High-frequency dust removing transformer

A transformer and high-frequency technology, which is applied in the field of high-frequency dust removal transformers, can solve the problems of dust removal efficiency drop, dust removal efficiency drop, transformer output voltage fluctuation, etc., and achieve the effect of dust removal efficiency improvement, volume reduction, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

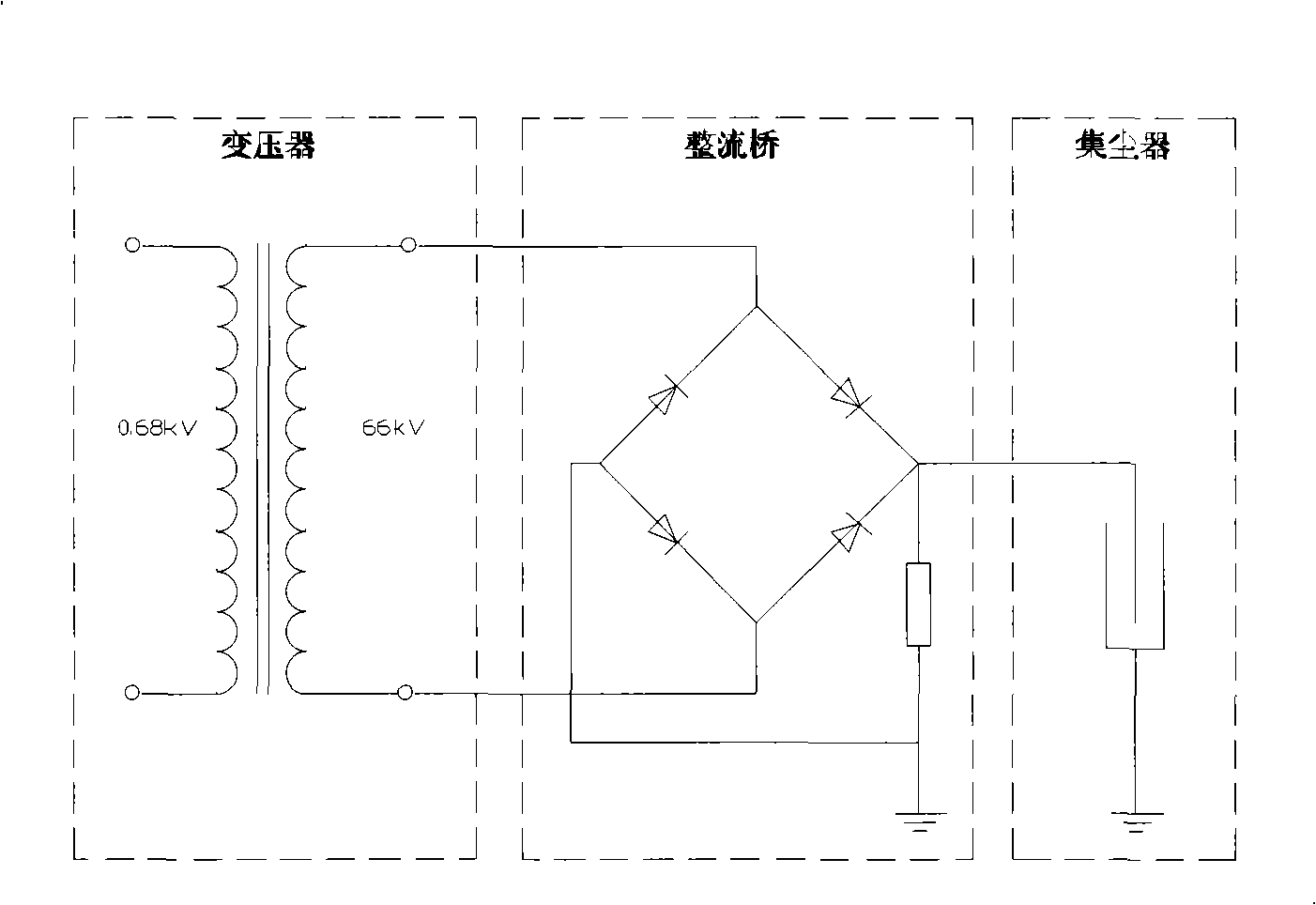

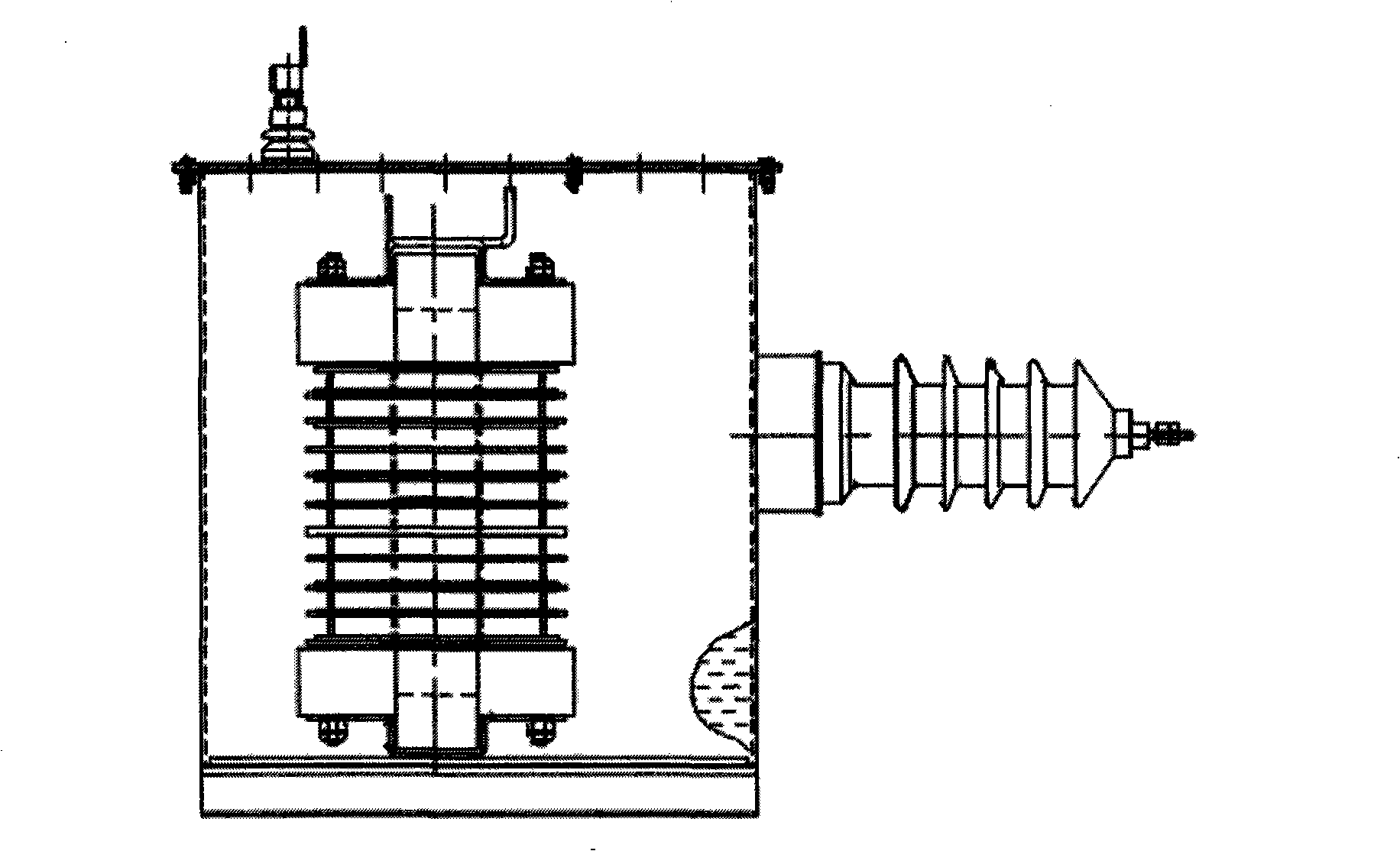

