Patents

Literature

182results about How to "Improve the site environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

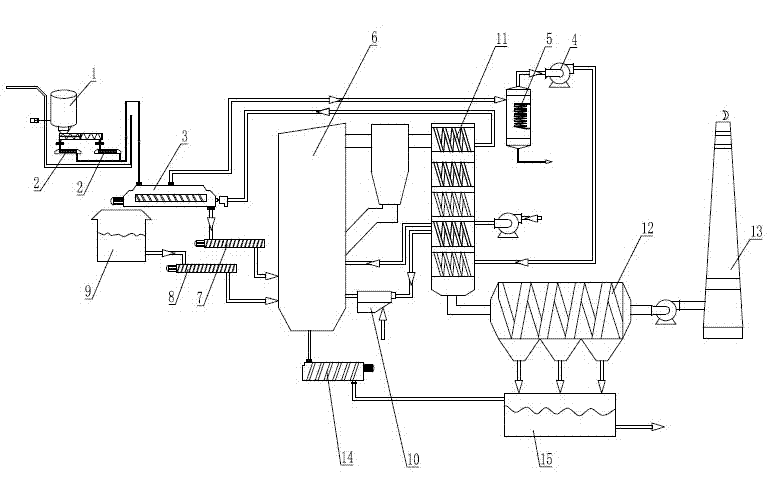

Water-containing sludge treatment method

InactiveCN102887619ANo protectionImprove operational reliabilitySludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeIncineration

The invention discloses a water-containing sludge treatment method which comprises the following steps of: conveying sludge into a sludge drying machine, heating and drying; conveying semi-dry sludge into a sludge incinerator; introducing air into the sludge incinerator after passing through an ignition device; enabling high-temperature smoke generated by incinerating sludge to pass through a waste heat recycling device, and then discharging the high-temperature smoke to the air through a smoke purifying and dust-removing system; and conveying residues generated by incinerating the sludge to an ash storage bunker. The semi-dry incineration of the sludge adopts the mode that the sludge directly passes through the sludge drying machine to reach a low-dryness and semi-dry degree and then enters the incinerator for being incinerated; and in the drying process, no full-dry sludge is generated, and the back-mixing operation is not needed. The water-containing sludge treatment method has the advantages that developed and reliable sludge drying and incineration devices are adopted, thus a system has high operation reliability; the dry sludge back-mixing operation is not needed for a semi-drying system, thus the dust quantity is low and the oxygen content and temperature are low during operation, the system is high in safety, and inert gas protection is not needed; and the whole system does not generate dust and odor during operation, and is environmental-friendly.

Owner:张开晓

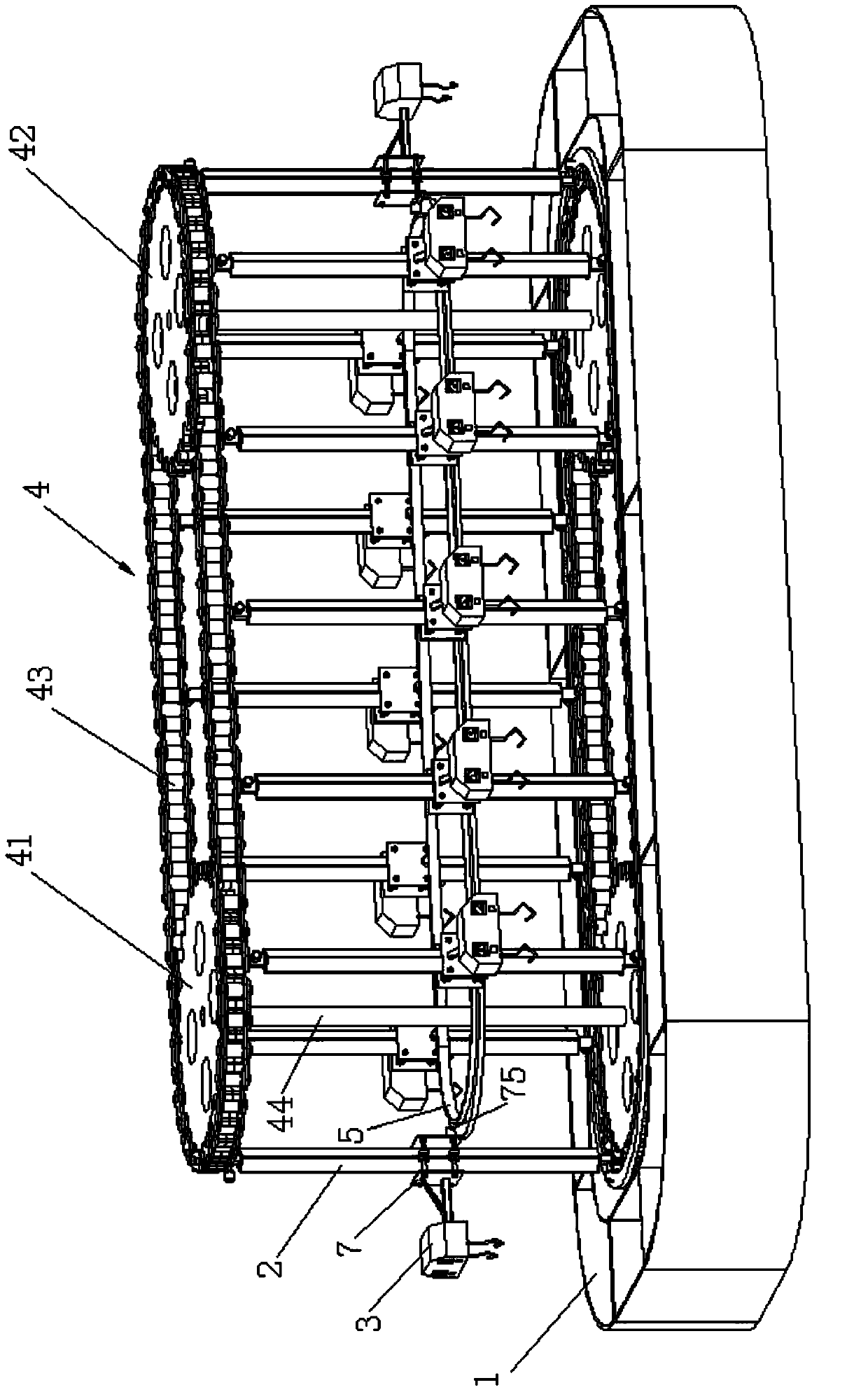

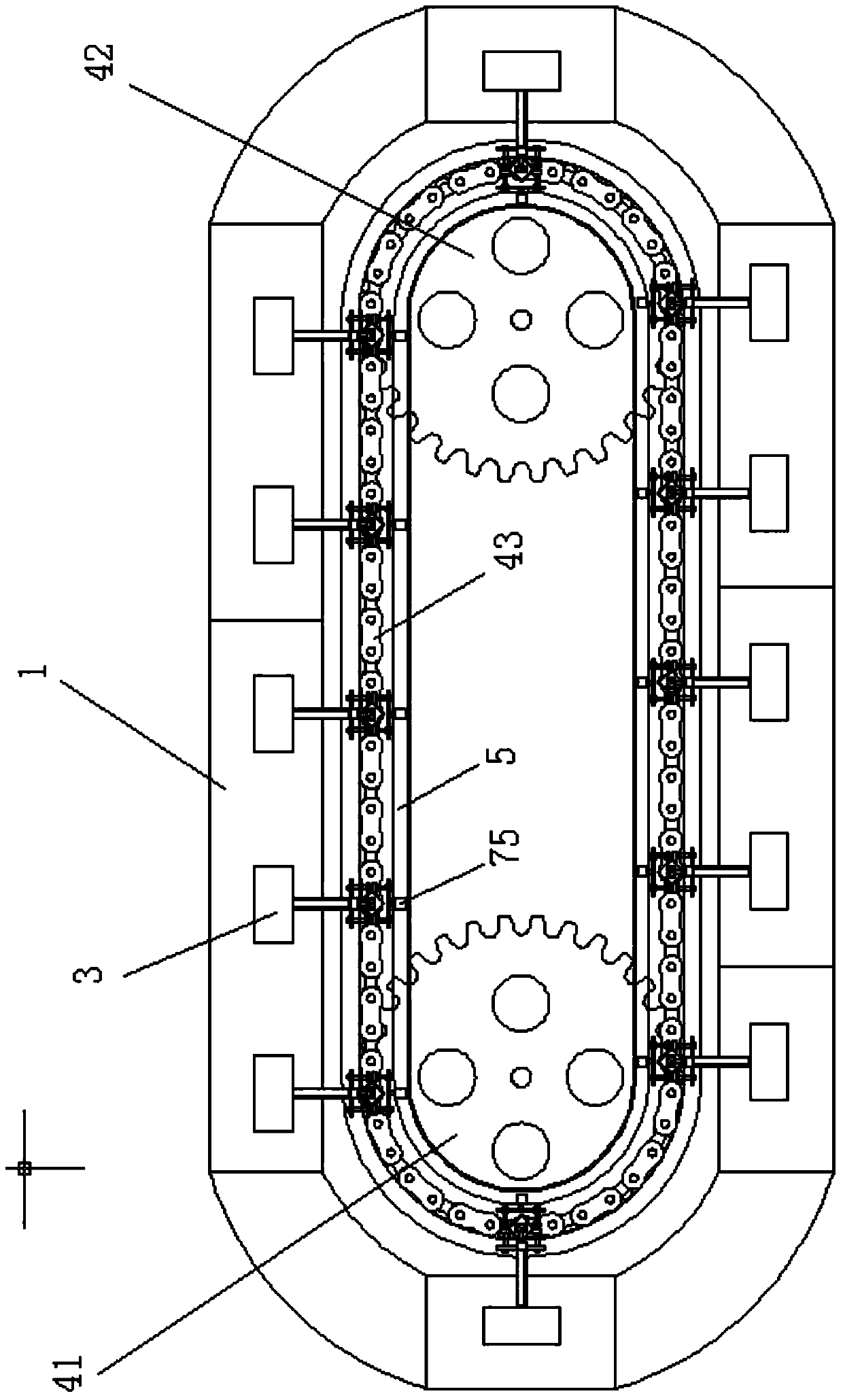

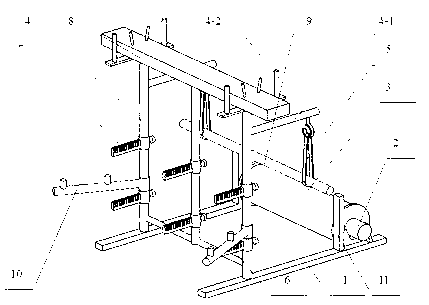

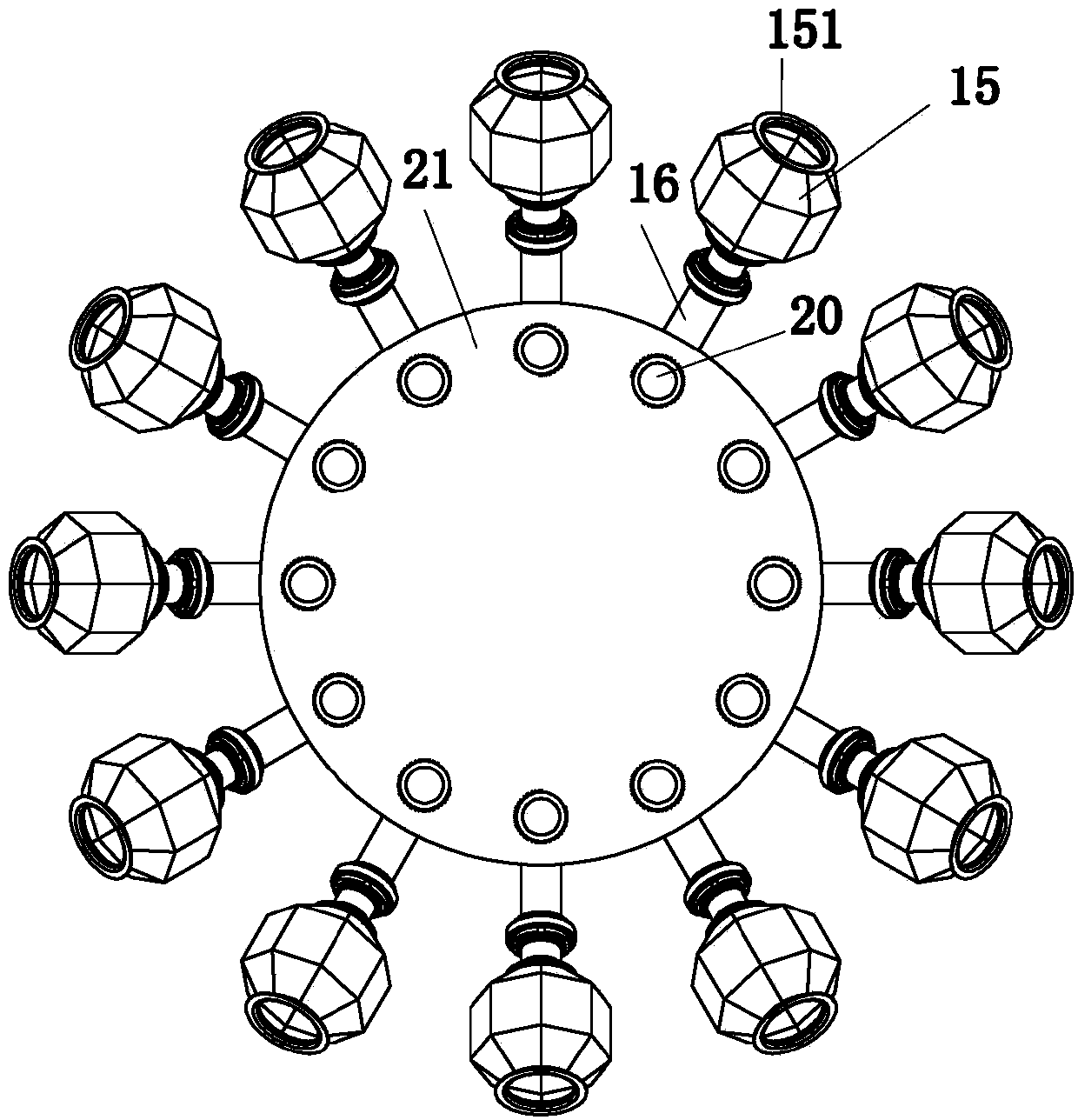

Automatic electroplating equipment for zipper head

ActiveCN103469270AImprove the quality of electroplatingImprove plating qualityCellsSlide fastenersControl systemEngineering

The invention provides automatic electroplating equipment of a zipper head. The equipment consists of electroplating grooves which are formed by a pre-electroplating treatment groove, an electroplating treatment groove and a post-electroplating treatment groove and are connected head-to-tail to form a closed ring, wherein an anode generator is installed on a vertical guide rail which is connected with a chain of a traveling device, the anode generator is further provided with an idler wheel which is placed on a horizontal circular track, and the circular track driven by a lifting device can ascend and descend. Under the effects of a control system, the traveling device and the lifting device, the anode generator intermittently travels on the circular track and circulates according to a sequence of ascending, traveling, descending and stopping. According to the invention, the zipper head is continuously electroplated through the automatic equipment, so that the electroplating production efficiency is greatly improved. Times of the steps are controlled through intelligent programs, so that the electroplating quality is high and the electroplating quality of the zipper head is enhanced. Meanwhile, the labor intensity of the workers is further reduced, and the field environment is improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

