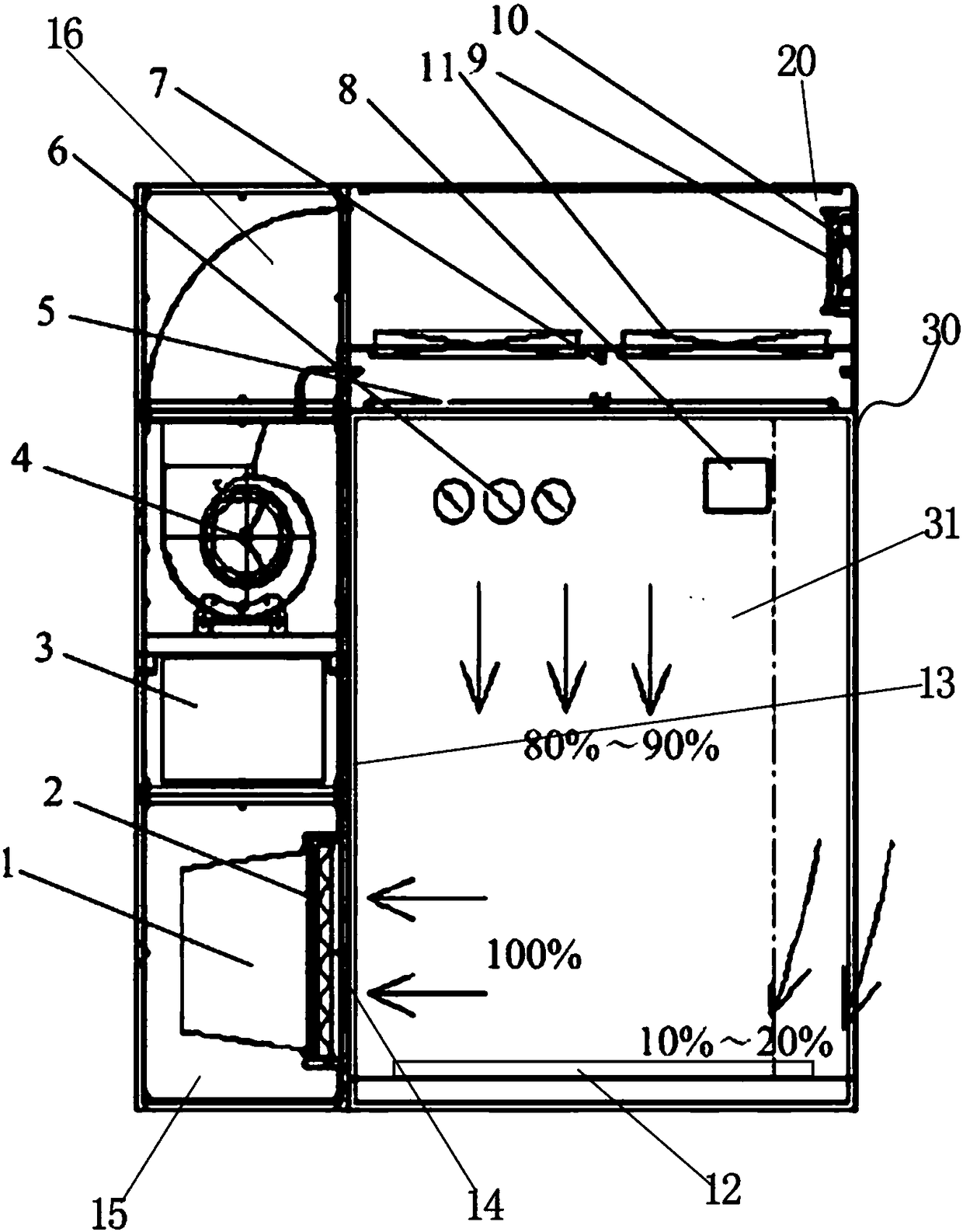

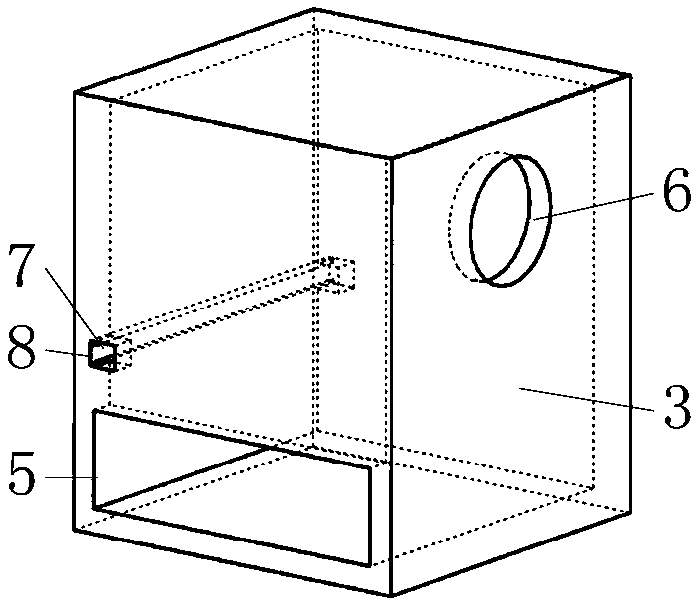

Negative-pressure weighing device and weighing method

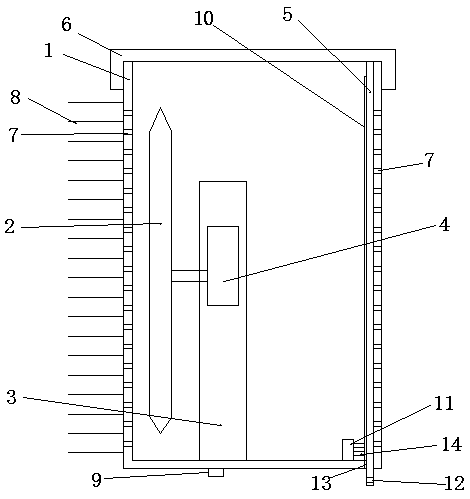

InactiveCN108593060AControl spilloverControlled riseDispersed particle filtrationWeighing apparatus using fluid action balancingEngineeringMechanical engineering

