Three-chamber electrodialysis hydrogen production fermentation reactor and hydrogen production method

An electrodialysis and reactor technology, which is applied in the field of fermentation reactors, can solve problems such as high energy consumption, and achieve the effects of increasing hydrogen production, realizing separation and recovery of by-products, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

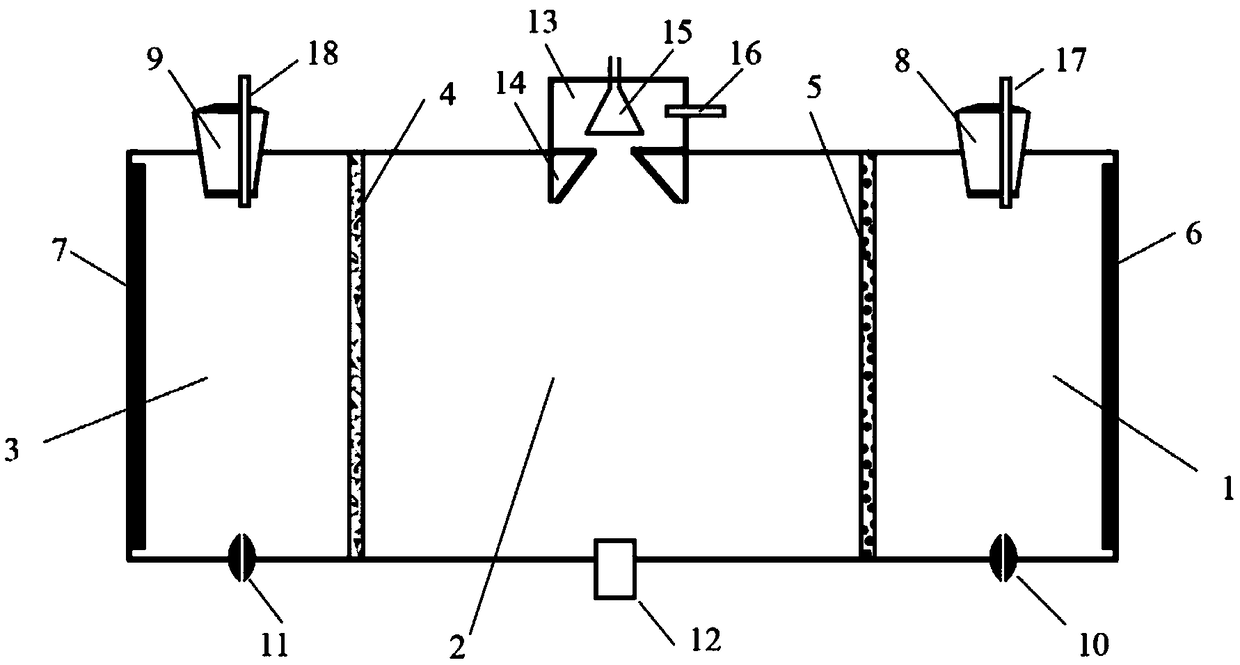

[0024] Embodiment 1: The method for producing hydrogen using the described three-chamber electrodialysis hydrogen production fermentation reactor comprises the following steps:

[0025] A. Make a three-chamber electrodialysis hydrogen production fermentation reactor. The reactor parameters are: the length, width and height of the anode chamber 3 and the cathode chamber 1 are 3cm, 4cm, and 5cm, that is, the volume is 60mL; The length, width and height are 6cm, 4cm, and 5cm, that is, the volume is 120mL; the dimensions of the cation exchange membrane 5 and the anion exchange membrane 4 are both 4cm×5cm, that is, 20cm 2 , The length, width and thickness of the graphite electrodes 6 and 7 are 5 cm, 4 cm and 0.2 cm.

