Patents

Literature

87results about How to "Efficient hydrogen production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

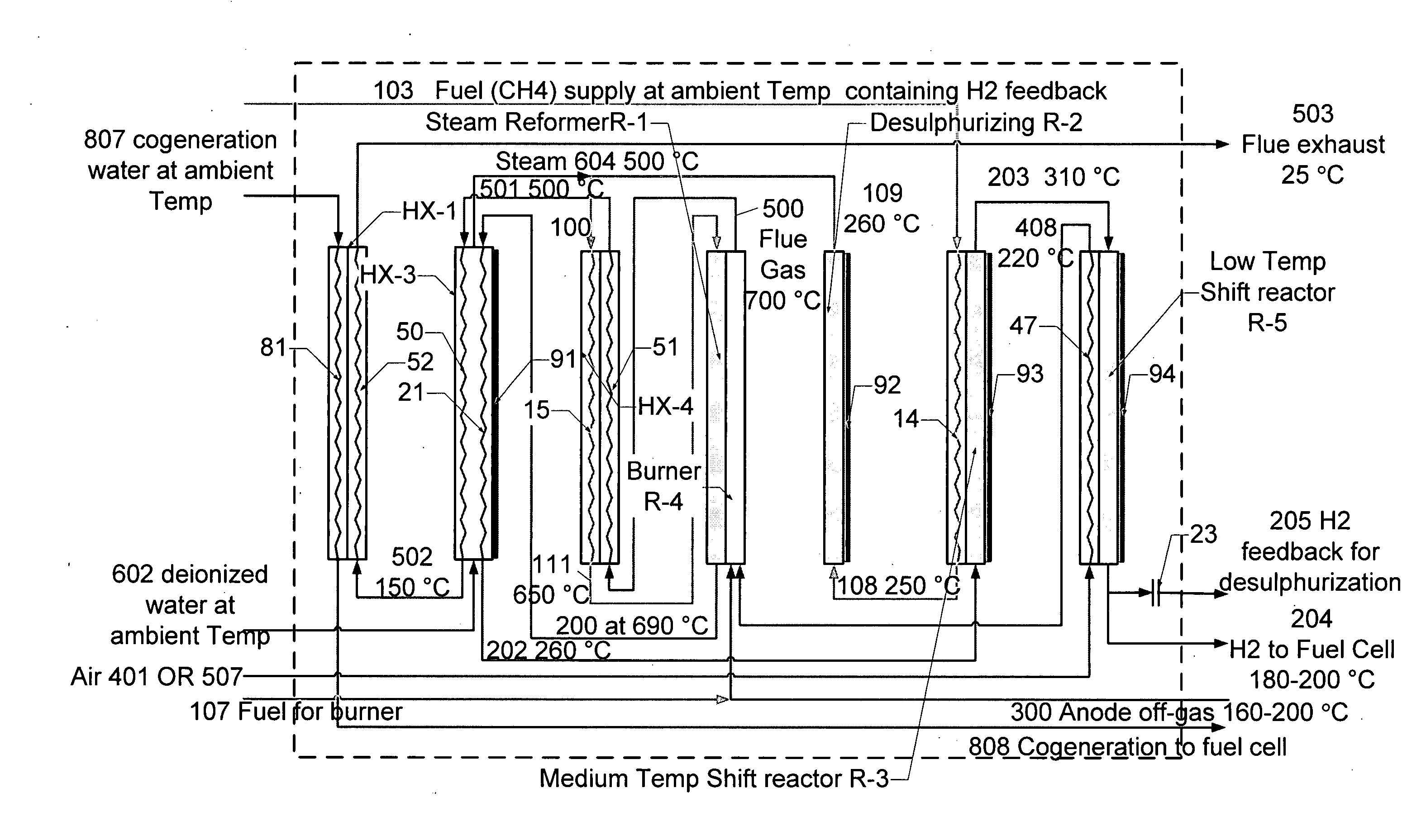

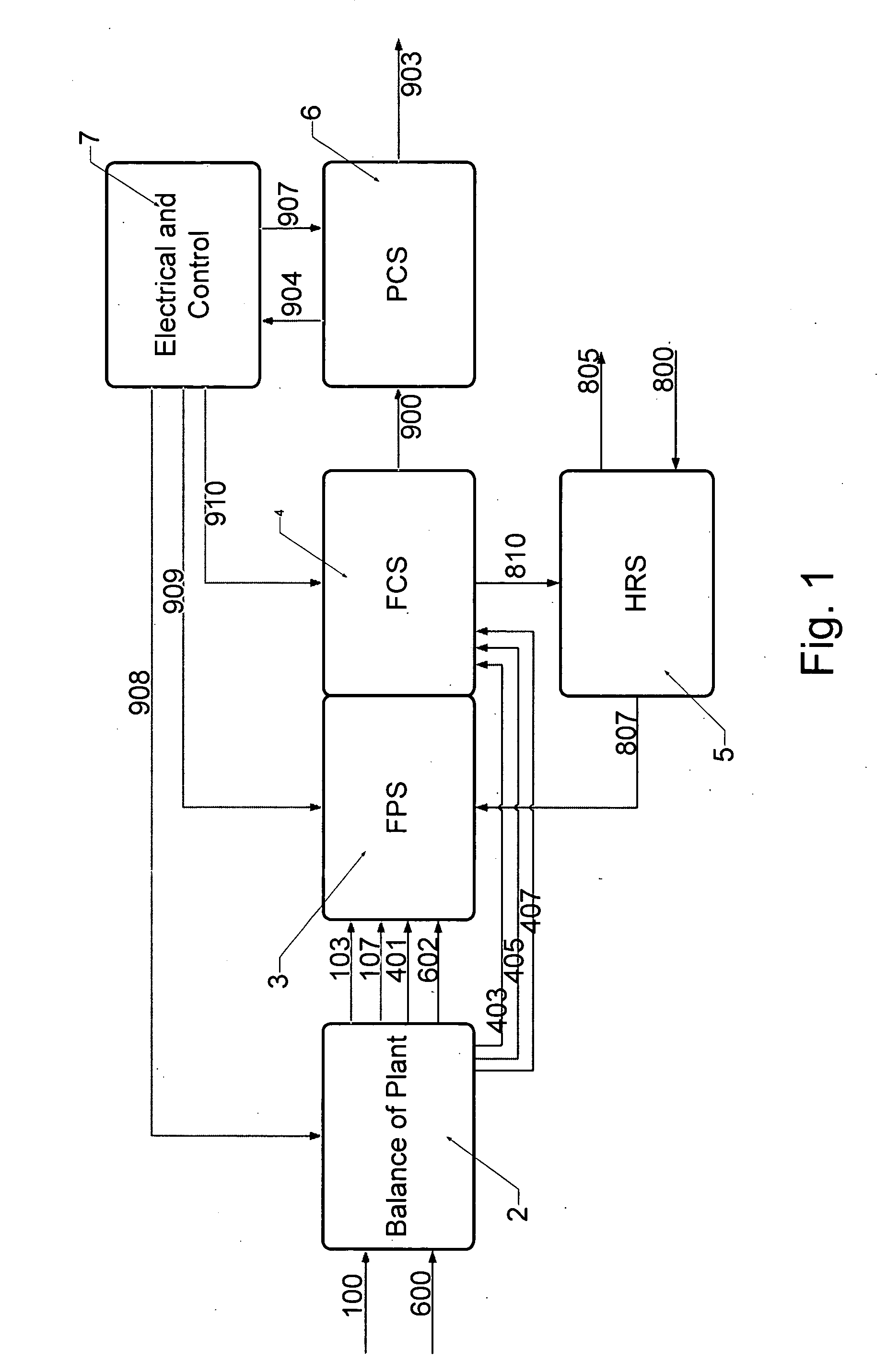

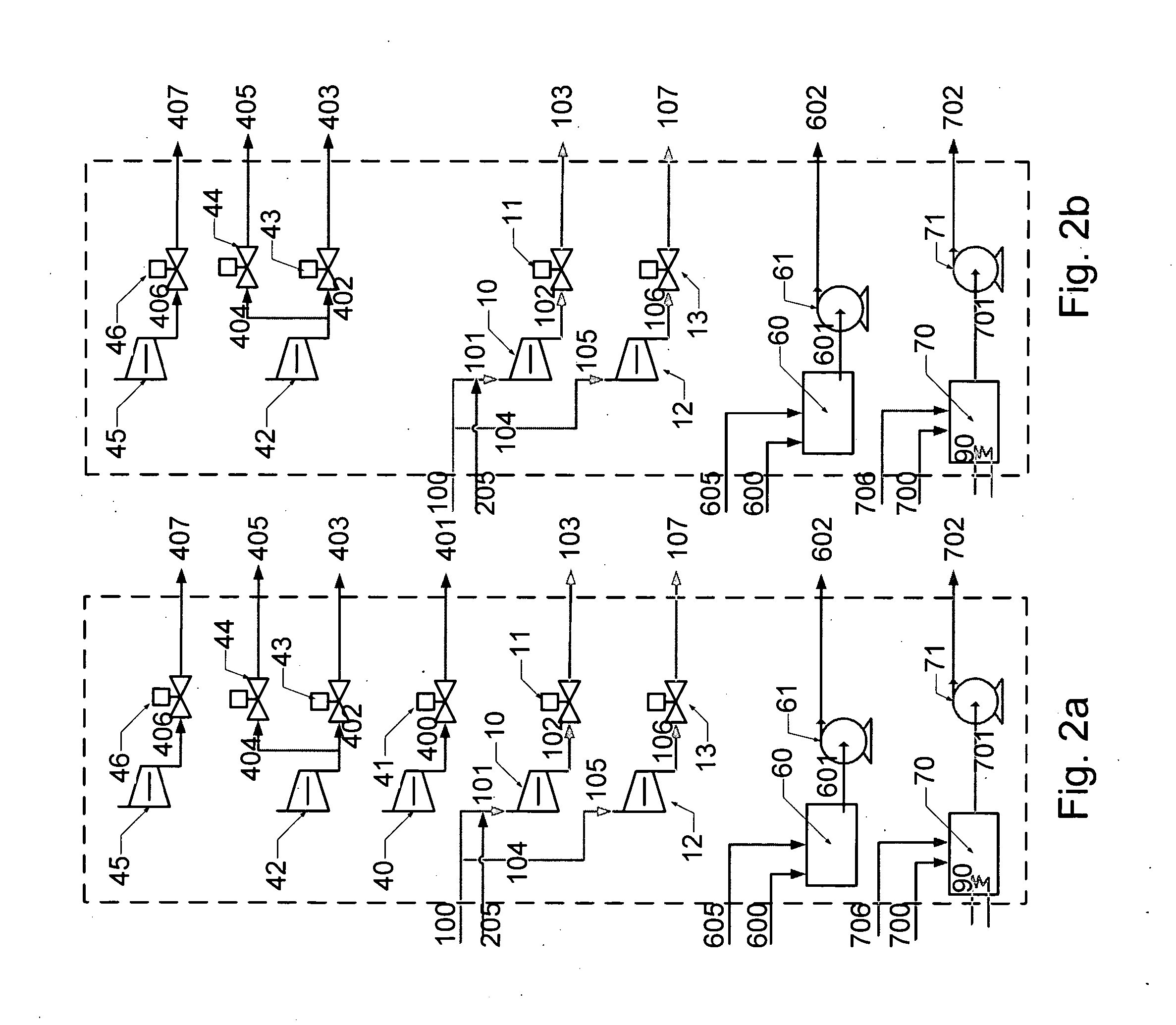

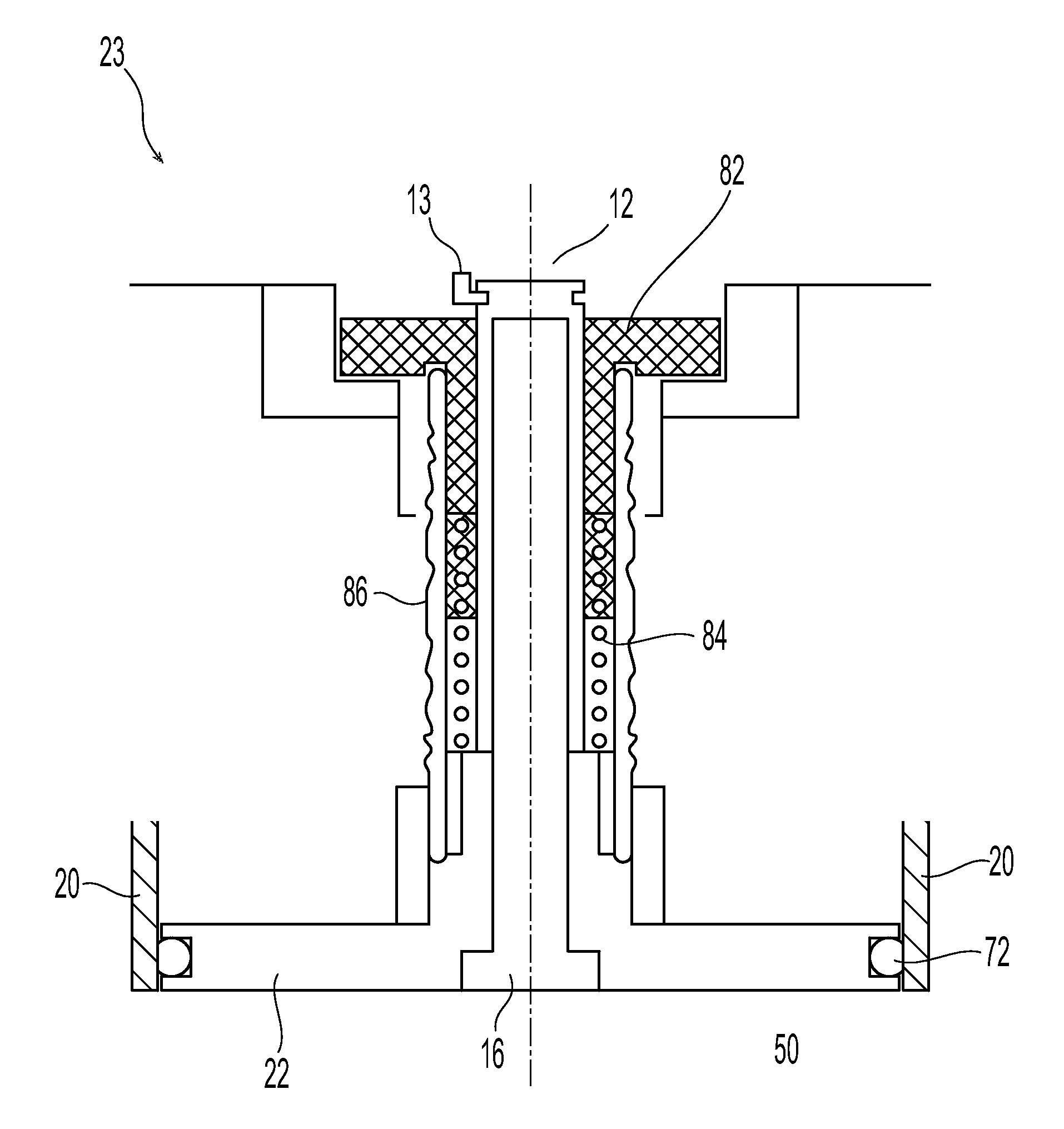

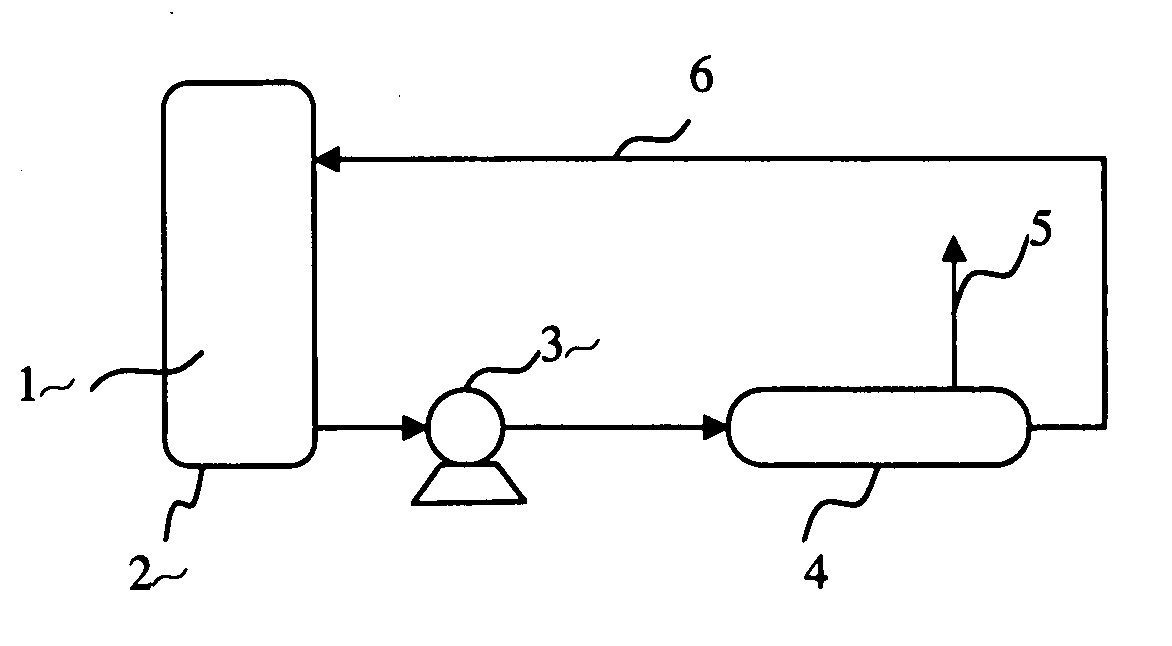

Combined heat and power system

InactiveUS20060199051A1Improve robustnessImprove reliabilityFuel cell heat exchangeFuel cells groupingHydrocotyle bowlesioidesCogeneration

There is described a combined heat and power, or cogeneration, system combining a fuel cell for generating electrical power with a thermal power source, the system comprising: a fuel processor for converting a hydrocarbon fuel into hydrogen in an output stream, the hydrogen rich output stream containing a low content of carbon monoxide; a high temperature hydrogen fuel cell system tolerant to low content of carbon monoxide of up to 5% receiving the output stream and an oxidant fluid stream; and a heat exchange system having a first module associated with the fuel processor and a second module associated with the fuel cell system connected at least in part in series to provide a thermal output.

Owner:HYTEON

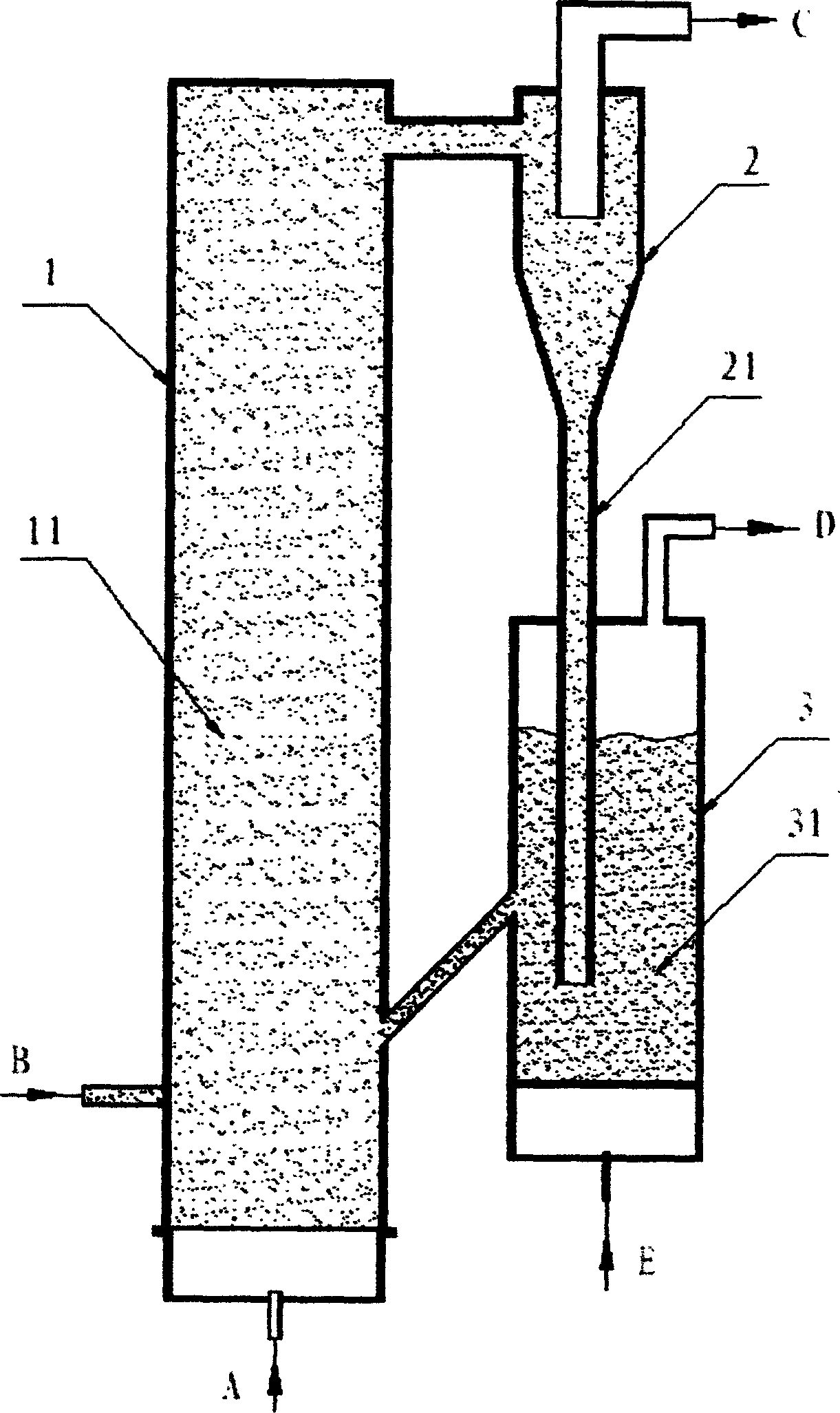

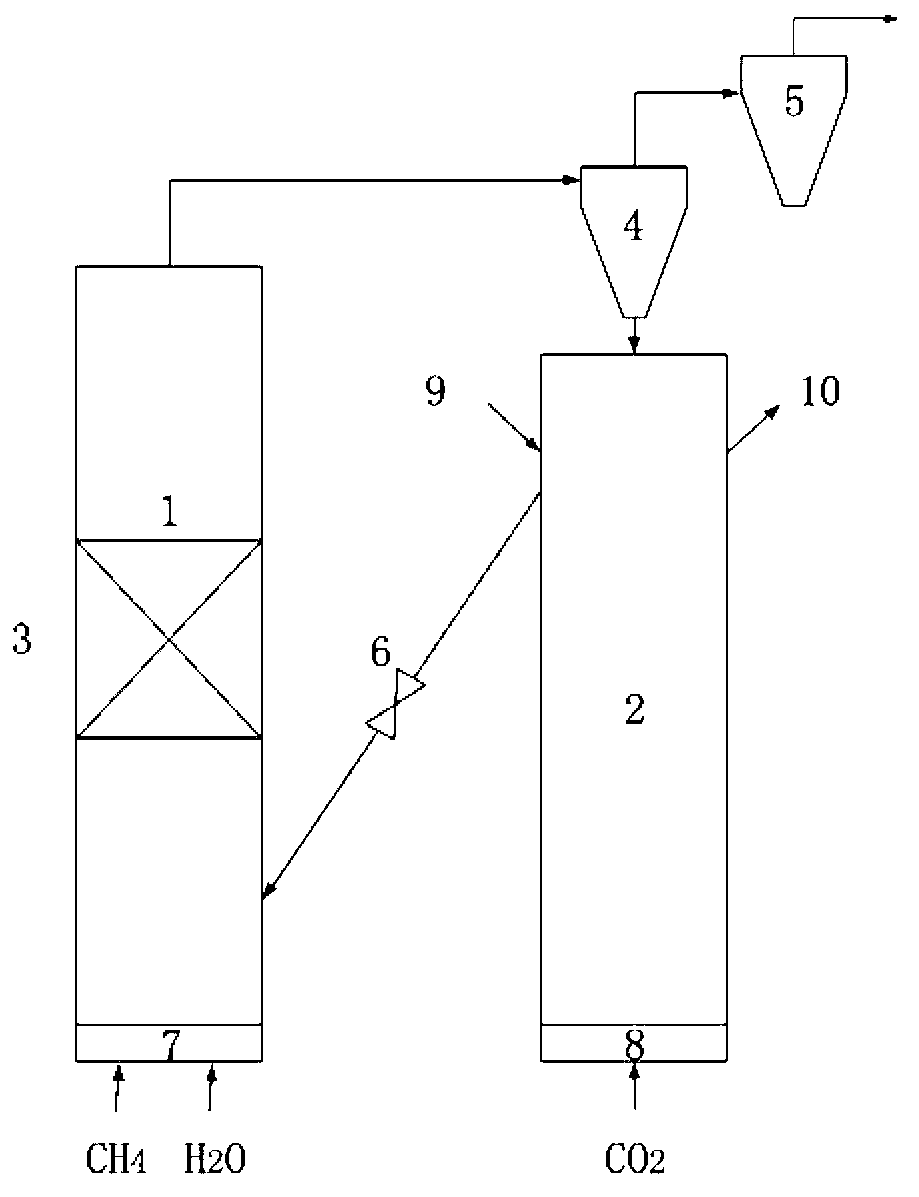

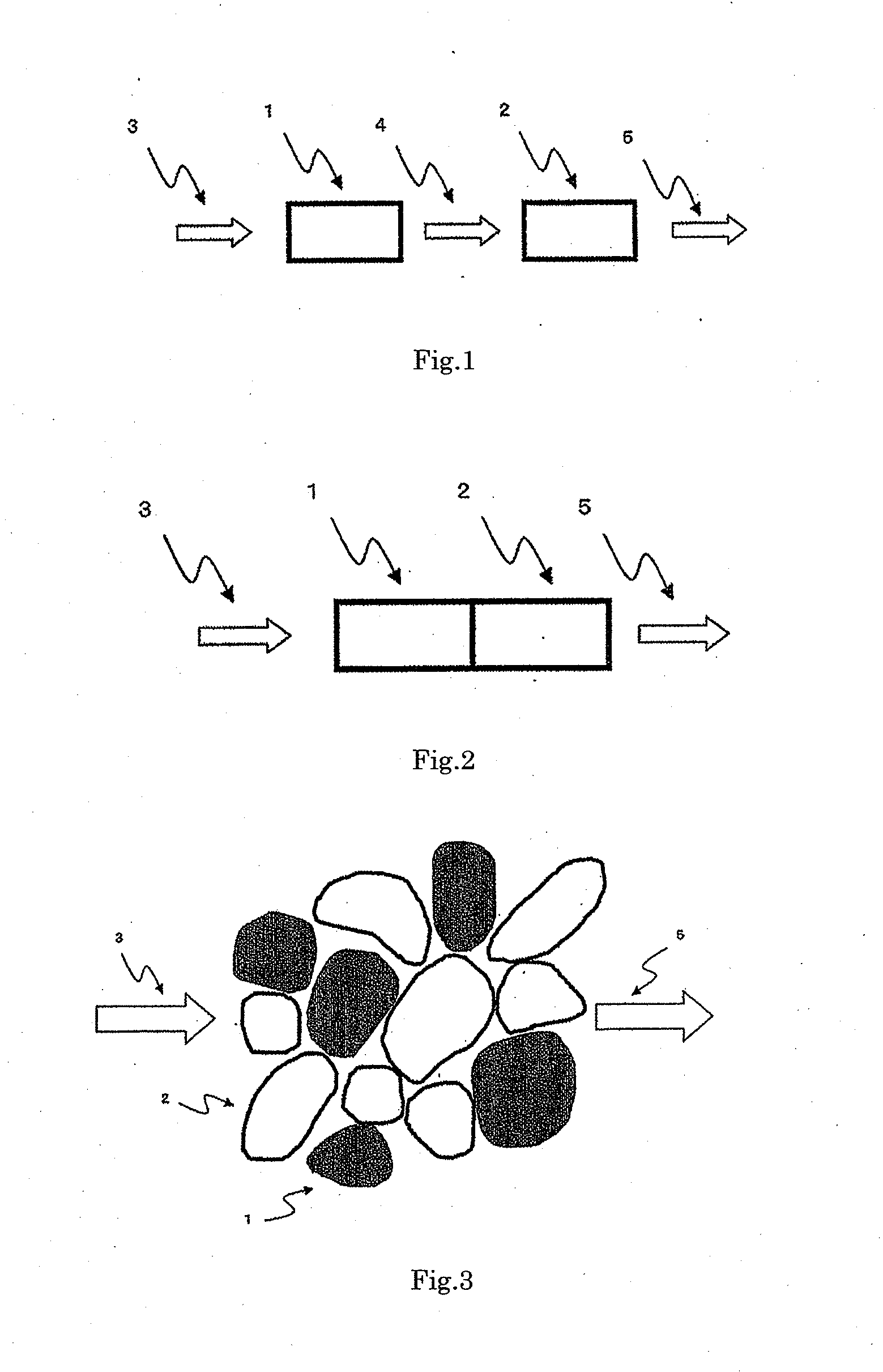

Biomass-gasifying hydrogen generating serial fluid bed apparatus and method

InactiveCN1608972AEfficient hydrogen productionSimple structureHydrogen productionGranular/pulverulent flues gasificationHydrogenDecomposition

The present invention is one method of generating hydrogen via catalytic thermolysis and gasification of biomass. The hydrogen generating apparatus consists of circulating fluidizing bed, cyclonic separator and bubbling fluidizing bed connected serially. The hydrogen generating process the fluidization of biomass with steam in circulating fluidizing bed with catalyst CaO / MgO grains; the catalytic thermolysis and gasification of biomass to produce hydrogen; the fixation reaction of CO2 in gas product with catalyst CaO / MgO grains to form CaCO3 / MgCO3; the separation of CaCO3 / MgCO3 grains and coke grains in cyclonic separator; burning of coke grains to promote the decomposition of CaCO3 / MgCO3 to release CO2 and high temperature CaO / MgO grains; and returning the high temperature CaO / MgO grains to the circulating fluidizing bed as catalyst and heat source.

