Iron alkali composite catalyst for direct liquefaction of coal

A composite catalyst, a technology for direct liquefaction of coal, used in physical/chemical process catalysts, preparation of liquid hydrocarbon mixtures, chemical instruments and methods, etc. The formation of asphaltenes and residues, the availability of raw materials, and the effect of good synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

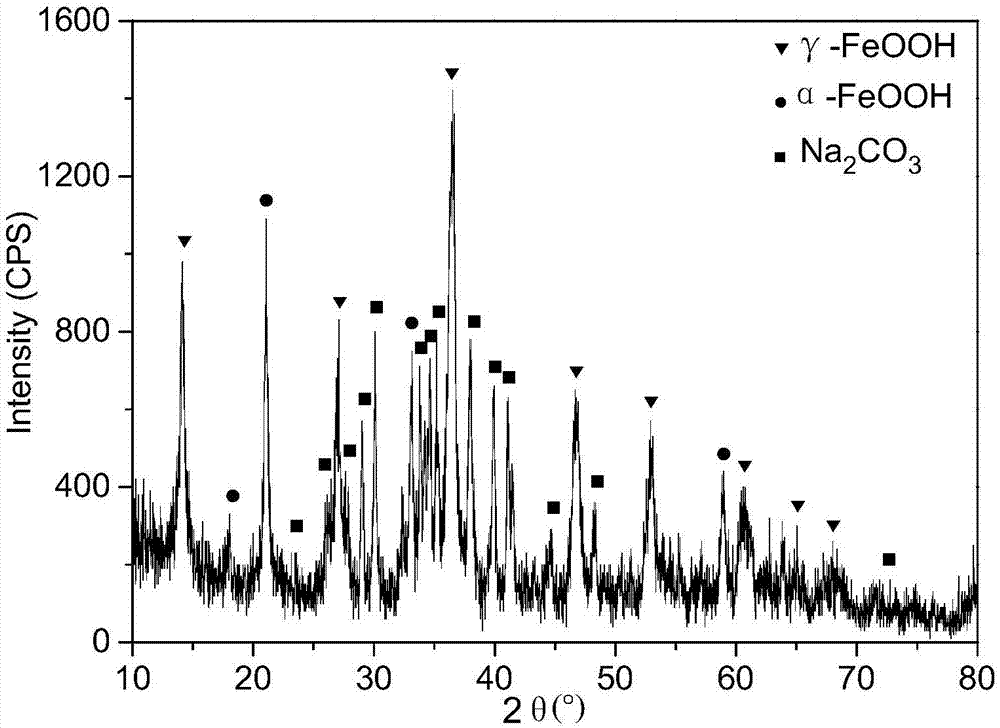

Image

Examples

Embodiment 1-5

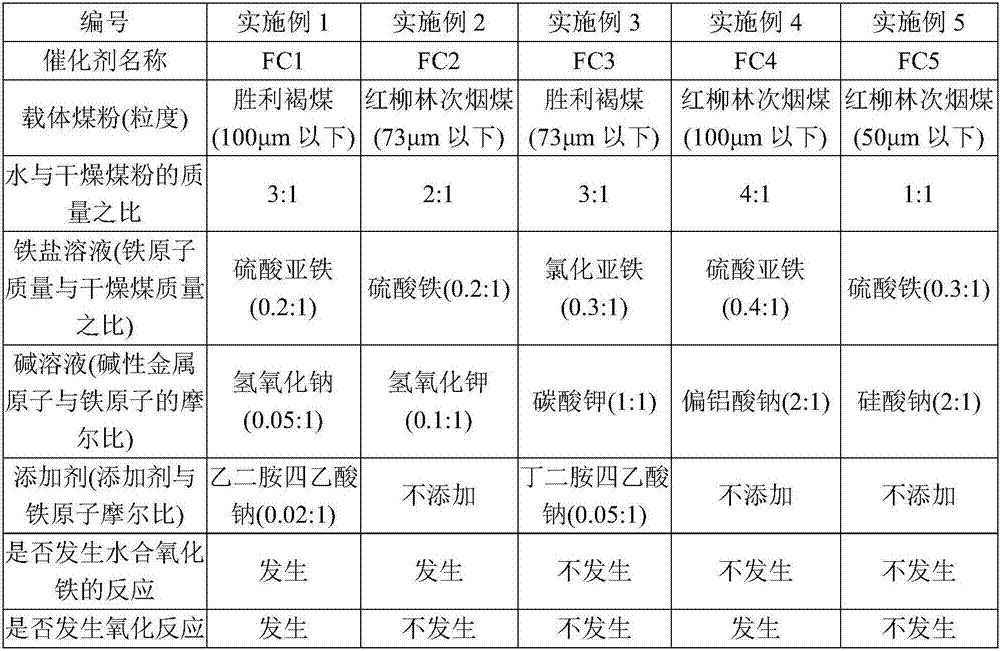

[0022] The catalyst prepared in Examples 1-5 is a supported composite catalyst FC1-5, and its preparation process is as follows: coal powder, iron salt solution, alkali solution and additives are mixed and stirred for reaction and then dried. The raw materials and conditions for its preparation are as follows:

[0023]

Embodiment 6-7

