Modular single-machine dust collector and its assembly method

A dust collector and modular technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as high cost, inability to use dust collectors for dust cleaning systems, waste of resources, etc., to improve work efficiency and assembly. Easy-to-assemble, simple-to-structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

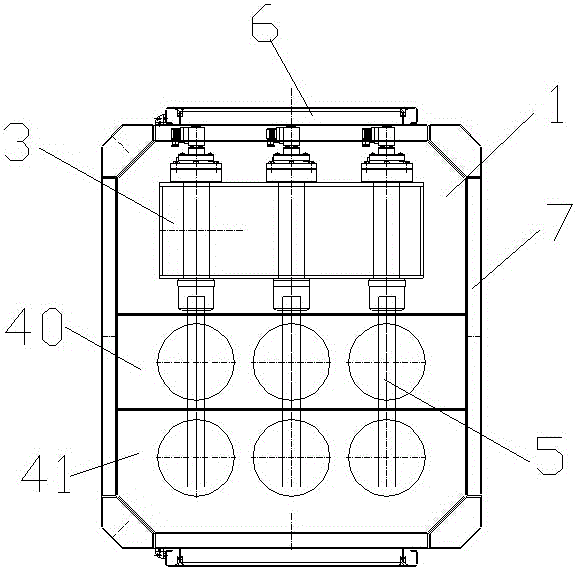

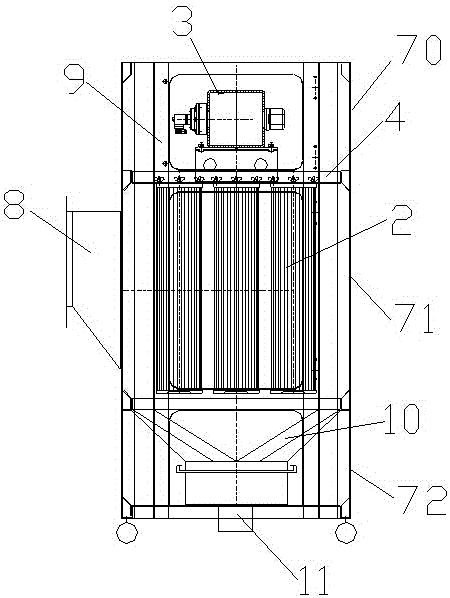

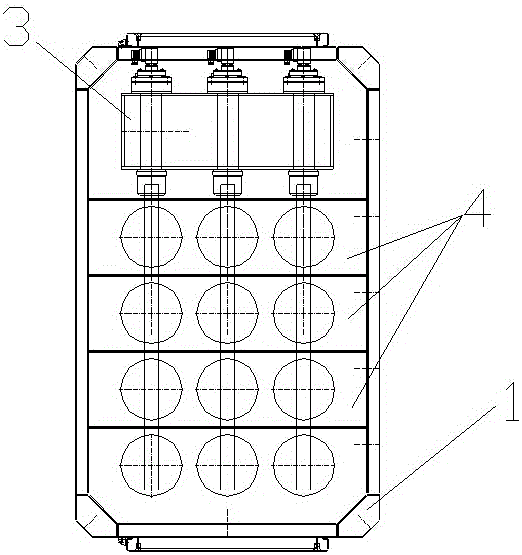

[0021] Embodiment 1: with reference to attached Figure 1-4 . A modular stand-alone dust collector, which includes a plurality of unit dust removal devices 1 and a plurality of porous plates 4; see the attached figure 2 , the unit dedusting device 1 is composed of an upper dust removal gas circuit 9, a middle filter cartridge 2 and a lower ash hopper 10; the lower ash hopper 10 includes a conical ash hopper 10 and a sealed drawer 11, the conical ash hopper 10 shrinks downward, and the conical ash hopper The ash hopper 10 can effectively prevent secondary dusting of the dust; the sealing drawer 11 is controlled by an automatic cylinder, and the sealing drawer 11 is located at the opening end below the conical ash hopper 10 to seal the ash hopper 10; the middle filter cartridges 2 are arranged vertically side by side , The left and right sides of the unit dust removal device 1 are respectively symmetrically provided with air inlets 8, which side of the air inlet 8 can be selec...

Embodiment 2

[0025] Embodiment 2: a method for assembling the modularized stand-alone dust collector described in Embodiment 1, which comprises the following steps:

[0026] ① According to the dust removal requirements, the dust removal scale is approved, and the number of unit dust removal devices 1 and perforated plates 4 is determined;

[0027] ②Install the porous plates 4 into the unit dust removal device 1 respectively, so that the filter cartridges 2 in the unit dust removal device 1 are all covered by the porous plates 4, and then replace the left and right side plates to suit the size;

[0028] ③ Lengthen the length of the blowing pipe 5 and add air nozzles so that the air nozzles on the blowing pipe 5 correspond to the openings of each filter cartridge 2 one by one to obtain the first splicing structure, see attached image 3 structure shown;

[0029] ④Through the bolts on the side plates 7 around the unit dust removal device 1, connect each unit dust removal device 1 to complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com