Powder silo and concrete preparation equipment

A technology of powder silo and powder material, which is applied in the field of concrete mixing, can solve the problems of high cost, excessive dust, dust emission from the top of the warehouse, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

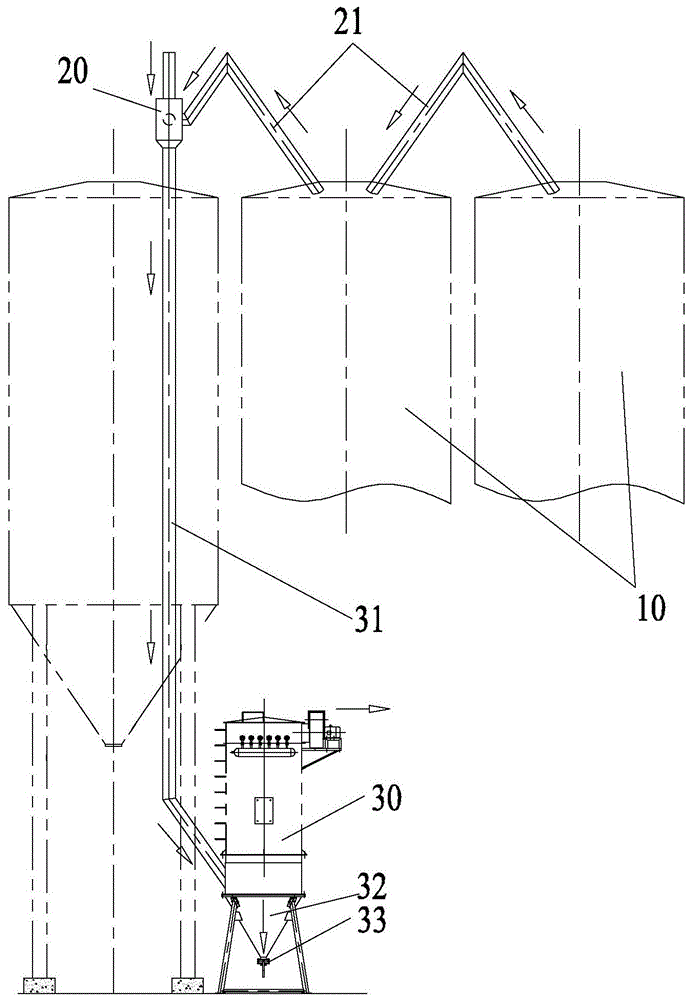

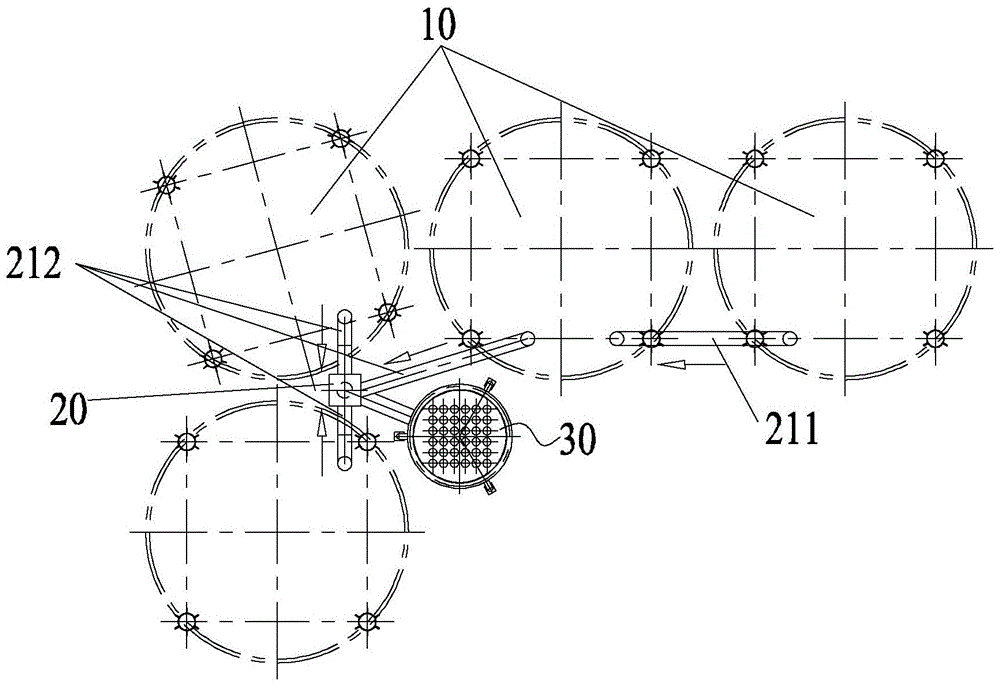

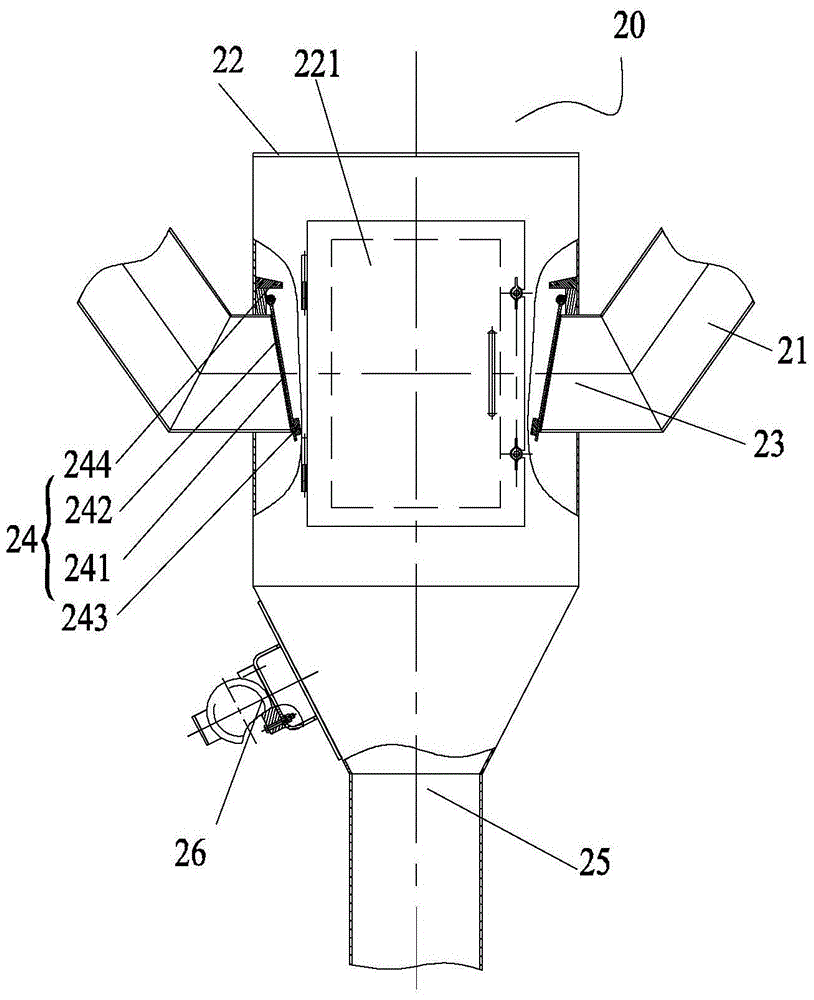

[0027] Such as figure 1 and figure 2 As shown, the powder bin according to the present invention includes a plurality of powder rooms 10, and also includes a dust collection device 20 and a dust removal device 30. The dust collection device 20 is arranged above the powder room 10, and passes through a plurality of dust collection pipes 21 are in unidirectional communication with a plurality of powder rooms 10 respectively; the dust removal device 30 is arranged on the ground and connected with the dust collection device 20 through the dust removal pipe 31 . In the present invention, a large amount of dust-laden high-pressure gas generated during loading of each powder room 10 is collected into the dust collection device 20 through a plurality of dust collection pipes 21, and the gas is transported to the dust removal on the working surface through the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com