Owner:SOUTHEAST UNIV

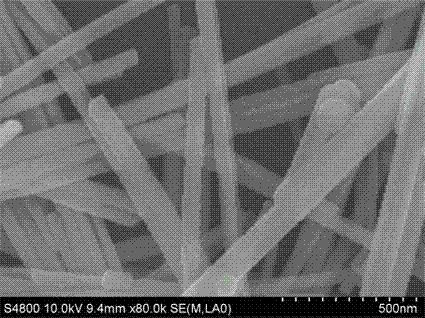

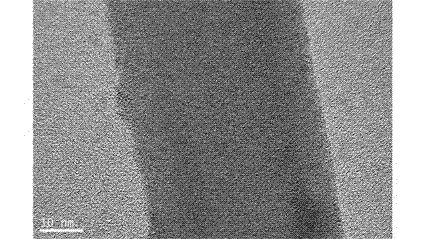

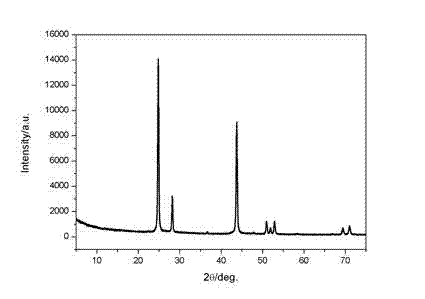

One-dimensional nanometer photocatalyst as well as preparation method and application thereof

InactiveCN103566953AImprove hydrogen production efficiencyEasy to preparePhysical/chemical process catalystsHydrogen productionEthylenediamineHydrogen production

The invention provides a one-dimensional nanometer photocatalyst as well as a preparation method and application thereof. The photocatalyst adopts a one-dimensional CdS nanometer rod structure modified by atom layer thickness MoS2; the formula is CdS: MoS2. The simple polylol pressurizing technology is adopted to realize the synthesis of the CdS: MoS2 composite nanometer photocatalyst; firstly, CdS nanometer rods with uniform size and regular morphology are synthesized in an ethanediamine system; then the polylol pressurizing reduction technology is adopted to decompose ATTM in situ on CdS to obtain the one-dimensional CdS: MoS2 composite nanometer photocatalyst. The catalyst has the solar photocatalytic water hydrogen preparation performance, can largely improve the efficiency of hydrogen production by using sunlight, and is suitable for the field of new energy development.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

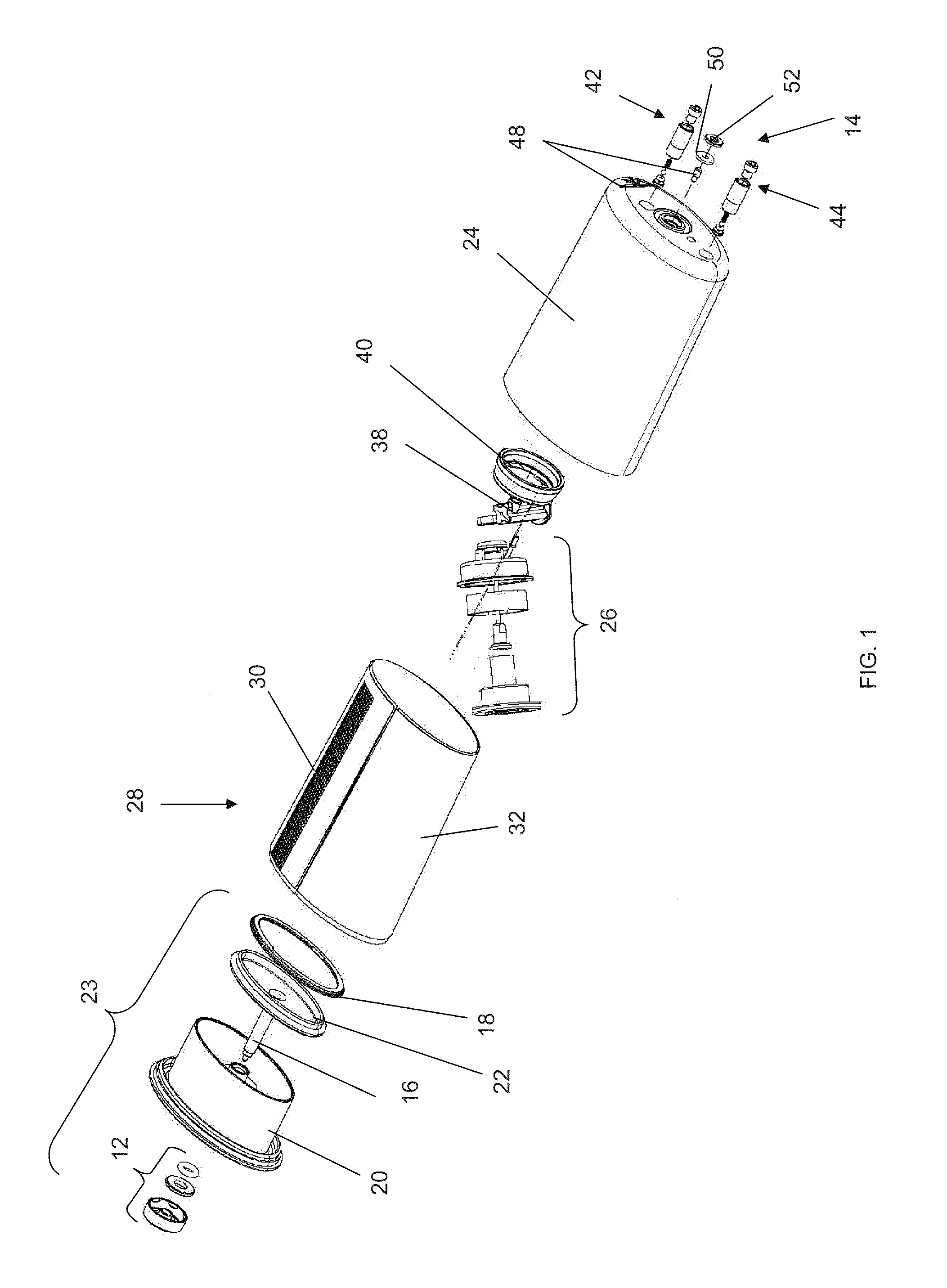

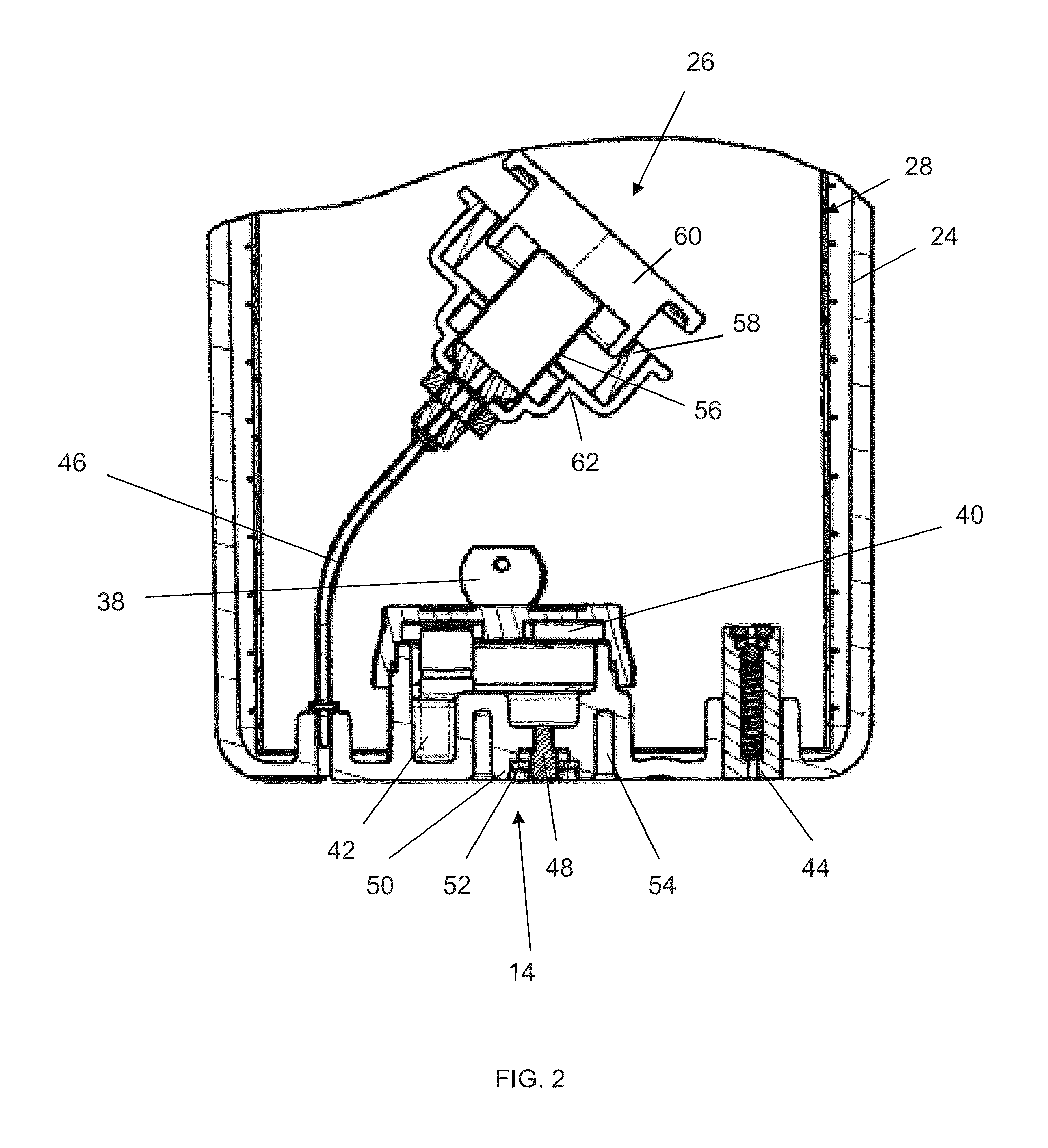

Gas Generator with Starter Mechanism and Catalyst Shield

ActiveUS20110099904A1Long shelf lifeEfficiently produce hydrogenMuffle furnacesRetortsProcess engineeringGas generator

The present application is directed to gas generators comprising a fuel mixture and a catalyst. The catalyst is contained in a self-regulated reactor or buoy, and selectively opens and closes to produce a gas in accordance with the demand for gas. This fuel mixture is generally a solution formed by dissolving a solid fuel component in a liquid fuel component. The mixing preferably occurs before the first use, and more preferably occurs immediately prior to the first use. The inventive gas generators preferably further comprises a starting mechanism that isolates the solid fuel from the liquid fuel or vice versa before the first use. In one embodiment, the starting mechanism further comprises a catalyst shield mechanism that isolates the catalyst in the reactor or buoy from the liquid and / or the solid fuel prior to the first use.

Owner:INTELLIGENT ENERGY LTD +1

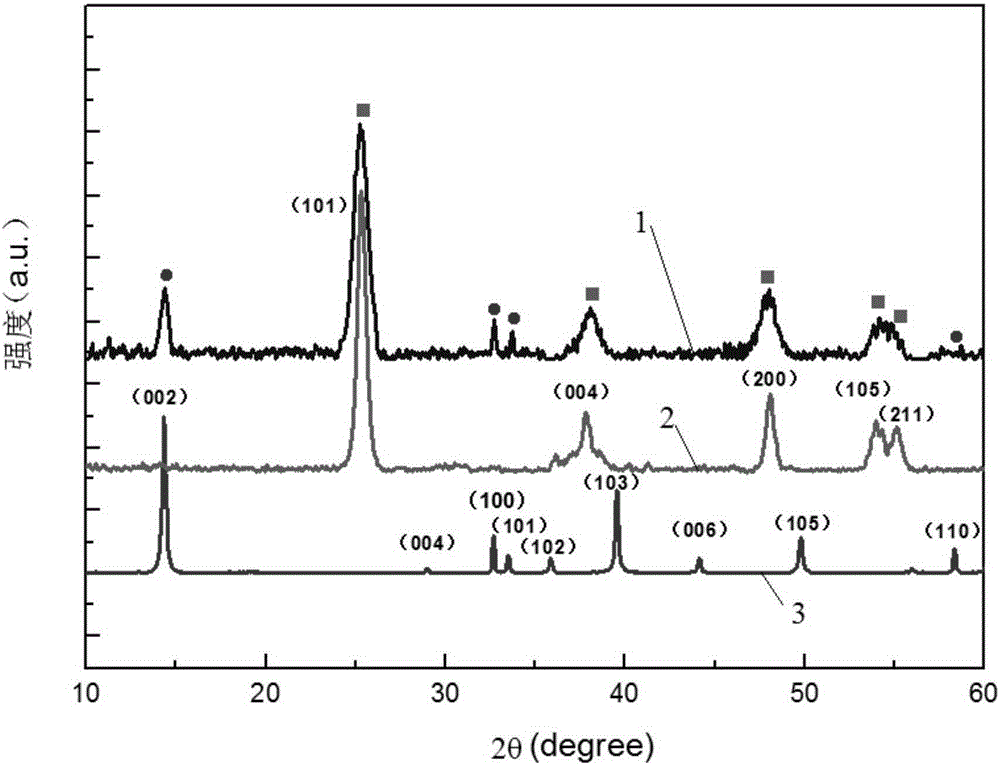

Preparation method of molybdenum disulfide-black titanium dioxide composite visible-light-driven photocatalyst for hydrogen production

InactiveCN105195133AUninterrupted outputEfficient hydrogen productionMetal/metal-oxides/metal-hydroxide catalystsLight drivenMolybdenum disulfide

The invention provides a preparation method of a molybdenum disulfide-black titanium dioxide composite visible-light-driven photocatalyst for hydrogen production, and relates to a preparation method of a visible-light-driven photocatalyst for hydrogen production. According to the preparation method, the technical problems that an existing molybdenum disulfide-titanium dioxide composite visible-light-driven photocatalyst is low in visible light utilization rate and hydrogen production efficiency are solved. The preparation method comprises the steps of 1 reagent mixing; 2 hydrothermal reaction performing; 3 thermal treating; 4 hydrogenating. The preparation method has the advantages that the prepared molybdenum disulfide-black titanium dioxide composite visible-light-driven photocatalyst for hydrogen production can efficiently produce hydrogen on the condition of visible light and can continuously produce the hydrogen under continuous six-hour radiation of the visible light and is not only high in hydrogen production efficiency but also good in stability. The preparation method is simple in preparation technology and experiment equipment, low in cost, high in benefit and capable of easily achieving commercialization.

Owner:HEILONGJIANG UNIV

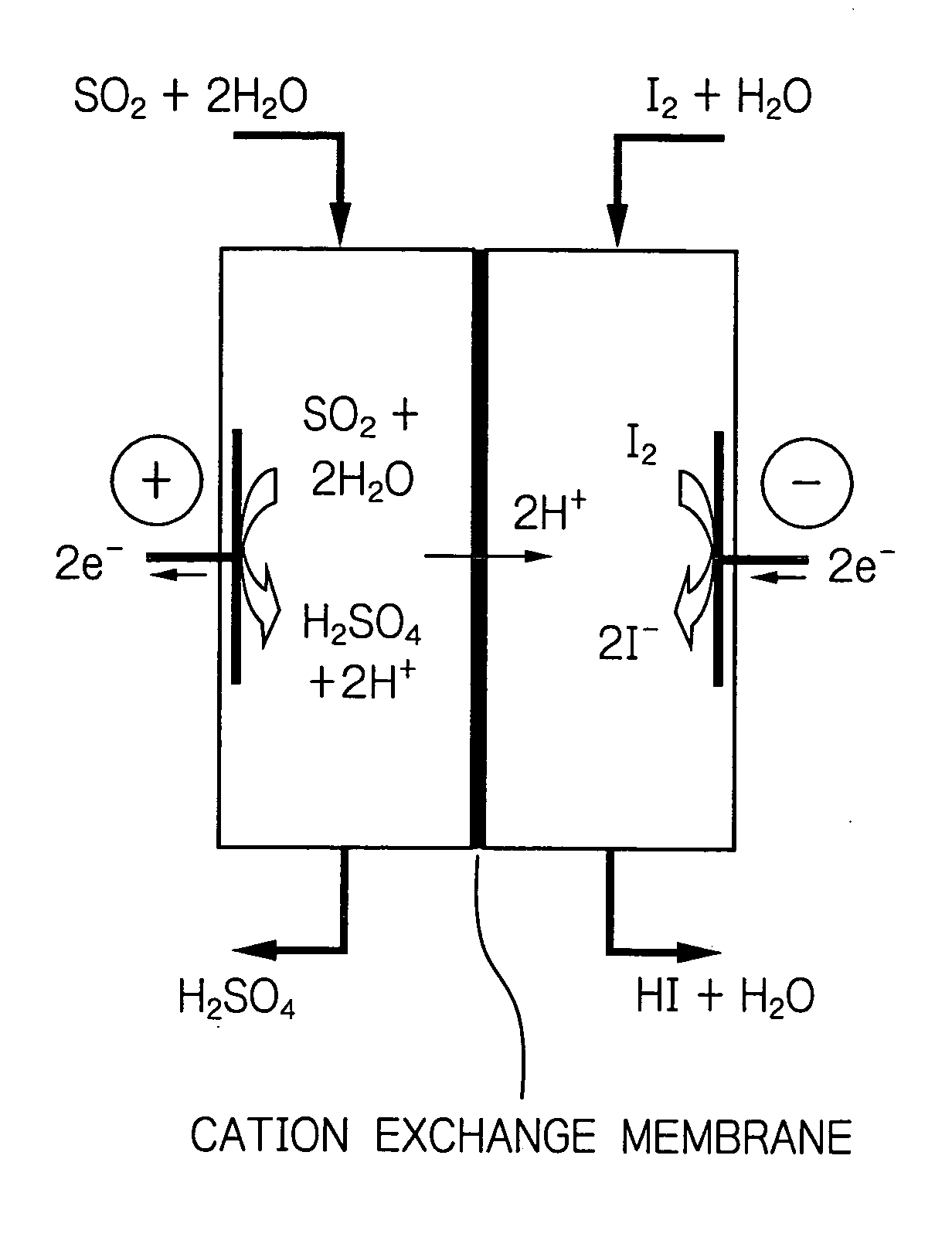

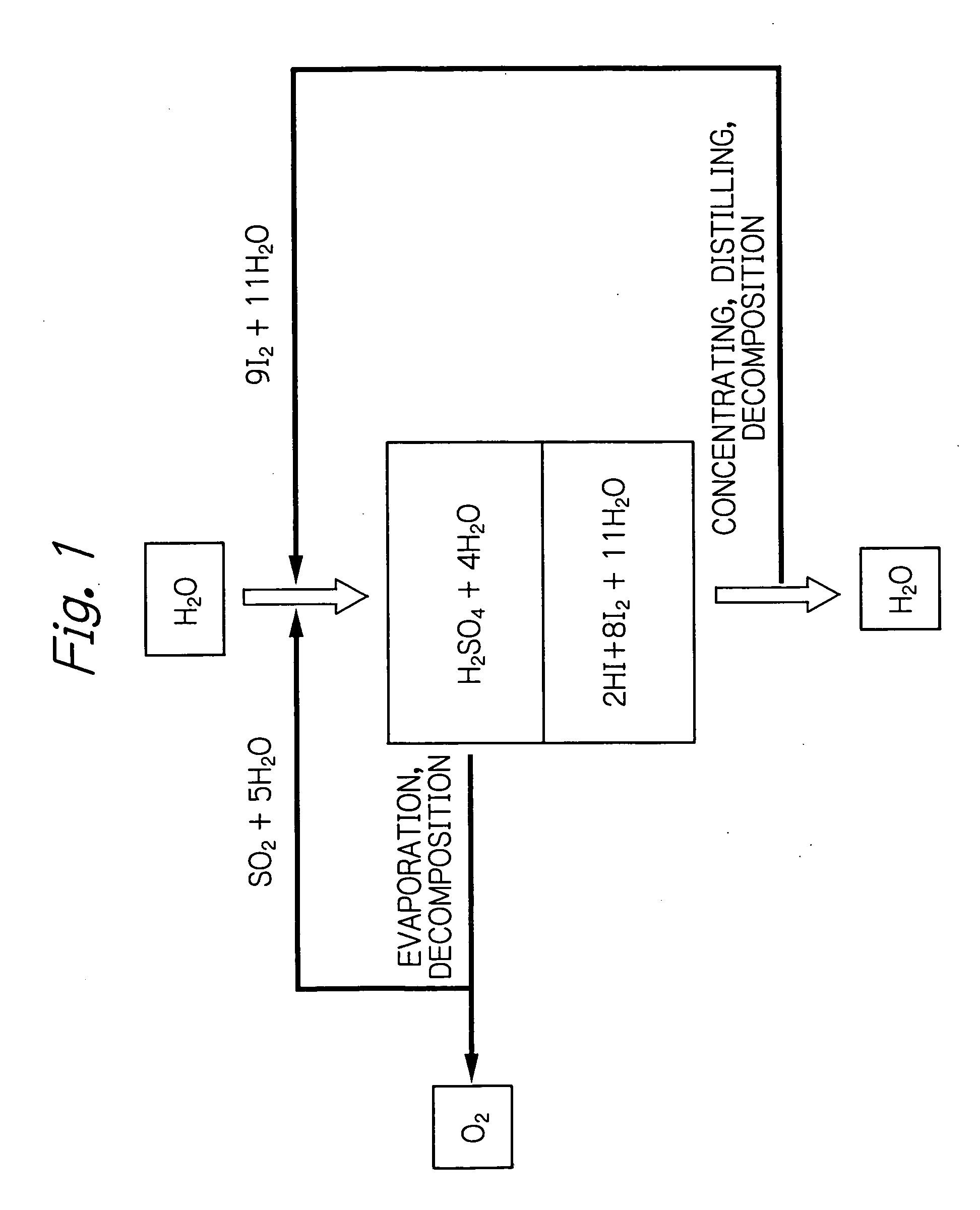

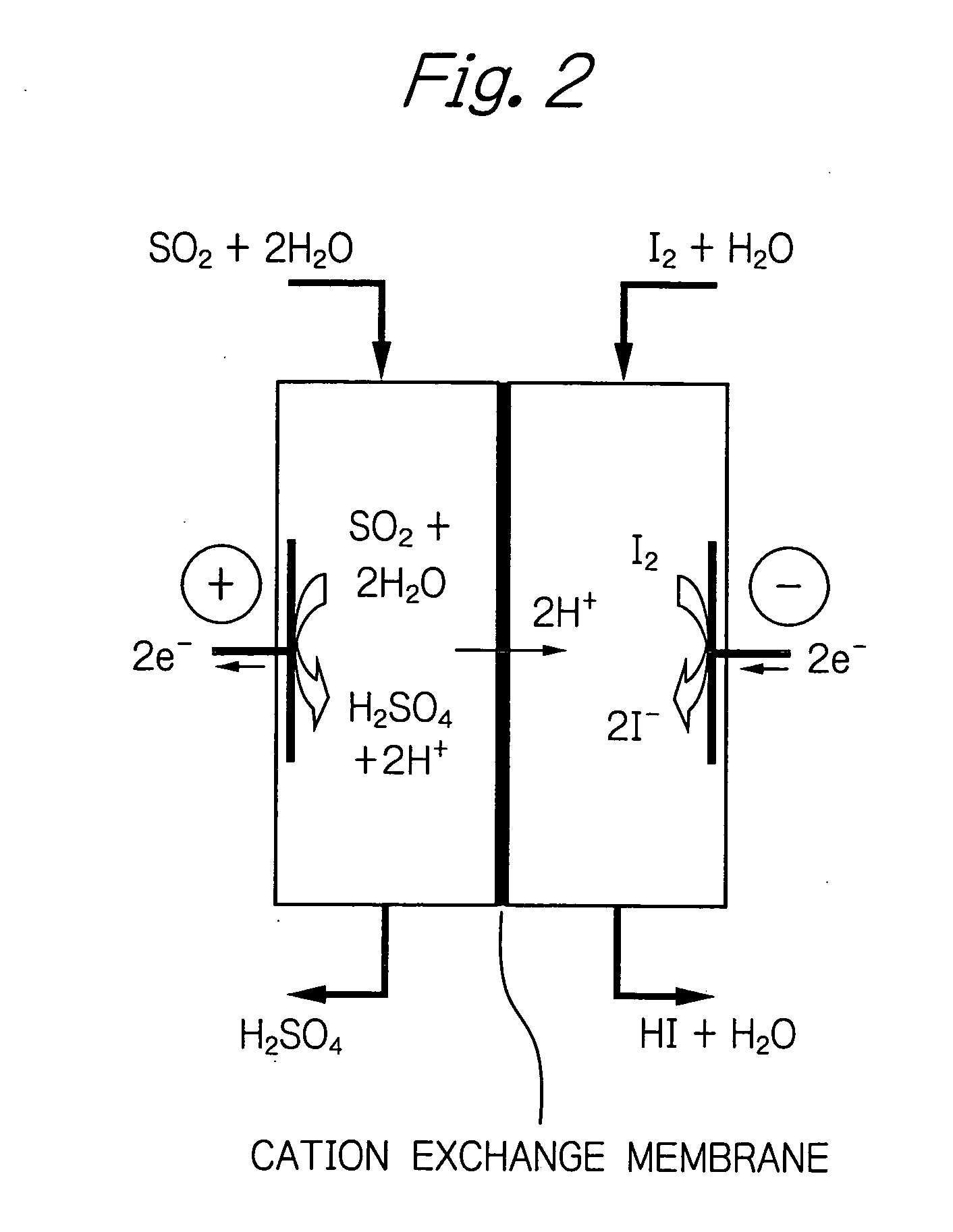

Process for efficient hydrogen production by thermochemical water splitting using iodine and sulfur dioxide

InactiveUS20050000825A1Reducing iodine and water inputEfficient production of hydrogenSemi-permeable membranesElectrolysis componentsChemistrySulfur dioxide

In the IS process, the reaction between sulfur and water is performed on the positive electrode side of a cation exchange membrane and the iodine-involving reaction is on the negative electrode side, so that the subsequent separating operation is eliminated to reduce the amounts of recycling iodine and water.