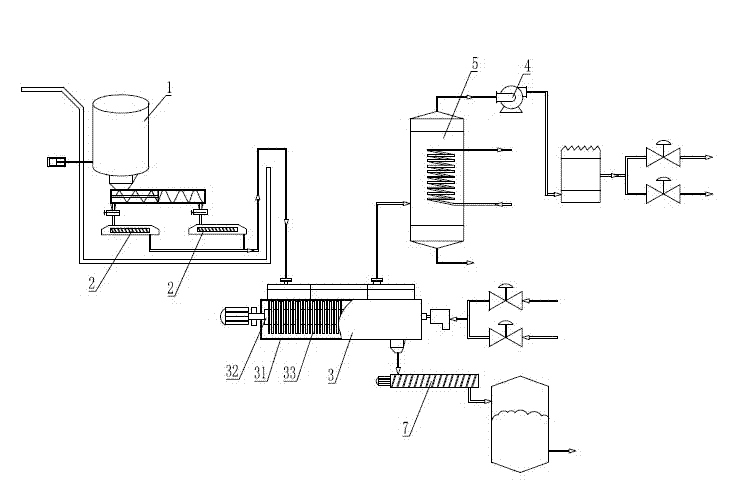

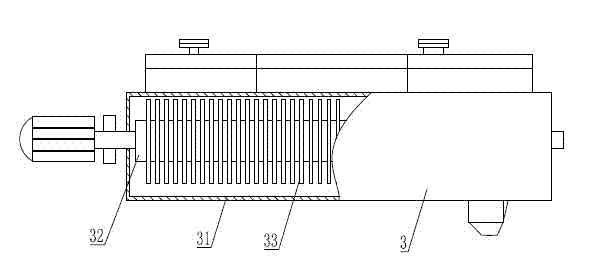

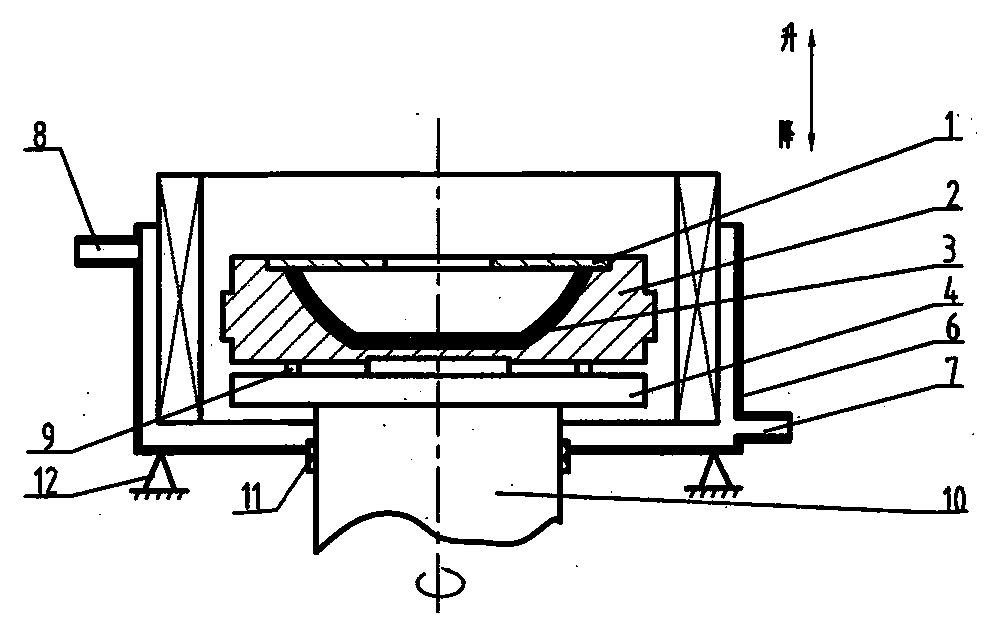

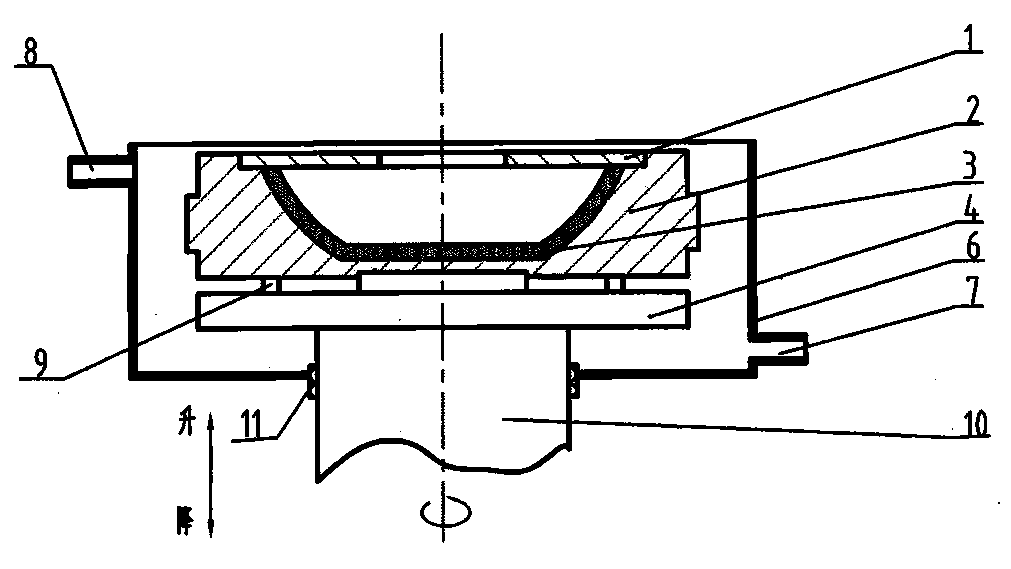

Method for preparing steel-based copper-alloy thermometal spherical bearing seat blank

The invention discloses a method for preparing a steel-based copper-alloy thermometal spherical bearing seat blank which is produced on a vertical centrifugal casting machine comprising an electric induction heating device and a cooling device. The preparation method sequentially comprises the steps that a steel shell of a bearing seat is preprocessed, and the preprocessed steel shell is placed on a rotary table of the vertical centrifugal casting machine; technological quantity of copper-alloy particles are added in the steel shell, and the rotary table is started; the heating device is started for heating to enable the copper-alloy particles to be molten; the steel shell is cooled to enable the molten copper-alloy to be solidified and metallurgically-bonded on the surface of the inner sphere of the steel shell to obtain the steel-based copper-alloy thermometal spherical bearing seat blank. The method has the advantages that the technological procedure is short, device investment is little, manufacturing cost is low, labor intensity is low, and the on-site environment is good.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

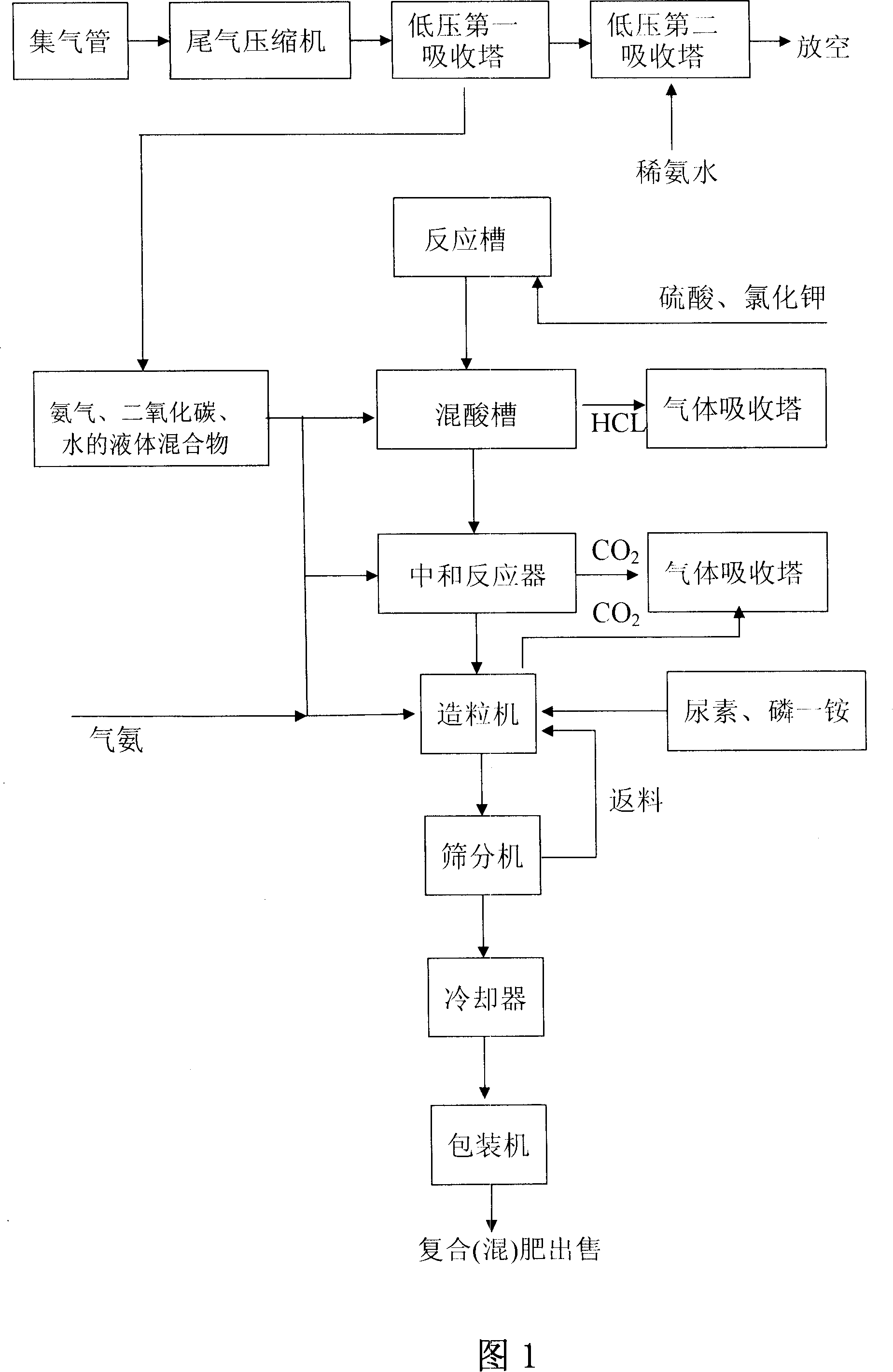

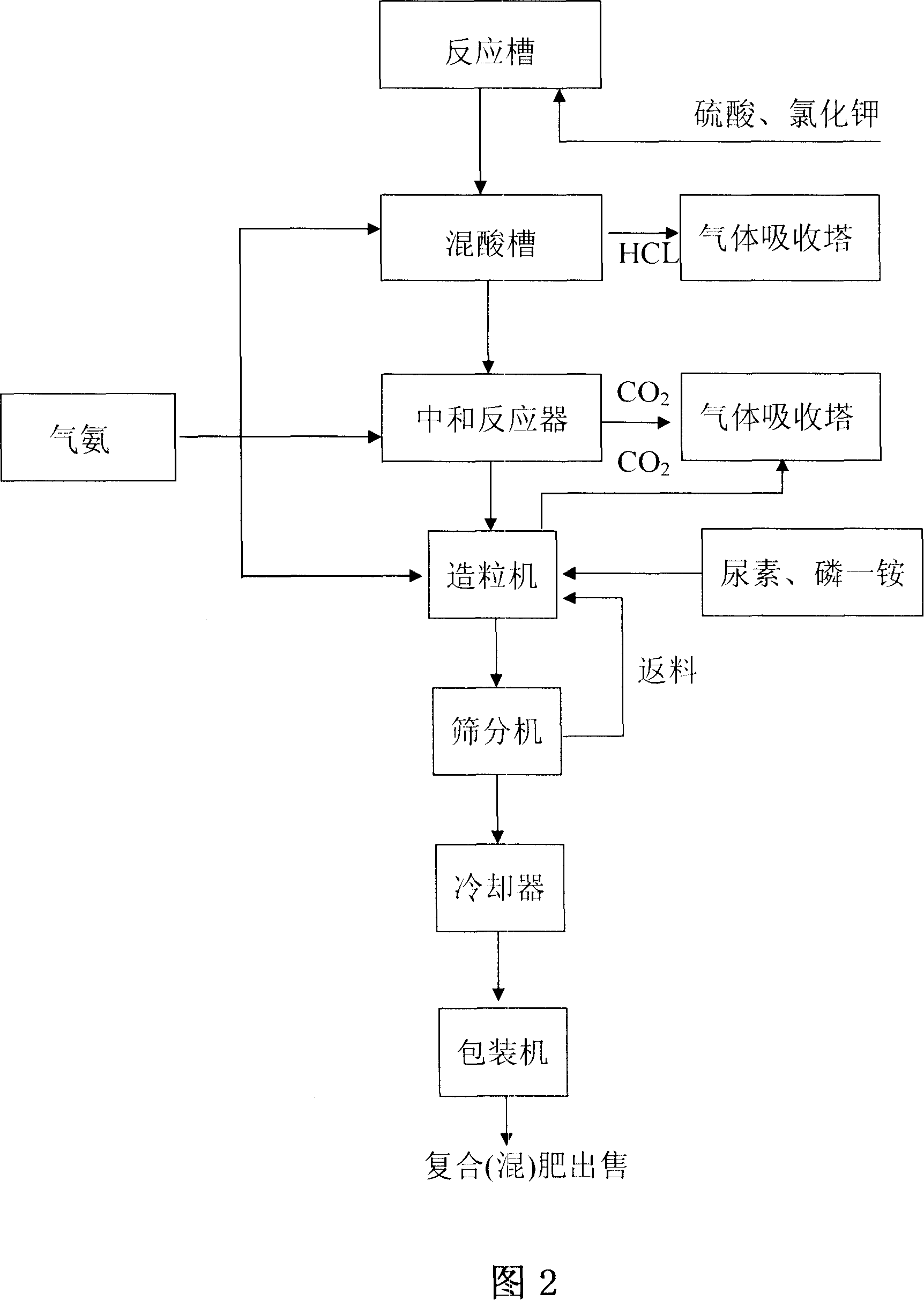

Technique for producing composite (compound) fertilizer by using liquid mixture of ammonia gas, carbon dioxide and water

InactiveCN101148374AIncrease added valueSimple structureCarbon dioxide producing fertilisersUrea compound fertilisersMelamineAmmonia gas

The process of producing composite fertilizer with the mixture of ammonia, CO2 and water from melamine producing plant, liquid urea plant and other plant includes pumping the mixture to the fertilizer producing shop, mixing, neutralizing, ammoniating and pelletizing to obtain high efficiency composite fertilizer. The present invention has high economic effect and environment friendship.

Owner:山东海化魁星化工有限公司

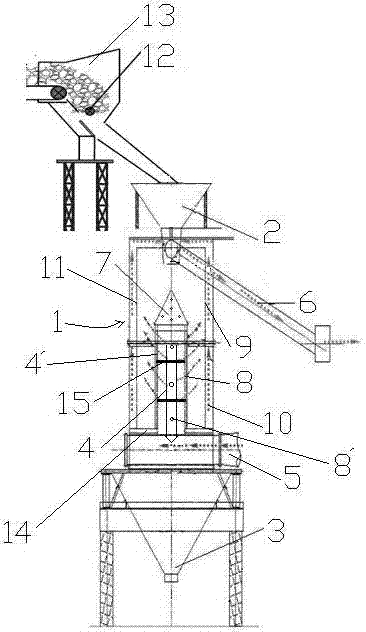

Vertical cooling and waste heat recovery furnace for sinters

ActiveCN103697707AReduce resistanceReduce power consumptionIncreasing energy efficiencyHandling discharged materialCold airFlue gas

The invention discloses a vertical cooling and waste heat recovery furnace for sinters, which comprises a feeding hopper and a discharge hopper, wherein the feeding hopper and the discharge hopper are respectively communicated with the top and the bottom of a cooling chamber; first and second air ducts are sequentially sleeved in the cooling chamber; the walls of the first and second air ducts are respectively provided with a plurality of air outlet holes; the top of the first air duct is provided with a cone distributor; the bottom of the second air duct is communicated with a cold air inlet pipe; the cooling chamber is provided with an inner sleeve; a plurality of vent holes are distributed in the wall of the inner sleeve; a hot air collecting cavity is formed between the inner sleeve and a housing of the cooling chamber; the upper part of the hot air collecting cavity is communicated with a hot waste gas exhaust pipe; and the bottom of the hot air collecting cavity is communicated with the discharge hopper. The invention provides a cooling system integrating sinter cooling with closed hot flue gas recovery and waste heat utilization; the vertical cooling and waste heat recovery furnace for the sinters operates under a negative pressure in the cooling process; emission of pollutants can be greatly reduced; the field environment is improved; and the heat recovery rate is improved.

