Patents

Literature

60results about How to "Full use of value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon material for negative electrode of lithium ion battery and preparation method thereof, negative electrode of lithium ion battery, and lithium ion battery

ActiveCN106486673AImproved magnification performanceHigh reversible capacityCell electrodesSecondary cellsHigh rateCarbide

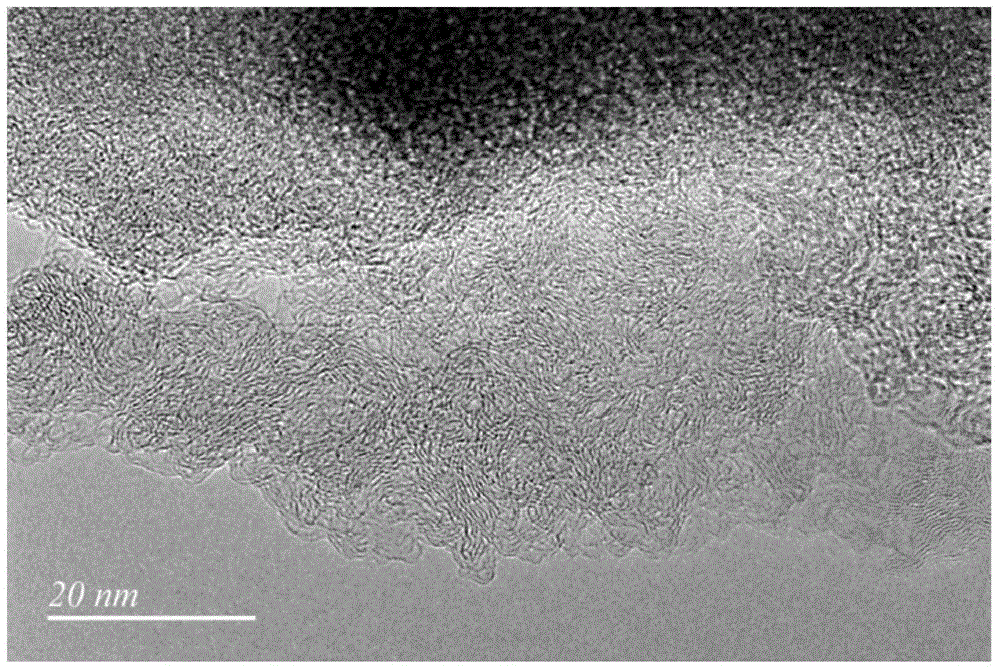

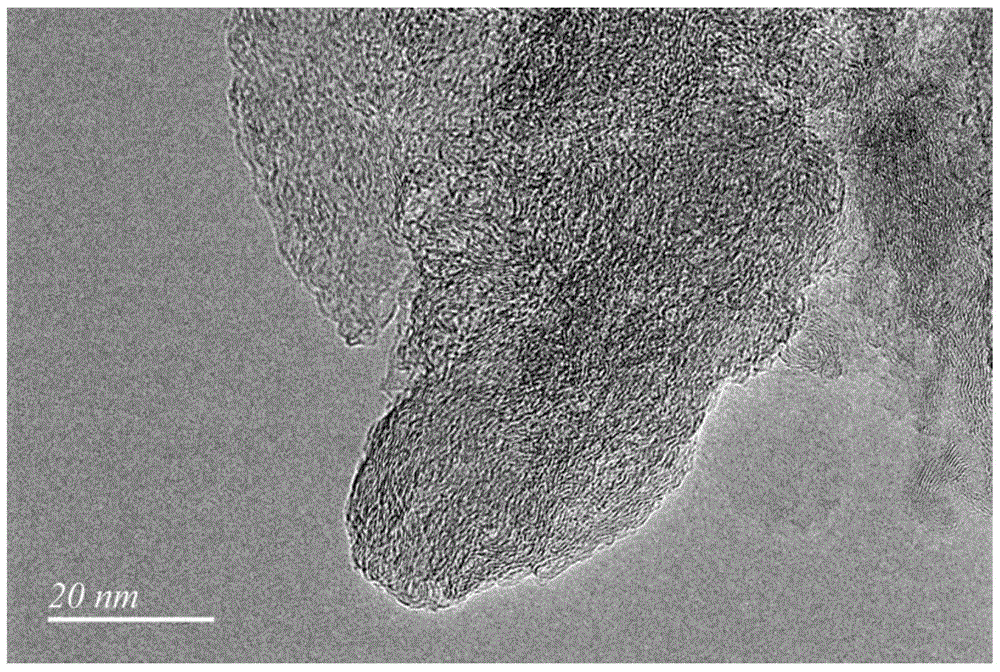

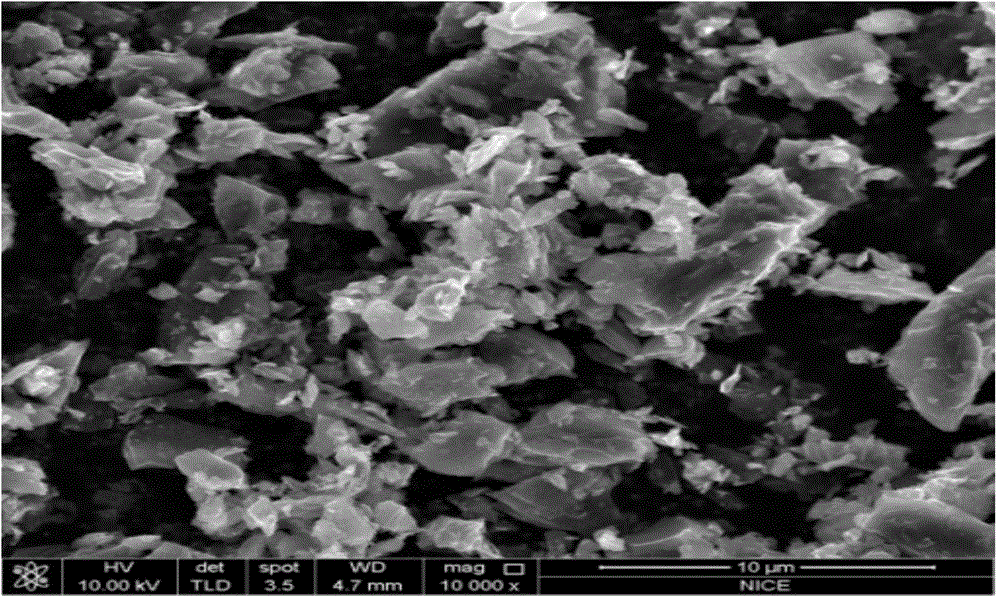

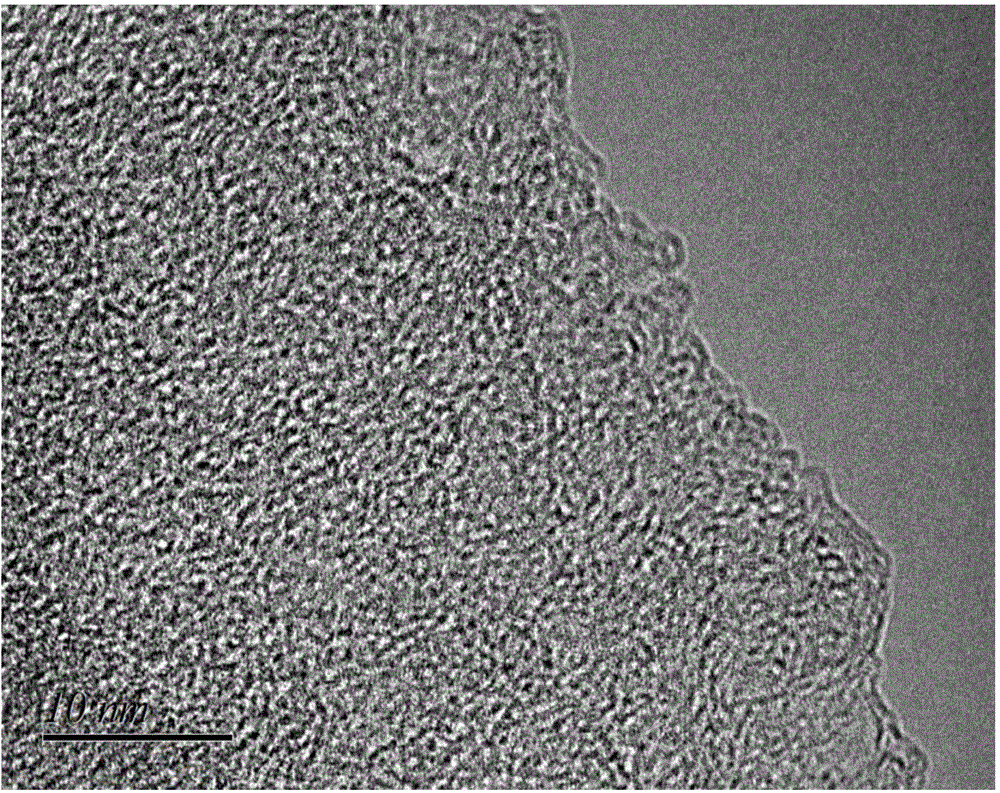

The invention provides a carbon material for a negative electrode of a lithium ion battery and a preparation method thereof, the negative electrode of the lithium ion battery, and the lithium ion battery. The method comprises the following steps: (1) subjecting residues of direct coal liquefaction and / or coal-tar pitch to thermopolymerization so as to obtain a thermopolymerization product; (2) stabilizing the thermopolymerization product so as to obtain a stabilized product; (3) pre-sintering the stabilized product and subjecting the pre-sintered product to ball milling so as to obtain a to-be-carbonized substance; and (4) carbonizing the to-be-carbonized substance so as to obtain the carbon material; wherein a hard carbon precursor or an organic solution of the hard carbon precursor is added in the step (3) and / or the step (4). The method can realize high-added-value utilization of the residues of direct coal liquefaction and prepares the carbon material with higher rate performance for the negative electrode of the lithium ion battery at low cost in virtue of simple process.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Carbon material for lithium ion battery negative electrode and preparation method for carbon material, lithium ion battery negative electrode and lithium ion battery

The invention provides a preparation method for a carbon material for a lithium ion battery negative electrode. The preparation method comprises the steps of performing polymerization on coal liquefaction residue, stabilizing the polymerization product and performing carbonization on the stabilized product. The invention provides the carbon material for the lithium ion battery negative electrode prepared by the method provided by the invention. The invention provides the lithium ion battery negative electrode, wherein the negative electrode contains the carbon material provided by the invention. The invention provides a lithium ion battery, wherein the negative electrode of the lithium ion battery contains the carbon material provided by the invention. According to the preparation method, the coal liquefaction residue is directly taken as the raw material; a thermal polymerization method is adopted without requiring a catalyst; the carbon material for the lithium ion battery negative electrode is prepared by the steps of polymerization, stabilization and carbonization; and therefore, the use of the catalyst is saved, a separating process and an organic solvent or a precipitator required by the separation after polymerization are saved as well.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

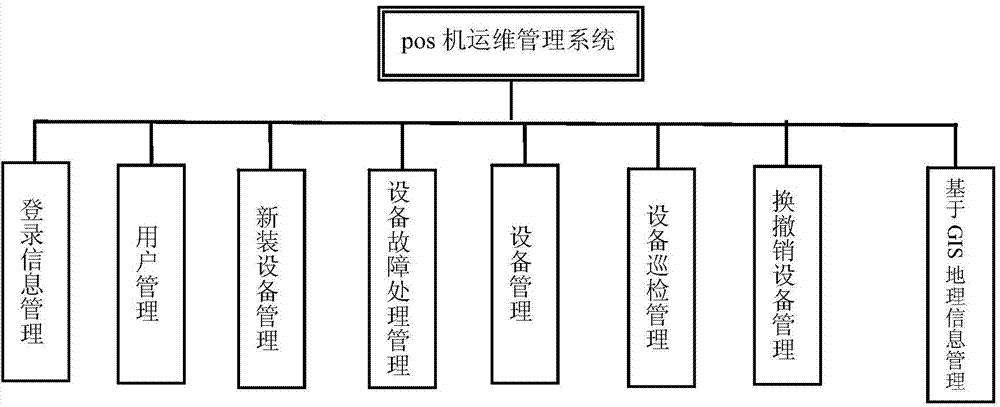

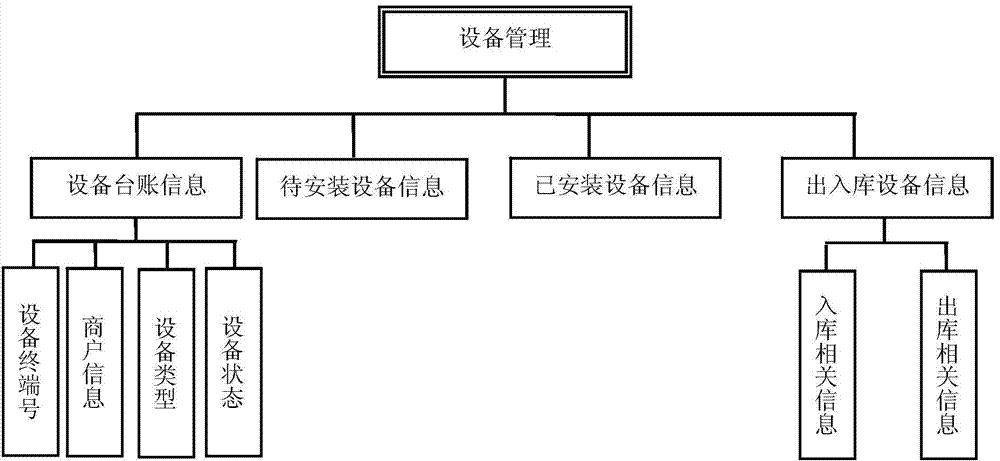

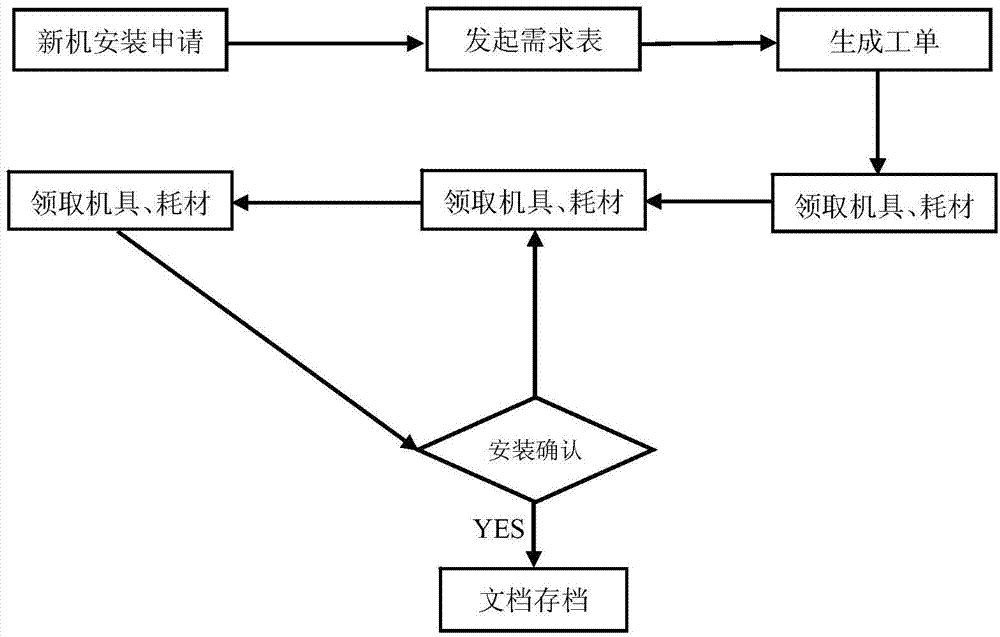

POS machine operation service system

InactiveCN103778504AImprove efficiencyStandardize and standardizeResourcesPoint-of-sale network systemsService systemService information

The present invention discloses a POS machine operation service system. The POS machine operation service system comprises the steps of: an information management module, a user management module, an equipment management module, a newly mounted equipment management module, an equipment failure processing management module, an equipment inspection management module, an equipment changing and withdrawing management module, and a GIS-based geographical information management module. Through the POS machine operation service system, comprehensive maintenance service information of an equipment file, an operation flow, user data, repairing and service condition, inspection condition, etc. are established for each operation item; so that area dividing, digital receiving and dynamic distribution are performed on traditional equipment mounting and maintenance operation through a digitalized and informationized interactive service platform.

