Metal oxide nano sheet supported carbon coated metal particle electrolysed water catalyst

A technology of metal particles and oxides, which is applied in the field of electrochemistry, can solve problems such as high overpotential, poor stability, and large power consumption, and achieve the effects of reducing the cost of hydrogen production, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

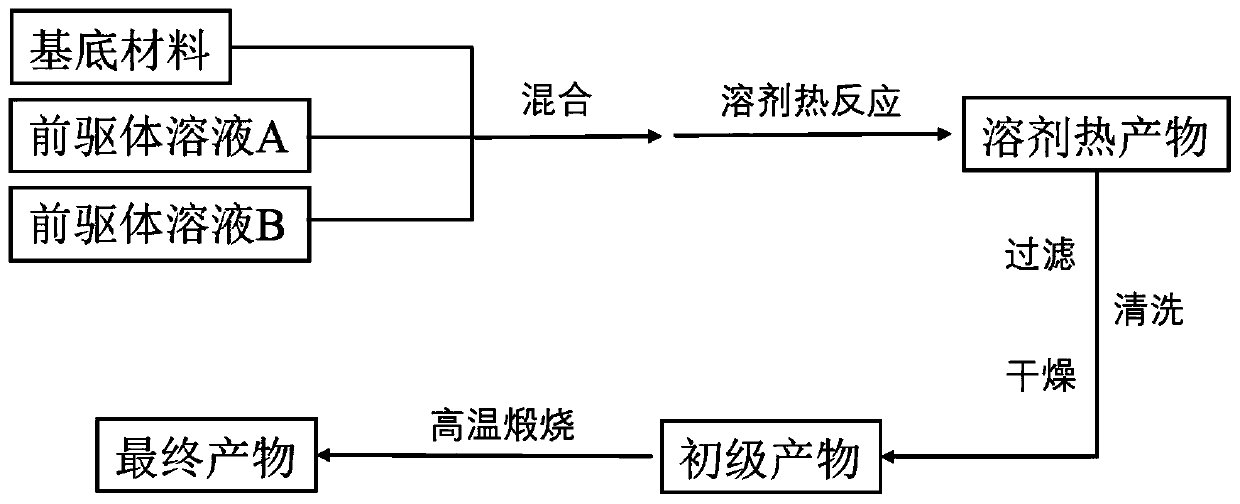

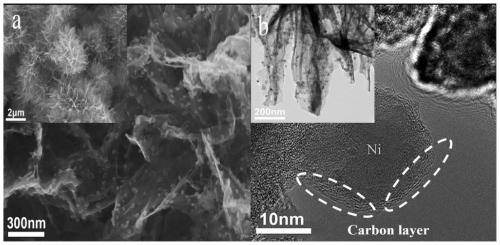

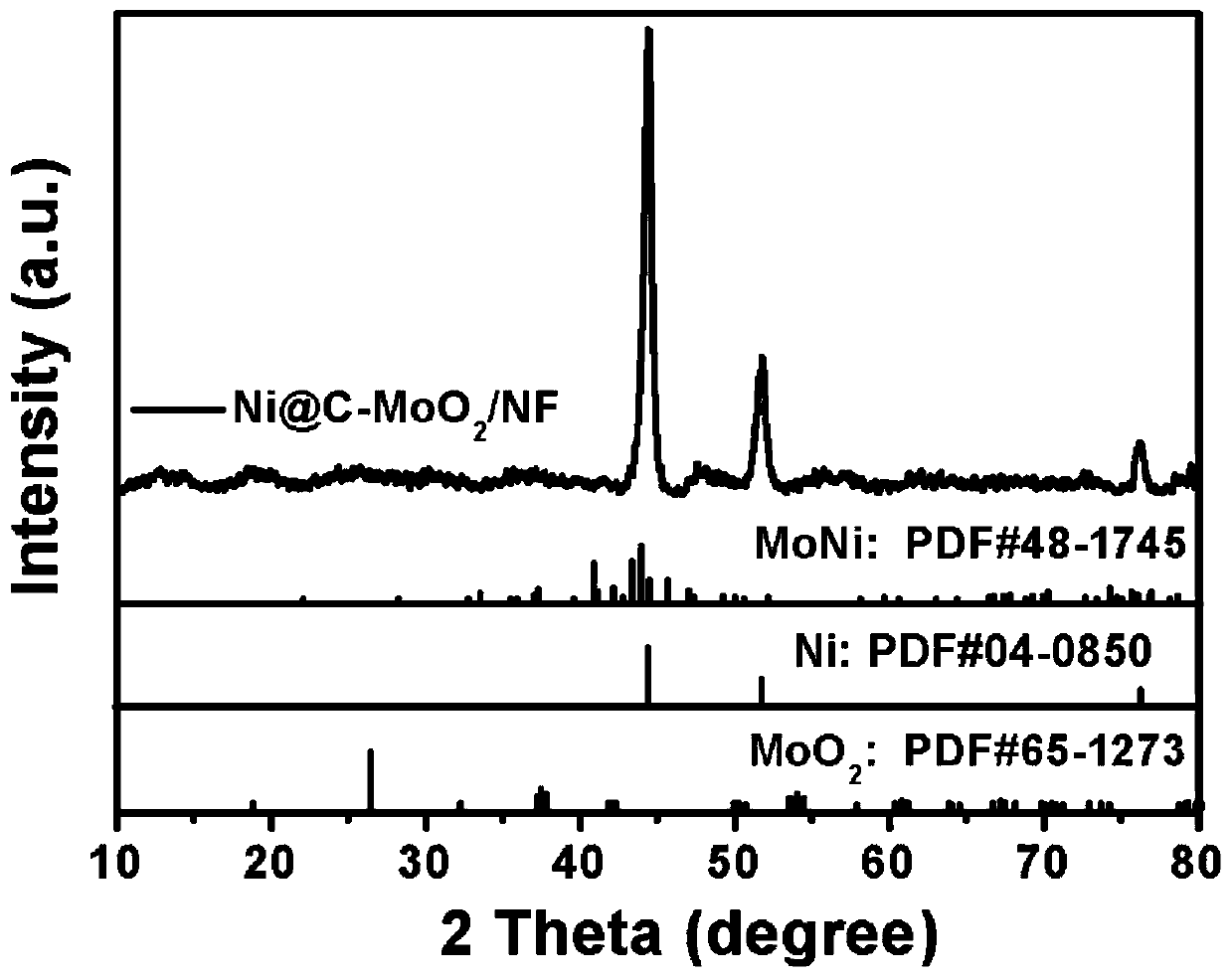

[0029] A carbon-coated metal particle electrolysis water catalyst supported by metal oxide nanosheets, prepared by the following method:

[0030] (1) Dissolve 500 mg of sodium molybdate in 30 ml of N,N-dimethylacetamide to prepare sodium molybdate N,N-dimethylacetamide solution, and dissolve 200 mg of nickel nitrate in 30 ml of N ,N-Dimethylacetamide is formulated into nickel nitrate N,N-dimethylacetamide solution, and then sodium molybdate N,N-dimethylacetamide solution and nickel nitrate N,N-dimethylacetamide Mix the solution, add 200 mg of carbon nanotubes, ultrasonically stir and disperse, first ultrasonically for 10 minutes, and then stir for 10 minutes to obtain a mixed suspension liquid. Put the mixed suspension liquid into a reactor with a capacity of 100 mL for solvothermal reaction. The solvothermal reaction temperature 120 degrees Celsius, heat preservation for 24 hours, after natural cooling, take out the product obtained after the solvothermal reaction, wash, filt...

Embodiment 2

[0033] A carbon-coated metal particle electrolysis water catalyst supported by metal oxide nanosheets, prepared by the following method:

[0034](1) 500 milligrams of sodium molybdate are dissolved in the ethylene glycol of 30 milliliters and are mixed with sodium molybdate ethylene glycol solution, and 200 milligrams of nickel nitrate are dissolved in 30 milliliters of ethylene glycol and are mixed with nickel nitrate ethylene glycol solution, and then Mix sodium molybdate ethylene glycol solution and nickel nitrate ethylene glycol solution, add 200 mg of carbon black, and ultrasonically stir to disperse, first ultrasonically for 10 minutes, then stir for 10 minutes to obtain a mixed suspension liquid, and put the mixed suspension liquid into a container with a capacity of 100 mL In the reaction kettle, carry out solvothermal reaction, the solvothermal reaction temperature is 150 degrees Celsius, keep warm for 14 hours, after natural cooling, take out the product obtained afte...

Embodiment 3

[0037] A carbon-coated metal particle electrolysis water catalyst supported by metal oxide nanosheets, prepared by the following method:

[0038] (1) Dissolve 500 mg of sodium tungstate in 30 ml of oleylamine to prepare sodium tungstate oleylamine solution, dissolve 200 mg of ferric nitrate in 30 ml of oleylamine to prepare iron nitrate oleylamine solution, and then dissolve sodium tungstate Mix the oleylamine solution and the oleylamine ferric nitrate solution, add 200 mg of graphene, and disperse with ultrasonic stirring, first ultrasonic for 10 minutes, then stir for 10 minutes to obtain a mixed suspension liquid, put the mixed suspension liquid into a reaction kettle with a capacity of 100mL, and carry out solvent Thermal reaction, solvothermal reaction temperature is 100 degrees Celsius, heat preservation for 48 hours, after natural cooling, take out the product obtained after solvothermal reaction, wash, filter, and vacuum dry for 24 hours to obtain the primary sample;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com