Owner:铜陵市富鑫钢铁有限公司

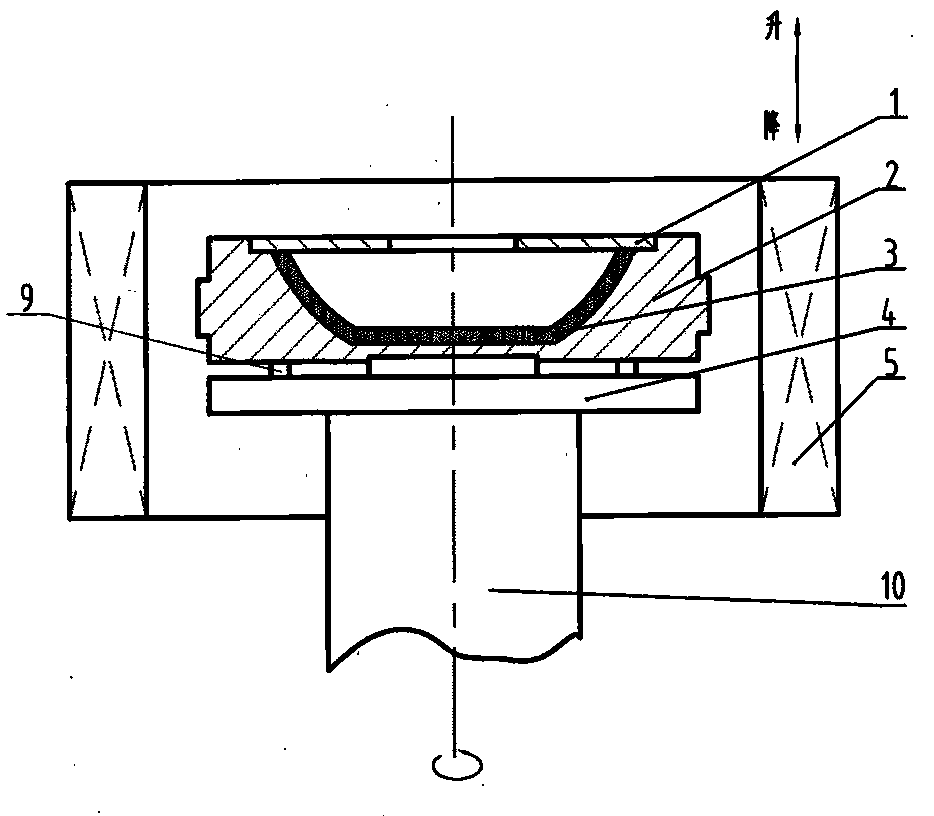

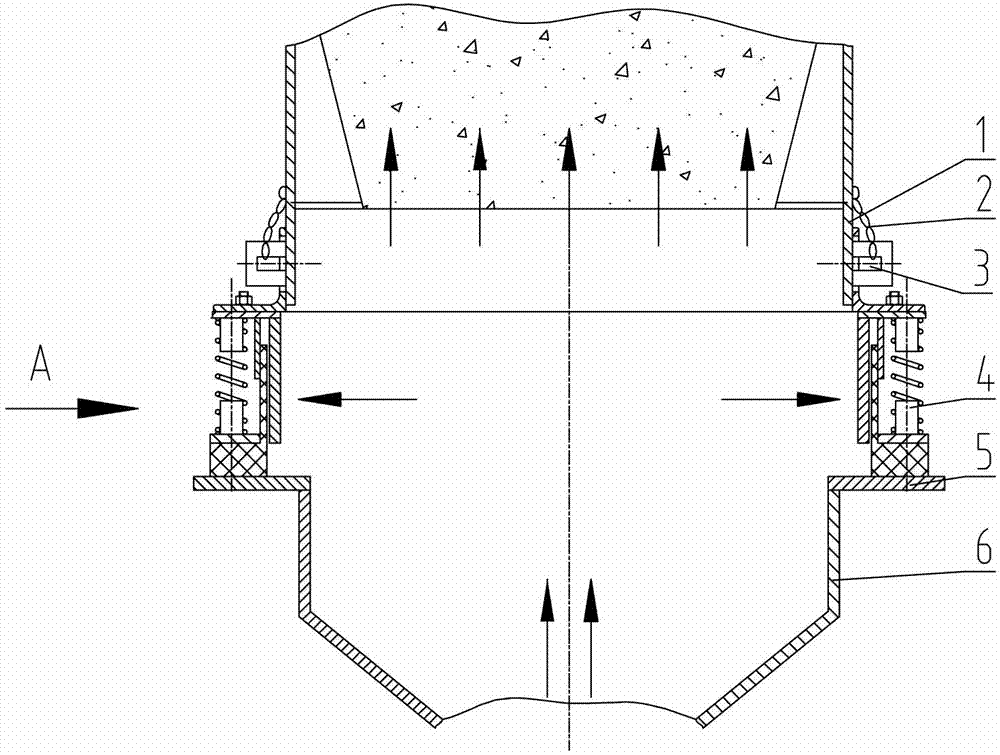

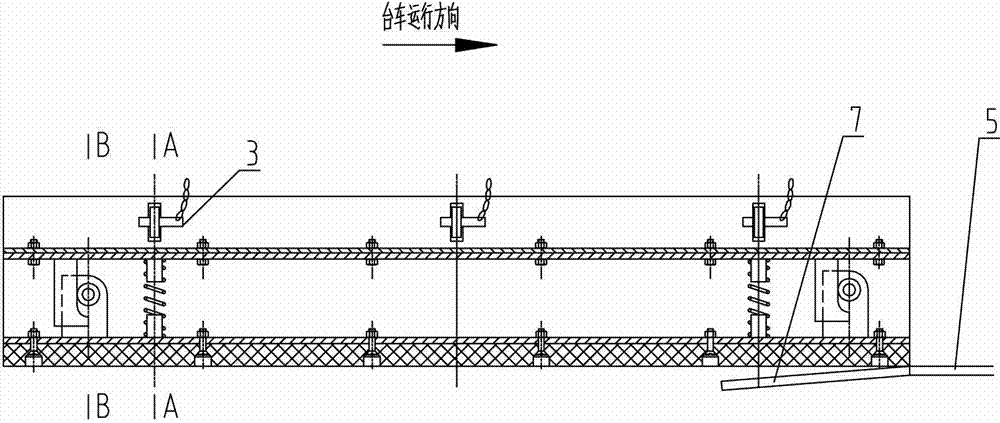

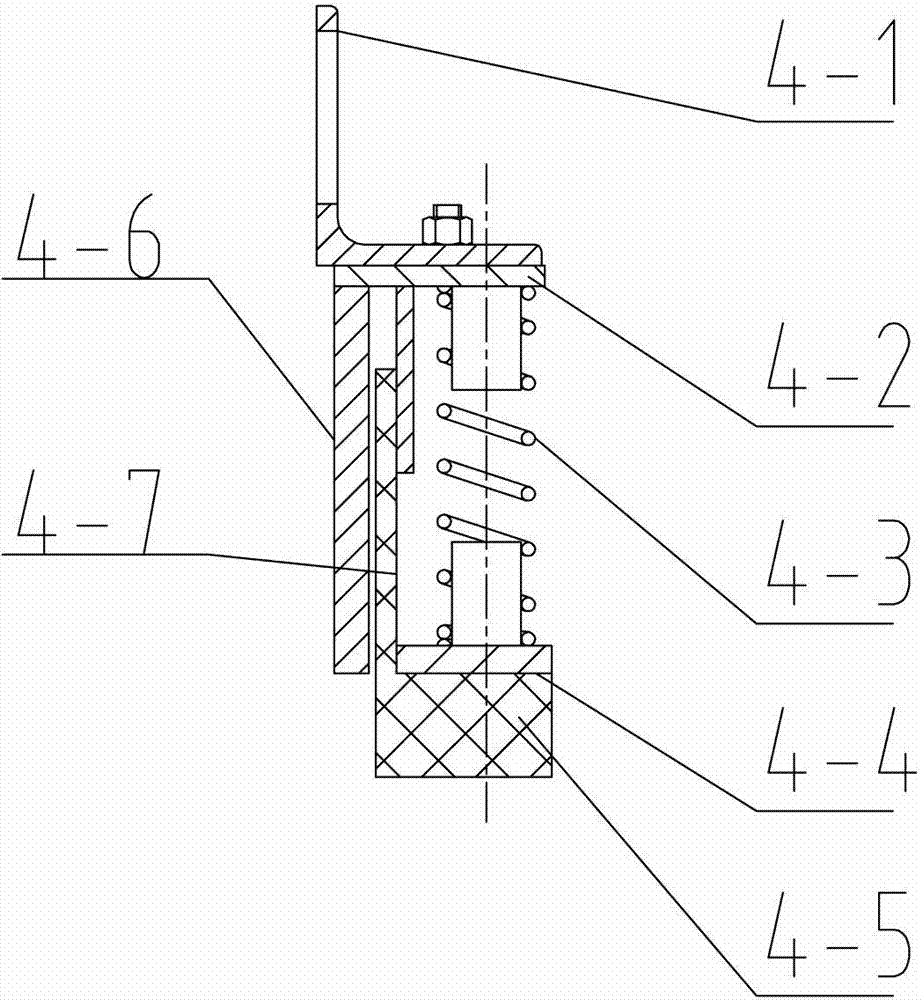

Three-dimensional limiting type elastic sealing device of lower breast board of circular cooler trolley

InactiveCN103047869AReliable contactThe sealing effect remains unchangedEngine sealsHandling discharged materialCircular discIdler-wheel

The invention relates to a three-dimensional limiting type elastic sealing device of a lower breast board of a circular cooler trolley. The elastic sealing device comprises the circular cooler trolley, lower breast boards of the trolley, a wind box and wind box sealing discs, wherein the wind box is arranged below the circular cooler trolley, and the wind box sealing discs are arranged at the upper part of the wind box; and the elastic sealing device is characterized in that an elastic sealing assembly is arranged between a lower breast board of the trolley and the corresponding wind box sealing disc and consists of an upper connecting seat, an upper limiting plate, a lower connecting seat, a lower limiting plate, a rubber sealing plate and springs, the upper connecting seats are provided with slot side plates, the springs are arranged between the upper connecting seats and the lower connecting seats, the slot side plates are mounted at one side (close to the breast boards) of the trolley, a vertical side sealing plate is arranged at one side of the upper end of each rubber sealing plate, the vertical side sealing plates are inserted into the slot side plates of the upper connecting seats and are connected with the upper connecting seats in a sliding way, the lower limiting plates are slot type limiting plates, and the upper limiting plates are inserted into slots of the lower limiting plates and are connected with the lower limiting plates through idler wheels and bolts. According to the three-dimensional limiting type elastic sealing device of the lower breast board of the circular cooler trolley, the sealing effect is good, and the spot environment of a circular cooler is effectively improved.

Owner:吴琳

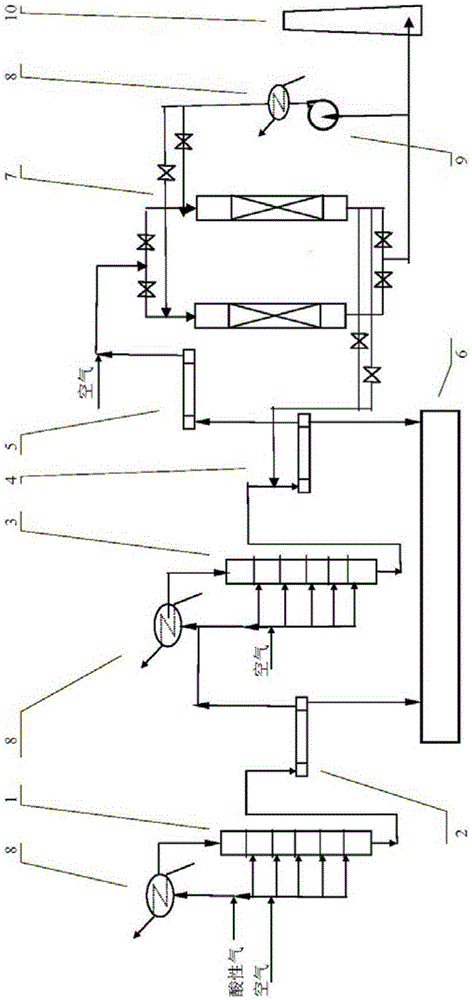

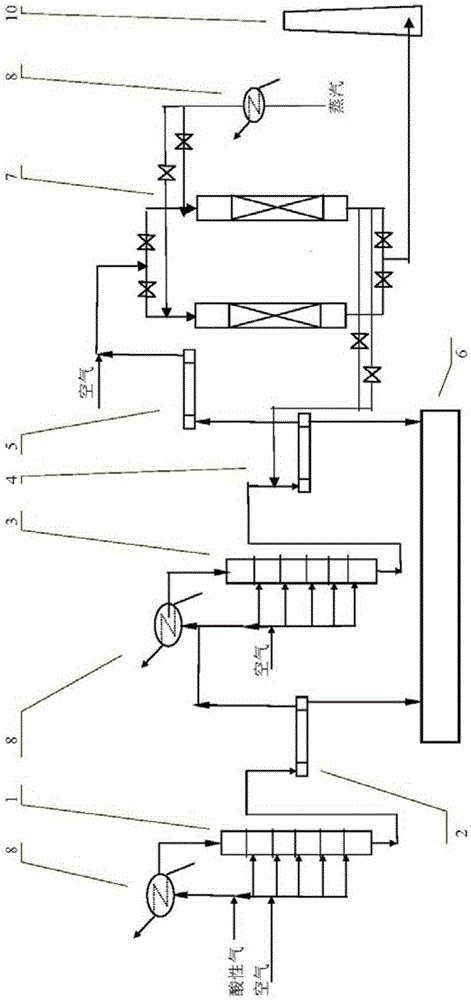

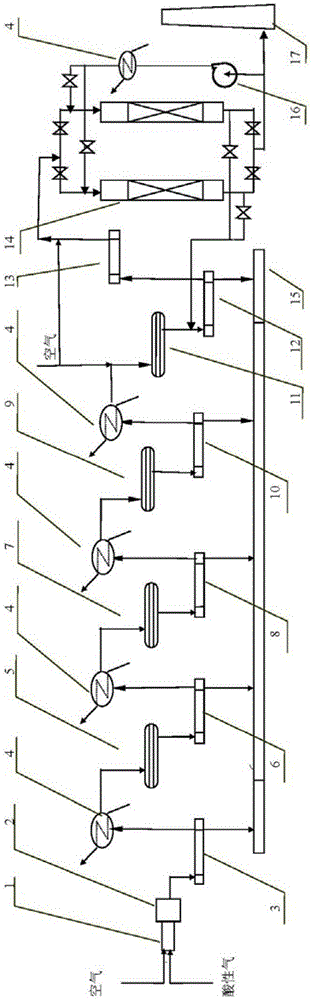

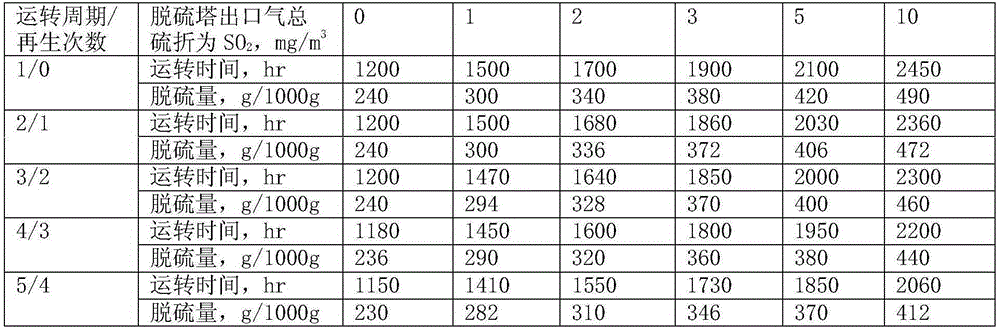

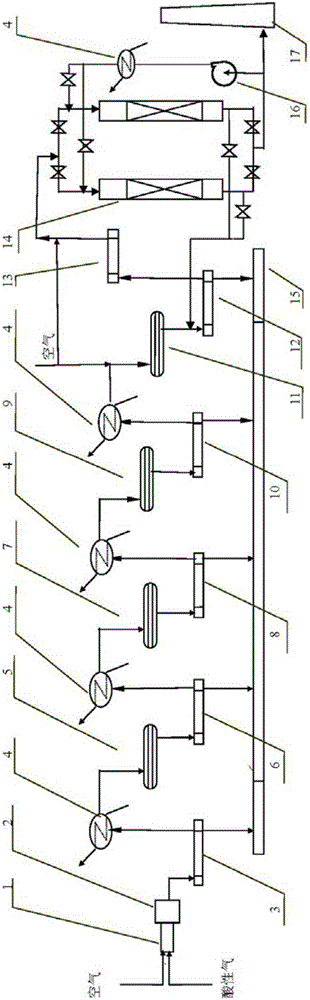

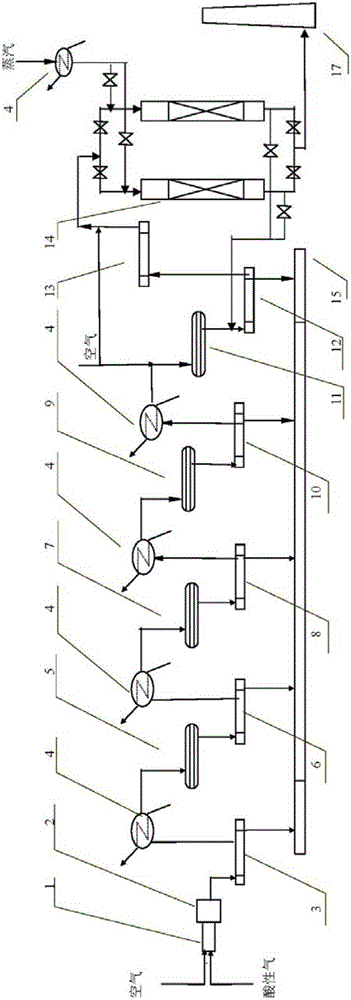

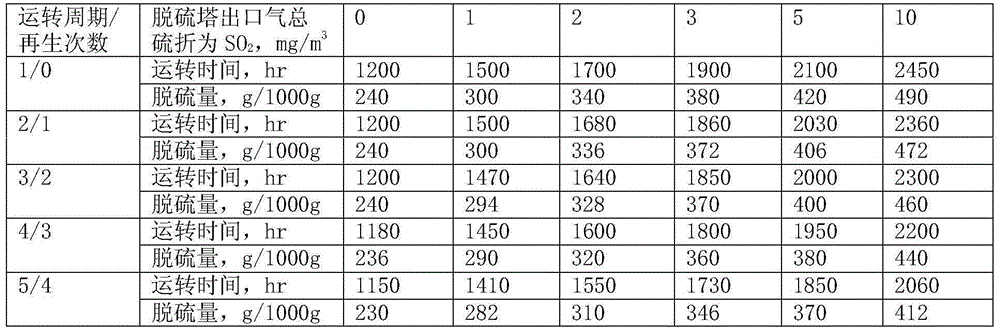

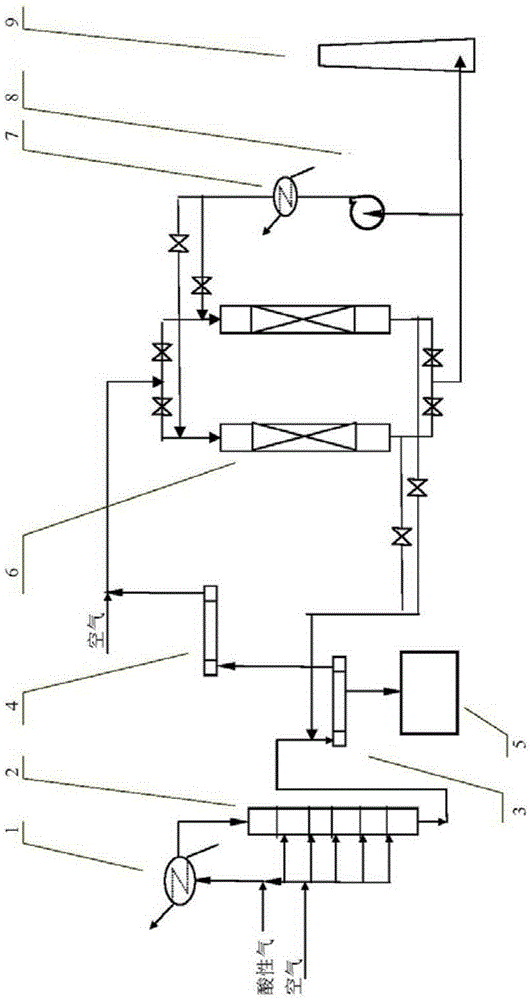

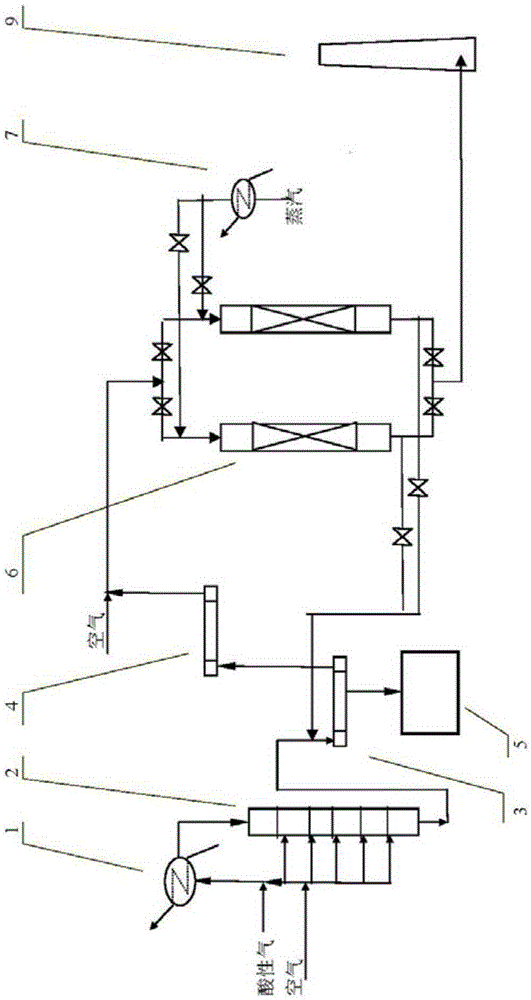

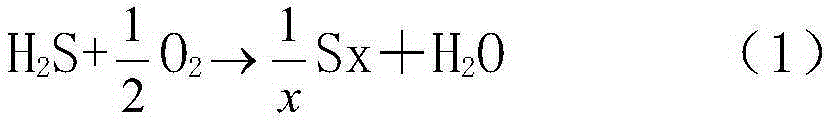

Low-sulfur discharging and sulfur recycling process of intermediate concentration acid gas