Owner:ZHEJIANG ACTIVETECH ELECTRONICS TECH CO LTD

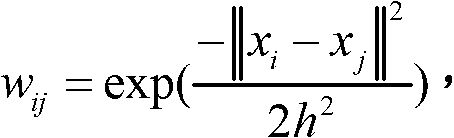

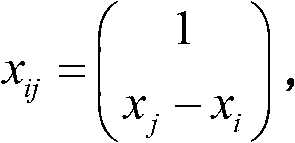

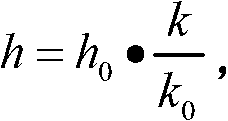

Self-adaptive parameter soft measuring method on basis of semi-supervised local linear regression

ActiveCN102708294AFull use of valueRemove the effects of measurement errorsSpecial data processing applicationsObservational errorSliding time window

The invention provides a self-adaptive parameter soft measuring method on the basis of the semi-supervised local linear regression, which comprises the following steps of: firstly, on the theoretical basis of a local linear regression scatter point flatting method, transforming the local linear regression scatter point flatting method into a semi-supervised learning method by a method of introducing unlabeled samples into a target equation of the unlabeled samples; then by utilizing a method of calculating a labeled sample set to estimate a slope, carrying out self-adaptive estimation to obtain an optimal gaussian kernel width parameter of a current labeled sample set; and finally, implementing parameter selection of the semi-supervised local linear regression learning method by utilizing a self-adaptive parameter selecting method and implementing the online update of a soft measuring model on the basis of a sliding time window mode. The invention sufficiently utilizes the value of the unlabeled samples. Aiming at the characteristics of the semi-supervised local linear regression, the influence caused by the labeled sample measuring error can be effectively eliminated and the prediction accuracy is improved. The soft measuring model is updated in real time by applying the sliding time window method, so that the model can well adapt to the change of input data.

Owner:SHANGHAI JIAO TONG UNIV +1

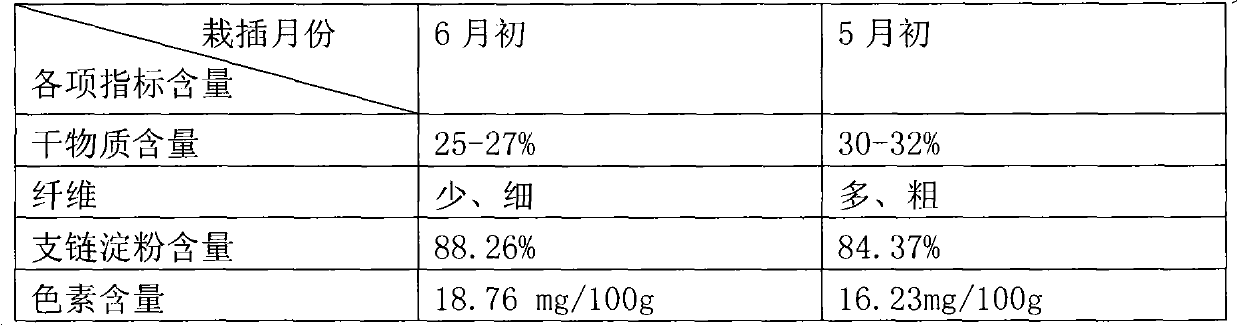

Sweet potato for processing preserved sweet potato and cultivation method and application thereof

InactiveCN101946613APromote expansionImprove baking qualityConfectionerySweetmeatsBiotechnologySugar

The invention discloses a sweet potato for processing preserved sweet potato and a cultivation method and an application thereof, belonging to the field of cultivation and processing of the sweet potatoes. The No.18 Ji sweet potatoes cultivated by adopting the cultivation method can be processed into the high-quality low-sugar purple preserved sweet potato without any additives by cleaning, shaping, steam-boiling, saccharification and baking. The preserved sweet potato has the characteristics of soft texture, low sugar content and translucent color and luster, is rich in anthocyanin and selenium element, has oxidation resistance and high free radical removing capacity which is 20 times of VE and 50 times of VC, and can prevent cardiovascular diseases, prevent tumors, prevent mutation, prevent radiation, delay aging, improve immunity and have good anti-cancer effect.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

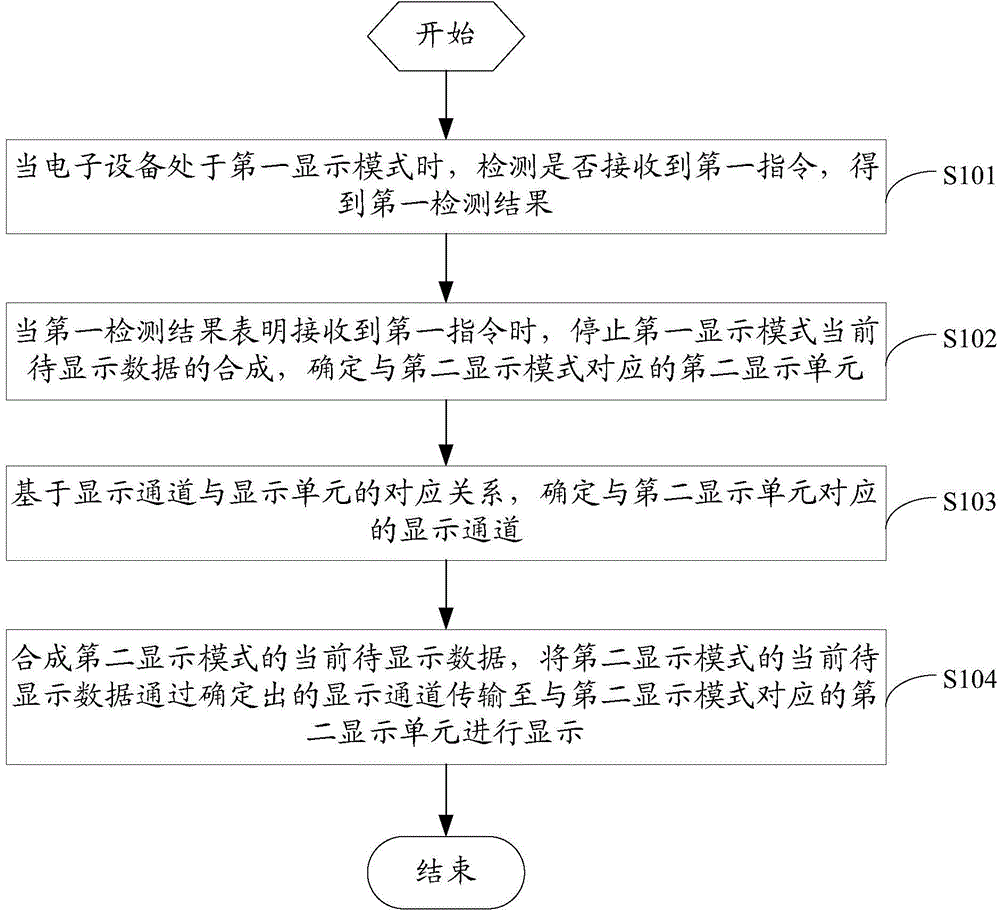

Display mode switching method and electronic device

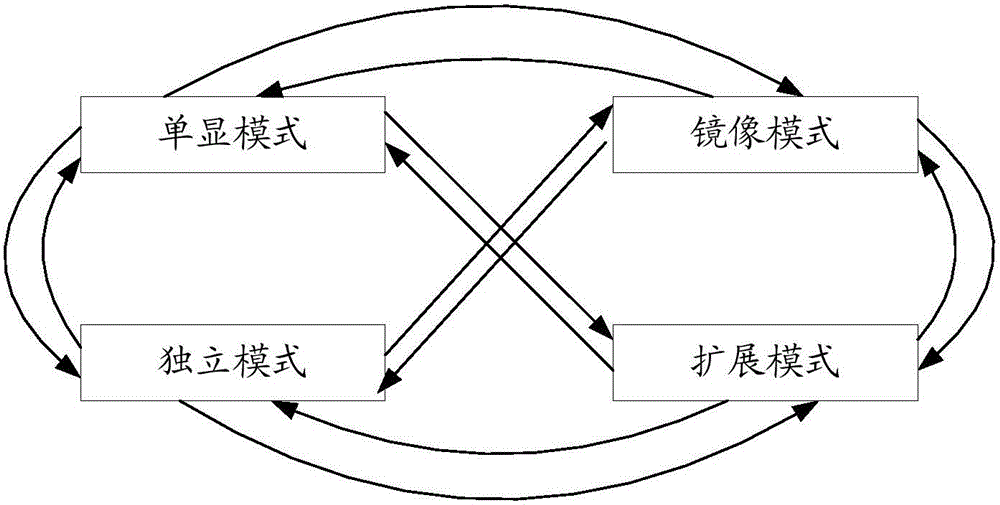

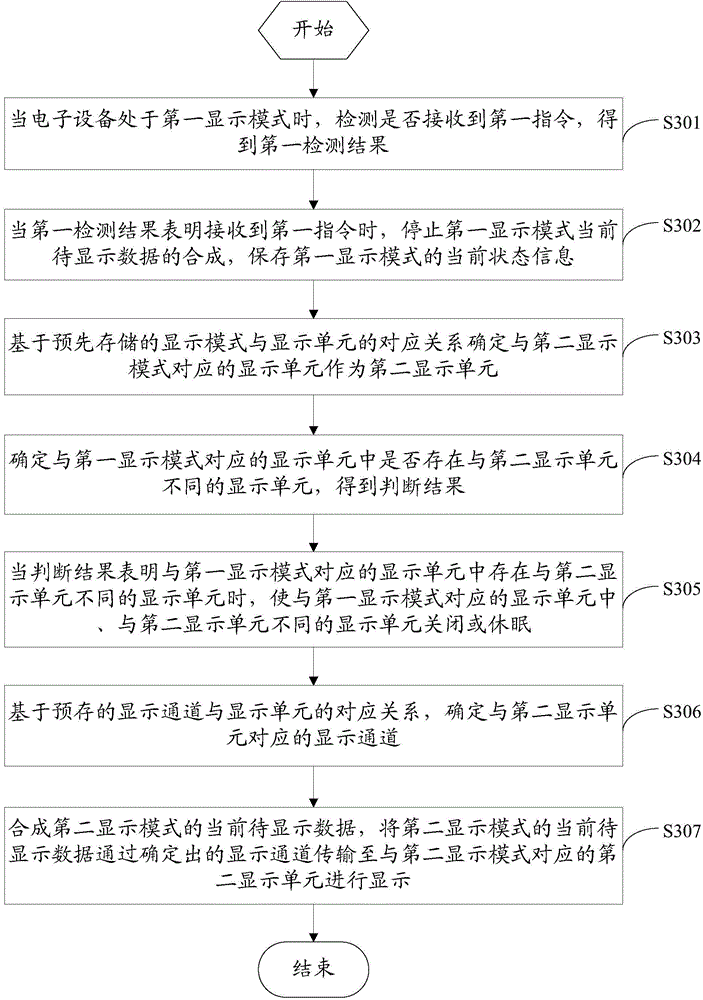

ActiveCN104679467AFull use of valueNovel application experienceDigital output to display deviceComputer scienceMode switching

The invention provides a display mode switching method and an electronic device. The display mode switching method comprises the steps of detecting whether a first instrument for switching a first display mode to a second display mode of the electronic device is received or not when the electronic device is in the first display mode, stopping synthesis of current data to be displayed in the first display mode and determining a second display unit corresponding to the second display mode when the first instrument is received, determining a display channel corresponding to the second display mode based on the correspondence relation of the display channel and the display unit, synthesizing current data to be displayed in the second display mode and transmitting the current data to be displayed in the second display mode to the second display unit corresponding to the second display mode through the determined display channel for displaying. By means of the display mode switching method and the electronic device, switching between different display modes can be achieved, and user experience is good.

Owner:LENOVO (BEIJING) LTD

Bio-organic fertilizer based on agricultural and forestry wastes and production method of bio-organic fertilizer

InactiveCN105152705AFull use of valueReduce pollutionBio-organic fraction processingOrganic fertiliser preparationEngineeringOrganic fertilizer

The invention discloses a bio-organic fertilizer based on agricultural and forestry wastes and a production method of the bio-organic fertilizer. The production method comprises the following steps of (1) pulverizing and mixing the agricultural and forestry wastes, accumulating to form a material pile, spraying water on the material pile, covering the material pile by using a plastic film, and fermenting naturally for 2-3 weeks; (2) covering the top of the material pile by using a layer of quick lime several days before fermenting is finished and continuing fermenting until fermenting is finished; (3) adding a common organic fertilizer base material of which the amount is 1 / 3-1 / 4 of that of the material pile in the fermented material pile, inoculating organic fertilizer fermenting bacterial liquid of which the amount is 0.01-0.02% of that of the material pile, uniformly mixing, spraying water and stacking, covering the material pile by using a plastic film, and fermenting for 2-3 weeks; and (4) inoculating functional bacteria, spraying functional bacterial liquid of which the amount is 0.01-0.02% of that of the material pile on the mature material pile, turning the pile and uniformly mixing, and stacking for 4-7 days to obtain the bio-organic fertilizer. The mixed agricultural and forestry wastes comprise at least 70% of waste mushroom stick pulverized materials.

Owner:安徽欧杰利生物技术股份有限公司

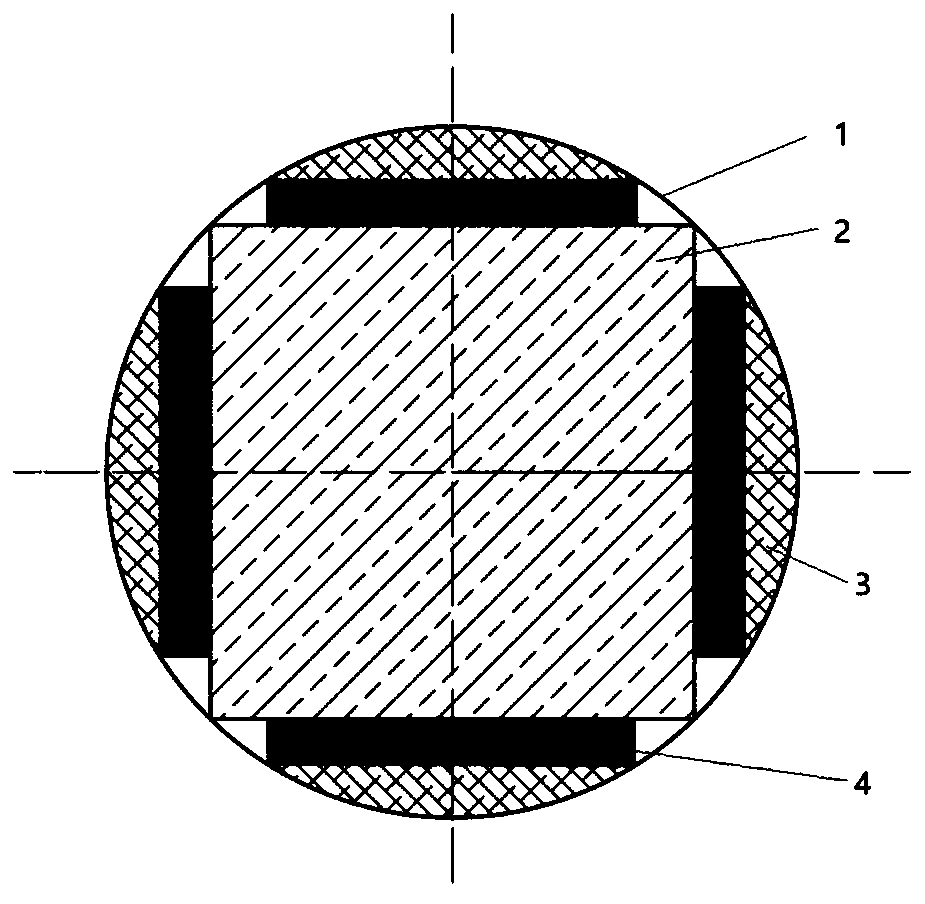

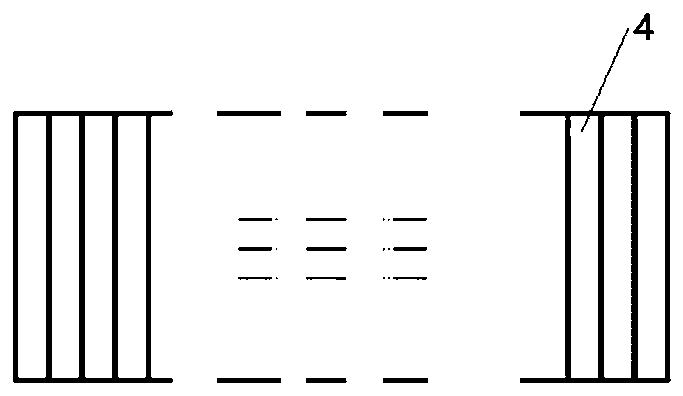

Manufacturing method for low-cost monocrystalline silicon chips for photovoltaic cells

InactiveCN111037766AReduce overall electricity consumptionReduce carbon footprintFine working devicesPhysicsSilicon chip

The invention discloses a manufacturing method for low-cost monocrystalline silicon chips for photovoltaic cells, and relates to the technical field of monocrystalline silicon chip manufacturing. Thesilicon chips produced by the method are cut from original waste monocrystalline flaw-pieces and has no crystal production cost; the cost of each produced silicon chip is reduced by 0.7 yuan and the selling price can be reduced by more than 20%, so that the silicon chips are tangible low-cost silicon chips.

