Fluidized-fixed composite bed reaction adsorption reinforced hydrogen production device and method by methane vapor reforming

A methane steam reforming hydrogen production technology, applied in the fields of chemical industry, energy, and oil refining, can solve the problems of high-temperature deactivation of catalysts, reduce catalyst activity and service life loss, and reduce the possibility of entering high-temperature regeneration zones. The effect of avoiding heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

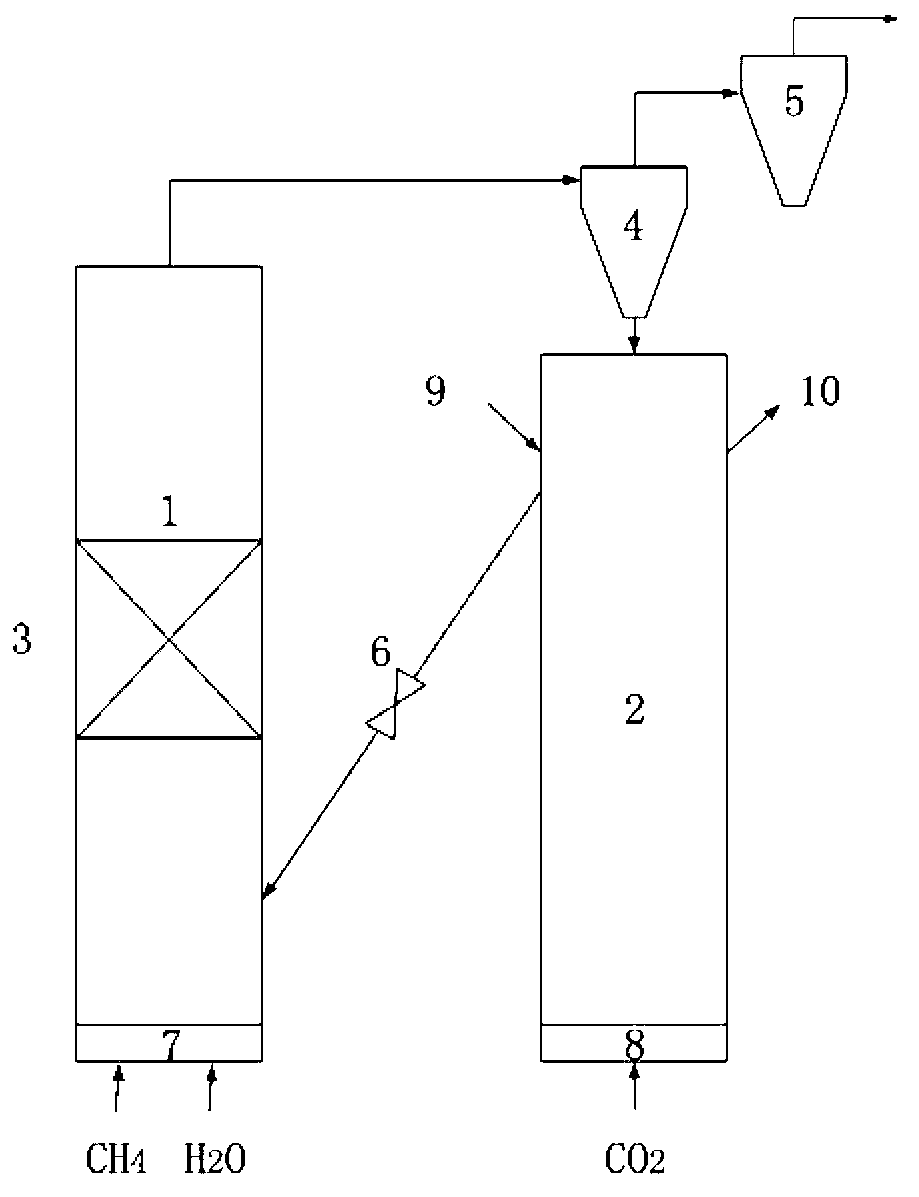

[0042] use as figure 1 In the device for hydrogen production by adsorption-enhanced steam reforming of methane, the fluidized-fixed composite bed reactor 1 adopts a riser reactor, and the dosage and specifications of the adsorbent and catalyst are as follows:

