Sodium sulfate and ammonium sulfate salt mixture separation method and vanadium precipitation waste treatment method

A separation method, sodium sulfate technology, applied in the direction of alkali metal sulfite/sulfite, ammonium sulfate, chemical instruments and methods, etc., can solve the problems of environmental pollution, poly-sodium hydroxide impurities, high equipment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

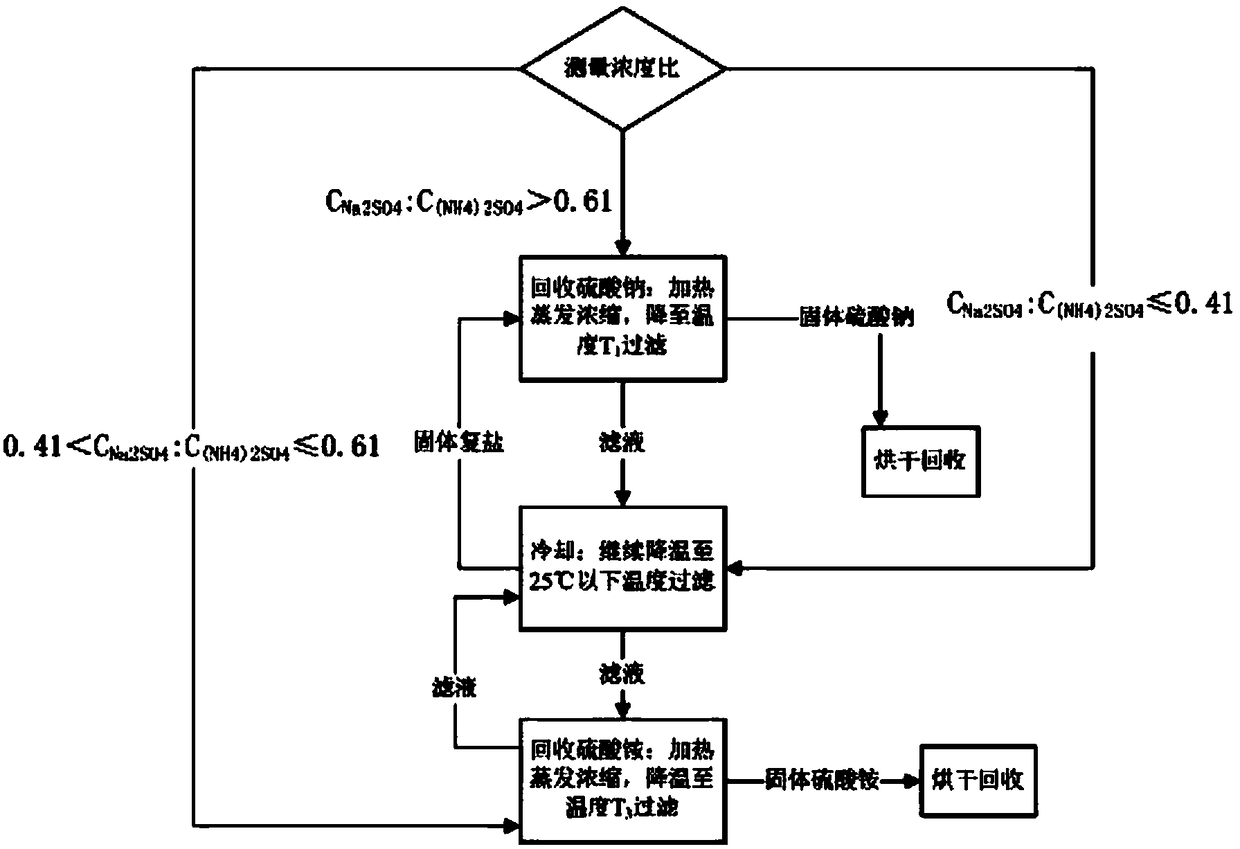

[0061] Please refer to figure 2 , This embodiment provides a method for separating mixed salts of sodium sulfate and ammonium sulfate.