Owner:江苏美科太阳能科技股份有限公司 +1

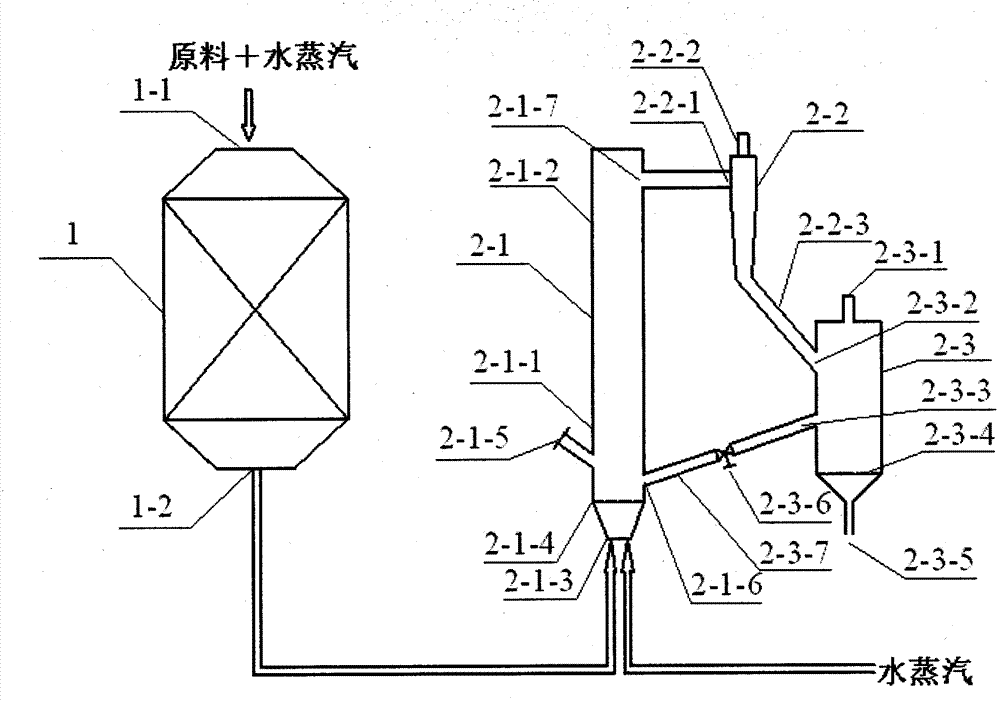

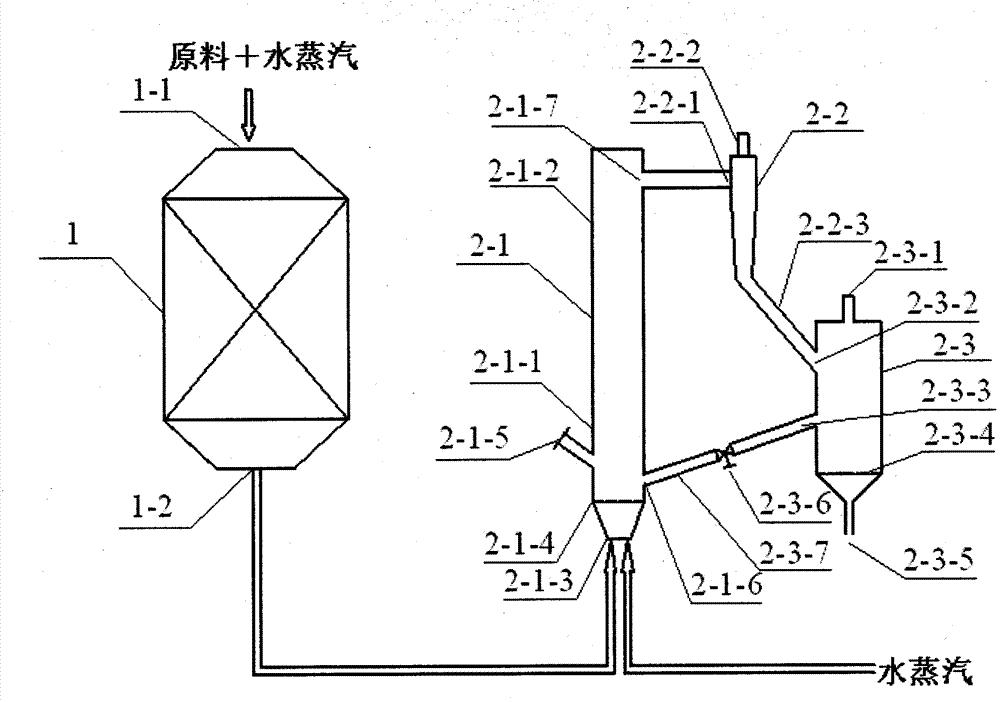

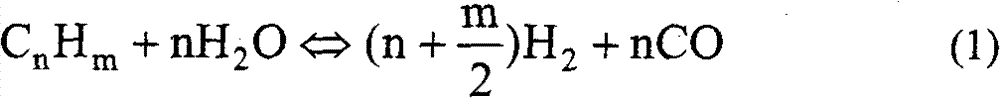

Hydrogen production method by steam reforming in combined reactor and device thereof

InactiveCN102730636AShort processReduce operating costsHuman health protectionHydrogenSteam reformingChemical industry

A hydrogen production method by steam reforming in a combined reactor and a device thereof belong to the technical field of a hydrogen production technology by steam reforming of light dydrocarbon. The device provided by the invention comprises a fixed-bed reactor and a half-cycle fluidized bed reactor. The method is realized by the use of the device, and natural gas or dry gas for oil refining or light oil is used as a raw material. The method comprises the following steps: reducing a nickel based catalyst, carrying out a catalytic reforming reaction in the fixed-bed reactor, carrying out a catalytic reforming reaction again as well as a carbon dioxide adsorption reaction in a riser reactor of the fluidized bed, carrying out gas-solid separation to prepare the hydrogen product, and regenerating and utilizing carbon dioxide adsorbent particles. The invention has characteristics of short process flow, simple operation, energy conservation, low production cost, high hydrogen production efficiency, high purity of the hydrogen product, complete utilization of resources, no environmental pollution and the like. The invention can be widely applied in hydrogen production by steam reforming. The hydrogen prepared by the adoption of the method can be extensively applied in the fields of petroleum, chemical industry, metallurgy and the like.

Owner:CHONGQING UNIV

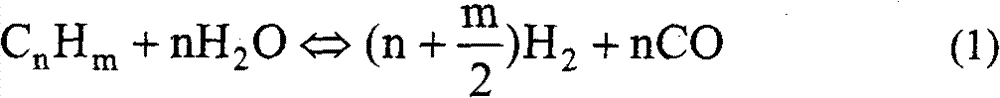

Secondary reheating system and method achieving efficient regeneration and steam exhaust optimization

The invention discloses a secondary reheating system and method achieving efficient regeneration and steam exhaust optimization, and relates to the field of thermal power generation. The system mainlycomprises a boiler, a regeneration steam turbine and a waste heat recovery system, wherein the waste heat recovery system replacing a traditional low-pressure heater is arranged between a condensatewater pump and feedwater of a seventh-stage low-pressure heater, condensate water is preliminarily heated by the waste heat recovery system through flue gas of the boiler and pipeline leaking steam ofthe regeneration steam turbine, and the waste heat recovery system is composed of a flue gas cooler, a low-temperature coal economizer and a sealing heater. The flue gas cooler, the low-temperature coal economizer and the sealing heater replace the traditional low-pressure heater to heat the feedwater, and steam exhaust energy losses of the steam turbine are reduced while heat of the boiler is recovered. The arrangement of a unit is optimized as a whole, efficient regeneration is further enhanced, and the complexity of the system is lowered. The coal consumption can be reduced by 2 g / kW.h to3 g / kW.h while the power supply efficiency of a traditional 1,000 MW secondary reheating unit is improved by 0.2% to 0.3%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for prolonging service life of slitting wheel of rolling mill

ActiveCN104532131AImprove wear resistanceHigh hardnessArc welding apparatusMetal rolling arrangementsEconomic benefitsAgricultural engineering

The invention discloses a method for prolonging the service life of a slitting wheel of a rolling mill. The method is characterized in that microalloying is carried out on the basis of the original Cr12MoV material of the slitting wheel for improving the abrasive resistance and the high-temperature strength of the slitting wheel, a metal element-tungsten is added to enable the average hardness of the slitting wheel to reach HRC60-63, the abrasive resistance is greatly improved and the service life of the slitting wheel is prolonged; the external profile dimension of the slitting wheel is increased by 15mm on the basis of the traditional slitting wheel, the diameter of the beveled edge of the slitting wheel is reduced by 1.5-2mm after the slitting wheel is abraded, and the service life of the slitting wheel is further prolonged; and when the slitting wheel is abraded severely, a D322 lime-titania type electrode is adopted to be overlaid on the slitting wheel, and the service life of the slitting wheel can be prolonged again. According to the method, the abrasive resistance of the slitting wheel can be effectively enhanced, the service life of the slitting wheel can be prolonged greatly and remarkable economic benefit can be created for enterprises.

Owner:安徽东方新材料有限公司

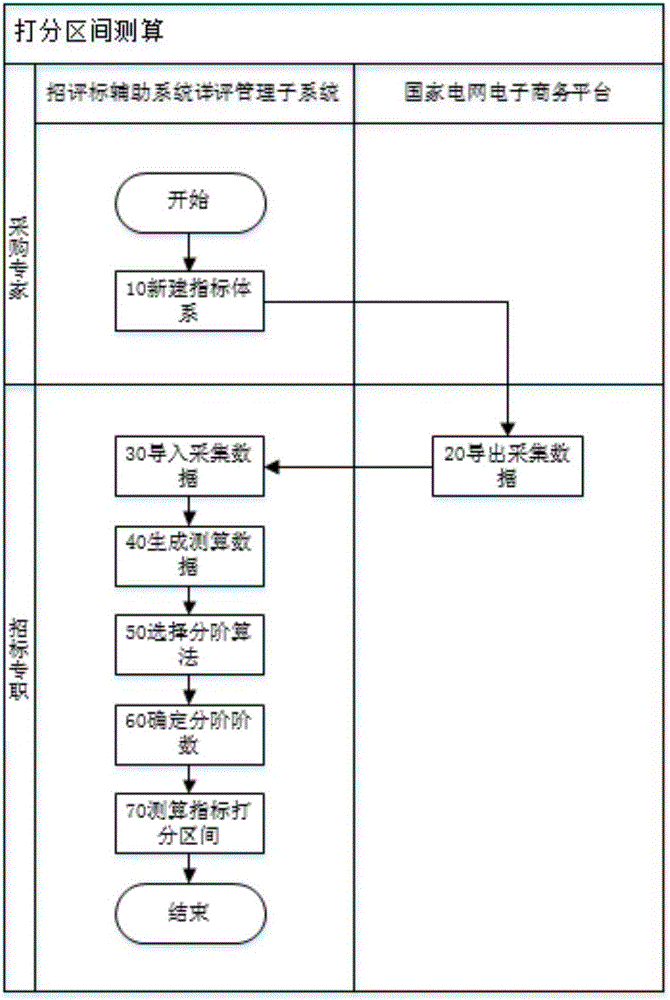

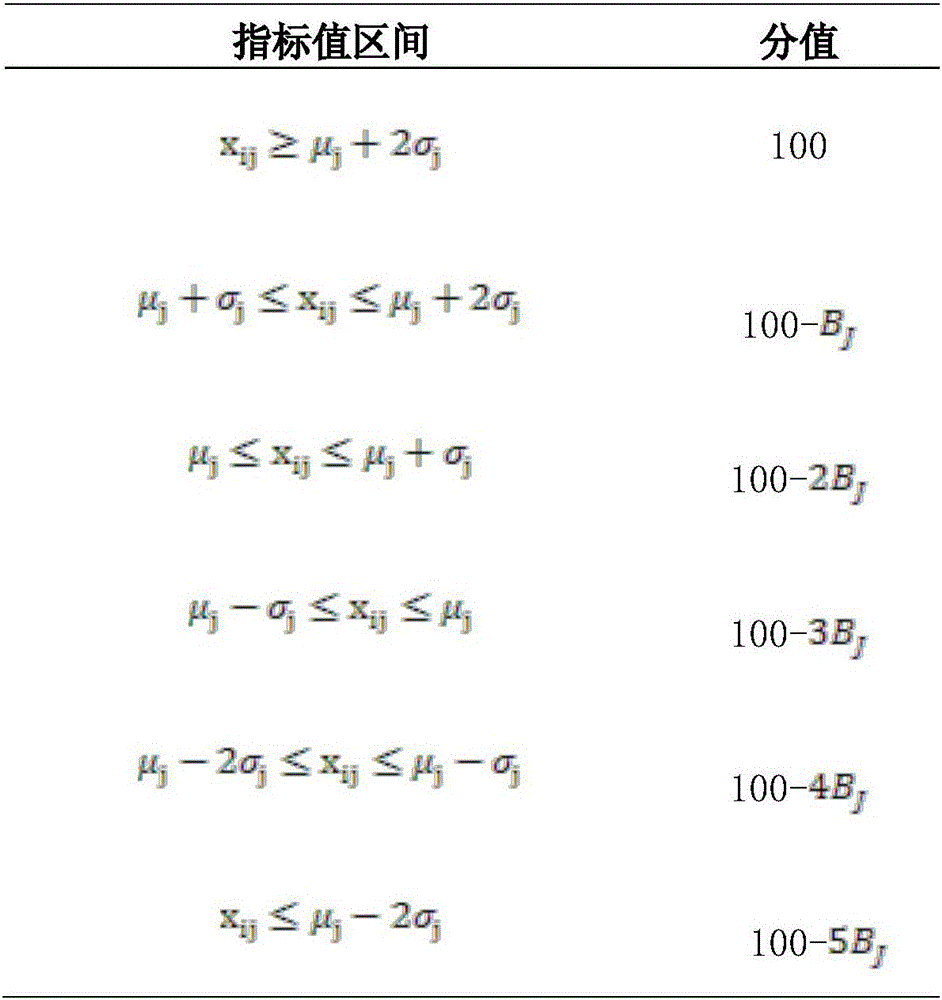

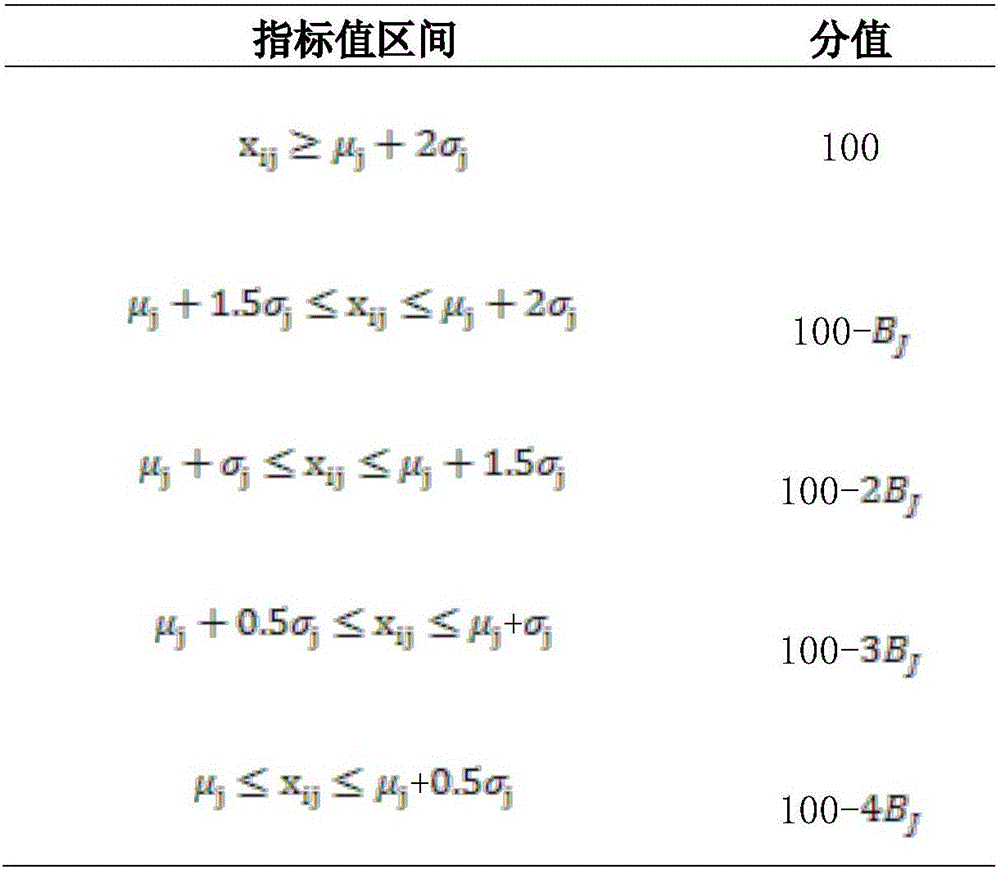

Automatic calculation method for detailed evaluation of scoring ranges in bidding and evaluation process

