Reaction device and method for hydrogen production by methane steam reforming

A technology for producing hydrogen from methane water vapor and reforming, which is applied in chemical instruments and methods, hydrogen, and bulk chemical production, etc., can solve the problem that the contact reaction between methane and water vapor and the catalyst cannot be guaranteed, and the methane conversion rate and product yield are affected. , reduce the adsorption efficiency of the adsorbent, etc., to achieve the effect of simple structure, low cost, and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

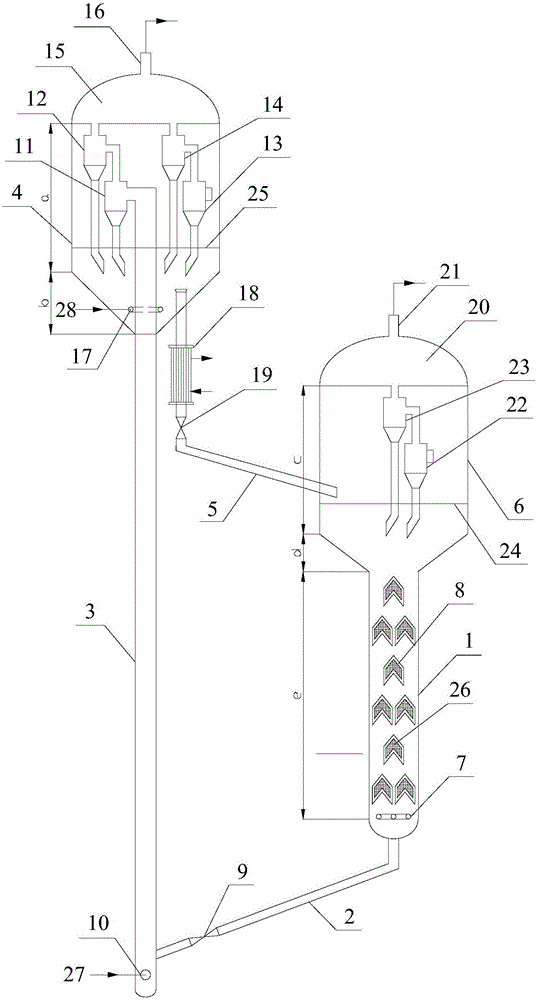

[0064] use figure 1 The reaction device shown is for steam reforming of methane to produce hydrogen, wherein:

[0065] The inner diameter of the reactor 1 is 100 mm, and the height e of the reactor 1 is 1.5 m (the height e does not include the height of the bottom head). The inner diameter of the cylindrical shell of the settler 6 is 300 mm, the height c of the shell of the settler 6 is 2.0 m, and the height d of the inverted truncated conical shell of the settler 6 is 0.8 m. The inner diameter of the cylindrical body of the regenerator 4 is 300 mm, the height a of the regenerator 4 body is 2.0 m, and the height b of the inverted truncated conical body of the regenerator 4 is 0.8 m. The feed distributor 7, lifting gas distributor 10, and regeneration gas distributor 17 are conventional dendritic gas distributors with a pore diameter of 1.5 mm and an opening ratio of 30%. The cross-sectional shapes of the inclined pipe 2 to be born, the conveying pipe 3 of the adsorbent to be...

Embodiment 2

[0072] Adopt the device and the method of the adsorption-enhanced methane steam reforming hydrogen production reaction identical with embodiment 1, difference is:

[0073] The particle size of the nickel-based catalyst is 1000 μm, the particle size of the carbon dioxide adsorbent is 70 μm, the molar ratio of methane and water vapor is 1:3, the top temperature of the reactor is 600°C, the bottom temperature is 550°C, and the gas The linear velocity is 0.4m / s, the regeneration temperature of the regenerator is 800°C, the top pressure is normal pressure, the regeneration time is 15min, the gas linear velocity in the dilute phase section of the regenerator is 0.5m / s, and the top pressure of the settler is 0.3MPa , the average temperature of the dense-phase adsorbent bed in the settler is 620°C, and the gas linear velocity in the dilute-phase section is 0.3m / s.

[0074] After carrying out the above reaction, analyze the gas product composition of the gas outlet pipe at the top of t...

Embodiment 3

[0076] Adopt the device and the method of the adsorption-enhanced methane steam reforming hydrogen production reaction identical with embodiment 1, difference is:

[0077] The particle size of the nickel-based catalyst is 1000 μm, the particle size of the carbon dioxide adsorbent is 70 μm, the molar ratio of methane and water vapor is 1:4, the top temperature of the reactor is 640°C, the bottom temperature is 590°C, and the gas linear velocity is 0.3 m / s, the regeneration temperature of the regenerator is 850°C, the top pressure is normal pressure, the regeneration time is 15min, the gas linear velocity in the dilute phase section of the regenerator is 0.4m / s, the top pressure of the settler is 0.3MPa, and the inner density of the settler is The average temperature of the phase adsorbent bed is 660°C, and the gas linear velocity in the dilute phase section is 0.25m / s.

[0078] After the above reaction was carried out, the gas product composition of the gas outlet pipe at the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com