Seawater hydrogen production conveying system and method based on existing offshore wind plant

A technology for conveying systems and wind farms, applied in pipeline systems, wind power generation, container filling methods, etc., to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

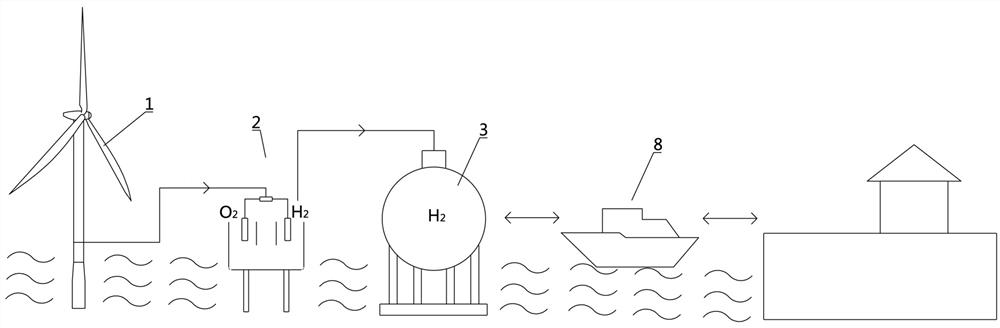

[0028] like figure 1 As shown, a seawater hydrogen production delivery system based on an existing offshore wind farm includes a wind generator 1, a seawater electrolysis cell device 2 and a hydrogen delivery unit, the wind generator 1 is used to convert wind energy into electrical energy, and the The seawater electrolysis cell device 2 is used to electrolyze seawater by using the electric energy supplied by the wind generator 1 , and the hydrogen delivery unit is used to transport the hydrogen produced by the seawater electrolysis cell device 2 to the land. Specifically, the hydrogen delivery unit includes a large hydrogen storage tank 3 and a transport ship 8, the large hydrogen storage tank 3 is used to store hydrogen, and the transport ship 8 is used to regularly extract the hydrogen from the large hydrogen storage tank 3 and Transport hydrogen to land. Wherein, the bottom of the large hydrogen storage tank 3 is erected on the seabed through a pile foundation, and the tra...

Embodiment 2

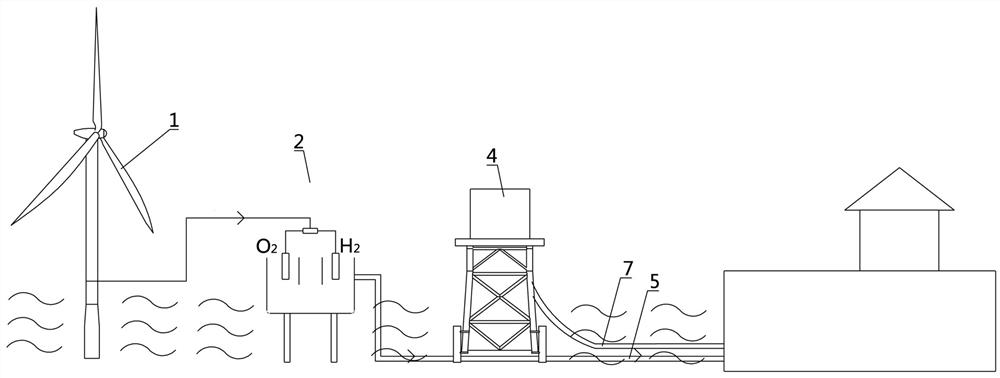

[0043] like figure 2 Shown: a seawater hydrogen production delivery system based on an existing offshore wind farm, including a wind generator 1, a seawater electrolysis cell device 2 and a hydrogen delivery unit, the wind generator 1 is used to convert wind energy into electrical energy, the The seawater electrolysis cell device 2 is used to electrolyze seawater by using the electric energy supplied by the wind generator 1 , and the hydrogen delivery unit is used to transport the hydrogen produced by the seawater electrolysis cell device 2 to the land. Specifically, the hydrogen delivery unit includes an offshore booster station 4, a transmission line 7 and a hydrogen delivery pipeline 5. The offshore booster station 4 is used to boost the current transmitted by the wind power generator 1. The transmission line 7 is used to transport the electric energy generated by the wind power generator 1, the hydrogen gas delivery pipeline 5 is used to transport hydrogen, the hydrogen g...

Embodiment 3

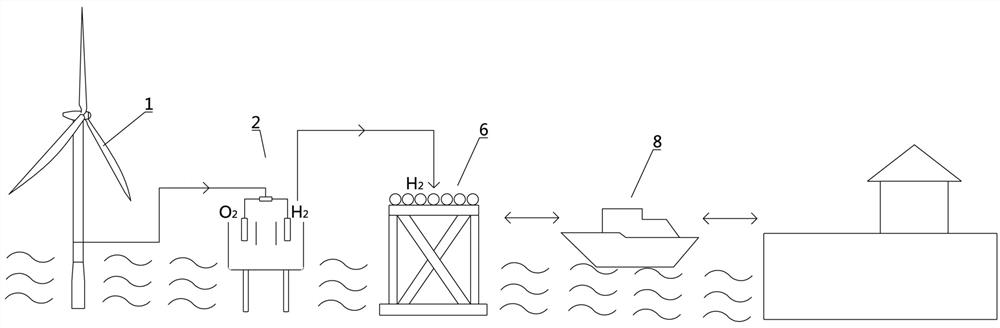

[0059] like image 3 As shown, a seawater hydrogen production delivery system based on an existing offshore wind farm includes a wind generator 1, a seawater electrolysis cell device 2 and a hydrogen delivery unit, the wind generator 1 is used to convert wind energy into electrical energy, and the The seawater electrolysis cell device 2 is used to electrolyze seawater by using the electric energy supplied by the wind generator 1 , and the hydrogen delivery unit is used to transport the hydrogen produced by the seawater electrolysis cell device 2 to the land. Specifically, the hydrogen delivery unit includes a plurality of small hydrogen storage tanks 6 and a transport ship 8, the small hydrogen storage tanks 6 are used to store hydrogen, and the transport ship 8 is used to transport the small hydrogen storage tanks 6 to land. Among them, the small hydrogen storage tank 6 is placed on the offshore platform, and the delivery ship 8 has a tank for hydrogen storage.

[0060] A me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com