Hydrogen production method by steam reforming in combined reactor and device thereof

A technology of reactor and steam, which is applied in the field of reforming hydrogen production in fixed bed-semi-circulating fluidized bed composite reactor, can solve the problems of reduced catalyst activity, high cost, complicated preparation process, etc., and achieve significant social benefits and Economic benefits, reduction of hydrogen production costs, and shortening of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

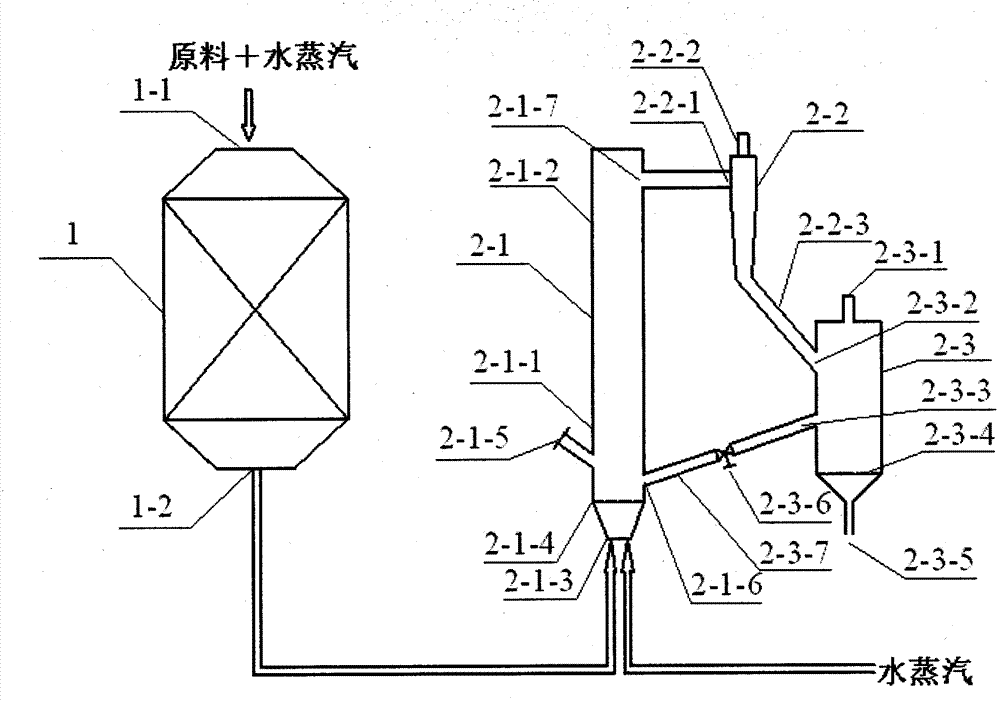

[0042] Such as figure 1 As shown, a combined reactor steam reforming hydrogen production plant includes two parts: a fixed bed reactor 1 and a semi-circulating fluidized bed reactor.

[0043] The fixed bed reactor 1 is a conventional fixed bed reactor. In the fixed-bed reactor 1, an industrial cylindrical nickel-based catalyst is installed. After the raw material and water vapor are passed through the gas inlet 1-1 at the top of the fixed bed reactor 1, in the fixed bed reactor 1, under the action of the industrial cylindrical nickel-based catalyst, high-temperature catalytic regeneration is carried out. The whole reaction produces a mixed gas. The mixed gas is transported to the gas outlet 1-2 at the bottom end of the fixed bed reactor 1 and the gas pipe and the gas inlet 2-1-3 at the bottom end of the fluidized bed riser reactor 2-1. In the fluidized bed riser reactor 2-1, under the action of nickel-based catalyst particles and carbon dioxide adsorbent particles, carbon d...

Embodiment 2

[0060] A compound reactor steam reforming hydrogen production device, same as embodiment 1. in:

[0061] The inner diameter of the fluidized bed riser reactor 2-1 is 300mm. The opening ratio of the first gas distribution plate 2-1-4 is 10%, and the hole diameter is 0.5mm. The particle size of the nickel-based catalyst particle is 500 μm, and the particle size of the carbon dioxide adsorbent particle is 45 μm; the mass ratio of the nickel-based catalyst particle to the mass of the carbon dioxide adsorbent particle is 1:10. The included angle between the return leg 2-2-3 of the cyclone separator 2-2 and the adsorbent regenerator 2-3 is 15°. The inner diameter of the upper circular tube of the adsorbent regenerator 2-3 is 500mm. The included angle between the inclined pipe 2-3-6 and the fluidized bed riser reactor 2-1 is 20°. The opening ratio of the second gas distribution plate 2-3-4 is 1%, and the hole diameter is 2.5mm.

[0062] A method for producing hydrogen by steam r...

Embodiment 3

[0068] A compound reactor steam reforming hydrogen production device, same as embodiment 1. in:

[0069] The inner diameter of the fluidized bed riser reactor 2-1 is 3000mm. The opening ratio of the first gas distribution plate 2-1-4 is 1%, and the hole diameter is 2.5mm. The particle size of the nickel-based catalyst particle is 800 μm, and the particle size of the carbon dioxide adsorbent particle is 150 μm; the ratio of the mass of the nickel-based catalyst particle to the mass of the carbon dioxide adsorbent particle is 1:2. The included angle between the return leg 2-2-3 of the cyclone separator 2-2 and the adsorbent regenerator 2-3 is 45°. The inner diameter of the upper circular tube of the adsorbent regenerator 2-3 is 5000mm. The included angle between the inclined pipe 2-3-6 and the fluidized bed riser reactor 2-1 is 30°. The opening ratio of the second gas distribution plate 2-3-4 is 15%, and the hole diameter is 0.5mm.

[0070] A method for hydrogen production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com