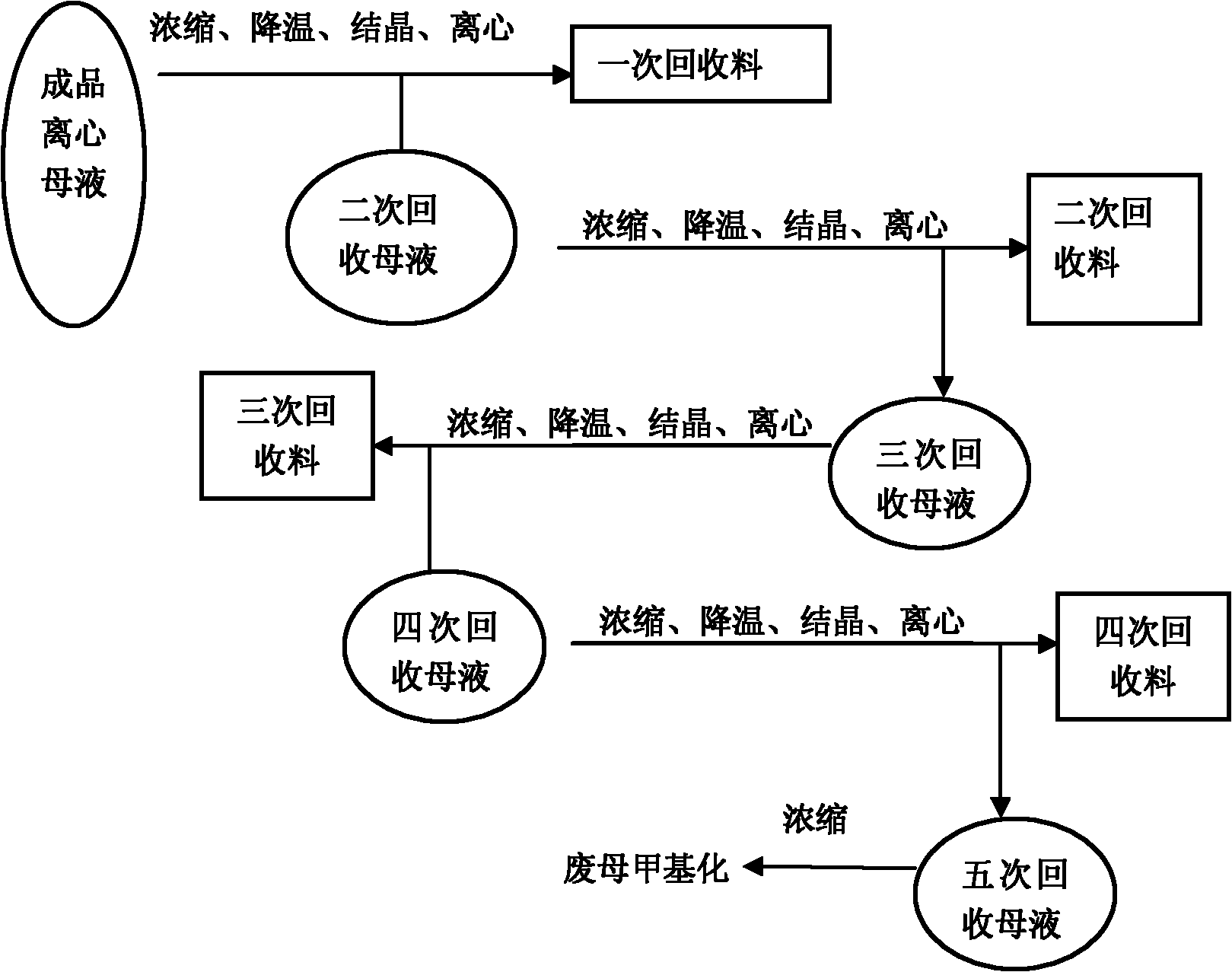

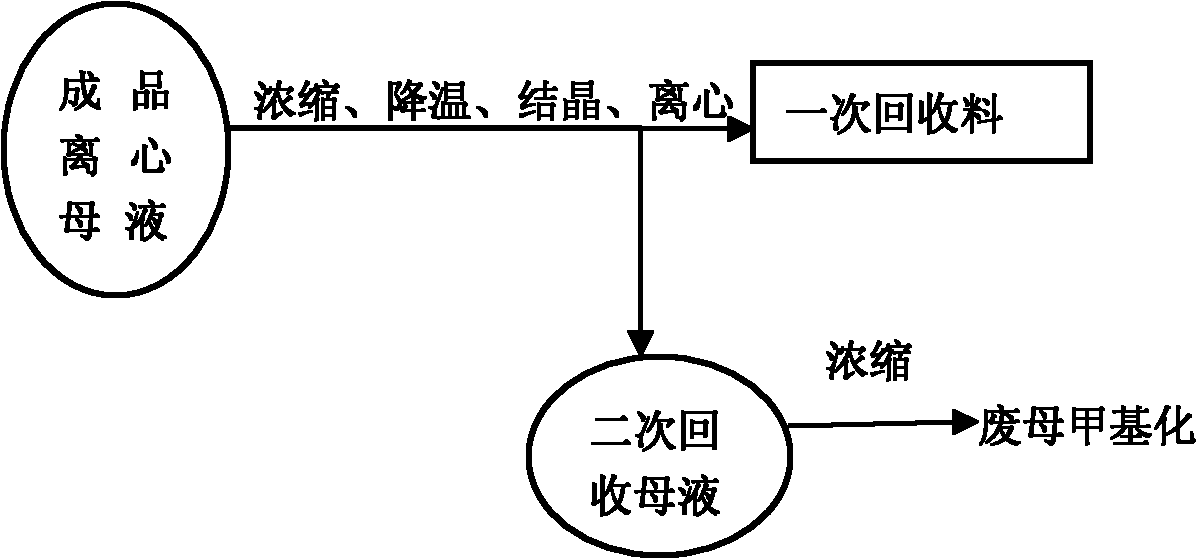

Recovery process of analginum finished product centrifugal mother liquid

A technology of centrifugal mother liquor and analgin, which is applied in the field of medicine and chemical industry, can solve the problems of potential safety hazards and non-compliance with environmental protection requirements, and achieve the effect of easy industrial production, compliance with environmental protection and audit requirements, and high crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Measure 4000ml of analgin finished centrifuged mother liquor, first use the recovery tower to concentrate to a density of 1.21g / ml, and then use a concentrator to concentrate, control the concentration temperature to 70±10°C, vacuum degree to -0.05MP, and concentrate to a density of 1.30 g / ml, its loss on drying is 18.0%; add anhydrous methanol (methanol purity ≥ 99%) to dissolve; after the material is completely dissolved, open the interlayer circulating water to cool down, cool down to 67°C after 1.5 hours, use salt water to cool down, and Cool down to 35°C in 3.5 hours, turn off the brine and prepare for centrifugation; adjust the speed of the centrifuge to 1200 rpm, feed and centrifuge, after centrifuging for 40 minutes, stop the centrifuge, wash with 230g of anhydrous methanol, centrifuge for 40 minutes, and discharge . The content of the crude product of Analgin in the primary recycled material of Analgin is 77.28%, and the crystallization rate of the finished cen...

Embodiment 2