InactiveCN106779428AFull use of valueReduce manual workloadOffice automationResourcesStatistical analysisWorkload

The invention discloses an automatic calculation method for detailed evaluation of scoring ranges in the bidding and evaluation process, and relates to a working method which applies a calculation method for index scoring ranges of bidding and evaluation scoring rubrics to an automatic calculation aid system for detailed evaluation of scoring ranges in bidding and evaluation based on statistical analysis of massive supplier qualification data. The automatic calculation system for the scoring ranges assists in generating scoring rubrics of bidding and evaluation, the mathematical and statistical analysis method of normal distribution stage algorithm is introduced, supplier qualification verification data are subjected to score range calculation, automatic generation of scoring ranges for scoring items is realized through a detailed evaluation management subsystem-a pre-bid management module of the bidding and evaluation aid system, data value is fully utilized, manual workload is reduced, and scientificity and objectivity of scoring range setting of scoring items are improved.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

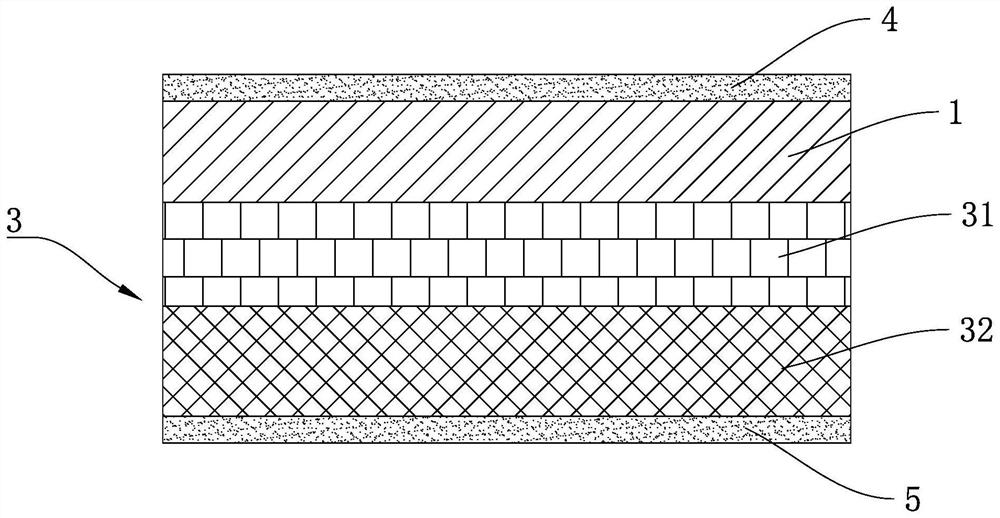

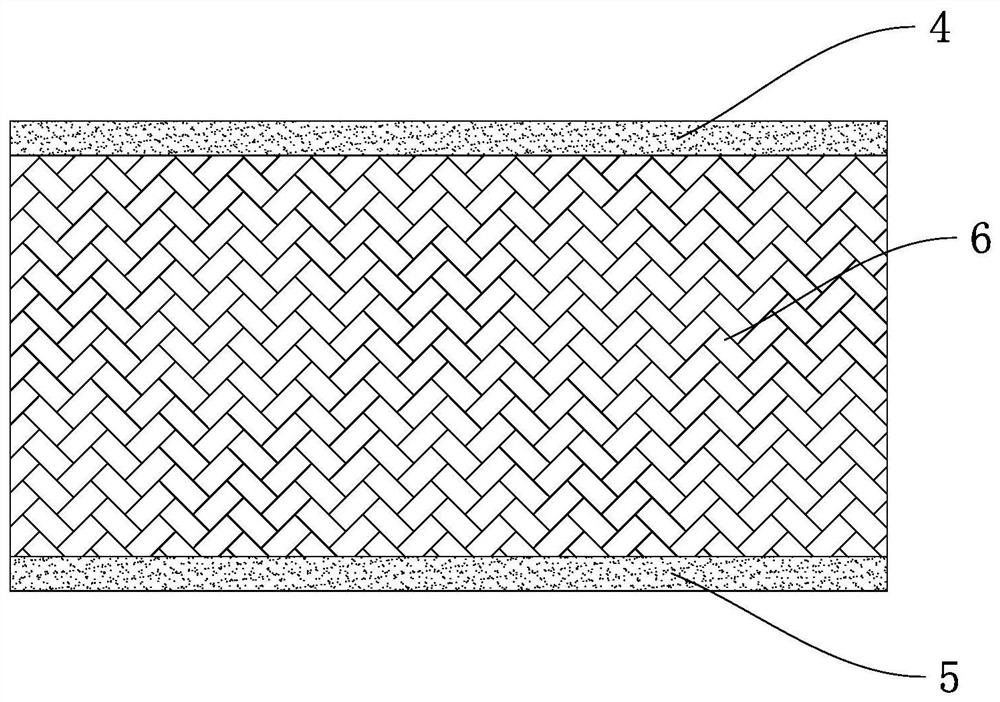

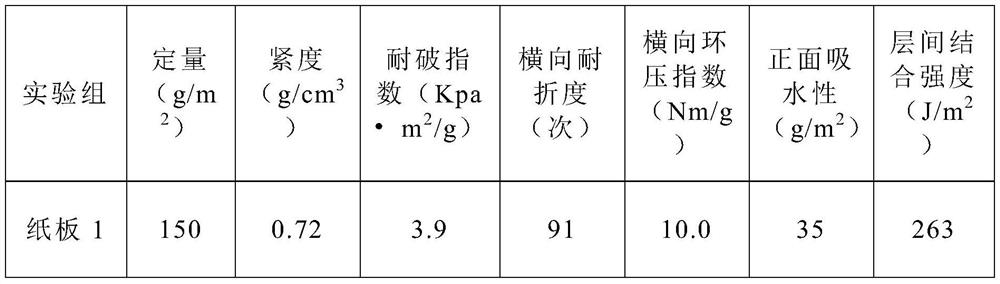

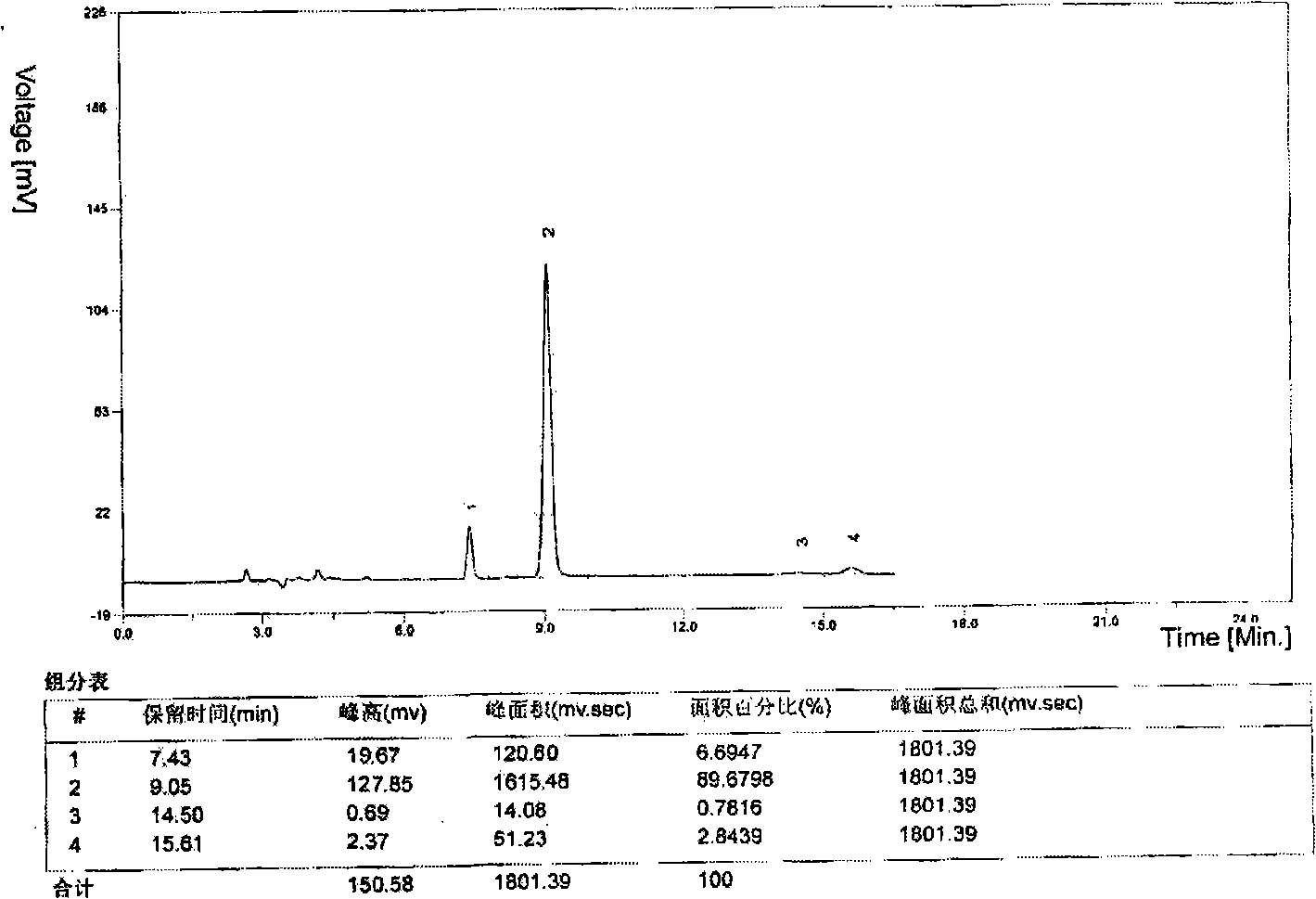

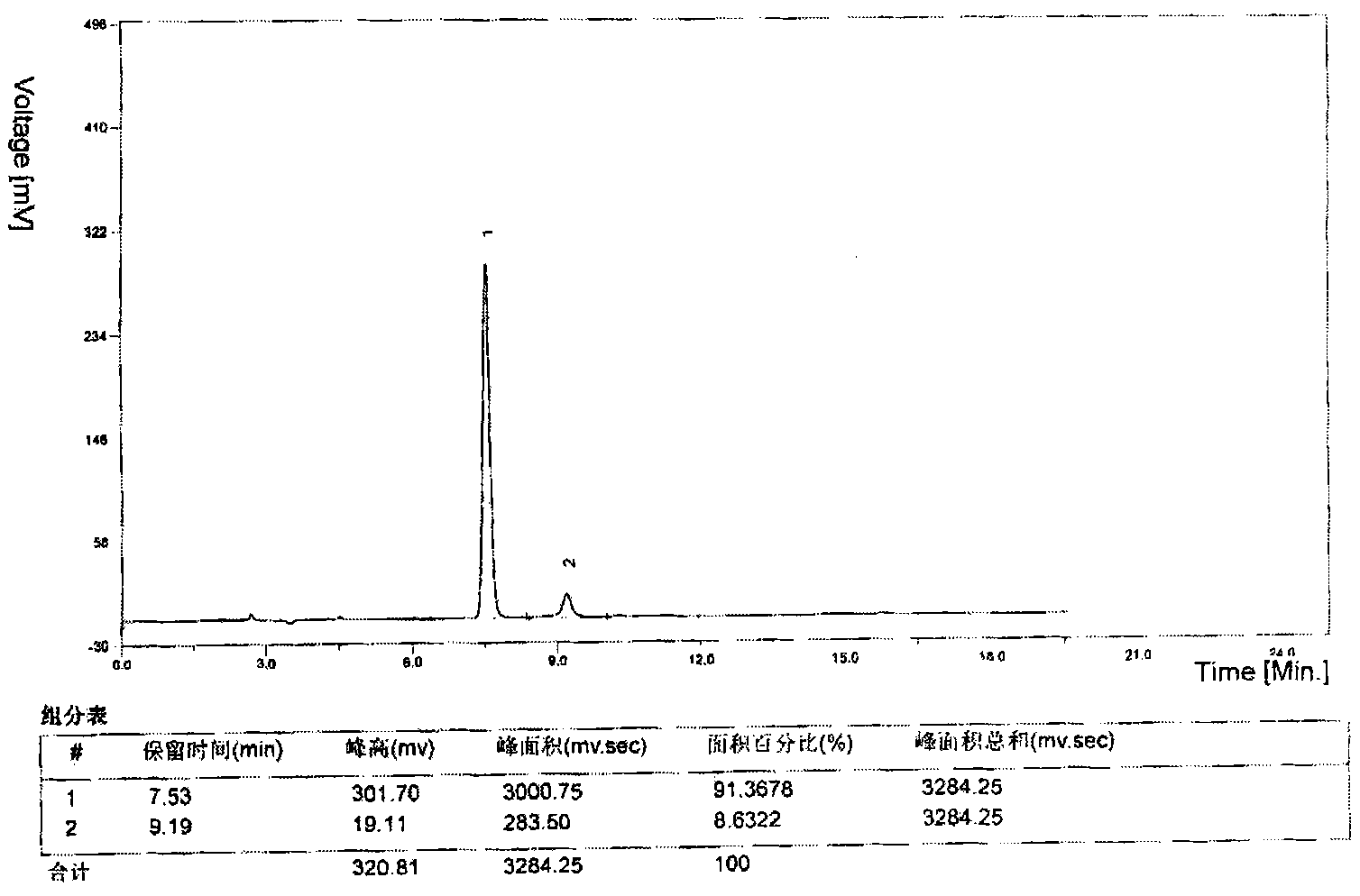

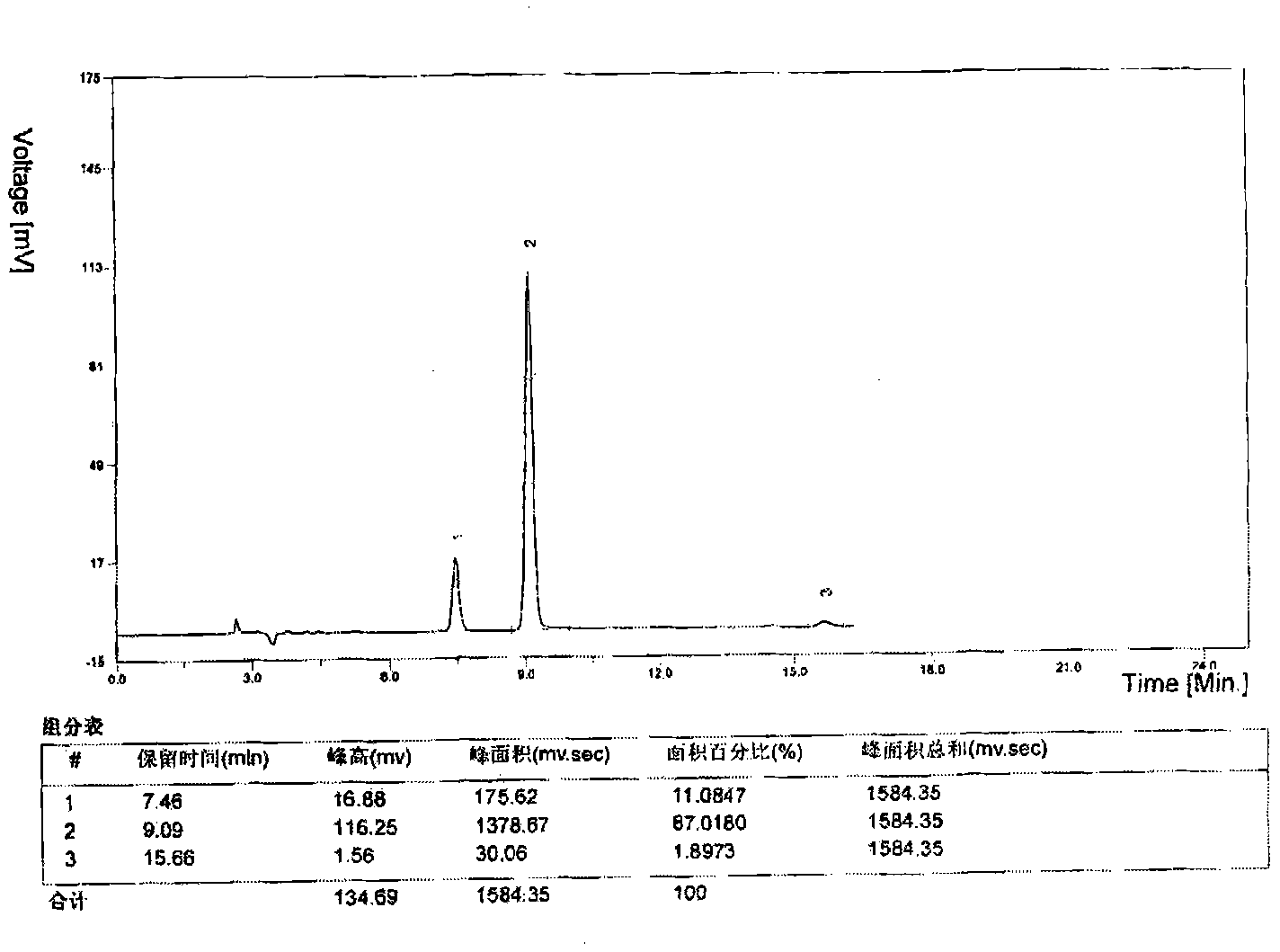

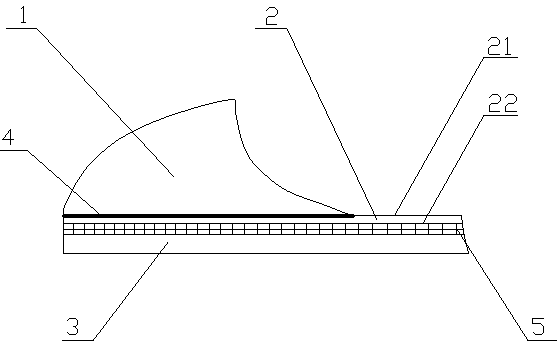

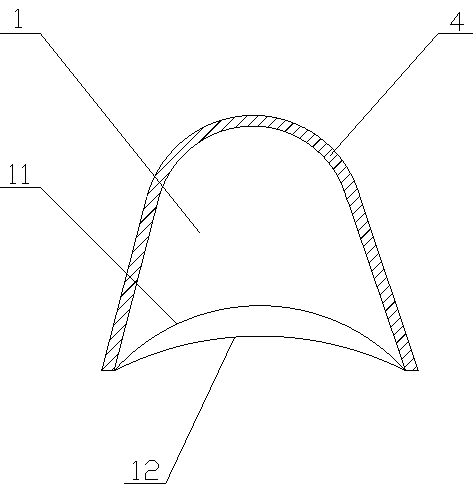

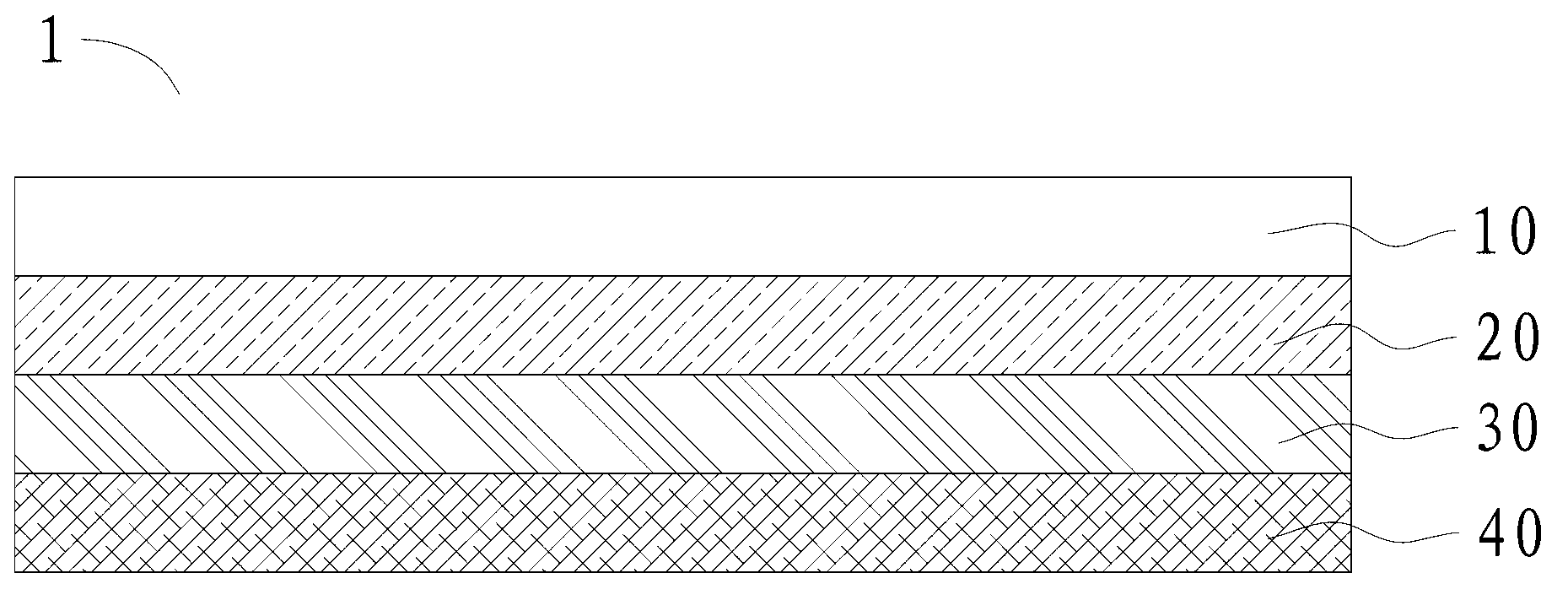

High-breakage-resistance multi-layer kraft board paper and preparation method thereof

PendingCN113073498AFull use of valueSimple structureWrappersWater-repelling agents additionFiberPaperboard

The invention belongs to the technical field of papermaking, and particularly relates to high-breakage-resistance multi-layer kraft board paper and a preparation method thereof. The invention provides high-breakage-resistance multi-layer kraft board paper and the preparation method thereof, and aims to solve the problems that in the prior art, a waste paper pulping preparation mode is mostly directly adopted when kraft paperboards are prepared, distinguishing is not carried out, the value of waste paper fibers cannot be utilized to the maximum extent, and the production cost is increased. The high-breakage-resistance multi-layer kraft board paper comprises a surface layer and a bottom layer, the surface layer is coated with a front surface sizing layer, the bottom layer is coated with a back surface sizing layer, and the total thickness of the surface layer and the bottom layer is more than five times of the total thickness of the front surface sizing layer and the back surface sizing layer. Wood pulp, long fibers, medium fibers and short fibers are respectively used as main components to form the surface layer and the bottom layer of the paperboard, so that the value of waste paper fibers is fully utilized, the fiber structure is optimized, the bursting index of kraft board paper products is improved, and the production cost is reduced.

Owner:JIAN GRP

Method for simultaneously preparing albiflorin and paeoniflorin