Owner:JAPAN ATOM ENERGY RES INST

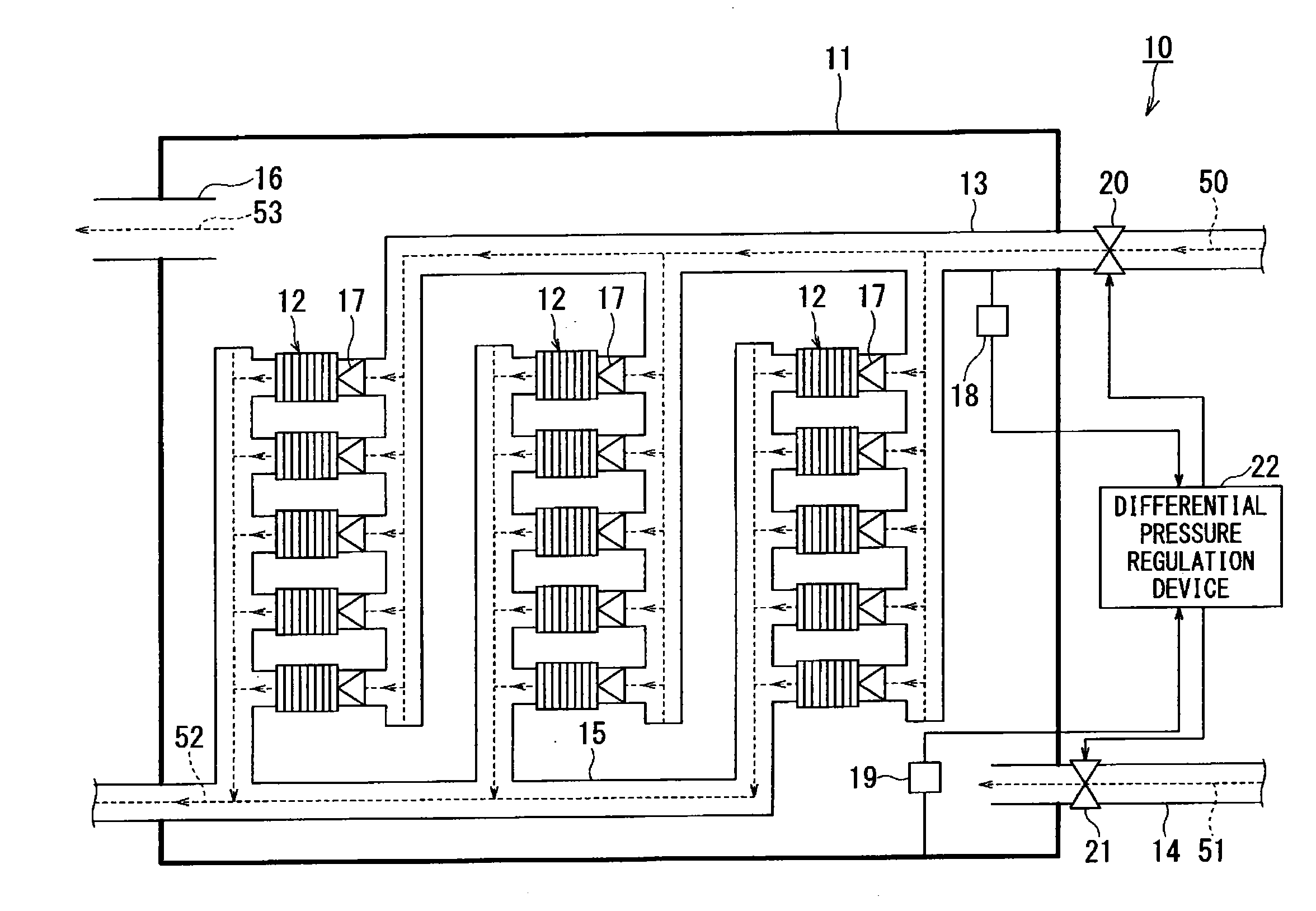

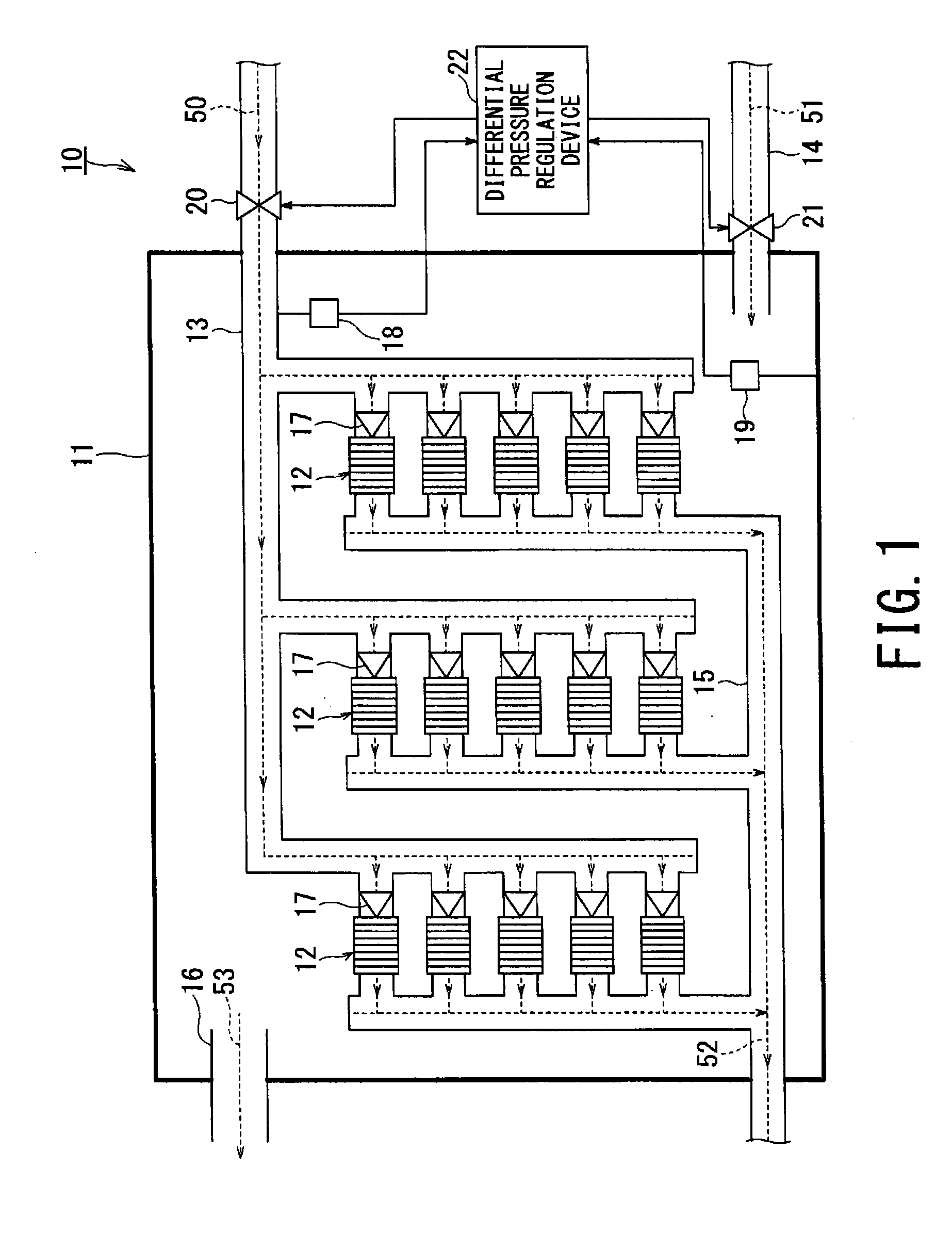

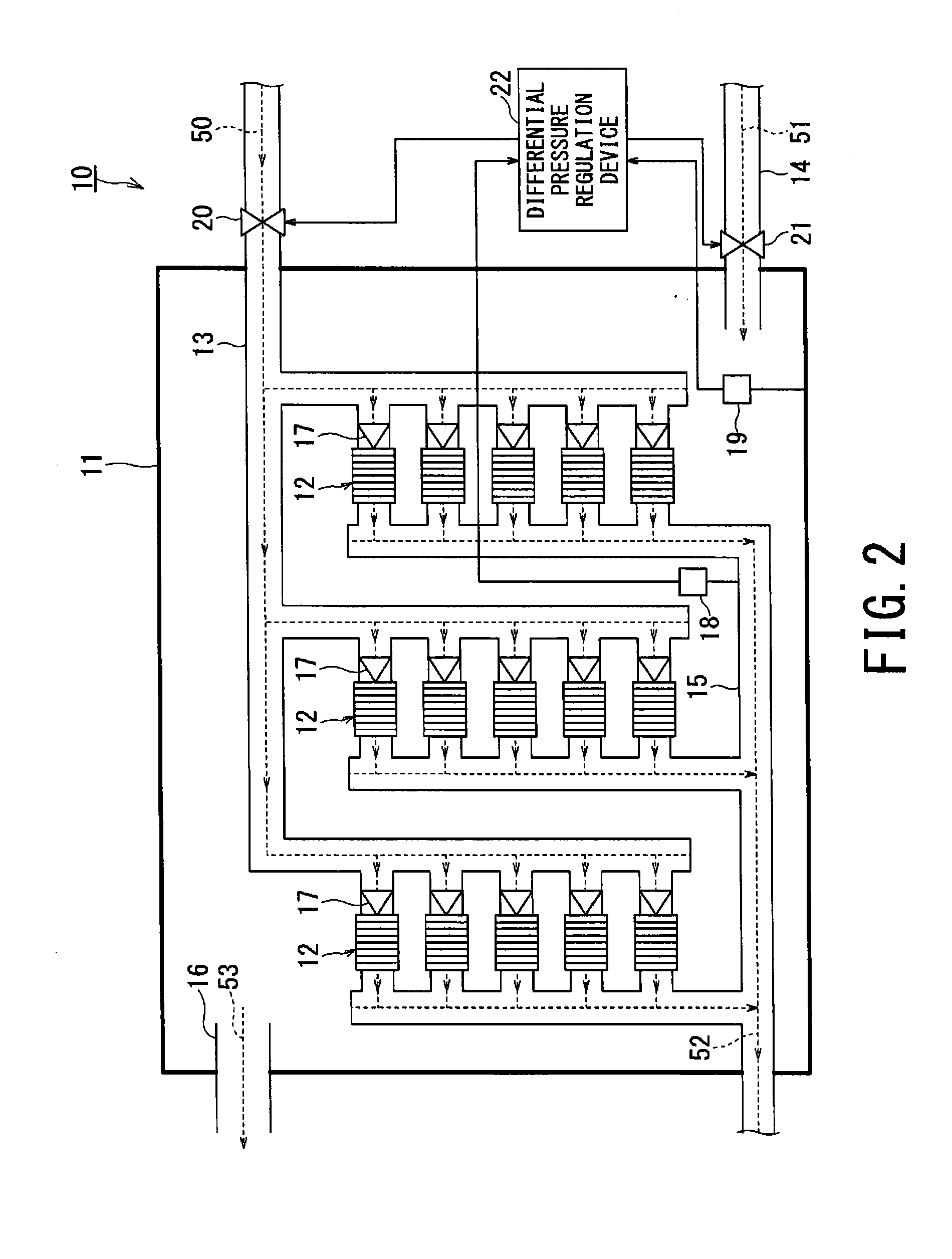

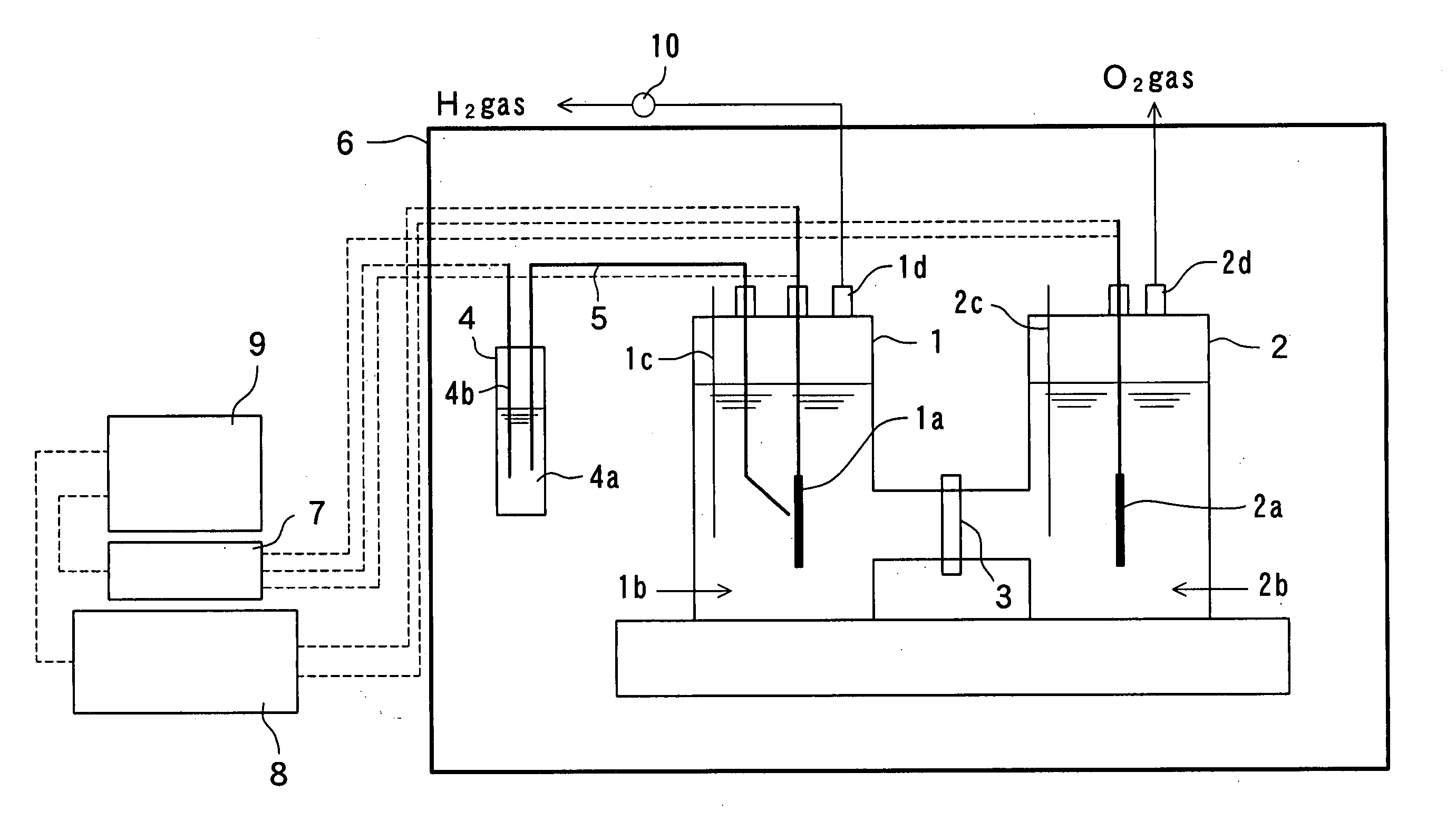

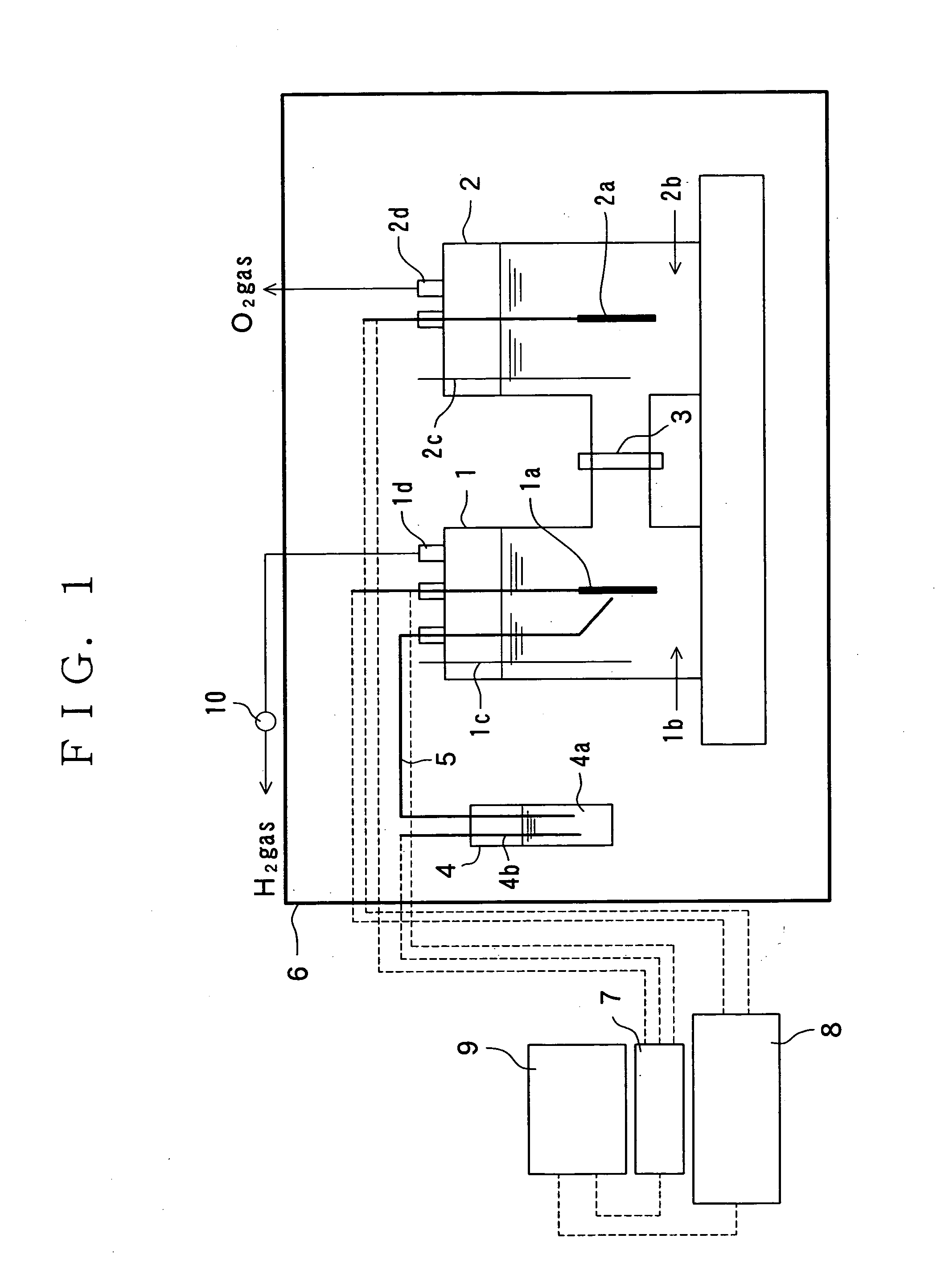

Hydrogen production system and method for producing hydrogen

ActiveUS20160060776A1Efficient hydrogen productionUniform flow rateCellsMachining electric circuitsElectrolysisEngineering

A hydrogen production system that achieves highly-efficient hydrogen production even when hydrogen is produced by using the plurality of cell stacks is provided.A hydrogen production system includes a plurality of cell stacks provided within a reaction containment, the cell stacks generating hydrogen by high temperature steam electrolysis by supplying steam to the plurality of cell stacks, a first flow path guiding the steam to each of the cell stacks, a second flow path causing a carrier gas containing air as a main component to flow into the reaction containment, and a flow regulation device provided at an inlet of the steam in each of the cell stacks, the flow regulation device regulating a flow rate of the steam caused to flow into each of the cell stacks to be uniform.

Owner:KK TOSHIBA

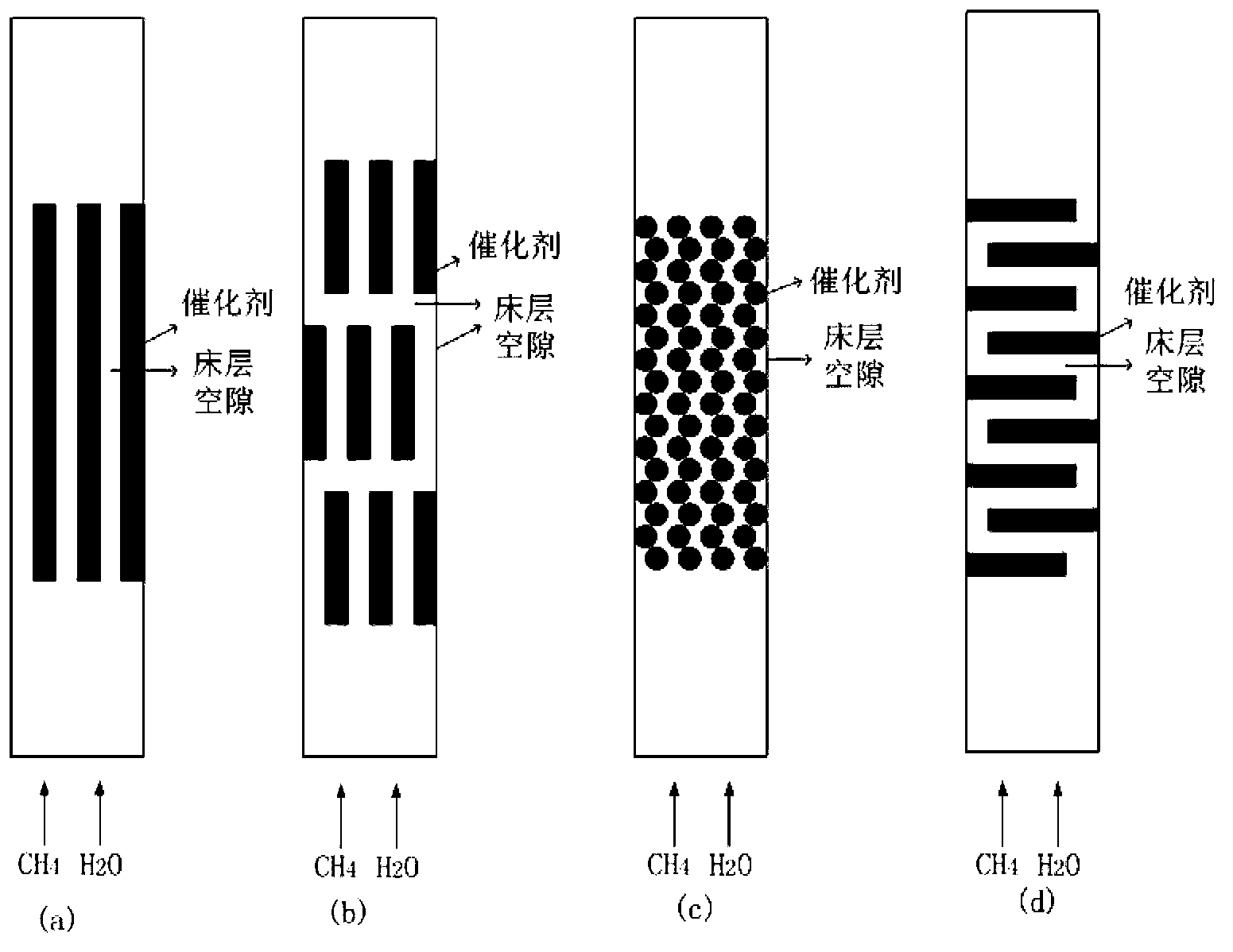

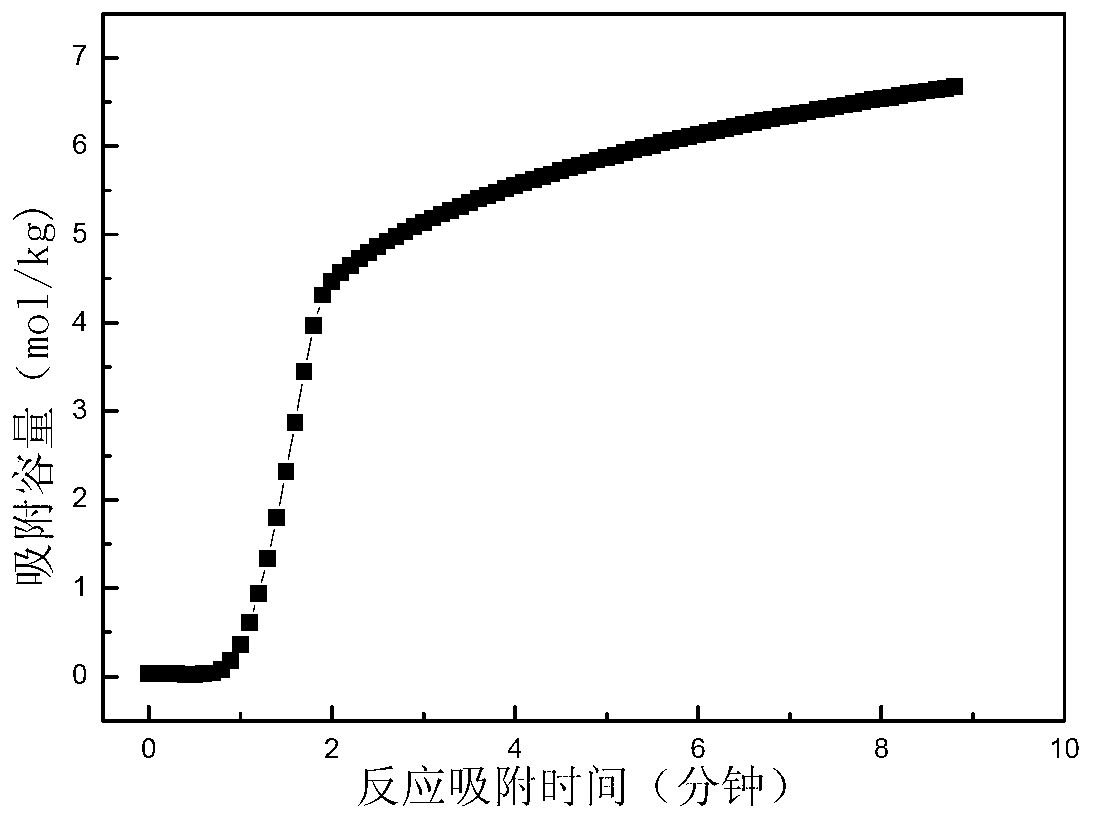

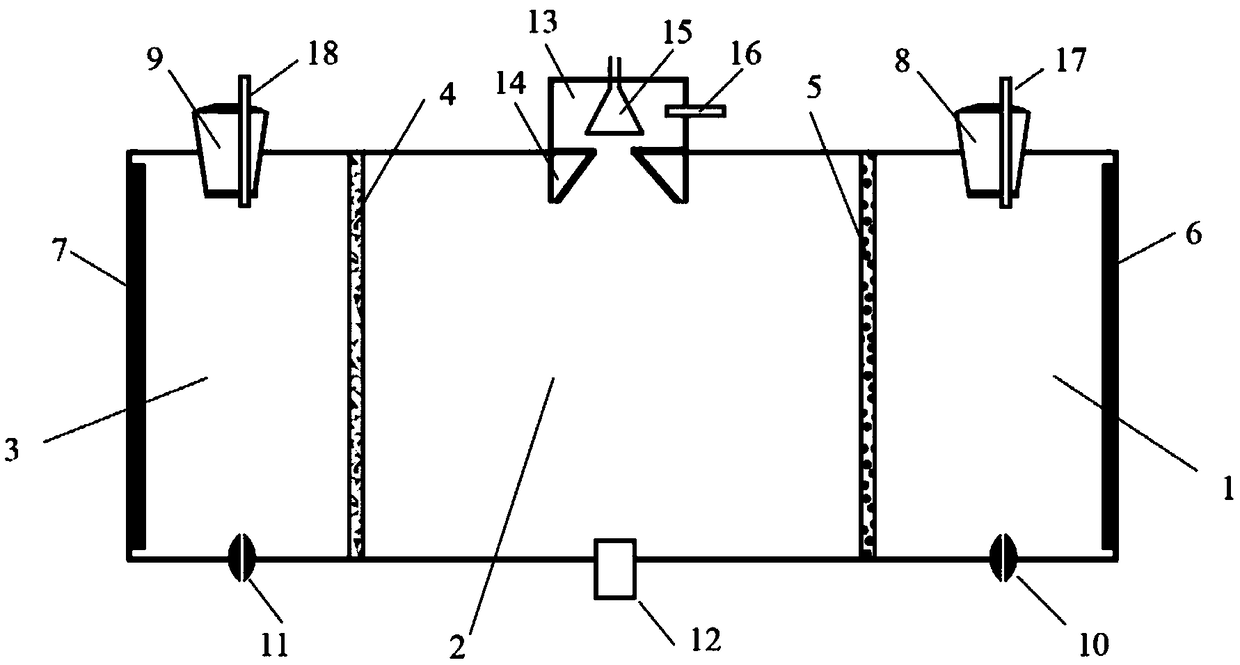

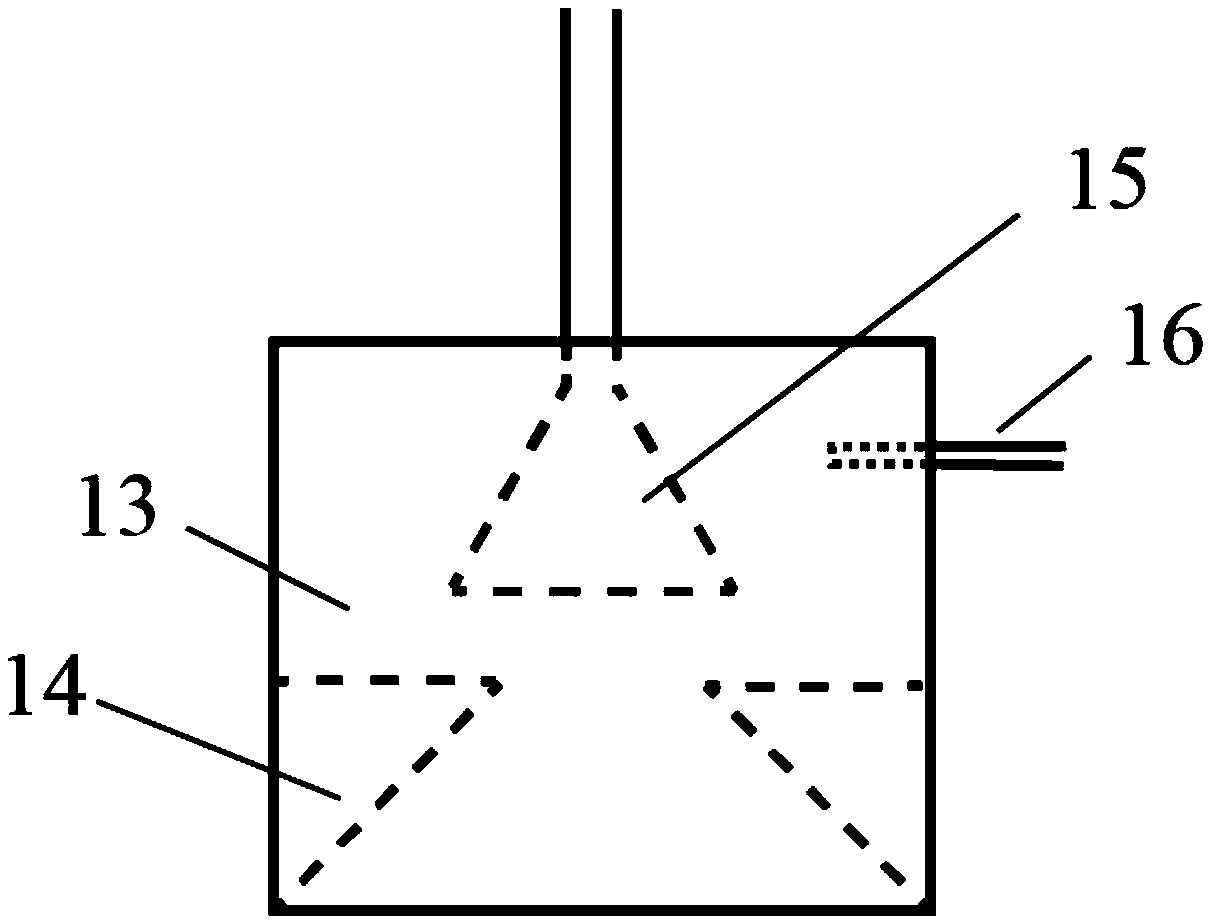

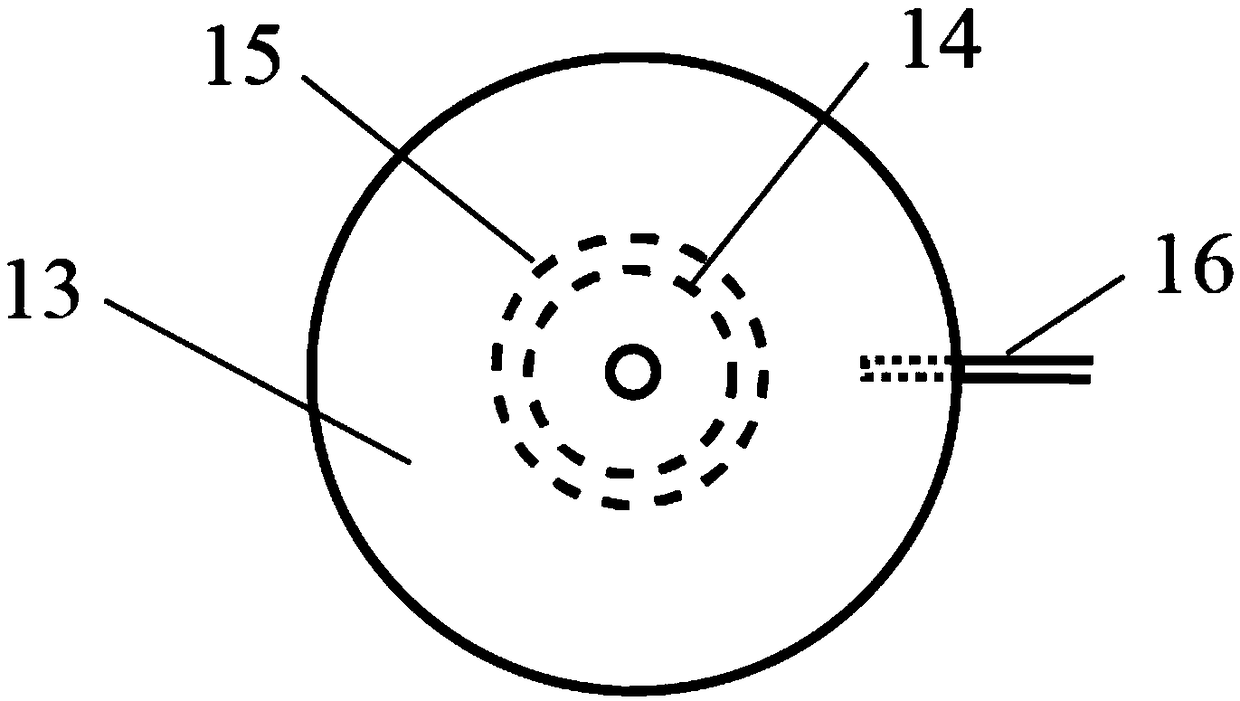

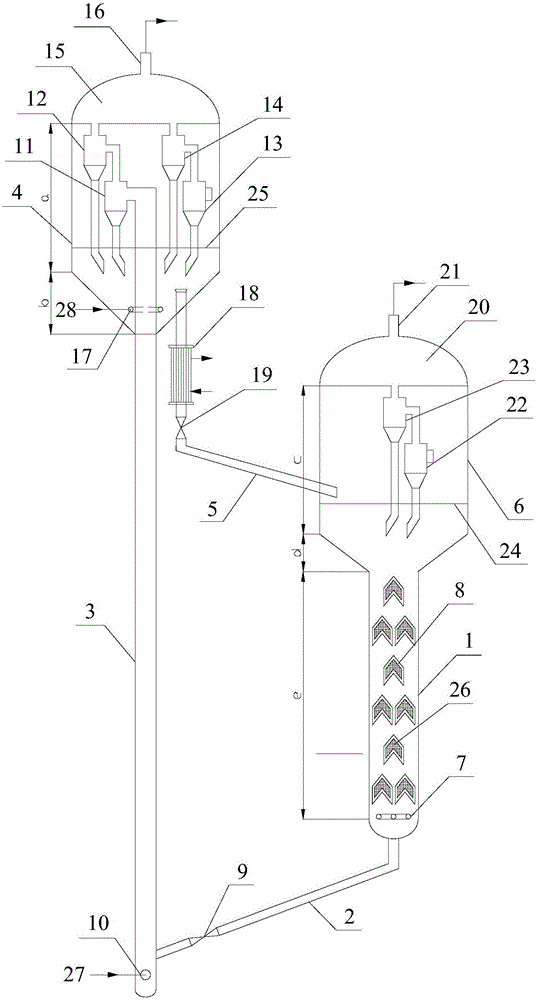

Fluidized-fixed composite bed reaction adsorption reinforced hydrogen production device and method by methane vapor reforming

ActiveCN103288049ASolve the problem of easy deactivation at high temperatureEfficient hydrogen productionHydrogenChemical recyclingCycloneSorbent

The invention discloses a fluidized-fixed composite bed reaction adsorption reinforced hydrogen production device by methane vapor reforming, which mainly comprises a fluidized-fixed composite bed reactor, a primary cyclone separator, a secondary cyclone separator and a regenerator. The invention also discloses a reaction adsorption reinforced hydrogen production method by methane vapor reforming, which comprises steps as follows: a nickel-base reforming catalyst is fixed and filled into the composite reactor in a specific mode; a nano or micro CaO-base CO2 adsorbent in a fluidized state can contact a catalyst bed layer, and the reaction adsorbs CO2 released by the reforming reaction; and the CO2 enters the separators and regenerator through the catalyst bed layer, and enters the fluidized-fixed composite bed reactor to be recycled. The method and device disclosed by the invention avoids the possibility of the catalyst entering the high-temperature regenerator, thereby prolonging the service life of the catalyst; and the invention solves the problem of unmatched service life between the catalyst and adsorbent when a single fixed bed or fluidized bed reactor is used for reaction adsorption to reinforce the methane vapor reforming reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Highly efficient hydrogen production method using microorganism

ActiveUS20060128001A1Highly efficient biological hydrogen generation capabilityIncrease the number ofFungiBacteriaMicroorganismCompound (substance)

It is intended to obtain anaerobic microbial cells in an amount sufficient for hydrogen generation reaction, impart a hydrogen generation function to an aerobic microorganism within a short time and provide an industrial advantageous method of producing hydrogen. The above object can be established by providing a highly efficient microbial hydrogen production method characterized by comprising culturing a microorganism having a formate dehydrogenase gene and a hydrogenase gene under aerobic conditions, culturing the resulting microbial cells under anaerobic conditions in a liquid culture medium containing a formic acid compound, and then using the thus obtained cells for hydrogen generation.

