Patents

Literature

150results about How to "Reduce the cost of hydrogen production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

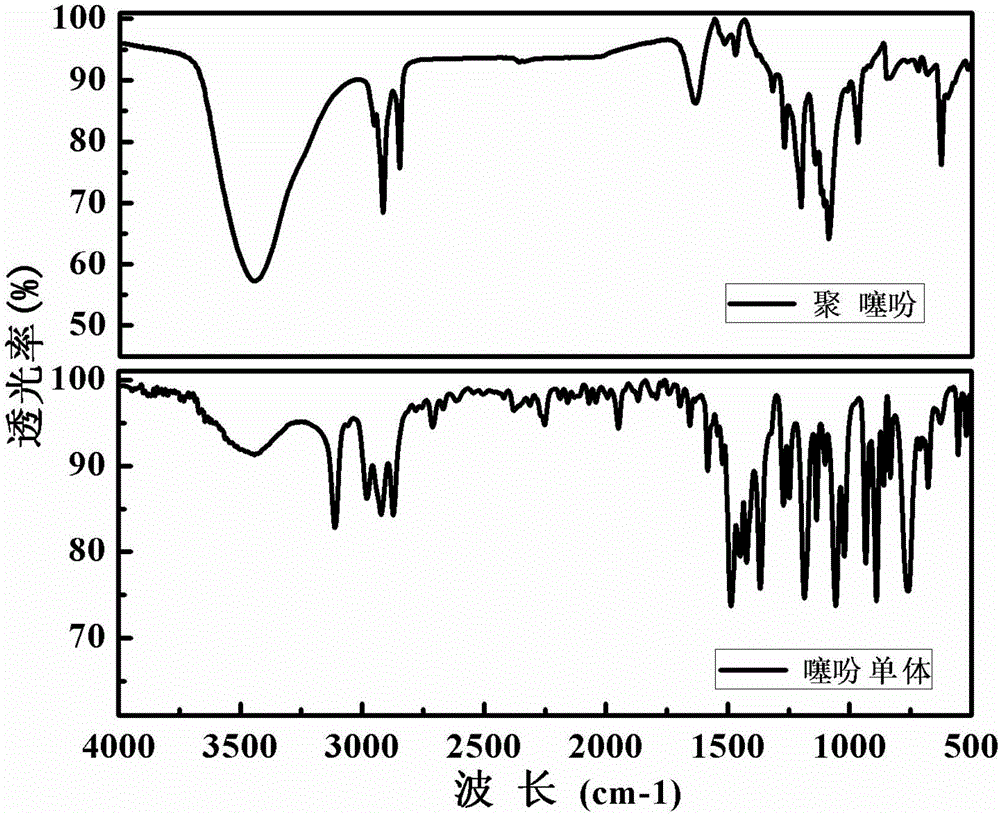

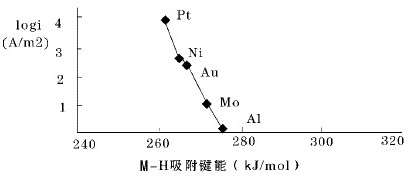

High-efficiency multi-element transition metal phosphide hydrogen-evolution catalyst and preparation method thereof

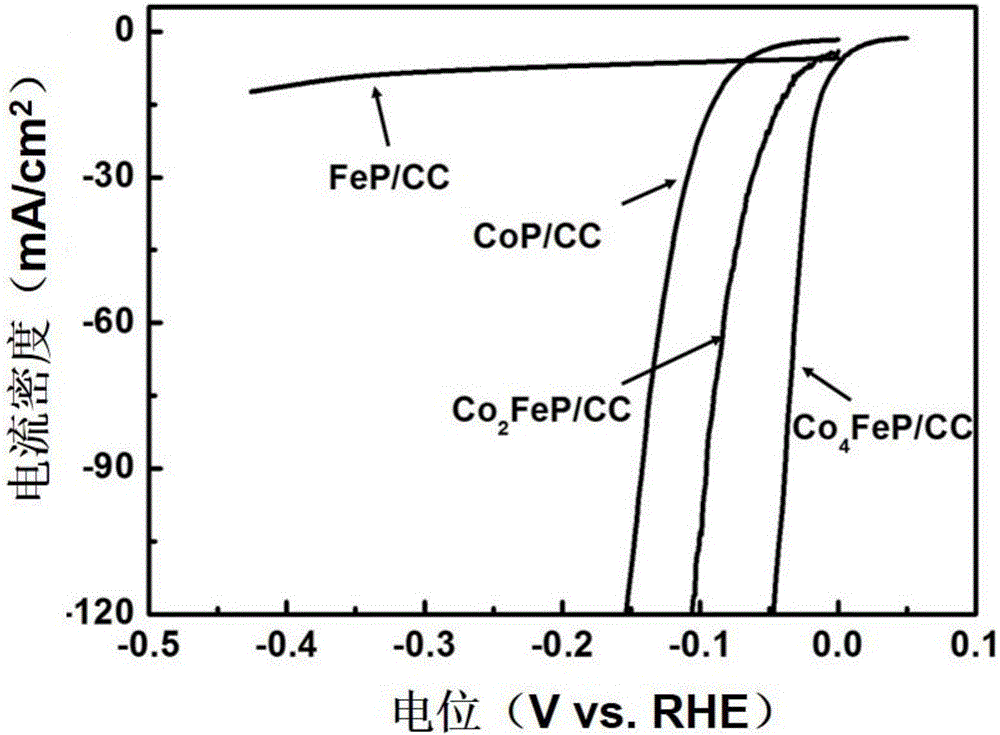

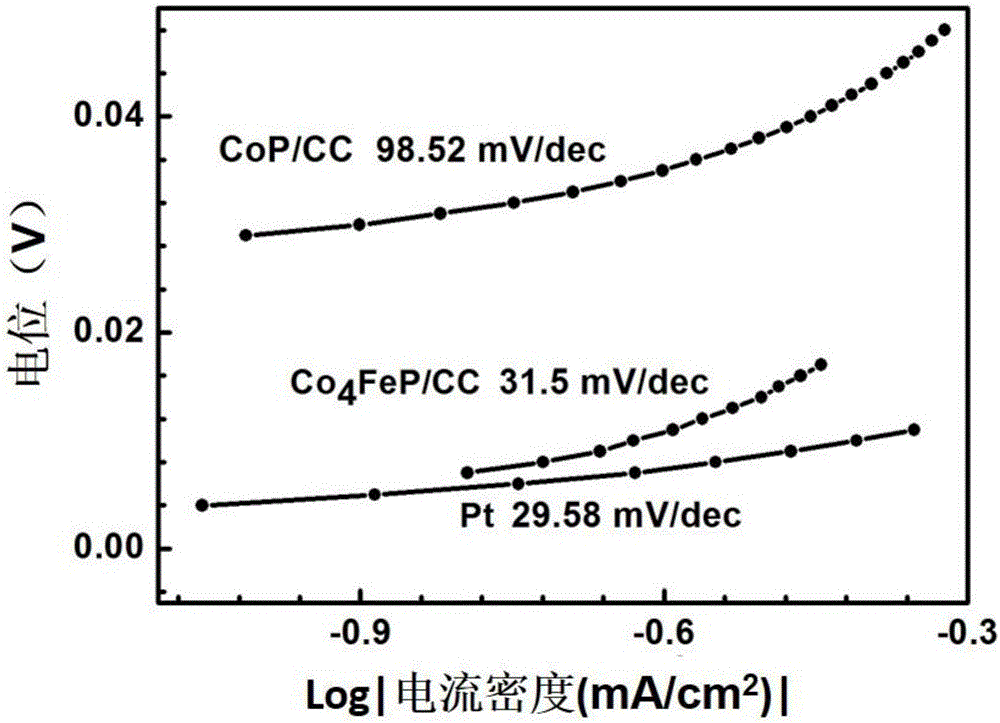

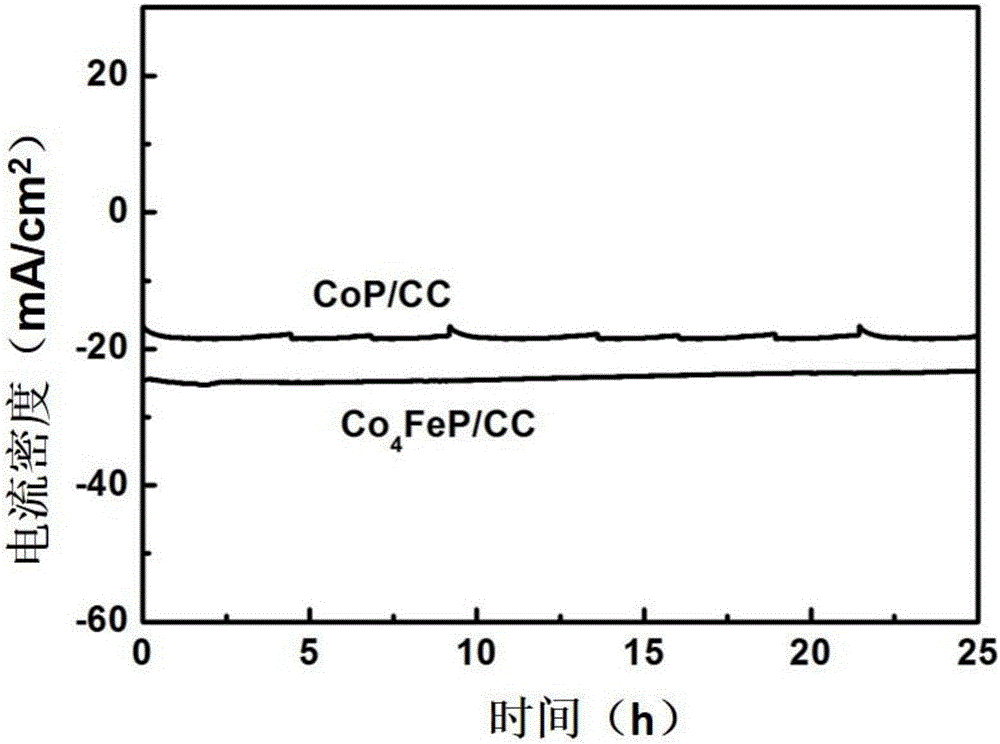

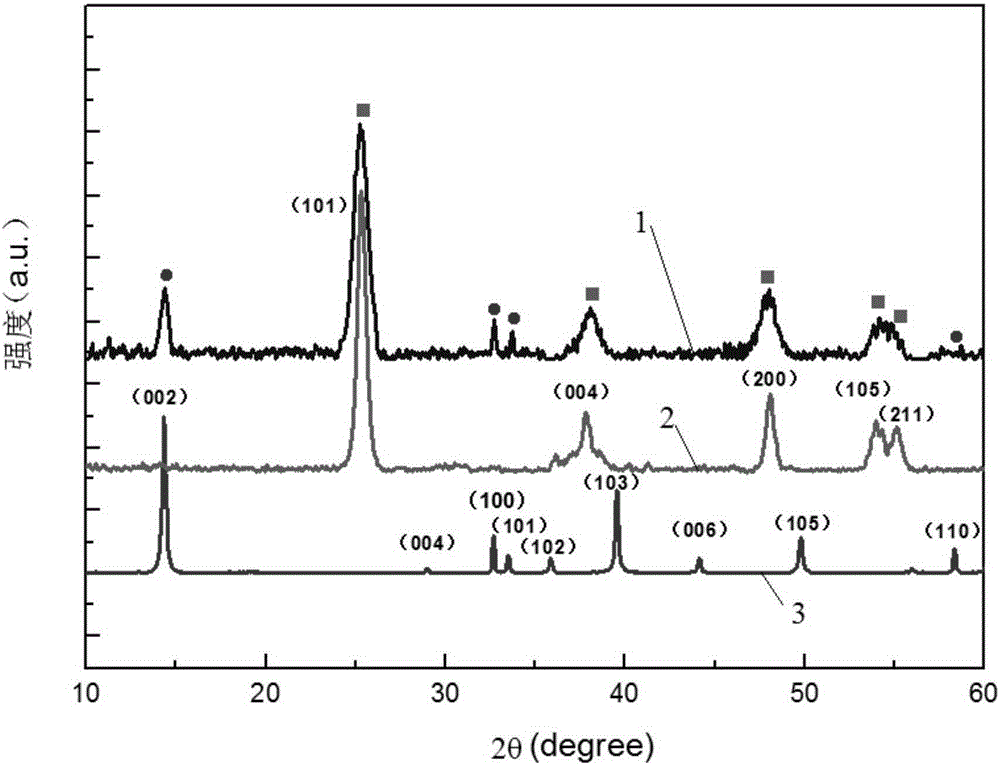

InactiveCN105720278AHigh catalytic activityReduce the cost of hydrogen productionCell electrodesIonTube furnace

The invention discloses a high-efficiency multi-element transition metal phosphide hydrogen-evolution catalyst and a preparation method thereof. The catalyst is Co<x>Fe<y>P and is formed by being loaded in carbon cloth by a hydrothermal method. The preparation method of the catalyst comprises the following steps of preparing a precursor by the hydrothermal method, adding a certain amount of a mixture of Co(NO<3>)<2>.6H<2>O and Fe(NO<3>)<3>.9H<2>O into deionized water to form an uniform mixed solution, placing the mixed solution in a reaction kettle, adding carbon cloth (CC) as a carrier, uniformly adding strong ammonia water, hermetically heating the mixed solution to 110-120 DEG C, carrying out heat preservation for 9-10 hours, taking out the CC, and drying the CC to obtain the precursor; and carrying out low-temperature phosphorization on the precursor, separately placing NaH<2>PO<2> and the precursor in an upstream and a downstream of a tube furnace, introducing nitrogen or inert gas, heating the tube furnace to 300-350 DEG C, and carrying out heat preservation for over 2 hours to obtain the hydrogen-evolution catalyst. Compared with the prior art, the hydrogen-evolution catalyst prepared according to the method is endowed with high-efficiency and stable catalytic hydrogen evolution capability in an acidic solution, and the hydrogen production cost through electrolysis of water can be reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of molybdenum disulfide-black titanium dioxide composite visible-light-driven photocatalyst for hydrogen production

InactiveCN105195133AUninterrupted outputEfficient hydrogen productionMetal/metal-oxides/metal-hydroxide catalystsLight drivenMolybdenum disulfide

The invention provides a preparation method of a molybdenum disulfide-black titanium dioxide composite visible-light-driven photocatalyst for hydrogen production, and relates to a preparation method of a visible-light-driven photocatalyst for hydrogen production. According to the preparation method, the technical problems that an existing molybdenum disulfide-titanium dioxide composite visible-light-driven photocatalyst is low in visible light utilization rate and hydrogen production efficiency are solved. The preparation method comprises the steps of 1 reagent mixing; 2 hydrothermal reaction performing; 3 thermal treating; 4 hydrogenating. The preparation method has the advantages that the prepared molybdenum disulfide-black titanium dioxide composite visible-light-driven photocatalyst for hydrogen production can efficiently produce hydrogen on the condition of visible light and can continuously produce the hydrogen under continuous six-hour radiation of the visible light and is not only high in hydrogen production efficiency but also good in stability. The preparation method is simple in preparation technology and experiment equipment, low in cost, high in benefit and capable of easily achieving commercialization.

Owner:HEILONGJIANG UNIV

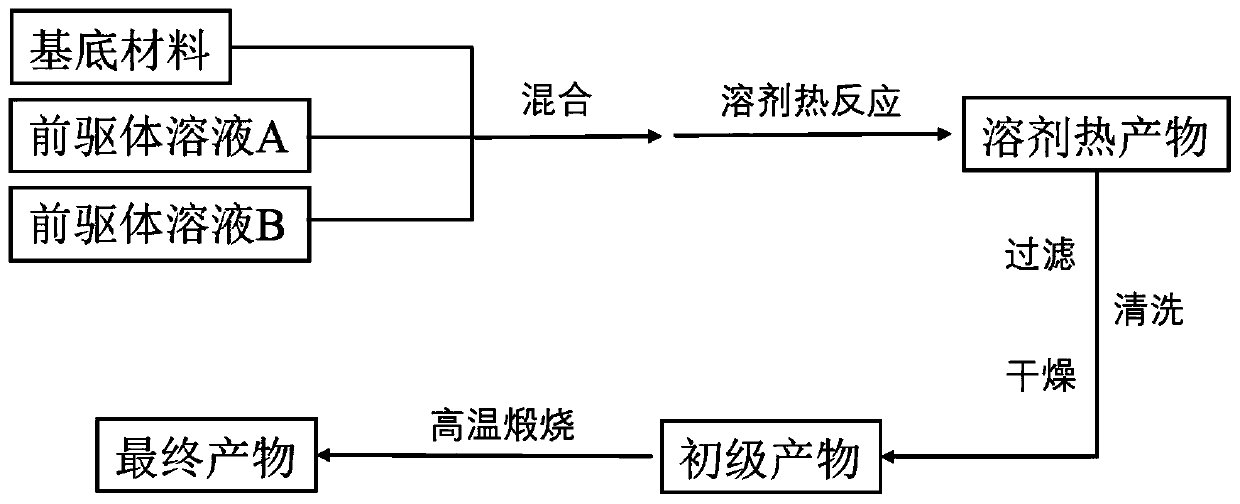

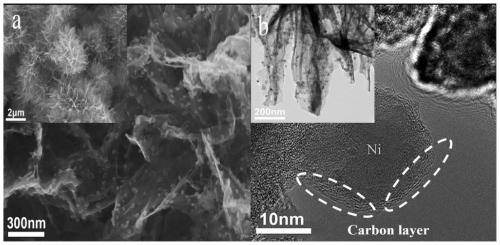

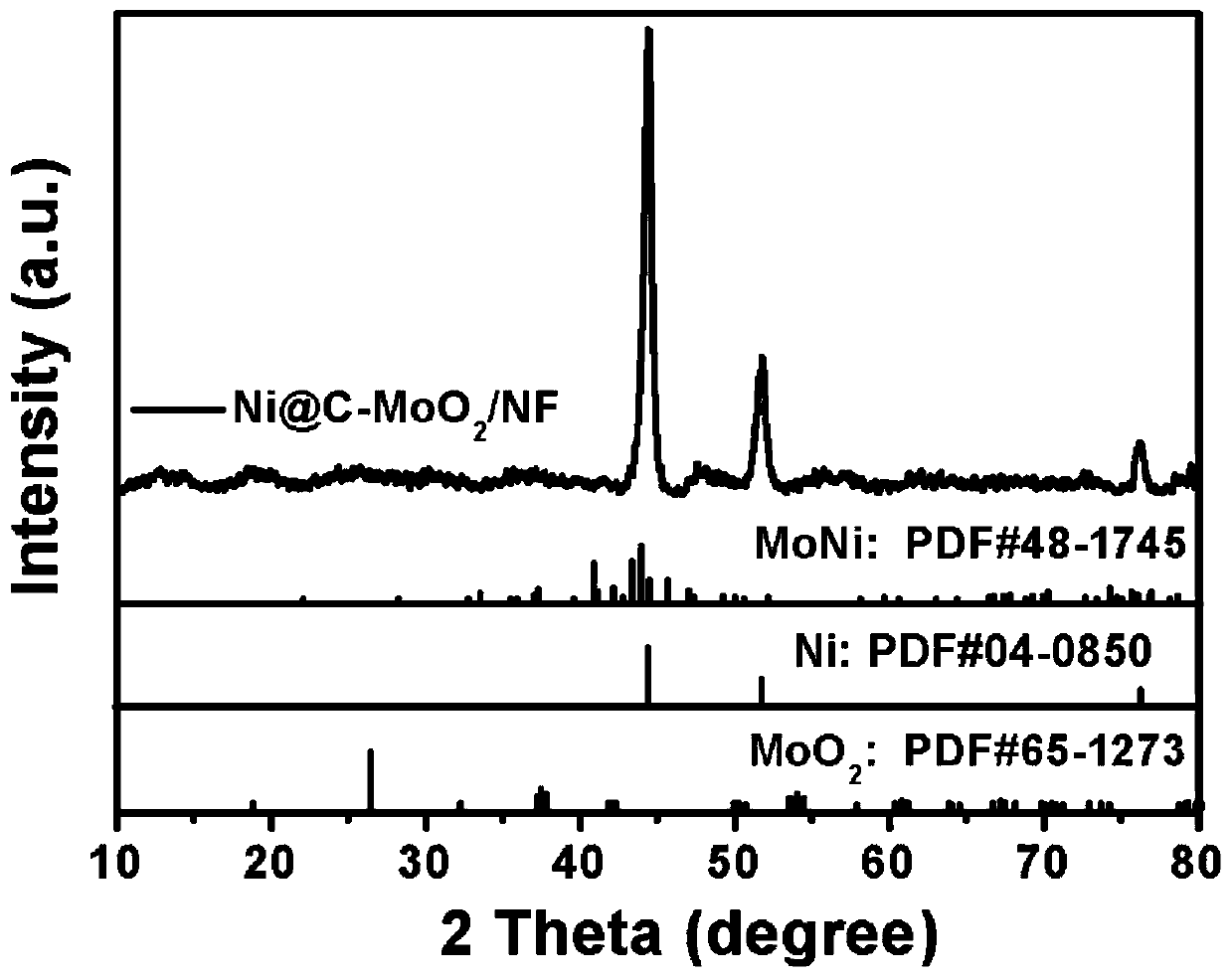

Metal oxide nano sheet supported carbon coated metal particle electrolysed water catalyst

ActiveCN109939691AGood activity and stabilityImprove electrochemical stabilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesMetal particleSolvent

The invention discloses a metal oxide nano sheet supported carbon coated metal particle electrolysed water catalyst which is prepared from the following steps: (1) dissolving a metal precursor A in asolvent to prepare a solution A, dissolving a metal precursor B in a solvent to prepare a solution B, mixing the solution A with the solution B, adding a substrate material, ultrasonically stirring the mixture to obtain a mixed suspension liquid, adding the mixed suspension liquid into a reaction kettle for a solvothermal reaction, cooling the reactant after the reaction to room temperature, taking out a material in the reaction kettle, and filtering, cleaning and vacuum drying the material to obtain an initial sample; and (2) introducing mixed gas of hydrogen and inert gas, and carrying out high-temperature calcining to obtain a final product. The product prepared by the method has relatively good electrolysed water catalytic activity and electrochemical stability, and the overpotential of the electrolysed water in the whole electrolytic cell is smaller than or equal to 1.48 V, thereby laying a technical foundation for lowering hydrogen making cost.

