Blackboard eraser capable of collecting chalk dust

A technology of chalk wiper and chalk dust, which is applied in the field of teaching aids, can solve the problems of no explanation anywhere, little effect of dust collection, no explanation of the specific structure and position of the filter device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

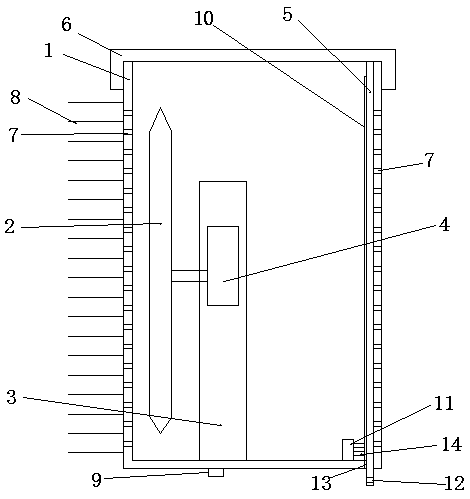

[0013] Such as figure 1 As shown, the chalk eraser that can collect chalk dust includes a square cylinder 1, paddle 2, bracket 3, motor 4, cylinder cover 6 and bristles 8, the top of the square cylinder 1 is open, and the cylinder cover 6 is covered on the square cylinder 1. On the opening of the top, the front and rear walls of the square cylinder 1 are provided with through holes 7 covering the wall surface. The bristles 8 are fixed between the through holes 7 on the front wall of the square cylinder 1, and at the bottom of the square cylinder 1. Bracket 3, a motor 4 is installed on the upper part of the bracket 3, the drive shaft of the motor 4 is connected to a pair of paddles 2, and the pair of paddles 2 rotate vertically and are close to the inside of the front wall of the square cylinder 1, and a battery is installed on the bracket 3 as a motor 4 drive power supply, the bottom surface of the square cylinder 1 is provided with a switch 9, and tracks (not shown in the fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com