Owner:RES INST OF INNOVATIVE TECH FOR THE EARTH +1

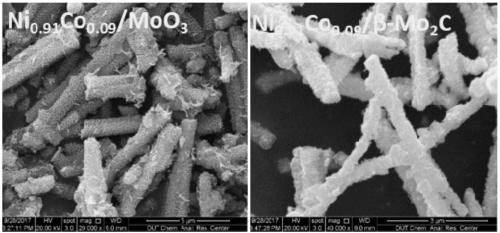

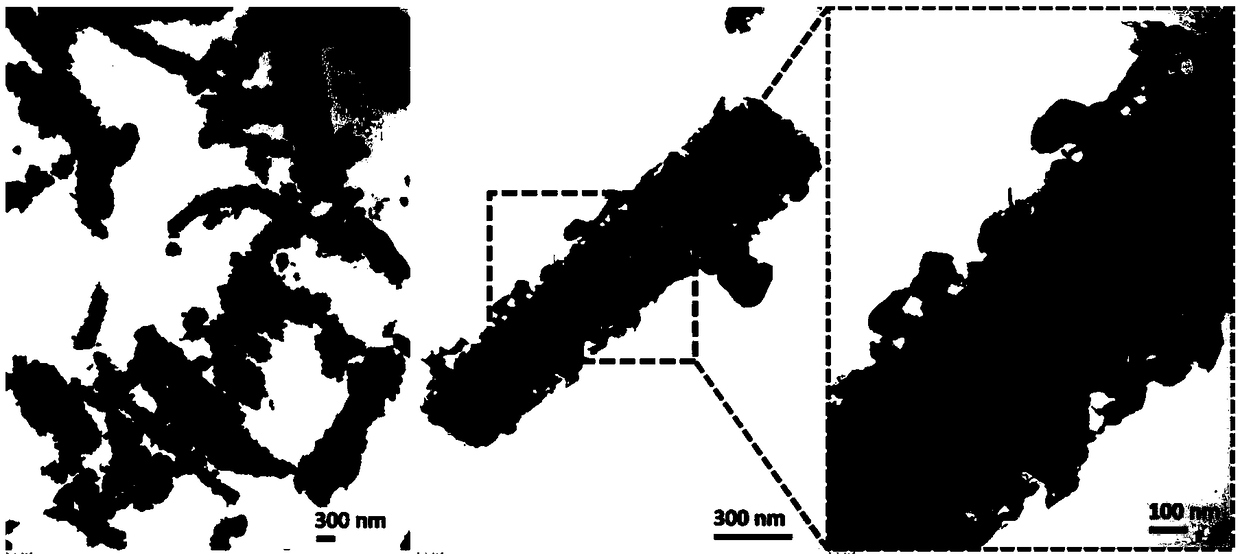

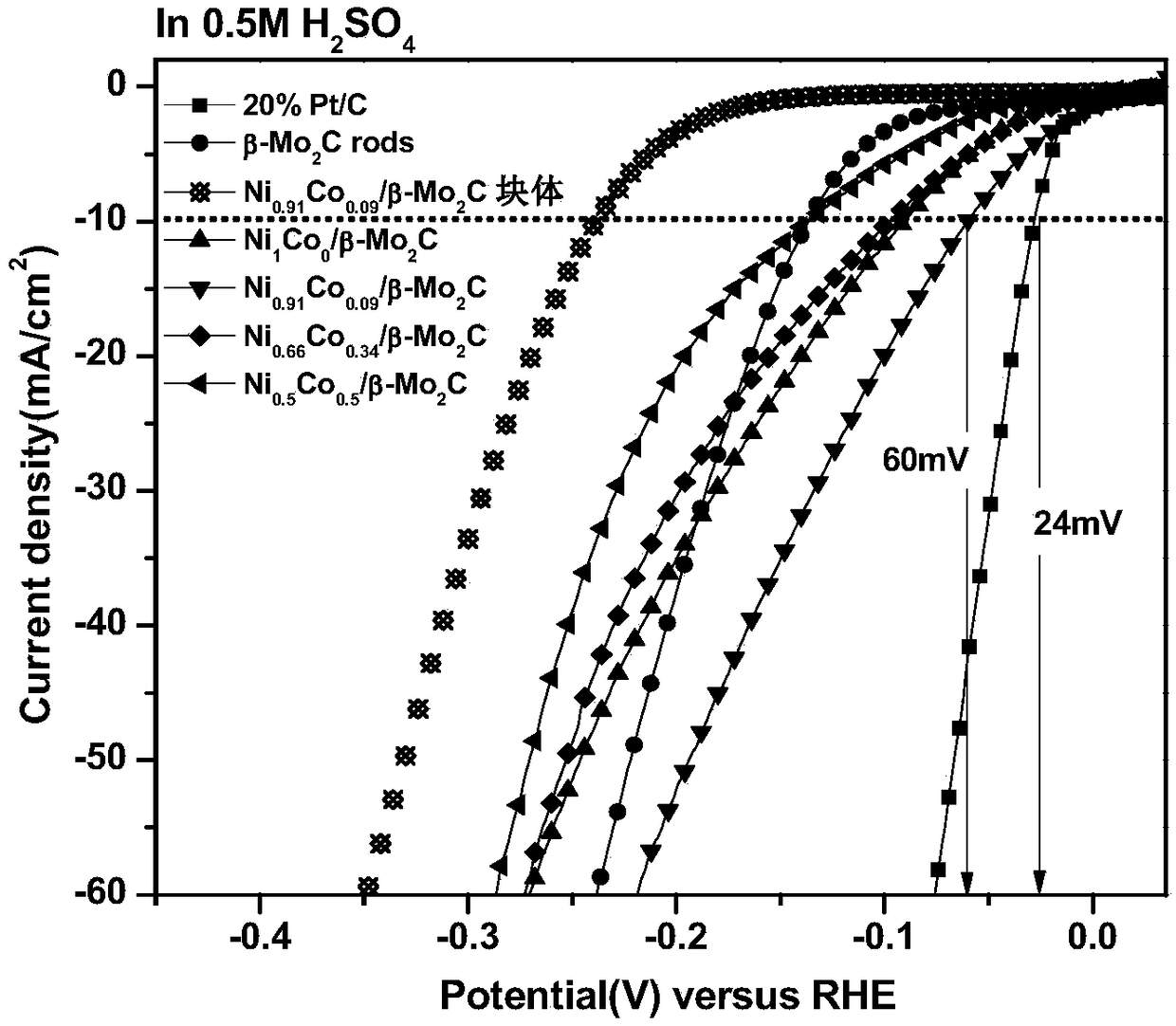

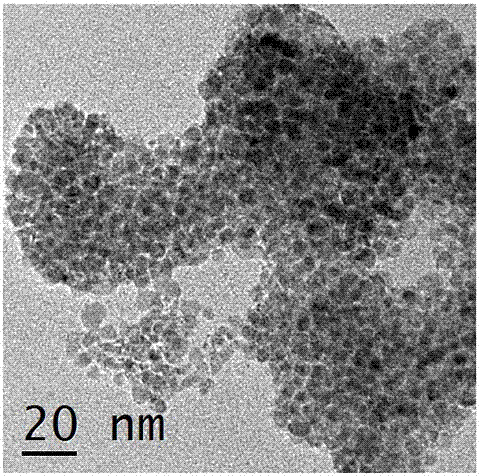

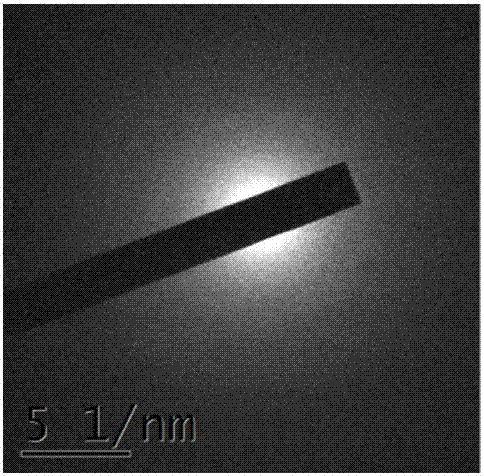

Nanosheet-nanorod coupled three-dimensional composite Ni-Co modified molybdenum carbide electrocatalysis hydrogen production catalyst and preparation method thereof

ActiveCN108940328AEffective dispersionImprove utilization efficiencyPhysical/chemical process catalystsElectrodesAir atmosphereWater baths

The invention discloses a nanosheet-nanorod coupled three-dimensional composite Ni-Co modified molybdenum carbide electrocatalysis hydrogen production catalyst and a preparation method thereof. The catalyst is a nanorod structure, and the nanorod is covered with a plicated nanosheet structure. In addition, bimetal Ni and Co are uniformly dispersed on the surface of the catalyst, and the molar ratio of the metal Ni to Co is 1: 0-1:1. The preparation method comprises the following steps; using MoO3 nanorod as a supporting network, adding nickel acetate and cobalt salt and fully stirring to forma suspension; placing the above suspension into water bath of 60-90 DEG C and stirring intensely for 4-7 h, standing overnight, filtering, washing and drying, and roasting in the air atmosphere of 450-550 DEG C. By the surface / interfacial effect between the molybdenum carbide material and loaded metal and based on the morphology features of the material itself, high dispersion of the metal Ni andCo is realized, and the catalytic active site is fully exposed. Meanwhile, with the strong interaction between the molybdenum carbide substrate and the loaded metal, stability of the catalytic material is effectively enhanced.

Owner:DALIAN UNIV OF TECH

Method of producing electrolytic hydrogen using rare element-deposit electrode

InactiveUS20050115841A1Simple processEasy to usePhotography auxillary processesNoble metal coatingsElectrolysisConstant current

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

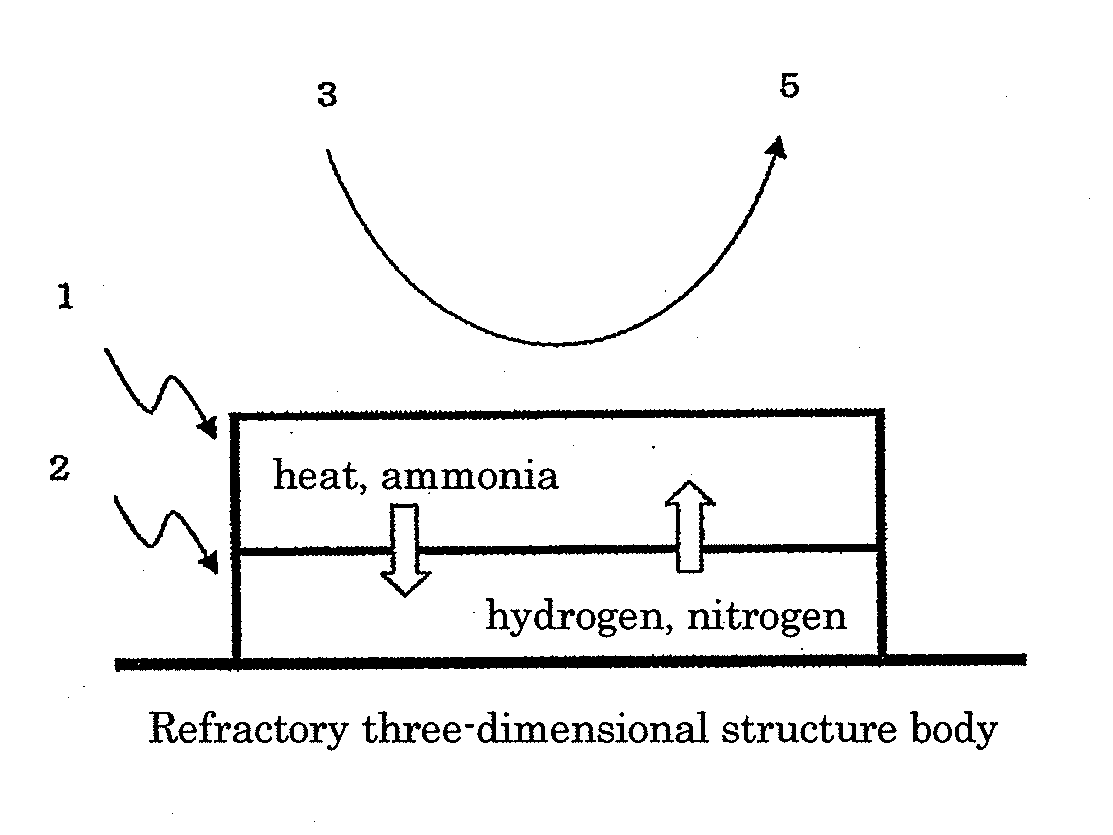

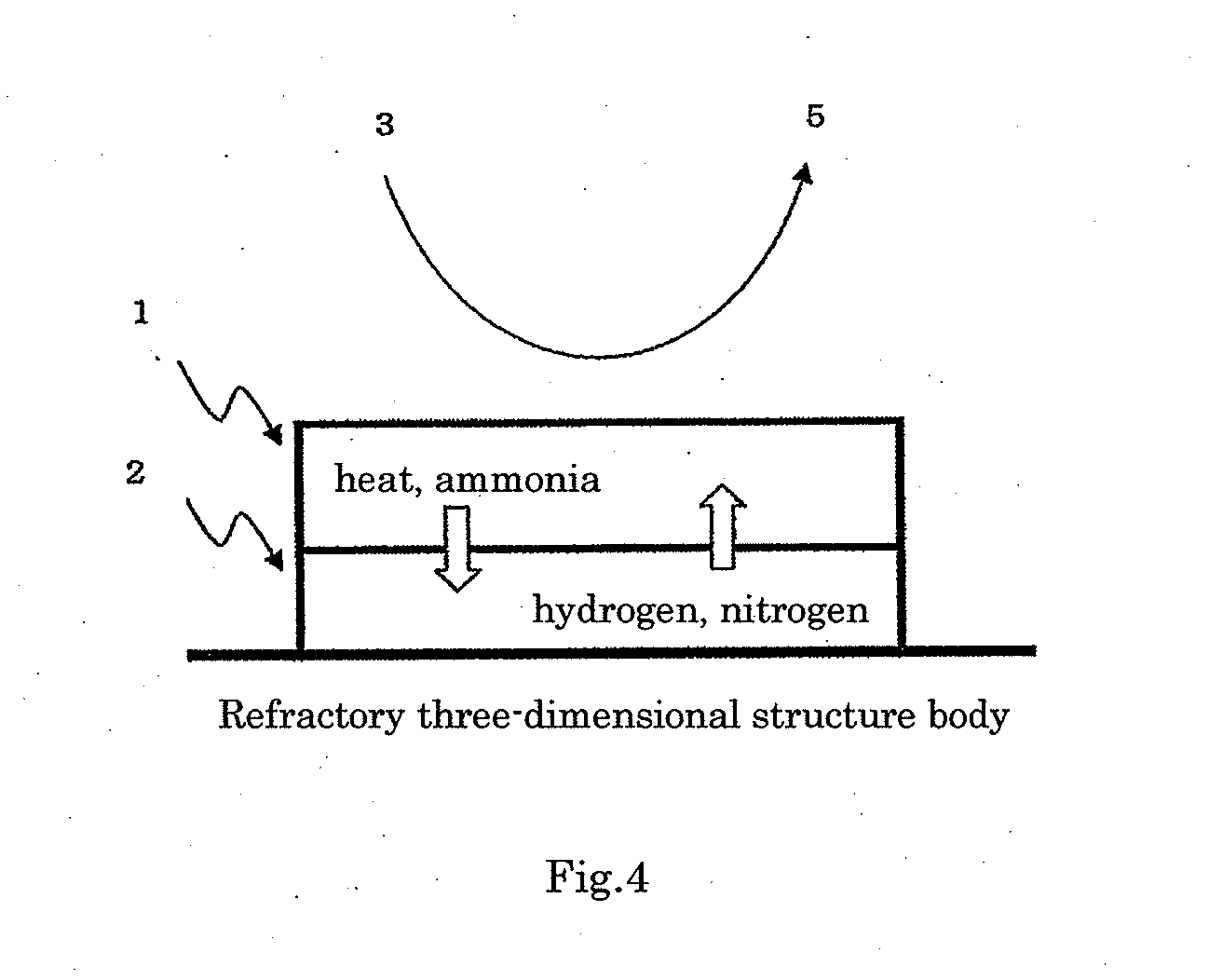

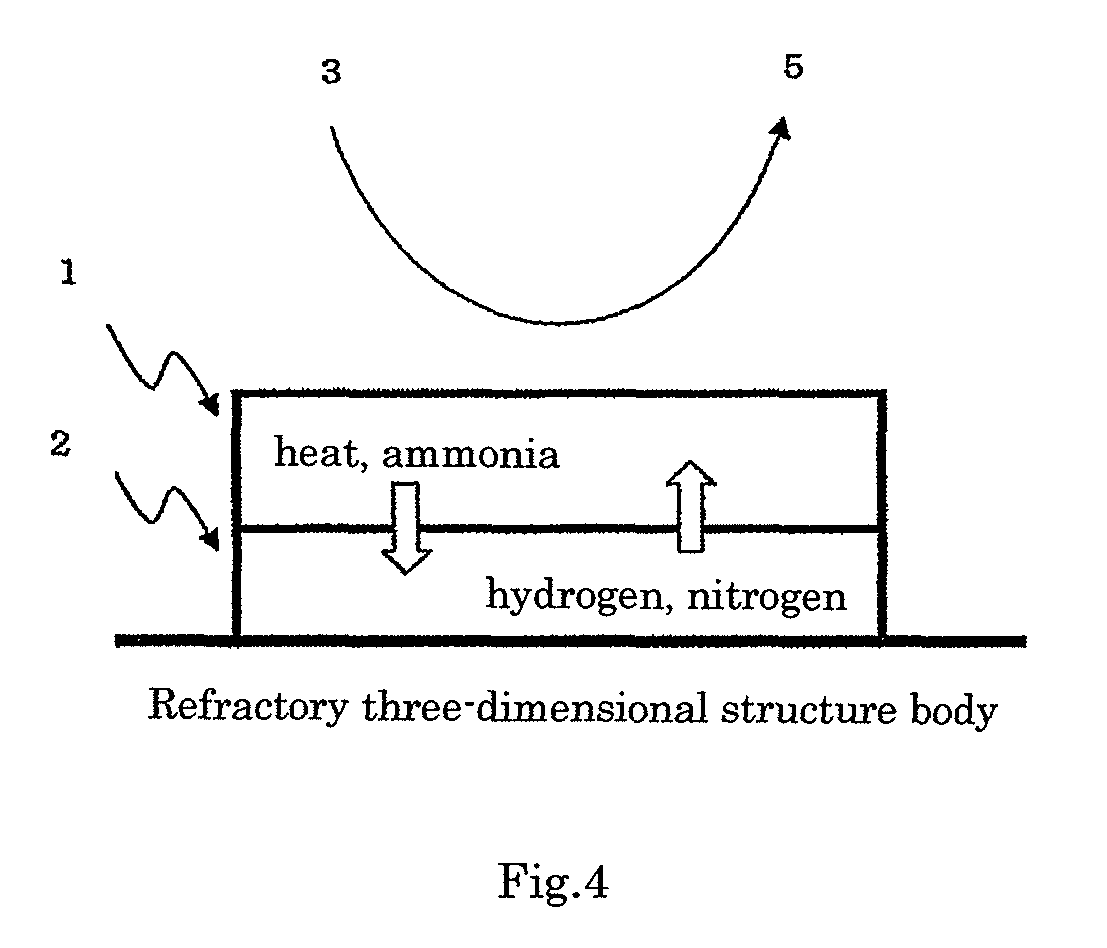

Catalyst for production of hydrogen and process for producing hydrogen using the catalyst, and catalyst for combustion of ammonia, process for producing the catalyst and process for combusting ammonia using the catalyst

InactiveUS20120015802A1Cheap and practical catalystImprove responseFuel supply regulationMolecular sieve catalystsHydrogenAmmonia

Disclosed is a catalyst which can be used in the process for producing hydrogen by decomposing ammonia, can generate heat efficiently in the interior of a reactor without requiring excessive heating the reactor externally, and can decompose ammonia efficiently and steadily by utilizing the heat to produce hydrogen. Also disclosed is a technique for producing hydrogen by decomposing ammonia efficiently utilizing the catalyst. Specifically disclosed is a catalyst for use in the production of hydrogen, which is characterized by comprising an ammonia-combusting catalytic component and an ammonia-decomposing catalytic component. Also specifically disclosed is a catalyst for use in the production of hydrogen, which is characterized by comprising at least one metal element selected from the group consisting of cobalt, iron, nickel and molybdenum.

Owner:NIPPON SHOKUBAI CO LTD

Steam reforming catalyst composition and process

InactiveUS20050025701A1Efficient hydrogen generationHigh valueHydrogenCatalyst activation/preparationSteam reformingHydrocarbon

A method for producing novel catalysts comprising of Group VIII metal along with a partially reducible metal oxide, zirconium oxide, lanthanum oxide and aluminum oxide is disclosed. These novel catalysts retain their catalytic activity even in the presence of significant quantities of sulfur compounds. This makes them attractive in the conversion of hydrocarbons into hydrogen; a process for the same is also disclosed.

Owner:MILLENNIUM RES LAB

Fuel oil for use both in internal combustion in engine and fuel cell

InactiveUS20030145514A1Easy to useEfficient productionHydrogenLiquid carbonaceous fuels2-methylbutaneFuel oil

A fuel oil for use both in an internal combustion engine and in a fuel cell containing 50% by volume or more of an alkylate gasoline, and, optionally, 1 to 50% by volume of isopentane, 1 to 12% by volume of a hydrocarbon having 4 carbon atoms, 7% by volume or less of an oxygen-containing compound, and 1 to 30% by volume of a desulfurized light naphtha; and a fuel oil for use both in an internal combustion engine and in a fuel cell containing 10 to 60% by volume of a desulfurized light naphtha, 40 to 90% by volume of a benzene-free reformed gasoline and 0 to 10% by volume of a hydrocarbon having 4 carbon atoms. Each of the above fuel oils is a fuel oil for a fuel cell which can produce hydrogen with good efficiency, has no adverse effect on reforming catalysts and electrodes for a fuel cell, and is reduced in deactivation of reforming catalysts and the like, and a fuel oil for an internal combustion engine which has a high octane number and can be used without causing knocking or the like.

Owner:IDEMITSU KOSAN CO LTD

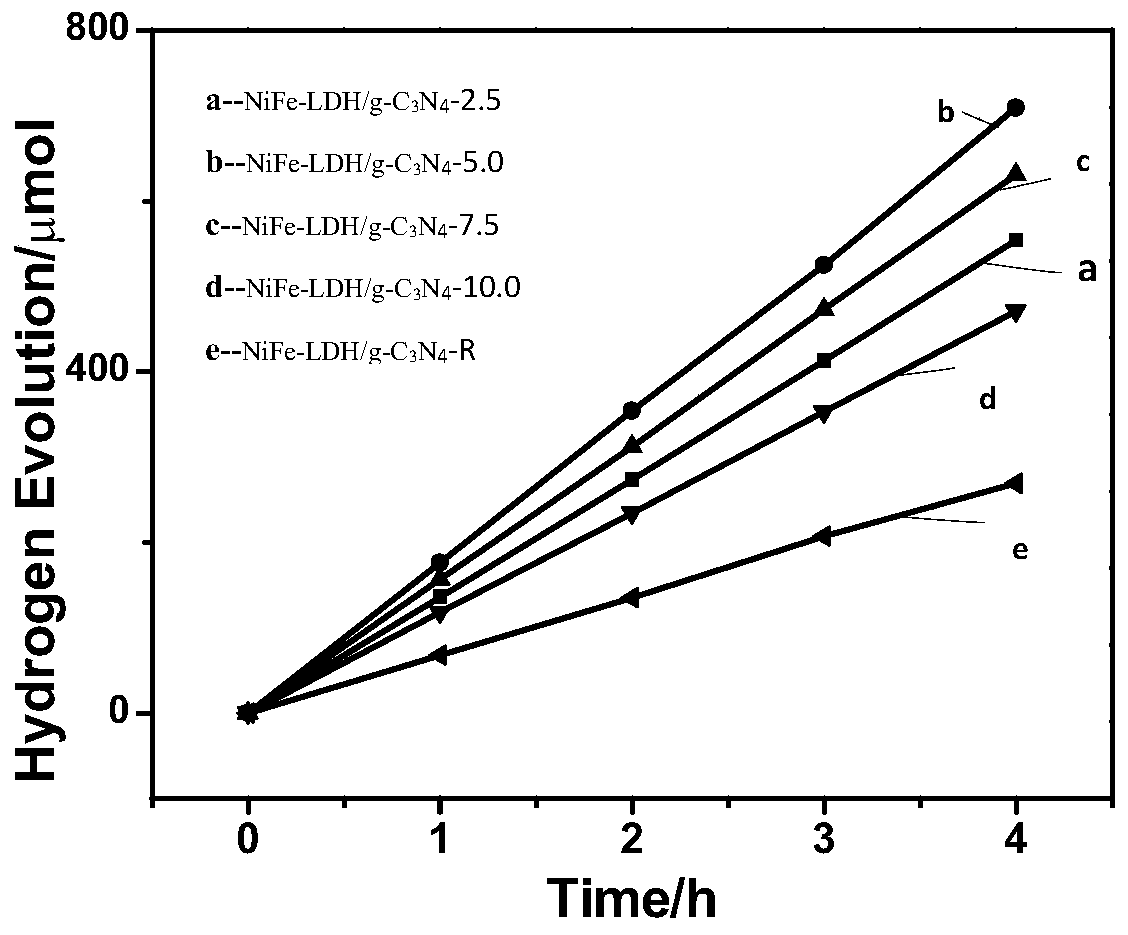

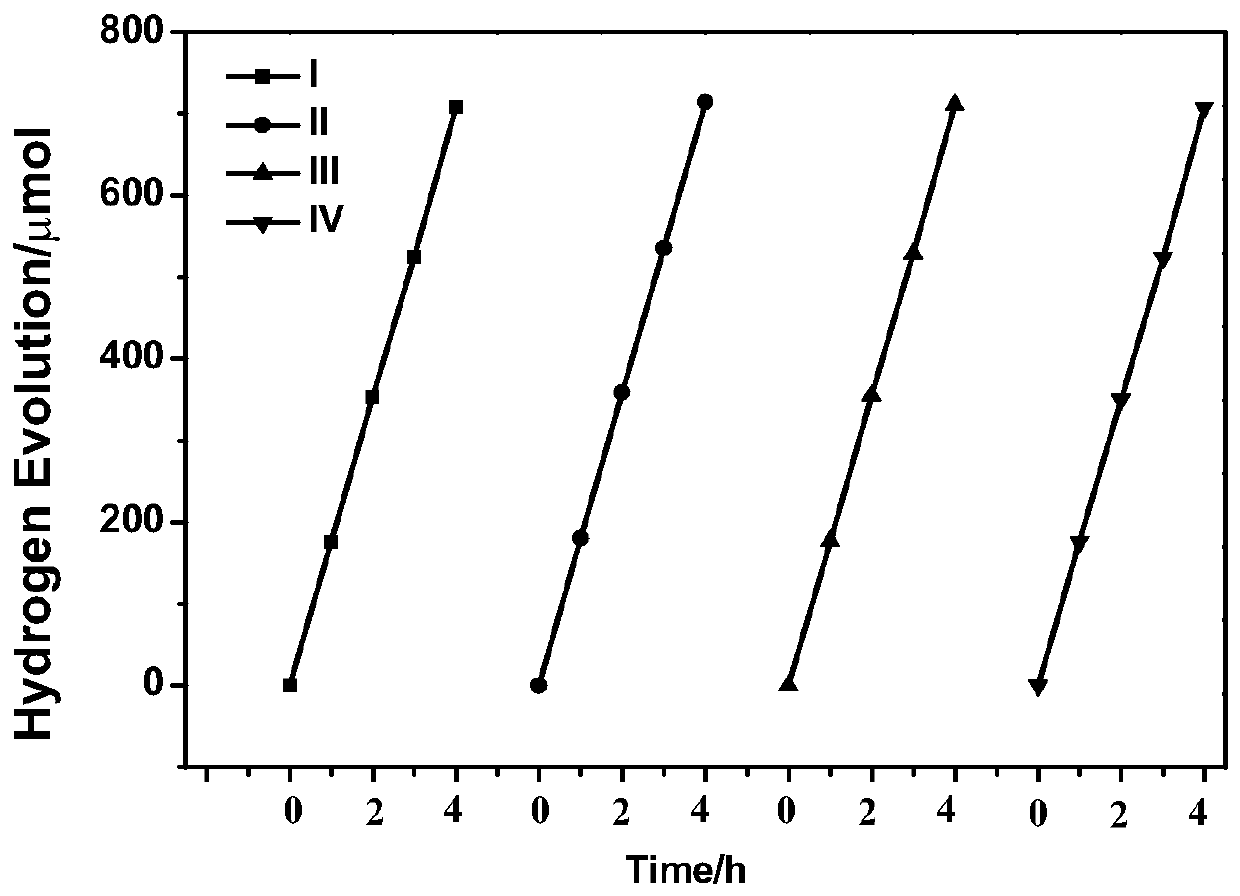

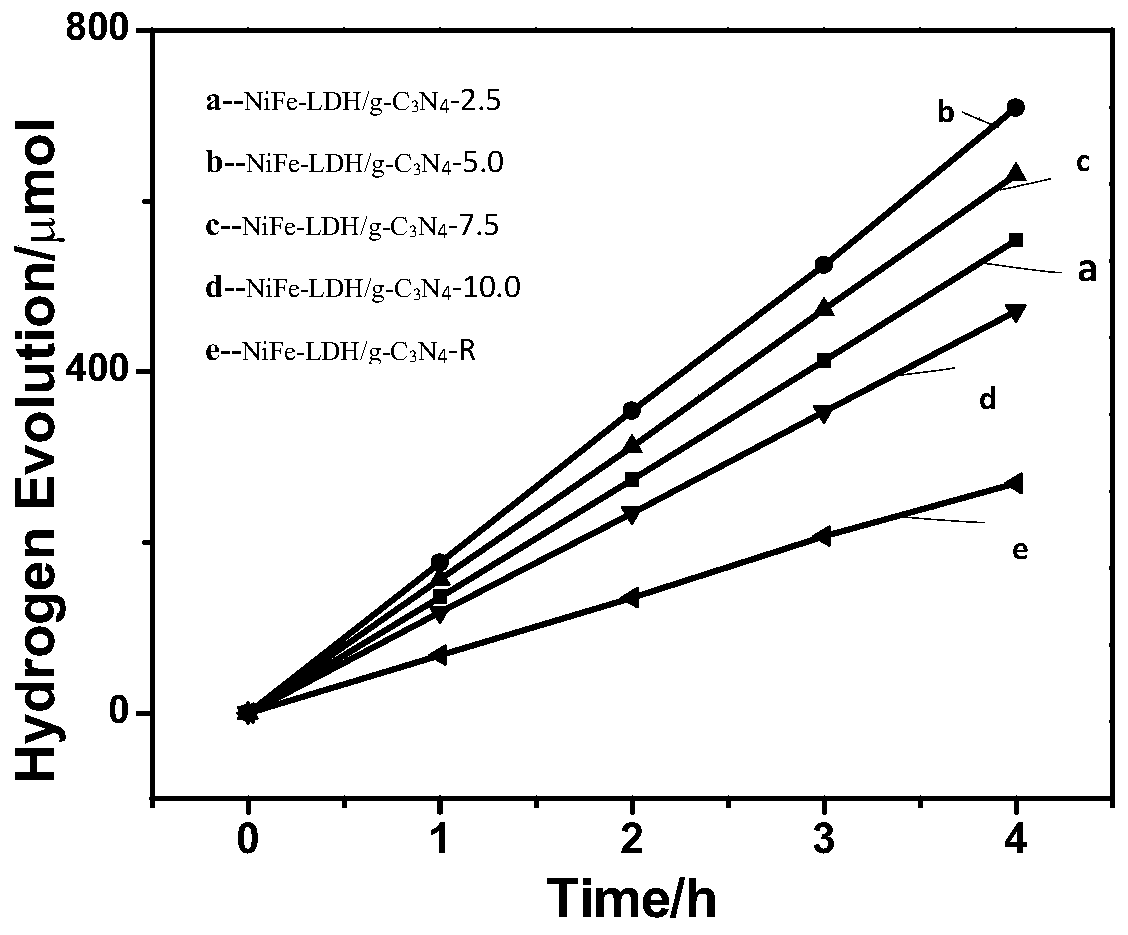

NiM-LDH/g-C3N4 composite photocatalytic material and preparation method thereof

ActiveCN111167499ALow costLarge specific surface areaPhysical/chemical process catalystsHydrogen productionHydration reactionNickel salt

The invention discloses a NiM-LDH / g-C3N4 composite photocatalytic material and a preparation method thereof. An alcohol-water mixed solvent is utilized, and g-C3N4, nickel salt, transition metal salt,a surfactant and a precipitator are added in the solvothermal treatment process, so that g-C3N4 can be stripped to obtain ultrathin porous g-C3N4, and meanwhile, ultrathin two-dimensional NiM hydrated hydroxide can be generated on the surface of g-C3N4 in situ. The preparation method disclosed by the invention is simple and feasible; good repeatability, safety and reliability; the NiM-LDH / g-C3N4composite photocatalytic material is an ultrathin two-dimensional composite photocatalytic material, which is simple in preparation method, relatively low in cost and high in specific surface area, greatly enhances the photo-induced electron hole separation efficiency and light absorption performance, has relatively high catalytic activity and stability for hydrogen production through visible light catalytic water splitting, and can realize efficient hydrogen production through visible light catalysis.

Owner:FOSHAN UNIVERSITY

Composite fuels for hydrogen generation

ActiveUS20070194273A1Increase energy densityReduce complexityElectrolysis componentsOther chemical processesHydrogenExothermic reaction

Composite fuels for hydrogen generation include materials that endothermically release hydrogen, materials that exothermically release hydrogen, and additives to promote endothermic reaction and to inhibit exothermic reaction.