Owner:GUANGXI UNIV

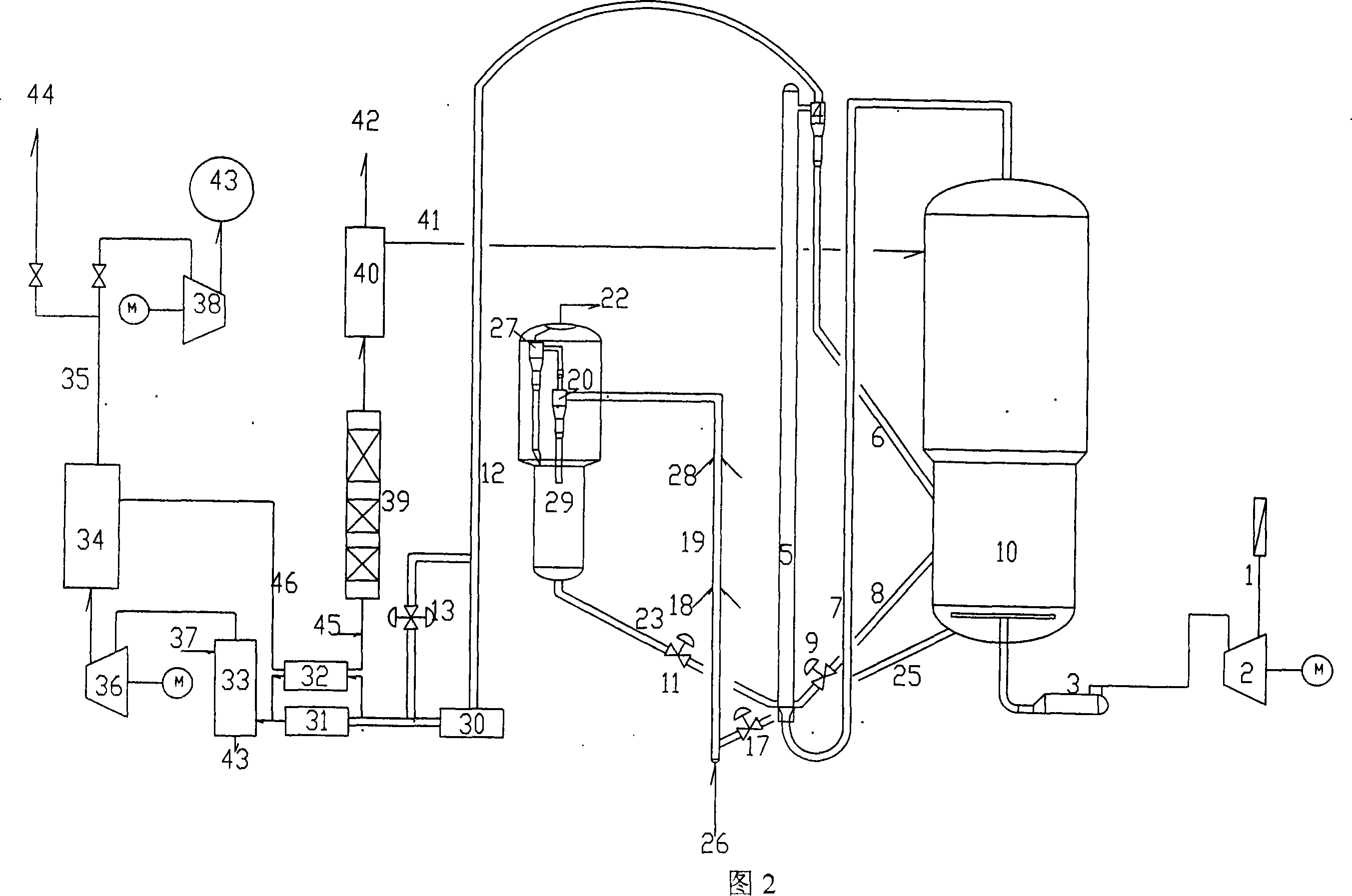

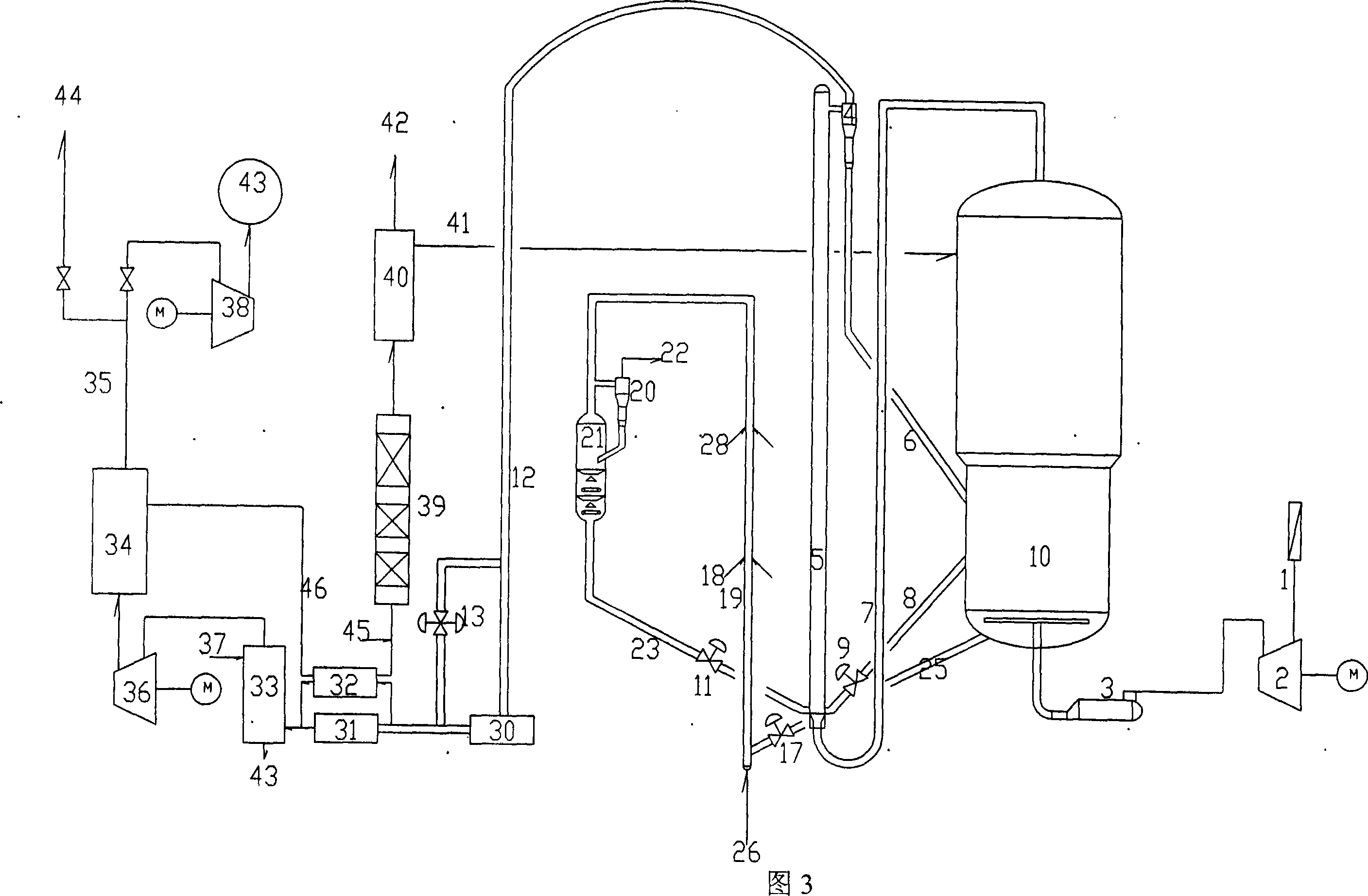

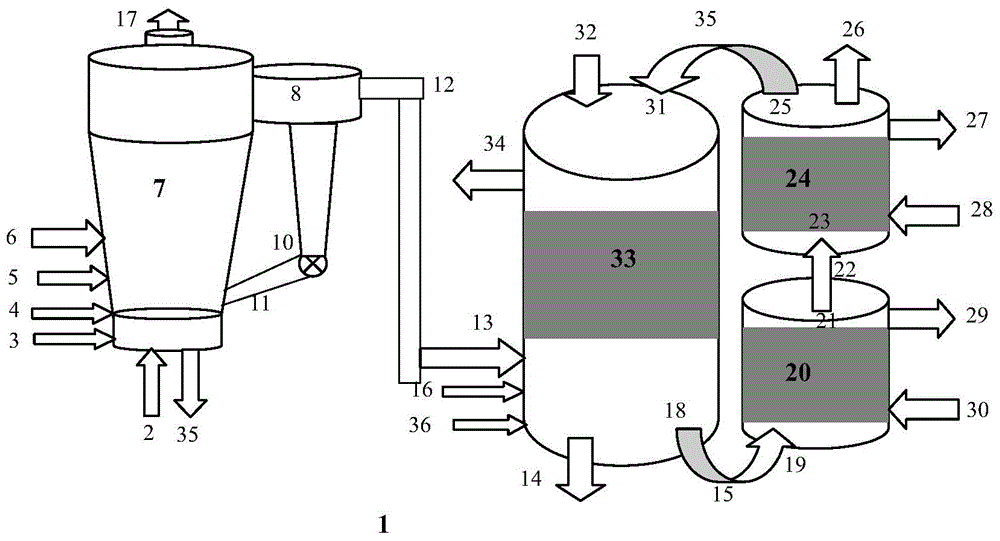

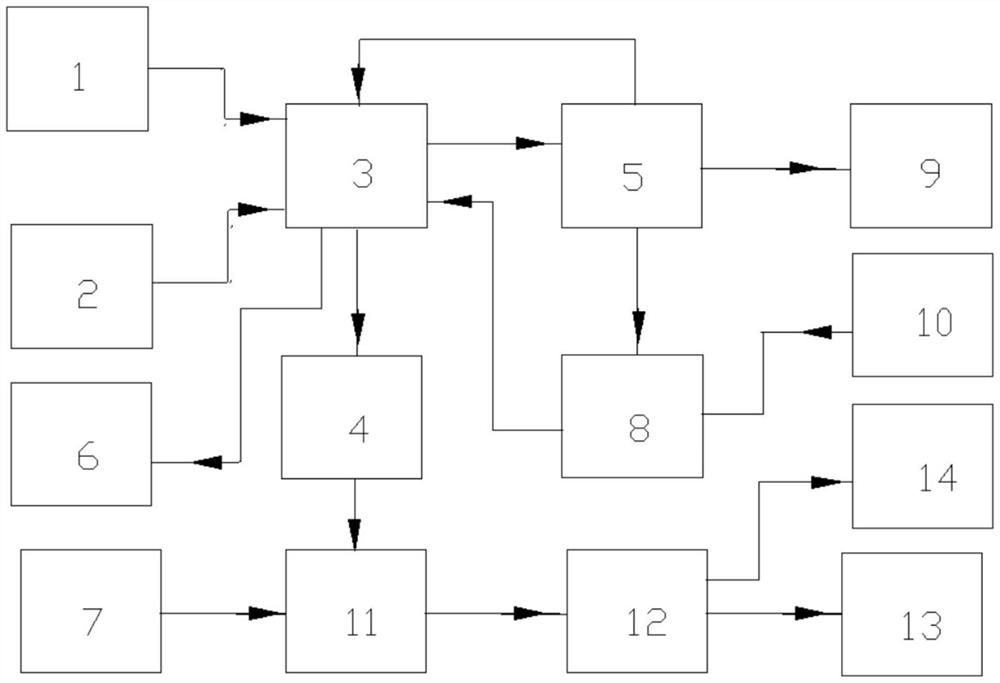

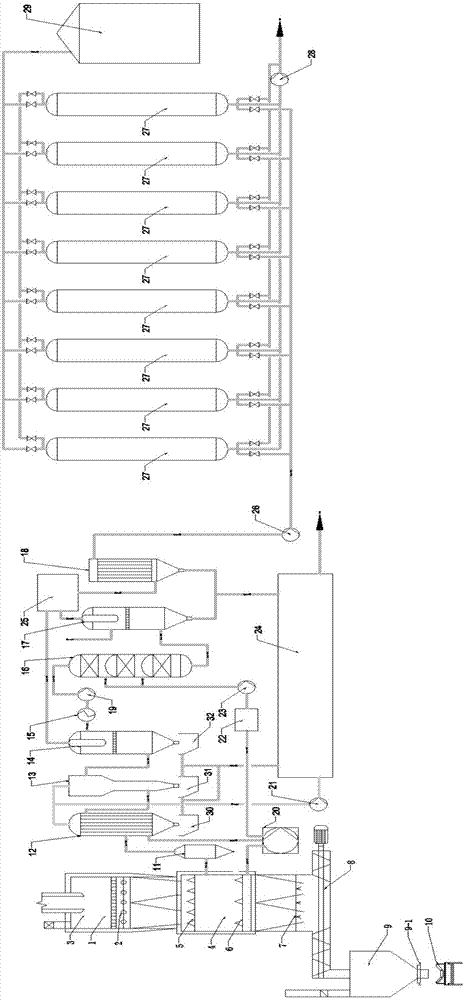

Combined production device of hydrocarbon production through methanol dehydration and hydrogen and carbon dioxide production through methanol reforming

InactiveCN101712883ALow calorific valueHigh calorific valueHydrogenCarbon compoundsGeneration processCarbon dioxide production

The invention relates to a combined production device of hydrocarbon production through methanol dehydration and hydrogen and carbon dioxide production through methanol reforming, which is characterized in that methanol is utilized as raw materials to co-produce petroleum, liquefying gas, hydrogen and carbon dioxide; heat generated during hydrocarbon production through methanol dehydration is used for a methanol reforming process; water generated during the hydrocarbon production through the methanol dehydration is used for the methanol reforming process; hydrogen generated by reforming can be used for a thermoelectric device and the like, and generated carbon dioxide is recovered and can be used for producing products such as food grade carbon dioxide and the like. The raw material methanol has rich sources. Petroleum and liquefying gas products satisfy the standards of clean fuel and has large product market demands. The hydrogen generated by a methanol reforming device is used as fuel and can realize near zero carbon dioxide emission in a thermoelectricity generation process.

Owner:国科瑞德(北京)能源科技发展有限公司

Method for preparing hydrogen and nitrogen by catalytic cracking regenerative fume

InactiveCN101143289ASimple processLow main air consumptionHydrogenProductsHydrogenGlobal wind patterns

The invention relates to a method of producing hydrogen and nitrogen by catalytic cracking regenerator gas. The invention has main content that: the high temperature oxygen-contained gas of a second regenerator enters to the bottom of a first regenerator, and is contacted, heated and burnt with a mixing catalyst composed of a carbon deposition catalyst in a self stripper and a regenerant in the second regenerator. The regenerating gas on the upper part of the first regenerator is separated from a half-regenerant by a cyclone separator. The generating gas enters into a pressure energy recovery system, and then enters into the subsequent hydrogen and nitrogen producing process. The half-regenerant enters into the second regenerator through a dipleg, and then is contacted and burnt with full burnt prevailing wind. The stripped carbon deposition catalyst backs into the first regenerator, and then a circulating is formed, in order to effectively use CO and CO2 in the regenerating gas and CO2 produced in the subsequent CO intermediate temperature changing process, and to improve the ratio of the carbon deposition on the first regenerator catalyst transferring into CO, and furthermore to improve the unit carbon deposition hydrogen yield rate of the catalyst.

Owner:高玉玲

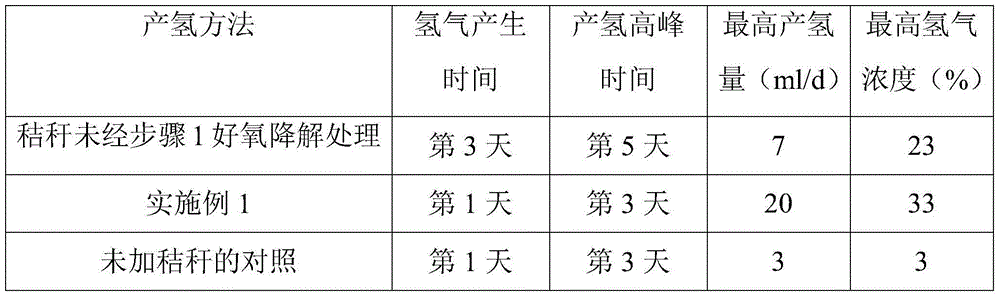

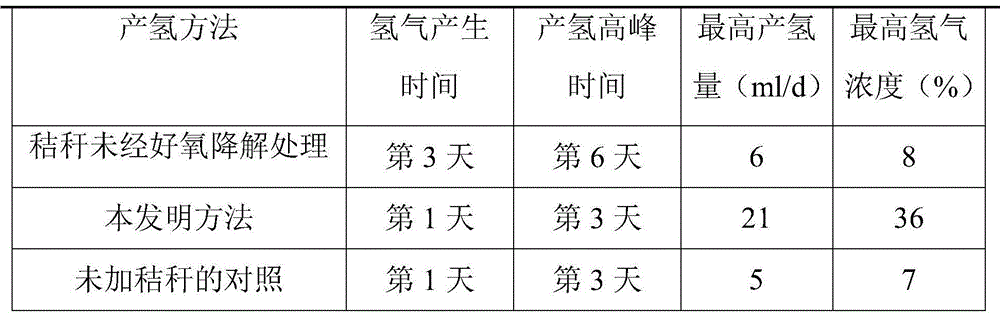

Method for preparing hydrogen from straws

InactiveCN103602715AEasily exposedImprove degradation efficiencyMicroorganism based processesFermentationNitrogenPre treatment

The invention discloses a method for preparing hydrogen from straws, which comprises the following steps: carrying out aerobic degradation on straws by using a composite microbial inoculum capable of degrading straws; cattle manure pretreatment: screening the cattle manure with a 50-mesh screen to remove granular solids and impurities, boiling for 30-60 minutes, and centrifugating to remove excessive moisture for later use; preparation of straw anaerobic degradation culture medium: preparing a liquid anaerobic degradation culture medium, and adding the straws subjected to aerobic degradation; and adding the pretreated cattle manure into the straw anaerobic degradation culture medium, charging nitrogen into the container to remove oxygen, sealing, and culturing at 60-70 DEG C at the rate of 120 r / min in a dark place. The method optimally combines anaerobic degradation and anaerobic fermentation, has the advantages of short required time for hydrogen production, low cost, no need of adding enzymes in the fermentation process and cheap raw materials, and greatly saves the cost.

