Wet dust collector

A wet dust collector and area technology, applied in the field of dust removal device and wet dust collector, can solve the problems of short service life of water pump, high use cost of wet dust collector, easy damage of water pump, etc., to save electric energy and improve water mist generation. Quantity and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

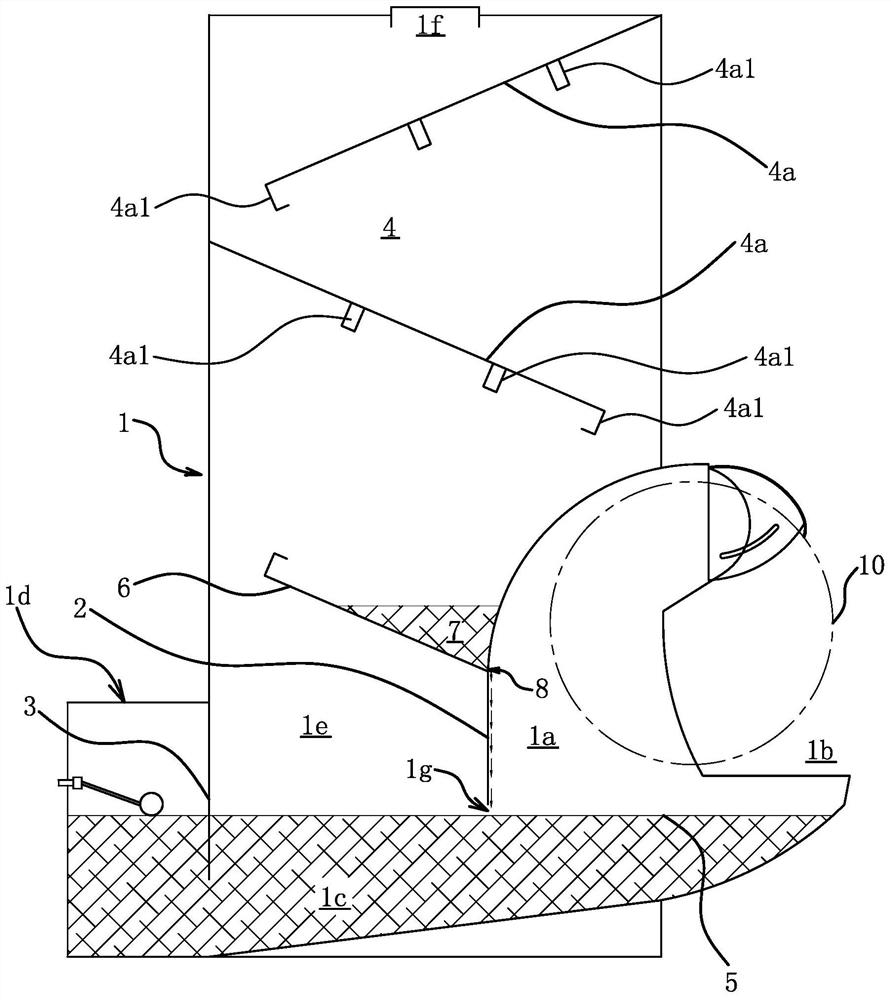

[0026] Embodiment one: if figure 1 As shown, the wet dust collector includes a housing 1 with an inner cavity. The front part of the inner cavity in the housing 1 is a dust inlet area 1a; a manipulation port 1b is opened on the front side wall of the dust inlet area 1a. The bottom of the inner cavity is the water holding area 1c, that is, the dust inlet area 1a is located above the front part of the water holding area 1c.

[0027] The rear part of the inner cavity is the air outlet area 1e, and the dust inlet area 1a and the air outlet area 1e are separated by a partition 2 fixedly connected with the housing 1, and the bottom of the partition 2 is vertically arranged. An air outlet 1f is opened on the top surface of the air outlet area 1e in the casing 1 . According to actual conditions, the air outlet 1f can be connected to the fan through a pipe, or the fan connected to the air outlet 1f can be directly fixed on the top plate of the housing 1 .

