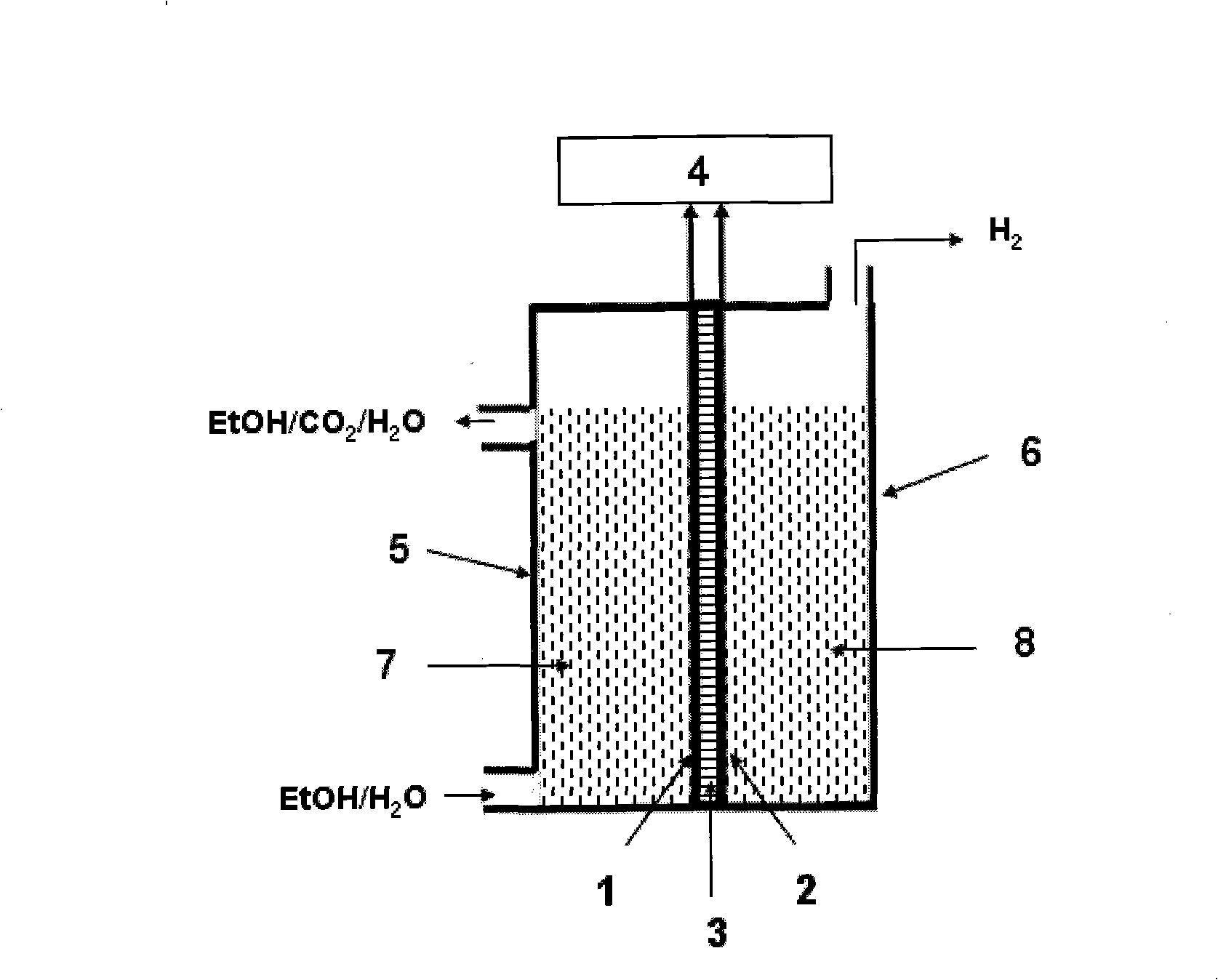

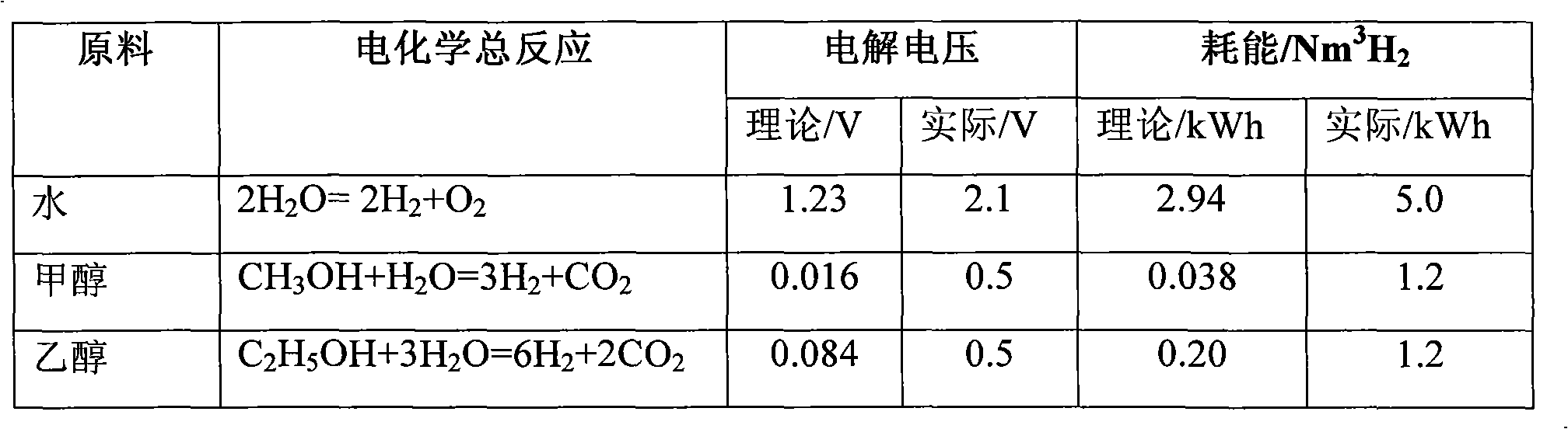

Method for preparing hydrogen by electrochemically reforming alcohol and device thereof

An electrochemical and catalyst technology, which is applied in the field of hydrogen production and hydrogen production by electrochemical reforming of alcohol, can solve the problems of unsuitable sustainable development, unsuitable economic and resource utilization, etc., so as to facilitate popularization and application and reduce energy consumption , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Two-electrode electrochemical reforming of methanol with a single-chamber structure. The anode catalyst is Pd, the cathode catalyst is Pd-Co-Fe, and the diaphragm is anion-conductive polyethersulfone-polyvinylpyrrolidone composite membrane. After adding alkaline methanol / water solution, a direct current is applied between the two electrodes, the positive electrode is the methanol oxidation electrode, and the negative electrode is the water reduction electrode. When the voltage reaches 0.4V, the negative electrode obviously produces hydrogen.

Embodiment 2

[0051] Double-electrode electrochemical reforming of ethanol with a single-chamber structure. The anode catalyst is Pd-Au, the cathode catalyst is Co-Fe, and the diaphragm is anion-conducting polyvinyl alcohol-based quaternary ammonium membrane. After adding alkaline ethanol / water solution, a direct current is applied between the two electrodes, the positive electrode is the ethanol oxidation electrode, and the negative electrode is the water reduction electrode. When the voltage reaches 0.4V, the negative electrode obviously produces hydrogen.

Embodiment 3

[0053] Two-electrode electrochemical reforming of methanol with a single-chamber structure. The anode catalyst is Pt-Ru, the cathode catalyst is Ni-Co, and the separator is an anion-conducting polymer membrane. After adding alkaline methanol / water solution, a direct current is applied between the two electrodes, the positive electrode is the methanol oxidation electrode, and the negative electrode is the water reduction electrode. When the voltage reaches 0.4V, the negative electrode obviously produces hydrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com