Visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system

A photoelectric catalysis and visible light technology, applied in electrochemical generators, electrolysis processes, electrolysis components, etc., can solve the problems of low performance of photocatalytic water splitting for hydrogen production, limiting the full utilization of visible sunlight, and small self-bias voltage, etc. Visible light response and photocatalytic performance, realizing effective utilization, and improving the effect of self-bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the visible light-responsive self-bias photocatalytic water decomposition system for generating hydrogen and generating electricity includes the following specific steps:

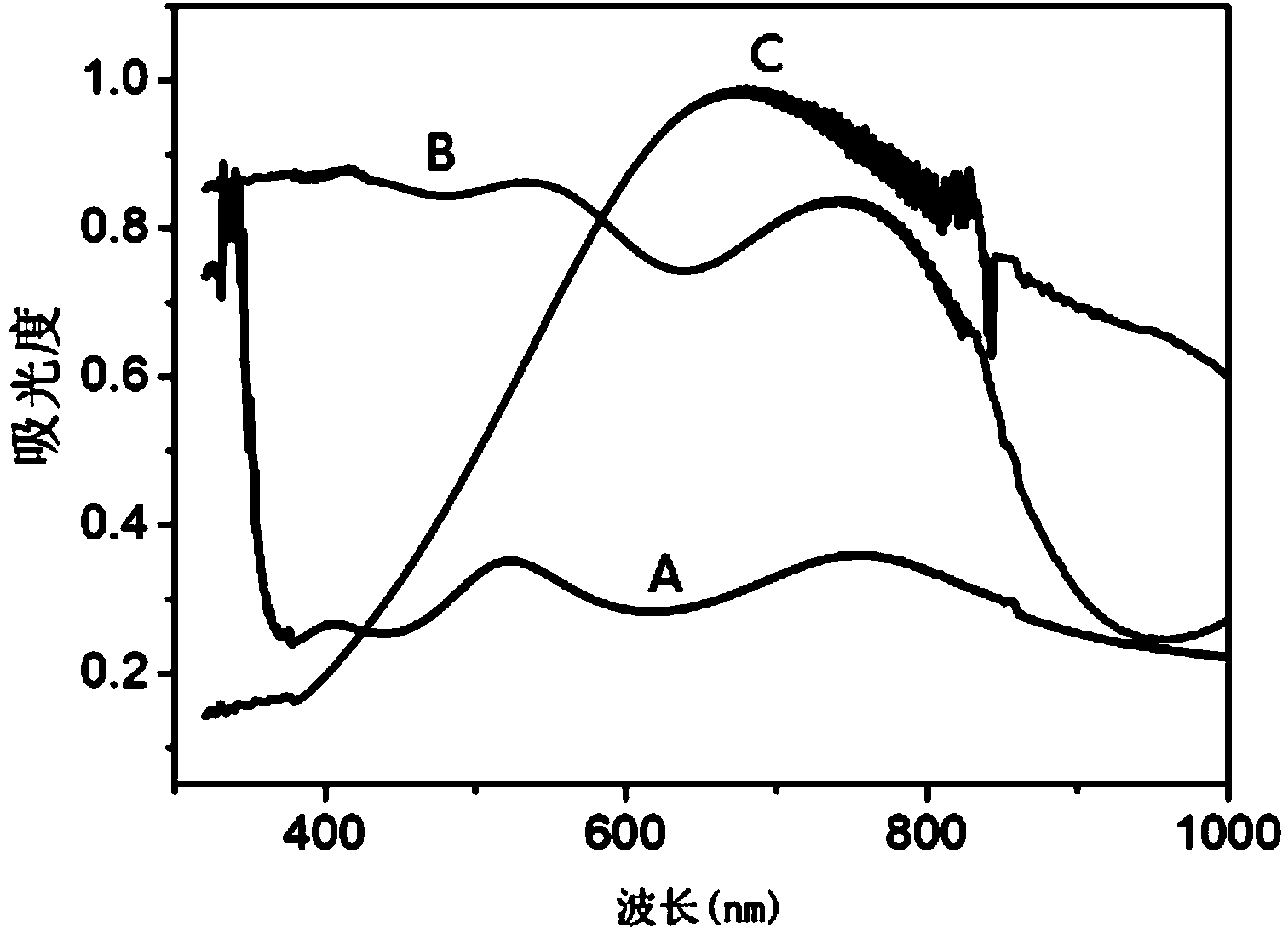

[0032] 1) Preparation of the visible light-responsive Bi 2 S 3 Sensitized TiO 2 A nanotube array film electrode, the method is: firstly, the cleaned metal titanium plate is used as an anode, placed in an aqueous solution containing 0.5% hydrofluoric acid, the platinum electrode is used as a counter electrode, and the voltage is adjusted to 20V, and the metal titanium plate is Anodizing for 60 minutes to obtain TiO made of metal titanium and titanium surface 2 TiO 2 nanotube array material, then the titanium-based TiO 2 After the nanotube array material was sintered at 500°C for 1 hour, TiO with anatase phase was obtained 2 Nanotube array thin film material; with the TiO with anatase phase 2 The nanotube array thin film material is used as the substrate, and 0.5ml50mM B...