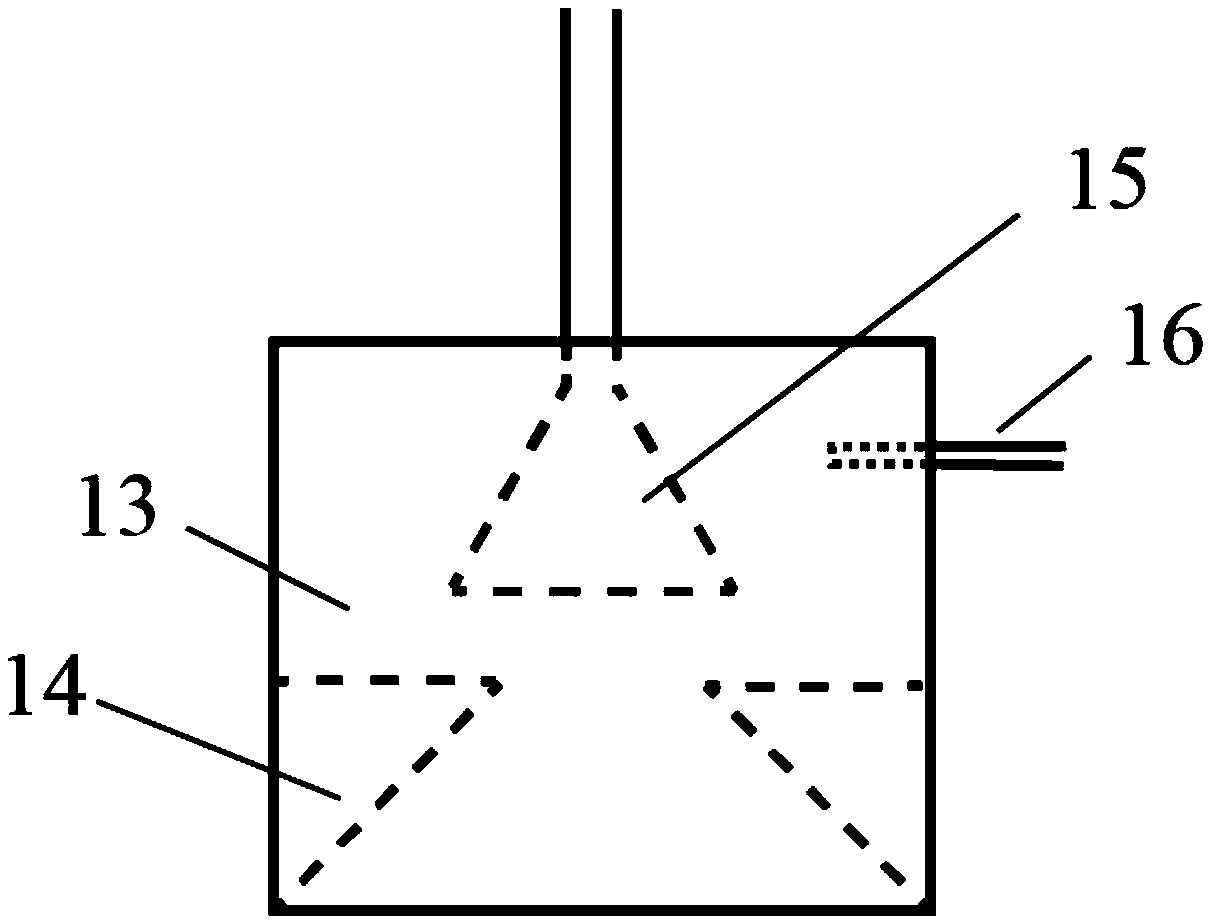

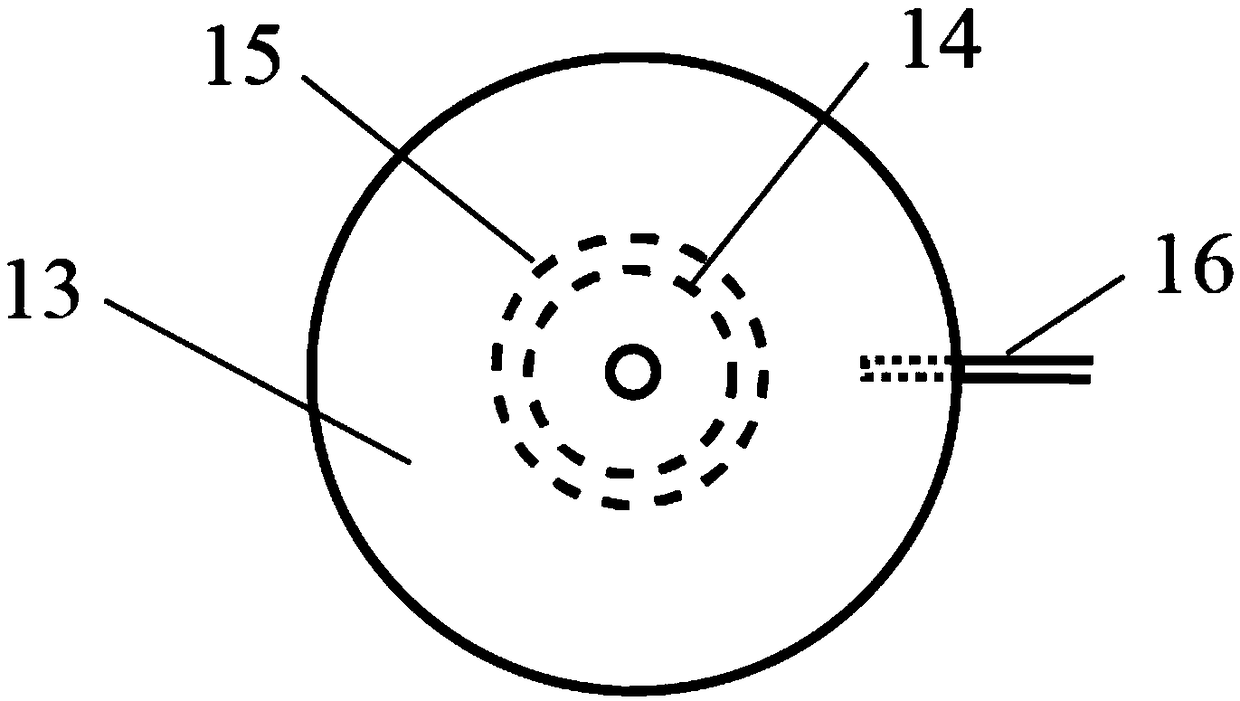

[0026] B. Connect the gas collection chamber 15 in the fermentation chamber 2 with an external gas collection bag to collect the gas generated during the dark fermentation process.

[0027] C. Inoculate the activated sludge with a volume ratio of 10% in the fermentat...

Embodiment 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step C, inoculate activated sludge with a volume ratio of 10% and add substrate glucose and ammonia nitrogen to simulate high ammonia nitrogen organic wastewater, so that the concentration of glucose in the fermentation chamber is 10g / L, NH 4 + The concentration is 3000mg / L, and other operating and experimental parameters are the same.

[0032] see Figure 4A to Figure 4E , a in the figure is a traditional fermentation reactor, and b is a three-chamber electrodialysis hydrogen production fermentation reactor of the present invention.

[0033] As can be seen from the figure, compared with the traditional fermentation reactor under the same conditions, the hydrogen production in this embodiment was increased by 48%, and the concentration of volatile fatty acids in the fermentation chamber was reduced by 20%. 4 + The concentration was reduced by 59%, the concentration of volatile fatty aci...

Embodiment 3

[0035] Embodiment 3: Utilize the simulated fermentation liquid acetic acid to carry out the removal experiment.

[0036] The difference between this embodiment and Embodiment 1 is that in step C, acetic acid: 20 mmol / L is added to the fermentation chamber 2.

[0037] see Figure 5A to Figure 5B , as can be seen from the figure, the removal efficiency of acetic acid reached 95% after 96h. The enrichment concentration of acetic acid in the anode chamber can reach 25mmol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com