ActiveCN105314607ALow sulfur concentrationHigh desulfurization precisionEnergy inputSulfur preparation/purificationCatalytic oxidationCooling coil

The invention provides a low-sulfur discharging and sulfur recycling process of intermediate concentration acid gas. A purpose of desulphurizing low-concentration acid gas with H2S content of 5 to 20 percent can be achieved by treating the low-sulfur acid gas by virtue of a direct oxidation reactor, a selective oxidation reactor and two adsorption desulphurization towers which can be connected in series and parallel; the direct oxidation reactor is filled with a TiO2 sulfur recycling catalyst, the selective oxidation reactor is filled with a H2S selective oxidation catalyst, catalysts in the direct oxidation reactor and selective oxidation reactor are packed in multiple layers, an air inlet and a cooling coil pipe are respectively arranged between two layers, and the adsorption desulphurization tower is filled with a thermally-renewable catalytic oxidation adsorption desulphurization agent; by selecting the appropriate catalyst and desulphurization agent and precisely controlling the process condition of each step, the total sulfur contained in the process discharged gas is that SO2 content is less than or equal to 10mg / m<3>. By virtue of thermal regeneration, the service life of the catalytic oxidation adsorption desulphurization agent is greatly prolonged, and the desulphurization amount of the catalytic oxidation adsorption desulphurization agent is greatly increased. The process has the advantages of low sulfur emission, high sulfur recycling rate (approximate to 100 percent), long service life and large desulphurization amount of the desulphurization agent, fewer replacement times, less expense, good desulphurization agent removal and scrapping condition, safety and the like.

Owner:山东迅达化工集团有限公司

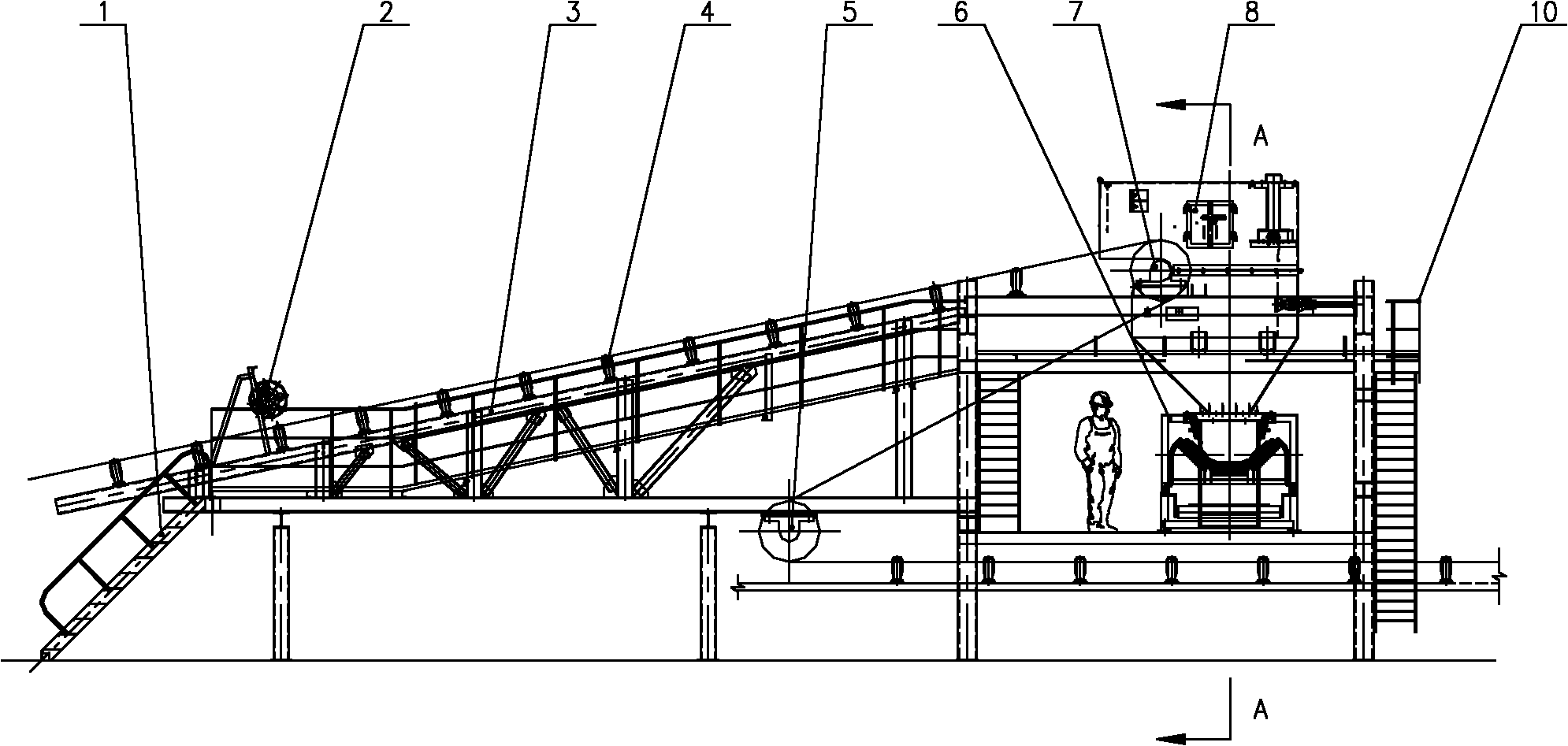

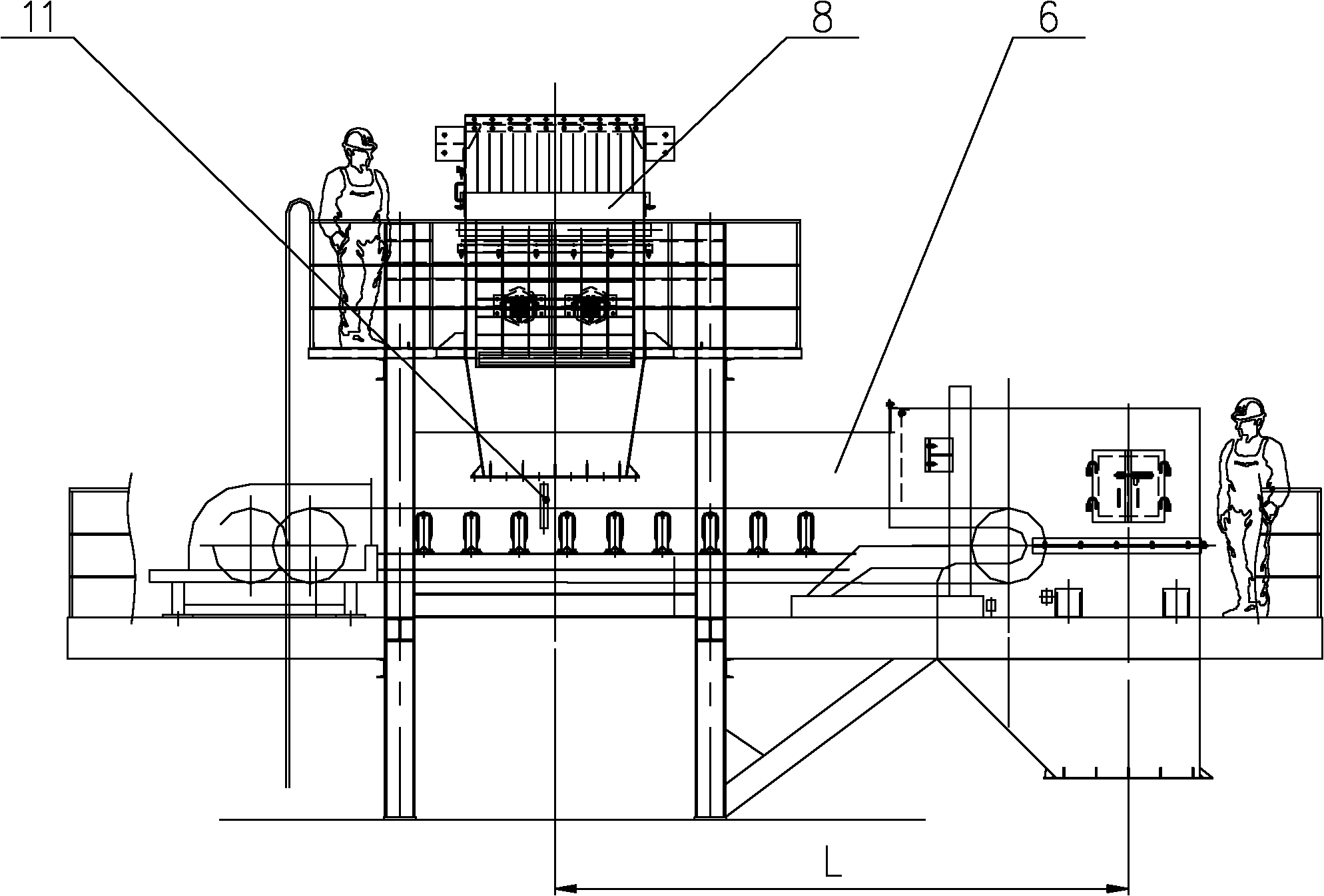

Multidirectional discharging method of mobile discharging car

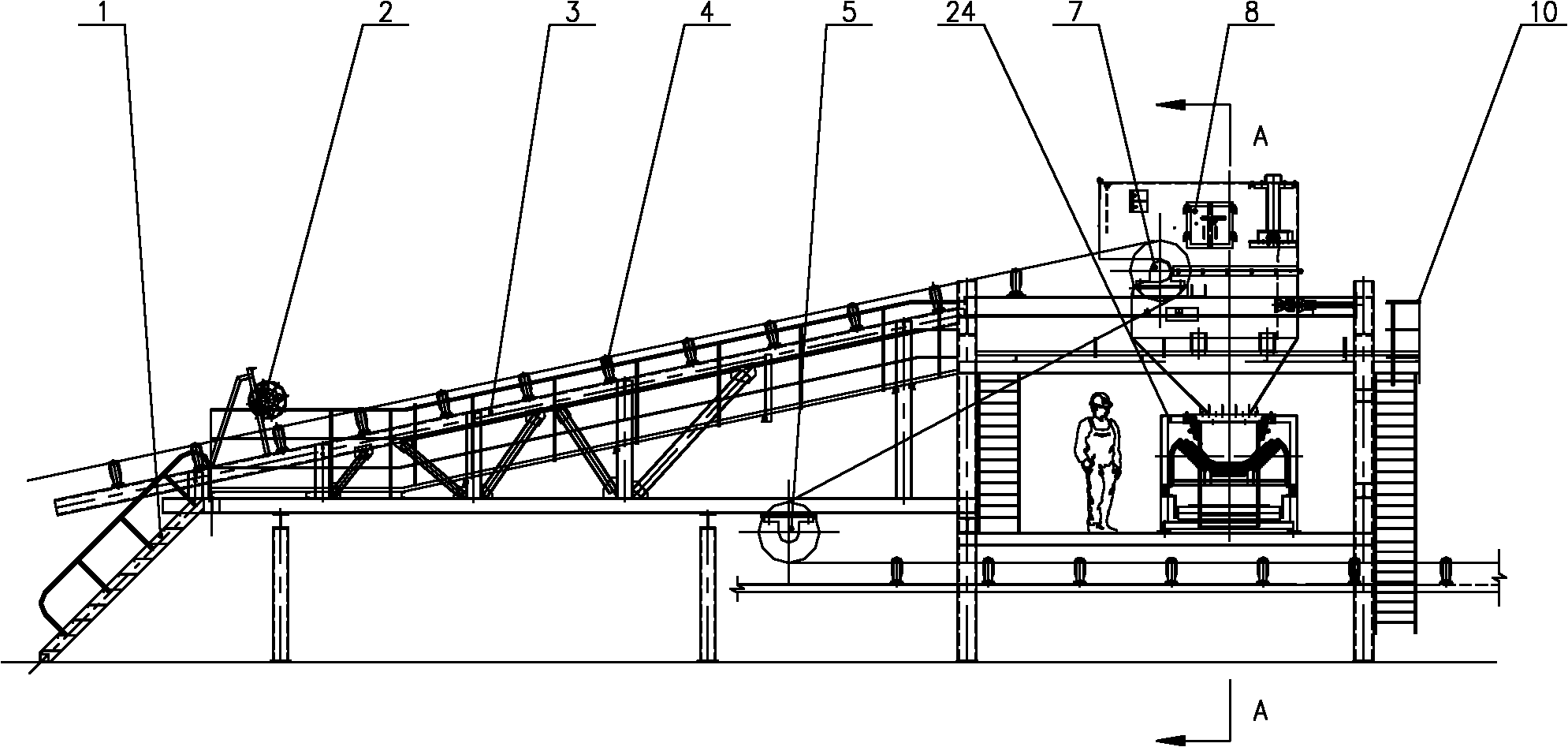

InactiveCN102249095AFlexible unloading methodIncrease economic benefitsConveyorsLoading/unloadingEconomic benefitsEnvironmental quality

The invention relates to a multidirectional discharging method of a mobile discharging car, and belongs to the technical field of a bulk material discharging device. The multidirectional discharging method is characterized in that materials are transferred into a belt conveyor at the lower part through a funnel and then are transported to the position above a discharging point for discharge; and by adjusting the horizontal distance between the discharging point of the belt conveyor and the outlet of the funnel, discharging position is adjusted without increasing overall height of the conveyor. The multidirectional discharging method has the beneficial effects that the materials can be flexibly discharged in multiple directions as required; the structure is compact, thus saving equipment installation space; a long chute is not used, thus avoiding phenomena such as material aggregation and blockage; by effectively controlling equipment height, discharging height difference is decreased, and dust generated during the material transfer process is reduced, and good dedusting and environmental protection effect can be obtained by utilizing dedusting equipment; and steel structural members in the equipment are simplified and diminished, thus the equipment can be conveniently installed and simply debugged, operated and maintained, and good economic benefit can be obtained. The mobile discharging car is particularly applicable to workplaces with narrow plant space and higher requirement on environmental quality.