[0025] The catalyst prepared in Example 6-7 is a mixed composite catalyst FC6-7. Among them, FC6 is made by directly mixing iron hydroxide and sodium carbonate, and the molar ratio of sodium atom to iron atom is 0.1:1; FC7 is made by directly matching iron sulfate and potassium silicate, and potassium atom and iron atom The molar ratio of atoms is 0.2:1.

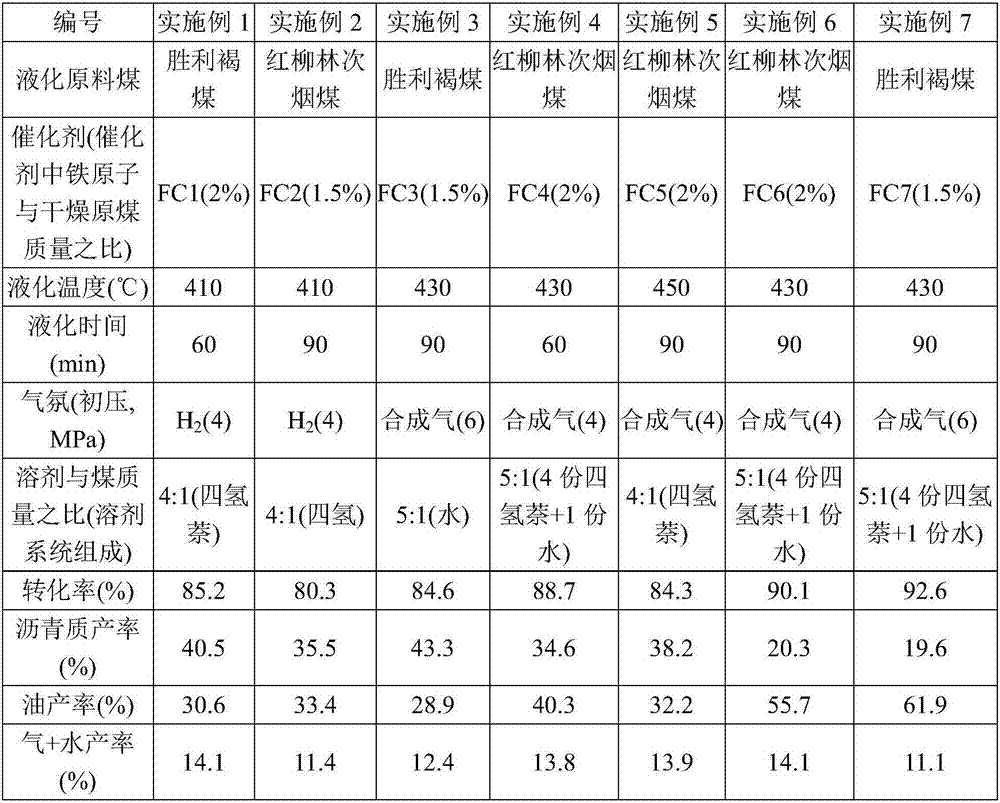

[0026] With the iron-alkali composite catalyst FC1-7 prepared in Examples 1-7 as the catalyst for direct liquefaction of coal, the direct liquefaction experiment of coal was carried out on a 500mL high-temperature and high-pressure reactor, and its experimental conditions and results are as follows:

[0027]

[0028] Note: Syngas refers to CO and H 2 Mixed gas (CO:H 2 =1.5:3.5); oil refers to n-hexane soluble matter; asphaltene refers to n-hexane-insoluble-tetrahydrofuran soluble matter; the conversion rate is equal to the sum of the yields of asphaltene, oil, gas and water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com