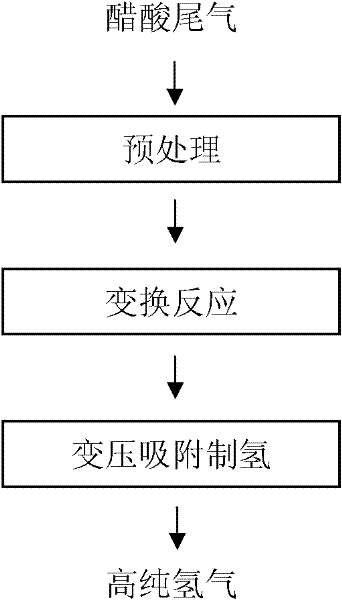

Method for producing hydrogen gas by using acetic acid tail gas

A tail gas and acetic acid technology, applied to chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve the problems of environmental pollution, waste of energy, increase the production cost of acetic acid, etc., and achieve good benefits, large hydrogen production, and resource saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

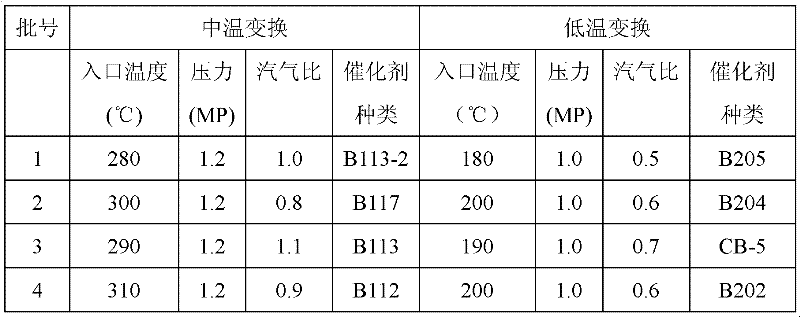

[0028] In this example, the first and second batches of acetic acid tail gas were subjected to impurity removal, medium-temperature shift, low-temperature shift, and hydrogen purification to obtain high-purity hydrogen.

[0029] The 1st batch ingredient content is CO: 69.34%, CO 2 : 9.58%, H 2 : 15.32%, N 2 : 2.7%, CH 4 : 3.06% and trace amounts of methyl iodide and acetic acid tail gas of methanol are first washed to remove methanol, and then adsorbed by activated carbon to remove methyl iodide. The ECD detector is used to detect that the content of methyl iodide is less than 50ppm. After removing impurities, the gas enters the shift reactor for medium temperature The shift reaction, the shift catalyst adopts the B113-2 medium temperature shift catalyst produced by Liaohe Catalyst Factory, the inlet temperature of the middle shift is 280°C, the steam-to-gas ratio is 1.0, the reaction pressure is 1.2MP, and the CO dry content of the middle shift outlet is 4.89% as detected b...

Embodiment 2

[0034] In this example, the 3rd and 4th batches of acetic acid tail gas underwent impurity removal, pressure swing adsorption separation of CO, medium temperature shift, low temperature shift and hydrogen purification to obtain high-purity hydrogen.

[0035] The 3rd batch composition content is CO: 70.82%, CO 2 : 9.45%, H 2 : 14.20%, N 2 : 2.59%, CH 4 : 2.94% acetic acid tail gas with trace amounts of methyl iodide and methanol is washed with water to remove methanol, and then adsorbed by activated carbon to remove methyl iodide. The ECD detector is used to detect that the content of methyl iodide is less than 50ppm, and the gas after impurity removal enters the PSA-CO system. The raw material is fed through the inlet port, and CO is obtained at the outlet port, and the desorption gas of the pressure swing adsorption is passed into the shift reactor to carry out the medium temperature shift reaction. ℃, steam-gas ratio 1.1, reaction pressure 1.2MP, gas chromatographic detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com