Owner:四川蓉加川大环保工程咨询设计有限公司

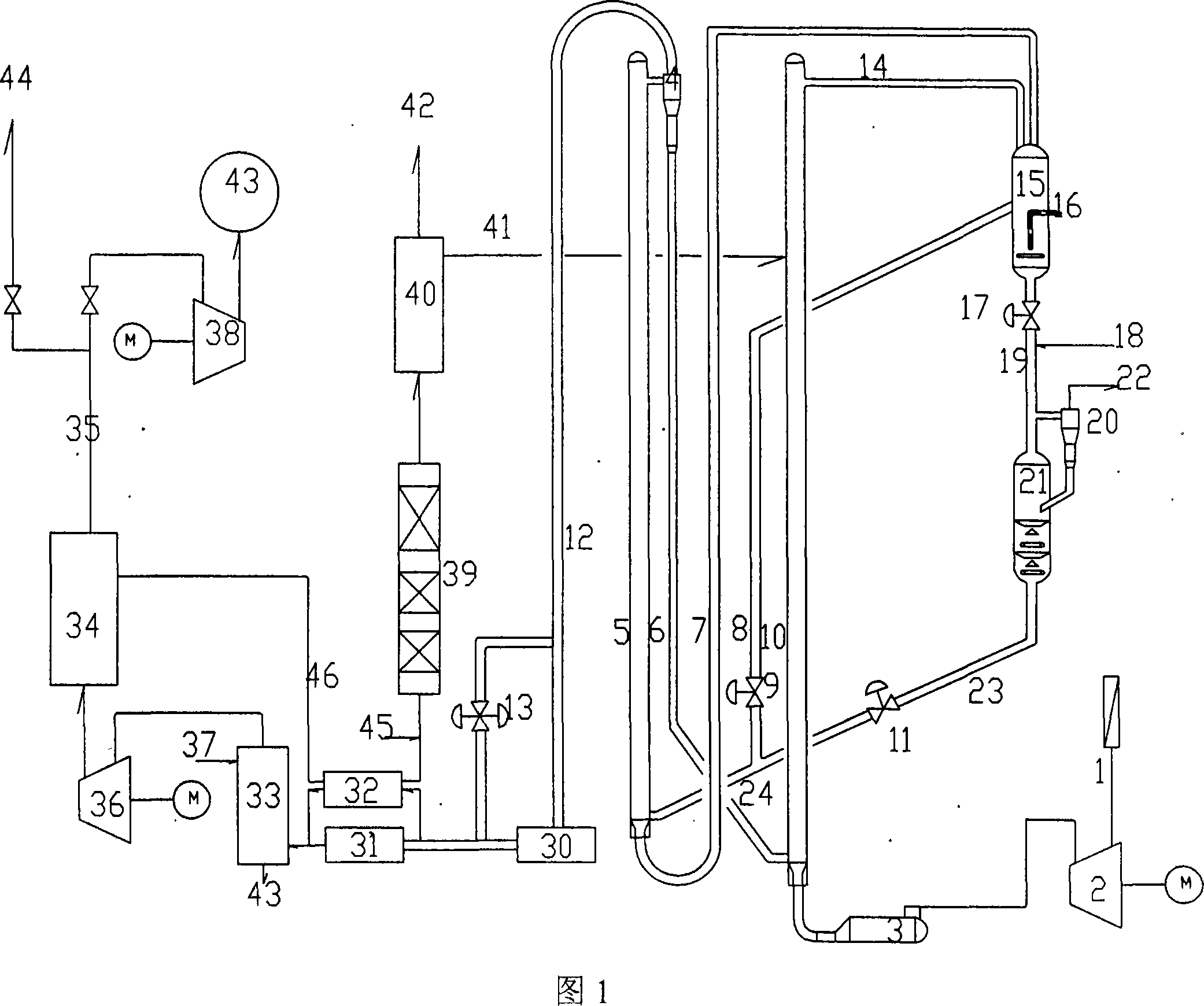

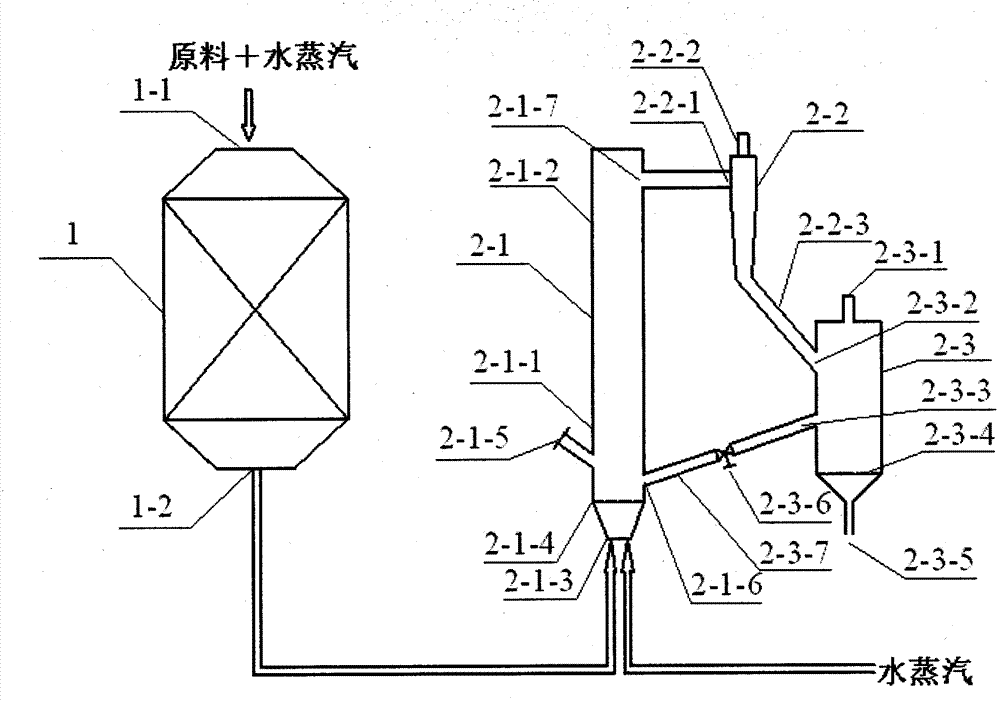

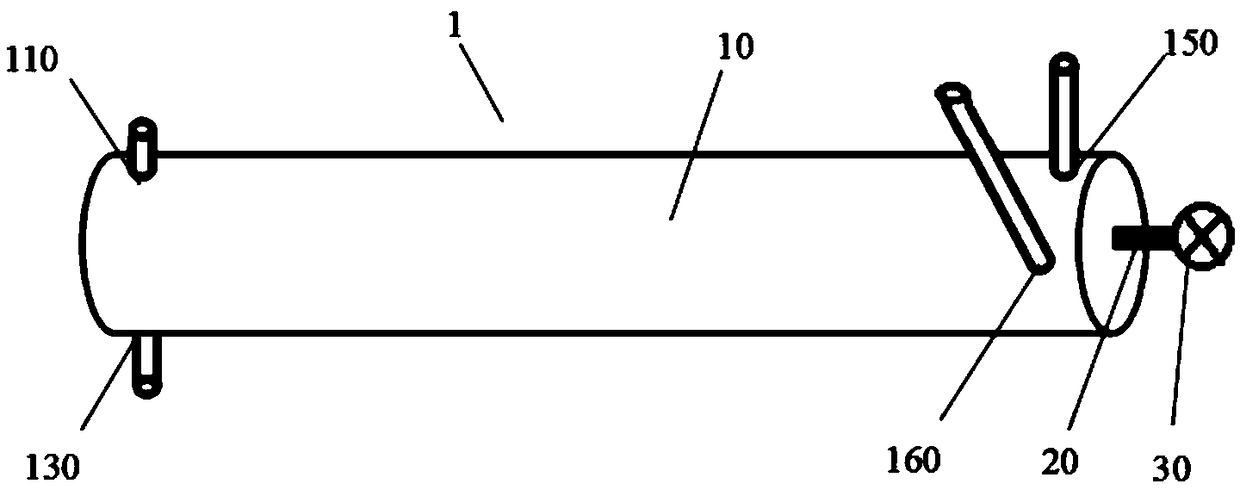

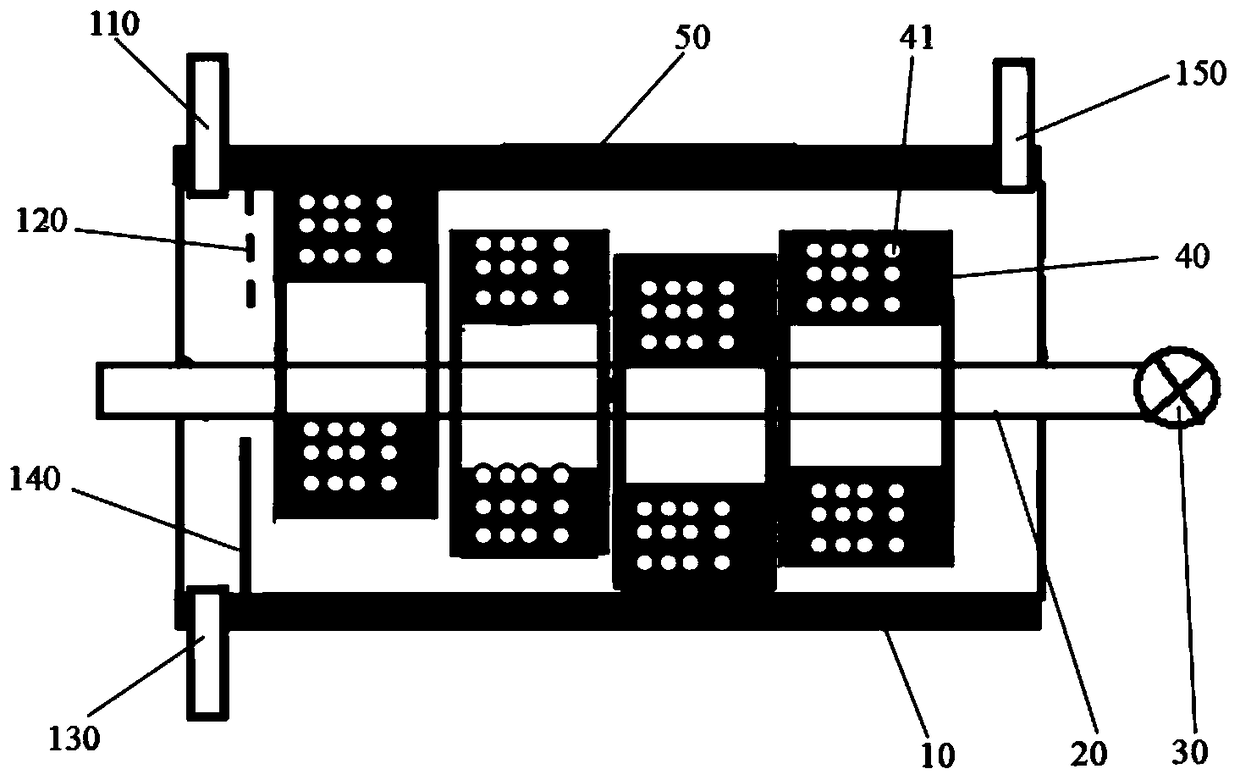

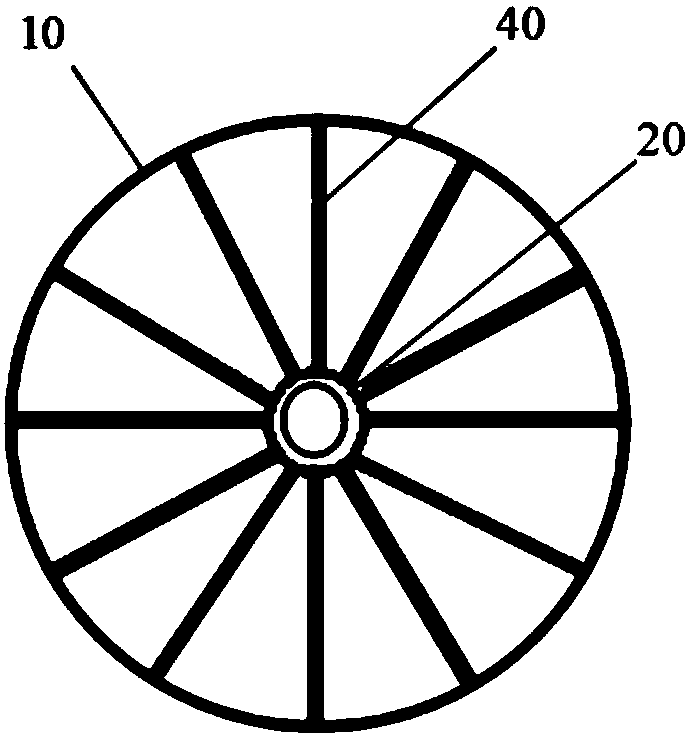

Hydrogen production method by steam reforming in combined reactor and device thereof

InactiveCN102730636AShort processReduce operating costsHuman health protectionHydrogenSteam reformingChemical industry

A hydrogen production method by steam reforming in a combined reactor and a device thereof belong to the technical field of a hydrogen production technology by steam reforming of light dydrocarbon. The device provided by the invention comprises a fixed-bed reactor and a half-cycle fluidized bed reactor. The method is realized by the use of the device, and natural gas or dry gas for oil refining or light oil is used as a raw material. The method comprises the following steps: reducing a nickel based catalyst, carrying out a catalytic reforming reaction in the fixed-bed reactor, carrying out a catalytic reforming reaction again as well as a carbon dioxide adsorption reaction in a riser reactor of the fluidized bed, carrying out gas-solid separation to prepare the hydrogen product, and regenerating and utilizing carbon dioxide adsorbent particles. The invention has characteristics of short process flow, simple operation, energy conservation, low production cost, high hydrogen production efficiency, high purity of the hydrogen product, complete utilization of resources, no environmental pollution and the like. The invention can be widely applied in hydrogen production by steam reforming. The hydrogen prepared by the adoption of the method can be extensively applied in the fields of petroleum, chemical industry, metallurgy and the like.

Owner:CHONGQING UNIV

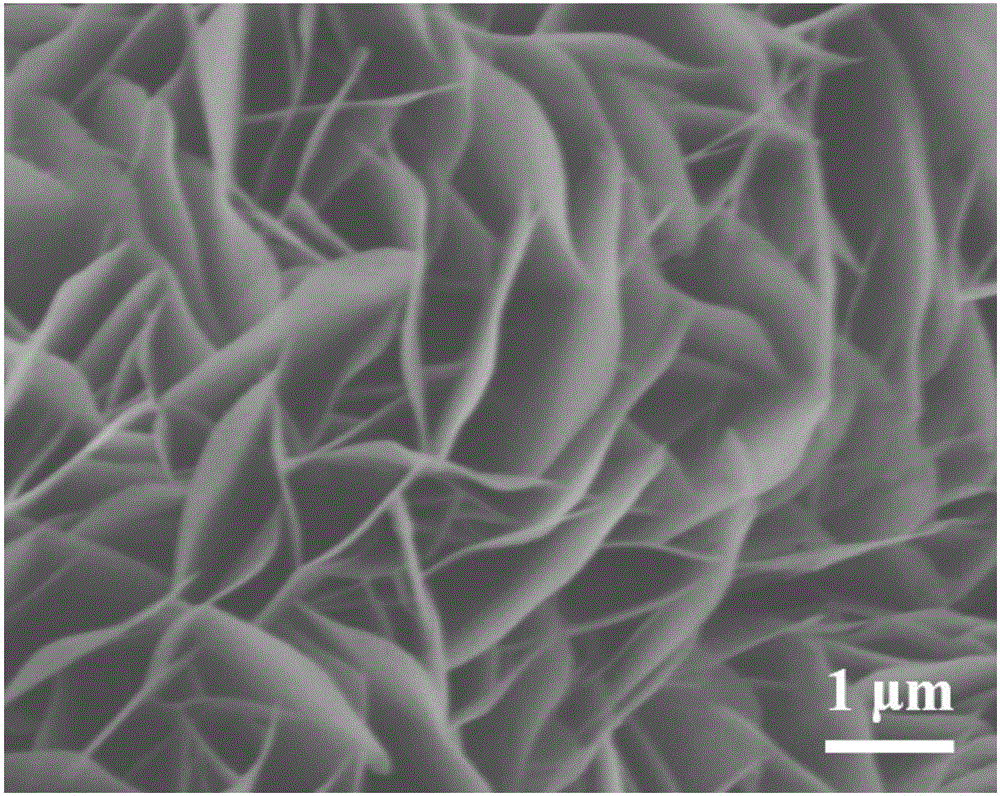

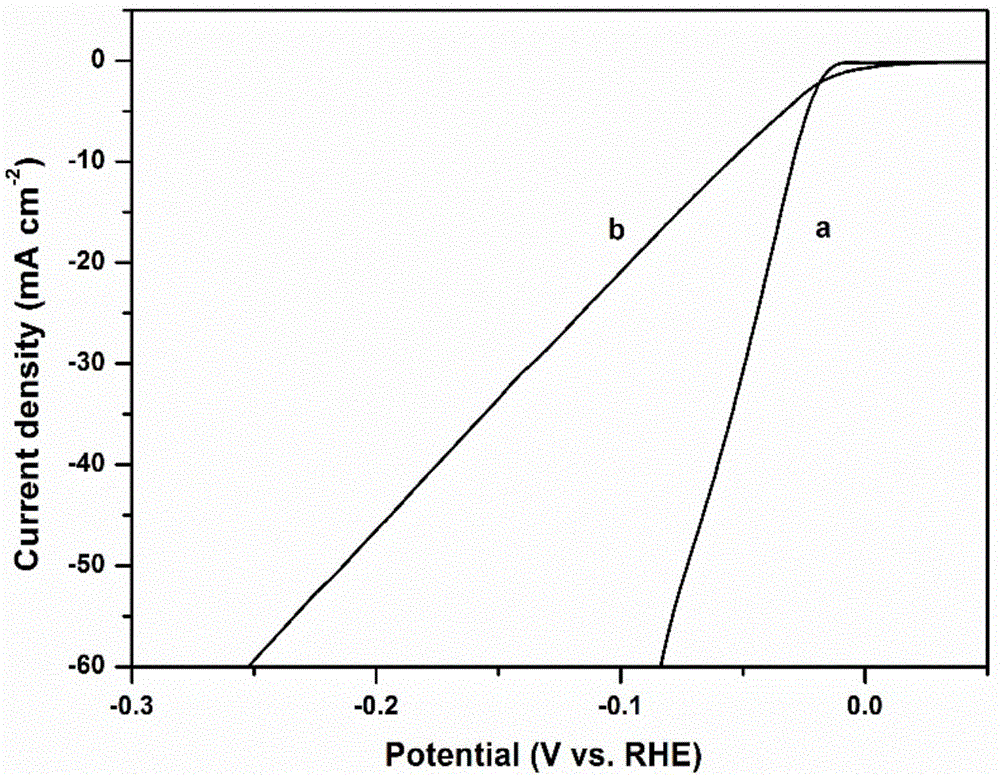

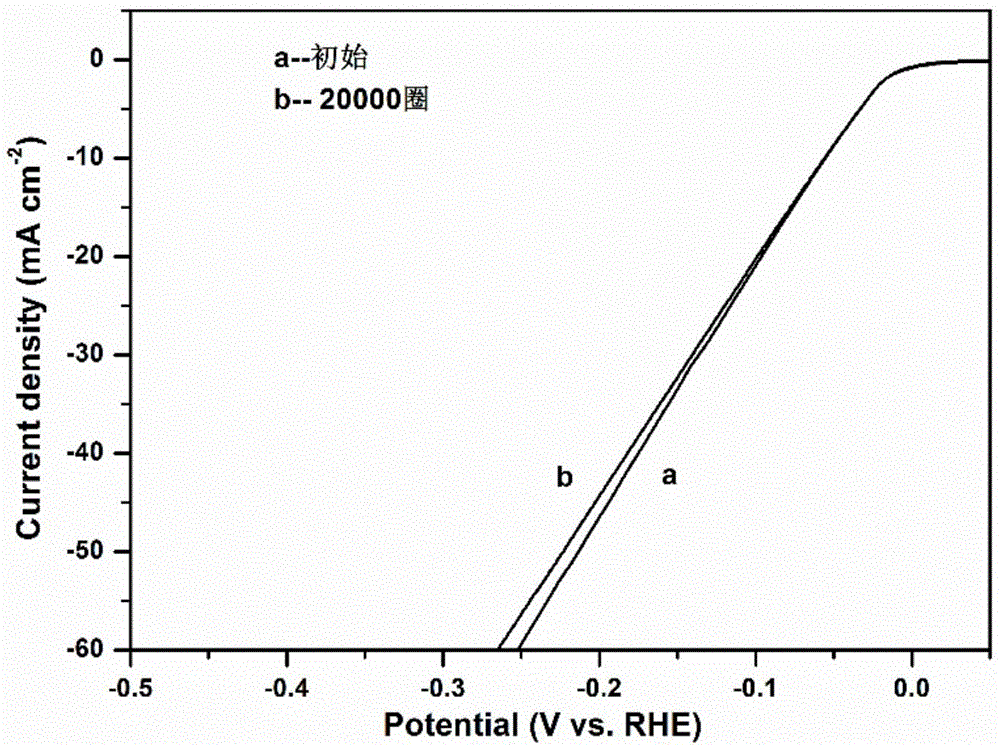

Monocrystal porous V2Se9 nanosheet array electro-catalysis material and preparation method thereof

InactiveCN106835190AHigh catalytic activityImprove stabilityElectrode shape/formsSingle crystalAmmonium metavanadate

The invention discloses a monocrystal porous V2Se9 nanosheet array electro-catalysis material. A V2Se9 nanosheet array grows on a conductive substrate, and V2Se9 is of a monocrystal porous structure. A preparation method of the monocrystal porous V2Se9 nanosheet array electro-catalysis material comprises the following steps: preparing ammonium metavanadate solution with the concentration of 1-4 mol / L, adjusting pH to be 1-3, transferring the solution to a reaction still, putting a conductive substrate in the reaction still, sealing the reaction still, carrying out first-time hydrothermal reaction, growing an ammonium metavanadate nanosheet array on the surface of the conductive substrate, taking out the conductive substrate, washing the surface of the conductive substrate with deionized water, and drying the conductive substrate; calcining the treated conductive substrate in the first step in a muffle furnace to obtain a porous V2O5 nanosheet array; rapidly transferring prepared sodium hydrogen selenide solution to the reaction still, obliquely placing the obtained conductive substrate in the reaction still, sealing the reaction still, then, putting the reaction still in a blasting drying oven, and carrying out second-time hydrothermal reaction; and preparing the V2Se9 nanosheet array. The monocrystal porous V2Se9 nanosheet array electro-catalysis material reduces the hydrogen production cost and has the catalytic activity equivalent to that of platinum.

Owner:CHONGQING UNIV

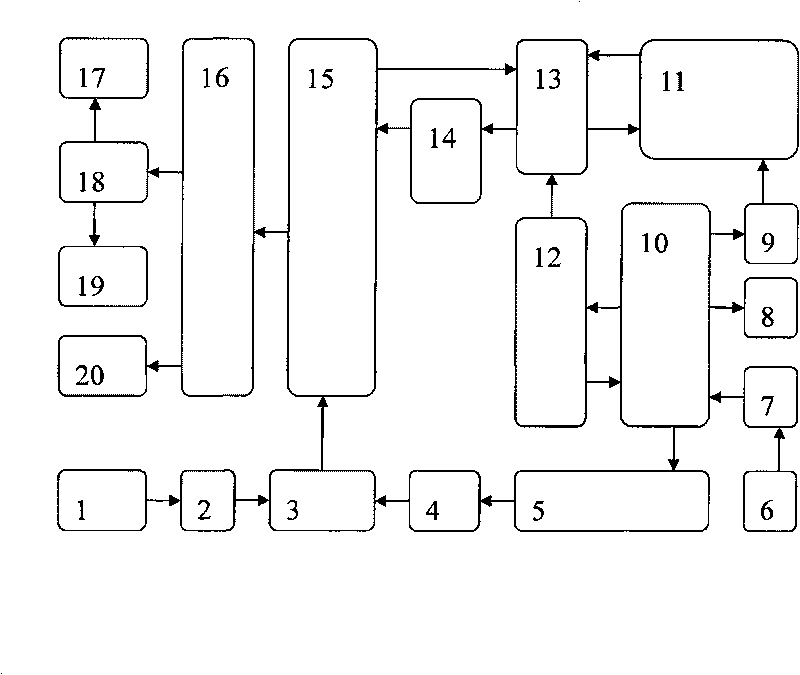

Wind-fire coupling multi-energy system based on hydrogen energy

PendingCN112510736AReduce the cost of hydrogenationAdd depthCellsEnergy inputElectrolysisLoad following power plant

The invention provides a wind-fire coupling multi-energy system based on hydrogen energy. The system comprises a wind power generation system, a thermal power generation system, a water electrolysis hydrogen production system, a fuel cell system and a hydrogen storage device, wherein the wind power generation system is connected with the water electrolysis hydrogen production system, when the peakshaving capacity of the thermal power generation system reaches the lower limit, surplus electric energy is used for supplying power to the water electrolysis hydrogen production system, the water electrolysis hydrogen production system is used for preparing hydrogen, storing the hydrogen in the hydrogen storage device, feeding the hydrogen into a fuel cell when the total power generation power is smaller than a load demand, and transmitting the hydrogen to a user when the total power generation power meets the load demand, when the total power generation power is smaller than the load demand, the fuel cell works to compensate the power shortage, excessive electric energy generated by a wind generating set electrolyzes water to produce hydrogen, the fuel cell system assists in power generation, and the deep peak regulation limit and economy of a thermal generator set are improved.