Owner:WISDRI ENG & RES INC LTD

A fertility-betterment type soil-conditioner and the preparation method thereof

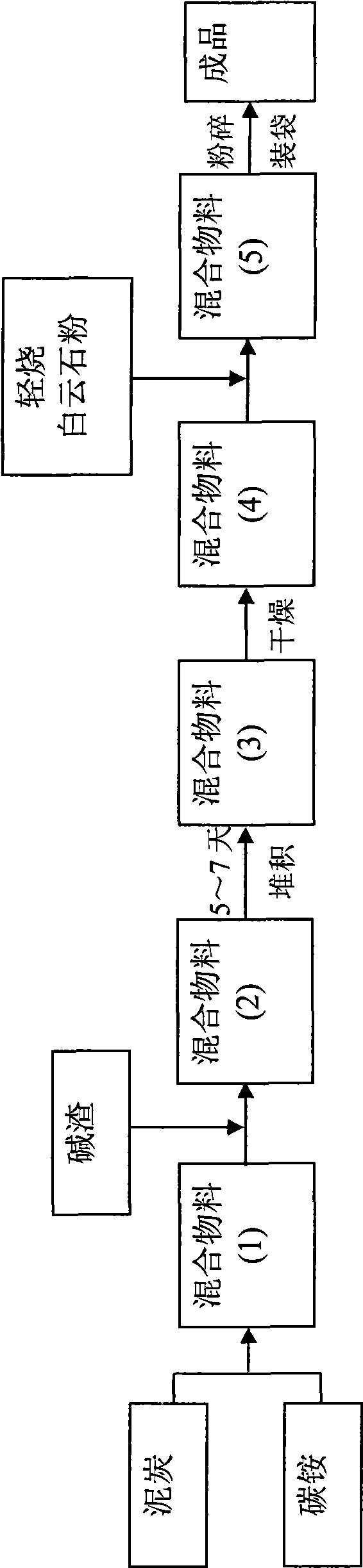

InactiveCN101544890ARaise the pHIncrease organic matterAgriculture tools and machinesOrganic fertilisersPeatMoisture absorption

The invention relates to the improvement and fertility betterment of farmland soil, particularly disclosing a fertility-betterment type soil-conditioner and the preparation method thereof. The soil conditioner is made by the following raw material of different weights: 50 to 55 portions of alkaline residue, 32 to 35 portions of peat, 12 to 14 portions of light-burned dolomite and 3 to 4 portions of ammonium bicarbonate. The preparation method is that the alkaline residue, the peat and the ammonium bicarbonate are mixed by the above weight proportion and stirred and accumulated for 5 to 7 days. Then the light-burned dolomite with the above weight proportion is added. At last, the soil conditioner is grinded and bagged. The soil conditioner of the invention has the advantages of good exterior, stable physicochemical characters, no moisture absorption and non-lumping, which can be widely used for improvement and fertility betterment of the southern acid soil and supplies balanced calcium, magnesium, and other nutrients for the crops.

Owner:广东省农业科学院土壤肥料研究所

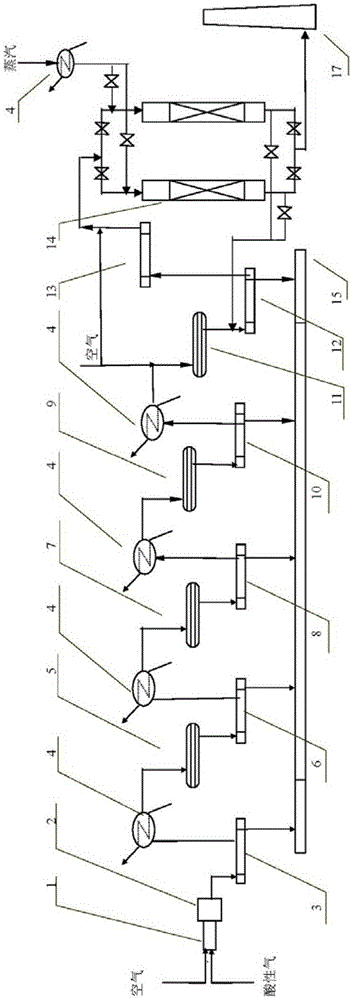

Sulfur recovery technology realizing low sulfur emission

ActiveCN105399057AHigh desulfurization precisionLow sulfur concentrationSulfur preparation/purificationCombustionConversion factor

The invention provides a sulfur recovery technology realizing low sulfur emission. The sulfur recovery technology comprises a combustion furnace, a first-stage Claus reactor, a second-stage Claus reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor and two adsorption desulfurization towers capable of being connected in series or parallel, and the devices are sequentially connected in series; the total sulfur conversion factor of process effluent gas is that SO2 is smaller than or equal to 10 mg / m<3> through proper selection of various catalysts and desulfurizers and accurate control of process conditions of steps. The desulfurizers after breakthrough are subjected to in-situ thermal regeneration by inert gas at the temperature of 250-300 DEG C, regenerated outlet gas returns to the combustion furnace, a condenser I behind the combustion furnace, a condenser II behind the first-stage Claus reactor, a condenser III behind the second-stage Claus reactor, a condenser IV behind the selective hydrogenation reduction reactor or a condenser V behind the selective oxidation reactor, sulfide such as elemental sulfur, H2S,SO2 and the like in the regenerated gas is recovered, and the total sulfur conversion factor of exhaust tail gas in the regeneration period of the desulfurization towers is that SO2 is smaller than or equal to 10 mg / m<3>. The sulfur recovery technology realizing low sulfur emission has the advantages of the low sulfur emission, the long-term operation of the desulfurizers, the high desulfurization capacity, the small number of replacement times, the low expenses and the like.

Owner:山东迅达化工集团有限公司

Treatment method of oil-containing sludge

InactiveCN108314290AHigh surface tension reduction abilityStrong flocculationDewatering/demulsification with chemical meansSludge treatment by de-watering/drying/thickeningAlkylphenolOil sludge

The invention discloses a treatment method of oil-containing sludge and belongs to the field of environmental engineering. The treatment method comprises the following steps of: introducing the oil-containing sludge into a separating groove, discharging into a deemulsifying groove for deemulsification after initially separating, and carrying out oil-water-sludge separation on deemulsified productsin an oil-sludge separating device; recovering dirt oil at the upper part, settling sludge-water mixture at the lower part, recovering clear liquor, and carrying out coagulation treatment, settling separation, mechanical dewatering, sludge drying and sludge incineration treatment in sequence on the sludge-water mixture at the bottom part and residual active sludge. Composite deemulsifying agentspreferred by the invention include a polyethylene polyamine blocked polyether deemulsifying agent, a silicon-containing deemulsifying agent, a phenolic-resin deemulsifying agent, an alkylphenol polyoxyethylene ether deemulsifying agent, a polyphosphoester deemulsifying agent or a polyaluminium-chloride deemulsifying agent. The deemulsifying method disclosed by the invention has the beneficial effects that the safe and environment-friendly effects are achieved, the water content of oil sludge can be reduced, most crude oil in the oil sludge can be recovered, and the difficulty of the followingtreatment of the sludge can be reduced.

Owner:YANGZHOU DAYANG WATER SUPPLY EQUIP

Low sulfur emission sulphur recovery process

ActiveCN105293445AHigh desulfurization precisionLow sulfur concentrationSulfur preparation/purificationTowerProcess conditions

The present invention provides a low sulfur emission sulphur recovery process, which comprises a burning furnace, a first stage Claus reactor, a second stage Claus reactor, a selective hydrogenation reduction reactor, a selective oxidation reactor, and two adsorption desulfurization towers capable of being connected in a series parallel connection manner, wherein the burning furnace, the first stage Claus reactor and the second stage Claus reactor are sequentially connected in series. According to the present invention, with the appropriate selection of each catalyst, the appropriate selection of the desulfurization agent, and the accurate control of each step process condition, the total standard sulfur in the process emission gas is that SO2 is less than or equal to 10 mg / m<3>; after the desulfurization agent penetrates, 250-300 DEG C inert gas is used to perform in-situ thermal regeneration, the regeneration outlet gas returns to the burning furnace, the condenser after the burning furnace, the condenser after the first stage Claus reactor, the condenser after the second stage Claus reactor, the condenser after the selective hydrogenation reduction reactor, or the condenser after the selective oxidation reactor to recover elemental sulfur, H2S, SO2 and other sulfides in the regeneration gas, and the total standard sulfur in the evacuation tail gas during the desulfurization tower regeneration process is that SO2 is less than or equal to 10 mg / m<3>; and the low sulfur emission sulphur recovery process has advantages of low sulfur emission, long desulfurization agent operating, high desulfurization capacity, less replacement frequency, low cost and the like.

Owner:山东迅达化工集团有限公司

Low concentration acid gas low-sulfur emission sulphur recovery process

ActiveCN105293446AExtend your lifeLarge amount of desulfurizationEnergy inputSulfur preparation/purificationChemistryScrap

The present invention provides a low concentration acid gas low-sulfur emission sulphur recovery process. According to the present invention, low concentration acid gas having a H2S content of less than 5% is treated by a selective oxidation reactor and two adsorption desulfurization towers capable of being connected in a series parallel connection manner so as to achieve the desulfurization purpose; a H2S selective oxidation catalyst is filled in the selective oxidation reactor, and a thermal renewable catalytic oxidation adsorption desulfurization agent is filled in the adsorption desulfurization tower; with the appropriate selections of the catalyst and the desulfurization agent, and the accurate control of each step process condition, the total standard sulfur in the process emission gas is that SO2 is less than or equal to 10 mg / m<3>; with the thermal regeneration, the service life and the desulfurization capacity of the catalytic oxidation adsorption desulfurization agent are substantially improved; and the process has advantages of low-sulfur emission, sulphur recovery rate of close to 100%, long desulfurization agent service life, high desulfurization capacity, less replacement frequency, low cost, good desulfurization agent unloading and scrap treatment conditions, safety, and the like.

Owner:山东迅达化工集团有限公司

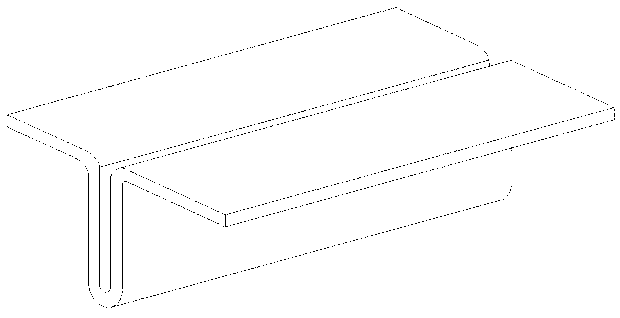

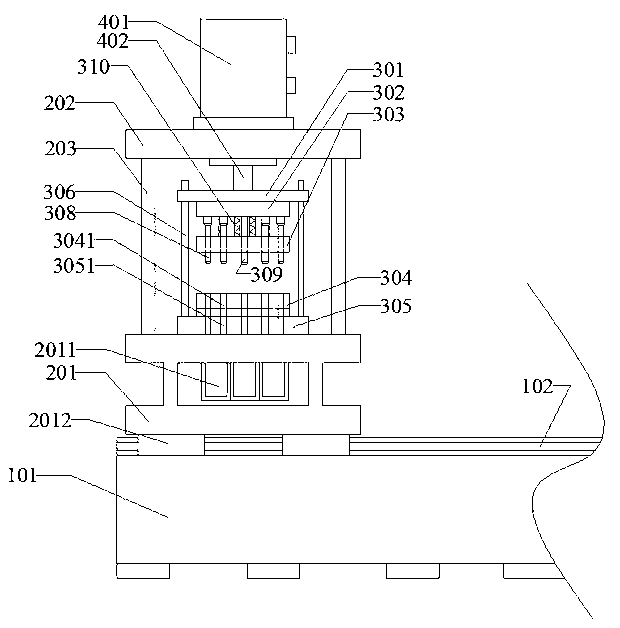

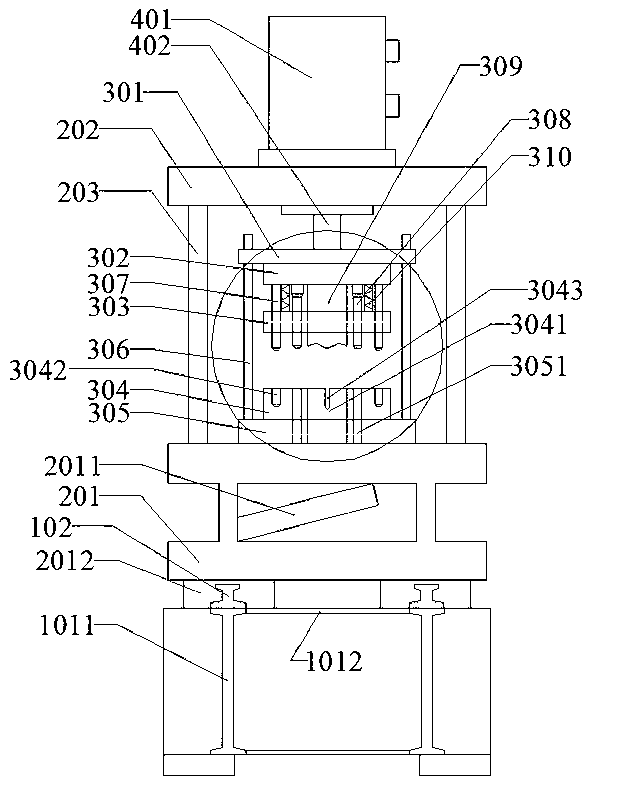

Continuous punching and shearing machine

The invention discloses an on-line continuous punching and shearing machine suitable for hollow guide rails. The continuous punching and shearing machine comprises a reciprocating running system, a punching system and a control system. The reciprocating running system comprises a slide rail base, a sliding execution member arranged inside the slide rail base and a slide rail which is disposed on the bottom surface of the slide rail base. The punching system comprises a movable die frame, a die group and a hydraulic execution member, wherein the movable die frame can move on the slide rail base along the slide rail, the die group is used for punching and shearing, and the hydraulic execution member is used for driving the die group to act. The control system comprises a master controller used for controlling the sliding execution member and the hydraulic execution member. The continuous punching and shearing machine has the advantages that field environments are improved, punching and shearing processes are combined, the production efficiency is greatly improved, the occupied area of processes is reduced, costs caused by back-and-forth transportation by workers are reduced, the labor intensity is reduced, a rodless cylinder is used for transmission, the structure is compact, the precision is high, and sizes of guide rails can be well guaranteed during shearing.

Owner:长江润发(张家港)机械有限公司

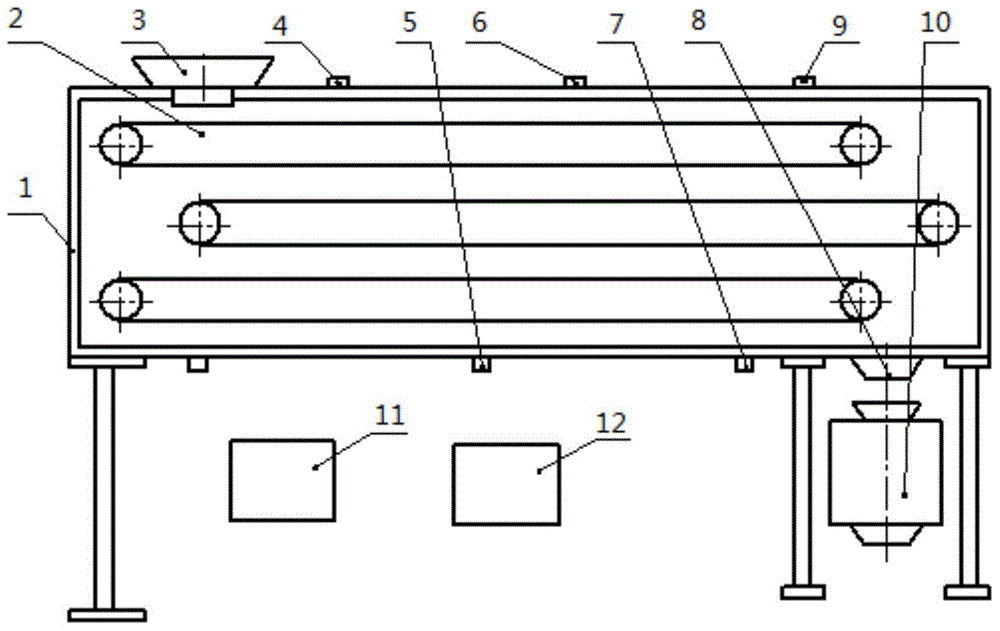

System and method of removing green peels of walnuts through ethylene gas ripening

ActiveCN104544491AReduce moisture contentThe amount of liquid squeezed out is reducedHuskingHullingRipeningBreakage rate

The invention discloses a system and a method of removing green peels of walnuts through ethylene gas ripening. Green-peeled walnuts are poured into a box from a feeder and dropped onto a top wire mesh conveying belt in the box, the green-peeled walnuts are slowly conveyed from an entry of the box to an exit of the box, and a gas ethylene generator enters the box during conveying and performs ethylene gas ripening to the green peels of the walnuts; after the green peels are ripened, the walnuts directly fall into a rubbing stripping unit from the tail end of a bottom wire mesh conveying belt, and the green peels and inner hard shells of the walnuts are separated. Gas ethylene is used to ripen the green peels o the walnuts and remove the green peels; removal rate of the green peels is high; breakage rate is low; yield of commercial walnuts is high; efficiency is high; the use of the gas ethylene in ripening the green peels prevents kernels from being contaminated, resulting in food contamination; meanwhile, the processing process is green.

Owner:SHAANXI UNIV OF SCI & TECH

Drafting frame and operating process

ActiveCN102704159AAvoid damageNot easy to knock downAuxillary apparatusStructural engineeringMechanical engineering

The invention relates to a drafting frame. The drafting frame comprises two underframes, warp beam supports, a drafting bracket, pull ropes, harness wire brackets, reed supporting rods, a warp thread supporting rod, reed supporting plate movable brackets and warp beam limiters, wherein a warp beam limiter is arranged at the rear end of each underframe of the drafting frame, and each warp beam support is arranged behind the warp beam limiter; warp threads are arranged in each warp beam support; the drafting bracket is arranged on the underframes; the brackets are arranged on the top of the drafting bracket, and a reed supporting plate is placed in the brackets; rear supporting rods are arranged on the rear side of the middle upper part of the drafting bracket, hooks are arranged on the rear supporting rods, and the pull ropes are arranged on the hooks of the rear supporting rods to lift up the warp thread supporting rod; the drafting bracket is supported by the supporting rods, and two harness wire brackets are sleeved on each supporting rod; and one reed supporting plate movable bracket is arranged between an upper harness wire bracket and a lower harness wire bracket on each supporting rod on the outer side of the drafting bracket. By designing the structure, compared with another drafting frame with the same type, the drafting frame is easier to operate, and is wider in application.