Owner:EION ENERGY CORP

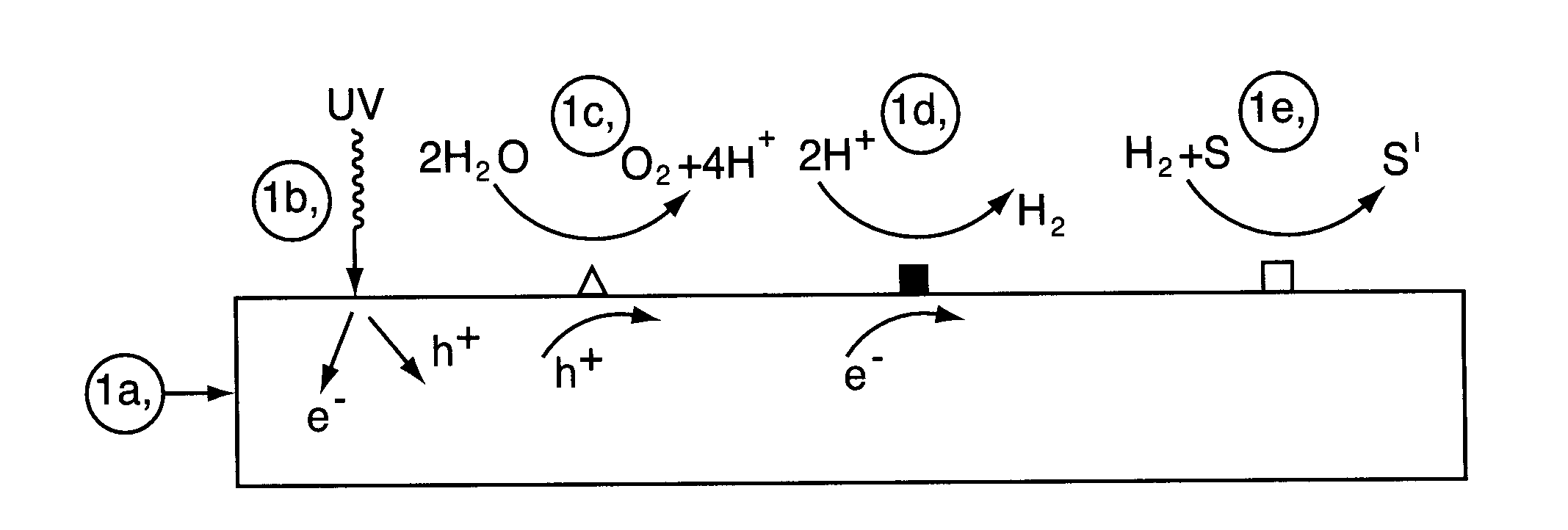

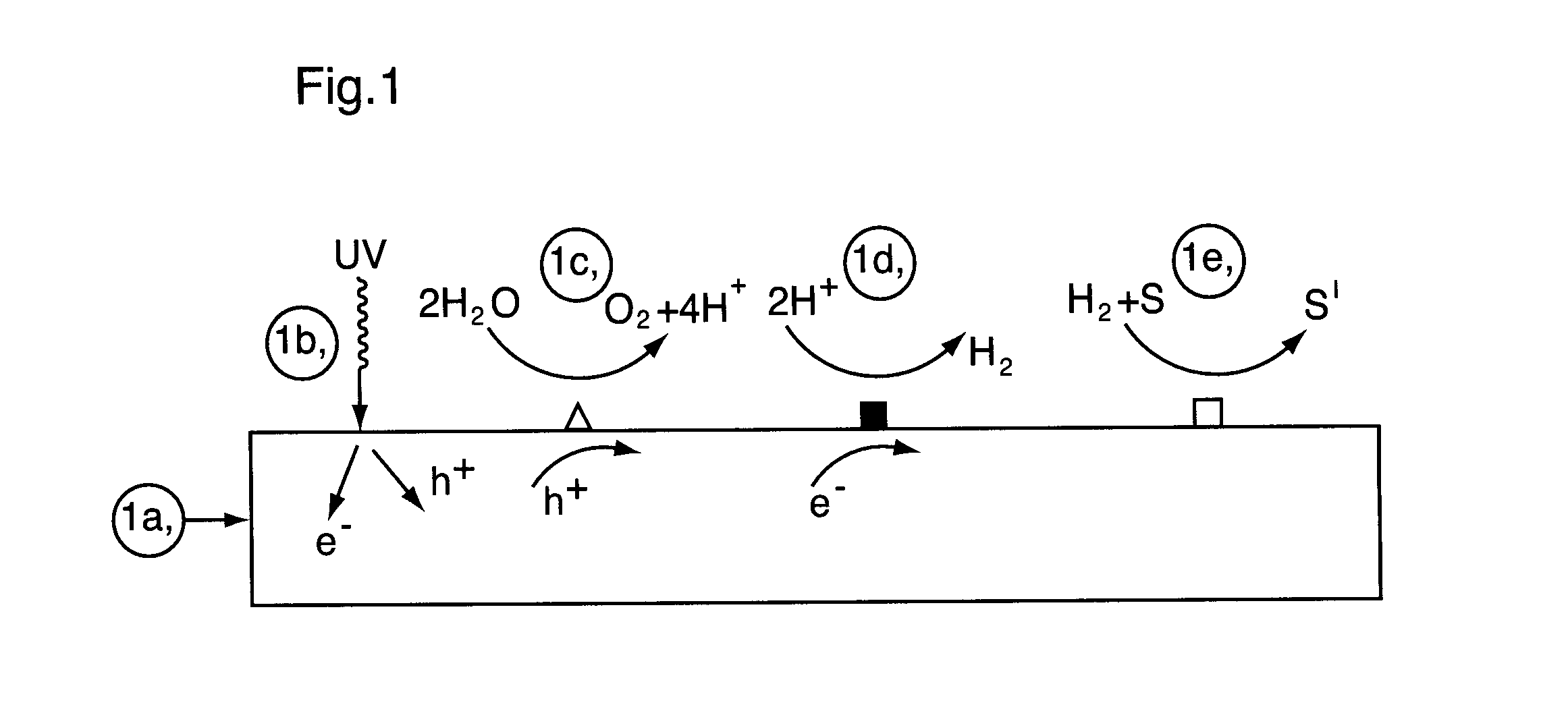

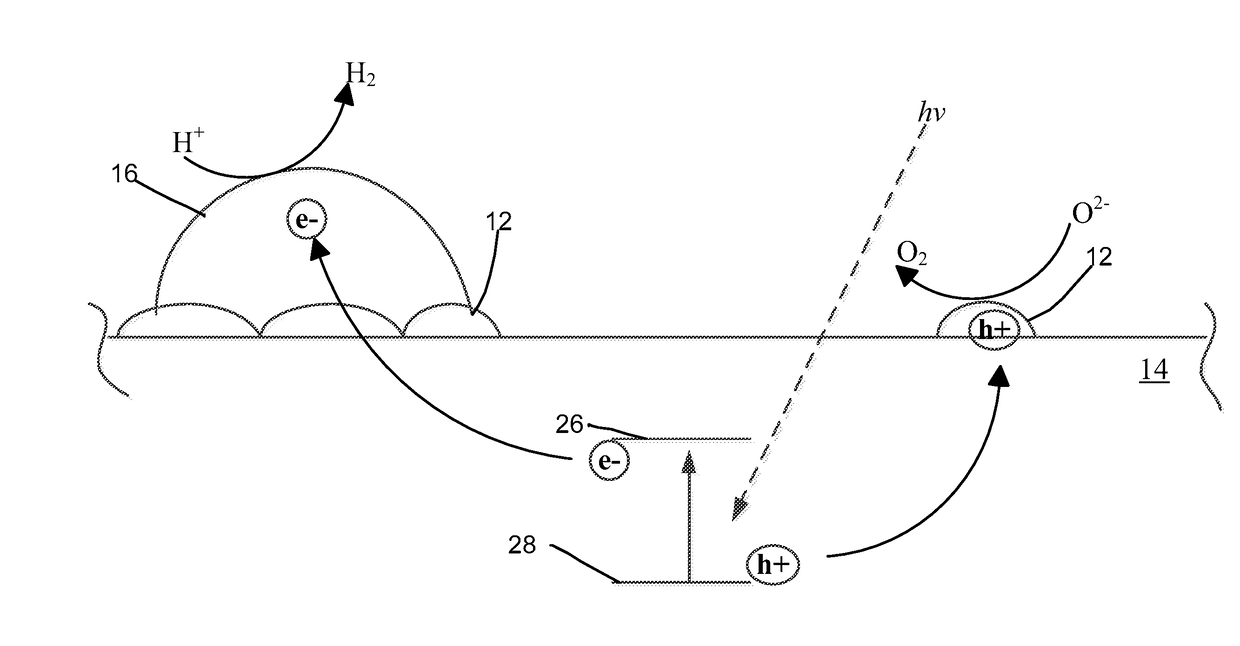

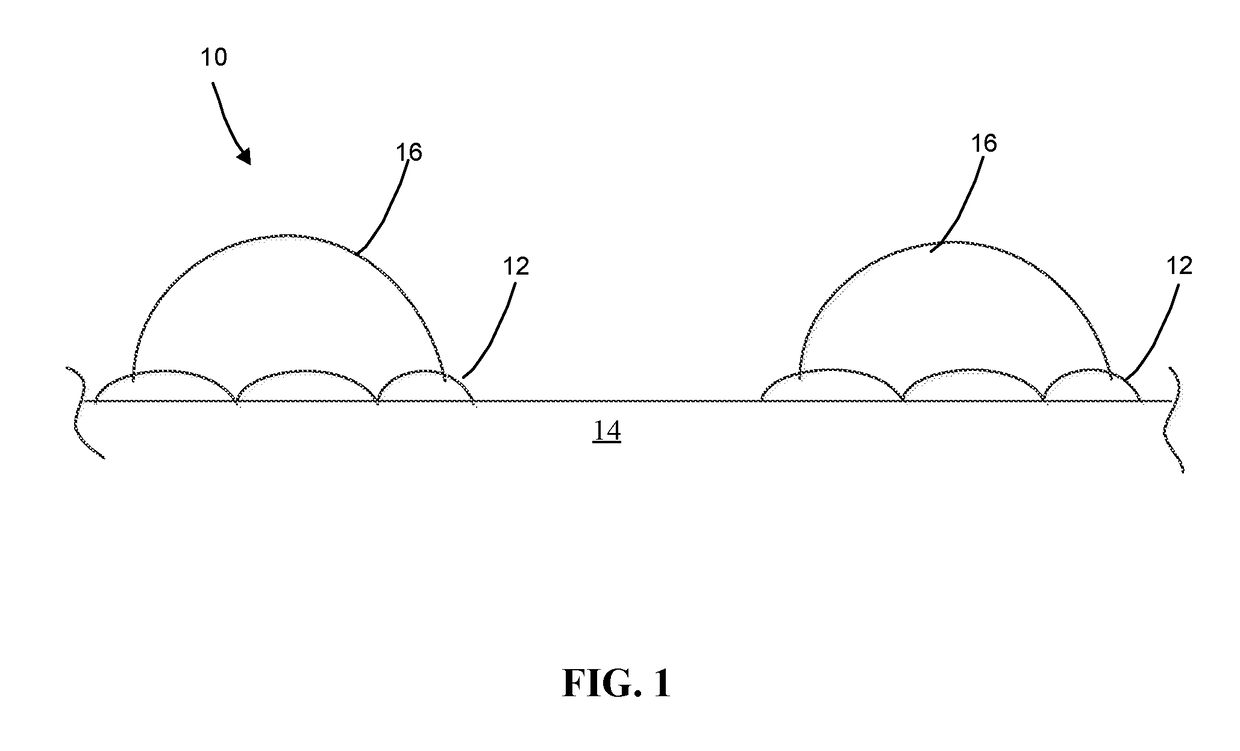

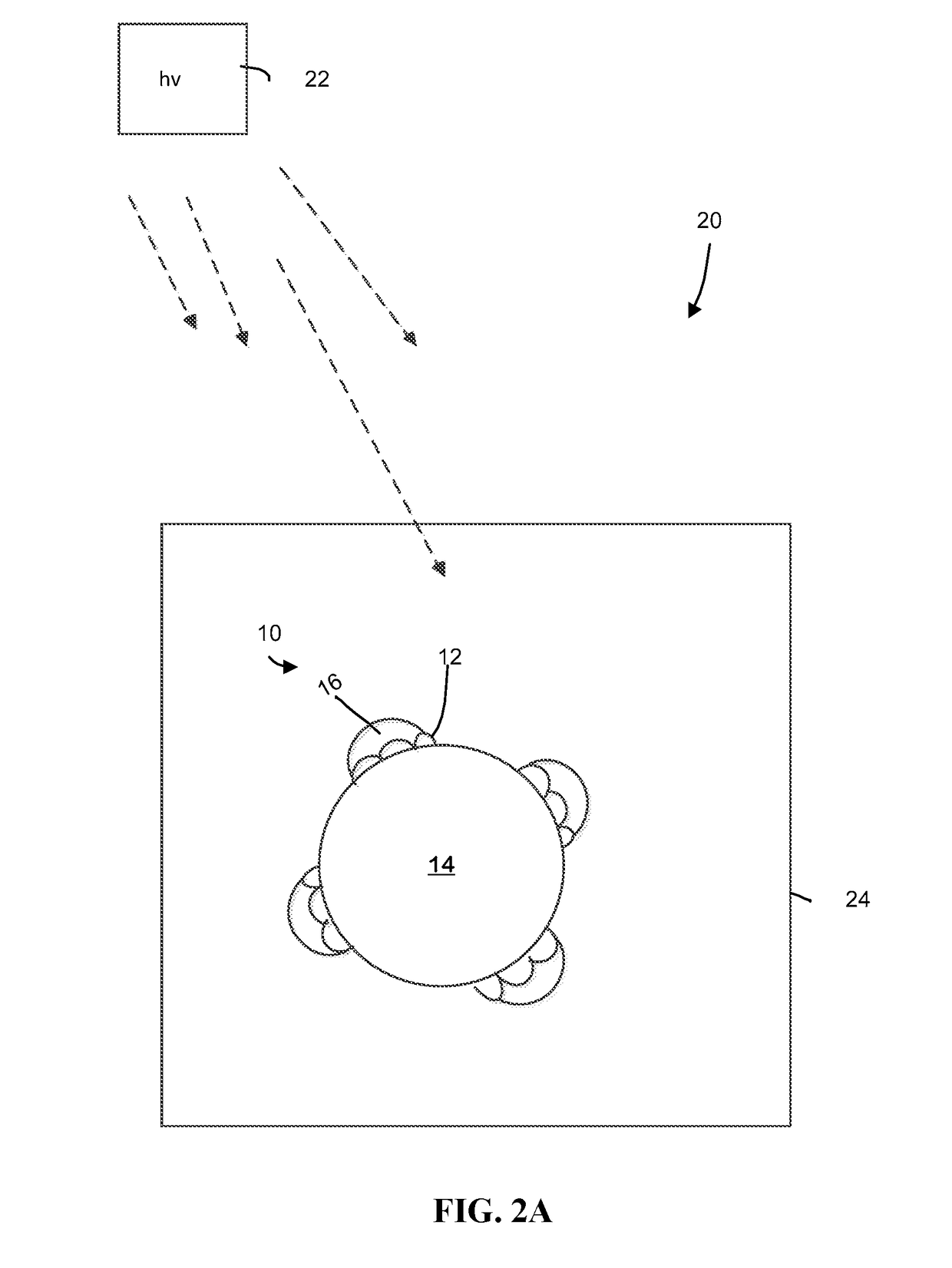

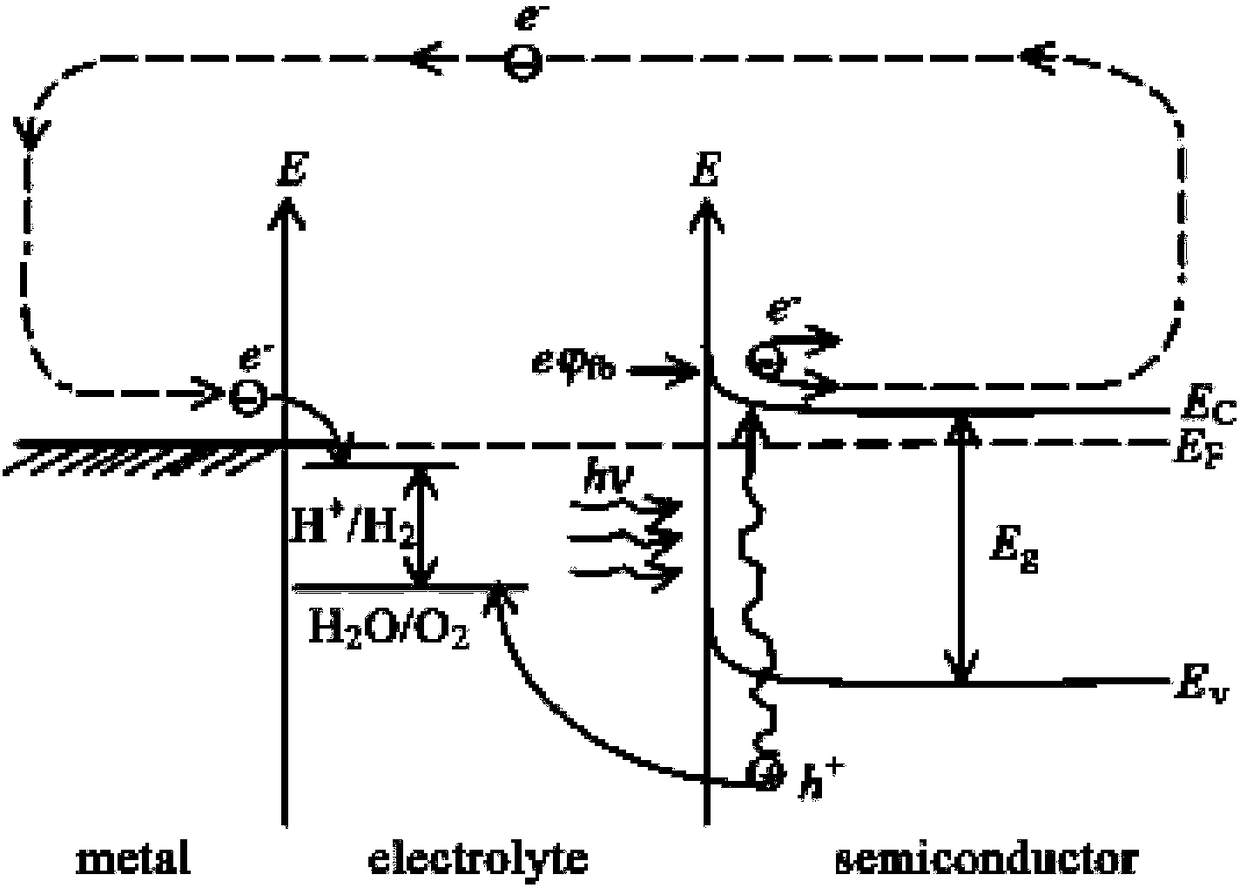

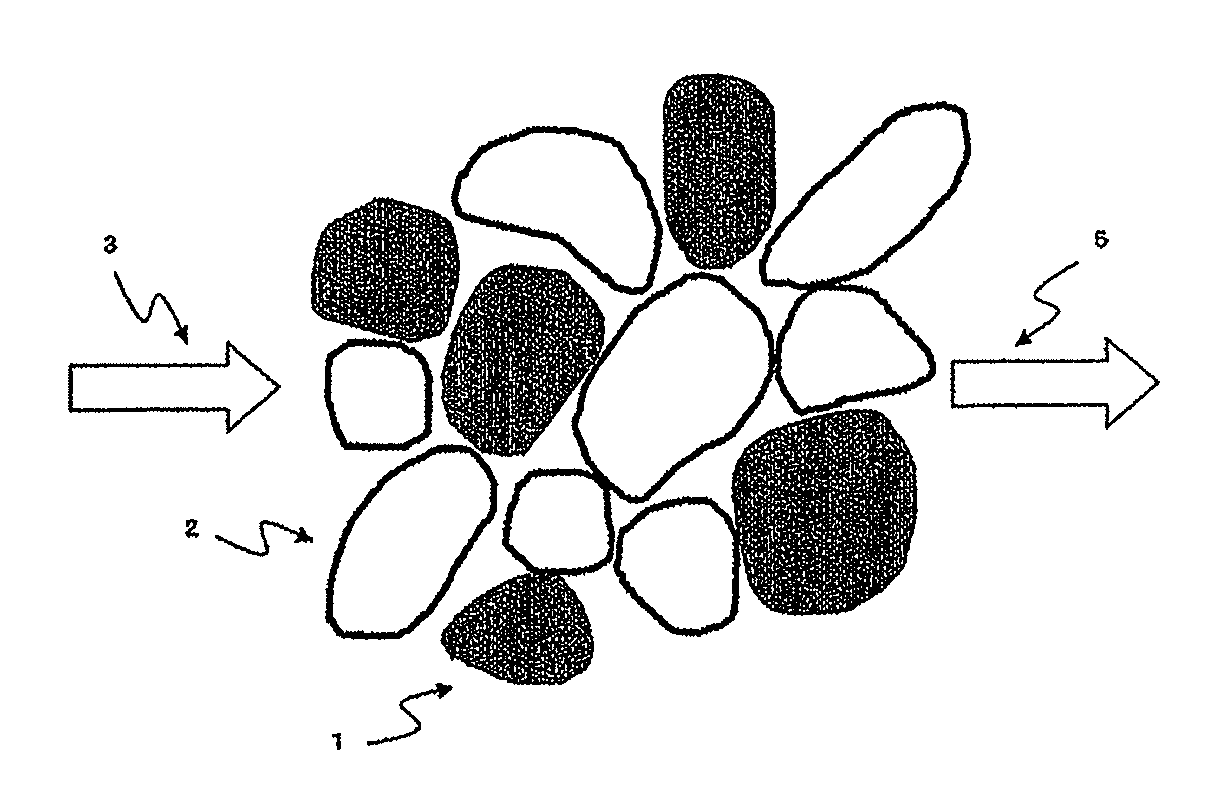

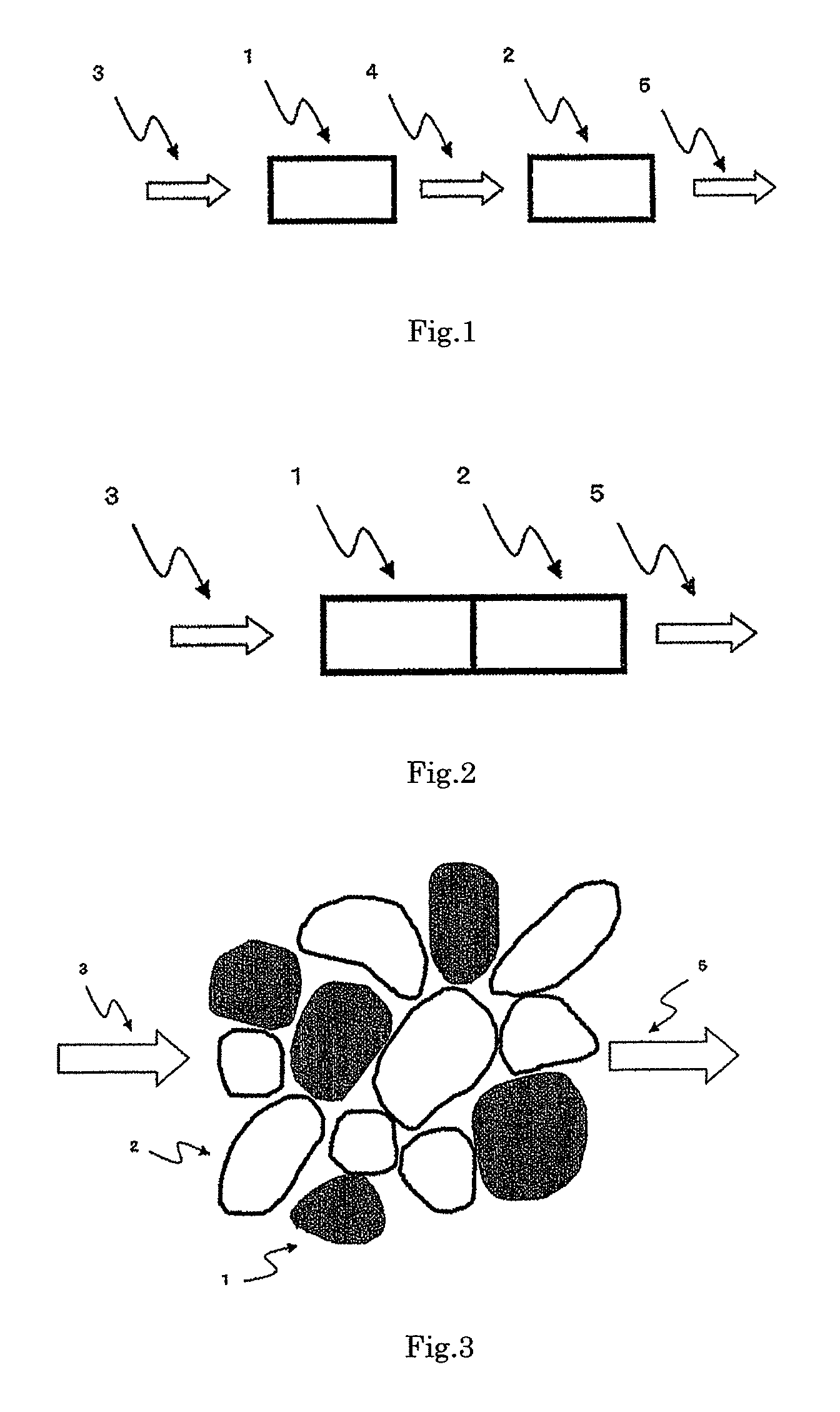

Photocatalyst composition of matter

InactiveUS20130082009A1Rapid chemical conversionStable and less compoundHydrogenOxygen/ozone/oxide/hydroxideHydrogenChemical compound

There is described a photocatalyst composition of matter comprising a support material. A surface of the support material configured to comprise: (i) a first catalytic material for catalyzing the conversion of H2O to H2 and O2, and (ii) a second catalytic material catalyzing reaction of hydrogen with a target compound. The photocatalyst composition of matter can be used to treat an aqueous fluid containing a target chemical compound, for example, by a process comprising the steps of: (i) contacting the aqueous fluid with the above-mentioned photocatalyst composition of matter; (ii) contacting the aqueous fluid with radiation during Step (i); (iii) catalyzing the conversion of water in the aqueous fluid to H2 and O2 with the first catalytic material; and (iv) catalyzing reaction of the target chemical compound in the aqueous fluid with hydrogen from Step (iii) in the presence of the second catalytic material to produce a modified chemical compound.