Owner:STATE GRID GASU ELECTRIC POWER RES INST +2

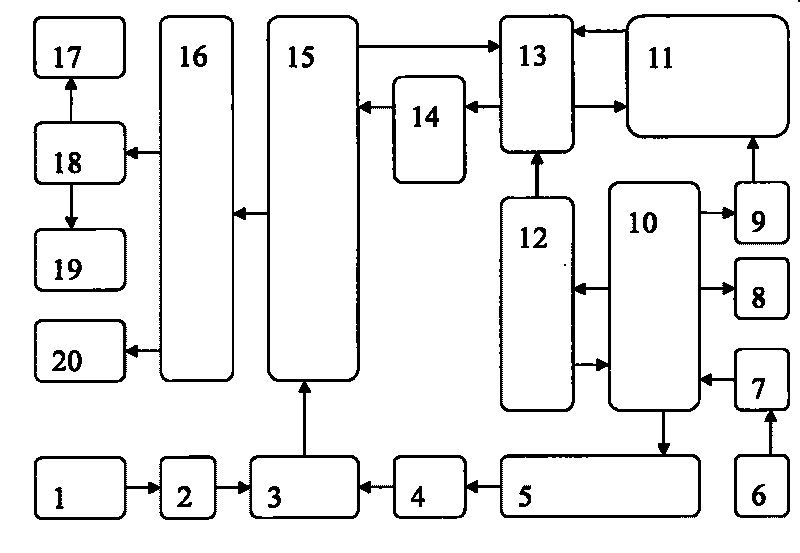

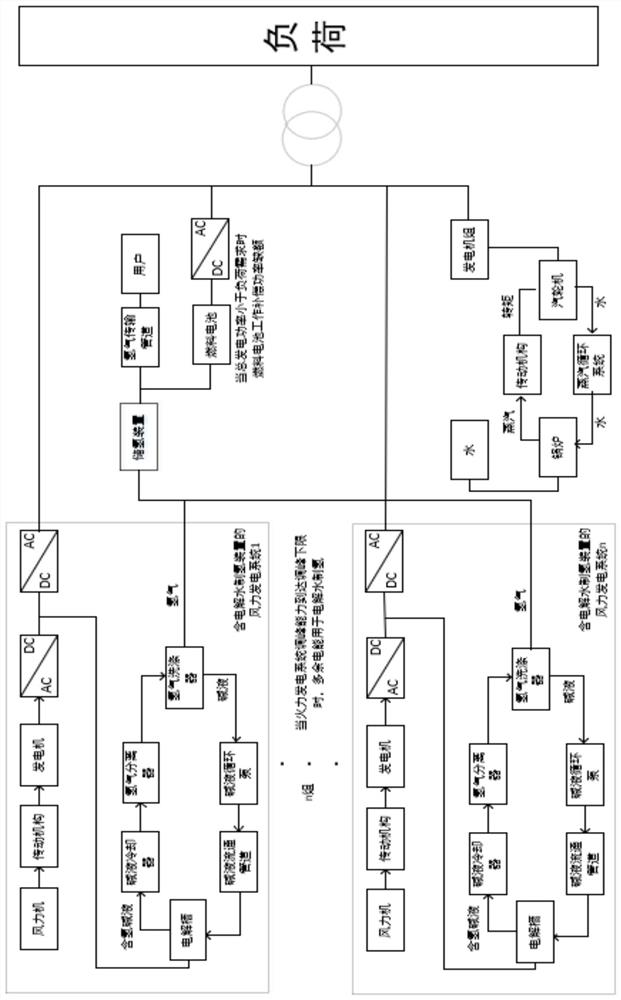

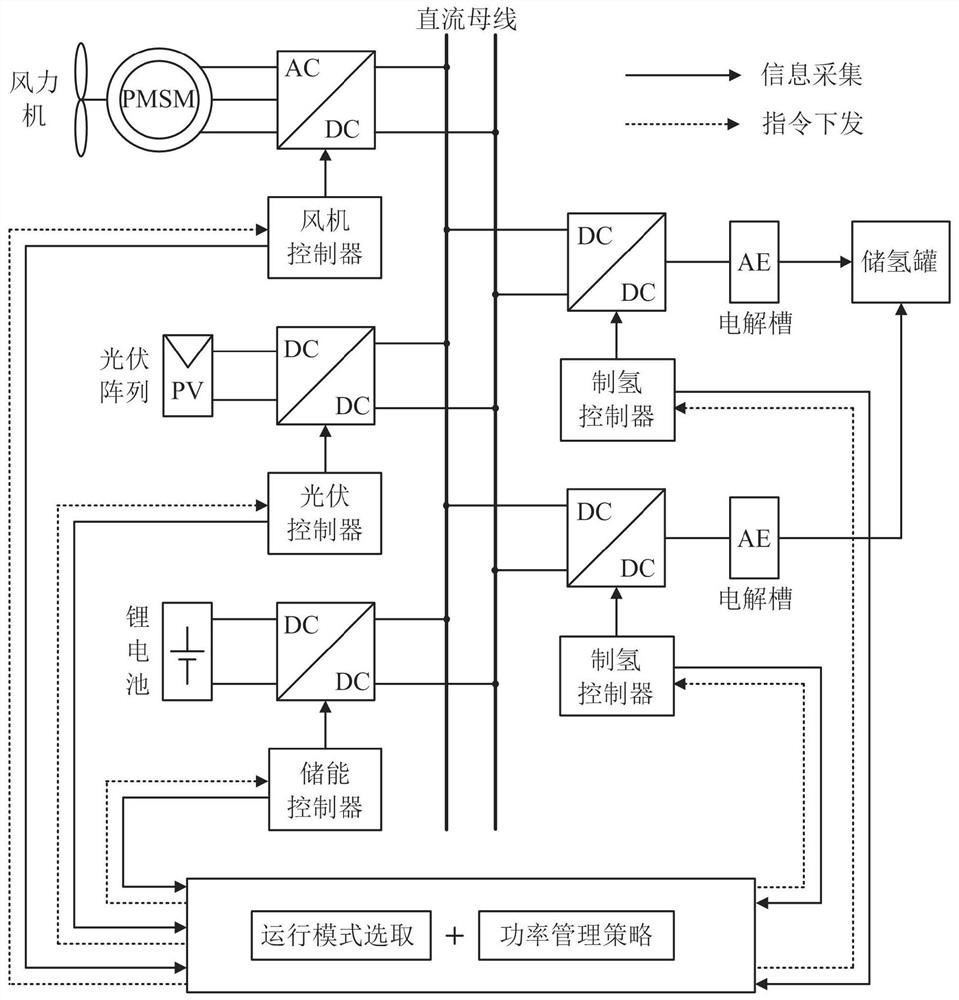

Electricity-hydrogen isolated island direct current micro-grid operation control method

PendingCN113612260AIncrease profitGuaranteed uptimeElectrical storage systemFlexible AC transmissionSolar powerMicro grid

The invention relates to an electricity-hydrogen isolated island direct current micro-grid operation control method. The method comprises the following steps of: 1, determining a switching condition between an operation mode of a system and different operation modes according to a difference between a wind-solar power generation system and a hydrogen production demand, a charge state of a lithium battery and a hydrogen state of a hydrogen storage tank; 2, determining interface device control strategies corresponding to a wind turbine generator, a photovoltaic power generation system, a lithium battery energy storage system and a hydrogen production unit in different operation modes; and step 3, determining interaction information of upper-layer power management and local equipment. According to the method, the power of the distributed power generation unit and the hydrogen production unit can be scheduled in real time according to the operation state of each unit of the system through a power management algorithm, and stable operation of the system is realized. The hydrogen production unit and the renewable energy are combined, so that the hydrogen production cost can be reduced, and the utilization rate of the renewable energy can be increased.

Owner:HEBEI JIANTOU NEW ENERGY CO LTD

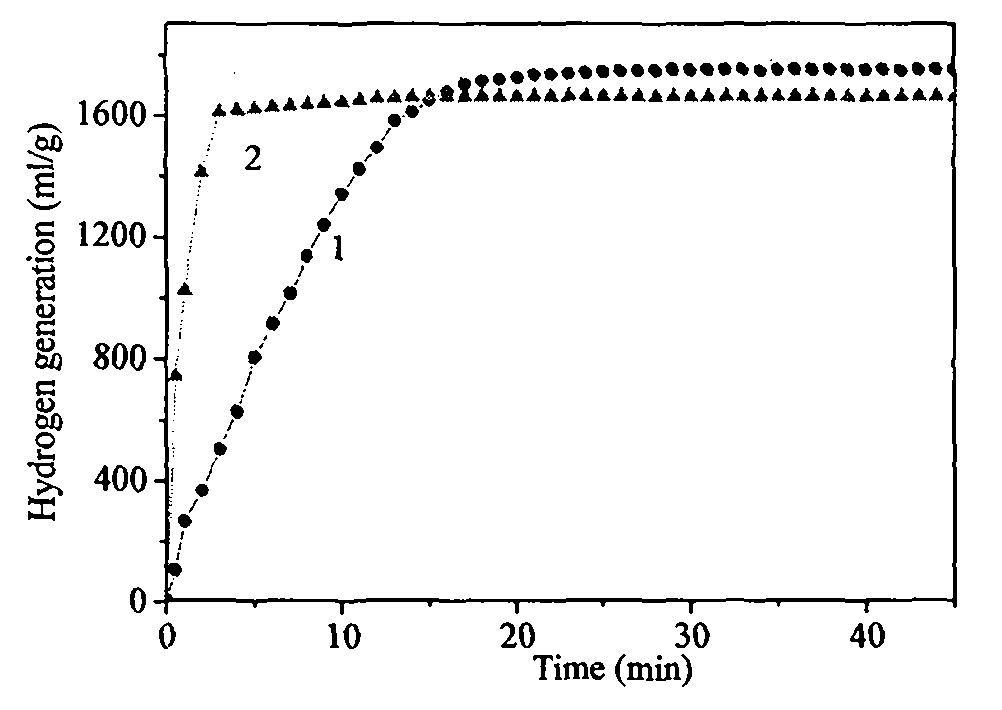

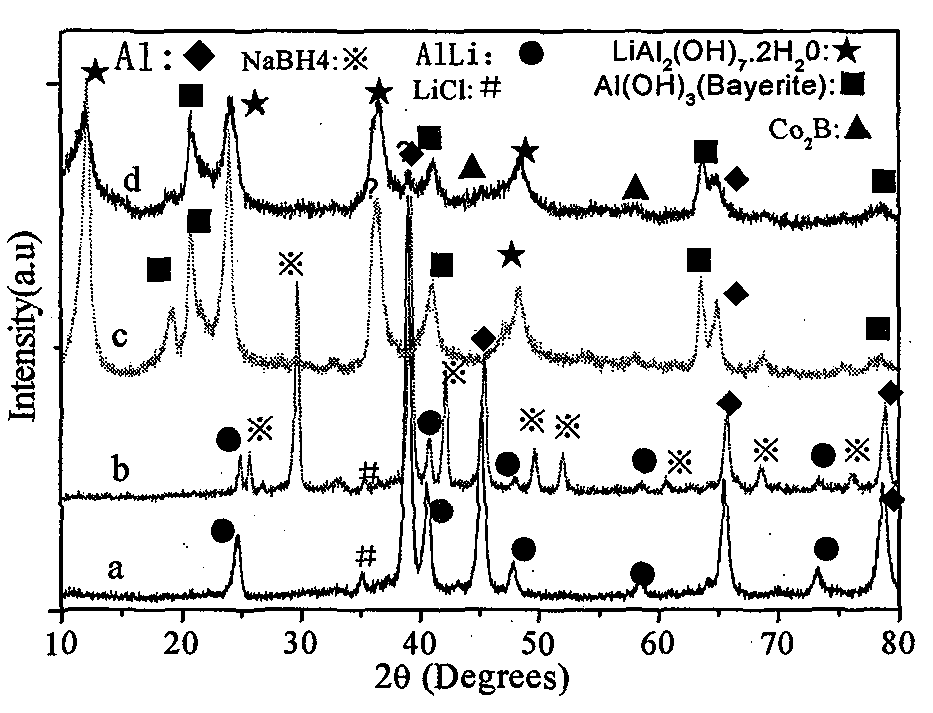

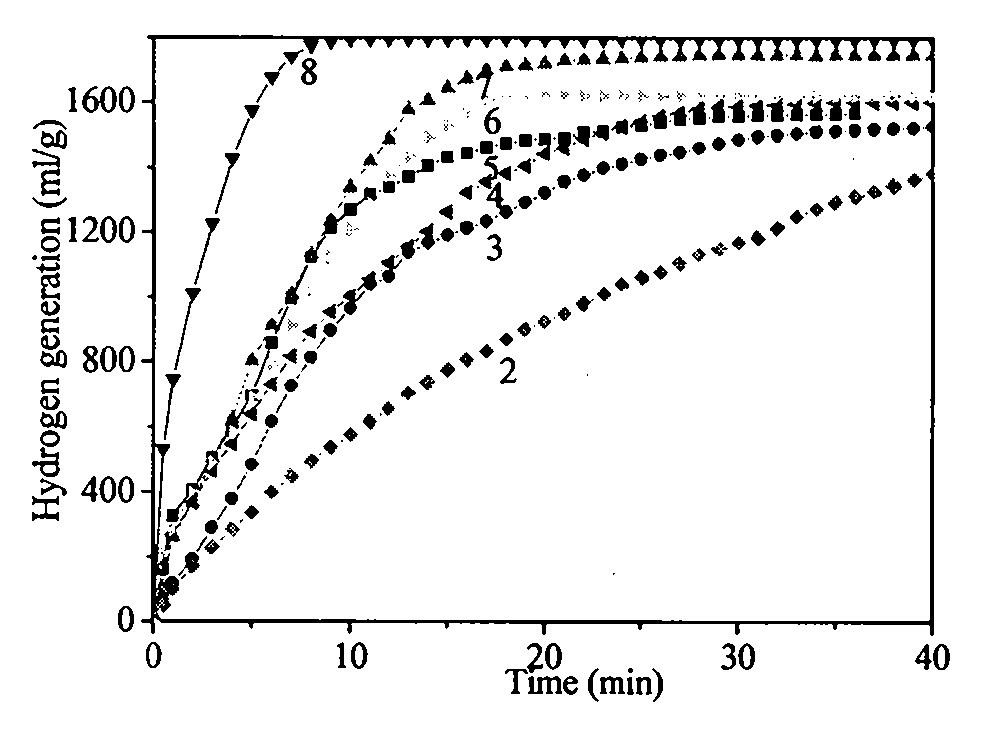

A kind of aluminum alloy/borohydride system for hydrogen production and preparation method thereof

InactiveCN102275874AObvious advantagesHigh hydrogen storage valueHydrogen productionMetallic lithiumCobalt metal

The invention relates to an aluminum alloy / borohydride system for hydrogen production and a preparation method thereof. The system comprises the following components in percentage by weight: 5-95% of aluminum alloy and the balance of borohydride, wherein the aluminum alloy consists of aluminum, an alkaline substance and an activator; the alkaline substance is one or more of lithium metal, calcium metal, lanthanum metal and strontium metal; the activator is one or more of cobalt metal, nickel metal, cobalt salt and nickel salt; and the aluminum content of the aluminum alloy is 30-95wt%, the total content of the alkaline substance is 1-30wt%, and the total content of the activator is 4-40wt%. By adopting the invention, the hydrogen storage value of the hydrogen production system per unit mass can be increased, and the hydrolysis performance of aluminum / borohydride can be improved.

Owner:CHINA JILIANG UNIV

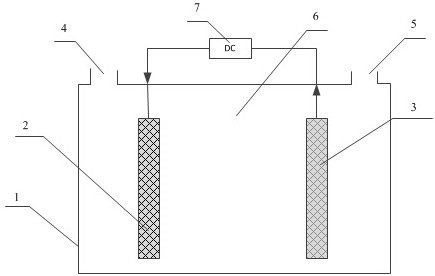

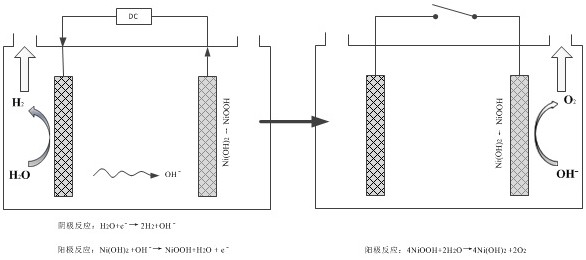

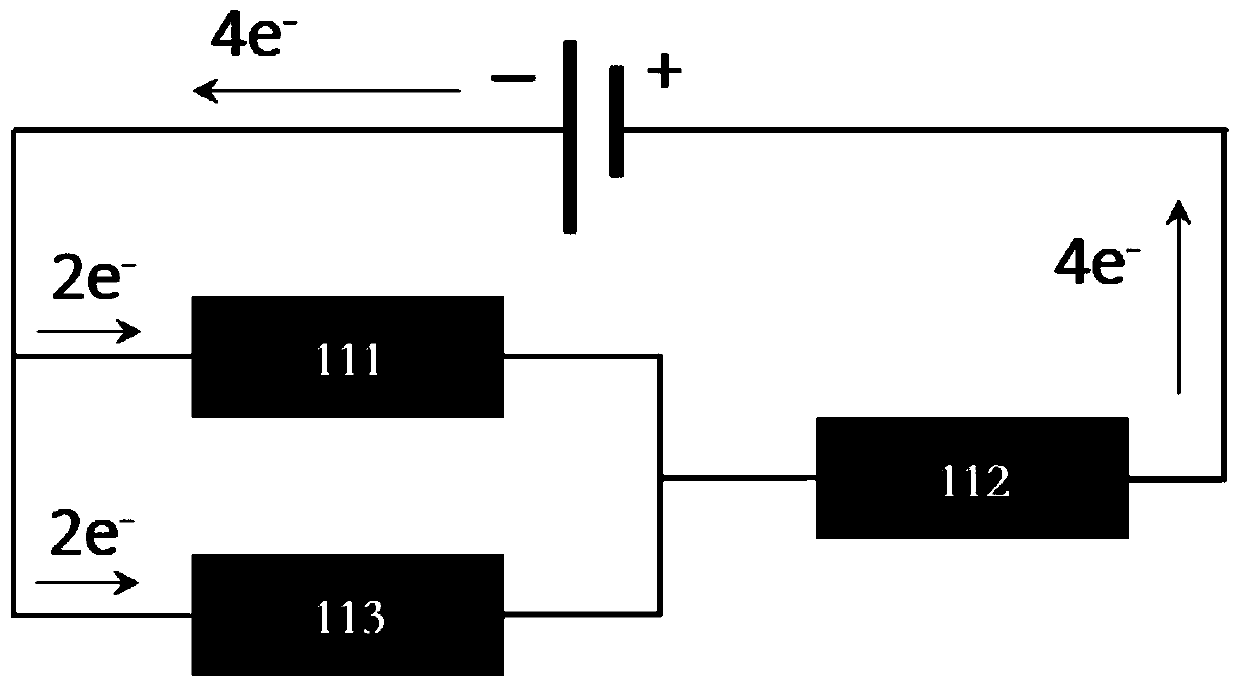

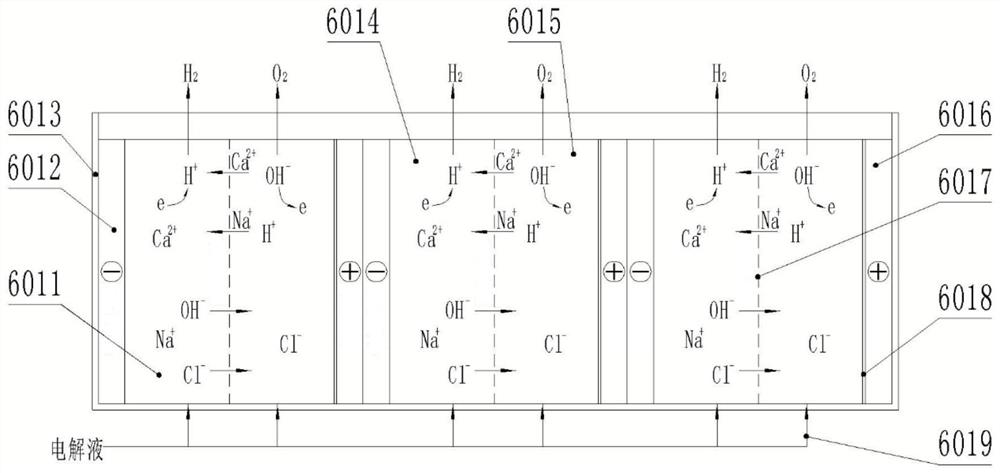

Method for producing hydrogen by electrolyzing water step by step and device thereof

PendingCN113151843ATo achieve separate productionIncrease transfer rateCellsNon-noble metal oxide coatingsElectrolytic agentElectrolysed water

The invention discloses a method for producing hydrogen by electrolyzing water step by step and a device thereof. The device comprises an electrolytic bath, a hydrogen evolution catalysis cathode electrode, a nickel hydroxide anode electrode, a hydrogen outlet and an oxygen outlet. Wherein the electrolytic bath does not comprise a diaphragm, and a cavity is formed in the electrolytic bath. The method for producing hydrogen by electrolyzing water comprises the following steps: firstly, switching on an external direct-current power supply of an electrolytic bath, so that water molecules in electrolyte are electrochemically reduced on the surface of a hydrogen evolution catalytic cathode electrode to produce hydrogen, and a Ni (OH)2 anode electrode is electrochemically oxidized into a NiOOH anode electrode; and then, a direct-current power supply outside the electrolytic bath is switched off, high-temperature saturated steam is introduced into the electrolyte of the electrolytic bath, the temperature of the electrolyte is ensured to reach 90-110 DEG C, at the moment, due to the thermodynamic instability of NiOOH, the anode electrode is decomposed and reduced into a Ni (OH)2 electrode, and oxygen is generated around the electrode. The hydrogen and the oxygen are prepared by electrolysis through the two steps, so that the high-purity hydrogen and the high-purity oxygen can be prepared, and the cost of hydrogen production by electrolysis of water can be effectively reduced.