Embodiment 1

[0037] First, the cleaned metal titanium plate is used as an anode, placed in an aqueous solution containing 0.5% hydrofluoric acid, and the platinum electrode is used as a counter electrode to adjust the voltage to 20V, and the metal titanium plate is anodized for 60 minutes to obtain metal titanium and titanium Surface TiO 2 TiO 2 nanotube array material, then the titanium-based TiO 2 After the nanotube array material was sintered at 500°C for 1 hour, TiO with anatase phase was obtained 2 Nanotube array thin film material, based on the TiO with anatase phase 2 The nanotube array thin film material is used as the substrate, and 0.5ml50mM Bi(NO 3 ) 3 and 100mM Na 2 S solution, wherein the Bi(NO 3 ) 3 The solution uses 1M acetic acid solution as a solvent, and after each drop, it is coated at 3000rpm for 20s, and alternately repeated 30 times to obtain Bi 2 S 3 Sensitized Ti-based TiO 2 nanotube array thin film material, the Bi 2 S 3 Sensitized Ti-based TiO 2 The n...

Embodiment 2

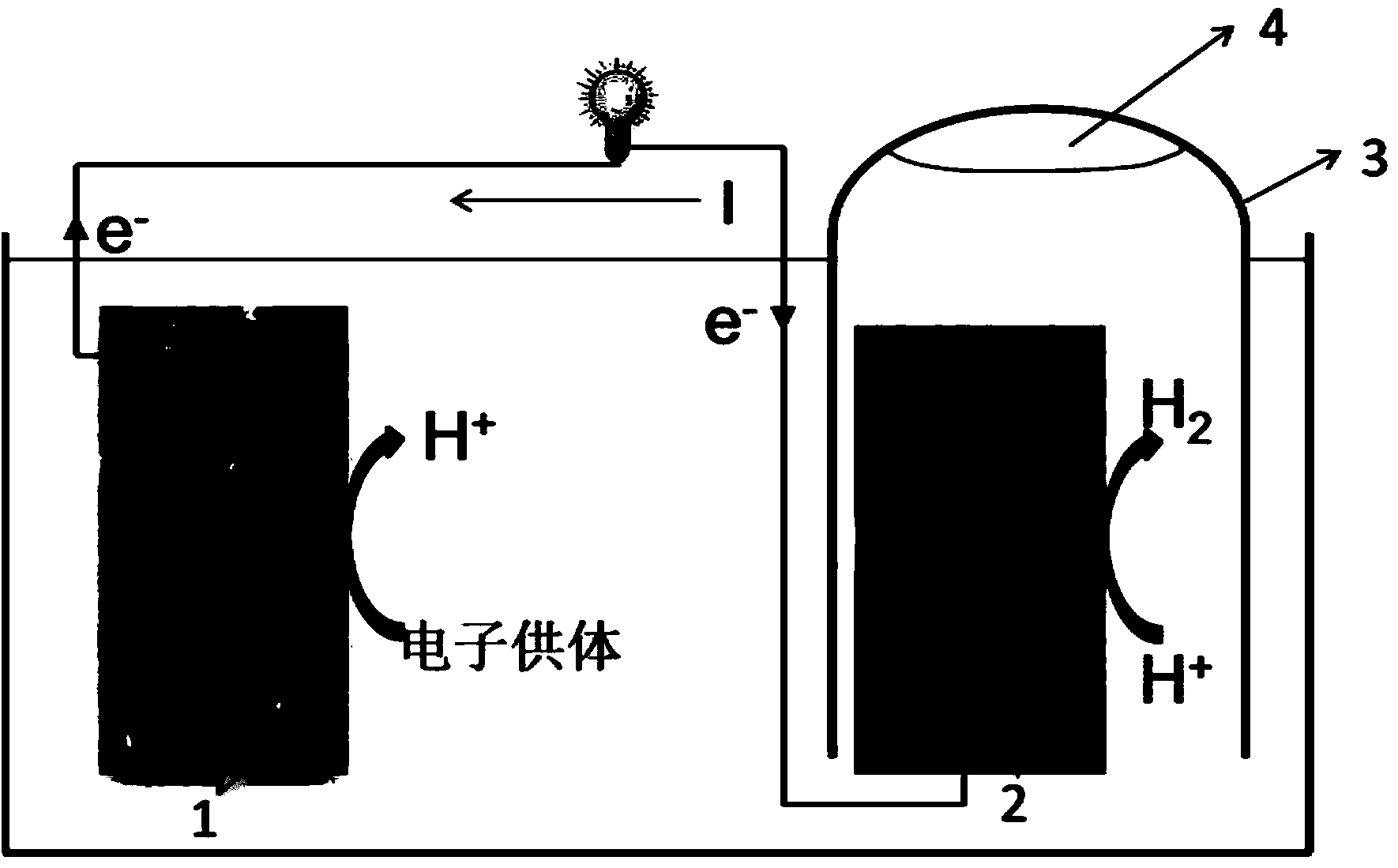