Owner:TROJAN TECH

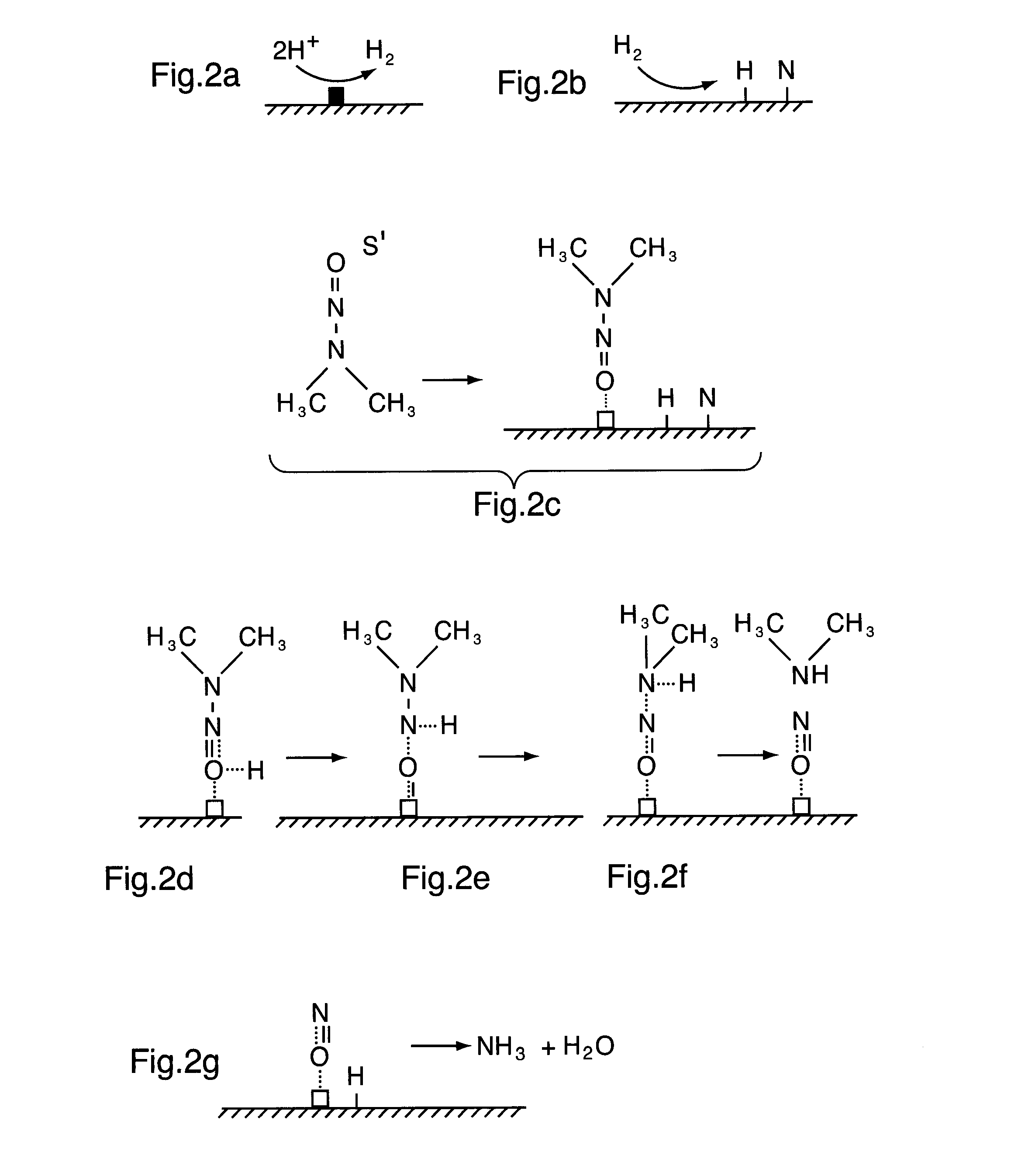

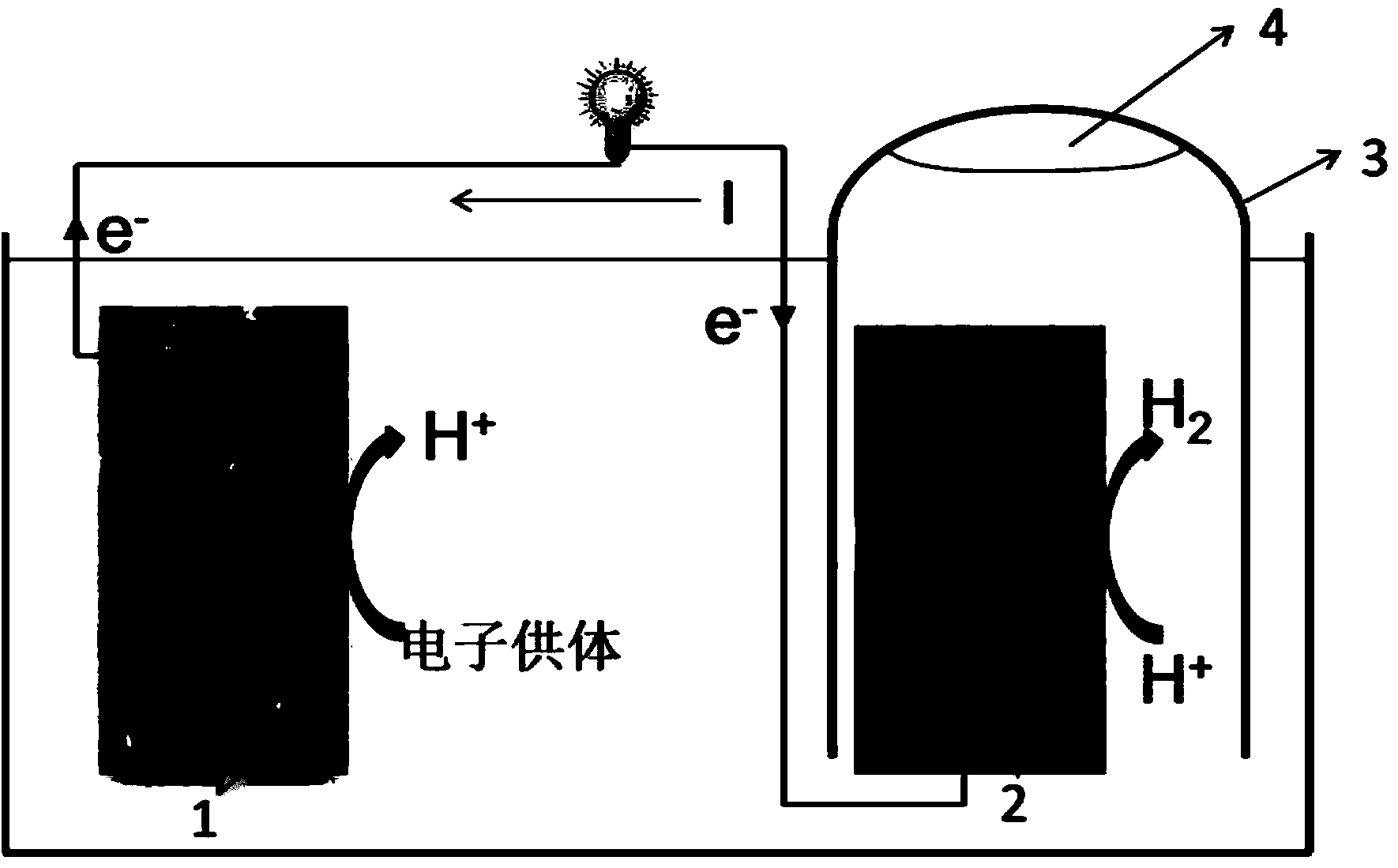

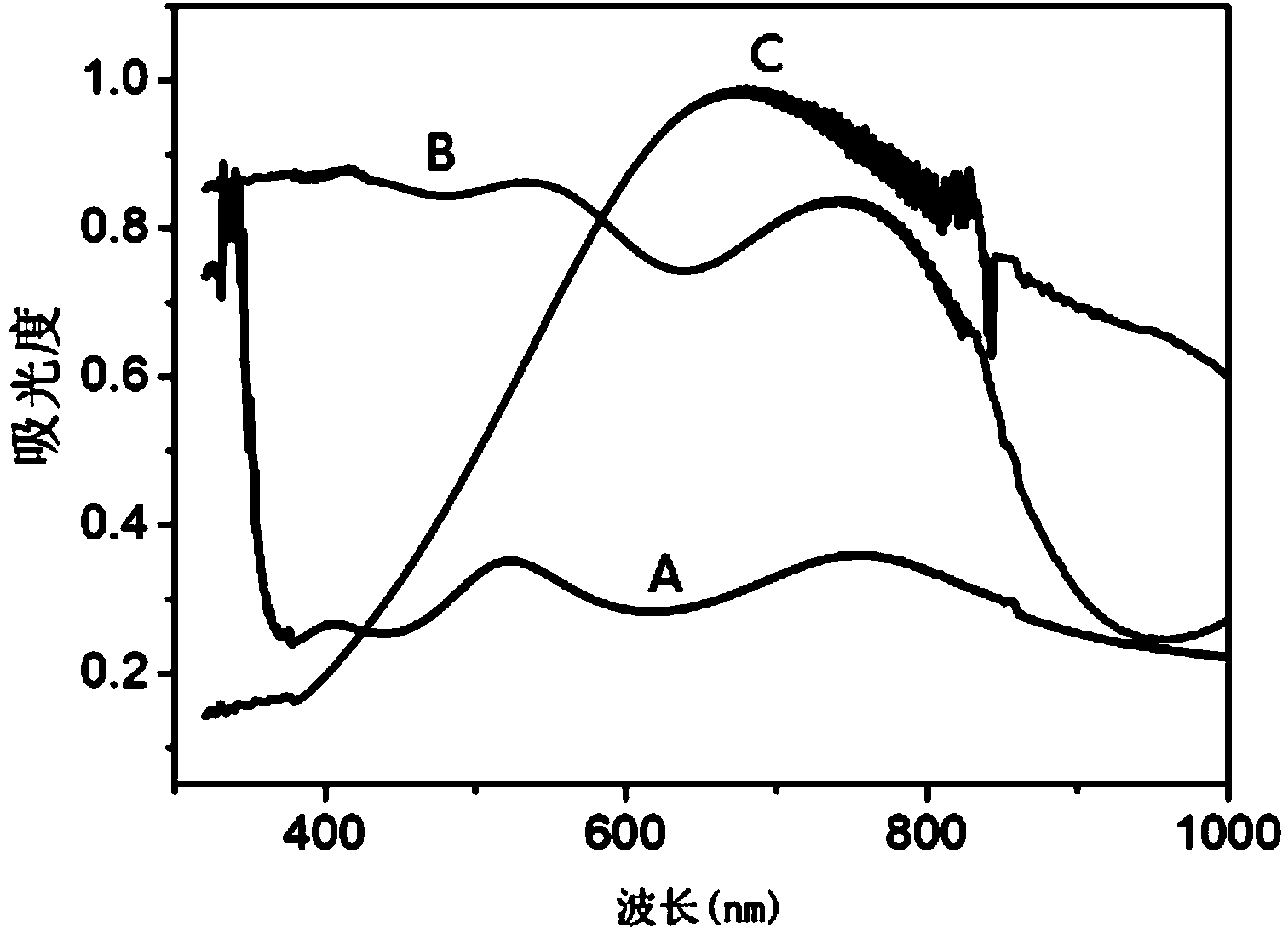

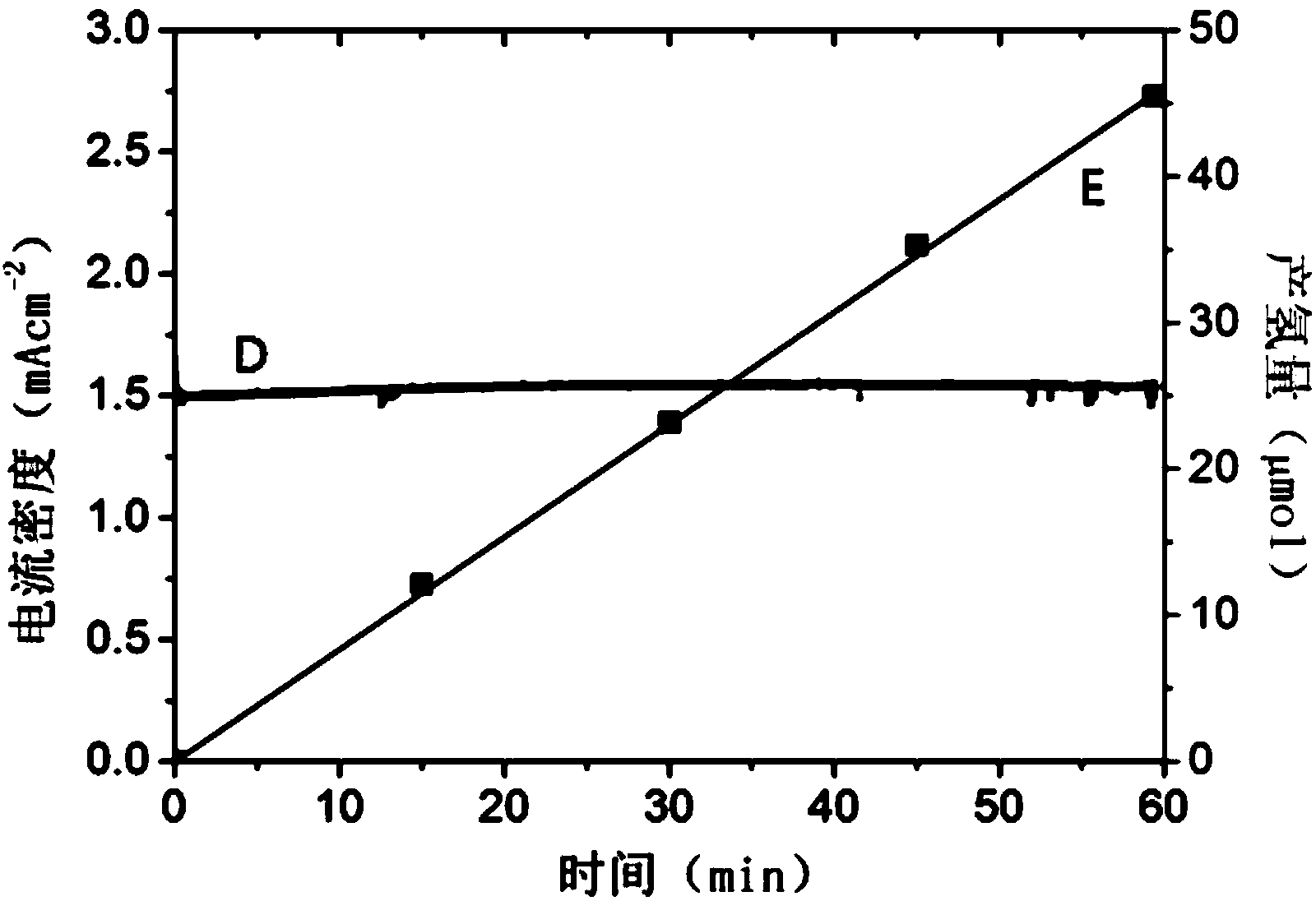

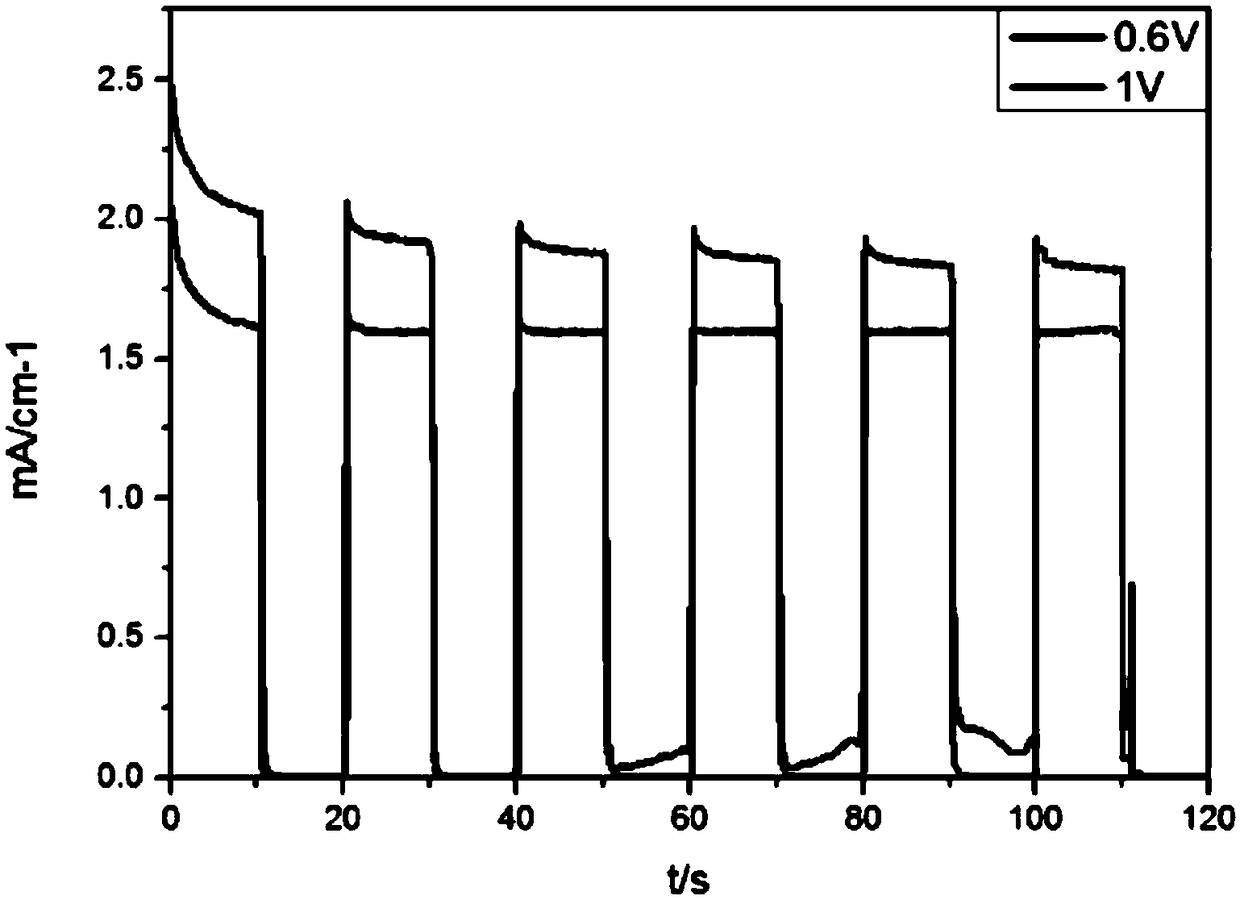

Visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system

InactiveCN104009123AImprove stabilityGood technical effectFinal product manufactureFuel cellsGas collecting tubeTio2 nanotube

The invention provides a visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system. The visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system comprises a visible-light response type Bi2S3 sensitized TiO2 nanotube array film photo-anode, a visible-light response type silicon cell photo-cathode decorated with platinum, an electrolyte, a visible-light source, a quartz reaction tank and a quartz gas collecting tube. The materials of the photo-anode and the materials of the photo-cathode are both high in visible-light absorption performance. The photo-anode and the photo-cathode are inserted into a 0.1-0.5 M Na2S electrolyte solution at the same time and are connected through an external circuit. The visible-light source is switched on to irradiate the photo-anode and the photo-cathode, the photo-anode and the photo-cathode respectively generate an electrode reaction and then form a loop through the external circuit, and therefore automatic-bias photoelectrical catalytic hydrogen production and electricity generation are achieved. The invention further discloses a preparation method of the visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system. The visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system can be applied to solar hydrogen production and electricity generation at the same time and has the advantages of visible-light response, efficient hydrogen production and electricity generation, good stability and low cost. The visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system and the preparation method of the system have an important significance in developing the solar hydrogen production and electricity generation technology.

Owner:SHANGHAI JIAO TONG UNIV

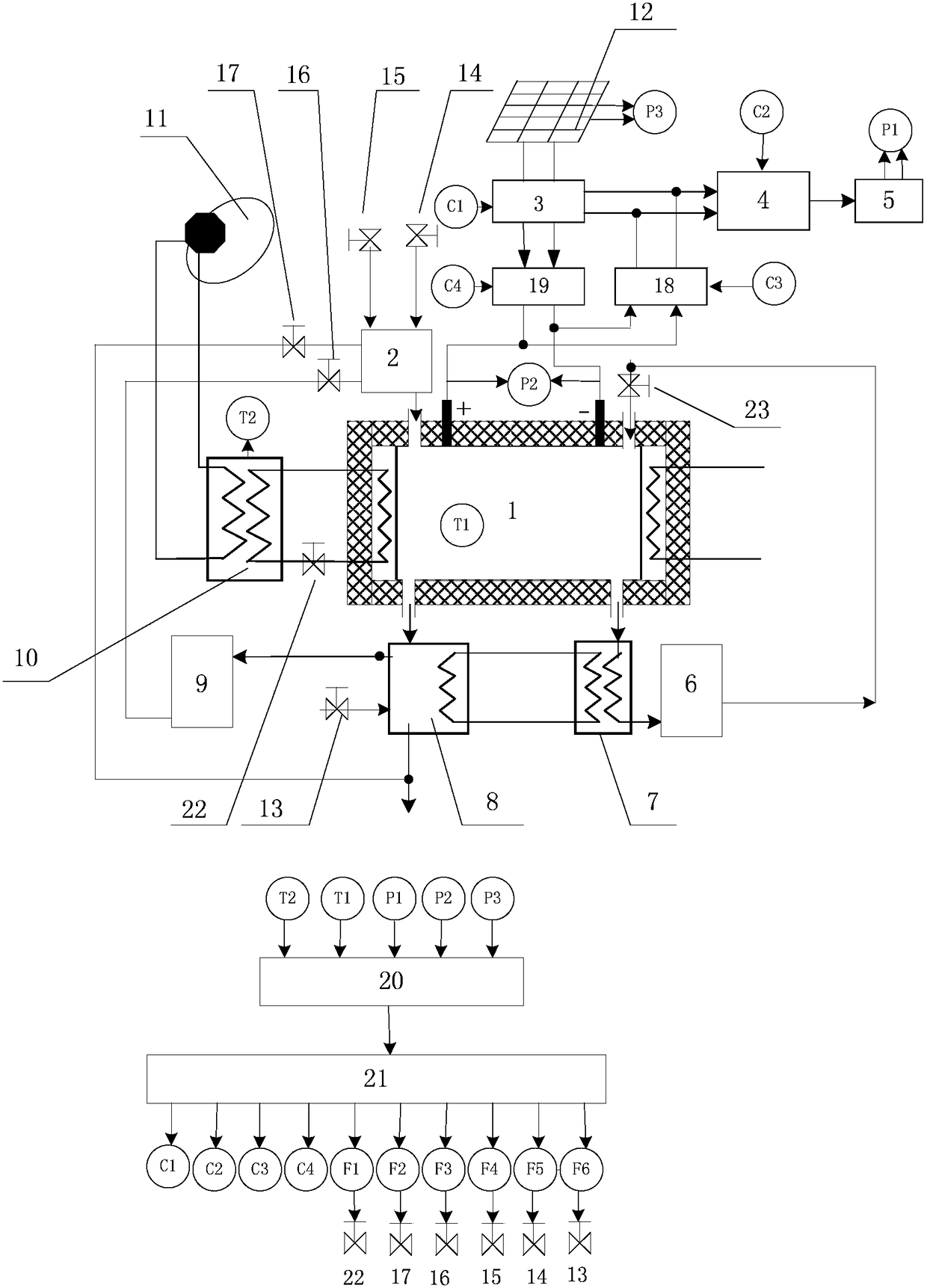

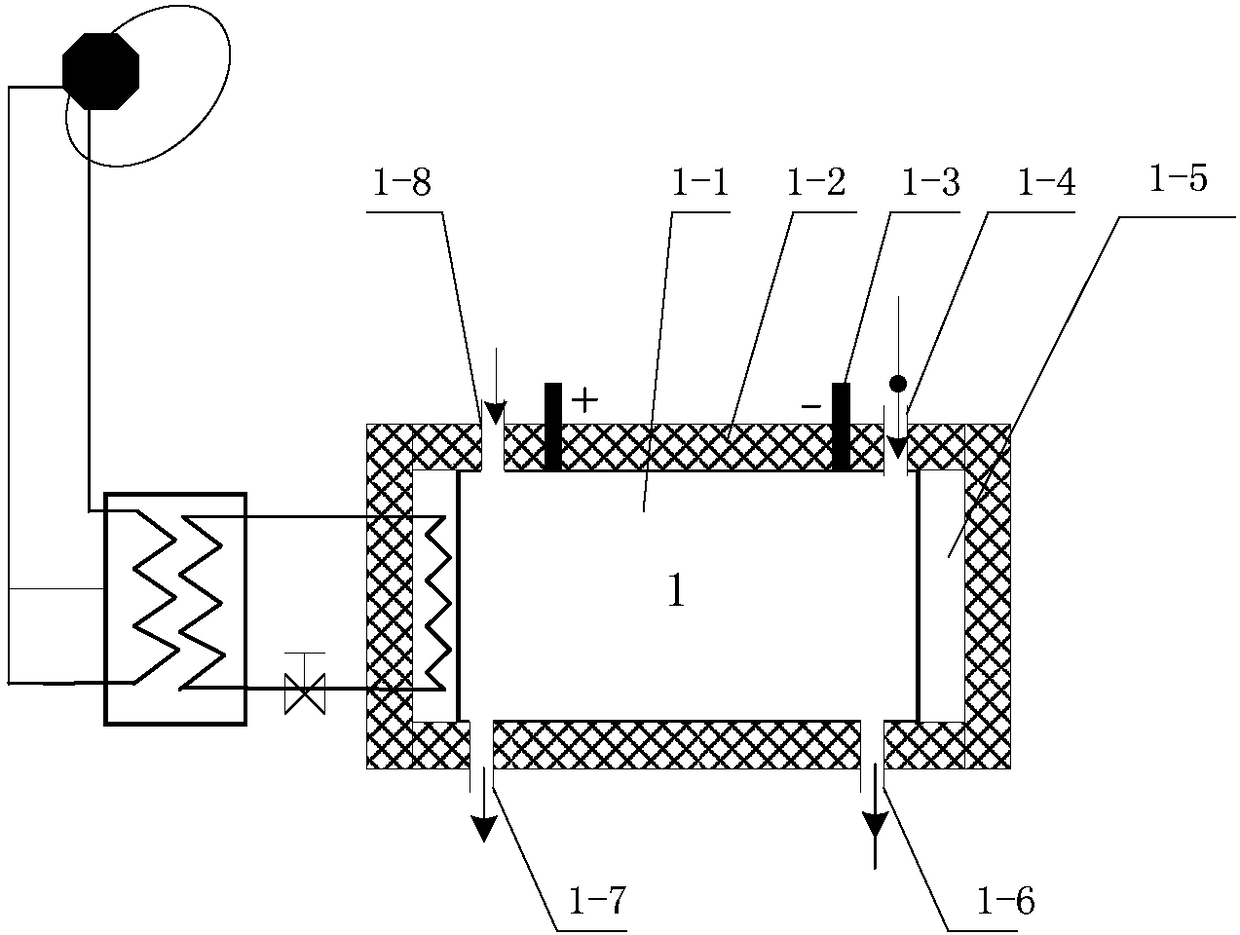

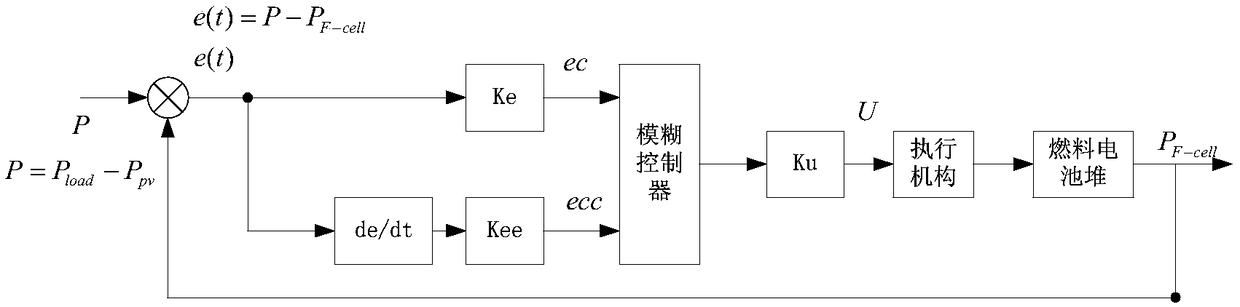

System and method for intelligently controlling thermoelectric energy of reversible high-temperature SOFC

ActiveCN108134113ARealize the purpose of energy storageContinuous power supply systemFuel cell heat exchangeReactant parameters controlNew energyWater source

The invention discloses a system and a method for intelligently controlling the thermoelectric energy of a reversible high-temperature SOFC (solid oxide fuel cell). The system comprises a fuel cell stack, a power supply system, an energy circulation system, a water supply system, a solar energy system, an oxidant circulation system and a control system; the power supply system supplies electric energy to the whole system, and the energy circulation system delivers a fuel to the fuel cell stack, generates electricity under the control of the control system, and controls the reversible processof the SOFC to realize the energy conversion of remaining electric energy; the water supply system supplies a water source to the system; the solar energy system is connected with the fuel cell stack;and the oxidant circulation system supplies an oxidant to the system. The method controls the working state and the output power of the SOFC mainly through a fuzzy control technology. The system andthe method realize SOFC and solar photovoltaic combined power generation, form the continuous, stable and reliable power supply system, and realizes the high-efficiency hydrogen production of the remaining electric energy through controlling the reversible process of the SOFC in order to achieve the purpose of new energy storage.

Owner:何嘉伟

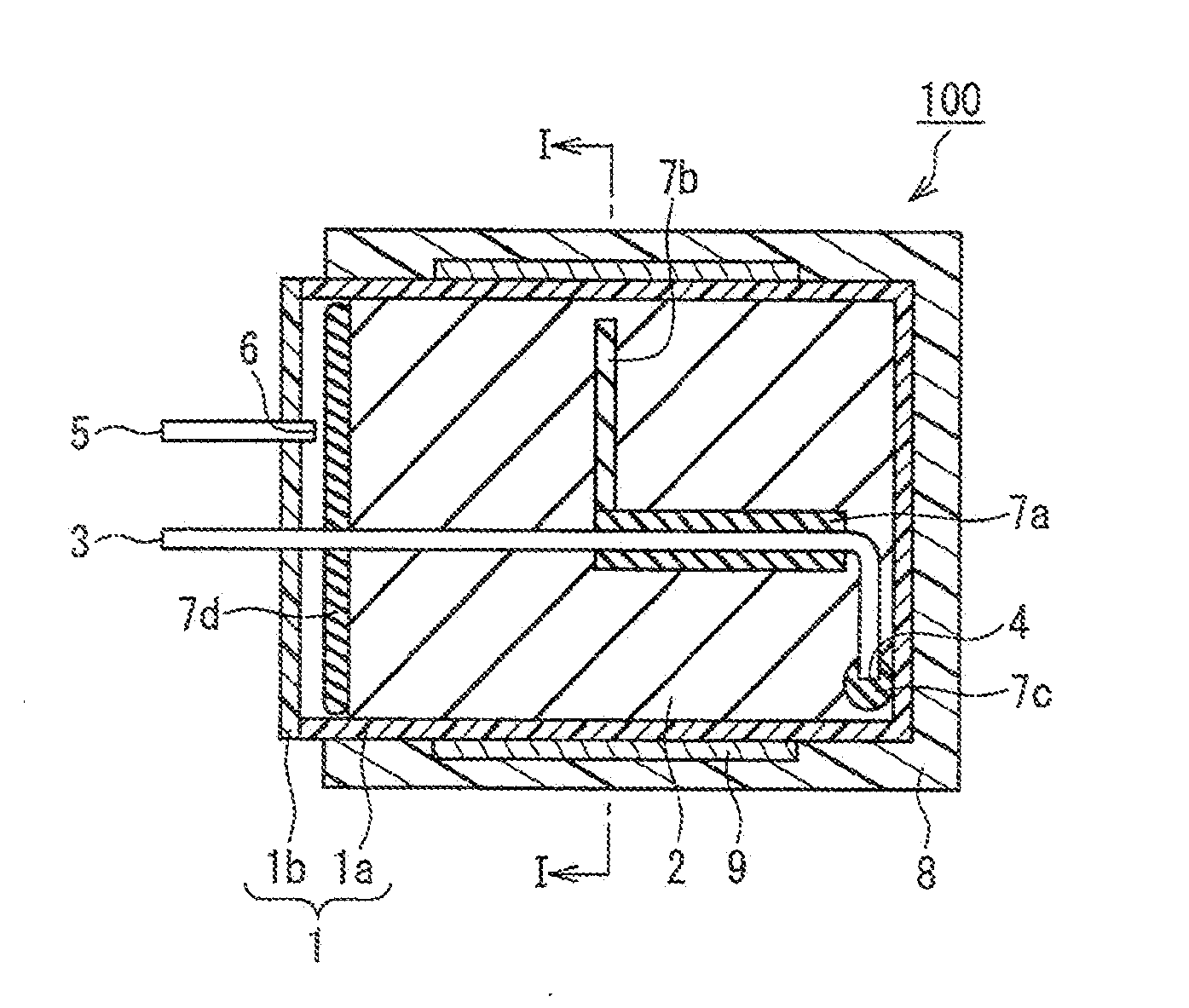

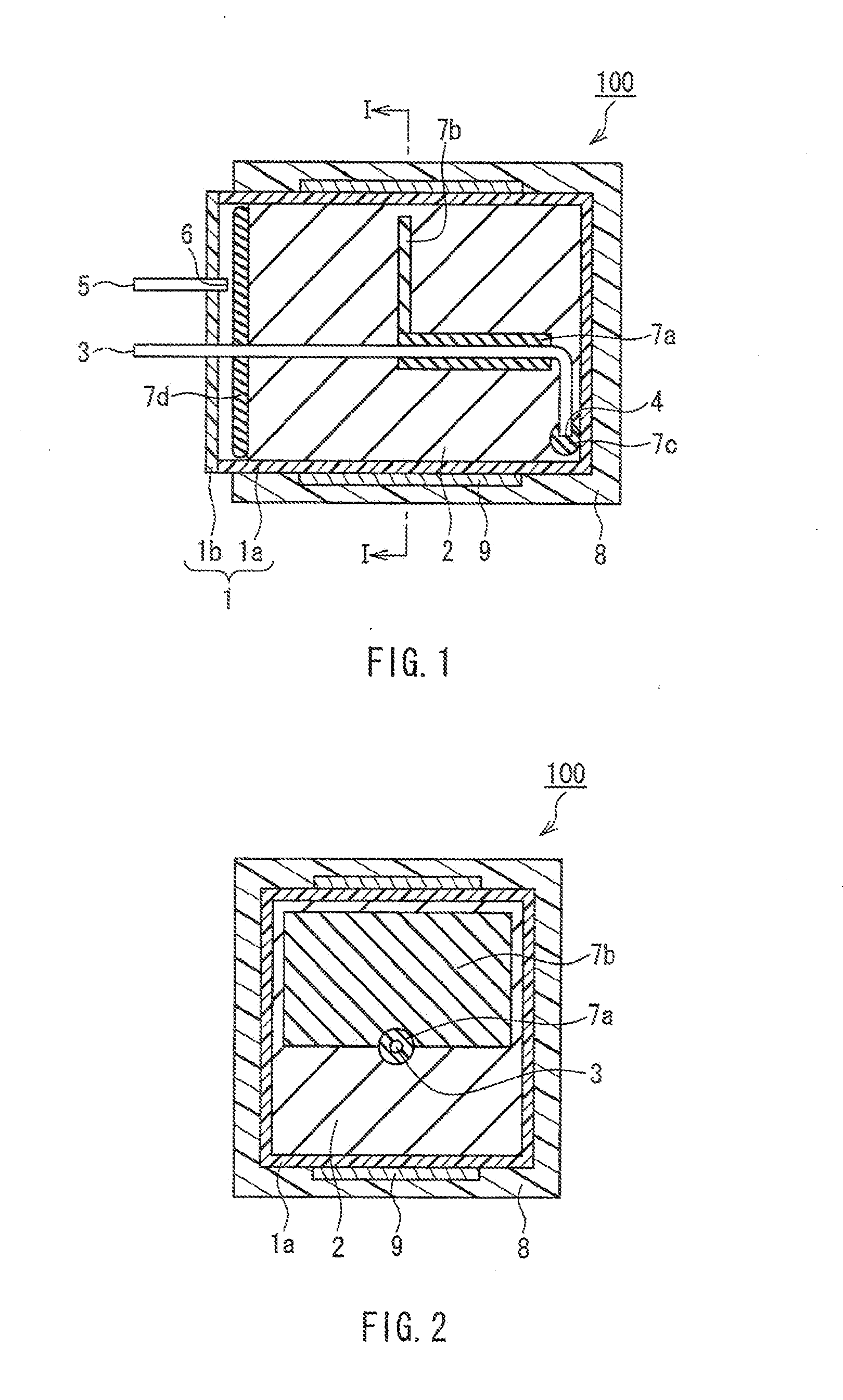

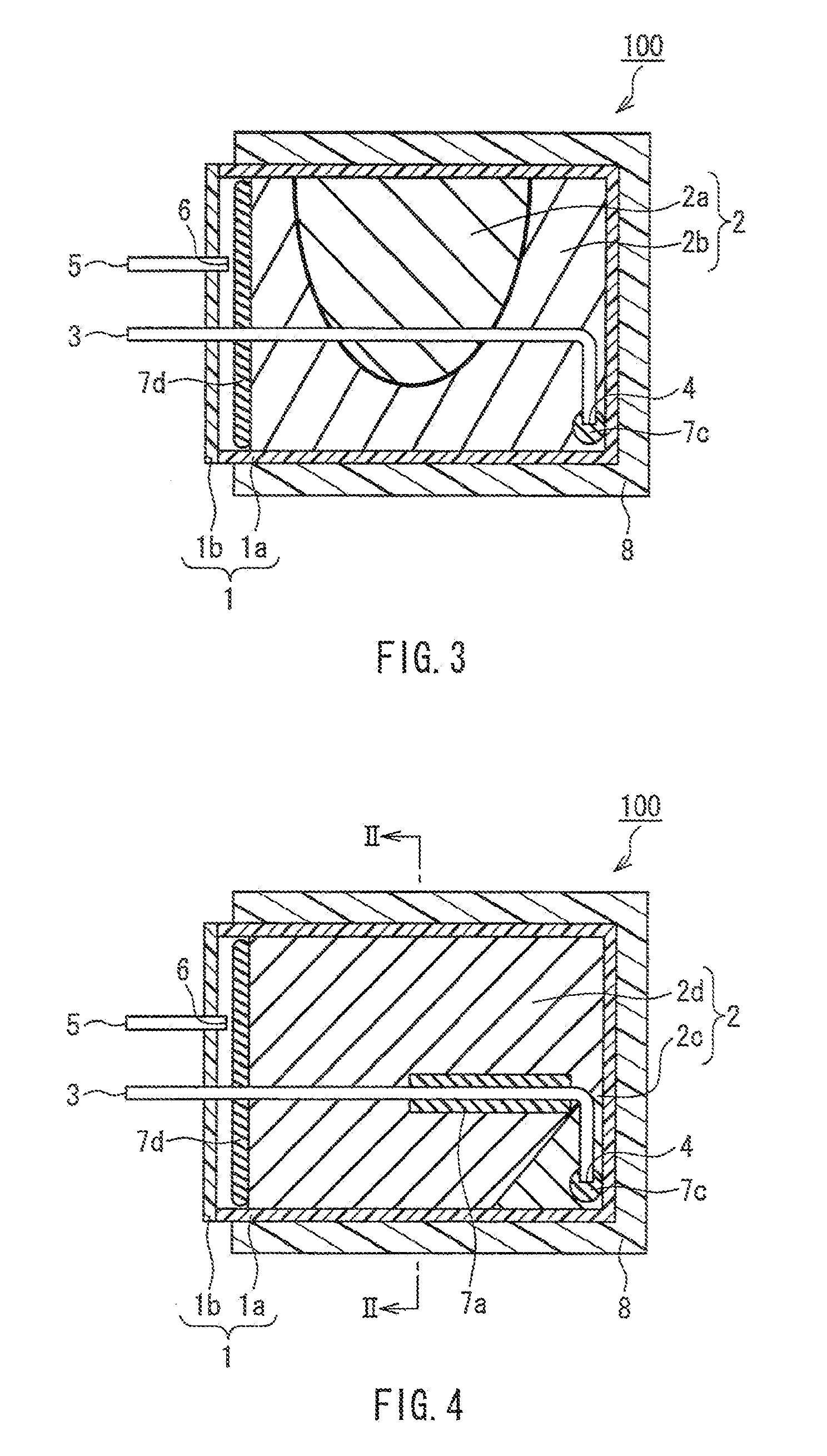

Hydrogen generator

InactiveUS20110008216A1Simple wayGenerate efficientlyReactant parameters controlTransportation and packagingHydrogenMarine engineering

A hydrogen generator of the present invention has a vessel for containing a hydrogen generating material including a metallic material for generating hydrogen by an exothermic reaction with water. The vessel includes a water supply pipe for supplying water into the vessel and a hydrogen outlet for discharging hydrogen generated in the vessel to the outside of the vessel. In the hydrogen generator, a wall surface of the vessel facing the hydrogen outlet is set as a reference plane, a water supply port at the end of the water supply pipe disposed inside the vessel is disposed in the vicinity of the reference plane, the water supply pipe includes a perpendicular portion extending from the vicinity of the center of the reference plane in a direction perpendicular to the reference plane, and a water absorbent is disposed on the periphery of the perpendicular portion of the water supply pipe and not disposed on a portion of 15% or more of an effective length of the perpendicular portion on the hydrogen outlet side.