InactiveCN102372750AFull use of valueHigh puritySugar derivativesHydroxy compound active ingredientsPurification methodsEconomic benefits

The present invention discloses a purification method for simultaneously preparing albiflorin and paeoniflorin. The method comprises: adopting a paeonia lactiflora medicinal material or a paeonia lactiflora extract as a raw material; adopting a column chromatography method to purify the paeoniflorin and the albiflorin. According to the present invention, the method of the present invention has characteristics of simple purification process, easy operation, high purification efficiency and short purification time; the high purity albiflorin and the high purity paeoniflorin can be prepared in the same process with low cost and low energy consumption, such that the purpose of environmental protection is achieved, economic benefits are improved.

Owner:张作光

Double-sided decorative ceramic plate and preparation method thereof

InactiveCN111152334AExpand the scope of useIncrease added valueOrnamental structuresSpecial ornamental structuresSpray driedTextile printer

The invention relates to a double-sided decorative ceramic plate and a preparation method thereof. The double-sided decorative ceramic plate is composed of a full-polishing glaze layer, a printing decorative layer, a ground glaze layer, a green body layer, the ground glaze layer, the printing decorative layer and a dry granular layer from bottom to top to form a composite layer structure. The preparation method comprises the steps of compacting into a green body, drying, spraying ground glaze, carrying out printing decoration, spraying full-polishing glaze, firing, spraying engobe at the backof a burnt brick, carrying out back printing decoration, spraying dry granules at the back, firing, carrying out double-sided polishing and packaging. According to the alternative scheme, by the technology that the ceramic plate is erected for glaze spraying and printing decoration and the ceramic plate is erected for firing, the double-sided decorative ceramic plate is fired and prepared once.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

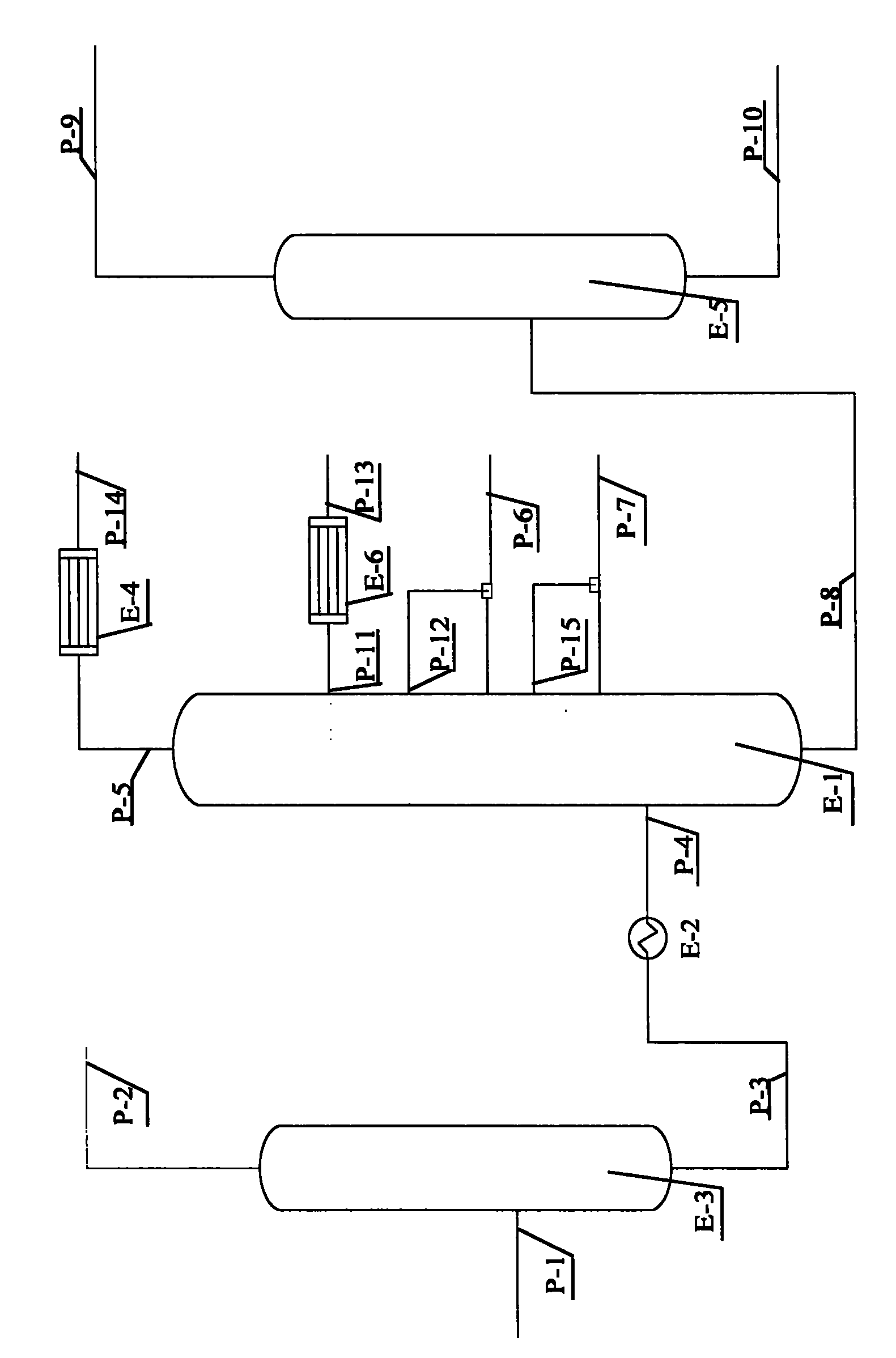

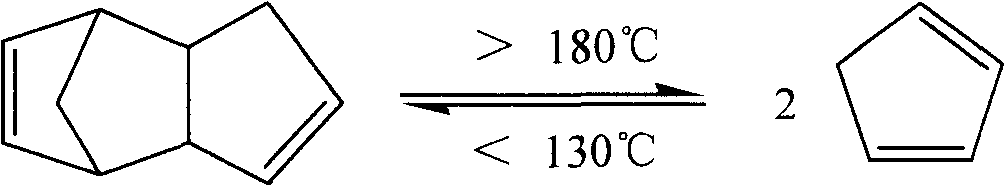

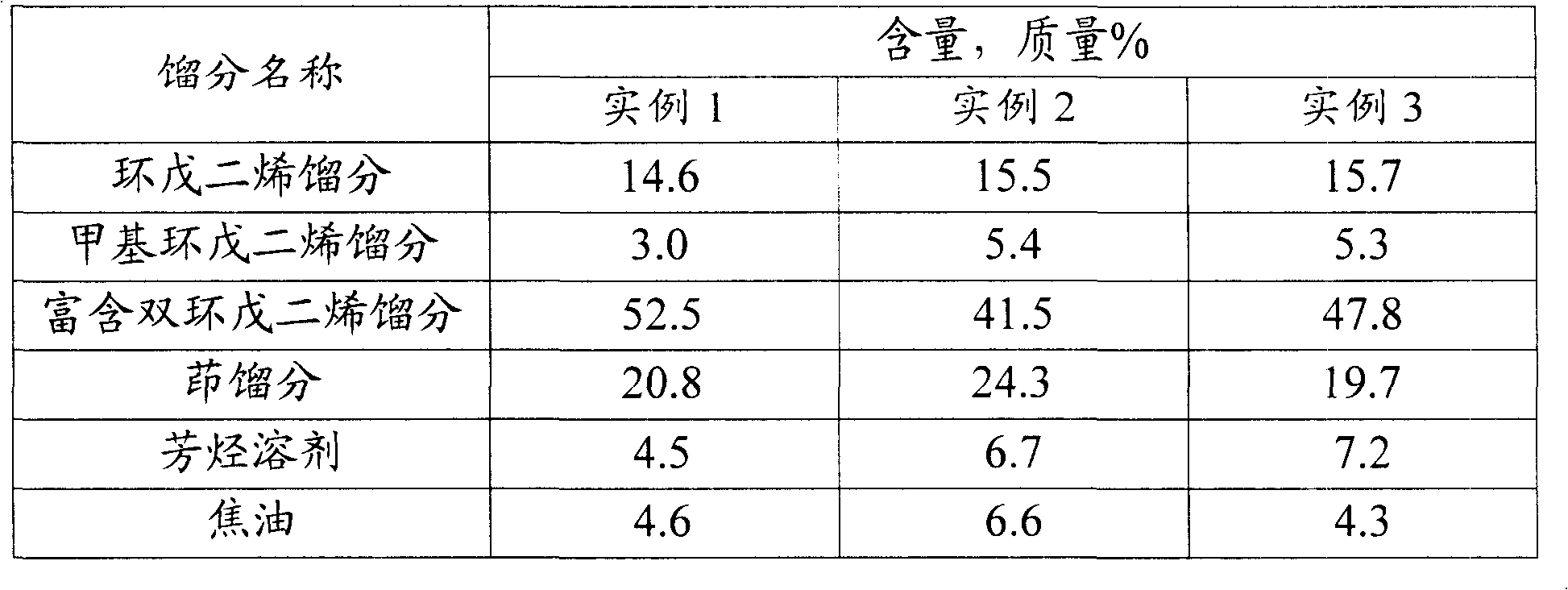

Separation utilization method for preparing ethene by-product C9+ fractioning by cracking

ActiveCN101190868BIncrease added valueFull use of valueDistillation purification/separationBenzenePetroleum resin

The invention relates to a method of separating and utilizing ethylene by product C9<+> distillate produced by cracking, and consists of the procedures: the C9<+> distillate is separated into ethylene distillate with rich benzene and distillate at the bottom of a rectifying tower by rectifying under reduced pressure; the distillate at the bottom of the rectifying tower is heated to 180 - 380DEG Cand rectified under normal pressure; cyclopentadiene distillate, methyl cyclopentadiene distillate, distillate with rich dicyclopentadiene, distillate with high content of indene and heavy end distillate are separated from the top of the rectifying tower to the bottom of the rectifying tower in turn. With the method, not only high quality petroleum resin is available, but cyclopentadiene and methyl cyclopentadiene can also be obtained at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