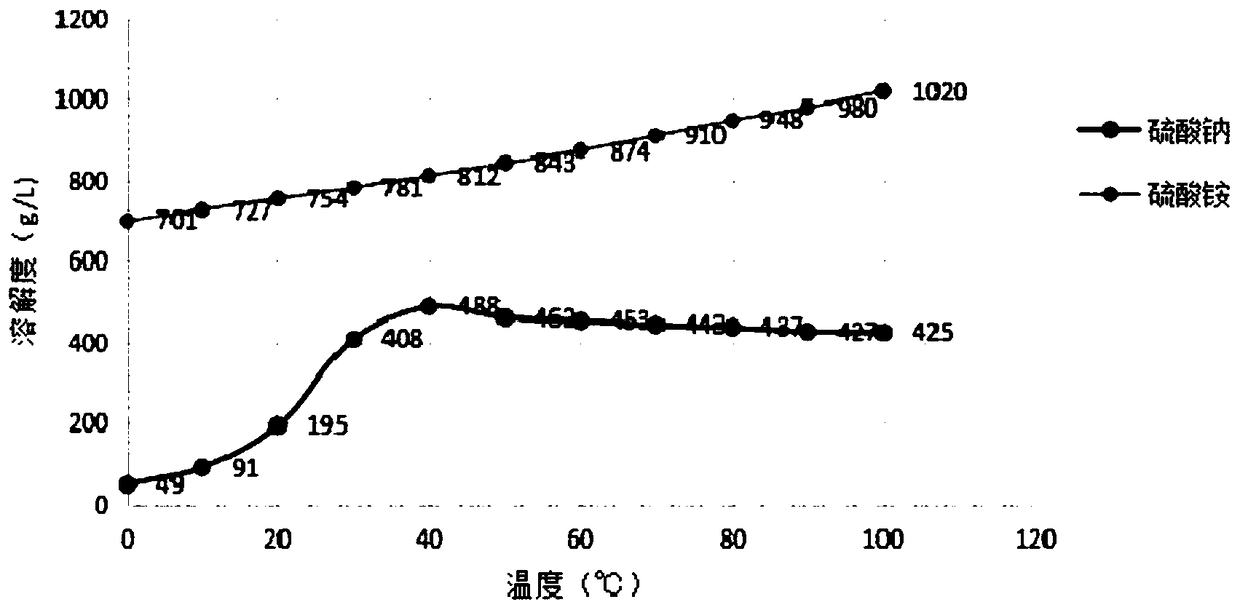

[0062] Before understanding the process of this embodiment, please refer to figure 1 Solubility curves for sodium sulfate and ammonium sulfate are shown, from figure 1 It can be seen that at 40°C, the solubility difference of sodium sulfate and ammonium sulfate is the smallest, which are 488g / L and 812g / L, respectively. and The ratio of 0.61, if the concentration of sodium sulfate in the mixed salt solution C Na2SO4 and the concentration of ammonium sulfate C (NH4)2SO4 If the ratio is greater than 0.61, then in the process of evaporating and concentrating the mixed salt solution, sodium sulfate always reaches supersaturation first and precipitates before ammonium sulfate. The mixed salt solution that meets this concentration requirement can directly separate part of the sulfuric acid through cooling and crystallization. sodium. And a...