Owner:WUJIANG FUHUA WEAVING

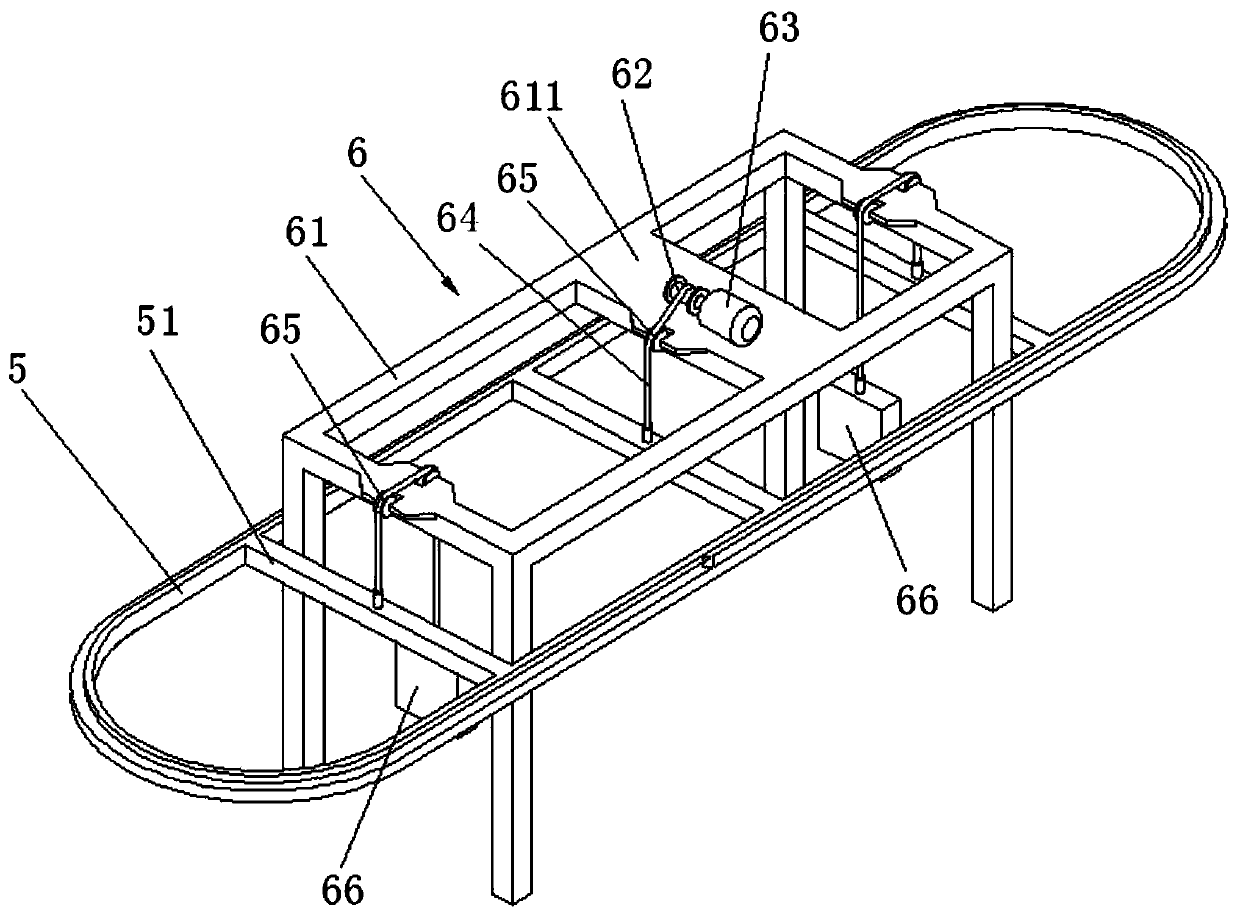

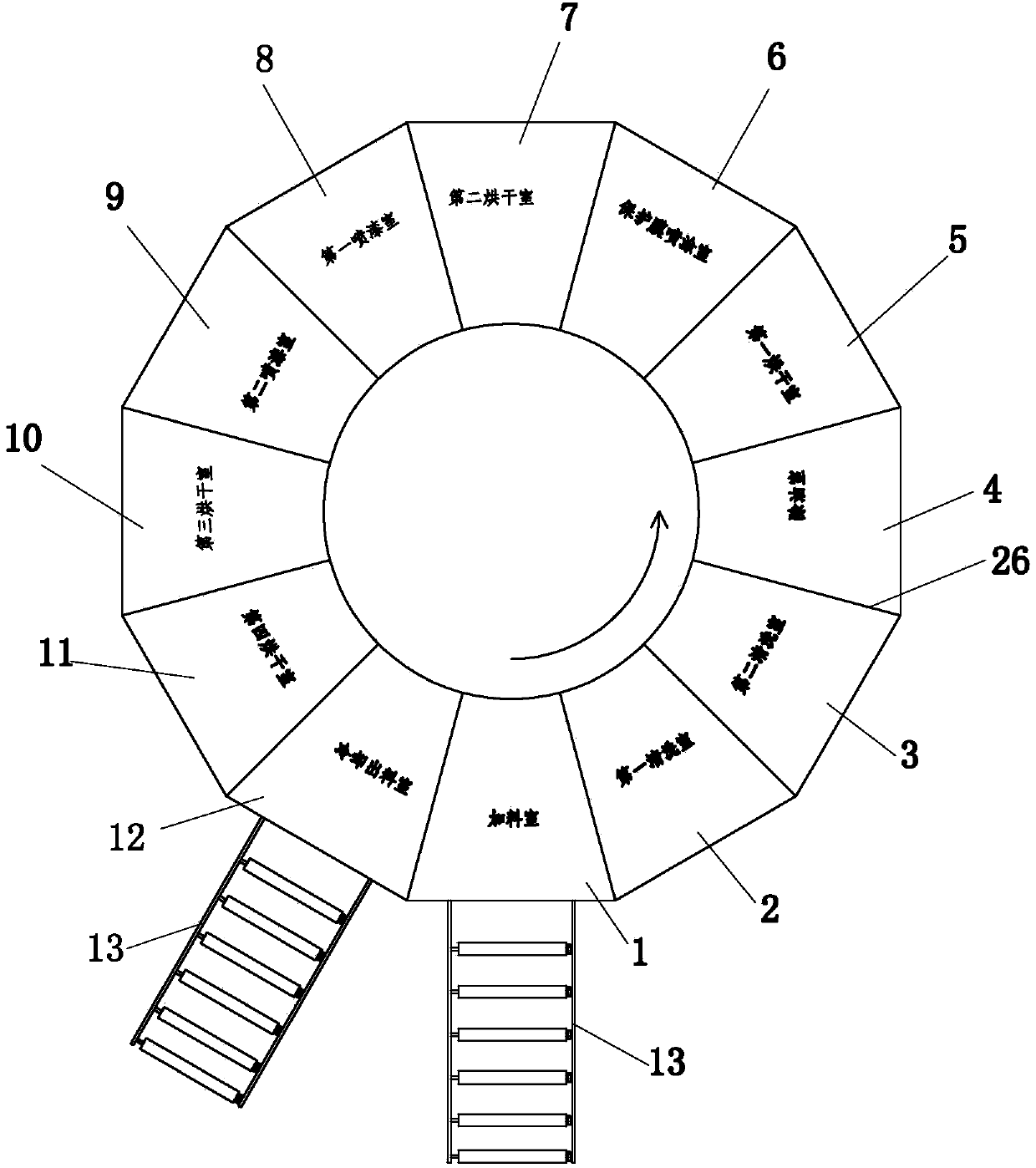

Automatic paint spraying method of zipper heads

ActiveCN103464353AIncrease productivityImprove qualityPretreated surfacesCoatingsEngineeringProcess design

The invention provides an automatic paint spraying method of zipper heads. The zipper heads are arranged in holding tools through automatic conveying devices quantitatively; through holes are distributed in the body walls of the holding tools; the holding tools which are provided with the zipper heads continuously and sequentially pass through a plurality of station chambers intermittently; every working procedure which is determined by the process design is achieved in the station chambers through the holding tools which are in the rotation state when the working procedures are accepted by the zipper heads; the station chambers are in head-tail connection to form an annular shape; the zipper heads are discharged out of the holding tools after the last working procedure is achieved. According to the automatic paint spraying method of the zipper heads, the working procedures required by paint spraying can be performed on the zipper heads continuously and manual flow is not required between the working procedures, so that the production efficiency is improved, the labor intensity of workers is reduced, meanwhile the standardized operation can be achieved, the quality of the paint spraying is easy to guarantee, the product quality is uniform, the qualified rate is high, and the site environment and the resource waste are also greatly improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

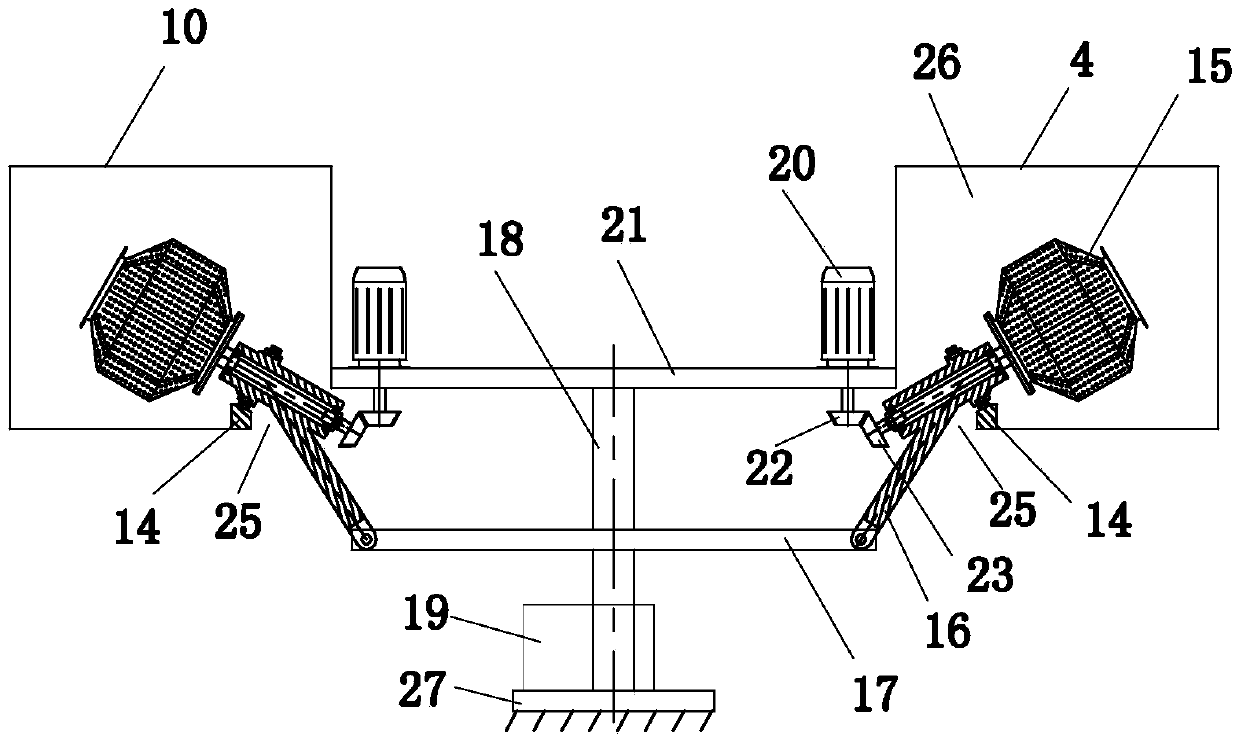

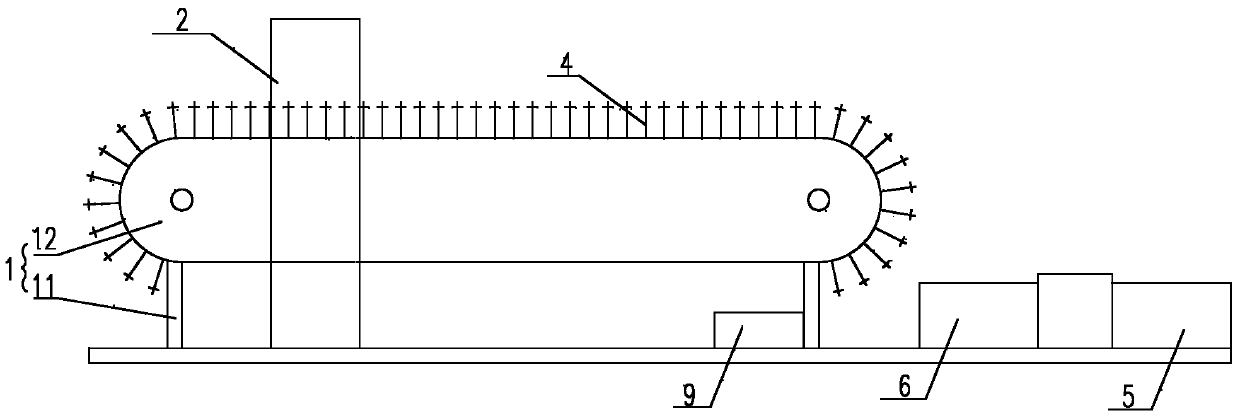

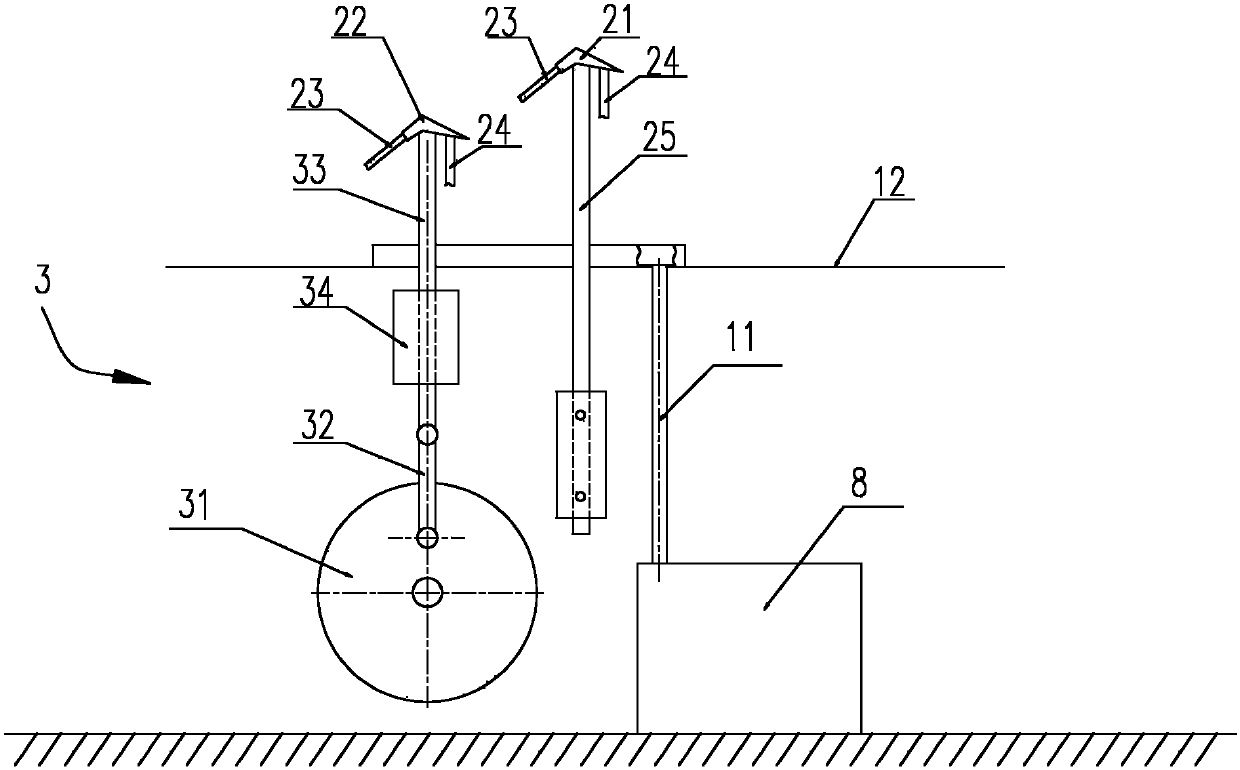

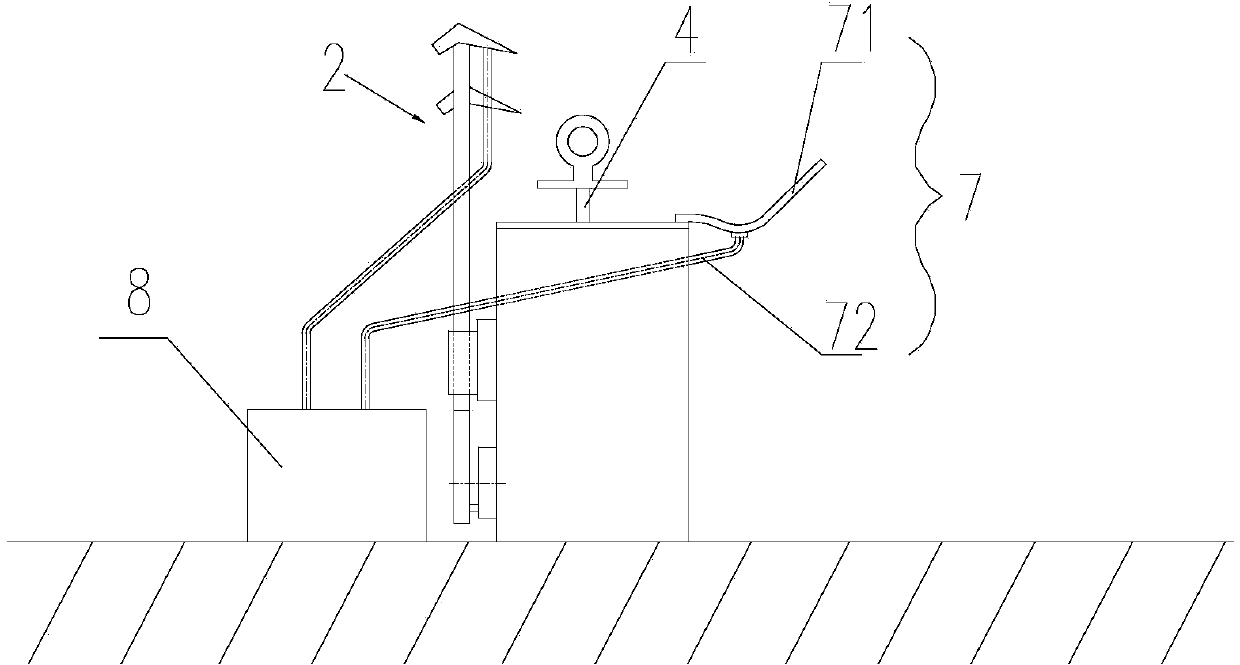

Automatic paint spraying system

ActiveCN104174530ASimple structureEasy to operateSpraying apparatusCleaning using toolsReciprocating motionEngineering