Owner:HITACHI MAXELL ENERGY LTD

Metal deposition using potassium iodide for photocatalysts preparation

InactiveUS20170312744A1Efficient productionSmall particlesCatalyst activation/preparationHydrogen productionElectrically conductivePotassium iodine

Photocatalysts and methods of using photocatalysts for producing hydrogen and oxygen from water are disclosed. The photocatalysts include an iodide modified photoactive material having an electrically conductive material attached to the iodide ions.

Owner:SABIC GLOBAL TECH BV

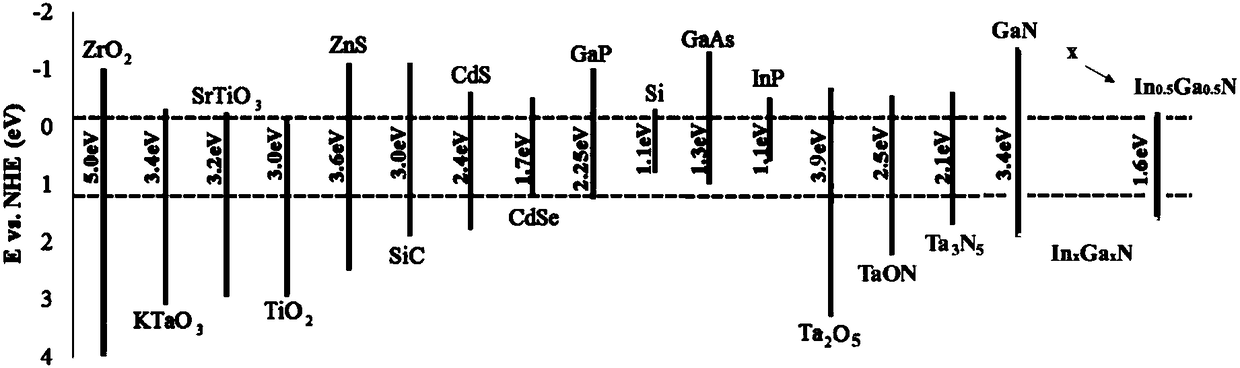

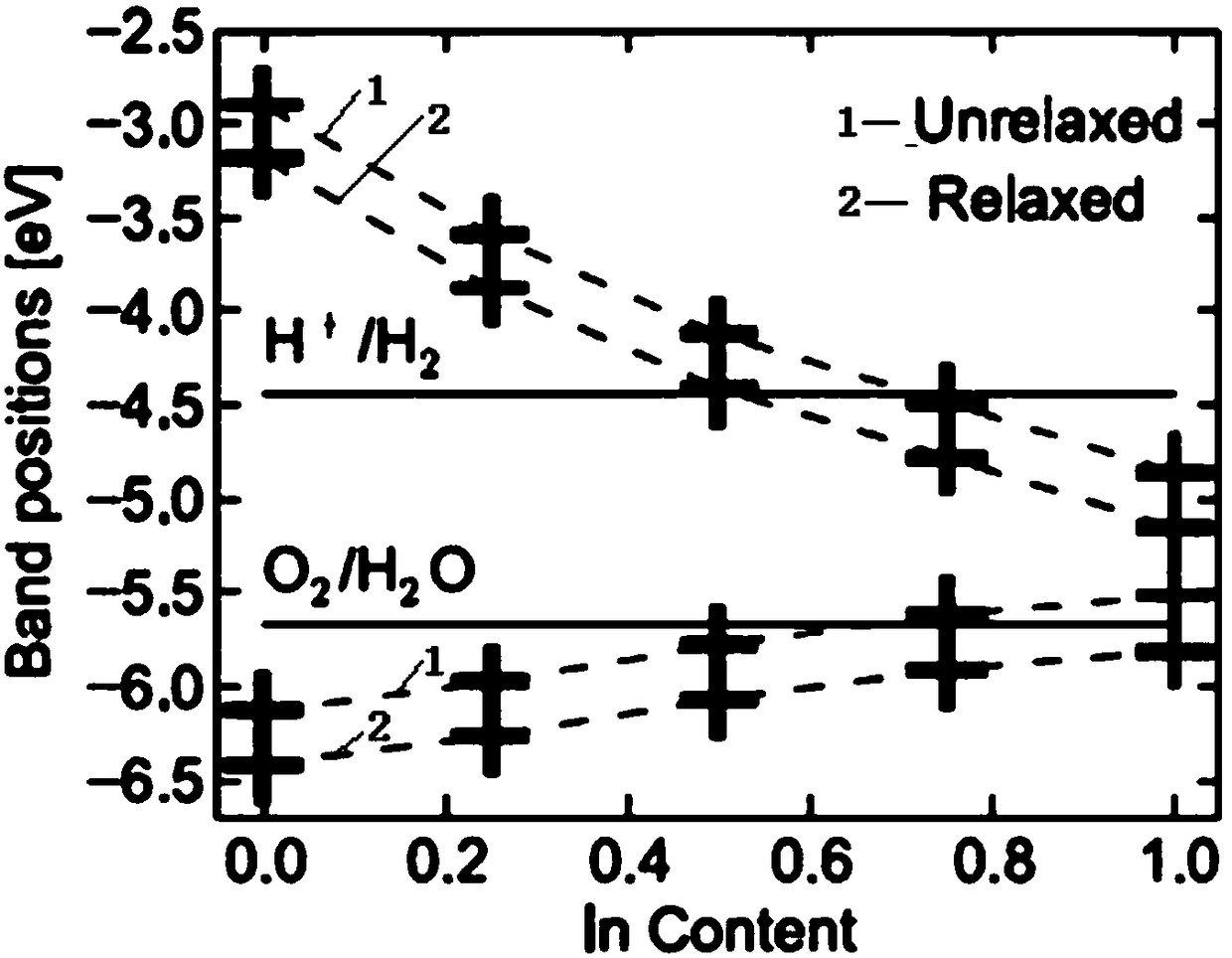

Photoelectrode with growth of InxGa1-xN nanowires on tantalum substrate and preparation method of photoelectrode

ActiveCN108193230AStrong light corrosion resistanceHas the function of photo-splitting water to produce hydrogenCatalyst activation/preparationElectrodesNanowirePhotocatalytic degradation

The invention discloses a photoelectrode with growth of InxGa1-xN nanowires on a tantalum substrate. The photoelectrode comprises the Ta substrate, an intermediate layer and an InxGa1-xN nanowire layer, wherein the x is equal to 0.05-0.5, the intermediate layer comprises Ta nitride, is formed between the Ta substrate and the InxGa1-xN nanowire layer, and is matched with the energy level of the InxGa1-xN nanowire layer. A preparation method comprises the steps that a tantalum sheet is subjected to pretreatment through an anodic oxidation method in combination with a high-temperature ammoniationmethod to form the intermediate layer, and then a VLS-CVD method is adopted to make the InxGa1-xN nanowires grow on the treated tantalum sheet. According to the designed photoelectrode with a Ta / (Ta2N / TaN / TaN5) / InxGa1-xN nanowire structure, the intermediate layer matched with the energy level is constructed, so that efficiency of the photocatalytic decomposition water hydrogen production and thephotocatalytic degradation of organic pollutants in water is greatly improved, moreover, the method is simple, and an important application prospect in the aspect of solving the energy and environmentproblems is achieved.

Owner:XIAMEN UNIV OF TECH

Catalyst for production of hydrogen and process for producing hydrogen using the catalyst, and catalyst for combustion of ammonia, process for producing the catalyst and process for combusting ammonia using the catalyst

InactiveUS8962518B2Cheap and practical catalystEfficient productionHeterogenous catalyst chemical elementsCatalyst activation/preparationHydrogenCombustion

Disclosed is a catalyst which can be used in the process for producing hydrogen by decomposing ammonia, can generate heat efficiently in the interior of a reactor without requiring excessive heating the reactor externally, and can decompose ammonia efficiently and steadily by utilizing the heat to produce hydrogen. Also disclosed is a technique for producing hydrogen by decomposing ammonia efficiently utilizing the catalyst. Specifically disclosed is a catalyst for use in the production of hydrogen, which is characterized by comprising an ammonia-combusting catalytic component and an ammonia-decomposing catalytic component. Also specifically disclosed is a catalyst for use in the production of hydrogen, which is characterized by comprising at least one metal element selected from the group consisting of cobalt, iron, nickel and molybdenum.

Owner:NIPPON SHOKUBAI CO LTD

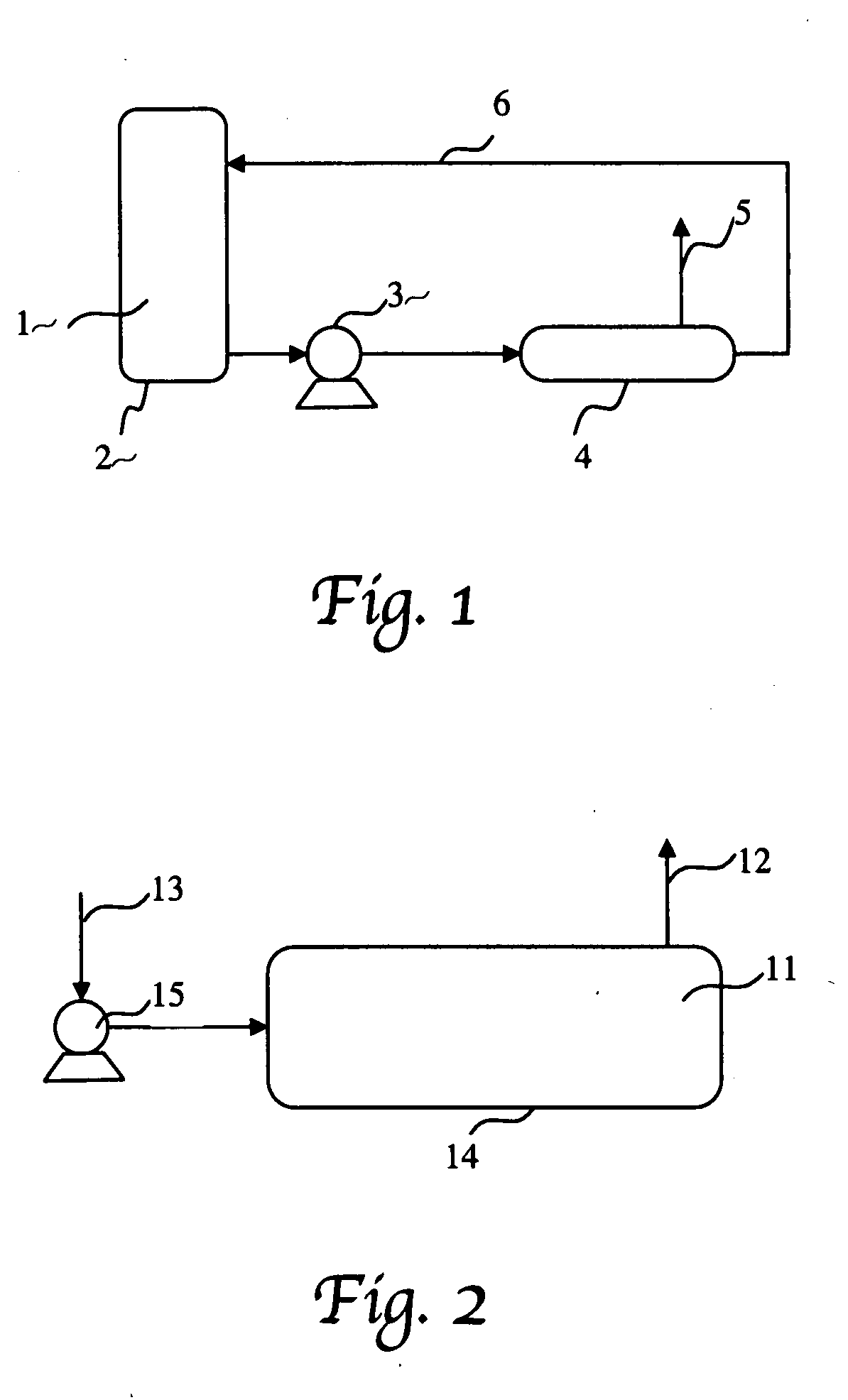

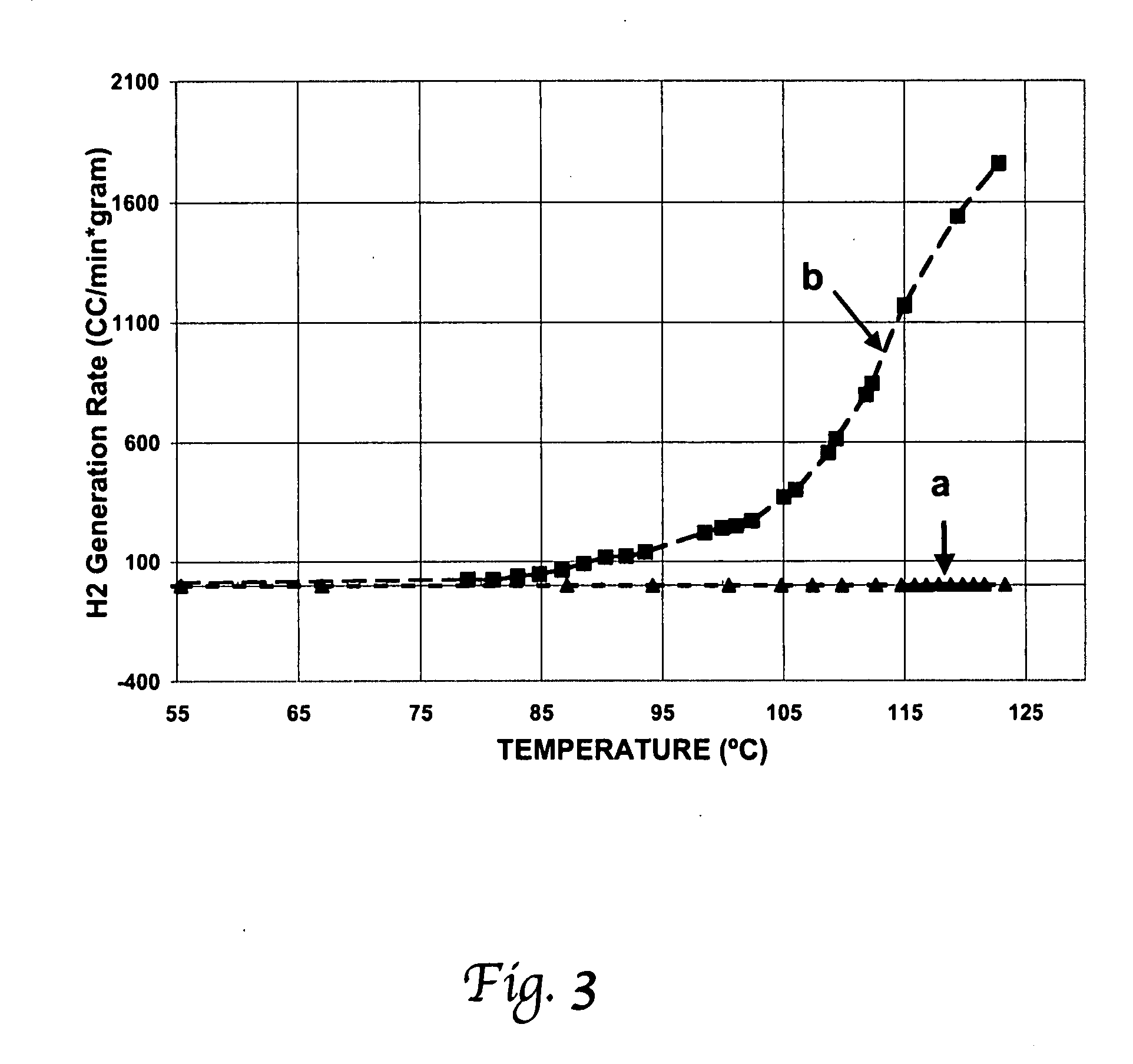

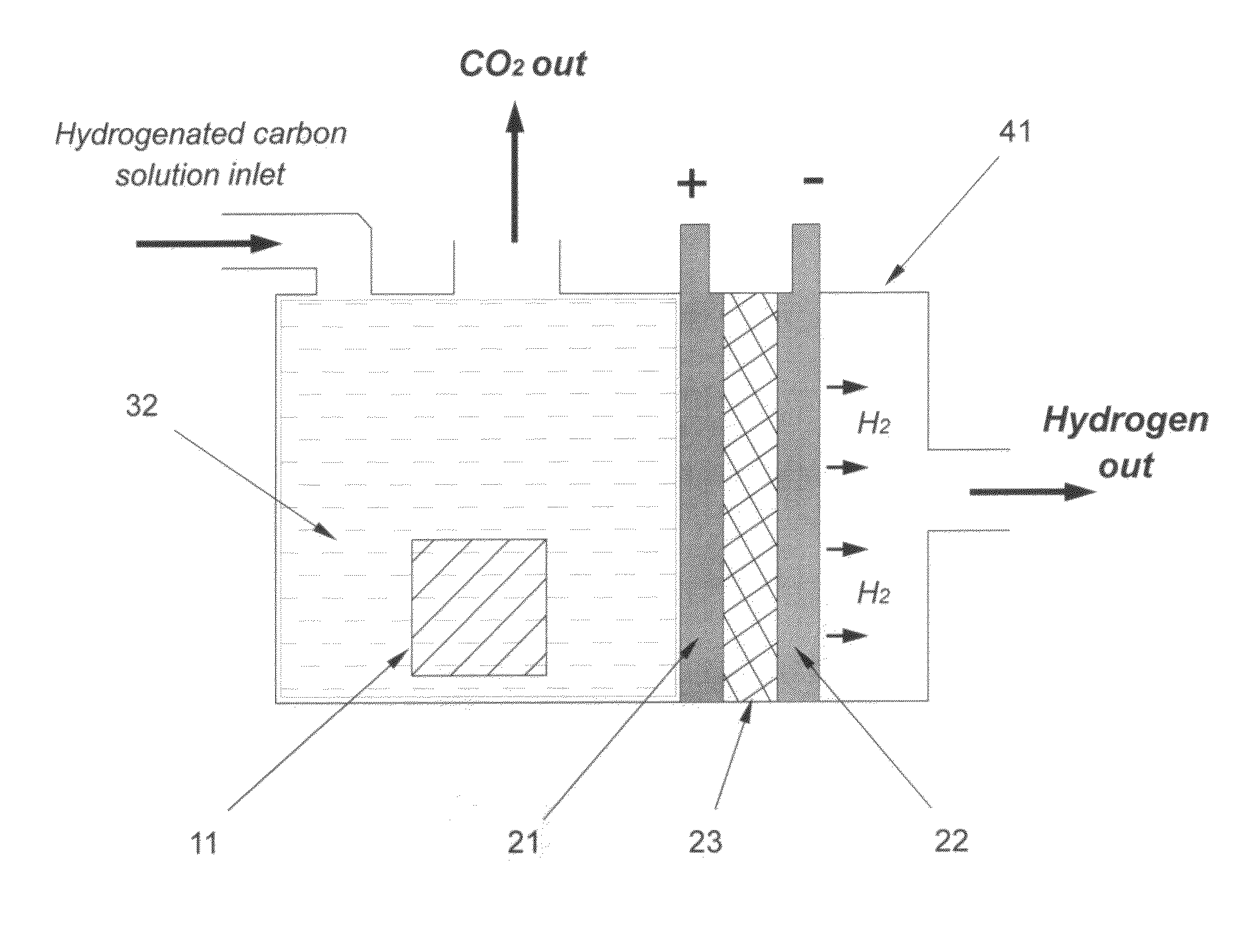

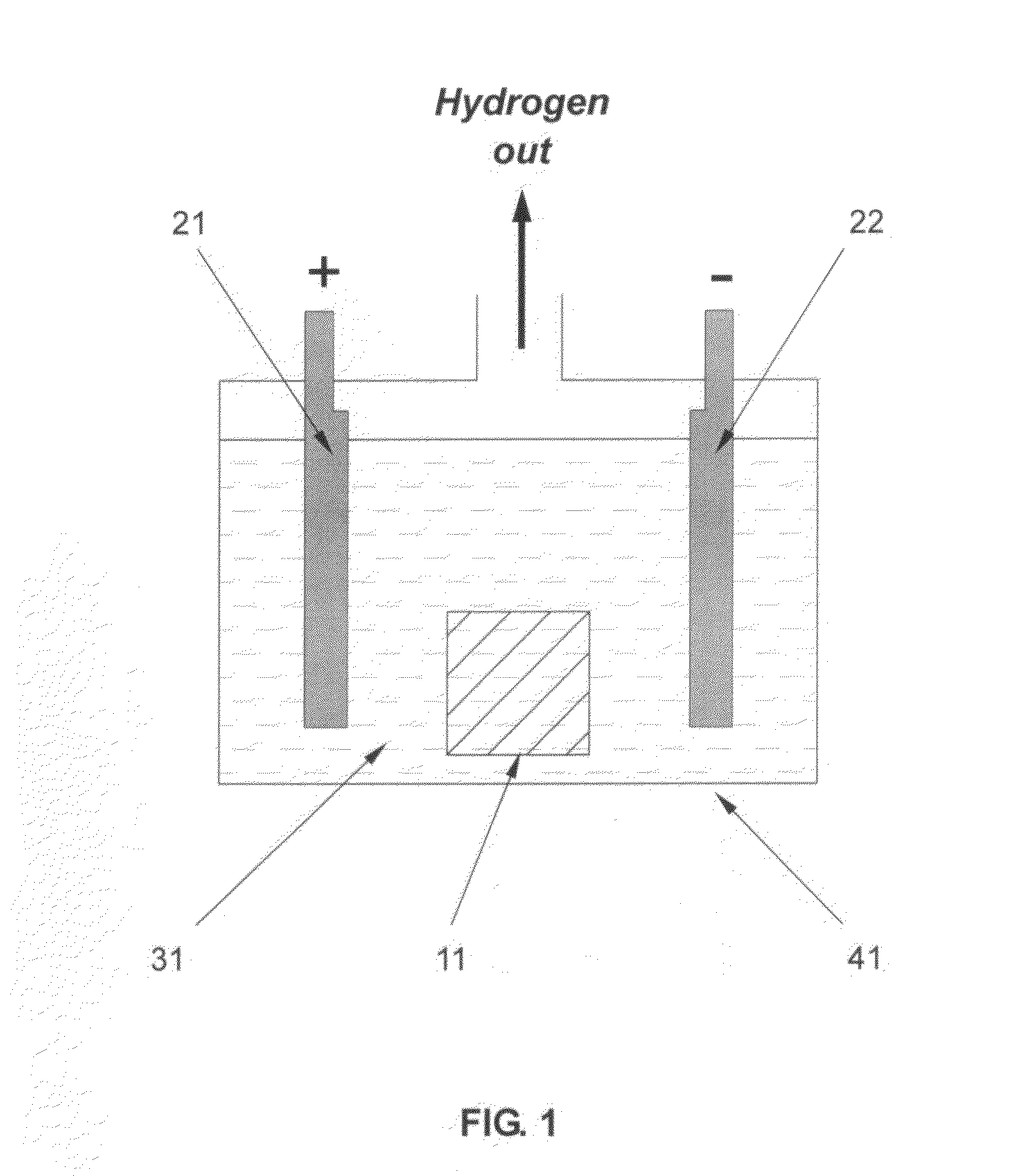

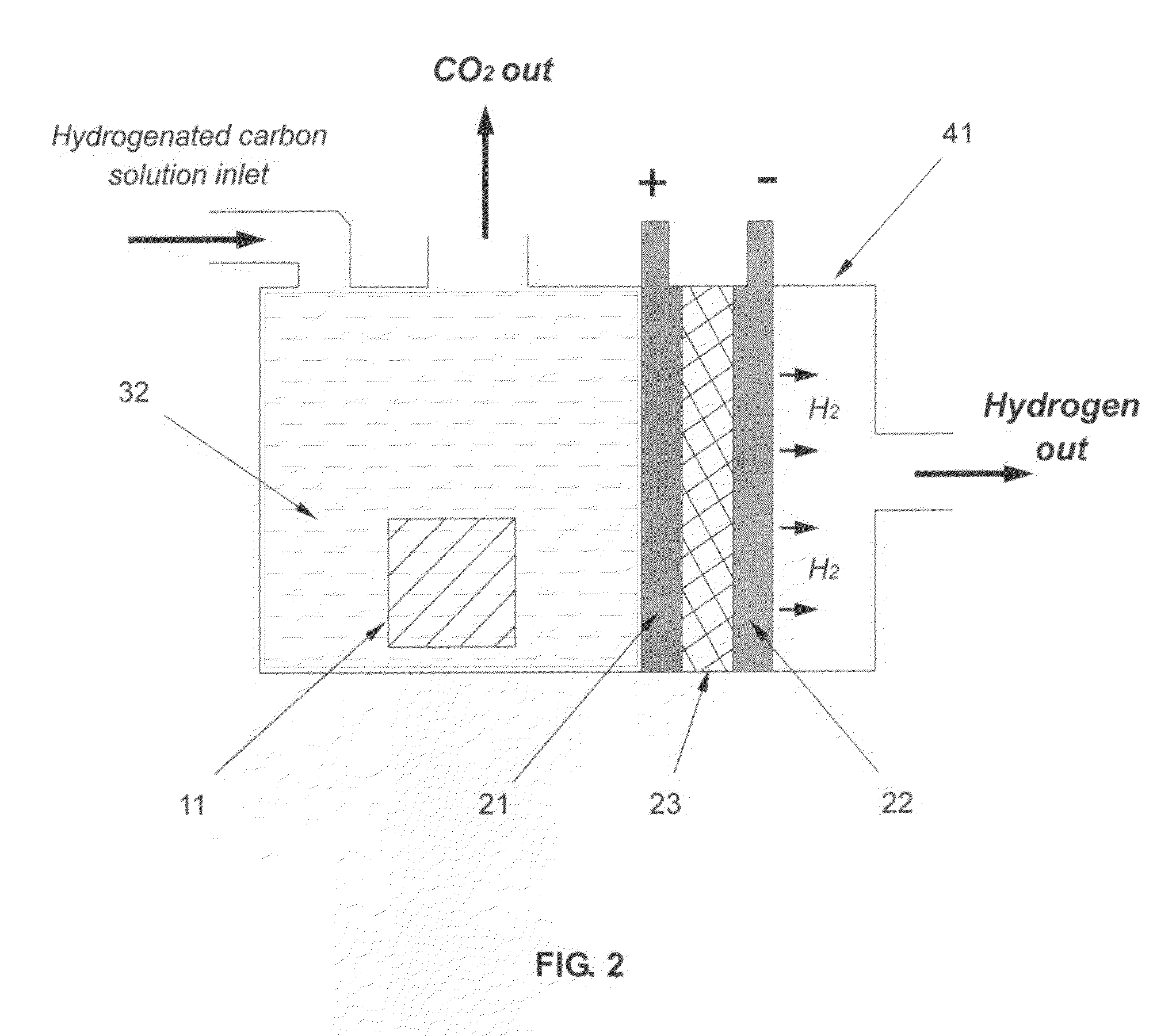

Infrared assisted hydrogen generation

ActiveUS20120061232A1Efficient hydrogen productionImprove hydrogen production efficiencyCellsHydrogen productionChemistryCeramic

This invention relates to a system and a method for achieving efficient production of hydrogen in a hydrogen generator, comprising at least a hydrogen generator, a liquid in said hydrogen generator to produce hydrogen from, and a ceramic that emits infrared at wavelengths covering at least a portion of 3-20 micrometers range so that said liquid can be excited with infrared at said wavelengths before or during the production of hydrogen for improved hydrogen production efficiency. The use of infrared-excited electrolyte solution in a hydrogen generator helps reduce the energy consumption, lower operating voltage, and thus reduce the cost of the production of hydrogen.