Owner:SHANGHAI SUN-HYDROGEN ENERGY TECH CO LTD

Method of preparing hydrogen gas by catalytic gasifying hydrolysis residue of cellulose castoff

InactiveCN1919722AImprove economyPromote the development of industrializationHydrogen productionFermentationCelluloseSyngas

The invention discloses a hydrogen preparing method of hydrolytic slag catalyzing gasification of cellulose waste, which is characterized by the following: adopting biological acid hydrolytic or enzyme hydrolytic waste as raw material; using catalyzing gasification method; preparing hydrogen-rich synthetic gas under fitful reacting temperature, pressure and time.

Process for preparing hydrogen from deoiled asphalt employing combustion gasification and CO2 in-situ adsorption-enhanced water-gas shift reaction in in-furnace calcium-spraying circulating fluidized bed

The invention discloses a process for preparing hydrogen from deoiled asphalt employing combustion gasification and CO2 in-situ adsorption-enhanced water-gas shift reaction in an in-furnace calcium-spraying circulating fluidized bed. The process comprises the following steps: gradually expanding a conical circulating fluidized bed of a hearth, carrying out partial air combustion on the deoiled asphalt on the lower part of the circulating fluidized bed, releasing heat for water vapor gasification on most of deoiled asphalt material; spraying a limestone desulfurization agent into a furnace, and carrying out desulfurization in a circulating fluidized bed furnace; feeding a synthesis gas generated by the circulating fluidized bed into a moving bed reactor; carrying out CO2 in-situ adsorption-enhanced water-gas shift reaction to prepare hydrogen; setting a water-gas shift moving bed reactor and a regenerator through the adsorption-enhanced water-gas shift reaction, so that successive and simultaneous movement, reaction and regeneration of an NiO / Al2O3 catalyst and an CaO adsorbent of adsorbing CO2 are carried out. By virtue of coupling of successive catalytic water-gas shifting and CO2 in-situ adsorption separation processes and enhanced water-gas shifting for heat and mass transfer, a high-purity hydrogen product can be continuously prepared by the synthesis gas from the circulating fluidized bed at 450-600 DEG C.

Owner:DALIAN UNIV OF TECH

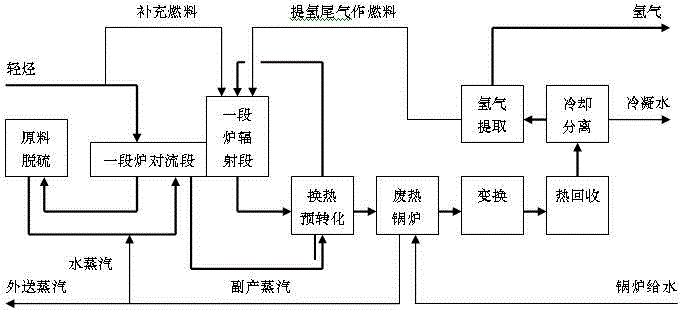

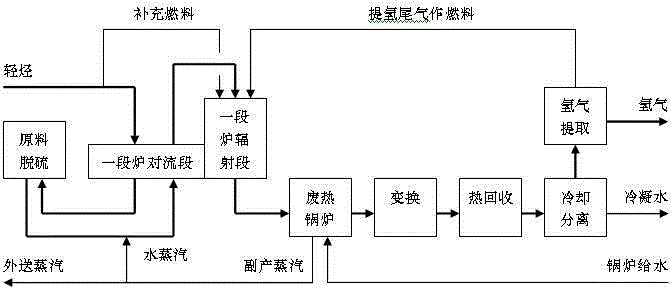

Method for producing hydrogen by light hydrocarbon primary steam reforming with heat exchange pre-reforming

ActiveCN104150440AReduce consumptionReduce the amount of by-product steamHydrogenEnergy inputSteam reformingThermodynamics

The invention belongs to the field of hydrogen production and in particular relates to a method for producing hydrogen by using light hydrocarbons as raw materials and adopting a light hydrocarbon primary steam reforming technology with heat exchange pre-reforming. The method is characterized by comprising the following steps: introducing a heat exchange type pre-reforming furnace, providing part of heat for reforming reaction by sensible heat of high-temperature reforming gas at the outlet of a primary steam reforming furnace, instead of part of fuel gas, and pre-reforming mixed raw material gas before entering the primary steam reforming furnace, so that a large amount of fuel required for the primary steam reforming furnace and a large amount of byproduct steam of a reforming gas waste heat boiler and a flue gas waste heat boiler at the convection section of the primary steam reforming furnace can be reduced, and the purposes of reducing the light hydrocarbon raw material and fuel consumption and the hydrogen production cost in a hydrogen production process can be achieved. Compared with a conventional method for producing hydrogen by the light hydrocarbon primary steam reforming technology, the method provided by the invention has the characteristics that the total light hydrocarbon consumption (raw materials and replenished fuel) can be reduced by about 7%-15%; at present, the price of light hydrocarbons is increasingly raised, the hydrogen production cost can be greatly reduced and the discharge of waste gas is reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

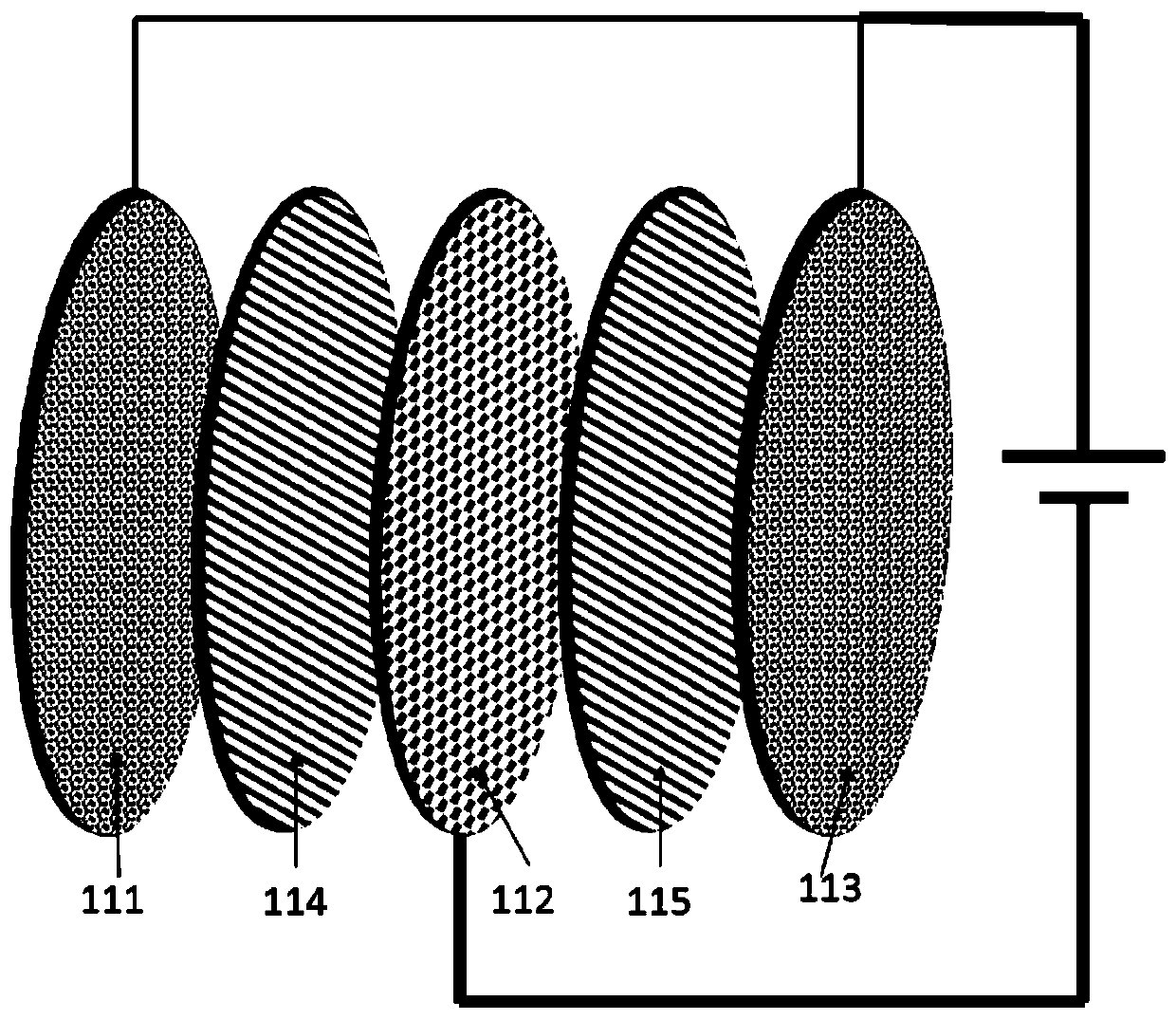

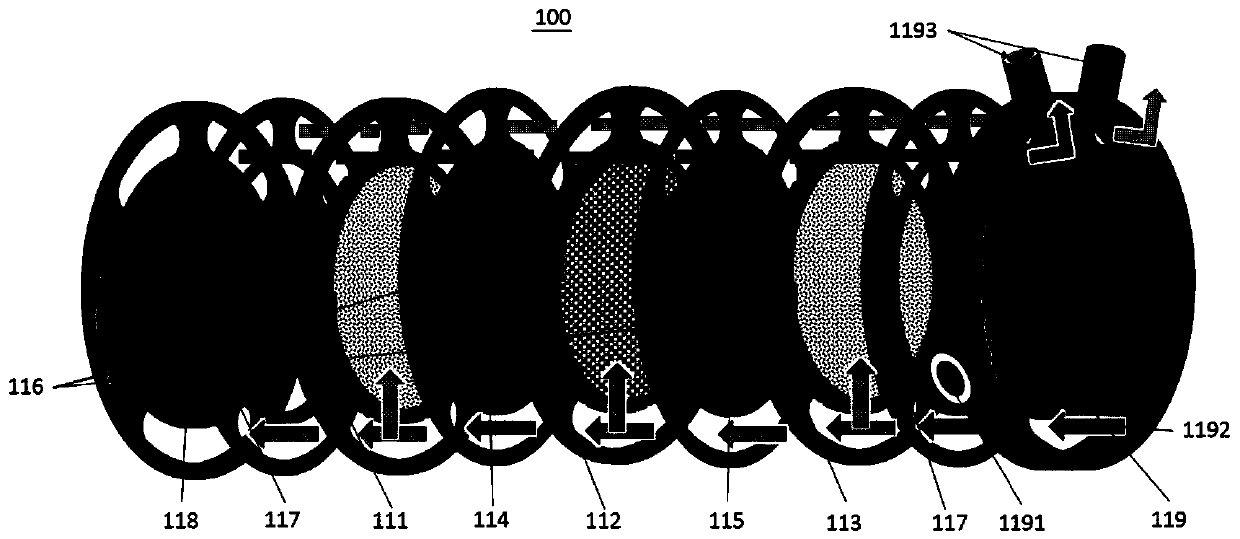

Water electrolysis produced gas pressure self-balancing device and application thereof

The invention discloses a water electrolysis produced gas pressure self-balancing device and an application thereof, and relates to the field of gas pressure self-balancing devices. The device comprises an electrolysis unit, the electrolysis unit comprises a first cathode, a common anode and a second cathode; the common anode is arranged between the first cathode and the second cathode, two side faces of the common anode are opposite to the first cathode and the second cathode respectively, the first cathode and the second cathode are connected in parallel and used for being connected with a negative electrode of an external power supply respectively, and the common anode is used for being connected with a positive electrode of the external power supply. An electrolysis unit without pressure difference can be formed; a special pressure balance part or system does not need to be additionally arranged; the complexity of an electrolysis system is effectively reduced, the cost is reduced,popularization and application of a water electrolysis hydrogen production and oxygen production technology are facilitated, particularly application to alkaline water electrolysis hydrogen productionand oxygen production can be achieved easily, water hydrolysis under a high pressure can be realized easily, the gas production pressure can also be remarkably improved, and the gas production efficiency is greatly improved.