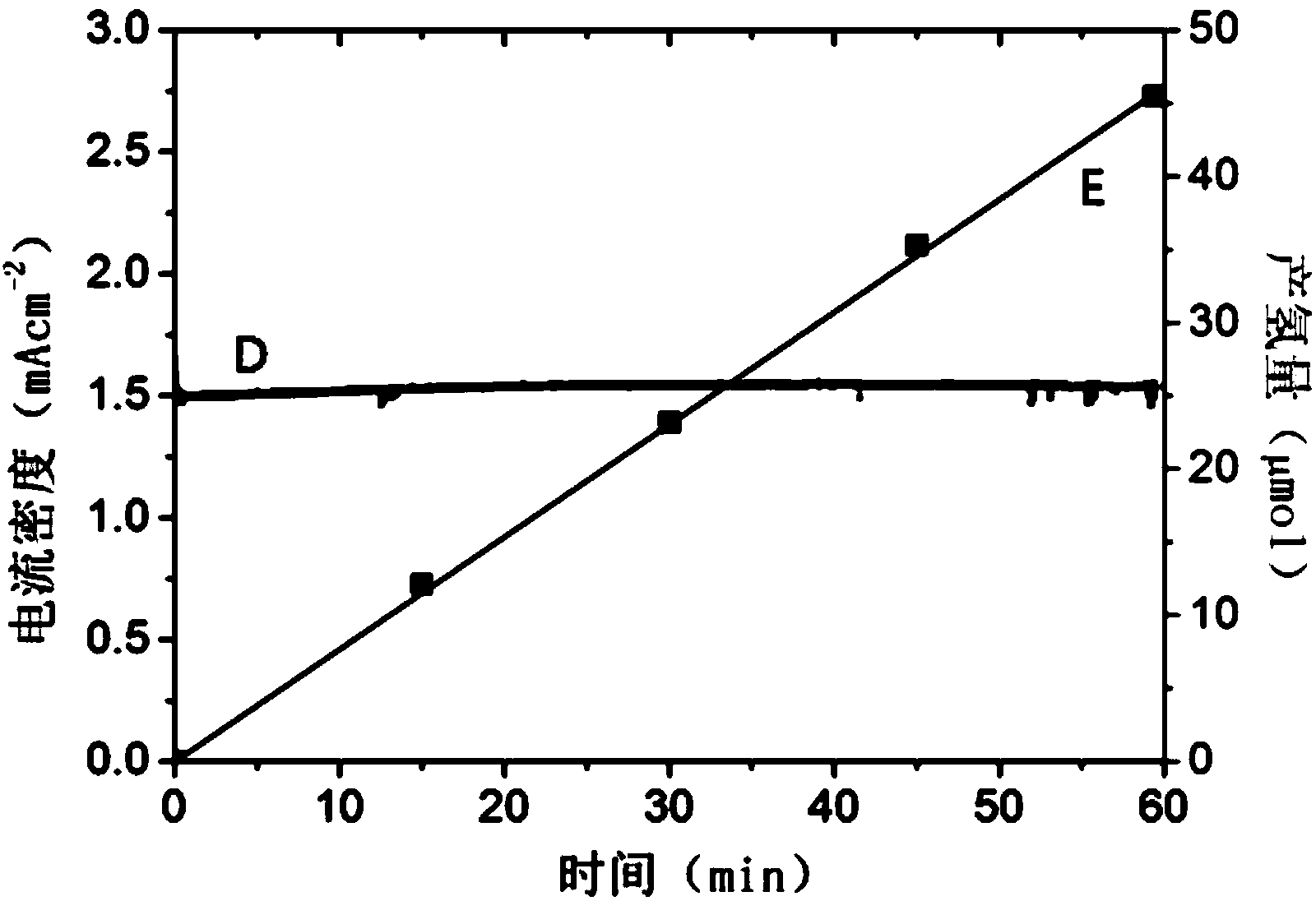

[0046] Bi in response to visible light 2 S 3Sensitized TiO 2 The nanotube array film electrode is used as the photoanode 1, and the visible light-responsive platinum-modified silicon cell electrode is used as the photocathode 2, respectively inserted with 0.1M Na 2 S electrolyte solution, and connected by external wires. Turn on the simulated sun light source (the light intensity is 100mW cm -2 ) irradiates the photoanode 1 and the photocathode 2, at this time the photogenerated electrons generated by the photocathode 2 convert the H in the electrolyte + Revert to H 2 , S in the electrolyte 2- On the photoanode 1, it is oxidized by the photogenerated holes, and the photogenerated electrons generated by the photoanode 1 are transmitted to the photocathode 2 through an external circuit and combined with the photogenerated holes, so as to realize photocatalytic hydrogen production and power generation at the same time. The hydrogen generation rate in this example is 43.1 μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com