The invention discloses a negative-pressure weighing device. The negative-pressure weighing device comprises a weighing box body; a weighing chamber is defined at the front part of the interior of theweighing box body; the bottom of the weighing chamber is provided with a weighing device; the rear part of the weighing chamber is provided with a back plate which plays a role of separation; the topof the weighing chamber is provided with a static pressure box; a filtering chamber is formed behind the back plate; the bottom of the back plate is provided with a filtering screen; the bottom of the filtering chamber is provided with a primary effect filter; the primary effect filter is corresponding to the filtering screen; the rear of the primary effect filter is provided with an intermediateeffect filter; the top surface of the intermediate effect filter is provided with a circulation fan; the circulation fan is connected with the static pressure box through an air pipe; the front sidesurface of the static pressure box is provided with a side air exhausting high-efficiency filter; the side air exhausting high-efficiency filter is provided with a regulating valve; and the bottom surface of the static pressure box is provided with a unidirectional flow high-efficiency filter. With the negative-pressure weighing device of the invention adopted, a dust removal requirement can be satisfied; dust overflow and rise can be controlled; the risk of dust cross-contamination can be avoided; the dust can be prevented from being inhaled by a human body and hurting the human body; the safety of an external environment and people in an indoor environment can be protected.

Owner:苏州天微至胜运动控制技术有限公司

Modular single-machine dust collector and its assembly method

ActiveCN105056659BMeet dust removal requirementsSimple structureDispersed particle filtrationFiltrationGas supply

Owner:NANFANG ENVIRONMENT PURIFYING EQUIP HANGZHOU

A control method, device and system for a dust removal fan

ActiveCN103032361BSave electricityMeet dust removal requirementsPump controlNon-positive displacement fluid enginesAir volumeControl system

The invention relates to an energy-saving technology, and discloses a control method, a control device and a control system for a dust removal fan. The method comprises the following steps of: acquiring a current material amount; and judging whether the current material amount is more / less than a preset material amount or not, starting gradually increasing / decreasing frequency from the preset motor frequency of the dust removal fan, and simultaneously acquiring the dust particle density of a dust raising point until an absolute value of a difference between the dust particle density of the dust raising point and preset dust particle density is less than or equal to a permissible error. A required basic air volume is judged on the basis of the current material amount, and an adjustment end point of the motor frequency is determined by regulating the motor frequency of the dust removal fan and simultaneously detecting the dust particle density of the dust raising point, so that the motor frequency of the dust removal fan can be regulated to an optimal numerical value capable of meeting dust removal requirements and avoiding the waste of the air volume, and electric energy consumed by the dust removal fan can be effectively saved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Built-in water-cooling and dust-removing device for fuel tank of road-header

ActiveCN103032420BImprove cooling effectMake up for the shortcomingsFluid-pressure actuator componentsFuel tankEngineering

The invention discloses a built-in water-cooling and dust-removing device for a fuel tank of a road-header, wherein a snakelike copper tube cooler is internally installed in the fuel tank to cool hydraulic oil; a water inlet of the snakelike copper tube cooler is connected with a water pressure safety valve through a high-pressure hinge joint and a rubber tube to adjust the water inlet pressure; a water outlet of the snakelike copper tube cooler is connected with a first connector of a ball valve through another high-pressure hinge joint and another rubber tube; a second connector of the ball valve is connected with a water spray bracket through another rubber tube; and water orifice of the water spray bracket sprays water to the tail part of a scraper conveyor. According to the built-in water-cooling and dust-removing device for the fuel tank of the road-header, the snakelike copper tube cooler is internally installed in the fuel tank, so that the hydraulic oil is directly and efficiently cooled, defects of the cooling method of a traditional external plate-fin type cooler are effectively overcame, and the cooling is rapid; and the used cooling water is used for removing dust when the road-header is in the cutting process, and the cooling water is fed into a roof bolter when the road-header is free from the cutting process, so that the hydraulic oil can be continuously cooled during two time periods of cutting work and cutting-free work, and the cooling water is also recycled effectively.

Owner:AEROSUN CORP

Wet dust collector

PendingCN114452756AReduce manufacturing costLow maintenanceCombination devicesUsing liquid separation agentEnvironmental engineeringMechanical engineering

The invention provides a wet dust collector, and belongs to the technical field of operation. The wet dust collector solves the problem that the moisture content of airflow in an existing wet dust collector is insufficient. The wet dust collector comprises a shell with an inner cavity, the inner cavity of the shell is provided with a water containing area, a dust inlet area and an air outlet area, the water containing area is located at the bottom of the inner cavity of the shell, the dust inlet area and the air outlet area are located above the water containing area, the dust inlet area and the air outlet area are separated through a partition plate, and the partition plate is fixedly connected with the shell; when the washing liquid is contained in the water containing area, an air passing gap is reserved between the bottom edge of the partition plate and the liquid level of the washing liquid; a medium separation structure is arranged in the air outlet area, and washing liquid separated by the medium separation structure can flow downwards along the side face of the partition plate and flow to the air passing gap. Under the action of the high-speed air flow, the flowing washing liquid is crushed into water drops and water mist, so that the content of the water drops and the water mist in the air flow is increased, and the water drops and the water mist can be fully mixed with dust.

