Combined method and combined system based on low-rank coal pyrolysis, water vapor coke quenching and water gas producing hydrogen

A water gas and water vapor technology, applied in separation methods, chemical instruments and methods, gasification processes, etc., can solve the problems of high operating costs, expensive raw materials, waste of water and heat sources, etc., and achieve full utilization of waste heat and less impurities in water gas. , Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a combined method for hydrogen production based on low-rank coal pyrolysis, steam, coke quenching, and water gas, including the following steps:

[0053] (1) Enter the semi-coke with a temperature of 600°C produced by the low-temperature carbonization furnace, and the oxygen-enriched air reacts with part of the semi-coke and then burns. The heat obtained from the combustion makes the remaining semi-coke warm up to 1000°C, and the obtained high-temperature semi-coke slowly descends;

[0054] (2) Continuously inject water vapor at 200°C upwards to make it pass upwards along the gap of the descending high-temperature semi-coke, and perform heat exchange with the high-temperature semi-coke;

[0055] (3) The water vapor heated to above 427°C through the heat exchange undergoes a gasification reaction with part of the high-temperature semi-coke, and the main component is H 2 and CO water gas;

[0056] (4) Collect water gas with a gas collecting umbre...

Embodiment 2

[0062] This embodiment provides a system for hydrogen production based on low-rank coal pyrolysis, steam quenching, and water gas; the system includes a three-stage water gas generator, and the water gas generator is preferably a cylinder with an outer steel cylinder lined with a refractory material Body structure; the water gas generator includes a warming bin, a water gas generating bin, and a semi-coke cooling bin connected sequentially from top to bottom through the semi-coke channel;

[0063] in:

[0064] The semi-coke inlet at the top of the temperature increasing chamber is connected to the semi-coke outlet of the low-temperature carbonization furnace; an air distribution burner and a high-temperature flue gas channel are arranged in the temperature increasing chamber;

[0065] The bottom of the water gas generating bin is provided with a steam injector with an upward spout; the upper part of the water gas generating bin is provided with a water gas collecting umbrella,...

Embodiment 3

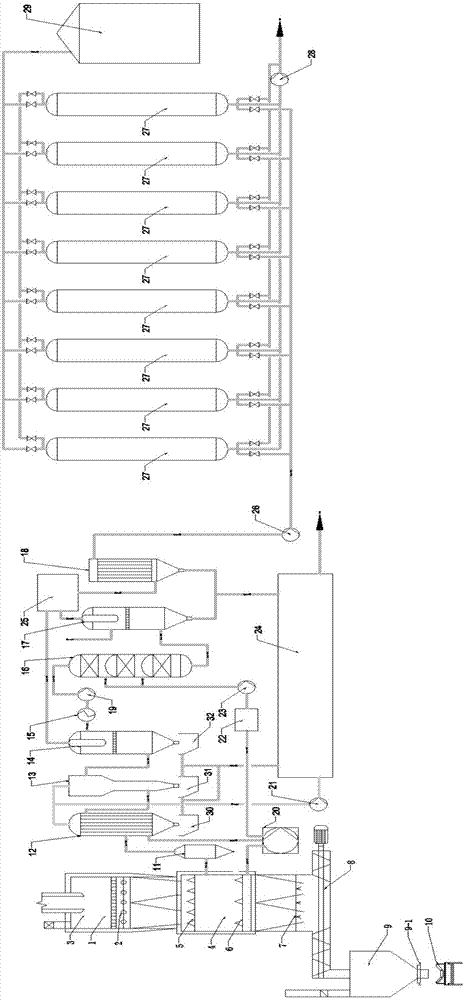

[0068] This embodiment provides a system based on low-rank coal pyrolysis water vapor coke quenching water gas hydrogen production, such as figure 1 shown. In the system:

[0069]The feed port of the red-hot semi-coke warming bin 1 is connected to the coke outlet of the retort furnace, the air distributor 2 is installed in the middle of the warming bin 1, and the upper part of the warming bin 1 is equipped with a flue gas chamber 3 through the carbonization of the bridge pipe and the pyrolysis furnace The chambers are connected; the upper port of the water gas generating chamber 4 is connected with the lower port of the red-hot semi-coke temperature increasing chamber 1, the water vapor injector 5 is installed at the bottom of the water gas generating chamber 4, and the water gas collecting umbrella 6 is installed at the upper part of the water gas generating chamber 4; coke quenching by spraying The upper port of the bin 7 is connected with the lower port of the water gas ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com