Owner:ALDI FAR IR PROD INC

Preparation method and application of cerium oxide loaded nickel catalyst

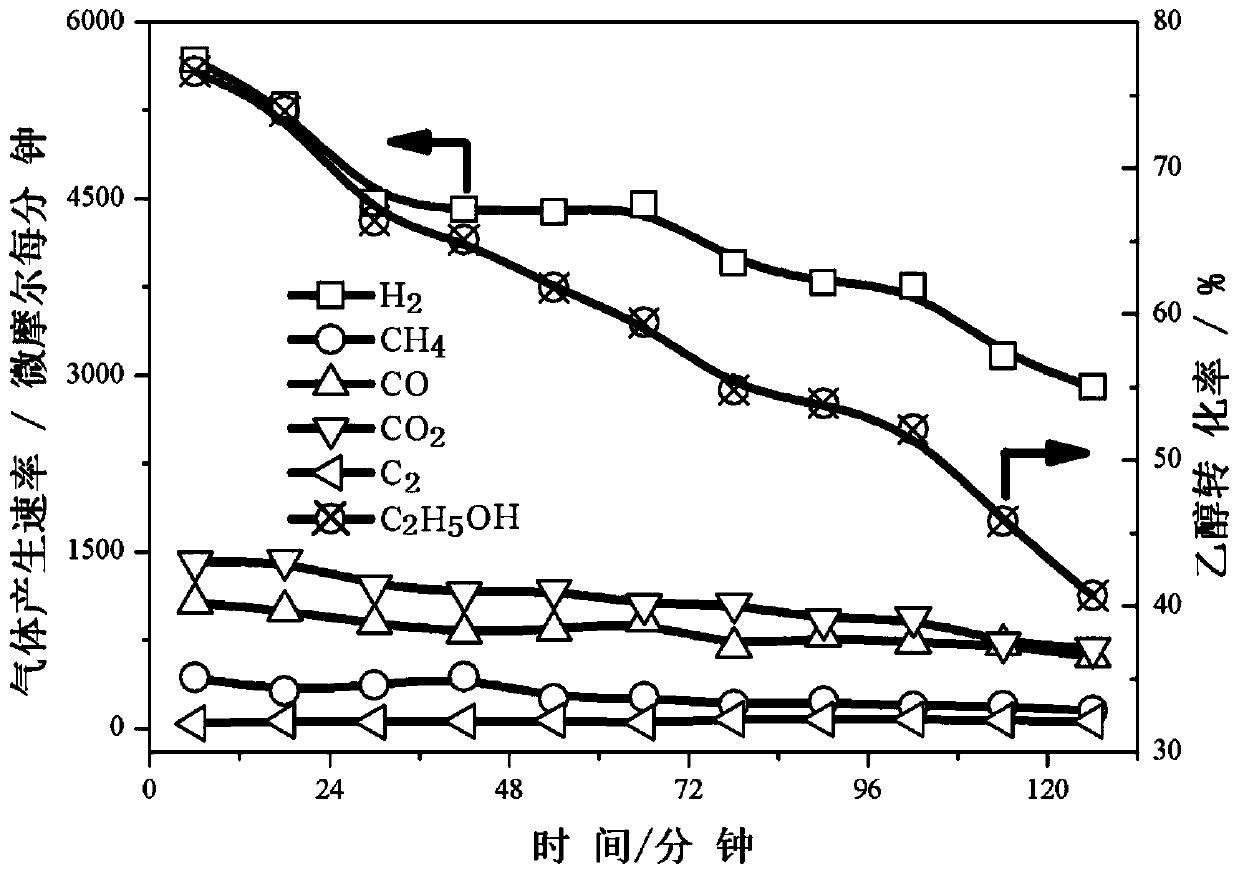

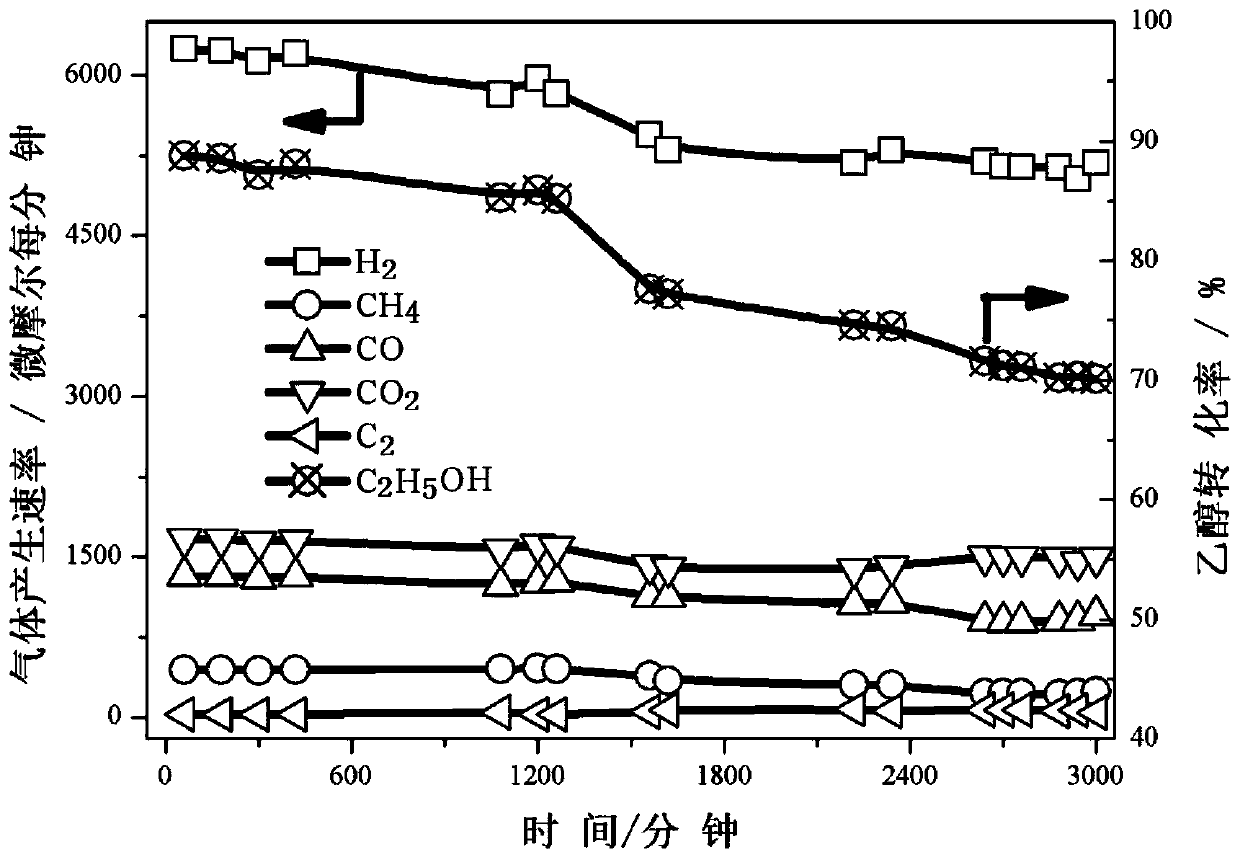

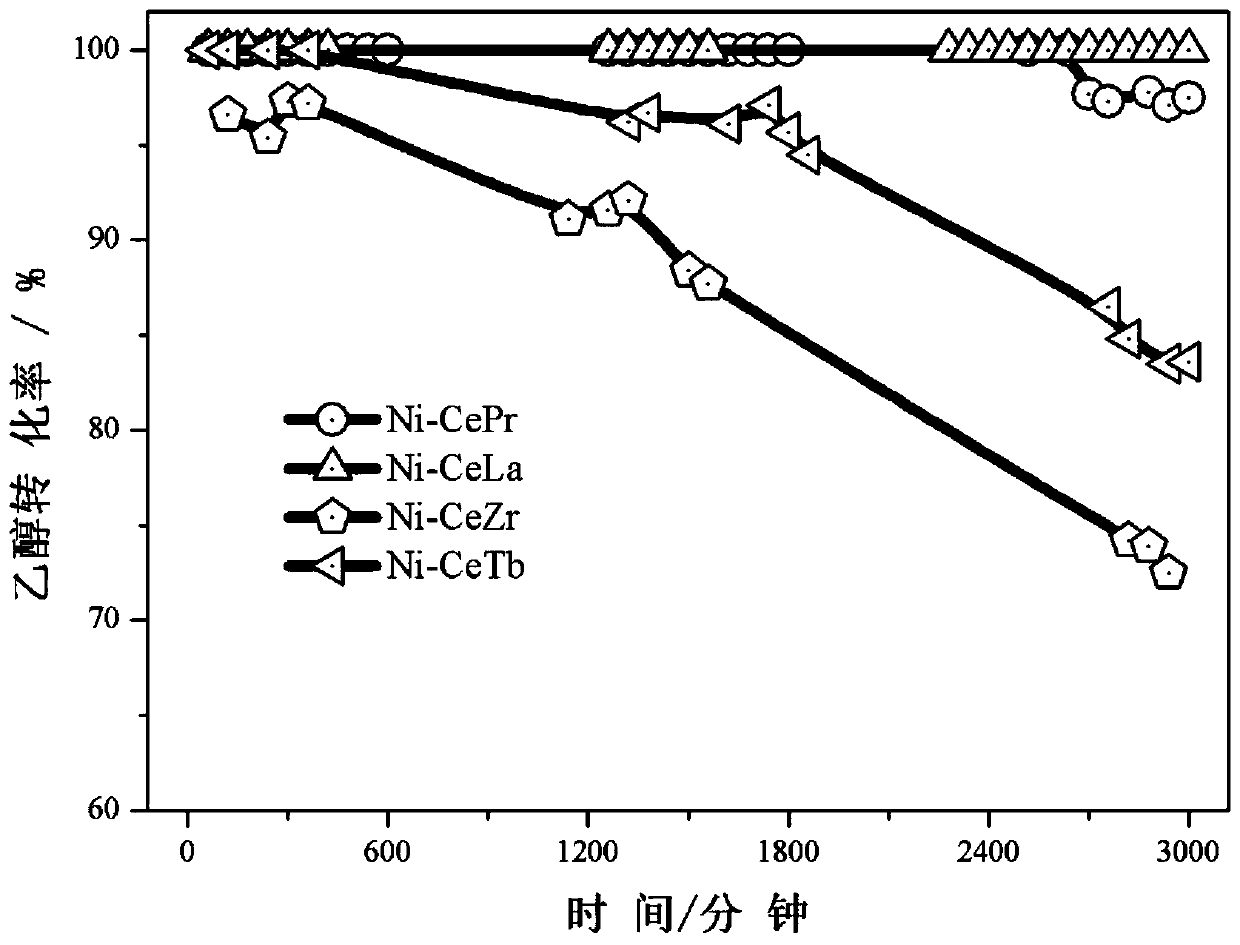

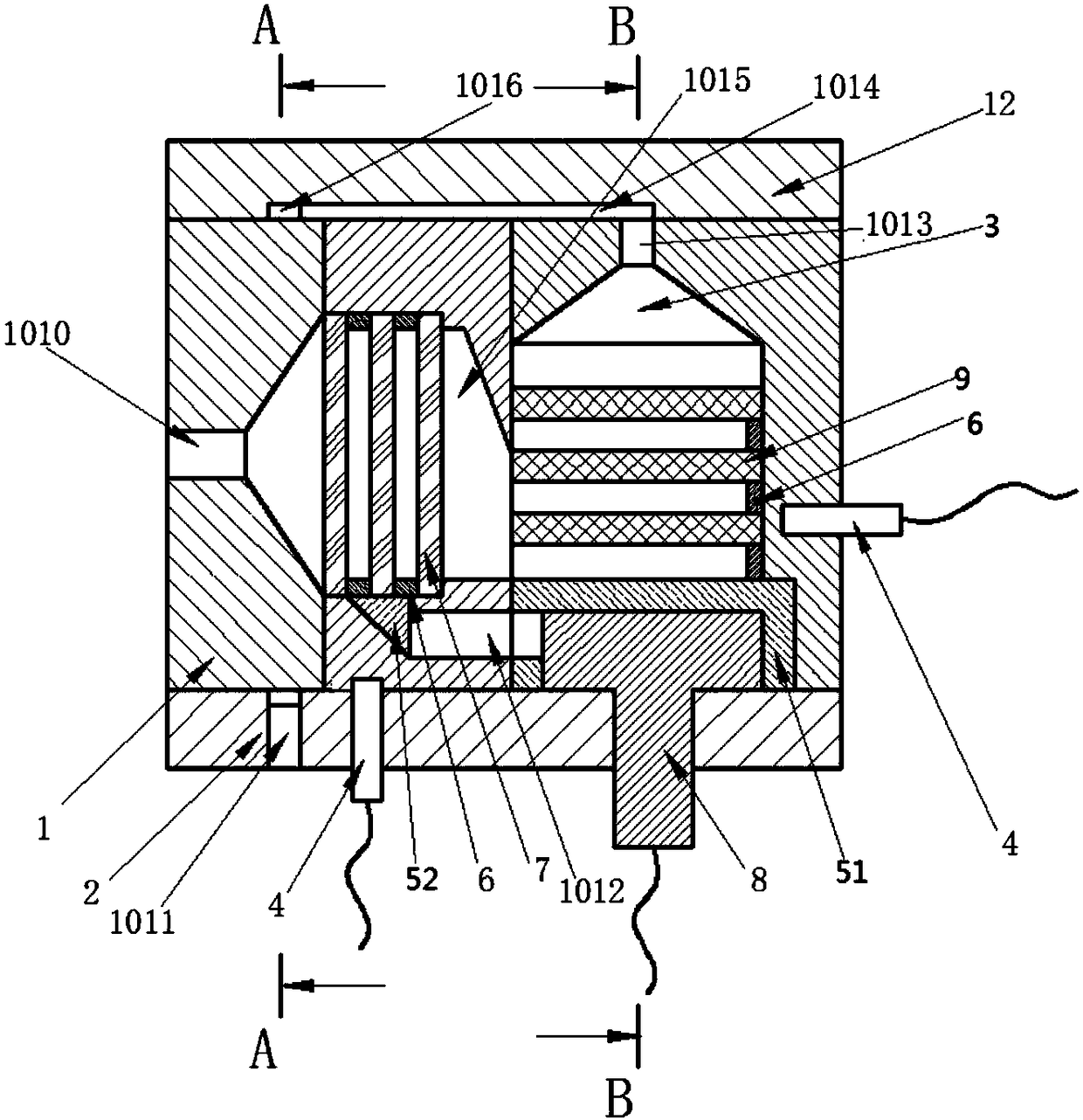

InactiveCN111389404AGood dispersionInhibition formationHydrogenHeterogenous catalyst chemical elementsSteam reformingHydration reaction

The invention discloses a preparation method of a cerium oxide loaded nickel catalyst. Cerium oxide serves as a carrier and nickel serves as an active component. The method includes: weighing cerium nitrate hexahydrate, nickel nitrate and citric acid, performing stirring, mixing and dissolving in water, then evaporating water to form a gel, and performing drying to obtain solid foam, grinding thesolid foam, performing roasting, and conducting cooling to obtain cerium oxide loaded nickel oxide, and performing reduction to obtain the cerium oxide loaded nickel catalyst. The invention also discloses a preparation method of a rare earth element doped cerium oxide loaded nickel catalyst and application of the two catalysts in hydrogen production from ethanol vapor. The catalysts prepared according to the invention can efficiently convert ethanol under the conditions of high ethanol feed, a low water-carbon ratio and a low reaction temperature, and can achieve stable hydrogen prodution. Thehydrogen production by ethanol steam reforming can achieve efficient hydrogen production under the conditions of low temperature, low water-carbon ratio and high ethanol feed.

Owner:TIANJIN UNIV

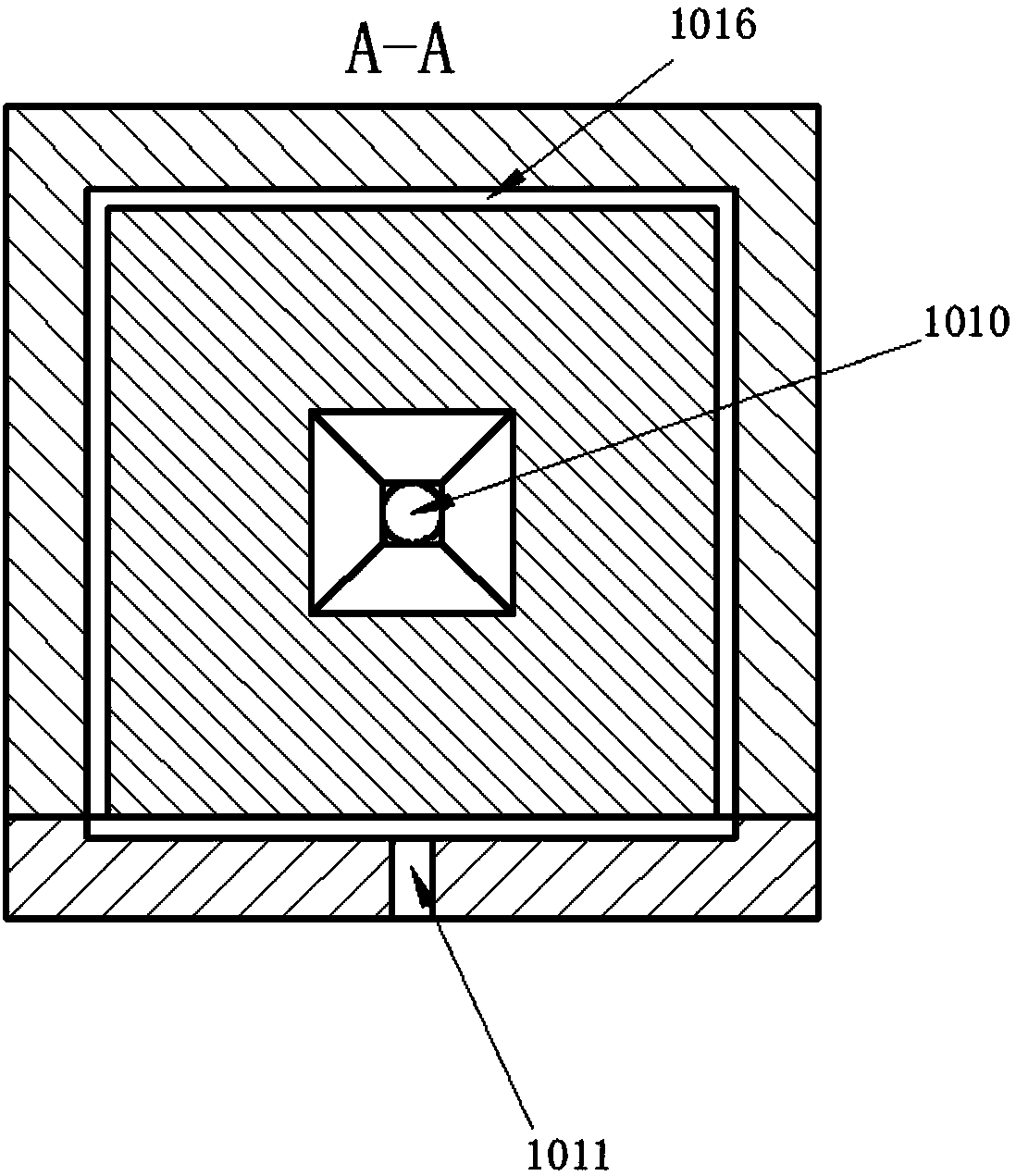

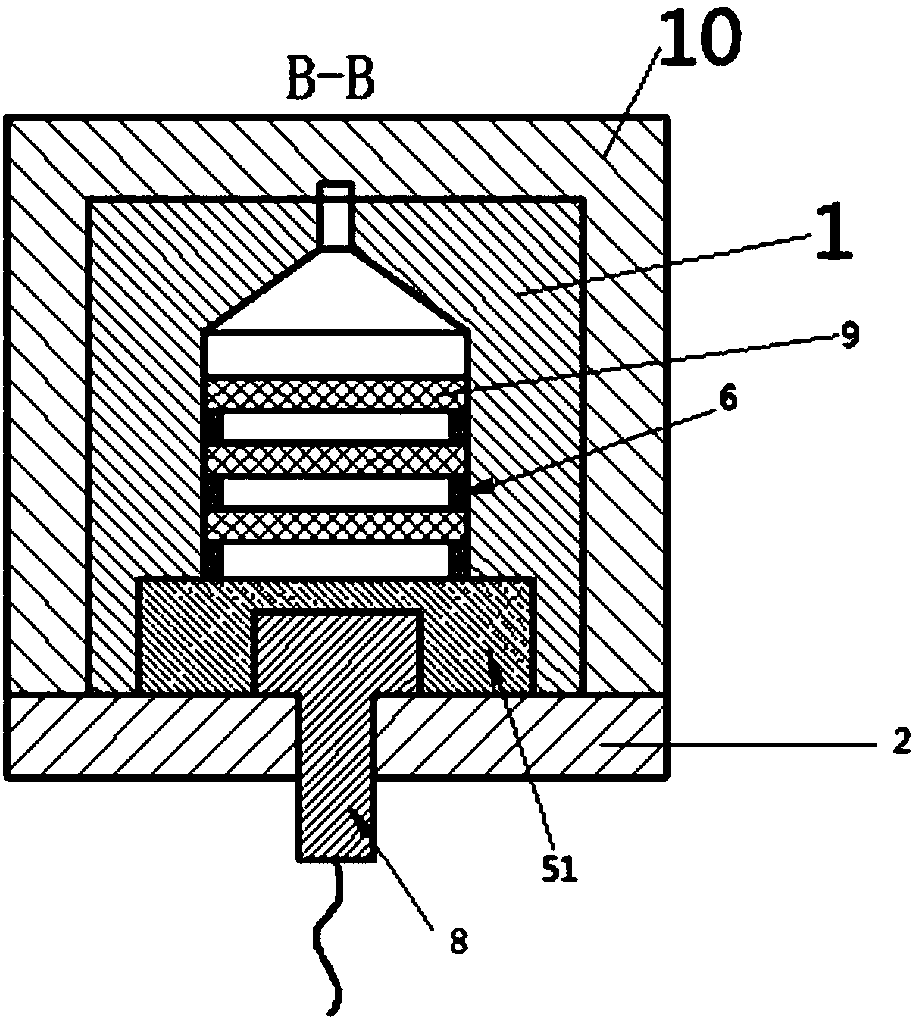

Micro-channel reactor

ActiveCN109078590AHeating evenlyEfficient use ofHydrogenChemical/physical/physico-chemical processesMethanol waterInsulation layer

The invention relates to the field of methanol water steam hydrogen production by reforming, and discloses a micro-channel reactor. The micro-channel reactor comprises a reactor body, a U-shaped heat-insulation layer and a bottom plate, wherein a unit comprising a feeding channel, an evaporation cavity, a reforming cavity, a gas outlet channel and a microwave generation cavity is formed in the cavity of the reactor body; the tail end of the feeding channel successively communicates with the evaporation cavity and the reforming cavity; the gas outlet channel is formed in the top of the reforming cavity; a microwave generator is arranged in the microwave generation cavity, and is arranged on the lower portion of the reactor body; the U-shaped heat-insulation layer is arranged on the outsideof the reactor body to wrap the top surface and the two side surfaces of the reactor body; and the bottom plate is arranged on the bottom of the reactor body, and is connected with the U-shaped heat-insulation layer. The micro-channel reactor has the advantages of high energy utilization rate, low manufacturing cost and uniform heating.

Owner:CHINA PETROLEUM & CHEM CORP +1

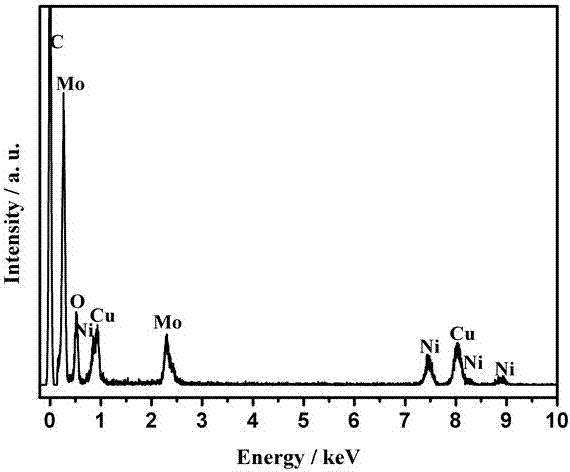

Non-noble metal catalyst used for N2H4BH3 complete hydrogen production, and preparation method thereof

ActiveCN106861708AExcellent performanceAbundant resourcesMetal/metal-oxides/metal-hydroxide catalystsNon noble metalNickel

The invention provides a non-noble metal catalyst used for N2H4BH3 complete hydrogen production, and a preparation method thereof. The non-noble metal catalyst is composed of non-noble metal copper, nickel, and molybdenum, and is prepared via simple and effective one-step reduction. According to the preparation method, sodium borohydride is taken as a reducing agent, and the non-noble metal catalyst is obtained via direct reduction of a mixed solution composed of a copper source, a nickel source, and a molybdenum source precursor at different ratio. The non-noble metal catalyst can be used for high efficiency catalyzing of boryl hydrolysis and hydrazino cracking of N2H4BH3 at 323K alkaline environment so as to realize complete hydrogen production, the transformation frequency (TOF) value is capable of reaching 108mol H2 mol metal<-1>h<-1>. The non-noble metal catalyst is simple to prepare, is low in cost, possesses high catalytic activity and stability, and is promising in development prospect.

Owner:JIANGXI NORMAL UNIVERSITY

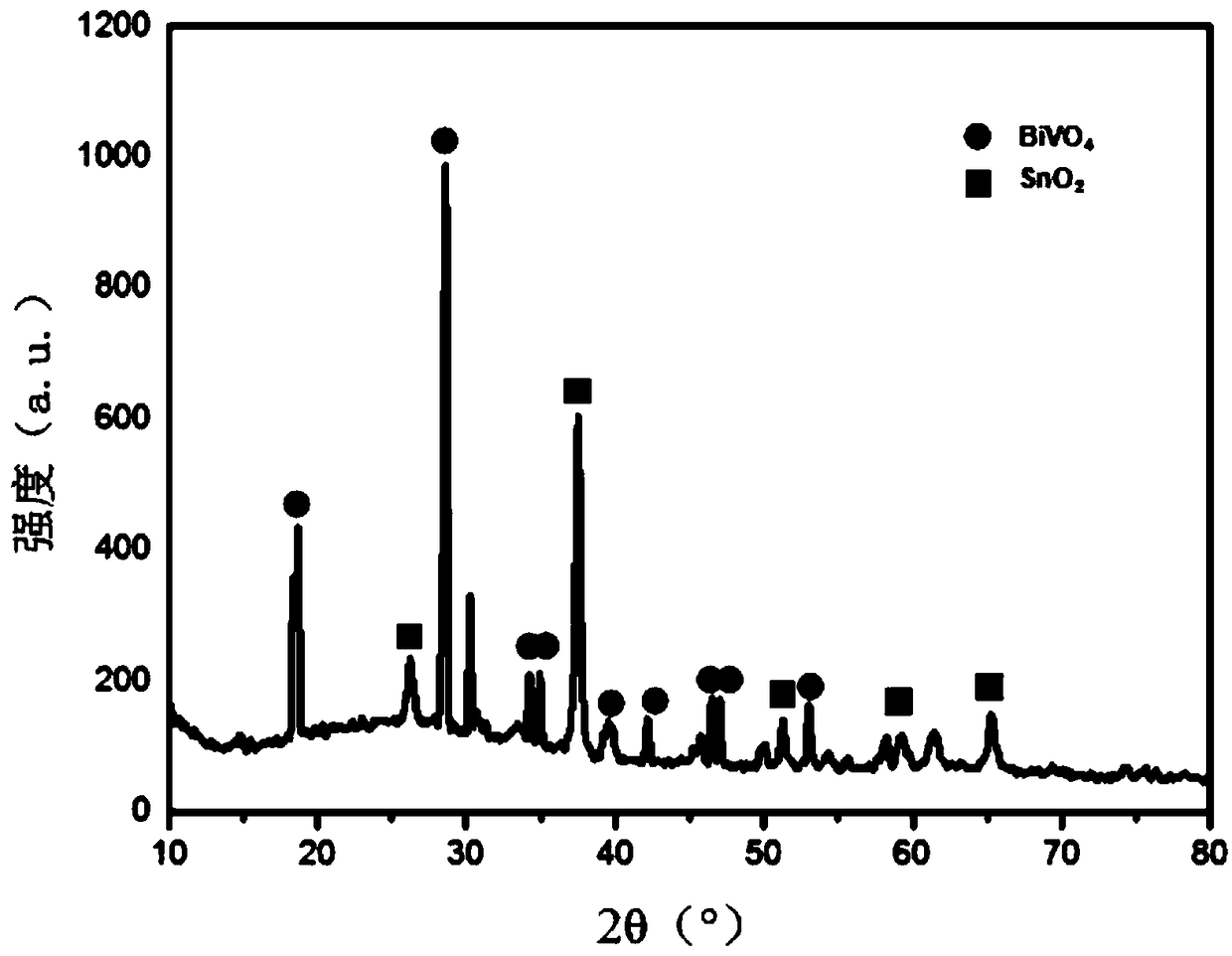

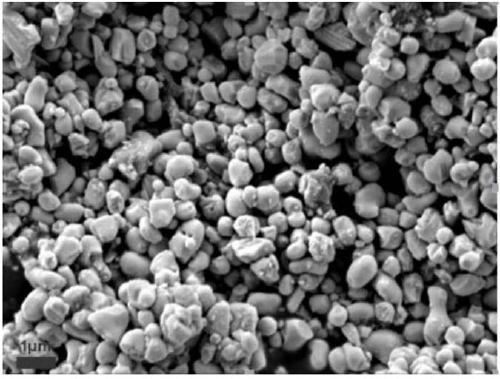

Method for treating wastewater and by-producing hydrogen by activating sulfate with photoanode

InactiveCN109133259ASolve processing problemsMild method conditionsWater/sewage treatment by irradiationWater treatment compoundsElectrolysisSulfate radicals

The invention relates to a method for treating wastewater and by-producing hydrogen by activating sulfate with a photoanode. The method comprises the steps as follows: a bismuth vanadate material is used as the photoanode and form a photoelectrocatalytic degradation system with a cathode material and a xenon lamp, wastewater in a photoelectrocatalysis reactor is subjected to photoelectrocatalyticdegradation, and sulfate is contained in the wastewater. Compared with the prior art, the method has the advantages that the bismuth vanadate material is used as the photoanode to produce an active oxidizing substance and matched with the cathode material to activate sulfate in the wastewater, sulfate radicals are produced to intensify the efficiency of photoelectrocatalytic degradation of pollutants in the wastewater, meanwhile, cathode electrolysis water is reduced to produce hydrogen, the hydrogen production performance is improved, and the method is convenient to operate and high in efficiency; the sulfate radicals are directly produced from the wastewater containing sulfate without addition of a PMS strong oxidizer, and the synergistic catalysis performance with hydroxyl radicals is substantially improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Three-chamber electrodialysis hydrogen production fermentation reactor and hydrogen production method

ActiveCN109294882AEfficient removalRealize separation and recoveryBioreactor/fermenter combinationsBiological substance pretreatmentsChemical industryVolatile fatty acids

The invention discloses a three-chamber electrodialysis hydrogen production fermentation reactor and a hydrogen production method. The three-chamber electrodialysis hydrogen production fermentation reactor includes: an anode chamber, a fermentation chamber, a cathode chamber, a cathode electrode, an anode electrode, an anion exchange membrane and a cation exchange membrane. The fermentation reactor is characterized in that: the cathode chamber and the fermentation chamber are separated by the cation exchange membrane; the anode chamber and the fermentation chamber are separated by the anion exchange membrane; the cathode electrode and the anode electrode are respectively disposed in the cathode chamber and anode chamber; and the cathode electrode and the anode electrode are inert graphiteelectrodes, the electrode surface area is the same as the ion exchange membrane surface area, the cathode electrode and the anode electrode are externally connected to a direct current power supply negative pole and positive pole respectively, the upper part of the cathode chamber is equipped with a first discharge and drain port, and the lower part is equipped with a first water inlet. The reactor provided by the invention can achieve effective removal and enrichment of ammonia nitrogen in high ammonia nitrogen organic wastewater and volatile fatty acids produced during fermentation, and canbe widely applied to biology, energy, chemical industry and other fields.

Owner:CHONGQING UNIV

Reaction device and method for hydrogen production by methane steam reforming

ActiveCN106517093ASimple structureReduced activityHydrogenHydrogen/synthetic gas productionSteam reformingHigh density

The invention provides a reaction device and a method for hydrogen production by methane steam reforming. The reaction device for hydrogen production by methane steam reforming is simple in structure, an adsorbent is regenerated regularly, a catalyst with the longer service life is not required to be frequently regenerated along with the adsorbent, and the energy consumption during regeneration is reduced and the reduction of the activity of the catalyst is avoided while the adsorption of the adsorbent can always meet the use requirement. A raw material flowing upwards makes countercurrent contact with the adsorbent lowing downwards, and the large-particle-size and high-density adsorbent cannot slide or be retained in a reactor and can be discharged from the bottom of the reactor timely and quickly; the raw material and the fixed catalyst can be fully contacted and react, produced CO2 is adsorbed by the adsorbent immediately, the chemical balance limitation is broken through, and the methane conversion rate is increased. The purity of obtained hydrogen is high, the hydrogen production efficiency is high, the cost is low, and the continuous, efficient and stable hydrogen production process can be realized.

Owner:SINOPEC ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com