Owner:安徽正义研磨环保科技有限公司

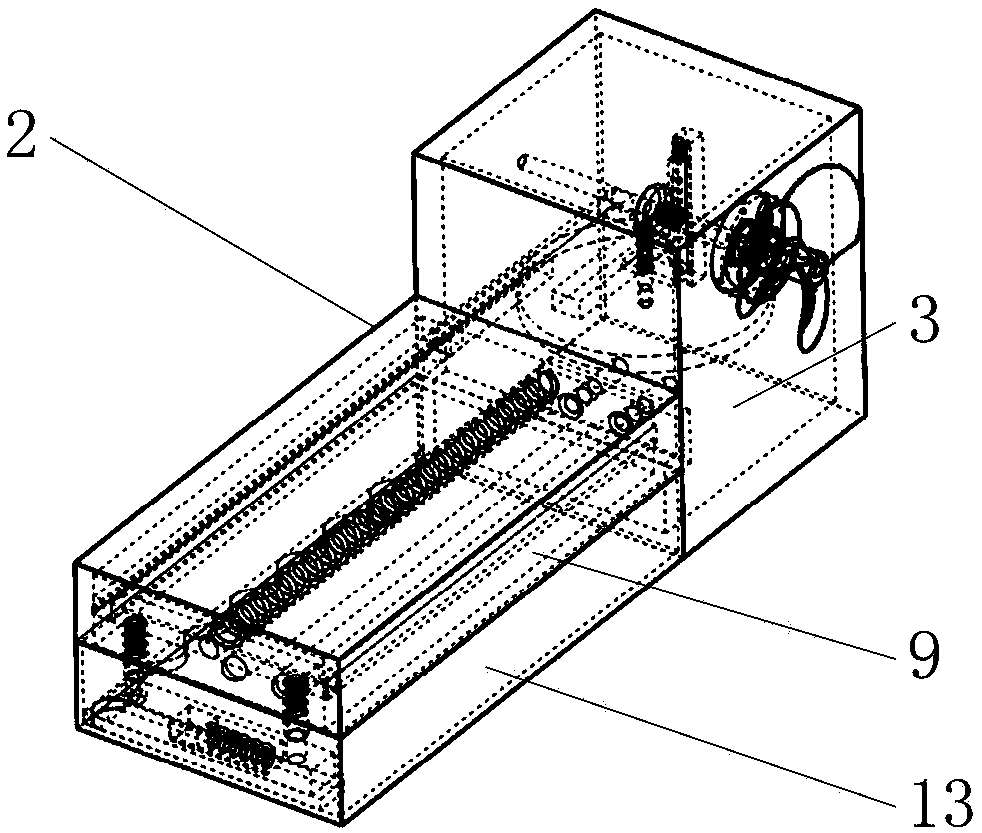

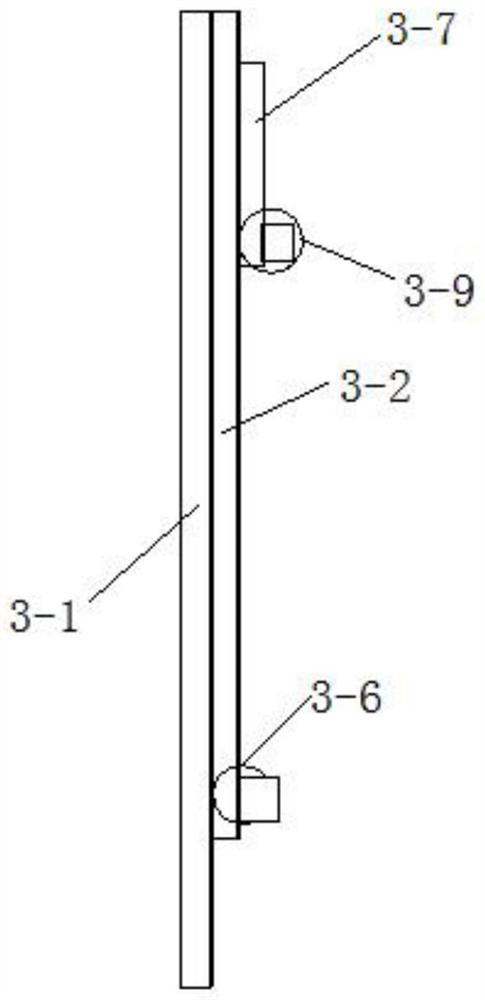

Blackboard eraser capable of collecting chalk dust

InactiveCN107639962AMeet dust removal requirementsImprove dust removal efficiencyBoard cleaning devicesBristleDrive shaft

The invention discloses a blackboard eraser capable of collecting chalk dust. The blackboard eraser comprises a square barrel body (1), paddles (2), a support (3), a motor (4), a barrel cover (6) andbristles (8). The top of the square barrel body (1) is provided with an opening, the barrel cover (6) covers the opening at the top of the square barrel body (1), through holes (7) fully covering thewall surface are formed in the front wall and the rear wall of the square barrel body (1), the bristles (8) are fixedly arranged between the through holes (7) in the front wall of the square barrel body (1), the bottom of the square barrel body (1) is provided with the support (3), the motor (4) is mounted on the upper portion of the support (3), a driving shaft of the motor (4) is connected withthe pair of paddles (2), and a filtering device is arranged in the square barrel body (1) and is close to the front of the rear wall of the square barrel body (1). The rotating paddles are utilized tosuck the dust into the square barrel body, and the blackboard eraser is high in dedusting efficiency and simple in structure and completely meets blackboard dust removing requirements.