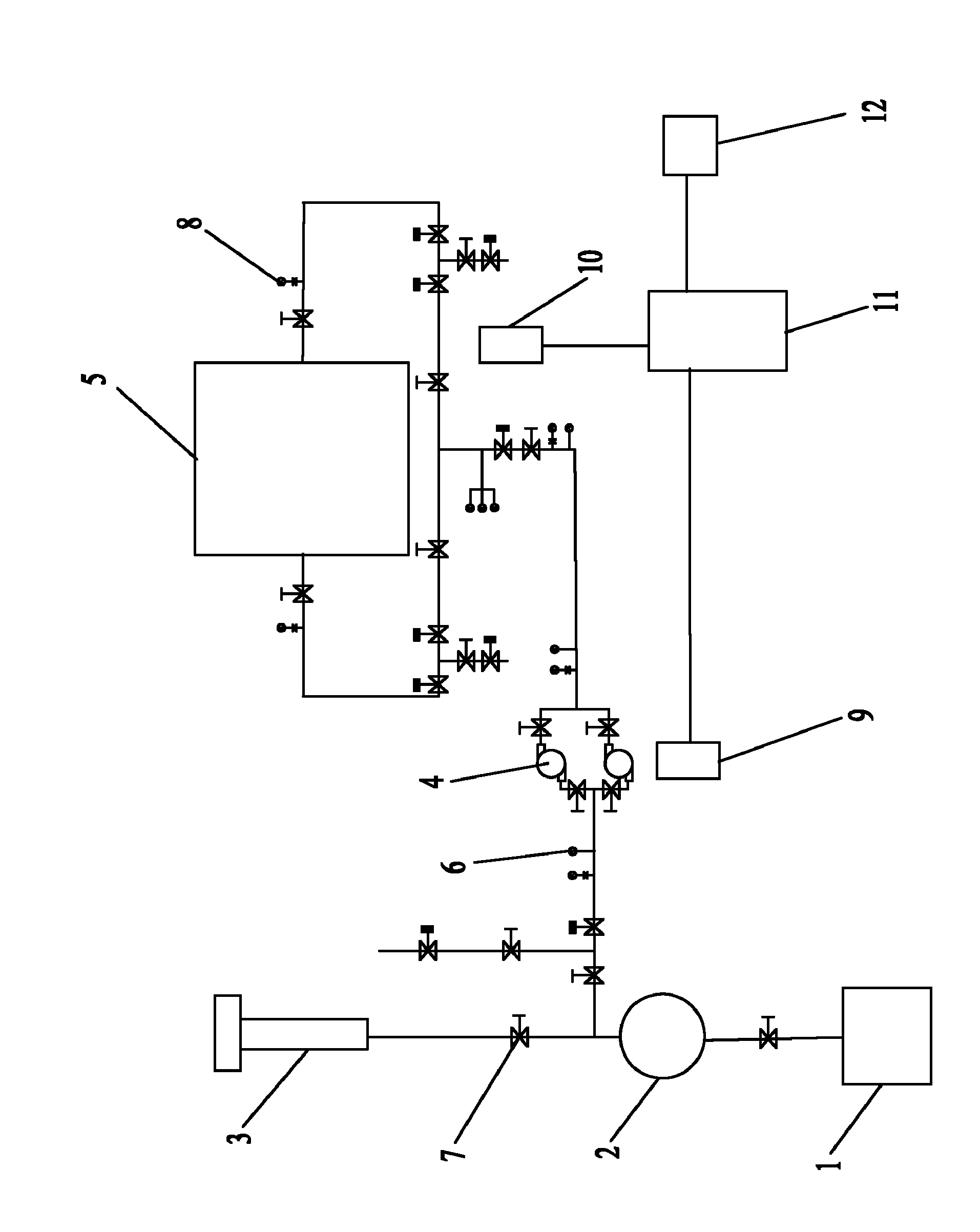

System for recycling biogas

InactiveCN102153193AImprove securitySave coal consumptionWaste based fuelTreatment with anaerobic digestion processesSulfur dioxideCoal

The invention relates to the technical field of biogas recovery, in particular to a system for recycling biogas. The system for recycling the biogas comprises a sewage station anaerobic treatment system, a biogas storage tank, a torch, a roots blower and a boiler, wherein an outlet of the sewage station anaerobic treatment system is communicated to an inlet of the biogas storage tank through a pipeline; an outlet of the biogas storage tank is communicated to an inlet of the torch through a pipeline; the outlet of the biogas storage tank is communicated to an inlet of the roots blower through a pipeline; and an outlet of the roots blower is communicated to the boiler through a pipeline. In the invention, biogas generated by the sewage station anaerobic treatment system is pressurized by the roots blower and then is inducted into the boiler to be burnt, so that not only can the explosion phenomenon caused by the biogas discharged into air be avoided and the safety of biogas utilization be improved, but also the value that the biogas is used as energy is sufficiently utilized and the coal using amount of the boiler is reduced. Moreover, sulfur dioxide generated when the biogas is burnt can be desulfurized through a desulfurization system of the boiler, so as to fulfill the aim of reducing emission.

Owner:LEE & MAN PAPER MFG

Sodium sulfate and ammonium sulfate salt mixture separation method and vanadium precipitation waste treatment method

InactiveCN109110783AHigh recovery purityHigh yieldAmmonium sulfatesAlkali metal sulfites/sulfatesState of artWaste treatment

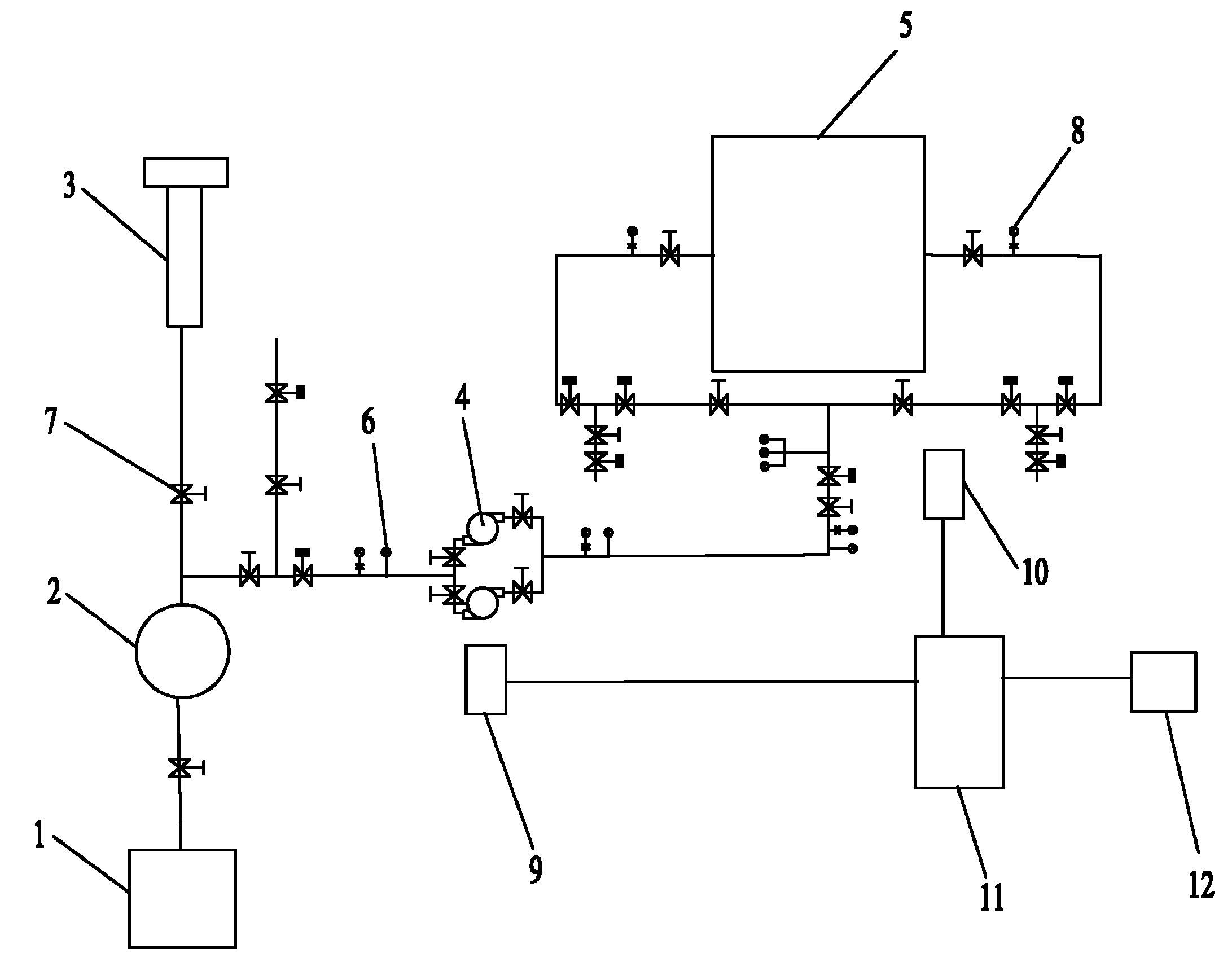

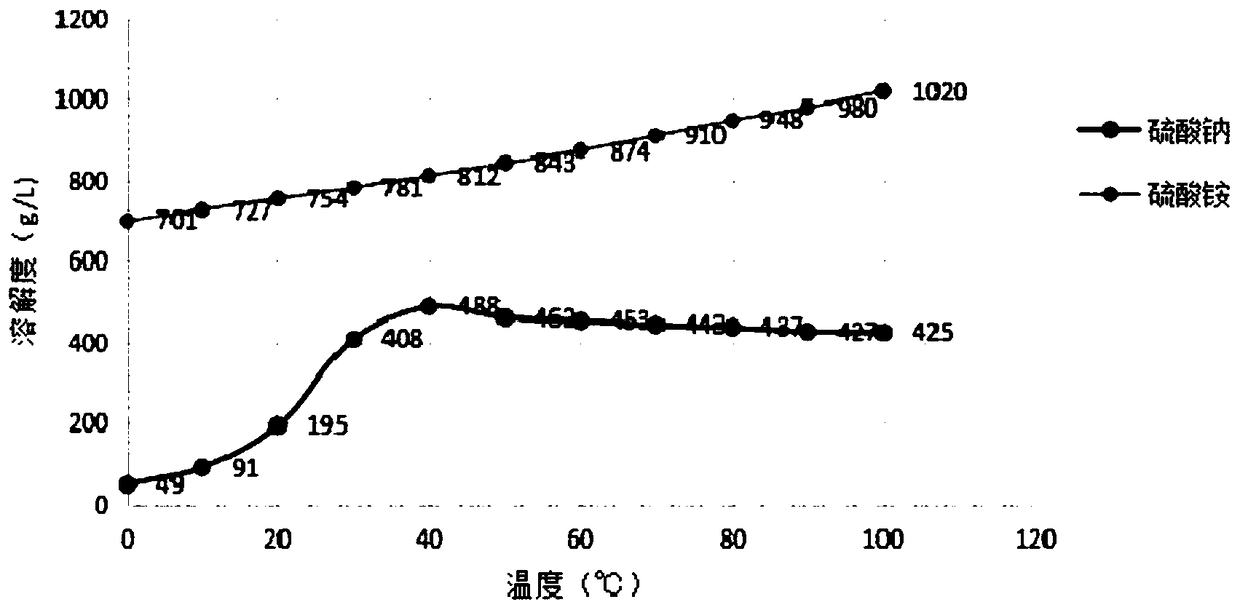

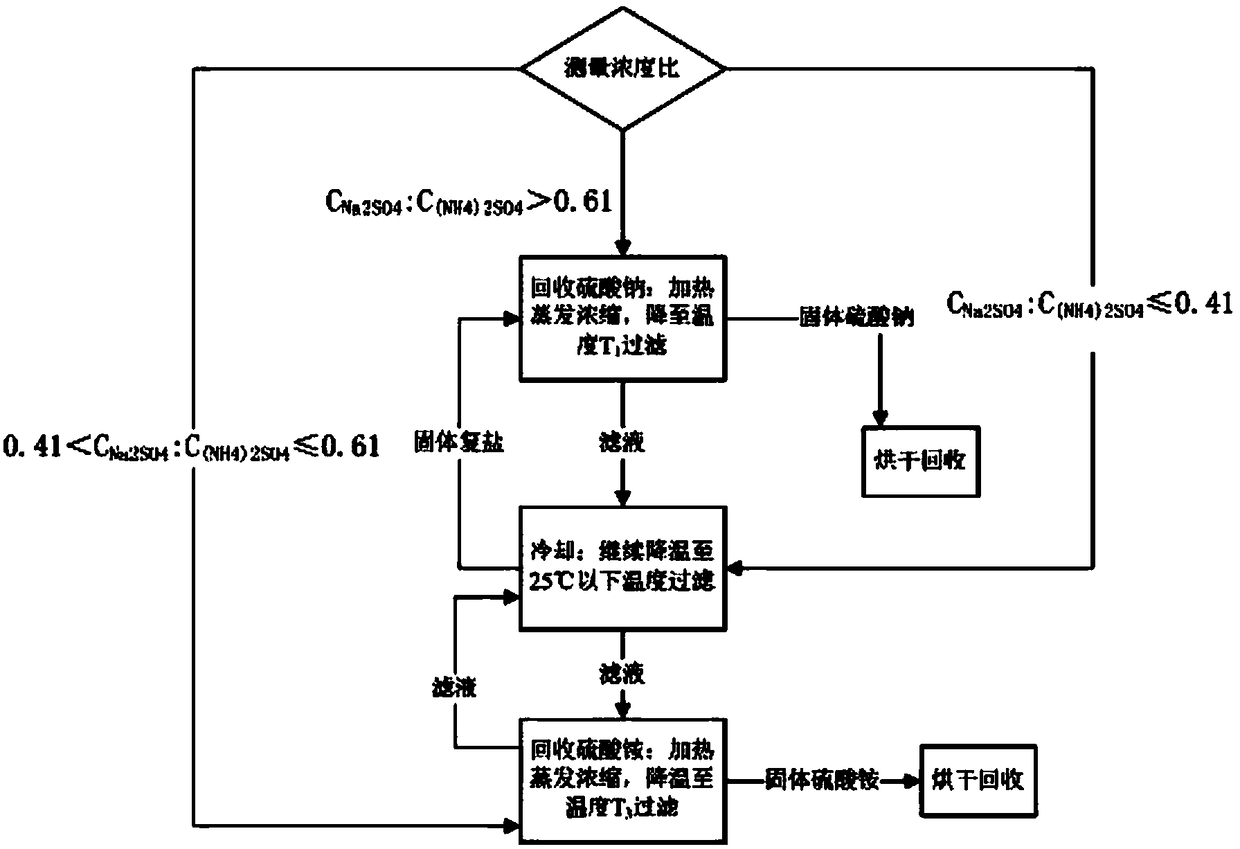

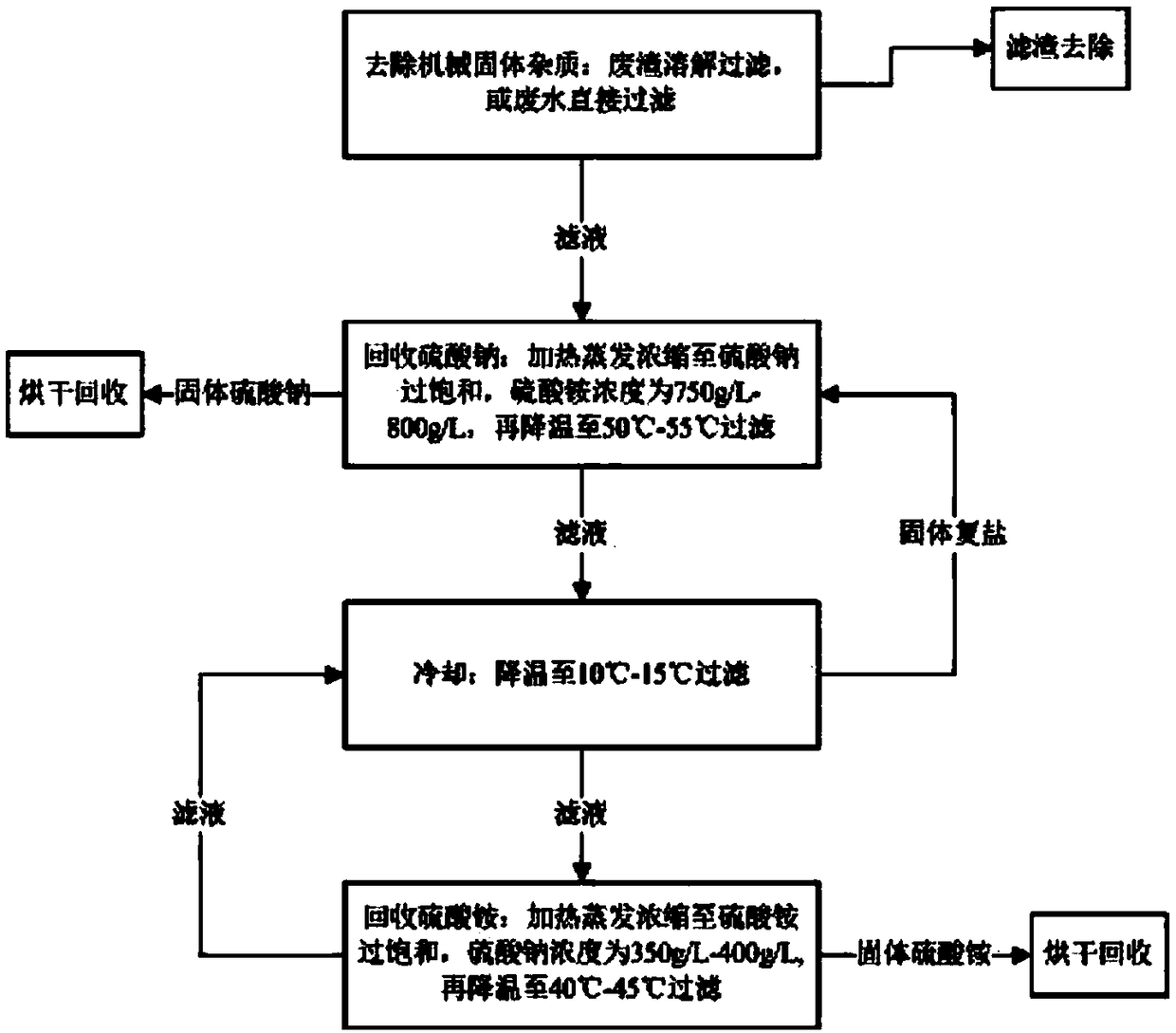

The invention belongs to the technical field of a chemical process and discloses a treatment method for vanadium precipitation wastes. The treatment method comprises: S1: removing mechanical impurities; S2: recovering sodium sulfate; S3: cooling to separate out complex salt; S4: recovering ammonium sulfate, wherein the complex salt obtained by cooling in the step S3 can be reused for the step S2 to carry out recovery of sodium sulfate, and filtrate obtained in the step S4 can be used for the step S2 to carry out recovery of sodium sulfate after being subjected to processing in the step S3 of cooling to separate out the complex salt, so as to form a closed cycle. Compared to the prior art, yield and quality of sodium sulfate and ammonium sulfate are improved, waste discharge is reduced, andthe method has great economic significance and environment-friendly significance.