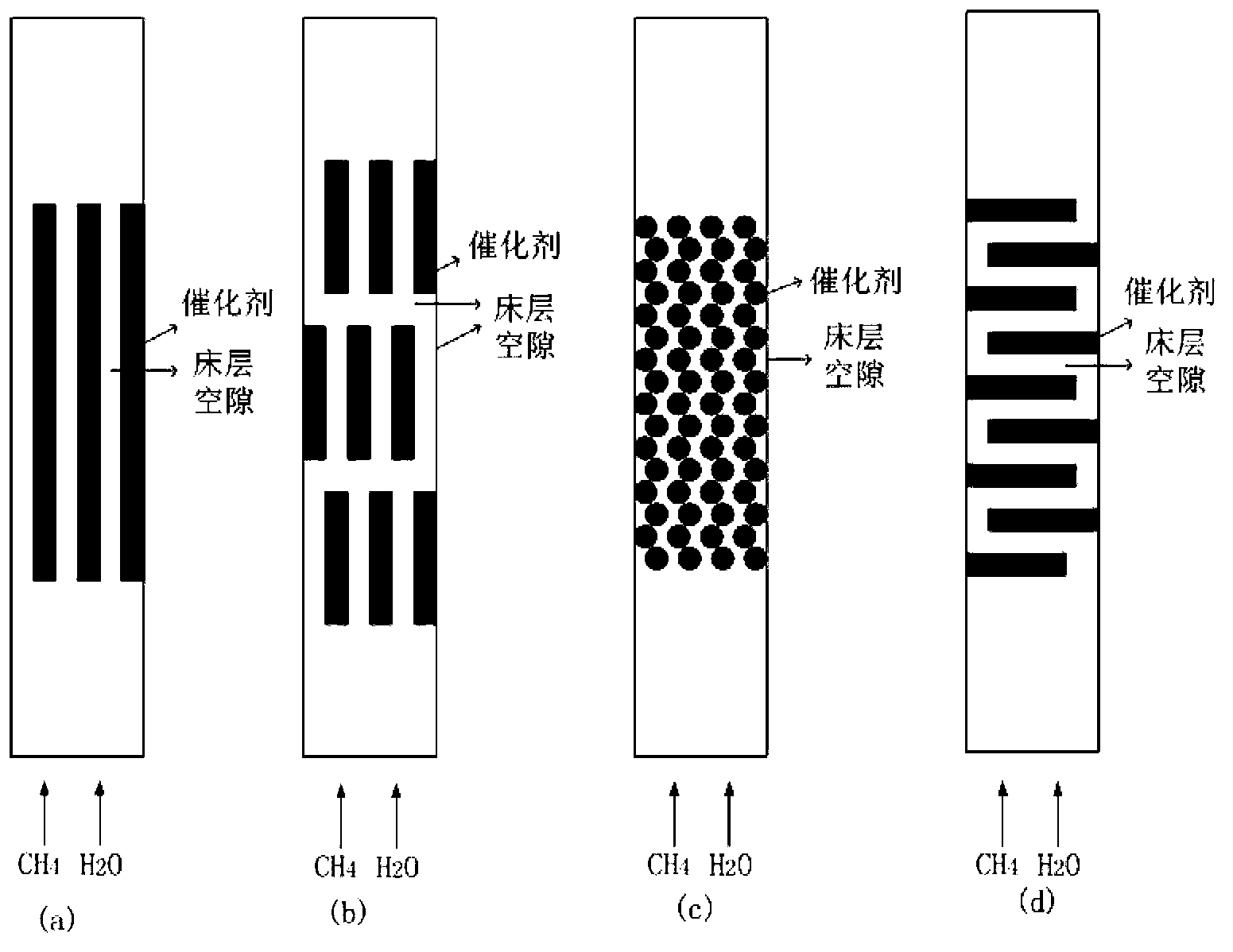

[0043] Nano-CaO-based CO 2 Adsorbent microspheres: the bulk density is 0.8g / cm 3 , the average particle size is 5 microns, and the amount of adsorbent is 3000g. riser reactor press figure 2 (a) is filled with a nickel-based catalyst, the catalyst is a Raschig ring with a diameter of 10mm and a length of 6mm, and a bulk density of 1.5g / cm 3 , catalyst consumption 1500g, bed porosity 0.4.

[0044] The operation steps are as follows:

[0045] (1) Pass the preheated mixture of water vapor and methane into the riser reactor 1, drive the adsorbent on the first gas distributor 7, and contact the catalyst 3 filled in the middle of the riser reactor. Adsorption enhanced reforming reaction; wherein the molar ratio of water...

Embodiment 2

[0051] use as figure 1 The shown adsorption enhanced methane steam reforming hydrogen production reaction device, the fluidized-fixed composite bed reactor 1 adopts a riser reactor, and the dosage and specifications of the adsorbent and catalyst are as follows:

[0052] Nano-CaO-based CO 2 Adsorbent microspheres: bulk density 0.8g / cm 3 , the average particle size is 100 microns, and the amount of adsorbent is 3000g. Nickel-based catalyst packed in riser reactor: according to figure 2 As shown in (b) filled with catalyst, the catalyst is a cylinder with a diameter of 10mm and a length of 6mm, with a solid density of 2g / cm 3 , catalyst consumption 1500g, bed porosity 0.7.

[0053] The specific operation steps are the same as in Example 1, wherein the mol ratio of water vapor and methane is 2:1, and the methane flow rate is 12L / min, the gas velocity of the riser reactor is 0.6m / s, and the temperature of the riser reactor is 650 °C, the regeneration temperature is 800°C, the...

Embodiment 3

[0056] use as figure 1 The shown adsorption enhanced methane steam reforming hydrogen production reaction device, the fluidized-fixed composite bed reactor 1 adopts a fluidized bed reactor, and the dosage and specifications of the adsorbent and catalyst are as follows:

[0057] Nano-CaO-based CO 2 Adsorbent microspheres, bulk density 0.8g / cm 3 , the average particle size is 20 microns, and the amount of adsorbent is 3000g. Nickel-based catalyst packed in fluidized bed reactor: according to figure 2 (c) shown in the filling, the shape is a seven-hole sphere, the particle size is 16mm, and the solid density is 2g / cm 3 , catalyst consumption 1500g, bed porosity 0.5.

[0058] The specific operation steps are the same as in Example 1, wherein the mol ratio of water vapor and methane is 6:1, and the methane flow rate is 15L / min, the fluidized bed reactor gas velocity is 3m / s, and the fluidized bed reactor The temperature is 600°C, the regeneration temperature is 800°C, the reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com