[0026] Measure 4000ml of analgin finished centrifuged mother liquor, concentrate it with a concentrator, control the concentration temperature at 81.5±10.5°C, vacuum degree at -0.07MP, concentrate to a density of 1.40g / ml; add 90kg of anhydrous isopropanol, and continue to concentrate When the weight loss on drying is 14.5%, add isopropanol (isopropanol purity ≥ 99%) to dissolve; after all the materials are dissolved, open the interlayer circulating water to cool down, and cool down to 60°C after 2.0 hours, then use salt water to cool down, after 4.5 hours Cool down to 25°C, turn off the brine and prepare for centrifugation; adjust the speed of the centrifuge to 1200 rpm, feed the material for centrifugation, and after centrifugation for 40 minutes, stop the centrifuge, wash with 230g of anhydrous isopropanol and then centrifuge for 40 minutes, discharge the material . The content of the crude product of Analgin in the primary recycled material of Analgin is 78.33%, and the cr...

Embodiment 3

[0028] Measure 4000ml of analgin finished centrifuged mother liquor, first use the recovery tower to concentrate to a density of 1.225g / ml, and then use a concentrator to concentrate, control the concentration temperature to 89±2°C, vacuum degree to -0.08MP, and concentrate to a density of 1.45 g / ml, add dehydrated ethanol (ethanol purity ≥ 99%) 89kg, continue to concentrate until the loss on drying is 12.5%, then add dehydrated ethanol to dissolve, after the materials are all dissolved, open the interlayer circulating water to cool down, after 1.5 hours, cool down to 68°C, switch to brine to cool down, cool down to 25°C after 5.5 hours, turn off the brine and prepare for centrifugation; adjust the speed of the centrifuge to 1200 rpm, feed the material for centrifugation, and after centrifugation for 40 minutes, stop the centrifuge and use 230g of absolute ethanol After washing, centrifuge for 40 minutes and discharge. The content of the crude product of Analgin in the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com