Owner:李月波 +1

Method for preparing watermelon fruit vinegar

The invention discloses a method for preparing watermelon fruit vinegar. The method comprises the following steps: selecting mature watermelon and taking the red pulp part of the watermelon; separating the seeds from the pulp part, and then mincing the pulp part without seeds and sieving by using 20-mesh sieve; boiling by a pot and keeping boiling state for 1 to 3 minutes; cooling to room temperature and mixing the pulp part with glacial acetic acid, wherein the weight ratio of the pulp part to glacial acetic acid is 1:0.050 to 0.055; and then salting for 20 to 22 days; occasionally stirring the mixture during salting process; after salting, adding water which is 3 to 6 times more than the weight of the mixture; filtering by using a 100-mesh sieve; boiling the filtered liquid in the pot; then, cooling under an airtight condition; after cooling, adding 0.1wt% of benzoic acid to prepare the finished product of watermelon fruit vinegar. Compared with the prior art, the method provided by the invention has advantages of improving the value of the watermelon and fully utilizing the value of the watermelon when the yield of watermelon is high.

Owner:甘肃盐婆婆醋业有限责任公司

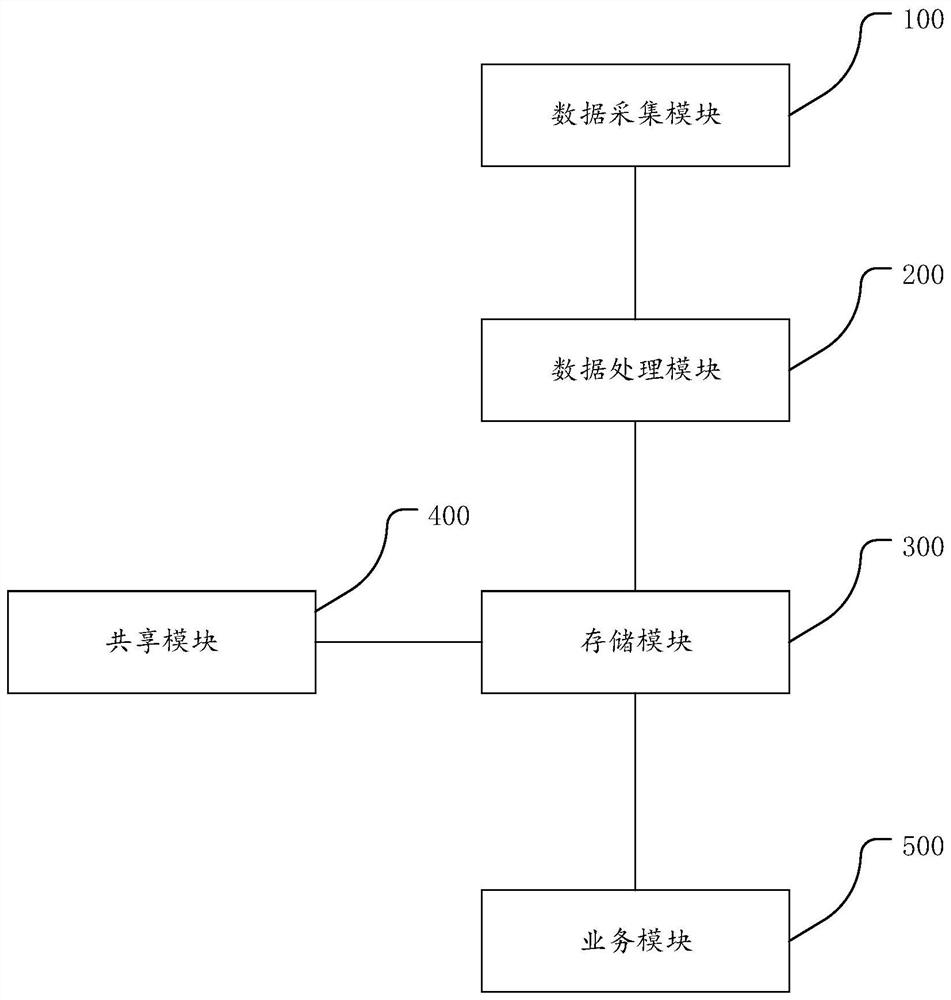

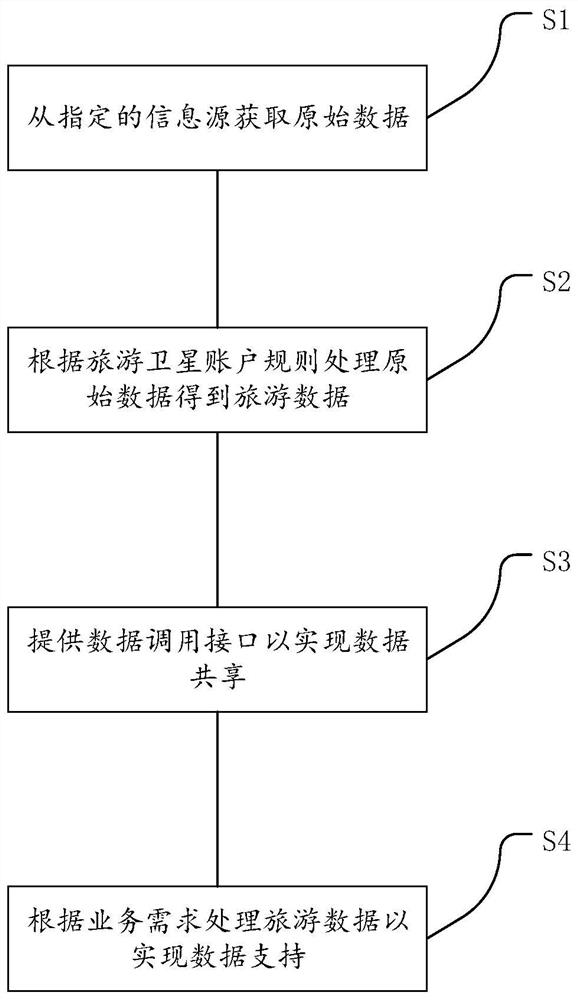

Travel data management system and method

InactiveCN111737217AGuaranteed immediacyFull use of valueData processing applicationsDatabase management systemsOriginal dataEngineering

The invention relates to a tourism data management system and method. The system comprises a data collection module which is used for obtaining original data from a specified information source; the data processing module is used for processing the original data according to tourism satellite account rules to obtain tourism data; the storage module is used for storing tourism data; the sharing module is used for providing a data calling interface to realize data sharing; the service module is used for processing the tourism data according to service requirements so as to realize data support;the data collection module is connected with the data processing module which is connected with the storage module, the storage module is connected with the service module, and the sharing module is connected with the storage module. Method suitable for system. According to the embodiment of the invention, the original data can be processed according to the tourism satellite account rule to obtainthe tourism data related to the tourism industry; the instantaneity of the data can be ensured through data sharing; for service requirements, corresponding travel data is provided to support service, and the value of the data can be fully utilized.

Owner:深圳市维度数据科技股份有限公司

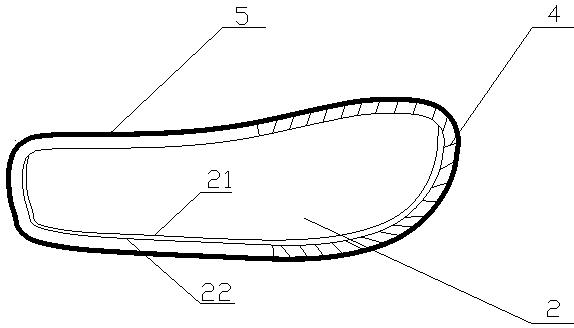

Dual-purpose slipper

The invention discloses a dual-purpose slipper which comprises an upper, a bottom lining and a sole. The obverse and reverse sides of the upper are provided with a warm shoe side and a sandal side. The bottom lining is composed of a warm layer and a cool layer fixedly connected to each other. Both the edge of the upper and the edge of the bottom lining are provided with raised covered edges. The upper is movably connected with the bottom lining through hook-loop fastener strips at the covered edges. The bottom lining is movably connected with the sole through a zipper arranged at the edges. The dual-purpose slipper is available for warm and cold seasons. When the warm shoe side and the warm layer of the slipper are connected, the dual-purpose slipper warms a foot and is soft to wear. When the sandal side of the slipper is connected with the cool layer, the slipper keeps the foot cool and is comfortable to wear. The value of the slipper is fully utilized. In addition, both the upper and the bottom lining of the slipper are detachable, so that the dual-purpose slipper is convenient to wash and air.

Owner:NANTONG XIYUN TRADE

Sticker for refrigerator and refrigerator with same

InactiveCN103017460ABeautiful appearanceHarmonious and unified appearanceDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses a sticker for a refrigerator and the refrigerator with the same. The sticker comprises a transparent base layer, a pattern layer arranged on the transparent base layer and provided with a predetermined pattern, and an adhesive layer arranged on the pattern layer. By utilizing the sticker, the appearance of the refrigerator is more attractive and the quality of the refrigerator can be improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Method of preparing wine by watermelon

InactiveCN103923805AIncrease the value of watermelonIncrease valueAlcoholic beverage preparationChemistryFiber

The invention relates to a method of preparing wine by a watermelon. The method is characterized by comprising the following steps: taking a mature watermelon; taking out red balloons in the watermelon; separating juice from the balloons by way of physical dehydration; filtering kernels in the juice; filtering fibrous matters in the juice; adding edible ethanol with the content of ethanol of 95% into the juice without kernels and fibrous matters within 8 hours without the balloons, wherein the weigh ratio of the juice and 95% edible ethanol is 1:(1.2-1.5); and then, in a closed space and at 24-40 DE C, continuously introducing clean air or oxygen into the juice / edible ethanol mixed liquid in 8-15 days to obtain the watermelon wine. Compared with the prior art, the method provided by the invention has the advantages of enhancing the value of the watermelon and fully using the value of the watermelon when the watermelon is rich in production.

Owner:叶贤忠

Production technology of russula vinosa lindblad powder

ActiveCN107411052ARich choiceSmall temperature differenceFood thermal treatmentFood preservationEngineeringFood material

The invention relates to a production technology of russula vinosa lindblad powder, and belongs to the field of production and processing of mushrooms. The production technology comprises five steps of performing cleaning, performing heating drying, lowering the temperature, performing ultrafine crushing, and performing sterilization and bagging, wherein the heating drying process is performed through control of procedures; and the ultrafine crushing is performed in the manner that the dried russula vinosa lindblad is transferred to an airflow type ultrafine crusher, airflows are used for crushing the russula vinosa lindblad, the air pressure is 0.2-0.4Mpa, and the ratio of air to solid is (2 to 1) to (3 to 1), so that the particle size of the obtained russula vinosa lindblad powder achieves 80[mu]m or below. Nutrient elements of the russula vinosa lindblad are reserved to the maximum extent, and the prepared russula vinosa lindblad powder can be rapidly prepared into various beverages and can also be added to various food materials, so that the nutrients of foods are increased. The russula vinosa lindblad powder has the efficacy of nourishing yin, invigorating the kidney, invigorating the brain and keeping young. The russula vinosa lindblad powder made by the method is long in storage time, convenient to transport and convenient to sell, and the business value of the russula vinosa lindblad is increased.

Owner:浦北县龙腾食品有限公司

Preparation method of regenerated buckwheat tea

The invention relates to the technical field of food, and particularly relates to a preparation method of regenerated buckwheat tea. The method comprises the following steps: cleaning dried buckwheat; putting the cleaned buckwheat into a steeping tank by virtue of an elevator and soaking the buckwheat for 5.5-6.5 hours; putting the soaked buckwheat into a steamer by virtue of the elevator, and steaming the buckwheat with steam for 40-50 minutes; drying the steamed buckwheat until the moisture content of the buckwheat is 15%-25%; husking the dried buckwheat in a machine by a roller husking method, separating buckwheat seeds from buckwheat shells, and separating dust from the buckwheat by a vibrating screen on the husking machine, thereby finishing purifying and dedusting of the buckwheat; classifying the separated buckwheat seeds, and preparing powder in various forms by virtue of a grading pulverizer; separating the powder at various grades, kneading dough from the powder, and pelletizing and frying the various powder; and screening fried tea grains, and removing excessive powder by sieving. The buckwheat tea prepared by the method is high in nutritive value and good in mouthfeel.

