Method for preparing hydrogen from straws

A technology of straw and hydrogen, which is applied in the field of using straw for biomass fermentation to prepare hydrogen, can solve problems such as inability to digest straw well, difficulty in hydrogen production, etc., and achieves a technology that is beneficial to the degradation of hydrogen-producing microorganisms, has good effect and high hydrogen yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. A method for preparing hydrogen from stalks, comprising the following steps:

[0029] 1. Utilize the microbial composite bacterial agent for degrading straw to carry out aerobic degradation of straw: use the patent number CN103194392A invention titled microbial composite bacterial agent for degrading straw and its method for degrading straw; the specific operations are: ① straw pretreatment: the straw Mix with dilute sulfuric acid at a mass ratio of 1:2, heat in an autoclave at a constant temperature of 150°C for 2 hours, then wash the straw with distilled water until the pH of the washing solution is 7, filter, and dry the straw at 60°C for later use; ②Preparation of straw Aerobic degradation medium: first prepare liquid aerobic degradation medium, then add the above-mentioned pretreated straw, add 0.5-1.5 g of straw per milliliter of liquid aerobic degradation medium; each liter of liquid aerobic degradation medium contains Components of the following mass: ammoniu...

Embodiment 2

[0039] 1. Using straw to prepare hydrogen includes the following steps:

[0040] 1. Carrying out aerobic degradation of straw by using a microbial compound agent for degrading straw: the same as in Example 1.

[0041] 2, cow dung pretreatment: with embodiment 1.

[0042] 3. Preparation of straw anaerobic degradation medium: Weigh 5 g of pretreated straw powder into 50 ml of liquid anaerobic degradation medium, and sterilize at 120° C. for 20 minutes. Wherein the components in the liquid anaerobic degradation medium are the same as those in Example 1.

[0043] 4. Add the pretreated cow dung to the straw anaerobic degradation medium in an amount of 1g per gram of straw, pass nitrogen gas for 3 minutes to remove oxygen, seal, avoid light, and shake at 65°C and 120r / min Fermentation and cultivation for 7 days. Simultaneously add the samples without pretreatment straw and no straw as comparative examples.

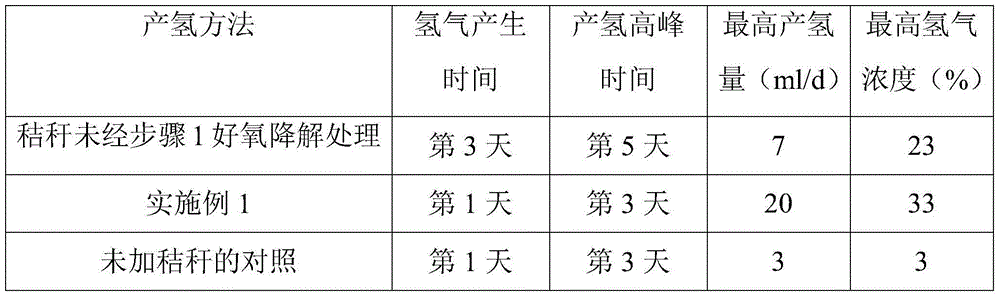

[0044] 2. The result of straw degradation to produce hydrogen

[0045]...

Embodiment 3

[0050] 1. Using straw to prepare hydrogen includes the following steps:

[0051] 1. Carrying out aerobic degradation of straw by using a microbial compound agent for degrading straw: the same as in Example 1.

[0052] 2, cow dung pretreatment: with embodiment 1.

[0053] 3. Preparation of straw anaerobic degradation medium: Weigh 5 g of pretreated straw powder into 50 ml of liquid anaerobic degradation medium, and sterilize at 120° C. for 20 minutes. Wherein the components in the liquid anaerobic degradation medium are the same as those in Example 1.

[0054] 4. Add the pretreated cow dung to the straw anaerobic degradation medium at an amount of 1.5g per gram of straw, pass nitrogen gas for 3 minutes to remove oxygen, seal, avoid light, shake at 65°C and 120r / min Fermentation culture was carried out for 7 days. Simultaneously, samples without pretreatment straw and fermentation temperature of 35° C. were added as comparative examples.

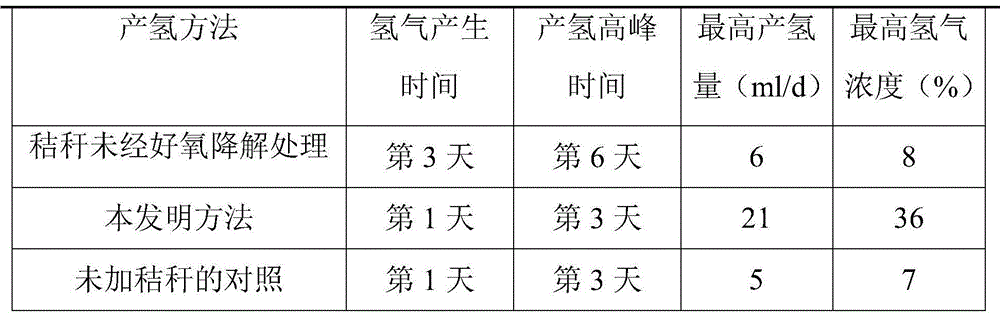

[0055] 2. The result of straw degra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com