The invention discloses an automatic paint spraying system comprises a circulating conveying device and a paint spraying mechanism which is arranged on one side of the circulating conveying device. The paint spraying mechanism comprises a dynamic spray gun and a static spray gun which are arranged side by side. The dynamic spray gun is driven by a spray gun driving device to do vertically reciprocating motions. The static spray gun is fixed on one side of the circulating conveying device. A workpiece loading seat is mounted on the circulating conveying device and, under driving of a rotation mechanism, rotates when moving on a relative position of the paint spraying mechanism. A paint mist recycling system is arranged on one side of the circulating conveying device. The automatic paint spraying system is simple in structure, convenient to operate, efficient in paint spraying and high in paint use ration. Compared with the manual paint spraying, the automatic paint spraying system has the advantages that work efficiency is improved by 30 times, spray mist discharging is decreased by 70% or above, the paint use ration is increased by 3 times or above, live environment of the paint spraying plants is greatly improved, and occupational damages and skill requirements for the operator are reduced.

Owner:CHONGQING CHENGYUAN MACHINERY

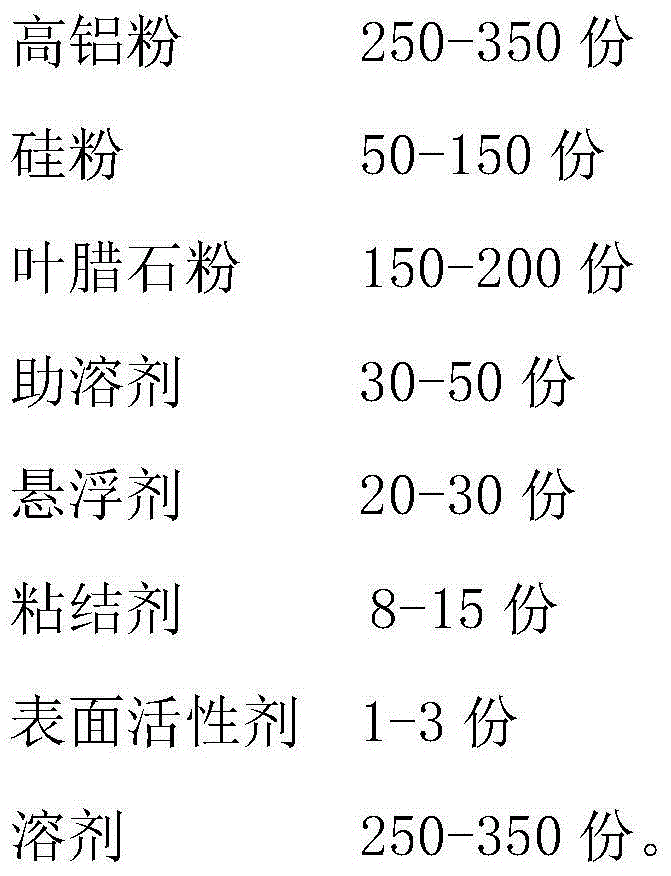

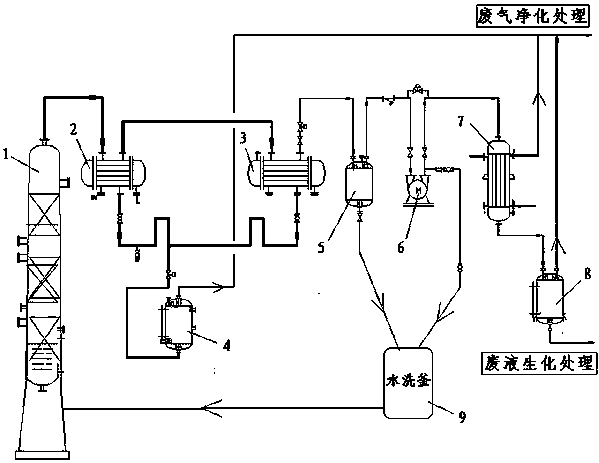

Environment-friendly alcohol group ceramic casting coating

ActiveCN104439049AGood sintering peeling propertiesImprove peeling effectFoundry mouldsFoundry coresSolventAluminium

The invention provides an environment-friendly alcohol group ceramic casting coating. The environment-friendly alcohol group ceramic casting coating comprises, by weight, 250-350 parts of high-alumina powder, 50-150 parts of silica powder, 150-200 parts of pyrophillite powder, 30-50 parts of cosolvent, 20-30 parts of suspending agents, 8-15 parts of binding agents, 1-3 parts of surfactant and 250-350 parts of solvent. The environment-friendly alcohol group ceramic casting coating overcomes the defects in the prior art and is high in refractoriness, good in sintering stripping effect, low in price and excellent in comprehensive performance.

Owner:TIANJIN NINGKANG TECH

Method for extracting nickel from copper electrolysis effluent

InactiveCN103725888ASimple and fast operationImprove separation efficiencyProcess efficiency improvementElectricityLiquid waste

The invention relates to a method for extracting nickel from a copper electrolysis effluent and relates to a method for comprehensively treating the copper electrolysis effluent. The method is characterized by comprising the extraction steps as follows: (1) copper removal is performed on the copper electrolysis effluent through electrowinning; (2) the copper removal end solution is subjected to acid and nickel salt separation to produce a recovered acid liquor and a recovered nickel liquor; (3), the recovered acid liquid obtained in the step (2) is returned to an electrolysis system, and the recovered nickel liquor is subjected to crude nickel sulfate production. The method is strong in nickel removal treatment capacity, the whole production process is closed, acid fog is not generated, and the environment protection is achieved; except the running of a pump, other electricity consumption does not exist, and the production cost is low; the product is a green nickel sulfate crystal with better physical appearance, and has stable quality.

Owner:JINCHUAN GROUP LIMITED

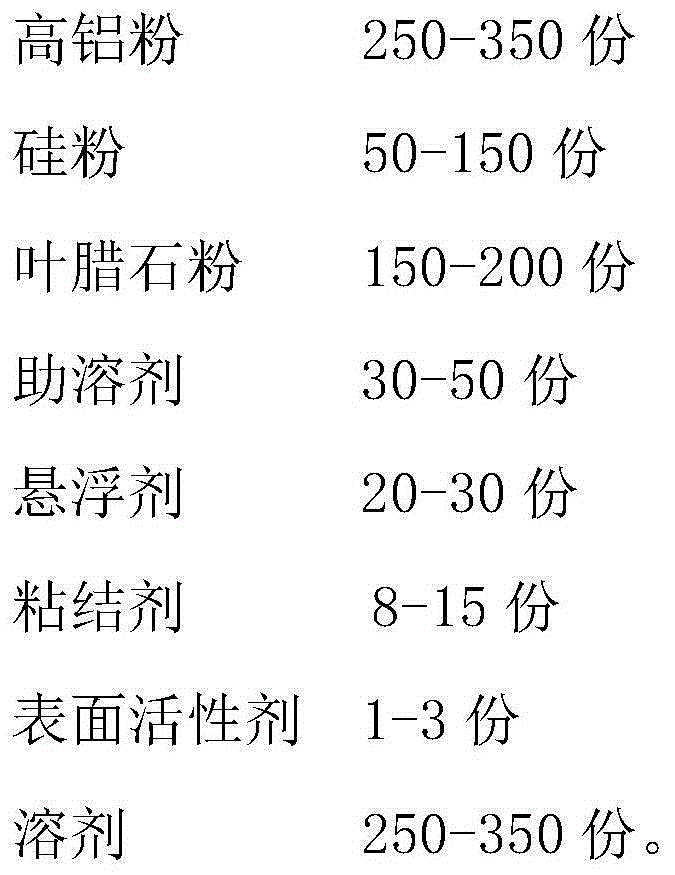

Trimethyl phosphite continuous reduced-pressure rectifying technology

InactiveCN107840858AReduce wearHigh tail gas recovery rateGroup 5/15 element organic compoundsExhaust gasSalt water

The invention discloses a trimethyl phosphite continuous reduced-pressure rectifying technology. A first-level water cooling condenser and a second-level salt water condenser are arranged at the top of a rectifying tower; a gas phase temperature at the top of a control tower is lower than 0 DEG C; after two levels of condensation, the gas phase is demisted by a demister and finally enters a vacuumpump; pressures in the control tower and the rectifying tower are negative pressures. After being condensed by the first-level condenser and the second-level condenser, liquid enters a rectifying reflux tank; the liquid after third-level condensation enters a receiving tank. The technology disclosed by the invention remarkably reduces loss of trimethyl phosphite, has high yield, lowers abrasion of the vacuum pump and realizes high recovery rate of tail gas.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

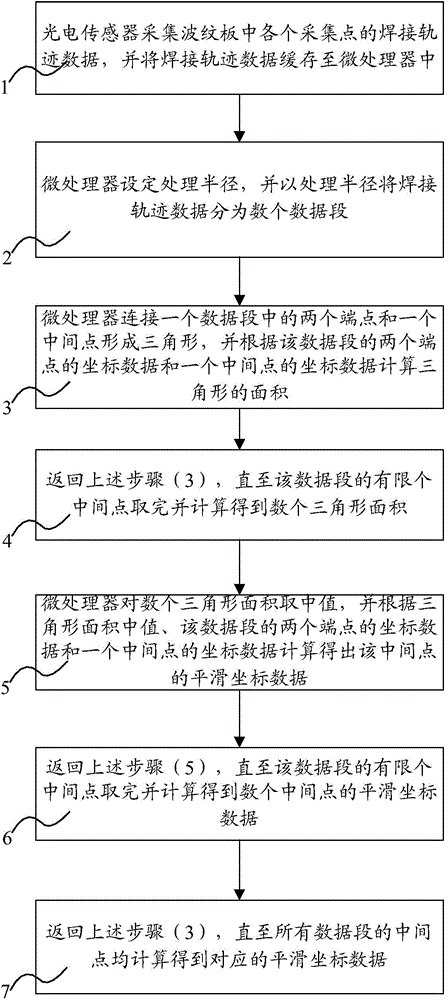

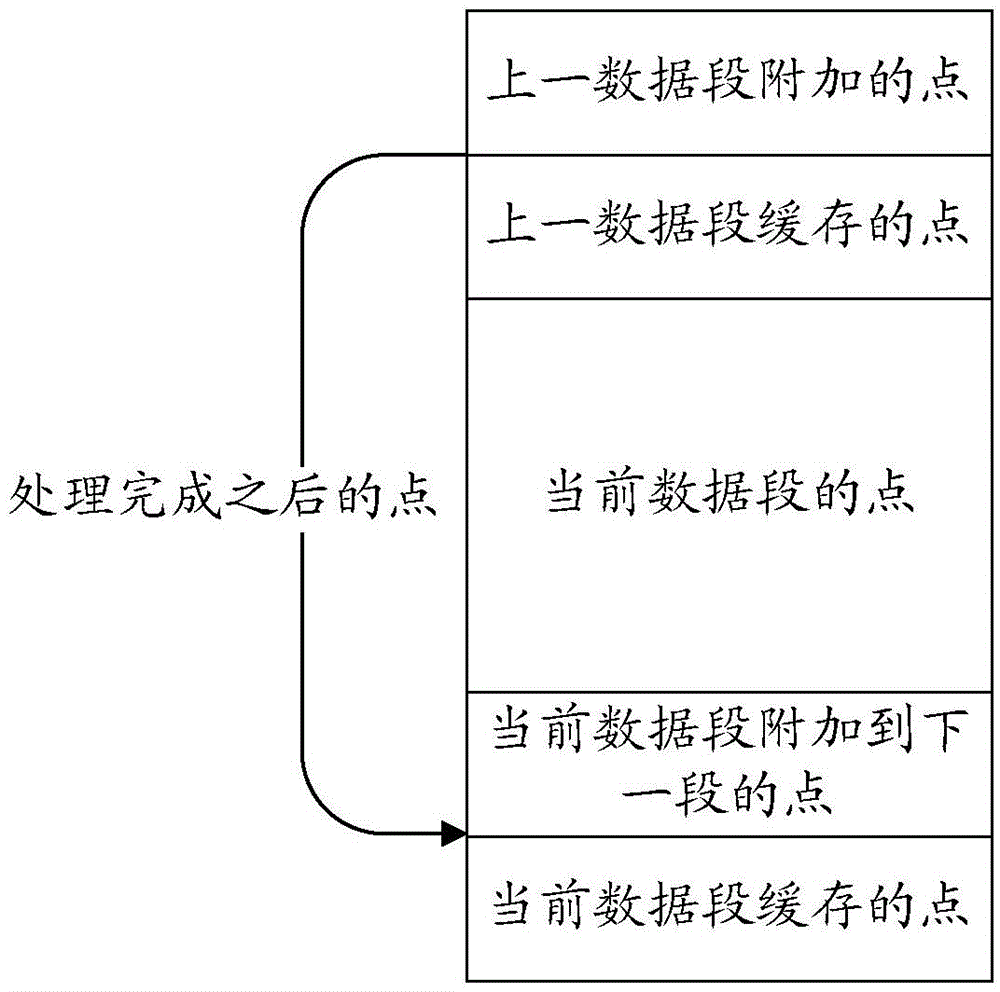

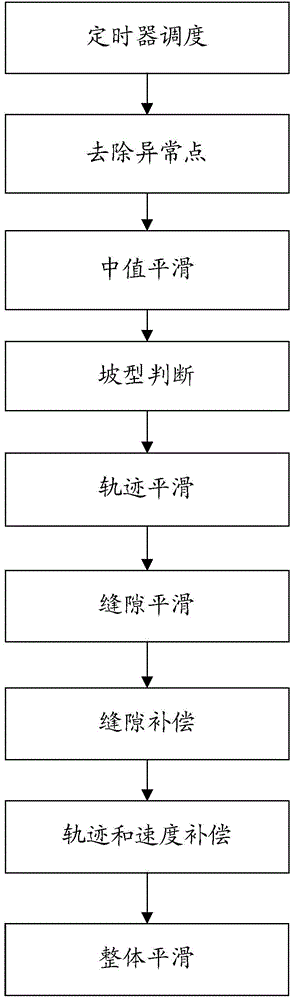

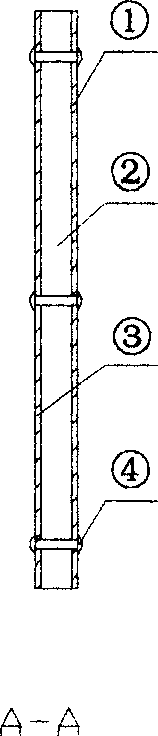

Corrugated plate welding track data smoothing method and system

ActiveCN104148777AReduce weldingImprove the site environmentWelding/cutting auxillary devicesArc welding apparatusData acquisitionEngineering

The invention relates to a corrugated plate welding track data smoothing method. The method comprises welding track data collection and welding track data smoothing. The invention further relates to a corrugated plate welding track data smoothing system. The system comprises a microprocessor and a photoelectric sensor, wherein the microprocessor comprises a welding track smoothing module, a compensation module and a data storage module. According to the corrugated plate welding track data smoothing method and system, collected data can be processed in real time during corrugated plate welding track data collection, the movement of a welding gun is controlled finally according to the information, automatic welding is achieved under the condition that the angle of the welding gun is fixed, the influence of heating deformation during welding is reduced, welding efficiency and quality are improved, cost is saved, portability is high, and the application range is wider.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH

Repeatedly used thermal insulation quilt and its application method

A cyclically used insulating shield is composed a main body consisting of internal layer, insulating layer, external layer and fire-proof layers on said internal and external layers, and the connecting mechanisms for the connection between said shields. It has high insulating, water-proof, fire-proof and oil-resistant functions.