Owner:王树欣

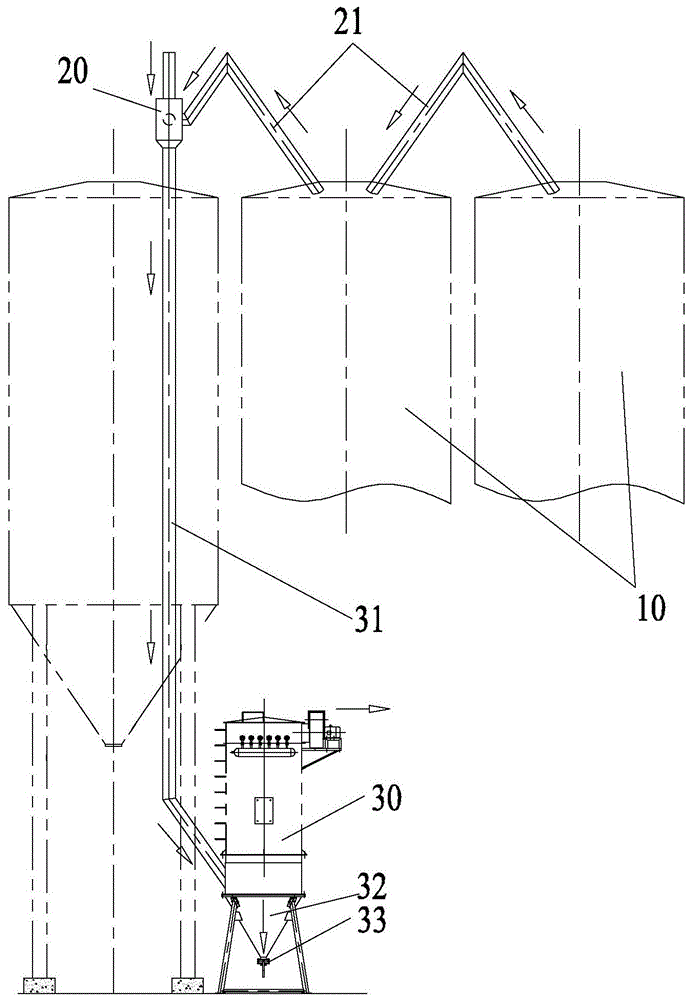

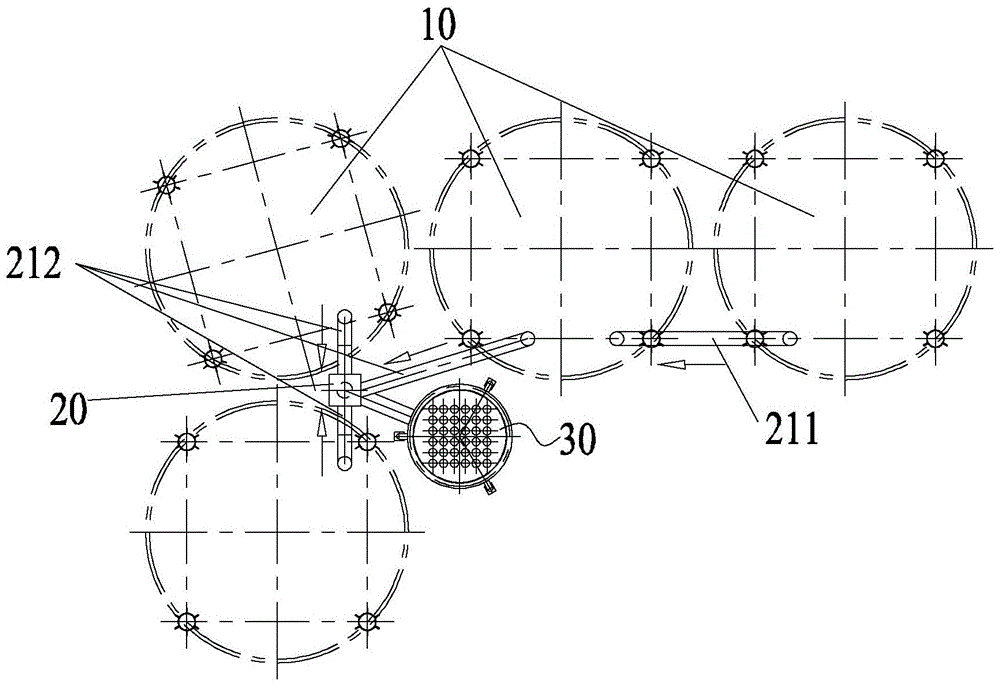

Powder silo and concrete preparation equipment

ActiveCN103587981BSolving Mixing ProblemsMeet dust removal requirementsLoading/unloadingMetallurgyProduct gas

The invention aims to provide a powder warehouse reducing cost and concrete preparation equipment. The powder warehouse comprises a plurality of powder rooms, a dust collecting device and a dedusting device, wherein the dust collecting device is communicated with the powder rooms through a plurality of dust collecting pipelines respectively in a one-way mode, and the dedusting device is connected with the dust collecting device through a dedusting pipeline. A large amount of high-pressure gas, generated when feeding is carried out through all the powder rooms, with dust is collected into the dust collecting device through the dust collecting pipelines and is conveyed into the dedusting device through the dedusting pipeline to be dedusted and filtered. Because the dust collecting pipelines are communicated with the powder rooms in a one-way mode respectively, powder mixing caused by parallel connection of the dust collecting pipelines of the powder rooms storing different kinds of powder is avoided, and accordingly requirements for carrying out dedusting among the powder rooms can be met through only one dedusting device; in addition, the number of the dedusting pipeline stretching out of the tops of the powder rooms to a working surface is only one, and therefore cost is effectively reduced.

Owner:ZOOMLION HEAVY IND CO LTD

Dust removing device

InactiveCN104190562AReduce entrainmentImprove dust removal efficiencyReversed direction vortexProduct gasAirflow

The invention provides a dust removing device, relating to the technical field of dust-containing gas dust removing equipment. The dust removing device comprises a cylindrical device body (1), wherein an inlet pipe bottom plate part (4) of a flue gas inlet pipe (3) of the dust removing device is of a structure in which a bottom plate outer side part (4) is higher than a bottom plate inner side part (6) connected with the device body (1); a lower barrel (2) comprises an upper conical barrel (7) and a lower conical barrel (8); and the device body (1) and the lower conical barrel (8) are communicated with an upper opening (9) of the upper conical barrel and a lower opening (10) of the upper conical barrel respectively. The dust removing device provided by the invention can realize a secondary separation effect; separated dust can be prevented from being carried by inner vortexes, so that the dust removing efficiency is improved; the flue gas inlet pipe adopts a special-shaped inlet structure so that the mutual interference between inlet gas and the inner vortexes is avoided; and gas flow working conditions in the dust removing device are effectively organized and the dust removing efficiency is improved.

Owner:ANHUI CONCH KAWASAKI ENERGY CONSERVATION EQUIP

A dust removal device for electrical automation equipment

ActiveCN110756519BChange the blowing rangeDust blowing range can be changed flexiblyDirt cleaningCleaning using toolsCircular discElectric machinery

Owner:ZHUHAI HENGQIN KUNPENG NEW ENERGY ENVIRONMENTAL PROTECTION TECH CO LTD

Spatial multi-dimensional dust removal device for electrical engineering

InactiveCN114769213AMeet dust removal requirementsReasonable structural designCleaning using gasesClassical mechanicsDust control

The invention discloses a spatial multi-dimensional dust removal device for electrical engineering, which comprises a base, supporting walking assemblies are respectively mounted at four opposite angles of the bottom end of the base, a vertical guide assembly is mounted in the middle of the upper end surface of the base, and a transverse guide assembly is mounted at the end part of the vertical guide assembly. A movable longitudinal guide assembly is installed on the transverse guide assembly, a first moving seat is installed on the longitudinal guide assembly, a dust removal mechanical arm assembly is installed on the first moving seat and comprises a base, a first arm rod and a second arm rod which are rotatably installed on the first moving seat, and a cleaning unit is installed at the end of the second arm rod; ventilation hoses are installed at the rear ends of the cleaning units correspondingly, and the other ends of the ventilation hoses are connected to the dust collection box and an air outlet of the air blower correspondingly. Movement of space height, width and depth is achieved, surface floating dust is blown more reasonably, dust collection is conducted through the dust collection head after blowing, and the dust collection requirement of large-scale electrical engineering is met.