Owner:GUANGDONG INST OF NEW MATERIALS

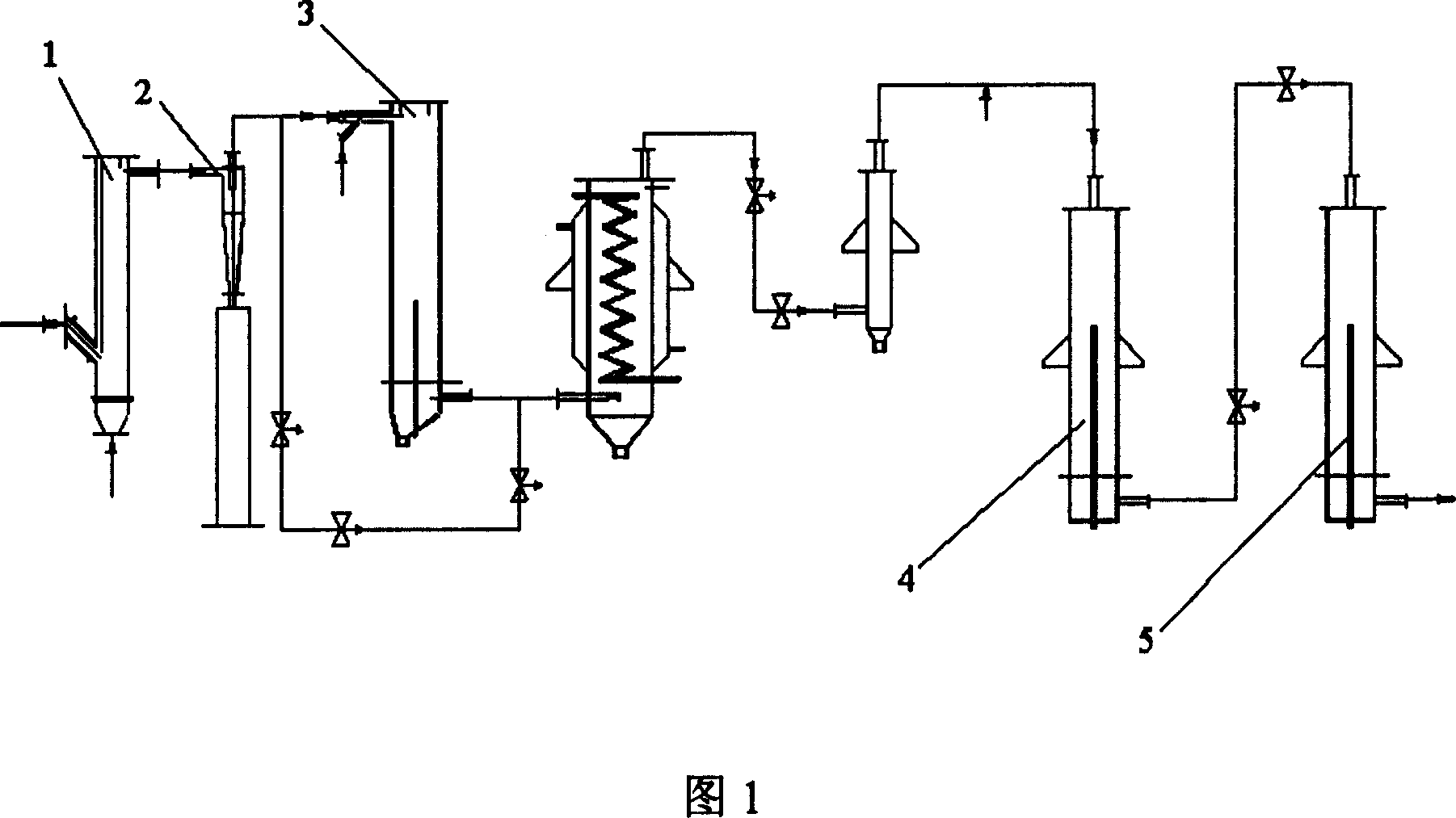

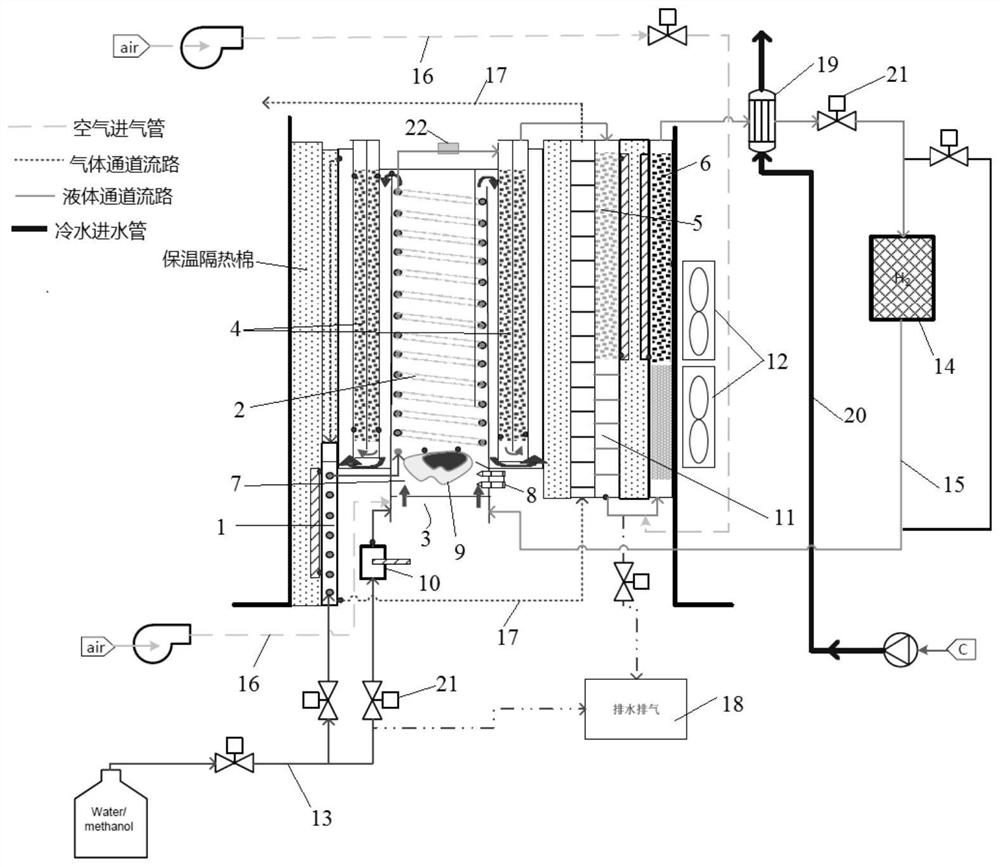

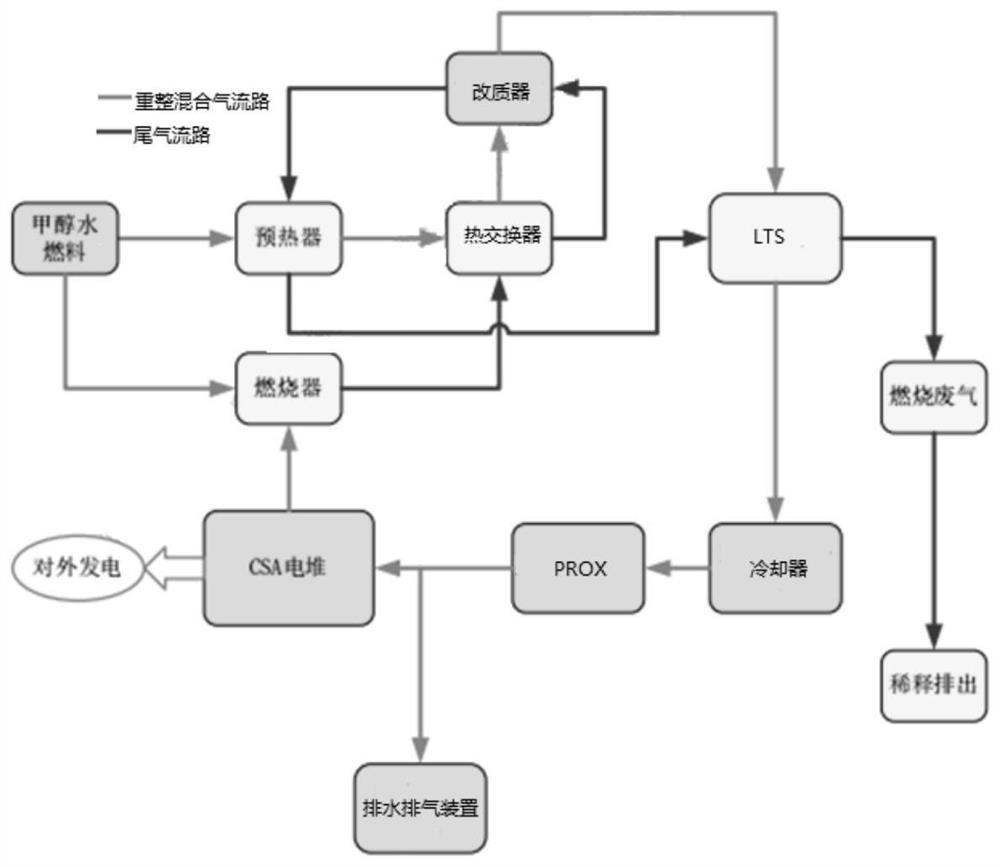

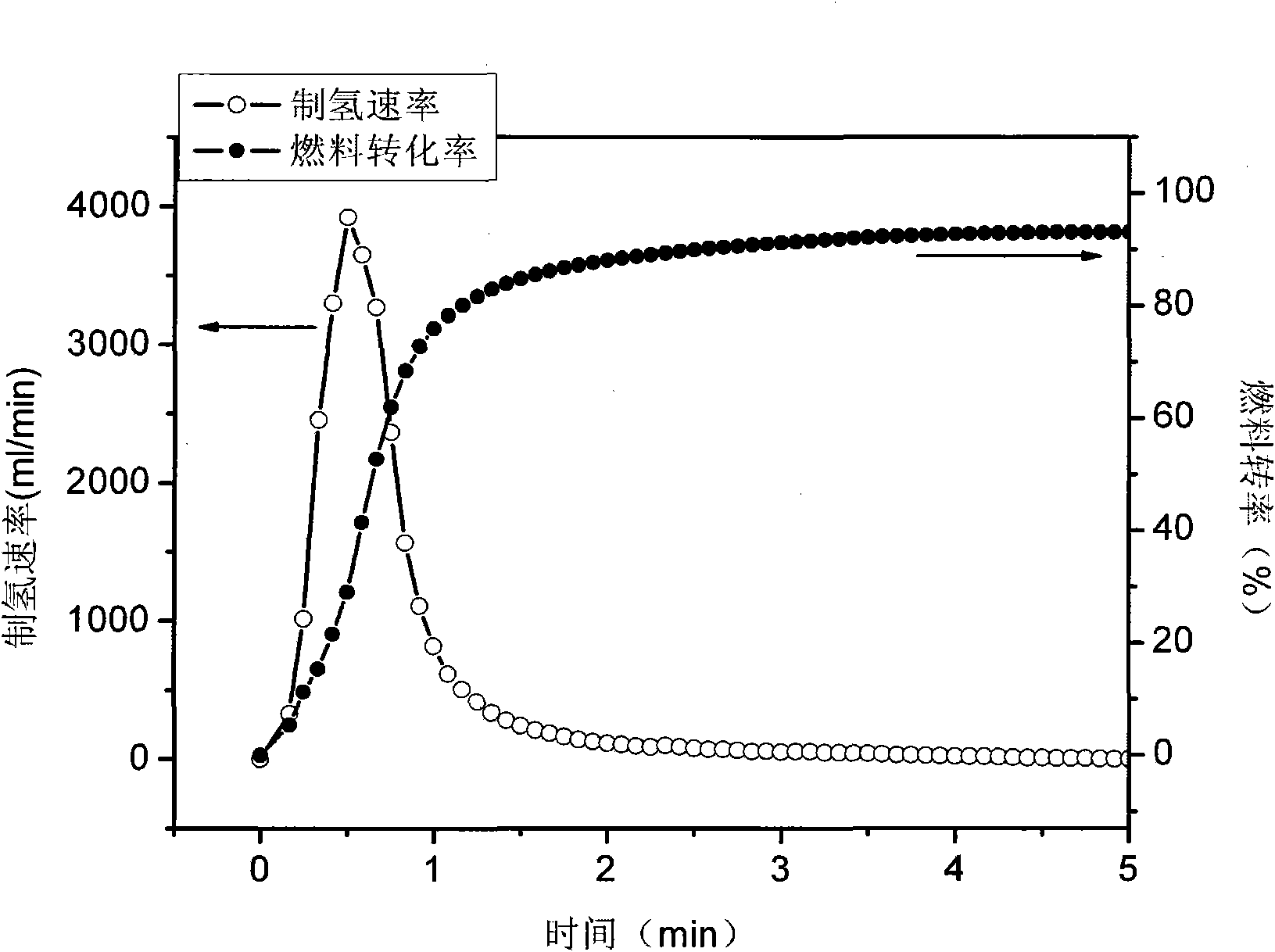

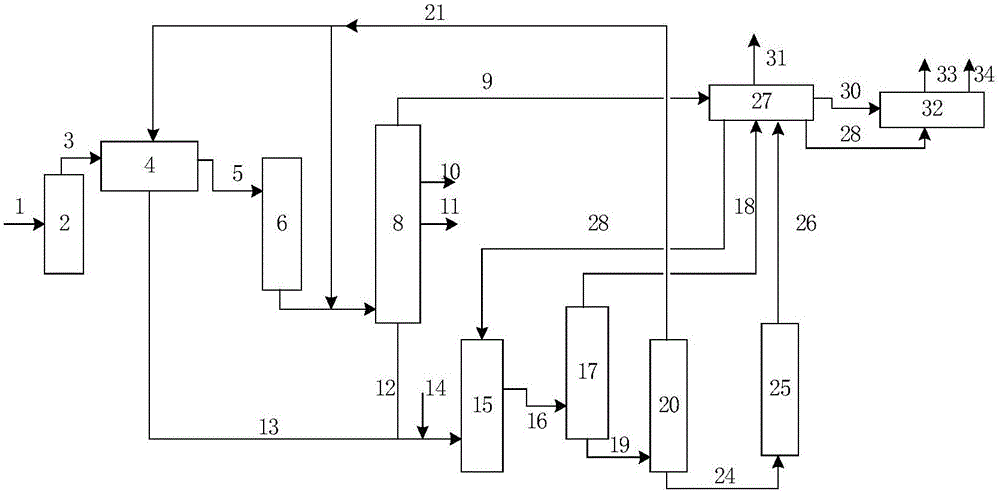

Methanol-water fuel reforming hydrogen production system

PendingCN111747378AReduce CO concentrationImprove the purification effectHydrogen separation using solid contactHydrogen/synthetic gas productionPtru catalystCatalytic oxidation

The invention discloses a methanol-water fuel reforming hydrogen production system. The system comprises a methanol-water fuel feeding pipe, an evaporator, a modifier, a CO oxidation removal device and a hydrogen-rich mixed gas conveying pipe which are connected in sequence. The CO oxidation removal device comprises an LTS catalytic oxidizer and a PROX catalytic oxidizer, a copper-zinc-based catalyst is arranged in the LTS catalytic oxidizer, and a ruthenium-based catalyst is arranged in the PROX catalytic oxidizer. The hydrogen-rich mixed gas is subjected to staged oxidation treatment throughthe LTS catalytic oxidizer and the PROX catalytic oxidizer, so that the CO concentration in the gas is gradually reduced to guarantee that CO is completely removed. According to the system, the conversion rate of methanol can reach 100%, CO in the reformed mixed gas can be completely removed, the starting time of the system is short, the reforming hydrogen production condition can be rapidly achieved, energy consumption is low, the hydrogen production speed is high, the hydrogen production cost is low, the energy conversion efficiency is high, environmental protection and energy conservationare achieved, and the power generation efficiency is high after the system is in butt joint with a fuel cell stack.

Owner:摩氢科技有限公司

System and method for comprehensive utilization of boiler sulfur-containing flue gas and fly ash

PendingCN112811454ASolve the difficulties of high temperature pyrolysis hydrogen productionReduce energy consumptionSilicaHydrogen productionSilicon dioxideSulfur containing

A system and method for comprehensive utilization of boiler sulfur-containing flue gas and fly ash are characterized in that a boiler flue outlet is connected to a Benzoic reaction device, the Benzoic reaction device is connected with a water supply device, a reactor exhaust device, an inlet of a sulfuric acid collection device and a hydrogen iodide decomposition device, the hydrogen iodide decomposition device is connected with an iodine recovery device, a hydrogen collection device, and a fourth inlet of the Benzoic reaction device, the iodine recovery device is connected with the iodine supply device, and an outlet of the iodine recovery device is connected with the Benzoic reaction device; the sulfuric acid collection device is connected with the aluminum sulfate preparation device, the aluminum sulfate preparation device is connected with an outlet of the boiler fly ash system and an inlet of the aluminum sulfate treatment device, and an outlet of the aluminum sulfate treatment device is connected with inlets of the aluminum sulfate storage device and the silicon dioxide treatment and storage device; and based on the system, sulfuric acid generated in the hydrogen production process is used for absorbing disulfur trioxide in the fly ash, meanwhile, silicon dioxide with high purity can be generated, aluminum sulfate and silicon dioxide with high additional value are formed, and waste substances are recycled.

Owner:XIAN THERMAL POWER RES INST CO LTD

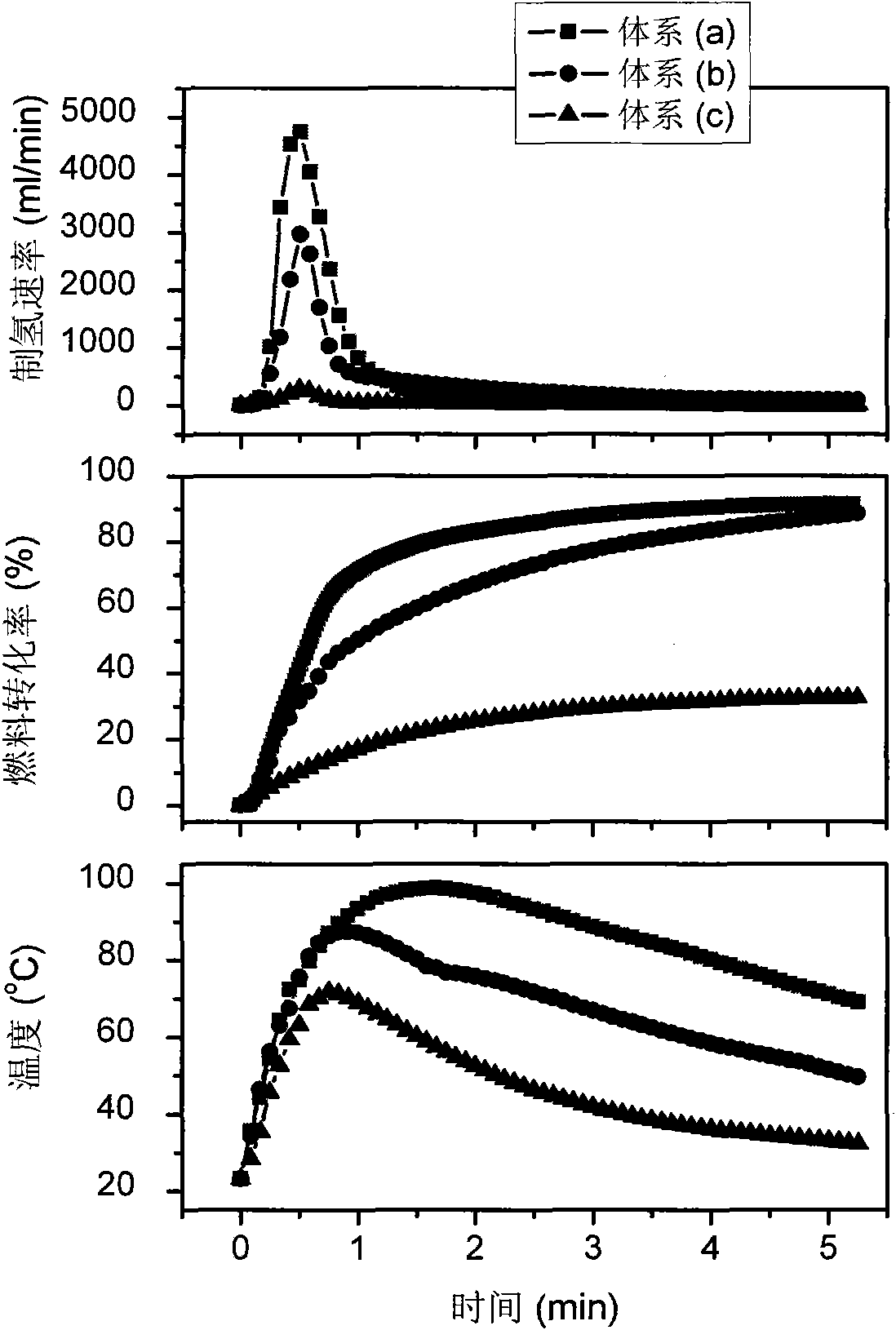

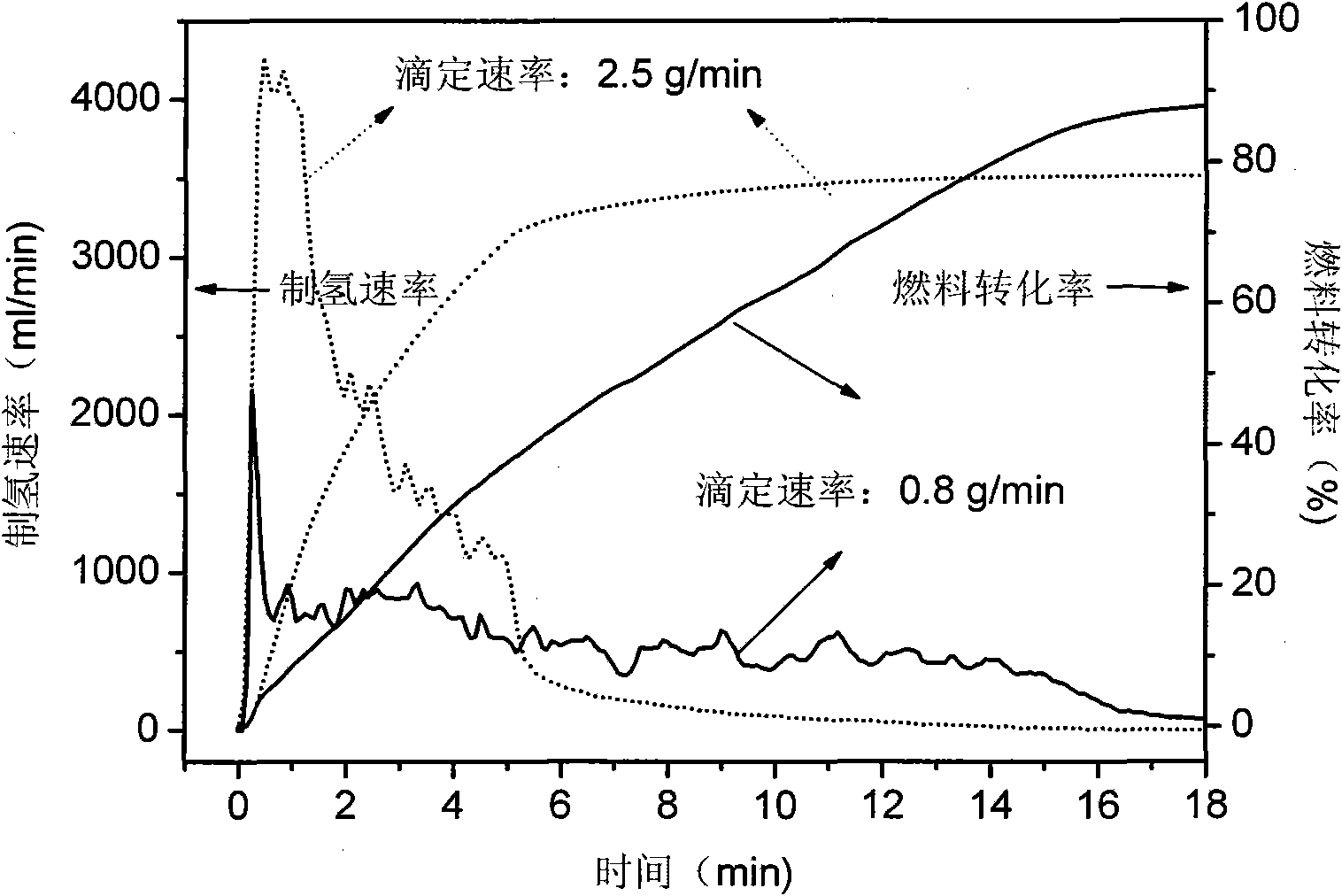

System and method for producing hydrogen by controllably hydrolyzing sodium borohydride/aluminum powder mixed solid fuel

InactiveCN102211757AHigh hydrogen storage densityAddressing Solubility LimitationsHydrogen productionControl mannerLiquid fuel

The invention relates to a hydrogen storing and producing technology, in particular to a system and method for producing hydrogen by controllably hydrolyzing sodium borohydride / aluminum powder mixed solid fuel. The system for producing hydrogen consists of solid fuel and liquid fuel, wherein the solid fuel is a mixture of sodium borohydride, aluminum powder and alkali; and the liquid fuel is a transition metal saline solution. In the method for producing hydrogen, the liquid fuel is taken as a hydrogen-producing reaction control preparation and is added into the solid fuel in a controlling manner, so that the immediate controllable hydrogen production can be realized according to the requirement. According to the system and method for producing hydrogen by hydrolyzing the mixed solid fuel, which are provided by the invention, the problems that the hydrogen production efficiency is low, the hydrogen production cost is high, and the like in the prior art can be solved; and the system and method have the advantages of high hydrogen production efficiency, favorable reaction controllability, high fuel conversion rate, simplicity and convenience in operation, relatively-low hydrogen production cost, and the like and can provide a moving hydrogen source for hydrogen combustion vehicles and various military and civil mobile and portable power supplies.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Binary and ternary transition metal hydrides as well as preparation method and application thereof

InactiveCN107519879ARaising the cost of hydrogen productionImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsElectrodesIridiumElectrolysis

The invention discloses binary and ternary transition metal hydrides, a preparation method and an application of the binary and ternary transition metal hydrides as an efficient and stable electro-catalytic hydrogen evolution catalyst. The catalyst has the molecular formula being HxMaRbYcO3, wherein M, R and Y are two or three different transition metals, the value of x ranges from 0.01 to 1, and the sum of a, b and c is equal to 1. M, R and Y are any two or three elements of scandium, titanium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, zinc, zirconium, niobium, molybdenum, rhodium, osmium, tungsten, tantalum and iridium. HxMaRbYcO3 as a water electrolysis catalyst has electrochemical performance in an acidic electrolyte equivalent to the performance of a commercial carbon-supported platinum catalyst, has very high stability and is prepared with a simple preparation process and easy to amplify. Therefore, HxMaRbYcO3 can serve as a substitute of the carbon-supported platinum catalyst, and the hydrogen production cost is effectively reduced.

