Hydrogen production energy storage method coupled with CO2 resource utilization

An energy storage method and resource utilization technology, which is applied in the field of hydrogen production energy storage where SPE is coupled with CO2 resource utilization, can solve problems such as low conversion efficiency, volatility, and intermittent hydrogen production by electrolysis, so as to reduce the cost of hydrogen production and realize Cogeneration of heat and power, the effect of improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

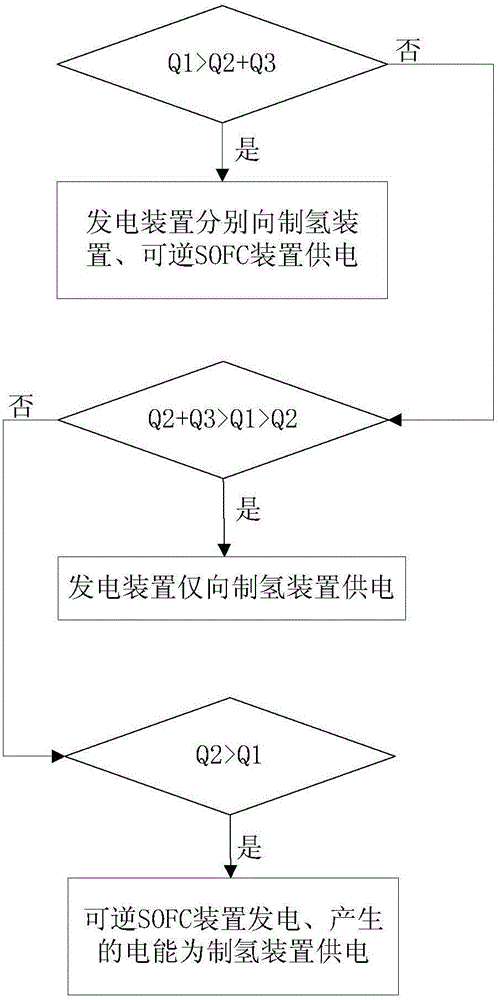

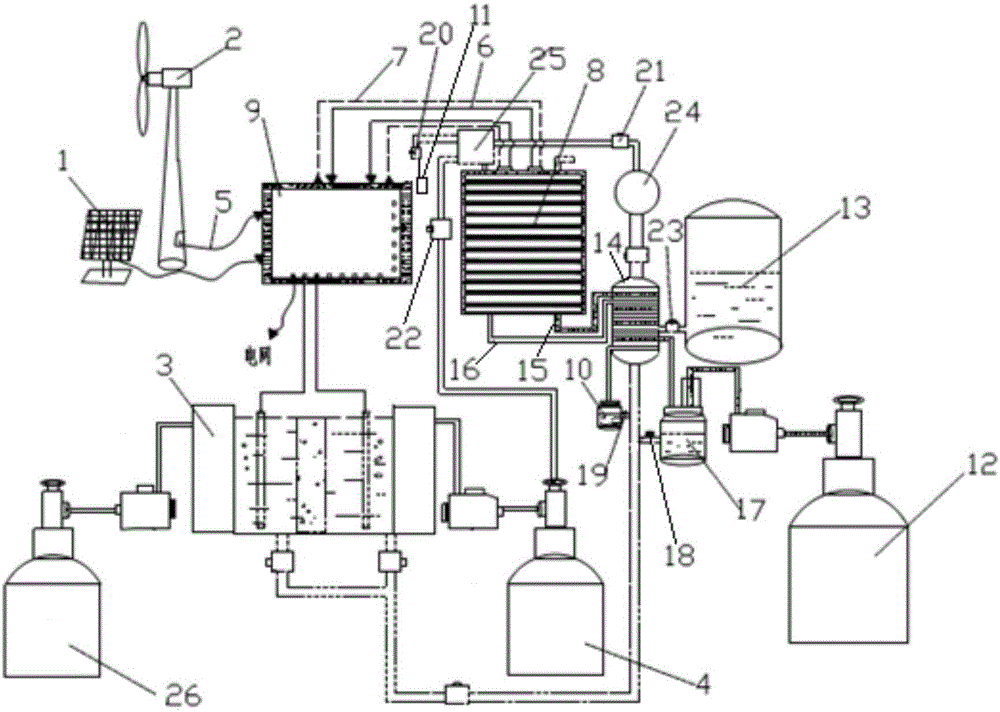

[0032] Such as figure 1 As shown, the coupling CO described in this example 2 The hydrogen production energy storage method of resource utilization can be used to control the power generation device that utilizes wind energy and solar power, the SPE hydrogen production device and the reversible SOFC device. The electricity consumption required by water Q2=58 kWh, the reversible SOFC device co-electrolyzes water and CO 2 The required power consumption Q3 = 95 kWh;

[0033] Under this condition, part of the electric energy generated by the power generation device supplies power to the SPE hydrogen production device, so that the SPE hydrogen production device electrolyzes water to produce hydrogen and oxygen, and the other part supplies power to the reversible SOFC device. At this time, the The reversible SOFC device enters the SOEC working mode, and co-electrolyzes water and CO under the action of nano-copper catalysts 2 Made with H 2 , CO, CH 4 and C 2 h 4 The mixed gas,...

Embodiment 2

[0036] Such as figure 1 As shown, the coupling CO described in this example 2 The hydrogen production and energy storage method of resource utilization is used to control the power generation device that utilizes wind energy and solar power, the SPE hydrogen production device and the reversible SOFC device. The electricity consumption required by water Q2=58 kWh, the reversible SOFC device co-electrolyzes water and CO 2 The required power consumption Q3 = 95 kWh;

[0037] Under this condition, the power generation device only supplies power to the SPE hydrogen production device, while the reversible SOFC device is cut off from power supply.

[0038] In this embodiment, the hydrogen electrode material of the reversible SOFC device is LSCM, the oxygen electrode material is BSCF, and the electrolyte is SDC.

Embodiment 3

[0040] Such as figure 1 As shown, the coupling CO described in this example 2 The hydrogen production and energy storage method of resource utilization is used to control the power generation device using wind energy and solar power, the SPE hydrogen production device and the reversible SOFC device, the power generation of the power generation device Q1=10 kWh, and the electrolysis The electricity consumption required by water Q2=58 kWh, the reversible SOFC device co-electrolyzes water and CO 2 The required power consumption Q3 = 95 kWh;

[0041] Under these conditions, the reversible SOFC device enters the SOFC working mode, uses the mixed gas produced by its own co-electrolysis as fuel and air to generate electricity, and the generated electric energy can reach 86 kWh, part of which is the SPE hydrogen production device power supply, and the rest of the power is connected to the grid.

[0042] In this embodiment, the hydrogen electrode material of the reversible SOFC devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com