Owner:HUAIBEI NORMAL UNIVERSITY

A street lamp capable of removing dust on the inner wall

ActiveCN109140337BImprove lighting effectsLow costMechanical apparatusLighting elementsReciprocating motionAtmospheric sciences

The invention belongs to the field of streetlamps and particularly relates to a streetlamp capable of removing dust on the inner wall. The streetlamp comprises a lamp pole and a streetlamp mechanism,wherein the streetlamp mechanism is mounted at the top of the lamp pole. The streetlamp utilizes wind energy to automatically remove the dust, and thus the maintenance cost of the streetlamp is greatly lowered; a worker does not need to climb to the top of the lamp pole for maintenance, and thus the possible danger caused by climbing of maintenance personnel is avoided; a centrifugal wheel can identify the magnitude of the wind speed, if the wind speed is small, the centrifugal wheel does not interact with a first rack, a dust removing strip does not play a role of dust removing, and if the wind speed is large, the centrifugal wheel interacts with the first rack, so that the dust removing strip conducts four-time reciprocating motion in a lampshade to complete clearing of the inner wall ofthe lampshade; and the dust removing strip swings leftwards and rightwards while sliding along the bottom of the inner wall of the lampshade under driving of a second rack, so that the stubborn dustin the lampshade is cleared, the dust removing effect in the lampshade meets the dust removing requirement to the maximum extent, and the using effect of the lampshade after dust removing is better.