Owner:WUHAN HYNERTECH CO LTD

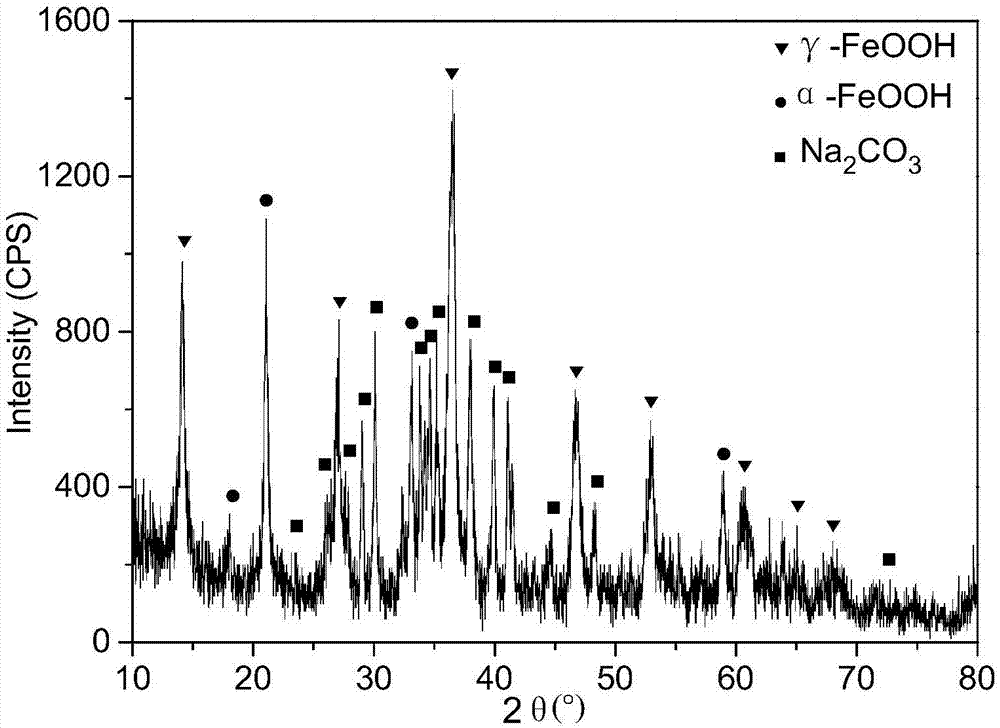

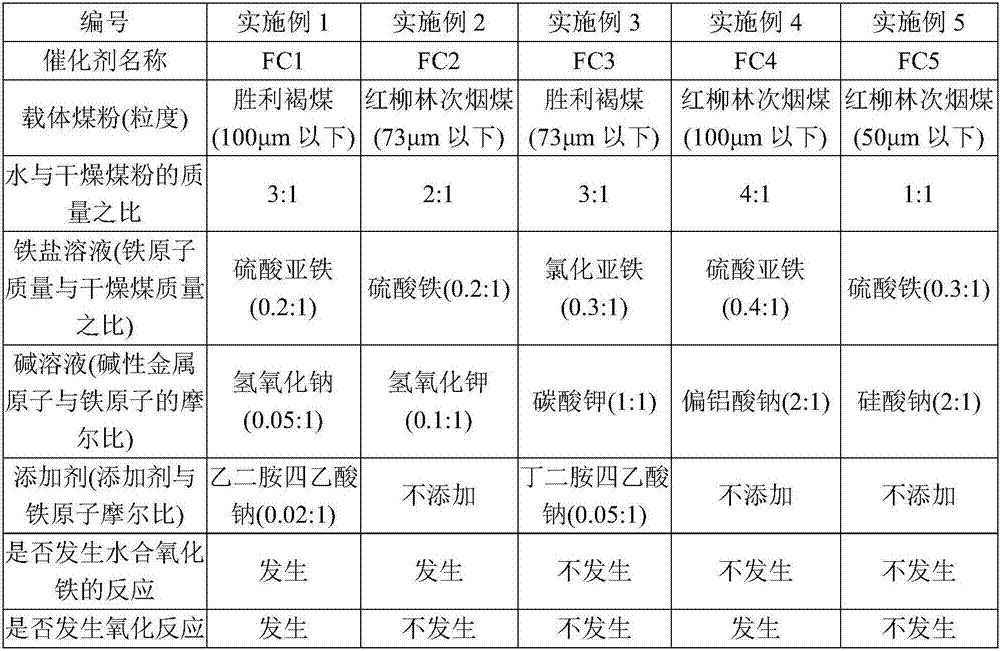

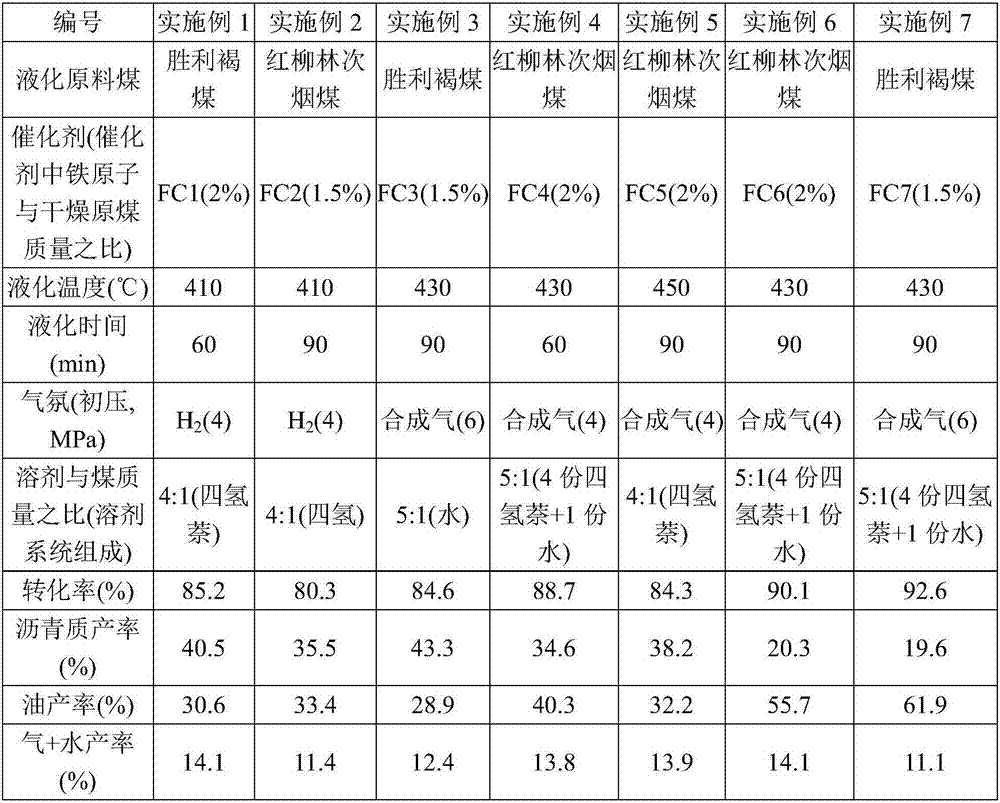

Iron alkali composite catalyst for direct liquefaction of coal

InactiveCN107349948ARaw materials are cheap and easy to getEasy to makePhysical/chemical process catalystsLiquid hydrocarbon mixture productionChemical reactionPrill

The invention relates to an iron alkali composite catalyst for direct liquefaction of coal. The catalyst can be a loaded type or a mixed type. The loaded catalyst is prepared by loading an iron active component and an alkali active component on the surface of coal particles through chemical reactions. The mass ratio of water to dry coal powder is (0.5-5):1. The mass ratio of iron atoms in the iron salt solution to dry coal powder is (0.1-0.5):1. The mole ratio of additive to iron atoms in the iron salt solution is (0-0.1):1. The mole ration of alkaline metal atoms in the alkali solution to iron atoms in the iron salt solution is (0.001-5):1. The mixed type catalyst is prepared by directly mixing iron containing substances and alkali containing substances, wherein the mole ratio of alkaline metal atoms to iron atoms is (0.001-5):1. The catalyst is suitable for direct liquefaction of coals in different systems and is capable of prominently improving the coal conversion rate and yield of oil. Moreover, the raw materials are cheap and easily available. The preparation is simple. The catalyst has a very good application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH +1

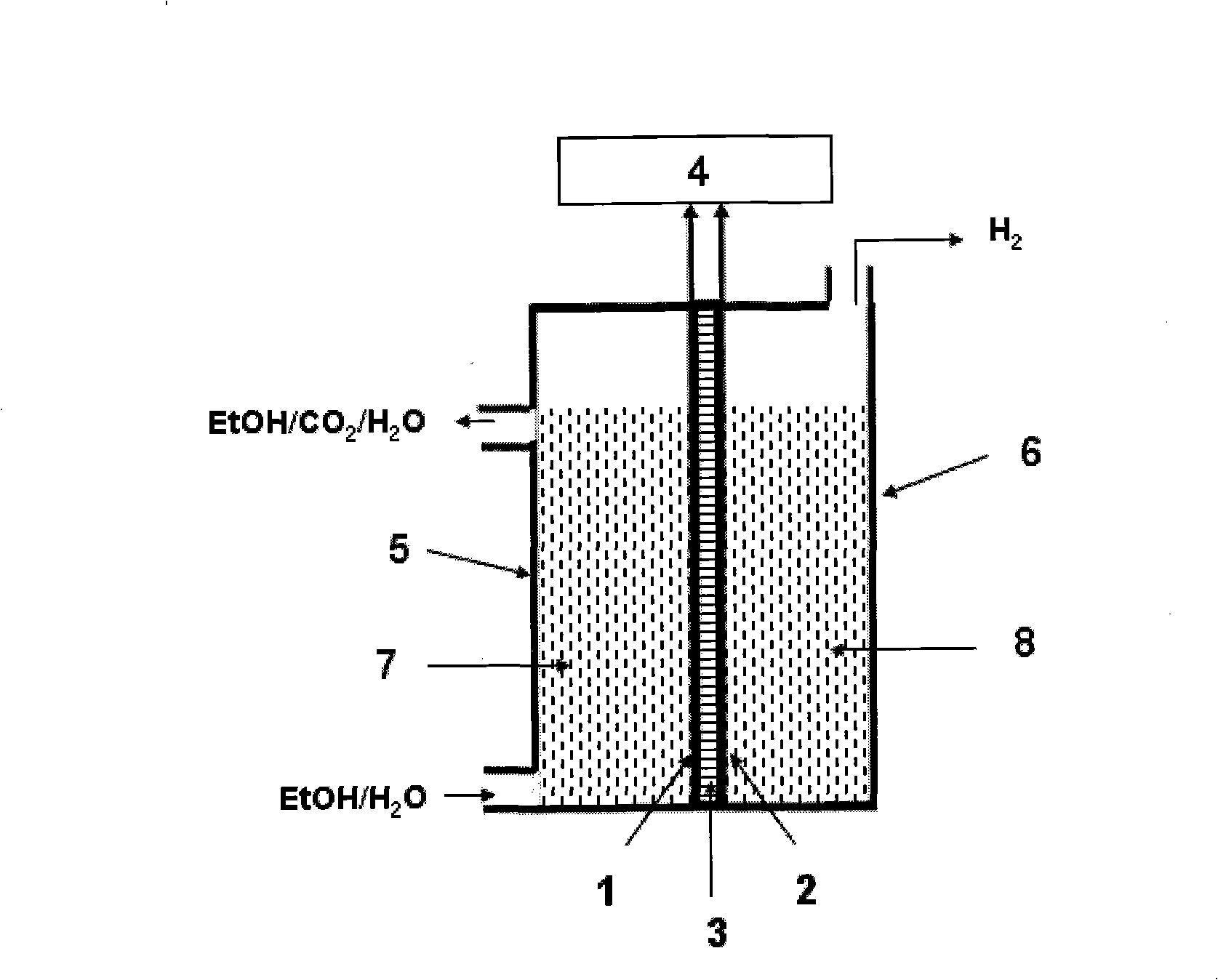

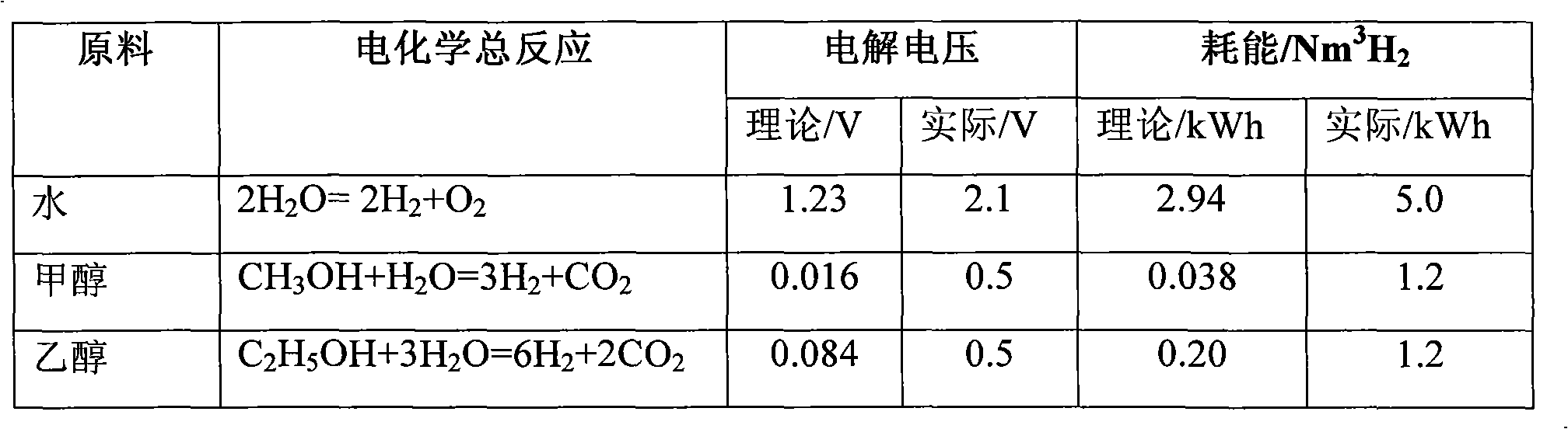

Method for preparing hydrogen by electrochemically reforming alcohol and device thereof

The invention provides a method for preparing hydrogen by reforming alcohol through galvano chemistry and a device thereof. The method comprises: the mixed liquid of alcohol and water enters into an anode chamber in a reforming groove through a circulation pump; DC voltage is applied between anode and cathode of the reforming groove, the alcohol and the water are reformed through galvano chemistry at the anode, and the water is restored to be hydrogen at the cathode to be precipitated. The device comprises a DC power supply, the mixed liquid of alcohol and water, a container used for storing the mixed liquid of alcohol and water, the anode chamber used for passing in and out of the mixed liquid of liquid alcohol and water, a cathode chamber used for storing water and a hydrogen collecting device connected with the cathode chamber; wherein, the anode chamber is separated from the cathode chamber by a solid anion conducting polymer film which is taken as electrolyte. By using the invention, the aqueous solution of alcohol enters into the reforming groove through the circulation pump, the alcohol and the water are reformed through galvano chemistry at the anode when being applied with certain DC voltage, and the water is restored to be hydrogen at the cathode to be separated out. The invention can be used for preparing hydrogen under the conditions of low voltage, cost and energy consumption.

Owner:SUN YAT SEN UNIV

Hydrogen production method

InactiveCN109019510AEasy to storeReduce the cost of hydrogen productionHydrogenFerroso-ferric oxidesBrown iron oxideChemistry

The invention belongs to the field of hydrogen production, and discloses a hydrogen production method. The method comprises the following steps: iron powder is in contact with oxygen-bearing vapor, the vapor in the oxygen-bearing vapor reacts with the iron powder, so that ferroferric oxide and hydrogen are produced; meanwhile, the oxygen in the oxygen-bearing vapor reacts with the iron powder, sothat iron oxide is produced and heat is released, and the released heat is provided for the reaction between the vapor and the iron powder, so that the vapor and the iron powder continue to react. Theiron powder as a main raw material for the hydrogen production method provided by the invention is cheap, not a hazardous article, easy to store, pressure-free and pollution-free; the whole production and reaction process is almost pollution-free and emission-free, and does not consume electricity; the volumetric ratio of the materials to hydrogen output is high, and 3000 cubic meters of hydrogencan be produced per cubic meter of iron powder; the hydrogen production cost is low, and after ferroferric oxide as a byproduct is recovered, the cost of per cubic meter of hydrogen is less than 0.5yuan; the process is simple, complex equipment, such as a compressor, is not needed, investment is savereduced, the hydrogen production method is easy and convenient to operate, and therefore the hydrogen production method can be widely applied into AIP (Air Independent Propulsion) submarines and the industrial field.

Owner:上海涛川能源科技有限公司

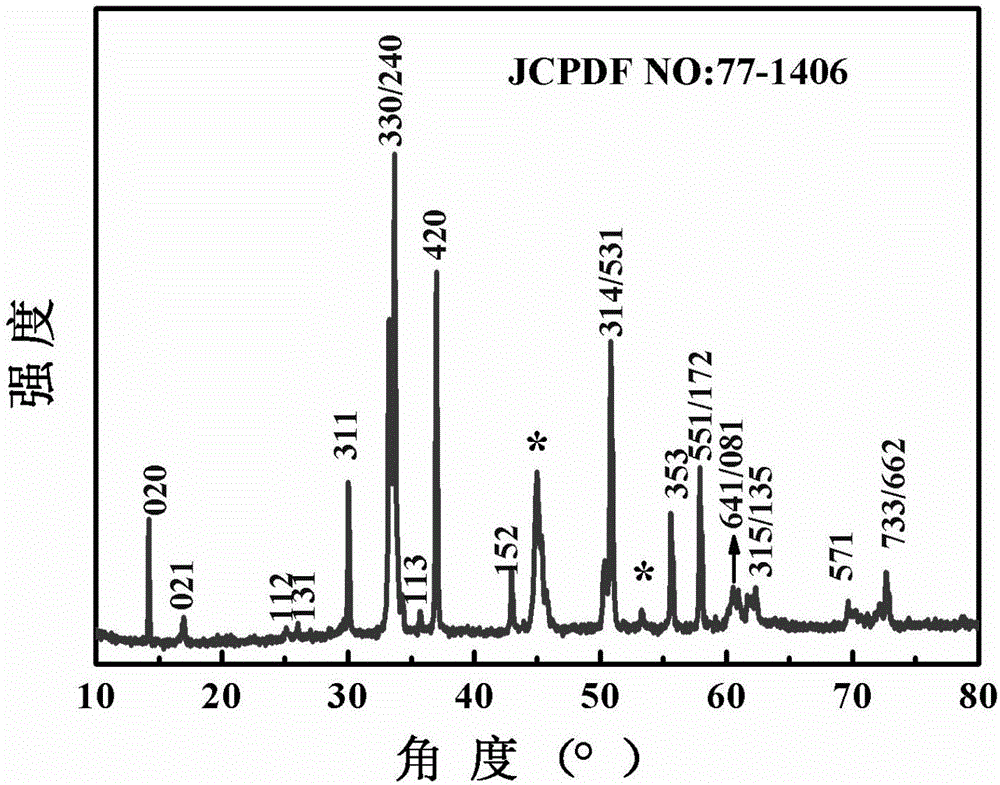

Nano-mesoporous oxygen carrier and preparation method thereof

InactiveCN106943987AImprove stabilityImprove adsorption capacityHydrogenOther chemical processesWater vaporRedox

The invention discloses a nano-mesoporous oxygen carrier. The oxygen carrier comprises, by mass, 20-50 parts of montmorillonite, 5-10 parts of TiO2, 5-10 parts of NiO, 5-10 parts of CeO2 and 10-20 parts of CaO. The invention also discloses a preparation method of the oxygen carrier. Multibasic oxide is compounded based on the nanolayer structure of natural montmorillonite, so the oxygen carrier is nano-mesoporous, and cheap large-scale industrial application is reached. Methane and water vapor enter the mesoporous structure prosperous in the surface of the oxygen carrier, the methane, water and the oxygen carrier undergo a surface redox reforming hydrogen production reaction, CO2 is adsorbed in situ, the endothermic reaction and the exothermic reaction are coupled in the hydrogen production process, and highly pure hydrogen is prepared in a high-efficiency and energy-saving manner. The preparation method has the advantages of simplicity, controllability and very low cost. The nano-mesoporous oxygen carrier improves the catalysis performance and the thermal stability of the oxygen carrier, and is friendly to environment.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

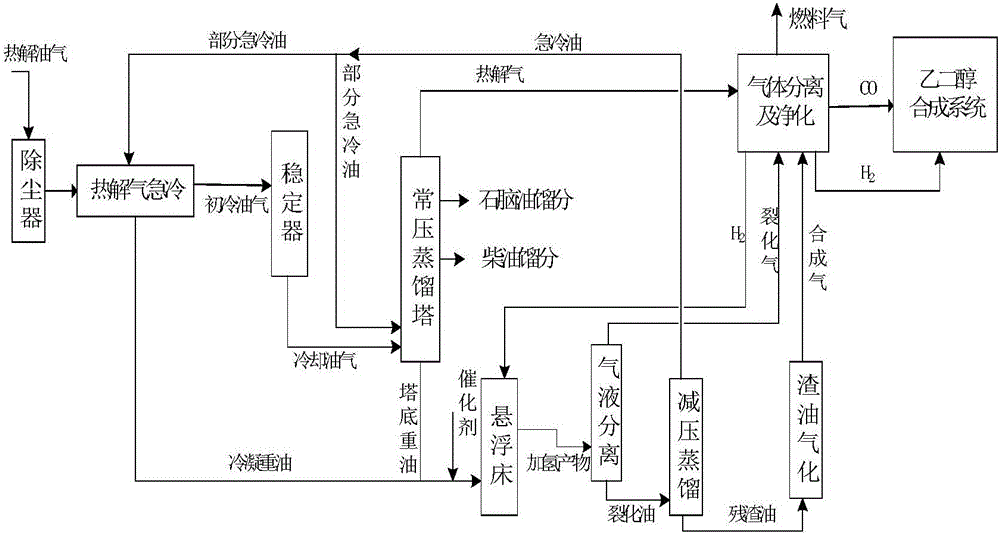

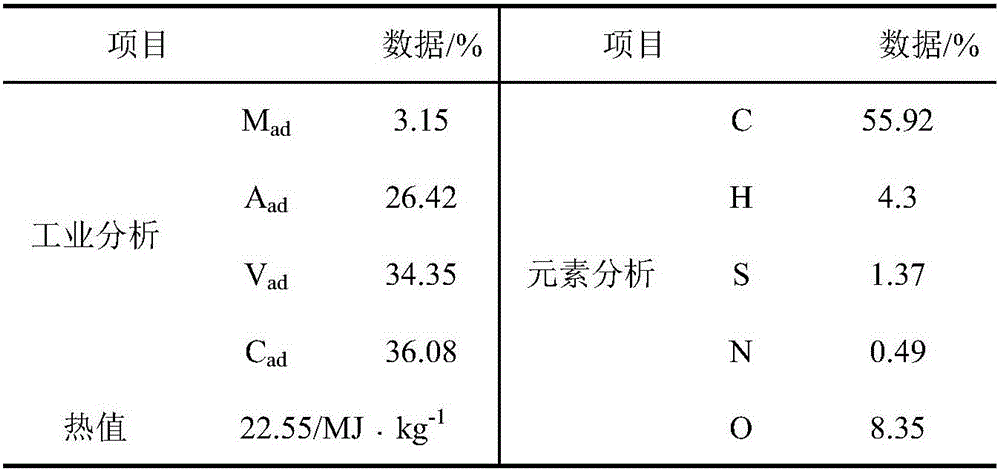

Combined system and method for processing oil gas generated by pyrolysis of low rank coal

InactiveCN105936834AAvoid it happening againIncrease flexibilityLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesFuel oilGlycol synthesis

The invention discloses a combined system and method for processing oil gas generated by pyrolysis of low rank coal. The system comprises a quench cooler, a normal pressure distillation column, a suspended bed hydrogenation reactor, a gas-liquid separator, a vacuum distillation tower, a residuum gasifying device, a gas separation and purification device, and a glycol synthesis system. The method comprises the following steps: quenching pyrolysis oil gas to generate cooled oil gas; subjecting cooled oil gas to normal pressure distillation to obtain heavy oil in the bottom of a distillation column and light fuel; cracking the heavy oil, separating gas and liquid to obtained cracked oil; subjecting cracked oil to vacuum distillation to obtain residual oil; gasifying the residual oil to obtain syngas; separating and purifying syngas to obtain hydrogen and carbon monoxide; and synthesizing carbon monoxide and hydrogen to obtain glycol. After vacuum deep extraction, the heavy residual oil is not returned to the suspended bed hydrogenation reactor, and thus the coking during the hydrogenation process in the suspended bed is avoided. The gas prepared from residual oil is used to produce glycol, the flexibility of heavy component processing is improved, and the economy of the technology is increased.

