Method of preparing hydrogen gas by catalytic gasifying hydrolysis residue of cellulose castoff

A technology of waste and cellulose, applied in the field of catalytic gasification to prepare hydrogen, to achieve the effects of promoting industrial development, protecting the environment, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

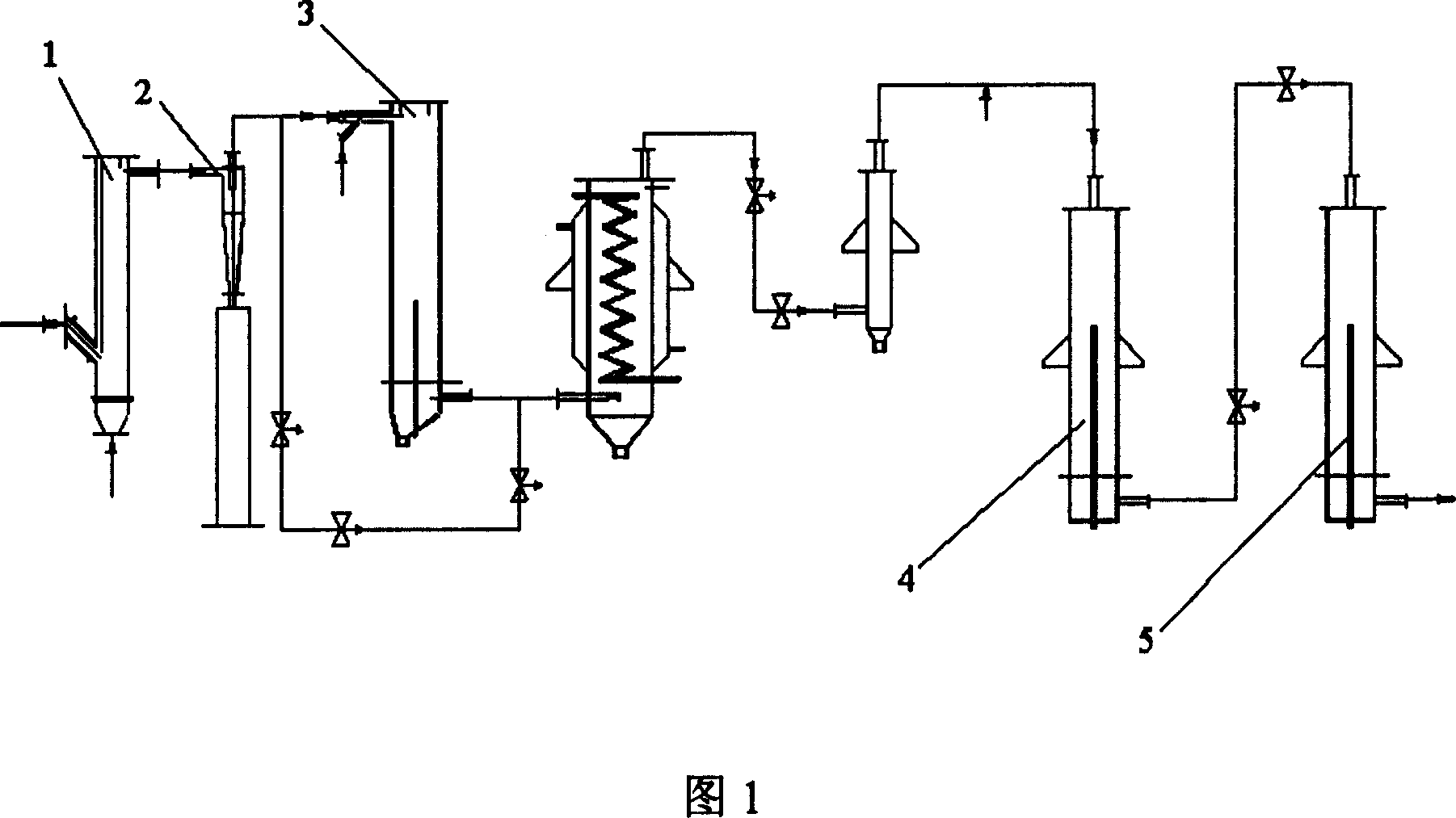

Image

Examples

Embodiment 1

[0030] The raw materials used are: the hydrolysis residue of sawdust and the hydrolysis residue of rice husk respectively account for 50% (by weight).

[0031] The hydrolysis residue of cellulose waste with a particle size of less than 3mm enters the fluidized bed gasifier 1, and undergoes gasification reaction with the water vapor entering the fluidized bed gasifier 1. The gasification reaction temperature is 750°C, and the gasification Reaction pressure (gauge pressure) 30mmH 2 O, the cellulose waste hydrolysis residue add-on is 2.0kg / h; The quality of water vapor and the mass ratio (S / B) of cellulose waste hydrolysis residue are 1.5;

[0032] The residence time of water vapor in the fluidized bed is 3.0 seconds, and the residence time of cellulose waste hydrolysis residue in the fluidized bed reactor is 6.0 seconds;

[0033] The vaporized gas discharged from the top of the fluidized bed reactor 1 enters the atmospheric pressure fixed bed catalytic reactor 3 filled with cat...

Embodiment 2

[0040] Except the gasification reaction temperature, other process conditions were the same as in Example 1, the gasification reaction temperature was 850° C., and the hydrogen content (volume percentage) in the gas after the reaction reached 85.6%.

Embodiment 3

[0042] Except the catalytic reaction temperature, other process conditions are the same as in Example 2, the catalytic reaction temperature is 750° C., and the hydrogen content (volume percentage) in the crude gas after the reaction reaches 82.5%.

[0043] From the above results, it can be seen that hydrogen production by catalytic gasification of cellulose waste hydrolysis residue is a better hydrogen production method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com