Owner:余燕秀

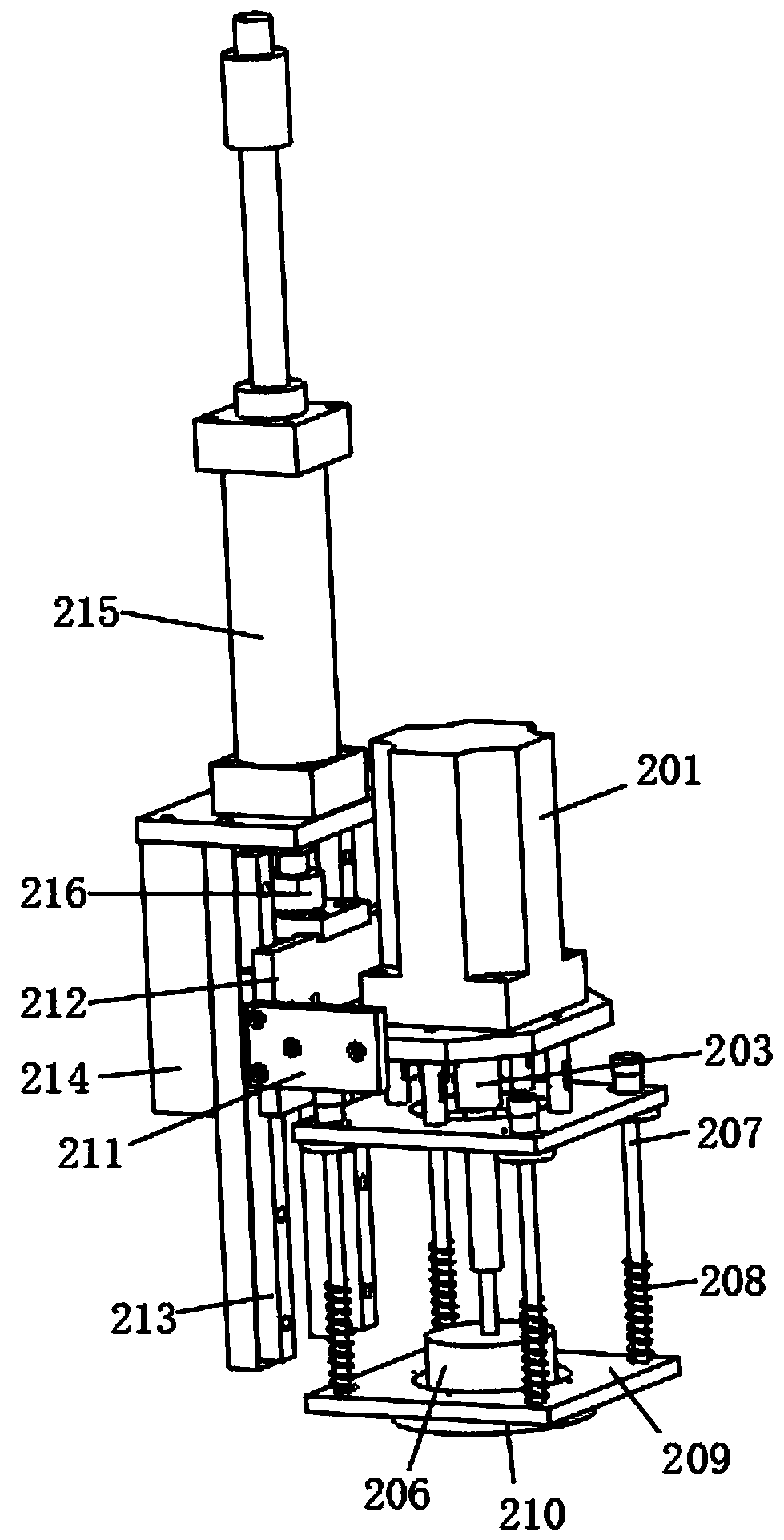

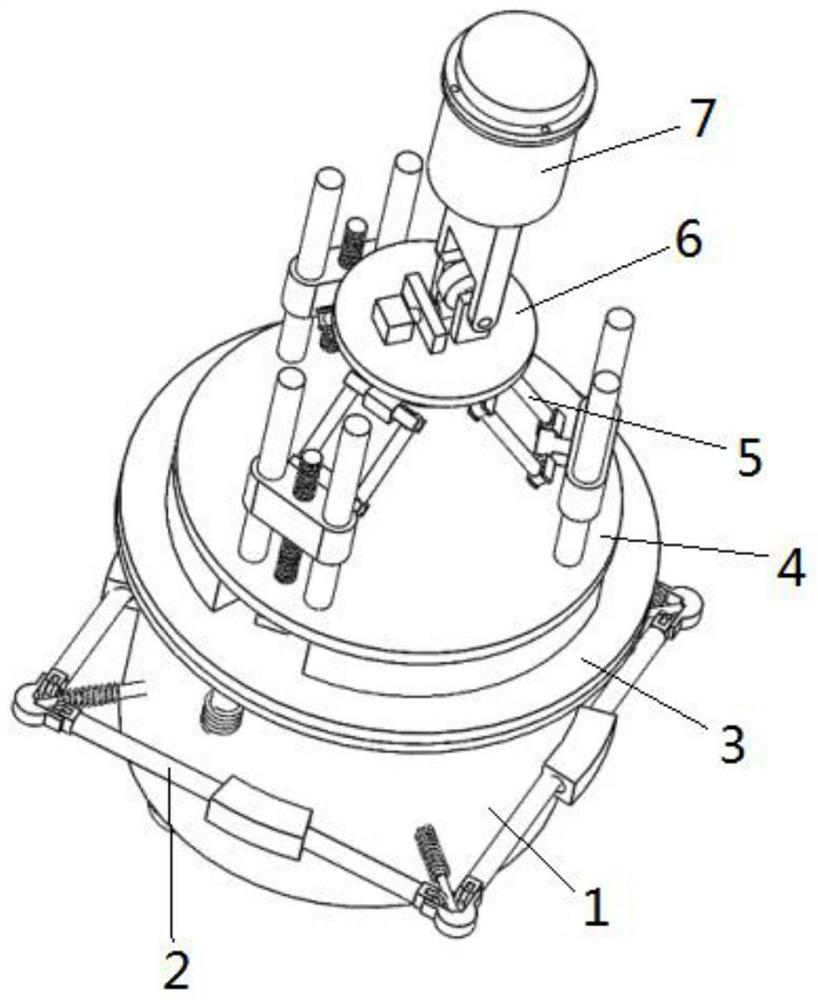

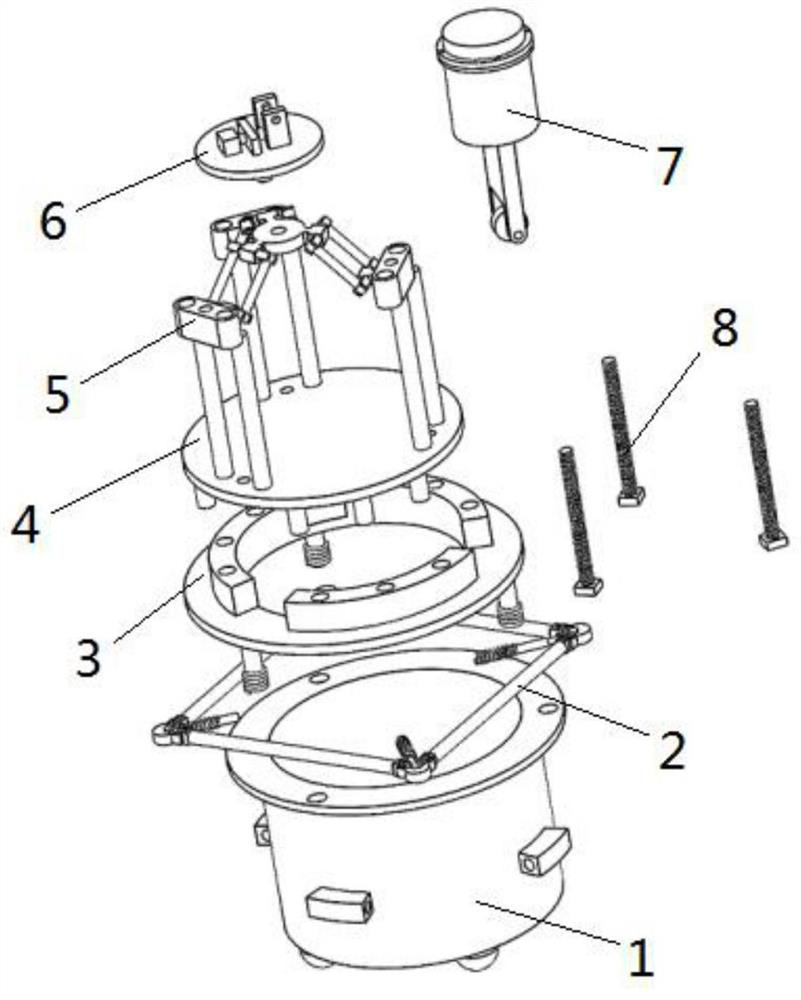

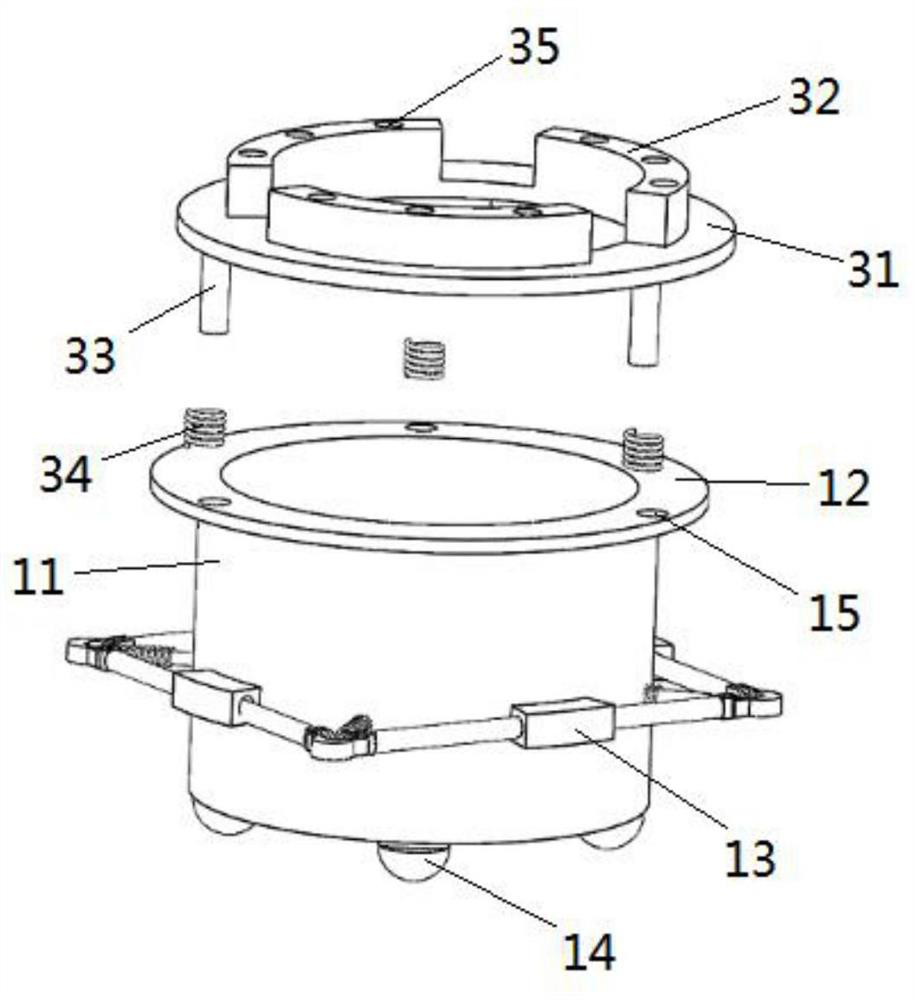

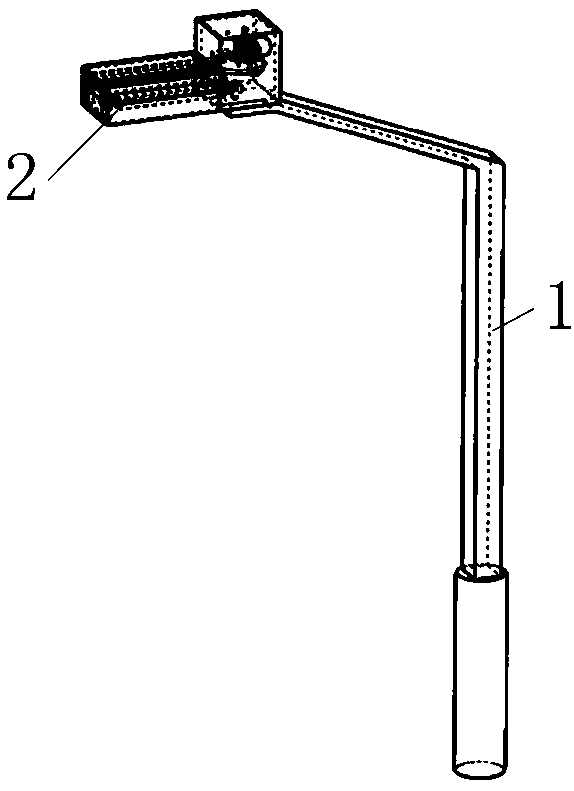

An adaptive cleaning robot

ActiveCN109938652BAvoid damageEasy to installMachine detailsFloor sweeping machinesSimulationActuator

The invention discloses an adaptively adjusted cleaning robot, which includes a mobile base, a balance adjustment mechanism for anti-collision, a buffer support mechanism for buffer adjustment, an intermediate adjustment seat, an intermittent adjustment mechanism, a transmission console, The cleaning actuator and three transmission mechanisms, the intermittent adjustment mechanism is installed on the middle adjustment seat, and the transmission mechanism drives the intermittent adjustment mechanism to move along the sliding guide column on the middle adjustment seat, the cooperation between the transmission console and the cleaning actuator, Drive the cleaning actuator to perform 0-90°rotation cleaning. The invention uses the structural design of the balance adjustment mechanism to play the role of collision buffer, reducing the collision of obstacles on the robot during walking, and the structural design of the intermittent adjustment mechanism to drive the height adjustment of the cleaning actuator and the adjustment of the horizontal plane angle, and through the transmission The design of the operating table can realize the cleaning of walls at different angles, and has the characteristics of strong adaptability and high cleaning efficiency.

Owner:杨骏成

Street lamp capable of removing dust by using wind energy

The invention belongs to the field of street lamps, and particularly relates to a street lamp capable of removing dust by using wind energy. The street lamp comprises a lamp rod and a street lamp mechanism, wherein the street lamp mechanism is installed on the top of the lamp rod; the street lamp achieves automatic dust removal by using the wind energy and costs of street lamp maintenance are lowered greatly; workers are not required to climb to the top of the street lamp rod for maintenance, possible danger that maintenance personnel during climbing is avoided; when the wind drives a drivingfan to rotate, a driving gear interacts with a first rack, so that a dust removal strip is reciprocated four times in a lampshade to clean the inner wall of the lampshade; automatic dust removal of the street lamp through wind energy is achieved; the dust removal effect in the lamp shade is obvious; and the dust removal requirements are achieved to the utmost extent.