Owner:SHENWU TECH GRP CO LTD

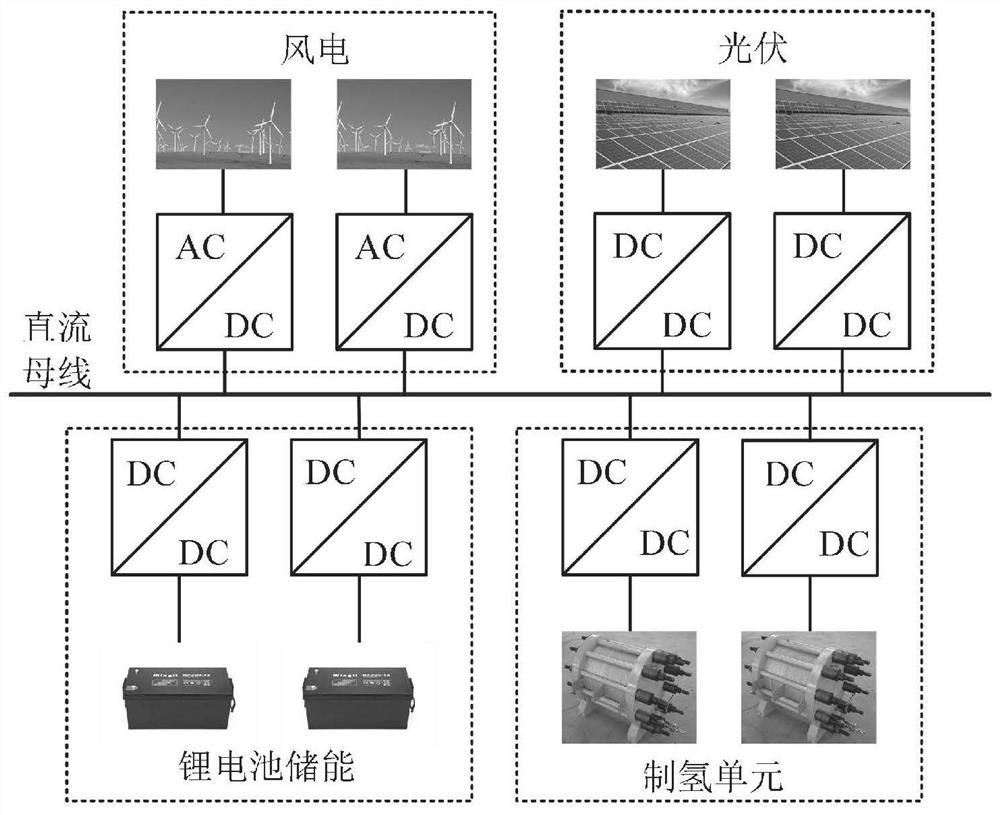

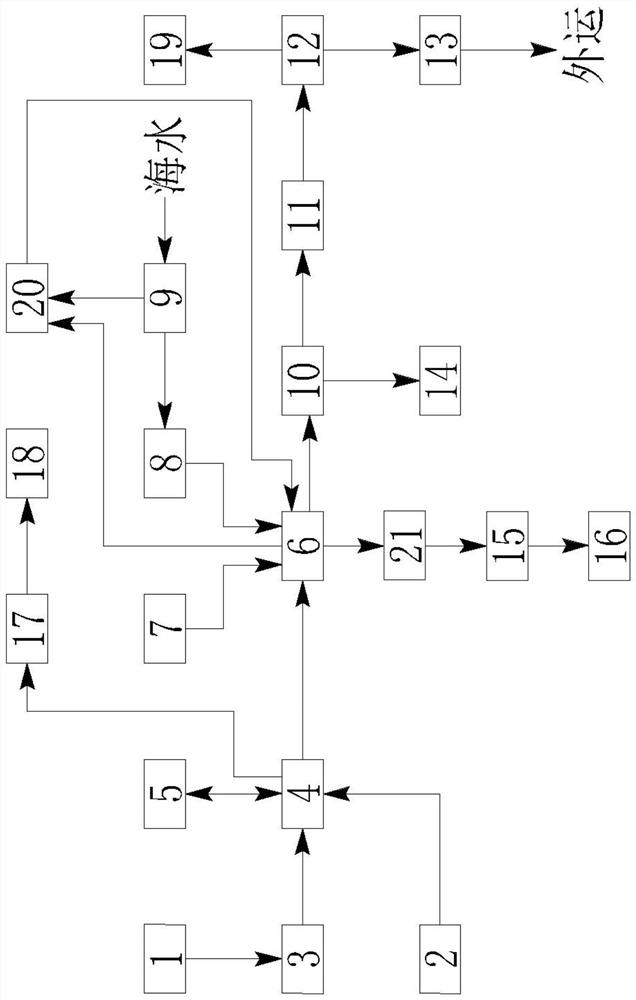

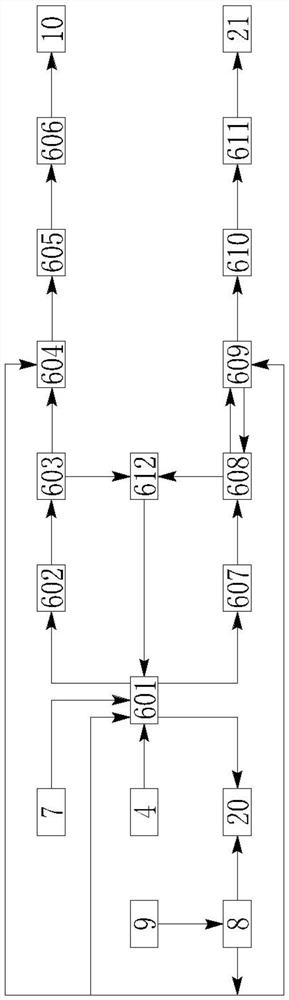

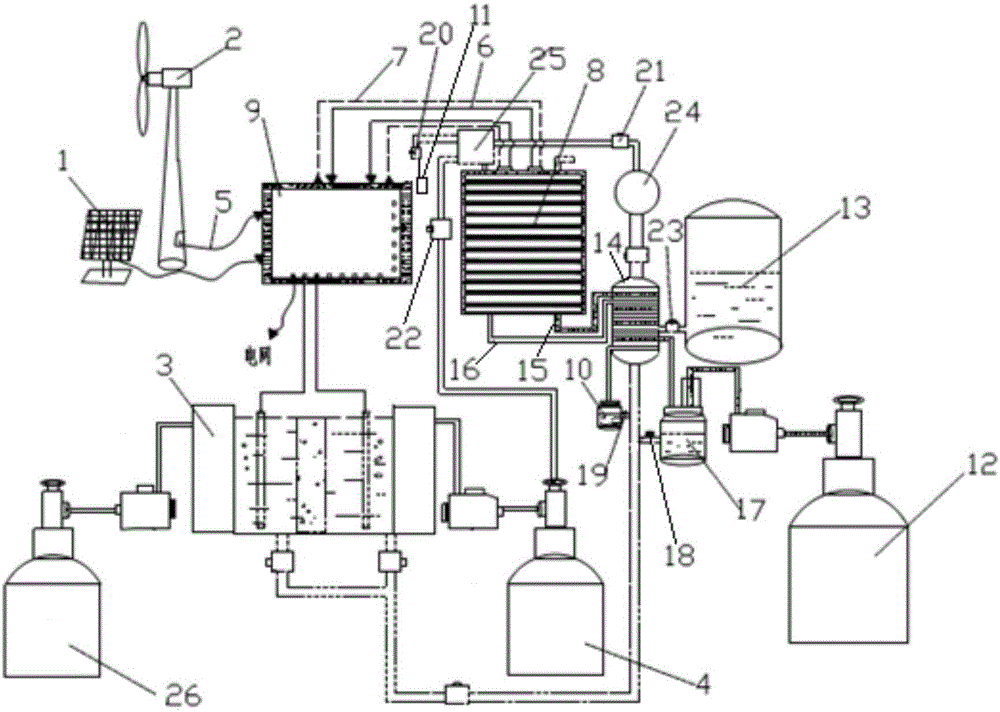

Wind-light-electricity-hydrogen storage integrated combined supply system for directly electrolyzing seawater to produce hydrogen and oxygen

ActiveCN113279001AReduce lossReduce electricity consumption costsElectrical storage systemCellsElectrolytic agentSeawater

The invention provides a wind-light-electricity-hydrogen storage integrated combined supply system for directly electrolyzing seawater to produce hydrogen and oxygen. The system comprises a wind power generation unit, a photovoltaic power generation unit, a seawater electrolysis-to-produce hydrogen and oxygen unit, an electrolyte cooling and desalting unit and a seawater pump station; the wind power generation unit and the photovoltaic power generation unit are connected with the seawater electrolysis-to-produce hydrogen and oxygen unit; the seawater pump station is connected with an electrolytic water tank of the seawater electrolysis-to-produce hydrogen and oxygen unit; a negative electrode and a positive electrode are arranged in the electrolytic water tank; the positive electrode is coated with a conductive coating with negative charges; and the electrolyte cooling and desalting unit is circularly communicated with the seawater electrolysis-to-produce hydrogen and oxygen unit. According tot the wind-light-electricity-hydrogen storage integrated combined supply system for directly electrolyzing seawater to produce hydrogen and oxygen, wind energy and solar energy renewable energy sources are converted into electric energy, the electric energy is provided for the seawater electrolysis-to-produce hydrogen and oxygen unit, so that the power consumption cost is reduced, and environmental protection is achieved; the seawater electrolysis-to-produce hydrogen and oxygen unit takes seawater as electrolyte, so that the loss of fresh water resources is reduced, the hydrogen production cost is reduced, the hydrogen production efficiency is ensured, the service life of the positive electrode is prolonged, and the development of hydrogen production by electrolyzing water is promoted.

Owner:HENAN HENGJU NEW ENERGY EQUIP CO LTD

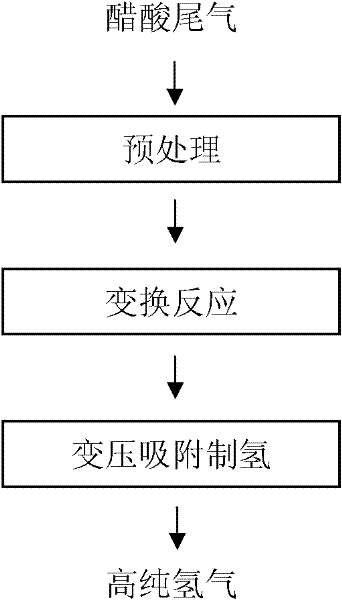

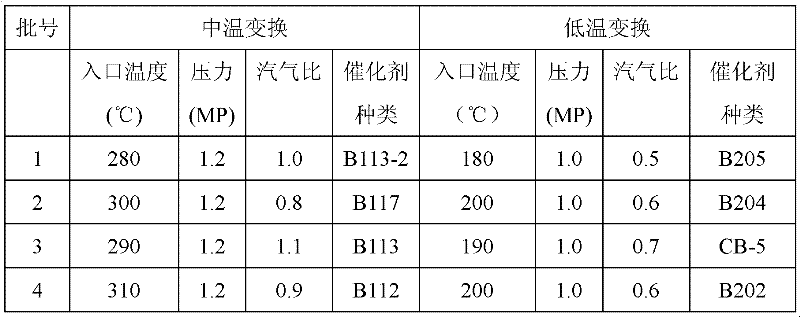

Method for producing hydrogen gas by using acetic acid tail gas

InactiveCN102530857AReasonable useTake advantage ofHydrogen separationEnvironmental resistanceAcetic acid

The invention discloses a method for producing hydrogen gas by using acetic acid tail gas. The high-purity hydrogen gas is obtained by pretreatment, water vapor transformation reaction and hydrogen gas purification, with the acetic acid tail gas as a raw material. The pretreatment means that impurities such as methyl iodide, methyl alcohol and the like in the acetic acid tail gas are removed, or further the impurities such as methyl iodide, the methyl alcohol and the like are removed and then CO in the impurities is adsorbed by pressure varying adsorption; and the tail gas obtained by recovering the CO is used for a transformation reaction. The method disclosed by the invention has the advantages of facilitation for saving resources and protecting environment, low investment, high hydrogen capacity and low cost.

Owner:EAST CHINA UNIV OF SCI & TECH +1

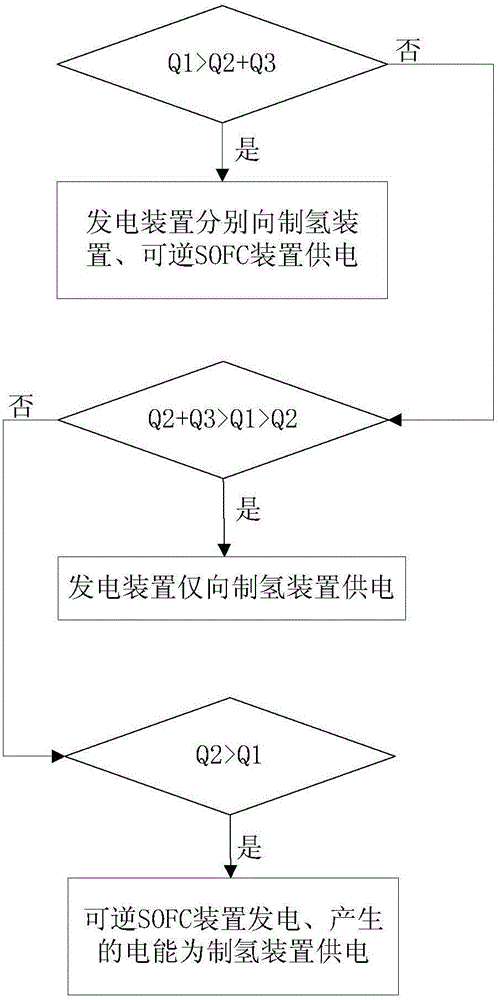

Hydrogen production energy storage method coupled with CO2 resource utilization

ActiveCN106086924ARealize resource utilizationEnsuring continuous hydrogen production by electrolysisCellsEnergy inputElectricityResource utilization

The invention provides a hydrogen production energy storage method coupled with CO2 resource utilization. The method is used for controlling a power generation device for generating electricity by using wind energy and solar energy, a hydrogen production device and a reversible SOFC device, and obtains a power generation quantity Q1 of the power generation device, a power use quantity Q2 needed by water electrolysis of the hydrogen production device and a power use quantity Q3 needed by electrolysis of water and CO2 of the reversible SOFC device; when Q1 is higher than Q2+Q3, the power generation device respectively supplies electricity to the hydrogen production device and the reversible SOFC device; when Q1 is lower than Q2+Q3 and higher than Q2, the power generation device only supplies electricity to the hydrogen production device; and when Q2 is higher than Q1, the reversible SOFC device enters a SOFC working mode, and generated electric energy supplies electricity to the hydrogen production device. The method stores renewable energy, realizes the resource utilization of CO2, effectively solves the intermittence and fluctuation problems of electrolytic hydrogen production caused by power generation through wind energy and solar energy, can prevent consumption of conventional electric energy, largely reduces the electrolytic hydrogen production cost, improves the electrolysis efficiency, prolongs the service life of the hydrogen production device, and improves the stability and the energy utilization rate of the hydrogen production device.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +4

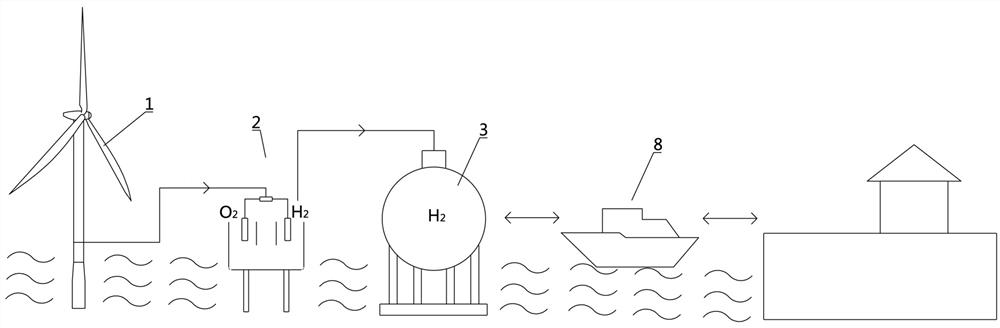

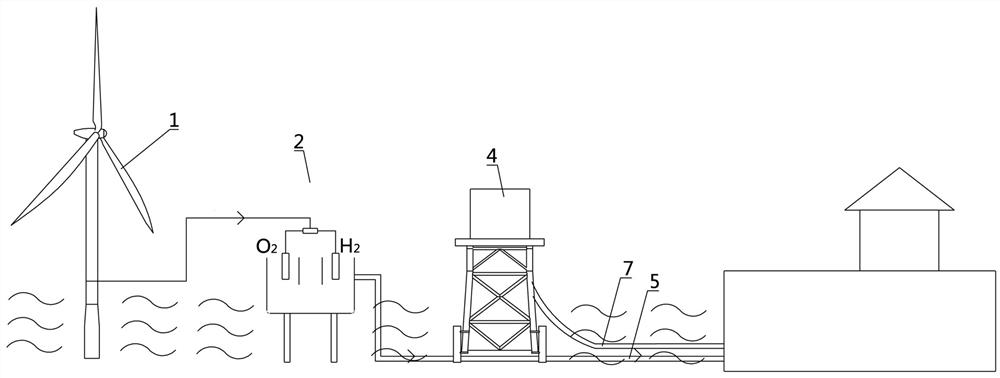

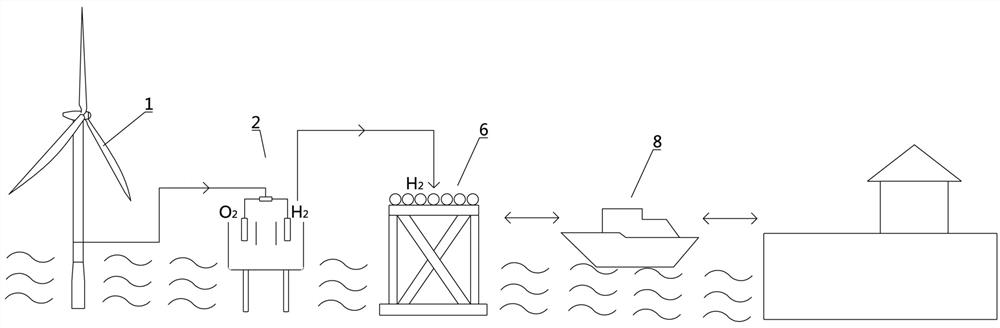

Seawater hydrogen production conveying system and method based on existing offshore wind plant

InactiveCN112161196AReduce the cost of hydrogen productionGas handling applicationsGas handling/storage effectsEnvironmental engineeringAtmospheric sciences

The invention belongs to the field of offshore wind power, and particularly relates to a seawater hydrogen production conveying system and method based on an existing offshore wind power plant. The system comprises a wind driven generator, a seawater electrolytic tank device and a hydrogen conveying unit, wherein the wind driven generator is used for converting wind energy to electric energy, theseawater electrolytic tank device is used for electrolyzing seawater by utilizing electric energy supplied by the wind driven generator, and the hydrogen conveying unit is used for conveying hydrogenprepared by the seawater electrolytic tank device to the land. According to the seawater hydrogen production conveying system and method based on the existing offshore wind power plant, offshore windpower and seawater hydrogen production are combined, the resource advantages of an offshore wind power plant are fully utilized, the seawater hydrogen production cost is reduced, and finally coordinated development of offshore green wind energy and seawater hydrogen production is achieved.

Owner:ZHEJIANG UNIV

Combined method and combined system based on low-rank coal pyrolysis, water vapor coke quenching and water gas producing hydrogen

ActiveCN106947541AQuality assuranceLarge sourceCombustible gas catalytic treatmentDispersed particle separationWater vaporCombined method

The invention relates to a combined method and a combined system based on low-rank coal pyrolysis, water vapor coke quenching and water gas producing hydrogen. The method includes the steps of: 1) increasing temperature of semicoke generated in a low temperature dry distillation furnace and enabling the semicoke to move down slowly; 2) continuously spraying water vapor upwardly so that heat exchange is carried out between the water vapor and the high-temperature semicoke; 3) after temperature increase through the heat exchange, performing a gasification reaction to the water vapor and a part of the high-temperature semicoke to generate water gas; 4) collecting, purifying and separating the water gas to produce H2 and CO, and performing a reaction to the CO to obtain H2, and mixing and purifying all of the H2 to obtain pure H2; and 5) in a moving down process, carrying out heat exchange to the other part of the high-temperature semicoke, which is not subjected to the gasification reaction, with the water vapor to reduce the temperature, and cooling the semicoke further and outputting the semicoke. In the invention, a hydrogen production method, which has lowest cost, is found for coal tar hydrogenation, wherein the raw material, semicoke, which is low in cost and high in quality, is completely utilized, and a coke quenching system and a hydrogen production system are optimized and integrated. The combined method has simplified process route, is convenient and safe to carry out, and is beneficial to industrial development of clean and high-effective utilization of coal.

Owner:新疆缘捷瀚科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com