Water electrolysis produced gas pressure self-balancing device and application thereof

A self-balancing, electrolyzed water technology, applied in the electrolysis process, electrolysis components, electrode shape/type, etc., can solve the problems of unfavorable hydrogen energy development and application, water electrolysis system cost and system complexity increase, and achieve improved gas production Efficiency, reduced complexity, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

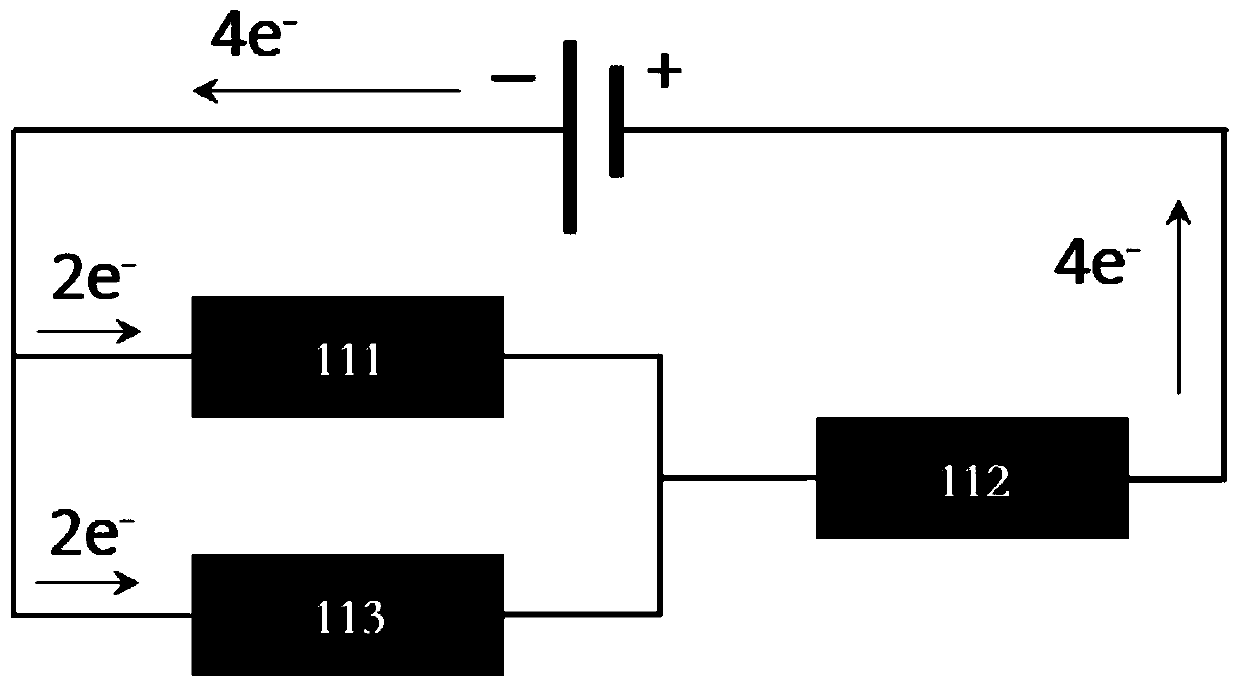

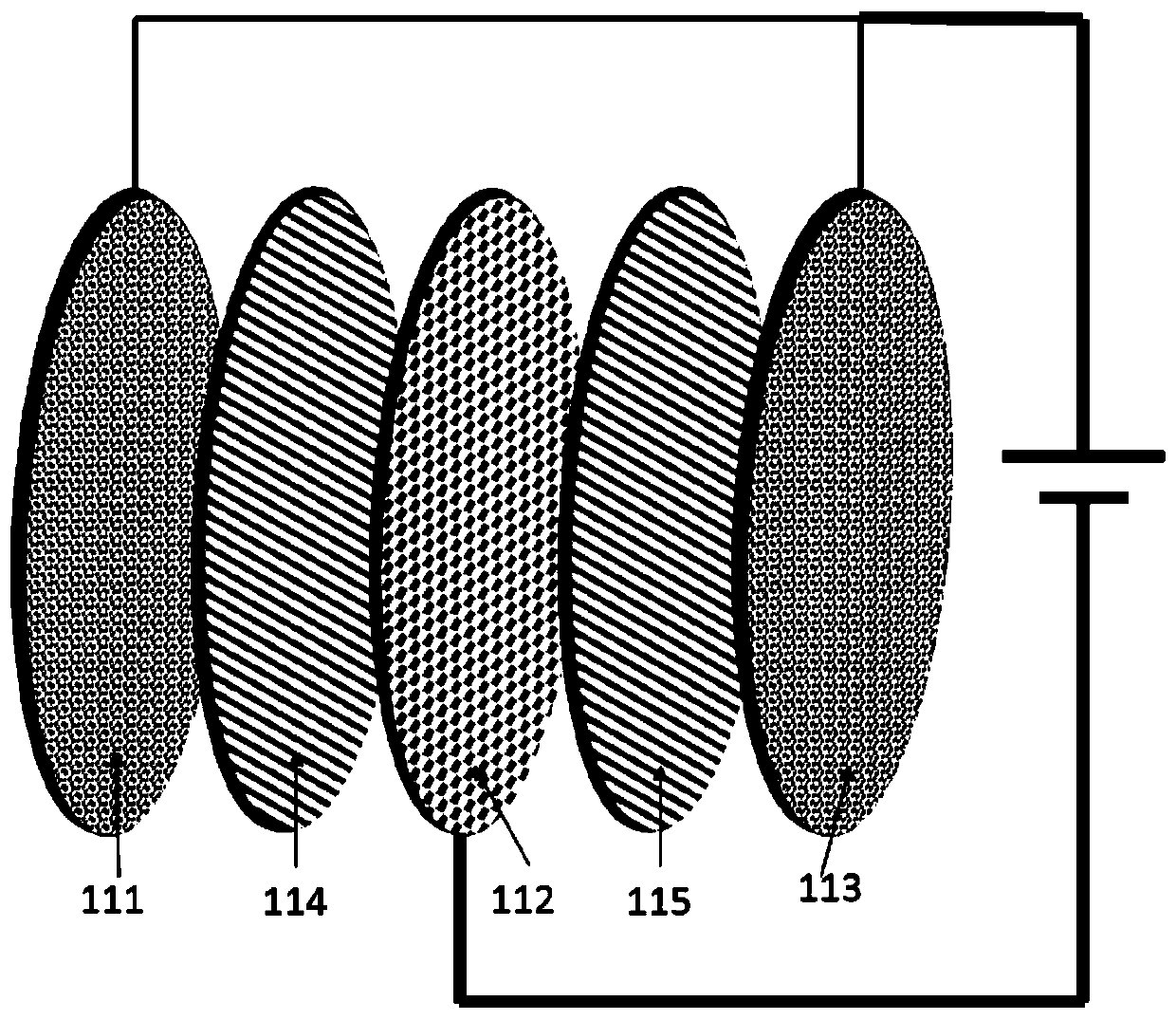

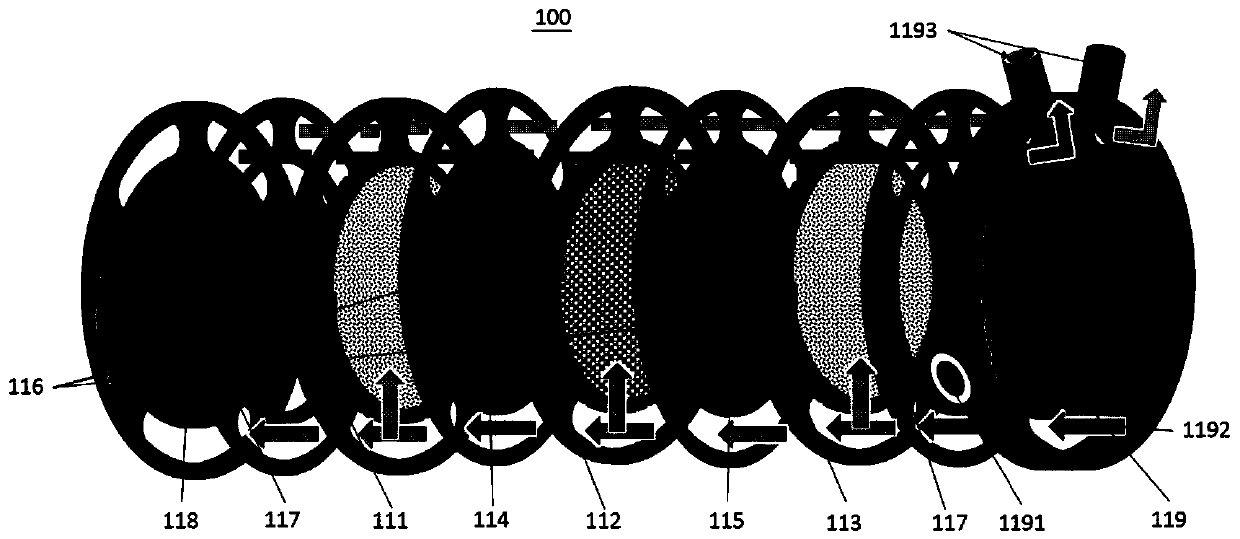

[0061] see figure 1 and figure 2 , the present embodiment provides a pressure self-balancing device 100 for electrolyzed water gas production, which includes a circular electrolysis unit, the electrolysis unit includes a first cathode 111, a common anode 112, a second cathode 113, a first diaphragm 114, a second Diaphragm 115, electrode holder 116, sealing ring 117, bipolar plate 118 and connecting plate 119 (as image 3 shown).