Owner:嘉兴市祥发织造股份有限公司

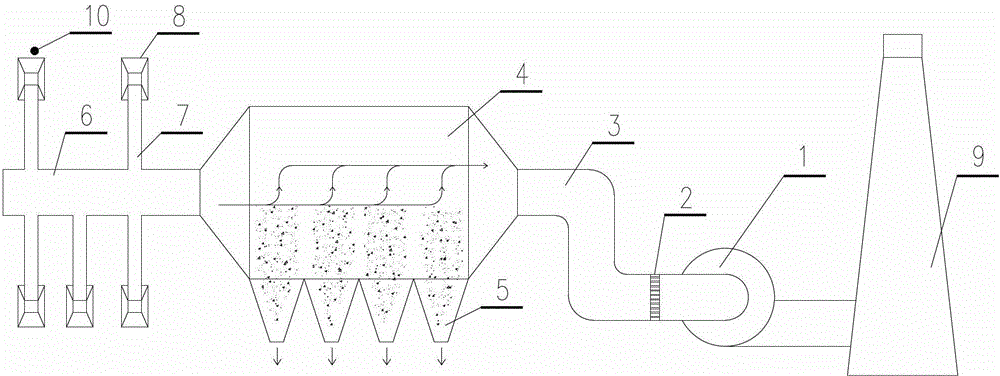

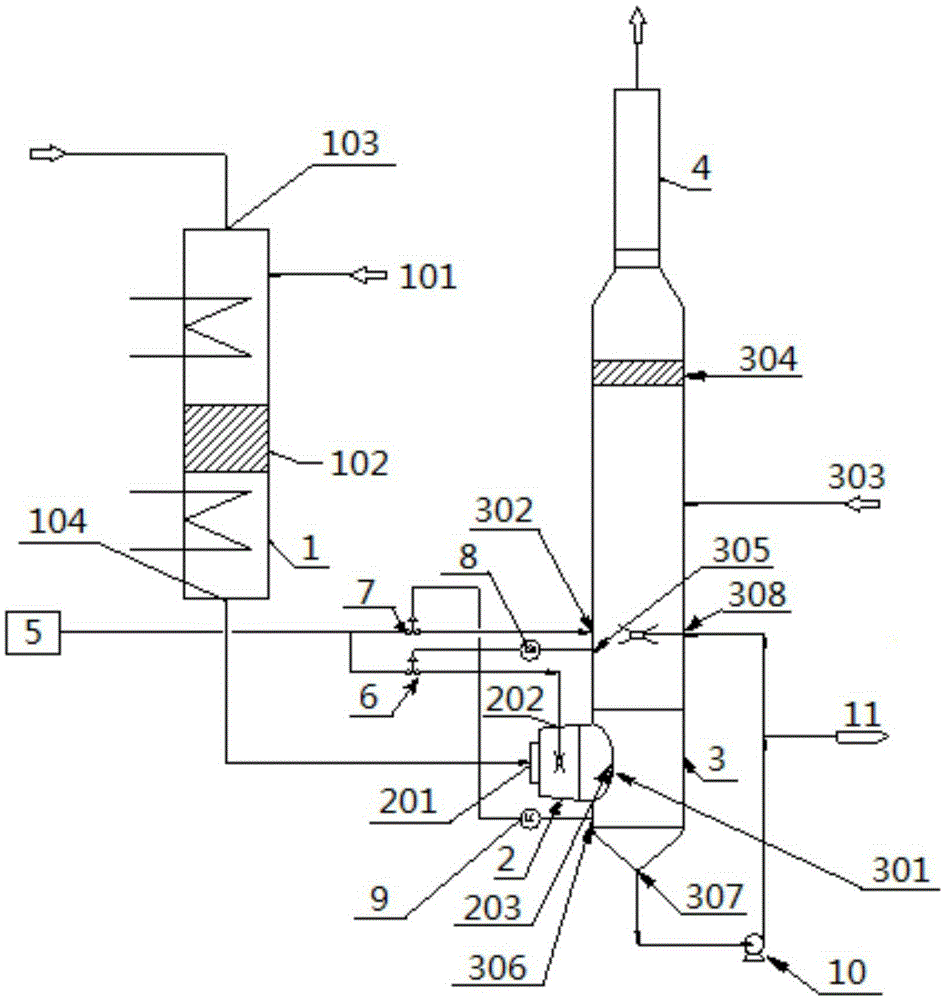

Flue gas desulfurization, denitration and dust removal device and method

InactiveCN106807192AMeet dust removal requirementsEasy to operateDispersed particle separationTemperature controlLine tubing

The invention discloses a flue gas desulfurization, denitration and dust removal device and method and belongs to the field of flue gas treatment by catalytic cracking. The device comprises a residual heat boiler, a cooler, a washing tower, a chimney, a water feeder, a temperature control valve and a liquid level control valve. A first flue gas inlet is formed in the top of the residual heat boiler and an ammonia gas inlet is formed in the upper part of the residual heat boiler; a denitration reactor is arranged in the middle of the residual heat boiler; a flue gas outlet is formed in the bottom of the residual heat boiler. A second flue gas inlet and a water inlet are formed in the lower part of the washing tower; an alkali liquid inlet is formed in the middle of the washing tower; a liquid and dust remover is arranged at the upper part of the washing tower and a chimney connector is arranged at the top of the washing tower. The cooler is provided with a gas phase inlet, a liquid phase inlet and an outlet. The flue gas outlet on the residual heat boiler, the gas phase inlet and the outlet of the cooler, the second flue gas inlet and the chimney connector of the washing tower, and the chimney are connected in sequence. The temperature control valve is arranged on a pipeline between the water feeder and the liquid phase inlet of the cooler; the liquid level control valve is arranged on a pipeline between the water feeder and the water inlet of the washing tower. The device disclosed by the invention can be used for carrying out desulfurization, denitration and dust removal treatment on flue gas from an FCC device.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Electrostatic spraying and dust-removing system

InactiveCN102698557BImprove filtration efficiencyMeet dust removal requirementsCombination devicesHigh pressureDistributor

The invention relates to an electrostatic spraying and dust-removing system. One end of a shell is an inlet of a dust-removing system while the other end of the shell is an outlet of the dust-removing system; an air flow distributor, an electrostatic spraying device, a filtering dust-collecting and washing device and a water separator are arranged in the shell orderly from the inlet to the outlet; at least one atomizing nozzle is connected to a water supply pipe in the electrostatic spraying device, a high pressure static ring is arranged in front of each atomizing nozzle; the high pressure static ring is connected with a high pressure static generator at the outer part of the system through a lead; a filler is arranged in the filtering dust-collecting and washing device, and the upper part of the filler is provided with a water pouring distributor; the water pouring distributor is connected with a system external water supply pipe through a water pipe; and the bottom part of the filler is provided with a water collecting disk, and the water collecting disk is provided with a water draining pipe. The system can satisfy the dust removing requirement of grains in different sizes in air, and has a relatively good effect to filter the powder dust with the grain diameter being more than 0.1 micro meters.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com