Anti-mixing material lining device for head funnels

A head funnel and anti-mixing technology, applied in the direction of transportation and packaging, conveyor objects, etc., to achieve the effect of easy disassembly, small structure occupation space, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

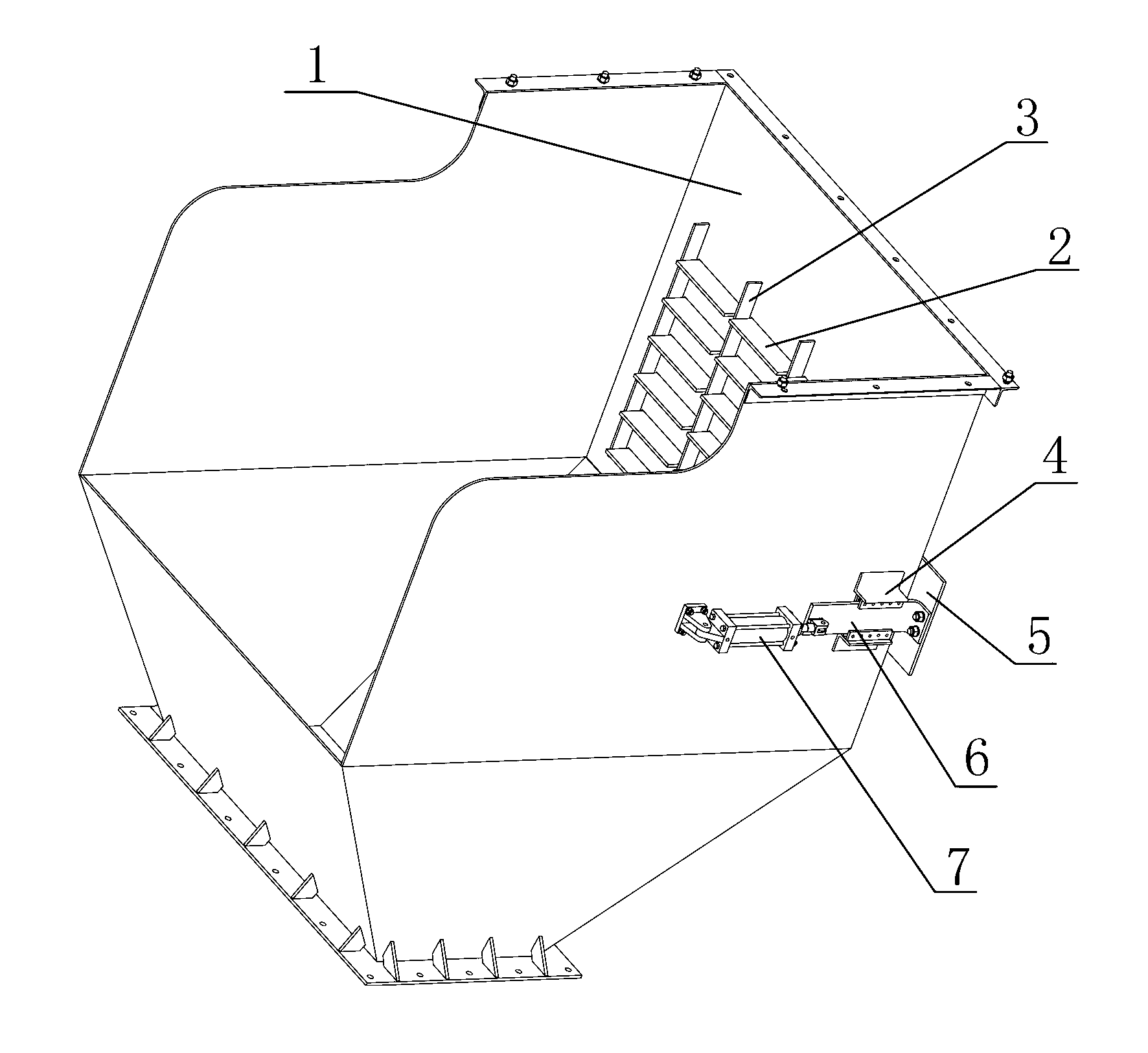

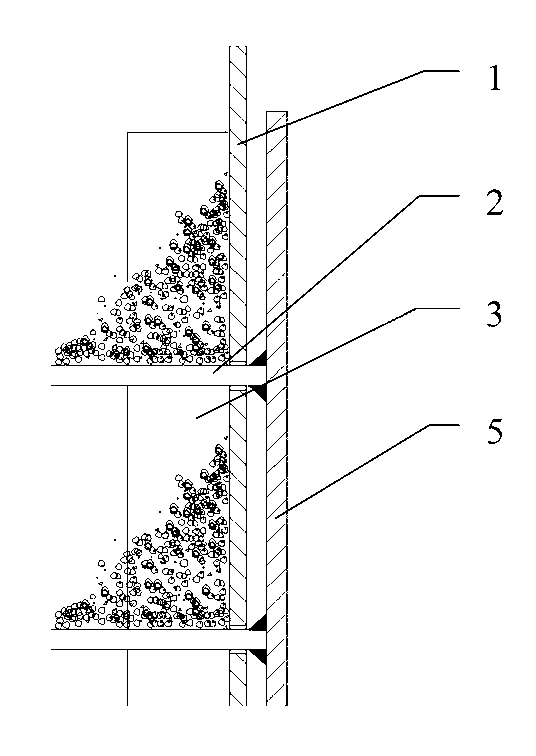

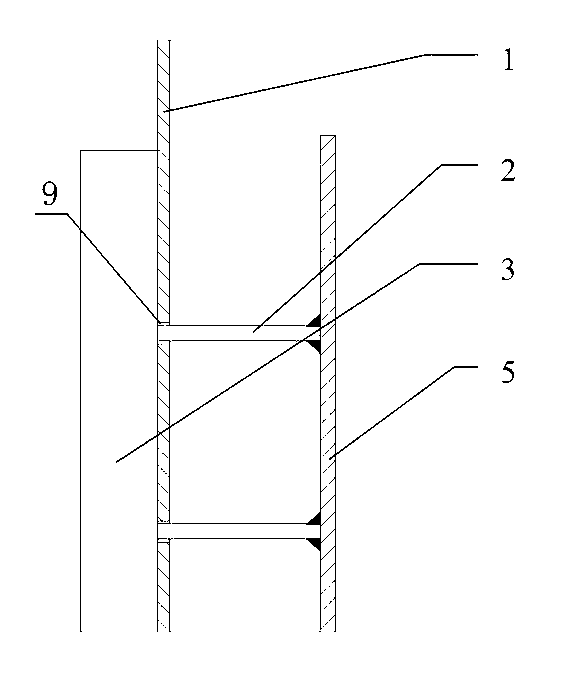

[0024] See attached Figure 1~2 , a head funnel anti-mixing material lining device of the present invention includes a funnel wall 1, a group of through holes 9 arranged in a rectangular array are opened on the material receiving surface of the funnel wall 1, and each through hole 9 is respectively inserted with A material-lined diaphragm 2 that can be inserted into and extracted from the through hole 9, these material-lined diaphragms 2 are uniformly installed on a base plate 5, and a guide plate 6 is installed on each side of the base plate 5, and each guide plate 6 is connected to a cylinder 7. Of course, the air cylinder 7 can also be replaced by a hydraulic cylinder, and similar replacements should also fall within the protection scope of the present invention. A guide seat 4 is arranged on both sides of the funnel wall 1 , and the guide plate 6 passes through the guide seat 4 . Guide rollers are arranged on the contact portion of the guide seat 4 with the guide plate 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com