Owner:KUNMING HONGTUDI YINGLONG FOOD PROCESSING

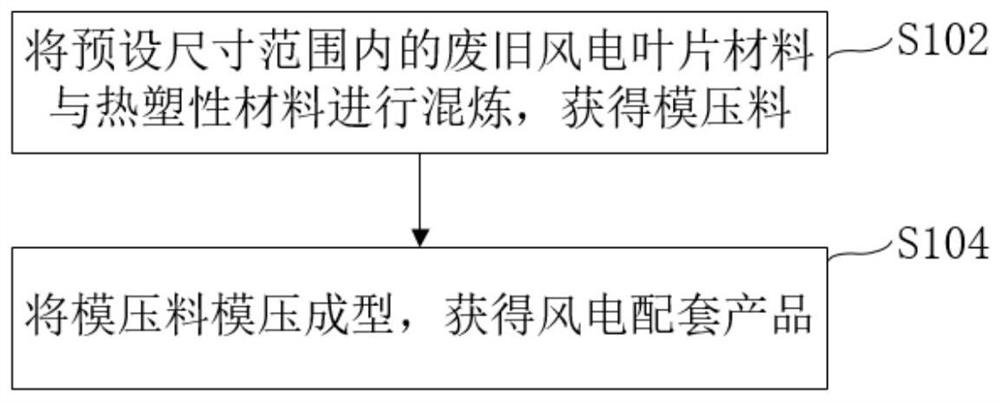

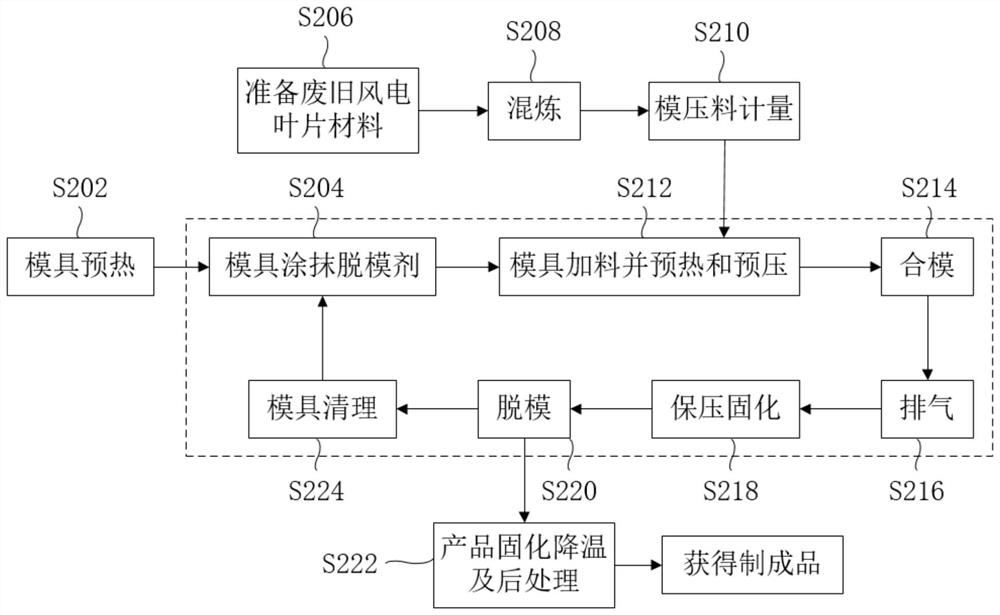

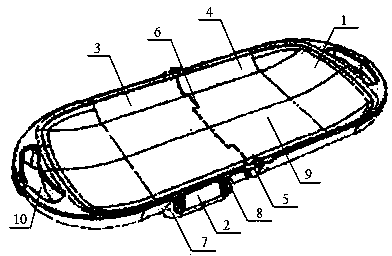

Waste wind power blade recycling method

PendingCN114619613ASolve the problem of ecological environment pollutionFull use of valueCompression moldingManufactured material

The invention provides a waste wind power blade recycling method, and relates to the field of waste wind power blade recycling. The method comprises the following steps: mixing a waste wind power blade material and a thermoplastic material in a preset size range to obtain a molded material; and carrying out compression molding on the molded material to obtain a wind power matching product. According to the method, solid waste can be greatly reduced, so that the problem of ecological environment pollution caused by the waste wind power blade is solved, the waste wind power blade is manufactured into the blade root platform or the manhole cover plate in a compression molding mode, and the service life of the blade root platform or the manhole cover plate is prolonged. The residual mechanical property and value of the waste wind power blade made of the glass fiber composite material can be fully utilized, and recycling and high-value reutilization of the waste wind power blade are achieved. Besides, compared with a traditional blade root platform and manhole cover plate manufacturing method, the blade root platform, the manhole cover plate and other wind power matching products manufactured through the method are mostly made of waste wind power blade materials, and therefore the raw material cost can be reduced.

Owner:GUODIAN UNITED POWER TECH

Folding deformable electronic scale

InactiveCN104132724AAvoid getting outFull use of valueSpecial purpose weighing apparatusLeft halfAdult stage

The invention discloses a folding deformable electronic scale which mainly comprises a scale pan and a data displayer. The folding deformable electronic scale is characterized in that the scale pan is divided by a half folding line into a left half scale pan body and a right half scale pan body, handles are arranged at the two ends of the scale pan, a displayer groove is formed in the edge of the left half scale pan body and used for containing the data displayer, and the data displayer is provided with a start key. The folding deformable electronic scale gives sufficient consideration to the growth speed of infants, can be used from the infant stage to the adult stage, and is convenient to move.

Owner:鲁辰超

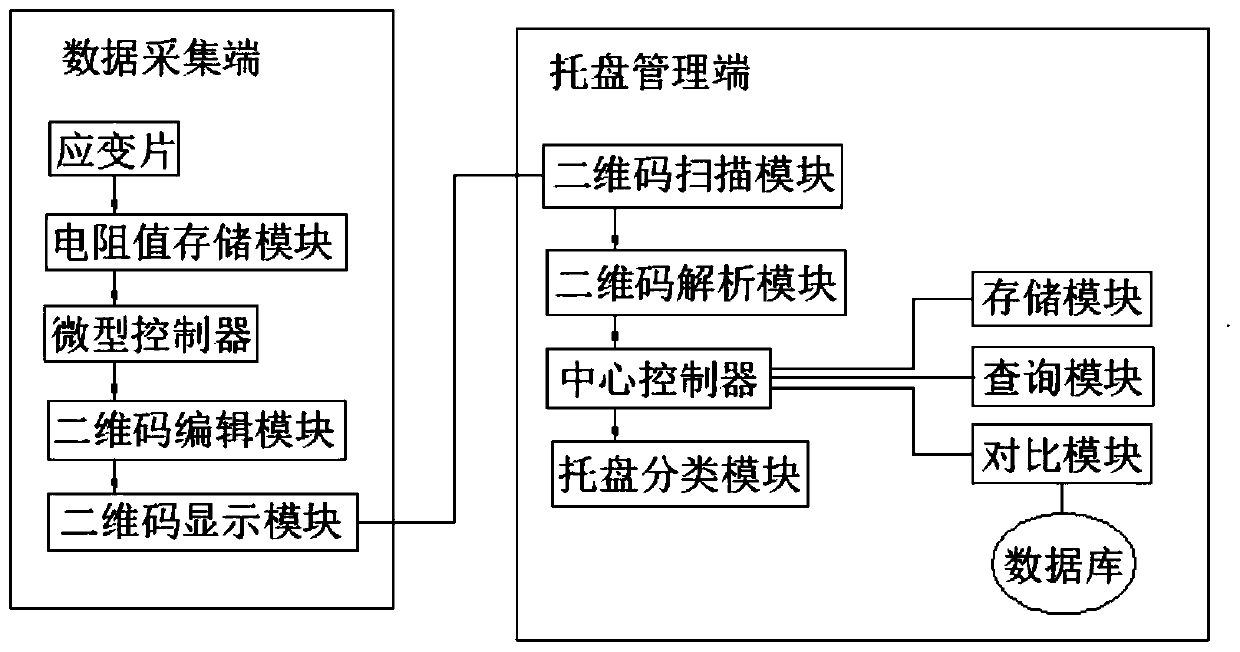

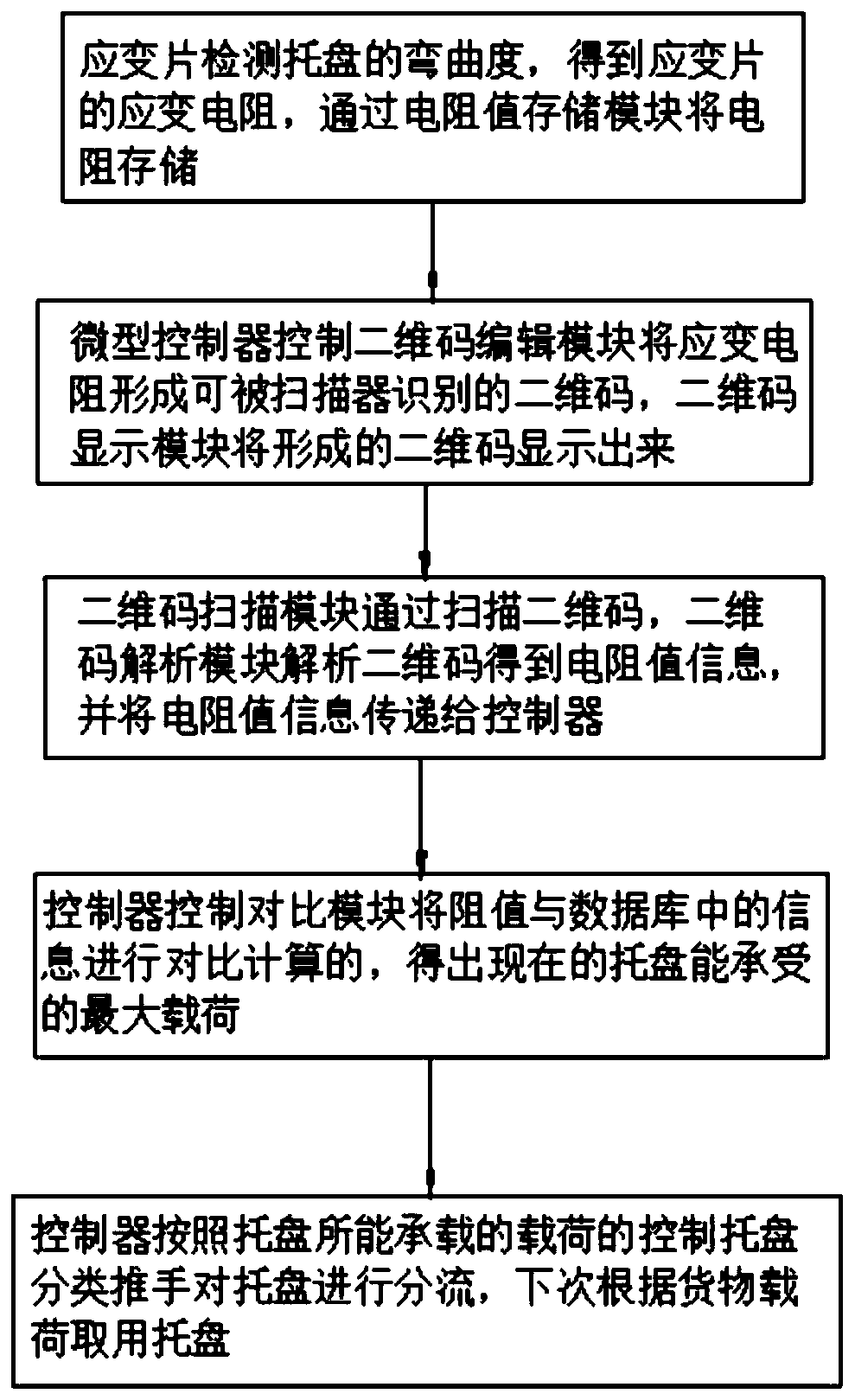

Standardized tray circulation management platform based on NB-LOT technology

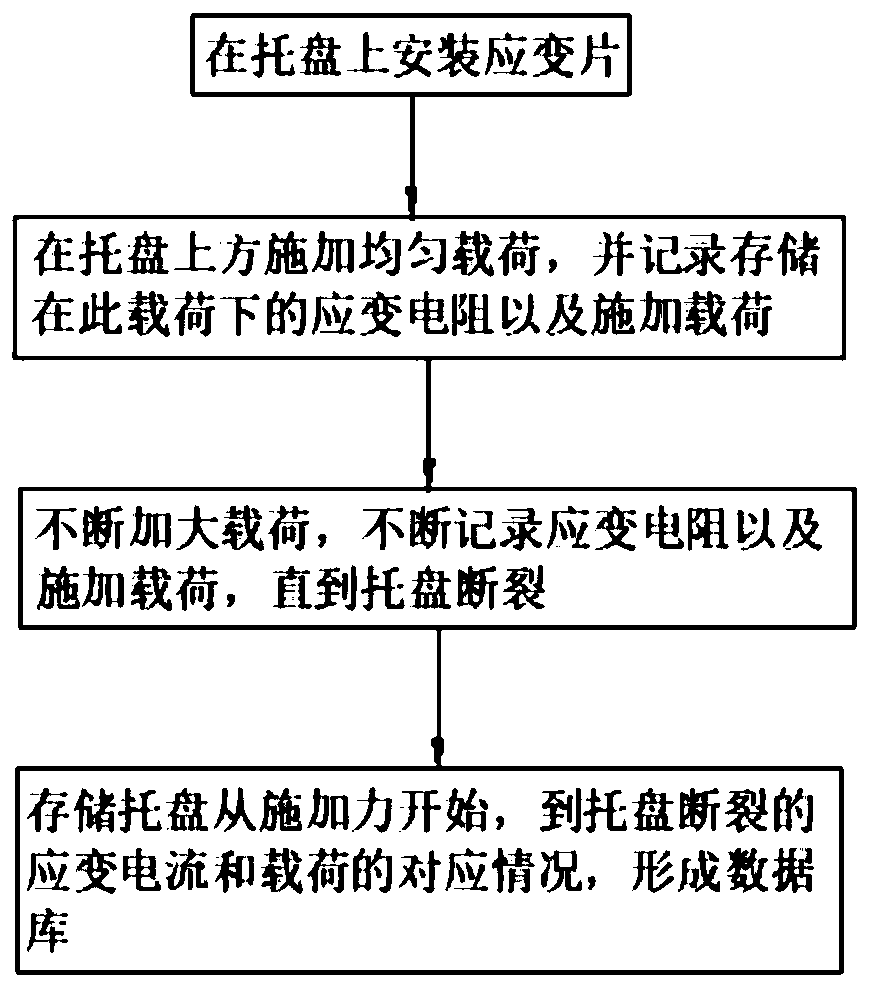

ActiveCN110991576AEasy to useRealize reasonable recyclingCo-operative working arrangementsMechanical conveyorsLogistics managementStrain gauge

The invention discloses a standardized tray circulation management platform based on an NB-LOT technology, and the platform comprises the following steps: enabling a strain gauge to detect the curvature of a tray, and obtaining the strain resistance of the strain gauge; the central controller controls the comparison module to compare and calculate the resistance value with information in a database to obtain the maximum load capable of being borne by the existing tray; the tray classification module is controlled to distribute the trays according to the loads borne by the trays; according to the standardized tray circulation management platform based on the NB-LOT technology, the trays are managed; the residual bearing capacity of the tray is calculated by detecting the strain of multipletrays according to the current situation of the strain gauge tray, so that the tray is ensured to be used within a proper weight, the reasonable recycling of the tray is realized, the effective working capacity of the tray is ensured, the value of the tray is fully utilized, and the logistics cost is reduced.

Owner:江苏佳利达国际物流股份有限公司

Hydrogen production method by steam reforming in combined reactor and device thereof

InactiveCN102730636BShort processReduce operating costsHuman health protectionHydrogenChemical industrySteam reforming

A hydrogen production method by steam reforming in a combined reactor and a device thereof belong to the technical field of a hydrogen production technology by steam reforming of light dydrocarbon. The device provided by the invention comprises a fixed-bed reactor and a half-cycle fluidized bed reactor. The method is realized by the use of the device, and natural gas or dry gas for oil refining or light oil is used as a raw material. The method comprises the following steps: reducing a nickel based catalyst, carrying out a catalytic reforming reaction in the fixed-bed reactor, carrying out a catalytic reforming reaction again as well as a carbon dioxide adsorption reaction in a riser reactor of the fluidized bed, carrying out gas-solid separation to prepare the hydrogen product, and regenerating and utilizing carbon dioxide adsorbent particles. The invention has characteristics of short process flow, simple operation, energy conservation, low production cost, high hydrogen production efficiency, high purity of the hydrogen product, complete utilization of resources, no environmental pollution and the like. The invention can be widely applied in hydrogen production by steam reforming. The hydrogen prepared by the adoption of the method can be extensively applied in the fields of petroleum, chemical industry, metallurgy and the like.

Owner:CHONGQING UNIV

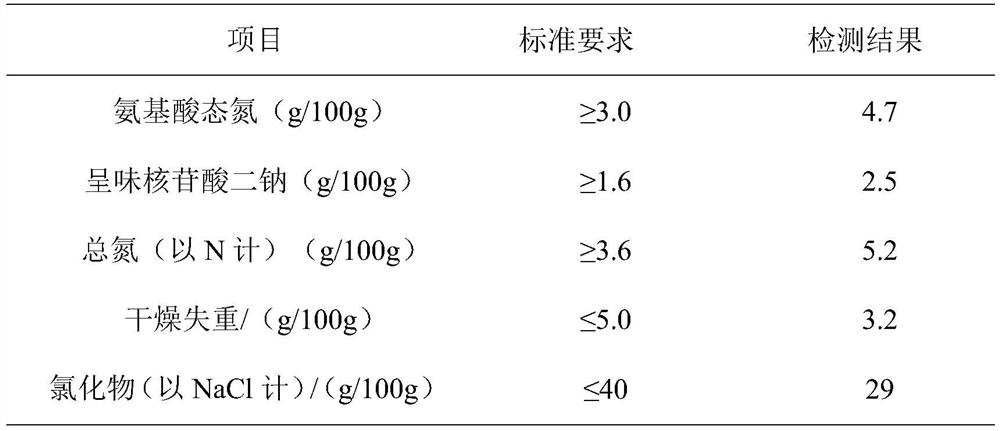

Preparation method of mushroom essence seasoning

The invention discloses a preparation method of a mushroom essence seasoning, and particularly relates to the technical field of edible mushroom processing. The preparation method comprises the following steps of breaking walls of rare edible mushrooms, pulverizing, carrying out enzymolysis for many times, and combining microwave extraction, reflux condensation extraction and the like to obtain arare edible mushroom concentrated extract with higher nutritive value. The mushroom essence seasoning is prepared by mixing the pasty mushroom concentrated extract with auxiliary materials, is rich inpolysaccharide while being used as a seasoning to provide delicate flavor and fragrance of edible mushrooms, can improve the health-care effect, and can be popularized in application of the mushroomessence seasoning.

Owner:湖北飘扬食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com