[0028] A medium separatio...

Embodiment 2

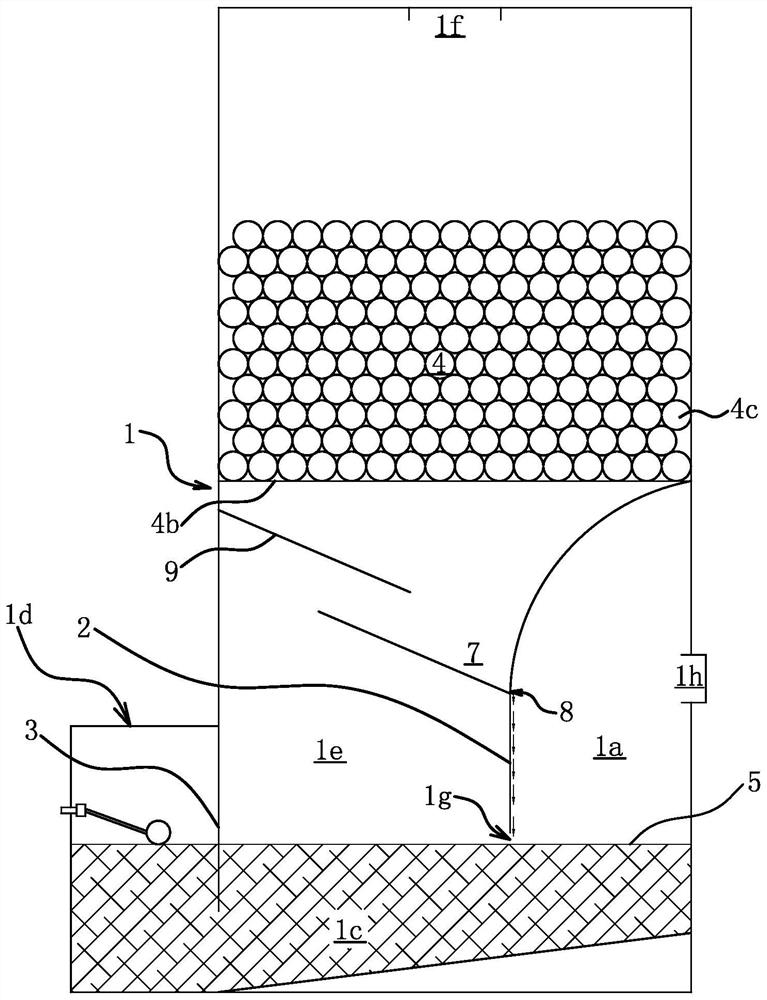

[0034] Embodiment 2: The structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities will not be described redundantly, and only the differences will be described. The differences are as follows: figure 2 As shown, the front side wall of the dust inlet area 1a is not provided with a control port 1b, but with an air inlet port 1h.

[0035] The medium separation structure 4 includes a bearing net 4b arranged in the middle of the air outlet area 1e, the bearing net 4b is connected to the housing 1, and a large number of hollow multi-faceted plastic balls 4c are filled in the air outlet area 1e; that is, the hollow multi-faceted plastic balls 4c are stacked On the carrying net 4b, a large number of multi-faceted plastic balls stacked together also have the effect of separating water mist and dust, and the number of multi-faced plastic balls can be flexibly adjusted according to the actual water mist and dust separation effect,...

Embodiment 3

[0037] Embodiment 3: The structure and principle of this embodiment are basically the same as that of Embodiment 1. The basic similarities are no longer redundantly described, and only the differences are described. The difference is that there is a drain on the bottom plate of the water storage tank 7 8. In this way, the washing liquid will flow downward along the surface of the partition plate 2 on the side of the air outlet area 1e, thereby forming a water curtain at the air passage gap 1g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com