Embodiment 2

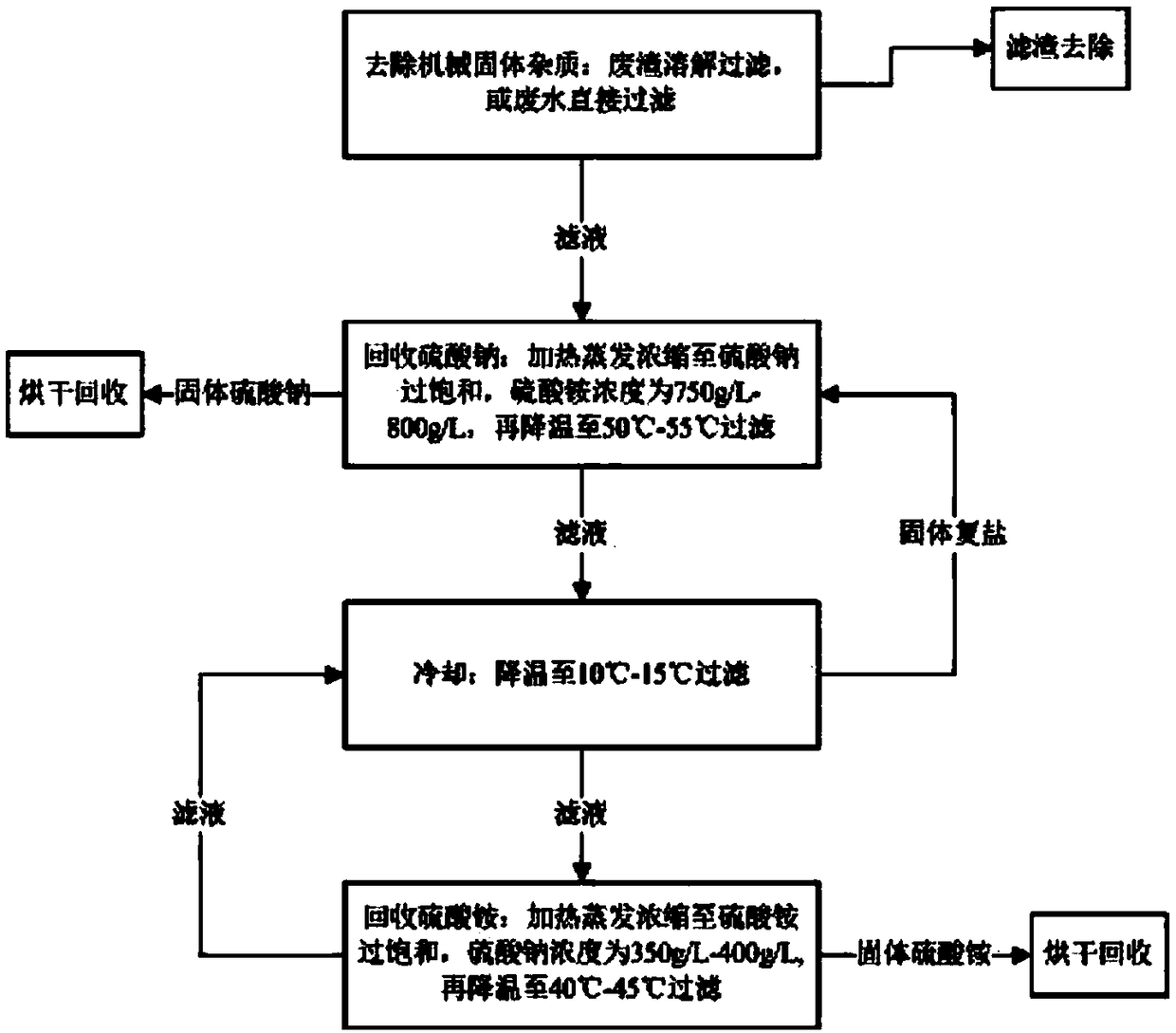

[0092] The present embodiment provides a kind of processing method of processing vanadium precipitation waste, specifically comprises the following steps:

[0093] Step 1. Removal of mechanical impurities: dissolving and filtering the vanadium-precipitated waste residue to remove mechanical impurities to obtain a mixed salt solution; or filtering the vanadium-precipitated waste water to remove mechanical impurities to obtain a mixed salt solution;

[0094] Step 2, recovery of sodium sulfate: heating and evaporating the mixed salt solution in the temperature range of 80°C-100°C until the sodium sulfate is in a supersaturated state, and the concentration of ammonium sulfate is close to but lower than the temperature T 1 When the solubility of ammonium sulfate; then the solution is cooled to temperature T 1 Filtrate to obtain solid sodium sulfate and filtrate, solid sodium sulfate is recovered, and the filtrate is subjected to step three operations;

[0095] Step 3. Cooling: Coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com