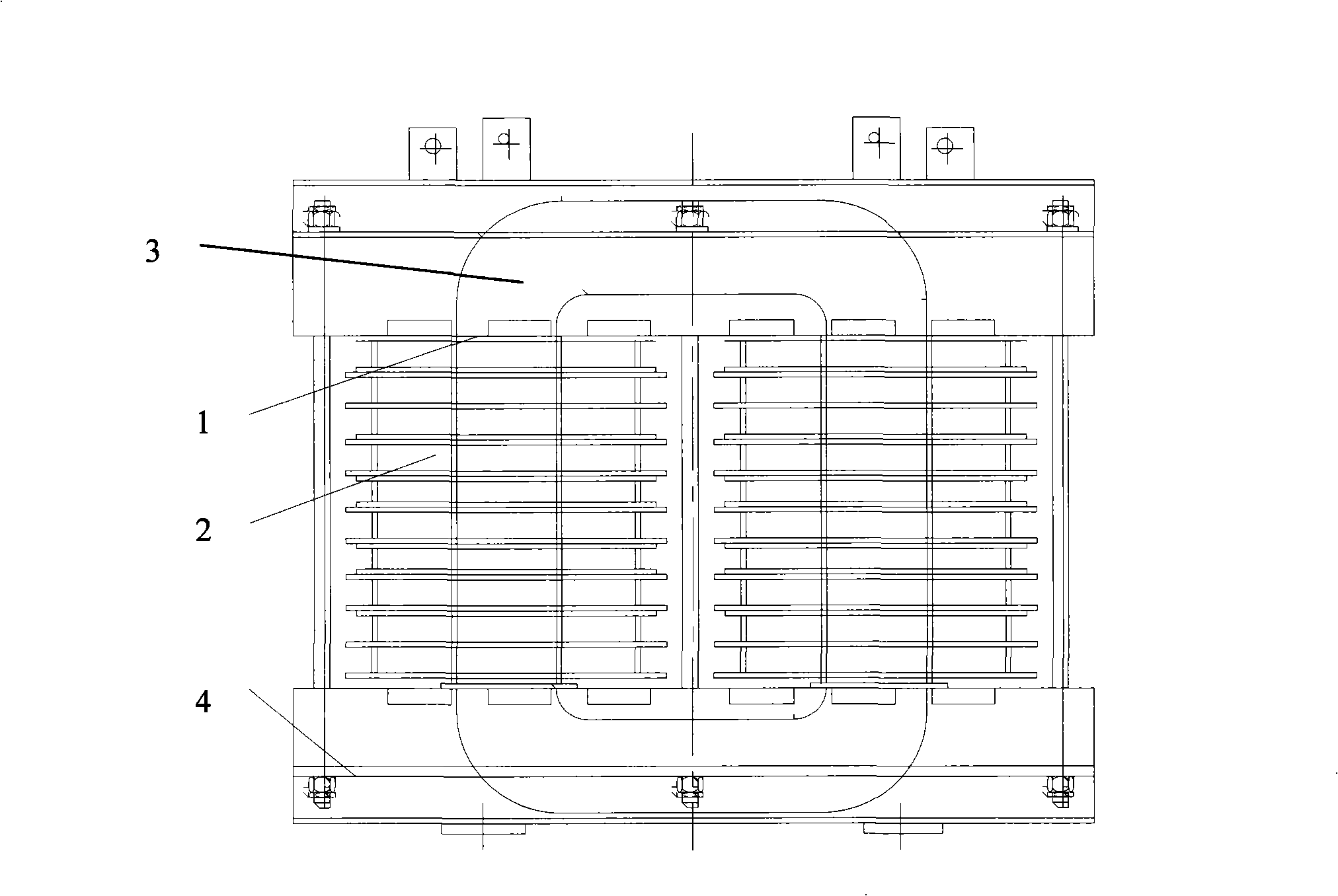

[0017] A high-frequency dust-removing transformer according to the present invention includes a low-voltage winding 1, a high-voltage winding 2 and an iron core 3. The iron core 3 is in the shape of a "mouth" formed by docking two and a half "mouths", and the iron core 3 is made of iron Made of oxygen material. The input voltage of the low-voltage winding 1 is 0.68kV; the output voltage of the high-voltage winding 2 is 66kV; the operating frequency of the transformer is 7-8kHz.

[0018] The low-voltage winding is wound with copper foil, and the high-voltage winding adopts a multi-cake continuous winding assembly structure. The low-voltage winding 1, the high-voltage winding 2 and the iron core 3 are fixed by the clip 4. Transformer oil is used for insulation and cooling.

[0019] The present invention completely solves the problems existing in the dust removal process of the existing power frequency transformer, so that the rectified waveform and impedance matching of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com