Hydrogen production method

A hydrogen and iron powder technology, applied in the field of hydrogen production, can solve the problems of high processing requirements of storage tanks, inability to be applied on a large scale, and large storage tanks, and achieve the effects of low hydrogen production cost, small volume and easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below, and the examples of the embodiments are intended to explain the present invention and should not be construed as limiting the present invention.

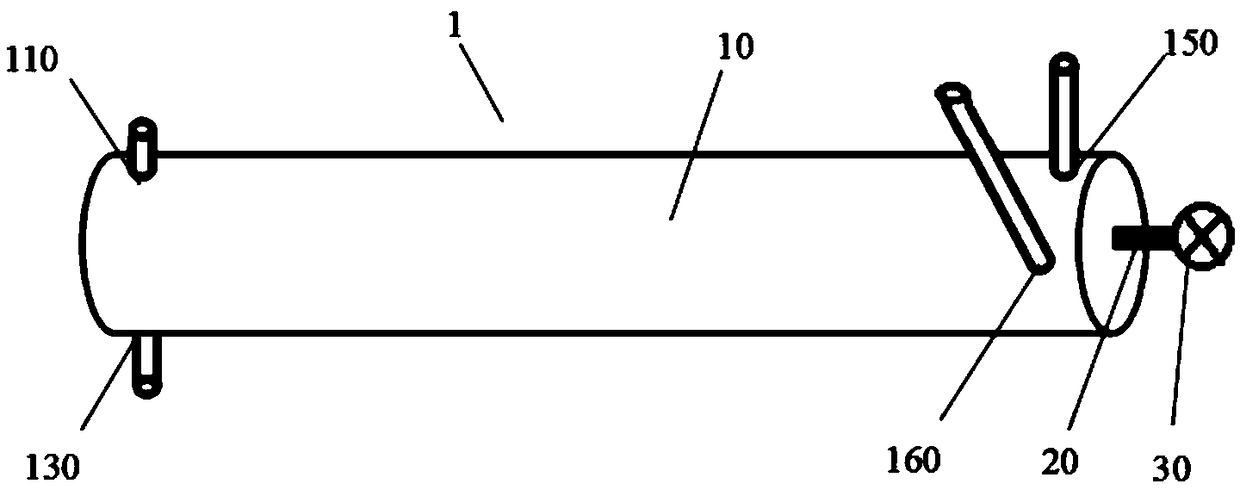

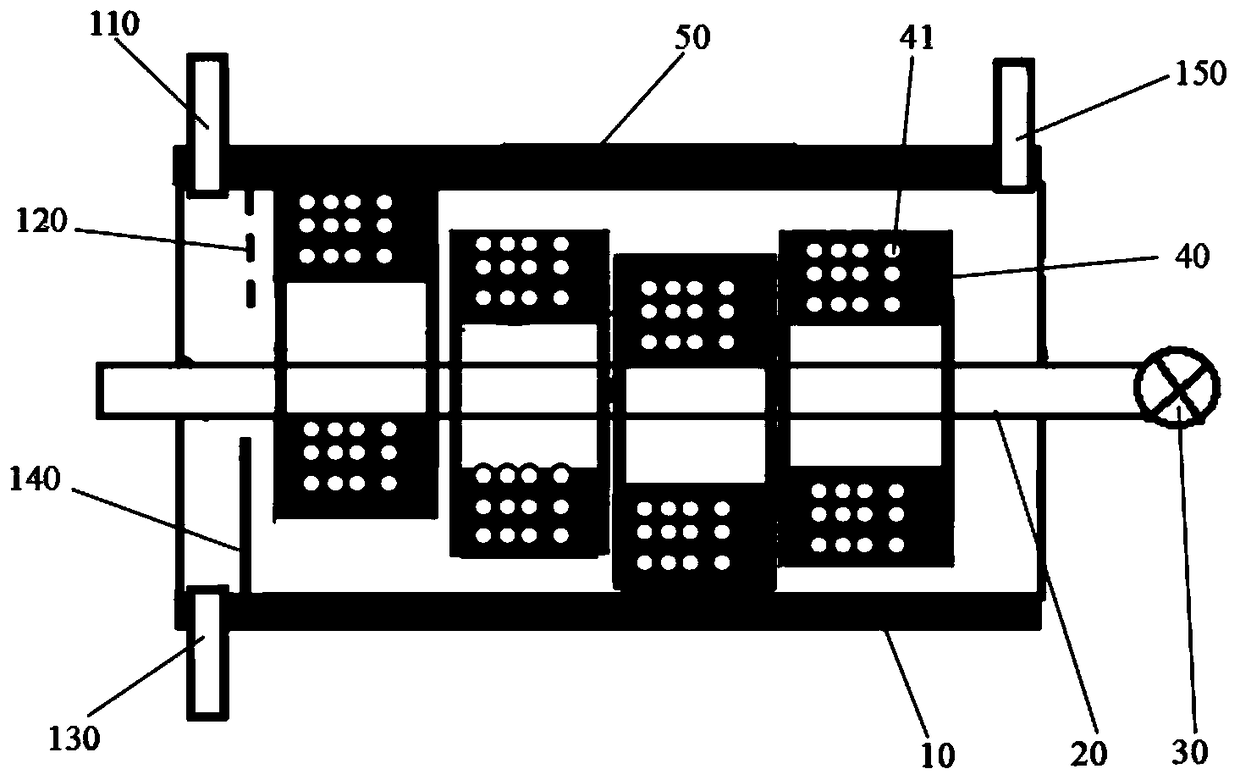

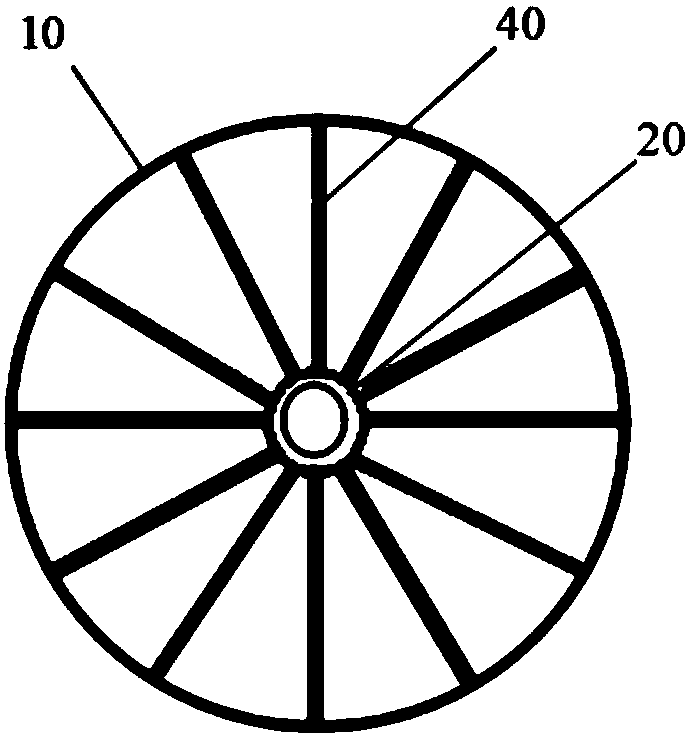

[0041] The method for producing hydrogen provided by the present invention comprises: contacting iron powder with oxygen-containing water vapor, and the water vapor in the oxygen-containing water vapor reacts with the iron powder to generate ferroferric oxide and hydrogen, while the oxygen-containing water vapor in the Oxygen reacts with iron powder to generate iron oxide and releases heat, which provides heat for the reaction between water vapor and iron powder to continue the reaction between water vapor and iron powder. Wherein, the oxygen-containing water vapor is preferably obtained by the following method: pressurize normal temperature water to 3-5 bar and atomize it, then mix it with oxygen and heat it with the heat source provided by the hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com