Built-in water-cooling and dust-removing device for fuel tank of road-header

A dust removal device and roadheader technology, which is applied to fluid pressure actuation devices, mechanical equipment, fluid pressure actuation system components, etc., and can solve problems such as slow cooling speed, limited quantity and volume, and limited space for coolers , to achieve high cooling efficiency, large contact area and stable water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

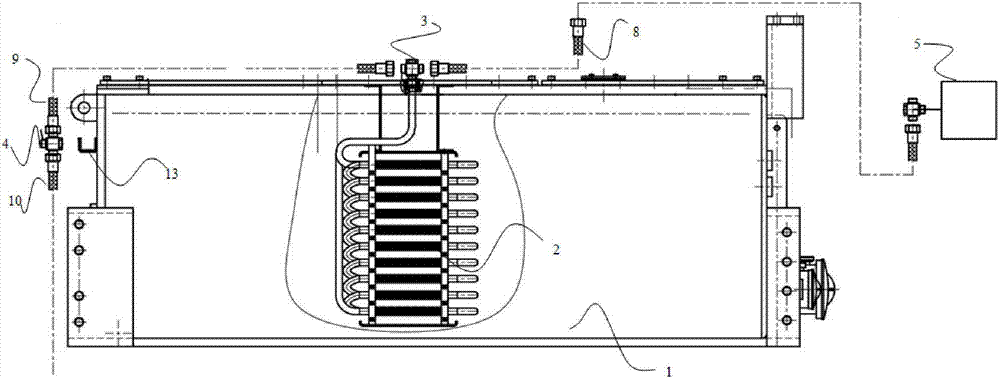

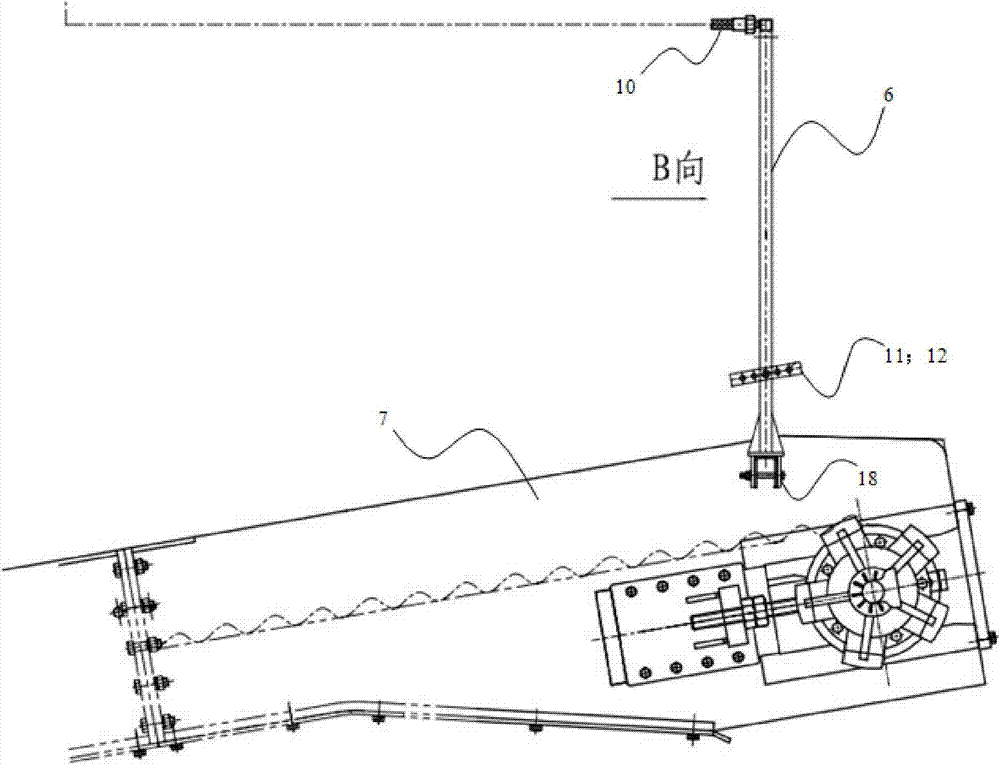

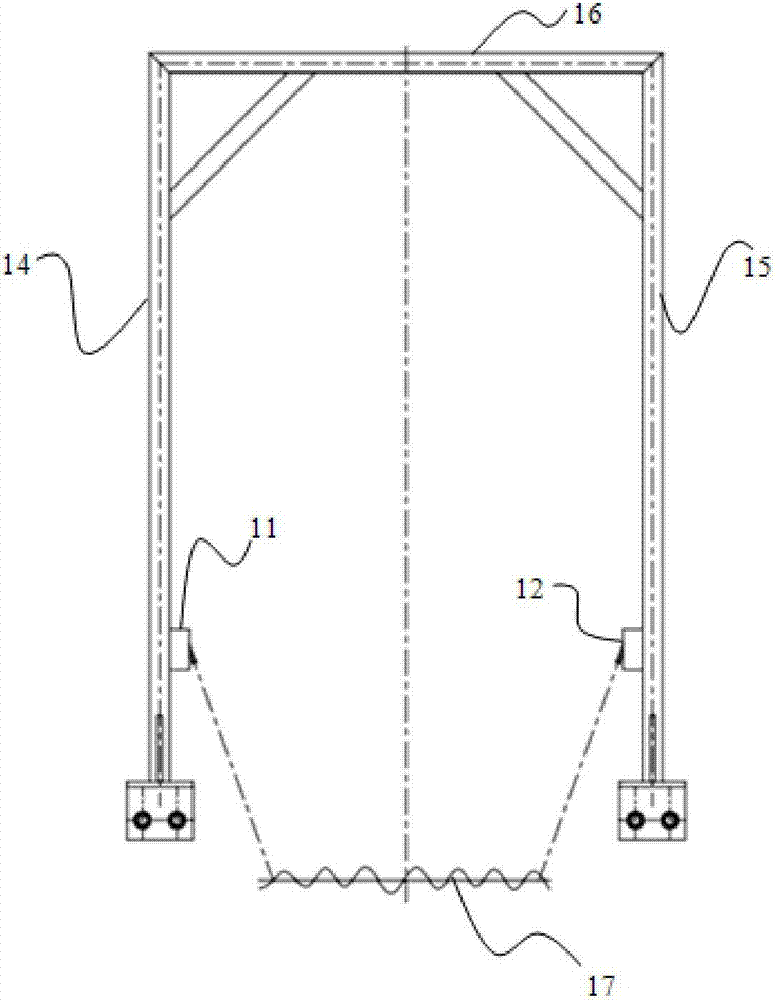

[0017] Example: The invention has a built-in water cooling and dust removal device for the oil tank of a roadheader, such as figure 1 , figure 2 As shown, it includes an oil tank 1, a serpentine copper tube cooler 2, two high-pressure articulated joints 3, a ball valve 4, a hose 8; 9; 10, a water pressure safety valve 5, a water spray bracket 6 and a scraper conveyor 7. The serpentine copper tube cooler 2 is built in the oil tank 1. The serpentine copper tube cooler 2 cools the hydraulic oil through heat exchange between the flowing cooling water and the hydraulic oil in the oil tank 1. The serpentine copper pipe in the spool is arranged in the oil tank 1, so the contact area with the hydraulic oil is large, the cooling water can fully exchange heat with the hydraulic oil, and the cooling efficiency is higher; the high-pressure articulated joint 3 is installed in the The serpentine copper tube cooler 2 extends out of the nozzle of the oil tank 1, and the pipeline direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com