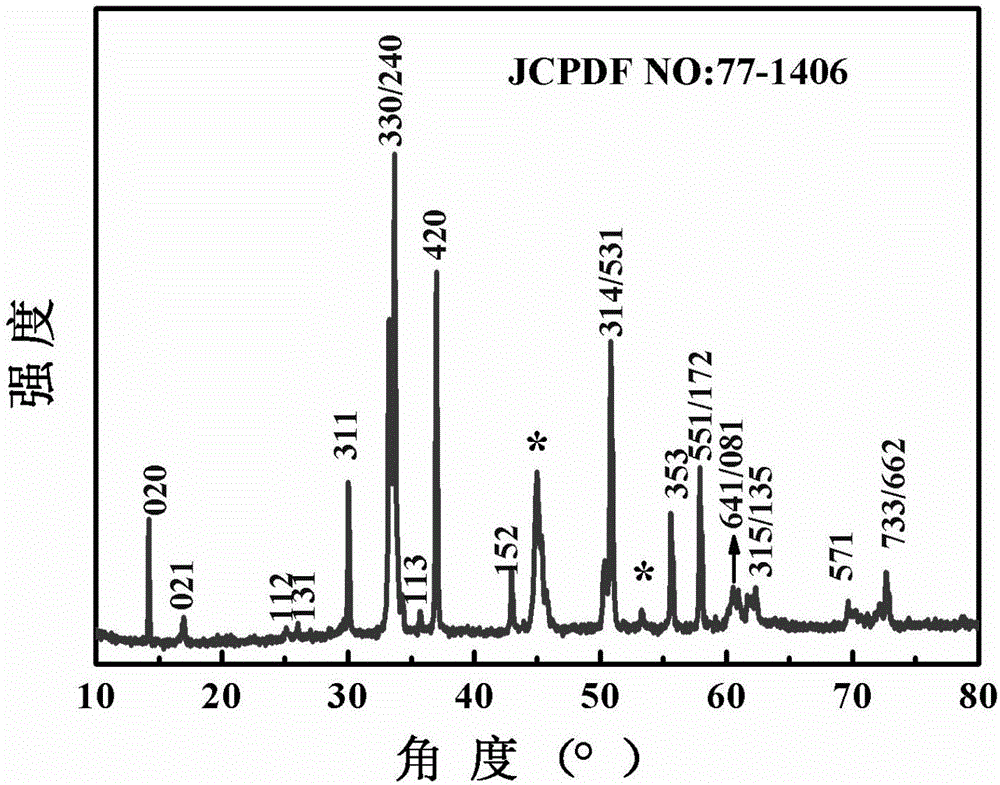

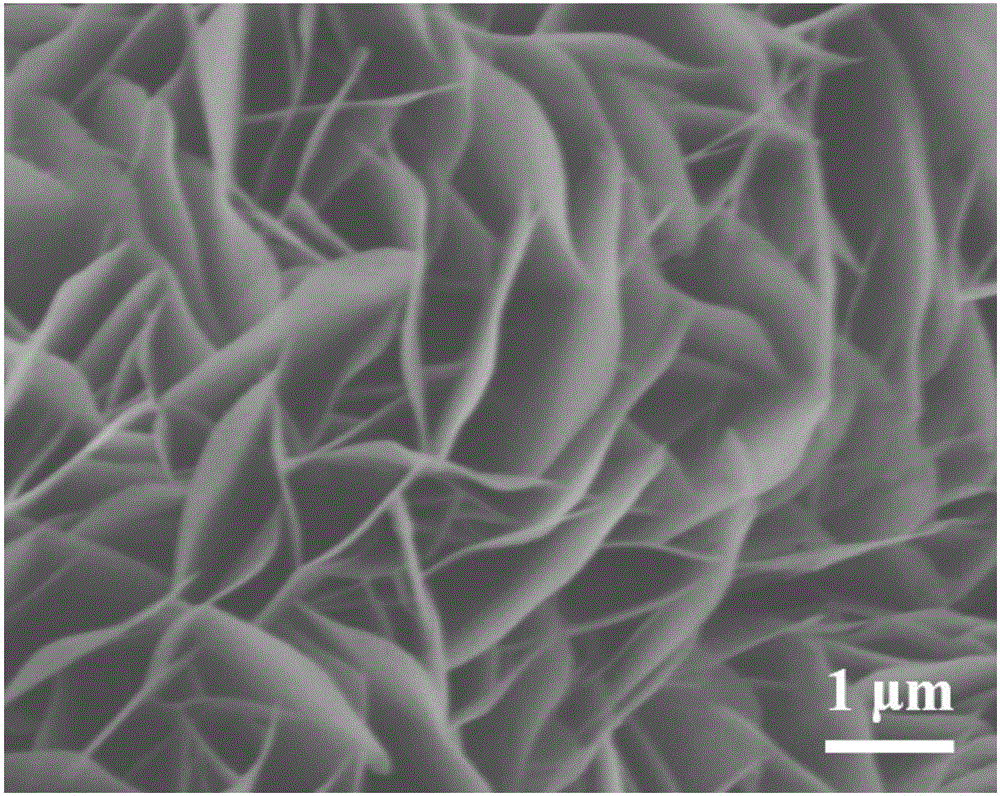

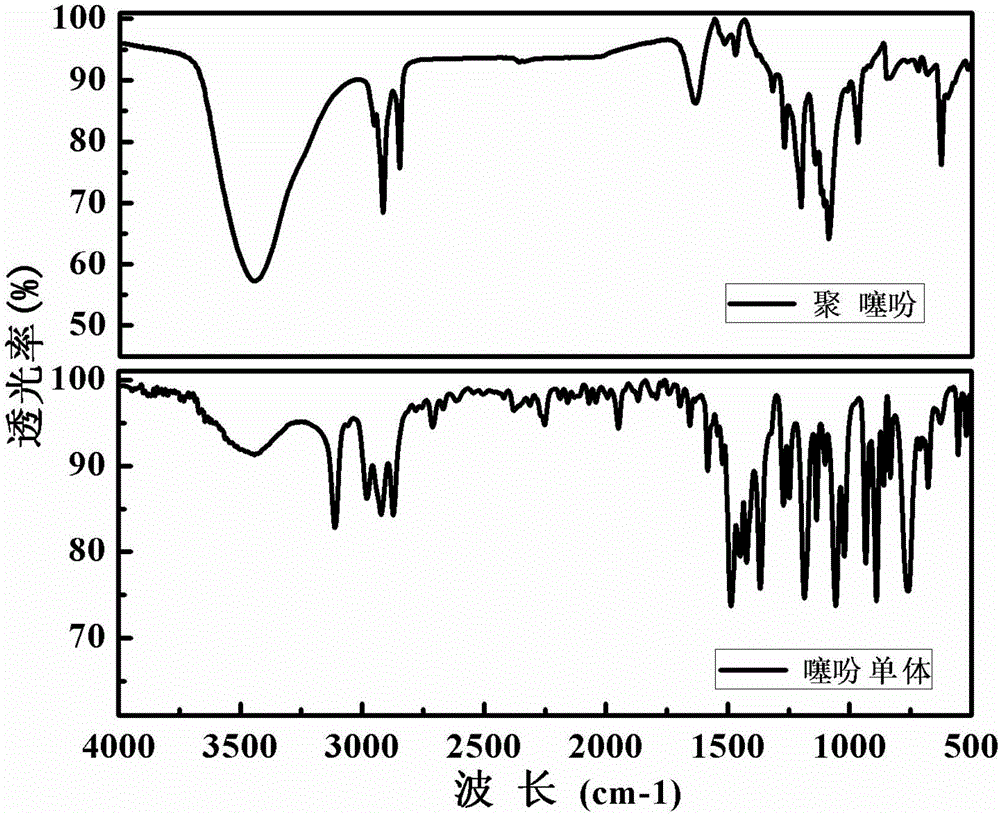

Monocrystal porous V2Se9 nanosheet array electro-catalysis material and preparation method thereof

A technology of nanosheet array and electrocatalytic material, which is applied in the field of preparation of single crystal porous nine-vanadium selenide nanosheet array electrocatalytic material and electrocatalytic material, which can solve the problems of high price, increased energy consumption, and increased reaction rate. , to achieve the effects of improved electrocatalytic activity, excellent stability, and reduced hydrogen production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1, according to the following steps to prepare a single crystal porous nine vanadium selenide nanosheet array electrocatalytic material:

[0029] (1) Prepare a hydrochloric acid solution with a concentration of 1 mol / liter as the first aqueous solution, put the nickel foam of the conductive substrate into the first aqueous solution and ultrasonically clean it for 5 minutes, then put the conductive substrate into absolute ethanol and ultrasonically clean it for 5 minutes, and take out the foam Nickel, placed in an oven to dry.

[0030] (2) The ammonium metavanadate solution with a preparation concentration of 1mol / liter is used as the second aqueous solution, and after 10 minutes of magnetic stirring, the pH value of the second aqueous solution is adjusted to 1 by using the first aqueous solution, and then transferred to the reaction kettle after 10 minutes of magnetic stirring , put nickel foam into the reaction kettle obliquely, seal the reaction kettle, put it...

Embodiment 2

[0035] Example 2, according to the following steps to prepare a single crystal porous nine vanadium selenide nanosheet array electrocatalytic material:

[0036] (1) Prepare a hydrochloric acid solution with a concentration of 0.5 mol / liter as the first aqueous solution, put the titanium sheet into the first aqueous solution and ultrasonically clean it for 5 minutes, then put the conductive substrate into absolute ethanol and ultrasonically clean it for 5 minutes, and take out the titanium sheet , put in an oven to dry.

[0037] (2) Prepare the ammonium metavanadate solution with a concentration of 4mol / liter as the second aqueous solution, use the first aqueous solution to adjust the pH value of the second aqueous solution to 3 after magnetic stirring for 10 minutes, and then transfer it to the reaction kettle after magnetic stirring for 10 minutes , place the titanium sheet obliquely into the reaction kettle, seal the reaction kettle, put it into a blast drying oven, raise th...

Embodiment 3

[0041] Example 3, according to the following steps to prepare a single crystal porous nine vanadium selenide nanosheet array electrocatalytic material:

[0042] (1) Prepare a hydrochloric acid solution with a concentration of 1 mol / liter as the first aqueous solution, put the copper sheet into the first aqueous solution and ultrasonically clean it for 5 minutes, then put the conductive substrate into absolute ethanol and ultrasonically clean it for 5 minutes, and take out the copper sheet , put in an oven to dry.

[0043] (2) Preparation concentration is the ammonium metavanadate solution of 3mol / liter as the second aqueous solution, utilizes the first aqueous solution to adjust the pH value of the second aqueous solution to 3 after magnetic stirring for 10 minutes, then transfers to the reaction kettle after magnetic stirring for 10 minutes , place the copper sheet obliquely into the reaction kettle, seal the reaction kettle, put it into a blast drying oven, raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com