[0062] The common anode 112 is arranged between the first cathode 111 and the second cathode 113, the first diaphragm 114 is arranged between the first cathode 111 and the common anode 112, and the second diaphragm 115 is arranged between the common anode 112 and the second cathode 113 . In this embodiment, the first cathode 111, the common anode 112 and the second cathode 113 are respectively fixed on the electrode holder 116 through preset grooves, and the electrode holder 116 is provided with a power connection port, which can connect an exter...

Embodiment 2

[0072] see Figure 6 , the present embodiment provides a pressure self-balancing device 100 for electrolyzed water gas production, which includes a circular electrolysis unit, the electrolysis unit includes a first cathode 111, a common anode 112, a second cathode 113, a first diaphragm 114, a second Separator 115 , electrode holder 116 , seal ring 117 , bipolar plate 118 and end plate 120 .

[0073] Among them, the end plate 120 is made of ferritic stainless steel, and the bottom is provided with two electrolyte inlets 1191, which are connected with the liquid inlets at the bottom of the electrodes of each electrolytic unit; The hydrogen, oxygen and electrolyte from each electrolysis unit are introduced into the gas-liquid separator for post-processing; the end plate 120 is fastened and sealed together with the electrolysis unit by 8 ferritic stainless steel bolts.

[0074] During electrolysis, the electrolyte enters from the inlet of the end plate 120, and then enters the e...

Embodiment 3

[0078] see Figure 8 , the present embodiment provides a pressure self-balancing device 100 for electrolyzed water gas production, which includes a circular electrolysis unit, the electrolysis unit includes a first cathode 111, a common anode 112, a second cathode 113, a first diaphragm 114, a second Diaphragm 115 , electrode holder 116 , sealing ring 117 , bipolar plate 118 , connection plate 119 and packaging plate 121 . In this application, the packaging plate 121 can be used to splice two electrolytic units to make them symmetrical.

[0079] The jumper mode of the large electrolysis unit 200 provided in this embodiment is the same as the jumper mode in Embodiment 1, and the structure of the large electrolysis unit 200 obtained is as follows Figure 9 shown.

[0080] The parallel connection mode of the electrolysis system 300 provided in this embodiment is the same as the parallel connection mode in Embodiment 1, and will not be described here again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com