Owner:北京英特莱科技有限公司

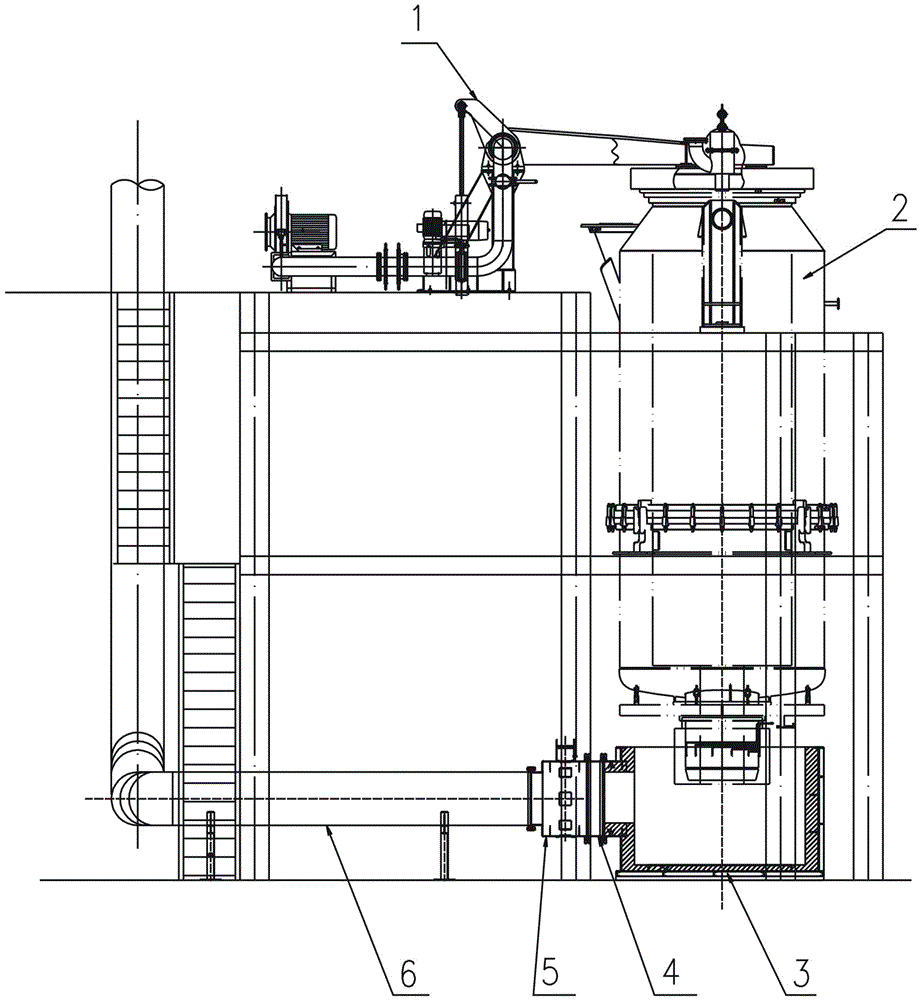

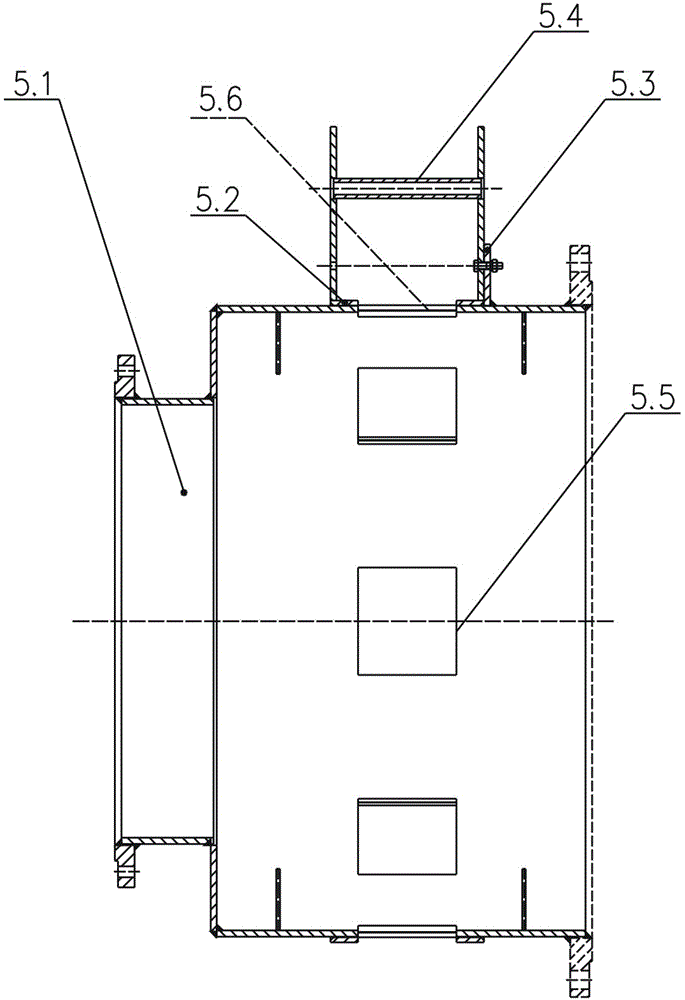

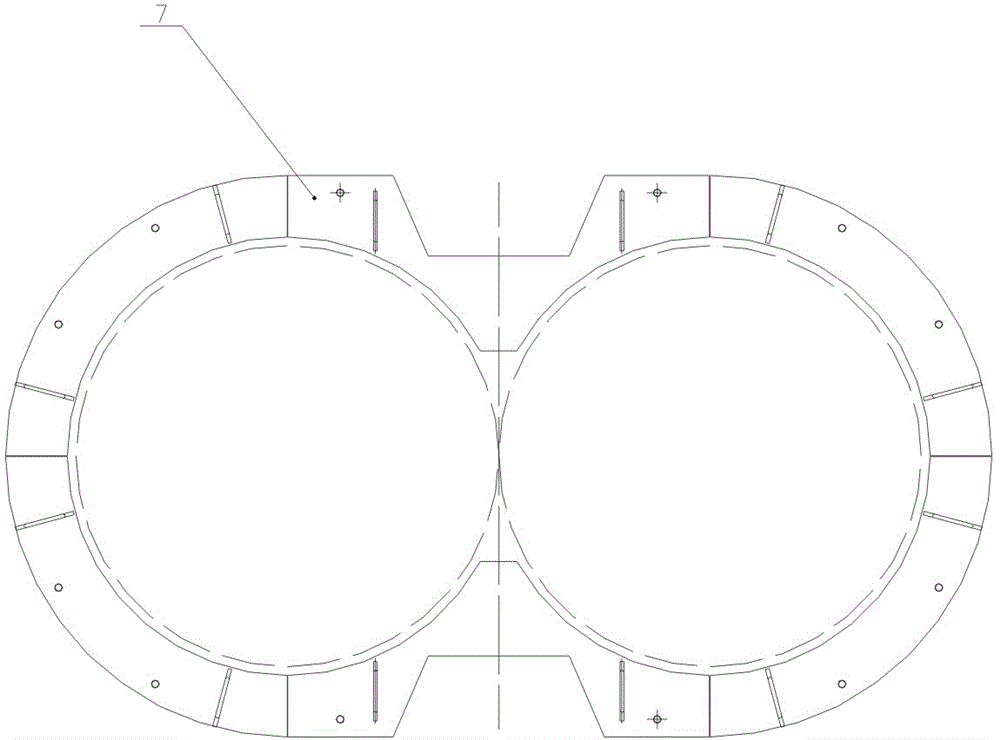

RH vacuum chamber baking system

InactiveCN102978344AControlled heatingGuaranteed baking qualityMelt-holding vesselsRetention timeProcess engineering

The invention discloses a RH vacuum chamber baking system which comprises a vacuum chamber baking device and a vacuum chamber, wherein the vacuum chamber baking device is provided with a baking cover; the baking cover is matched with the upper part of the vacuum chamber; a vacuum chamber insert tube is connected with a waste gas box; the waste gas box is provided with an exhaust port; the exhaust port of the waste heat box is connected with an air mixer through a control valve; and the air mixer is connected with a waste gas duct. By arranging the baking cover and control valve, in the vacuum chamber drying process, the opening of the control valve is reduced, the retention time of baking hot gas in the vacuum chamber is prolonged, the loss of heat is avoided maximally, and the heating of the baking waste gas on the lower part of the vacuum chamber can be effectively controlled, thereby promoting the temperature uniformity of the refractory material in the vacuum chamber; and in the vacuum chamber baking process, the control valve can be adjusted to control the flow rate of the waste gas by utilizing the draft formed by the chimney effect of the waste gas duct, thereby ensuring the baking speed and baking quality of the vacuum chamber.

Owner:WISDRI ENG & RES INC LTD

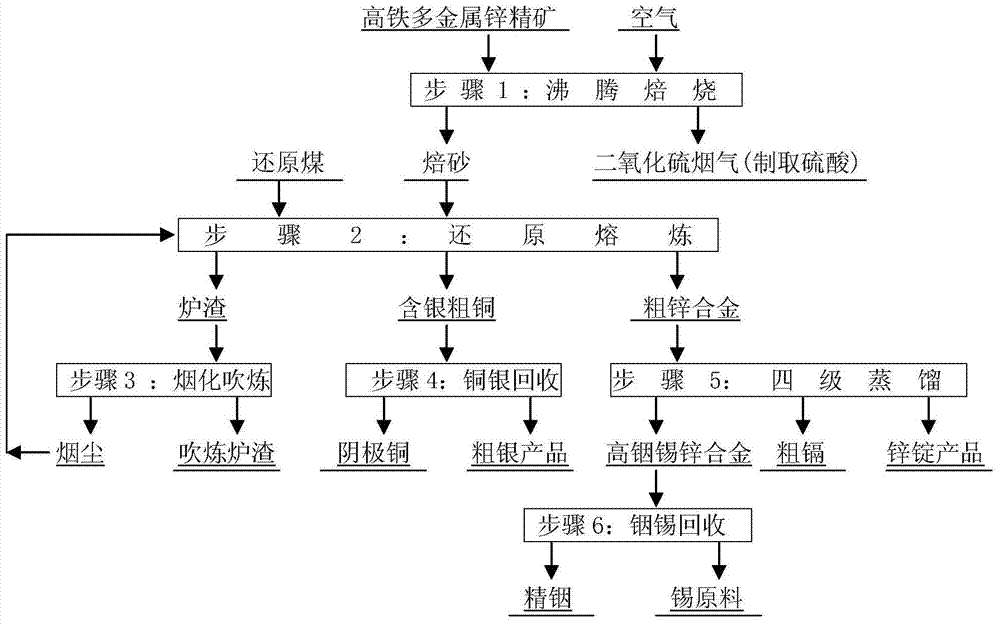

Method for treating high-iron and multi-metal zinc concentrate

ActiveCN103695635AEfficient recyclingAdvanced technical indicatorsPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention discloses a method for treating high-iron and multi-metal zinc concentrate. The method comprises the following steps of: boiling and roasting zinc concentrate containing 14-20 percent of Fe, 0.03-0.10 percent of In, 0.2-0.6 percent of Cu, 0.2-0.6 percent of Cd, 0.005-0.02 percent of Ag. 0.1-0.2 percent of Sn and 40-50 percent of Zn to produce flue gas and a roasted product; preparing sulfuric acid by using the flue gas; blending the roasted product in a reducing agent to be reduced and smelted to produce a crude zinc alloy, crude silver-containing copper and furnace cinder; blowing the furnace cinder to obtain soot and blown furnace cinder, returning the soot to be reduced and smelted, and selling the blown furnace cinder; extracting copper and silver from crude silver-containing copper; enabling the crude zinc alloy to enter a conventional distillation tower for performing four stages of distillation to produce a pyrogenic process distilled zinc product, a crude cadmium product and a high-indium, tin and zinc alloy; extracting indium and tin from the high-indium, tin and zinc alloy. The method is reasonable in process, good in comprehensive recovery, high in production efficiency, low in product cost, and clean and environment-friendly in production process.

Owner:LAIBIN CHINA TIN SMELTING

Bag-holding structure of air-bag tension holding type for valve mouth balance

The invention relates to the packing mechanism which is the air-cell swelling-sack holding structure used on the discharge mouth of the valve port balance. The air discharging pipes are out of the discharge mouth and between which and the pipe forms exhaust duct. The character is in that: the air cell is set besides of the exhaust pipe; the two ends of air cell are connected to the outside of exhaust pipe; the air pipe blowing to the air cell is set on the exhaust out pipe according to the air cell.

Owner:邱恩博

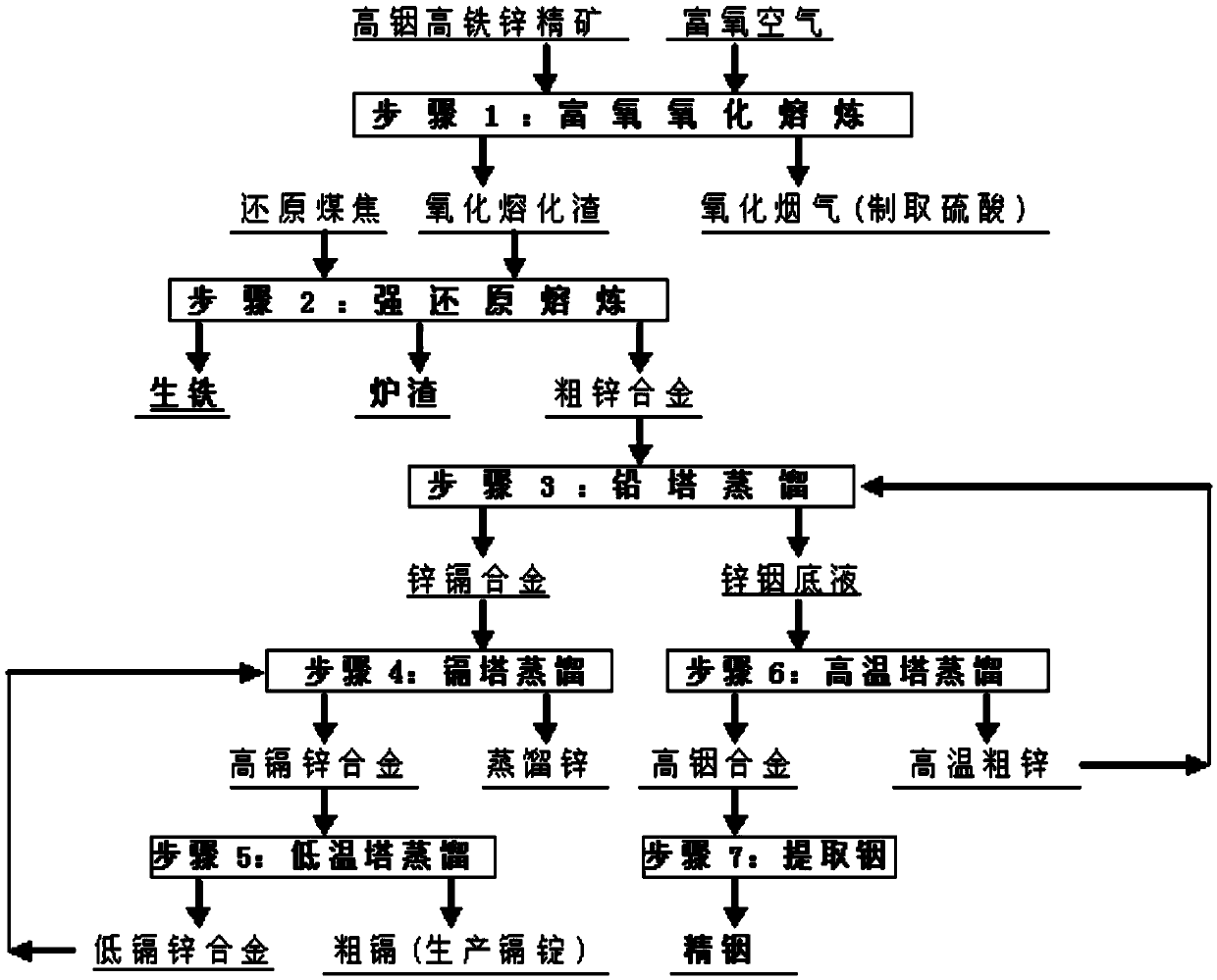

Method for processing zinc concentrate with high content of indium and iron

The invention discloses a method for processing zinc concentrate with high content of indium and iron. The method comprises steps of carrying out oxygen-enriched oxidizing smelting on the zinc concentrate so as to generate oxidized smoke and fused slag, preparing sulfuric acid through the oxidized smoke; allowing the fused slag to enter a reducing smelting furnace with a lead rain condenser for strong reduction smelting so as to generate crude zinc alloy, pig iron and slag; allowing the crude zinc alloy to enter a lead tower for distilling so as to generate a zinc-cadmium alloy and a zinc-indium base solution; allowing the zinc-cadmium alloy to enter a cadmium tower for secondary distilling so as to produce pyrogenic process distilled zinc and high cadmium-zinc alloy; casting and cooling down the pyrogenic process distilled zinc so as to obtain a zinc ingot product, distilling the high cadmium-zinc alloy in a low temperature tower so as to obtain crude cadmium and a low cadmium-zinc alloy, returning the low cadmium-zinc alloy back to the cadmium tower for distilling; distilling the zinc-indium base solution in a high temperature tower so as to generate a high indium alloy and high temperature crude zinc, returning the high temperature crude zinc back to the lead tower for distilling, and extracting indium from the high indium alloy through steps of 'crushing-leaching-extracting-replacing-electrolyzing'. The method has short technological processes and high production efficiency, has clean and environment-friendly production process, and does not discharge three wastes.

Owner:CENT SOUTH UNIV

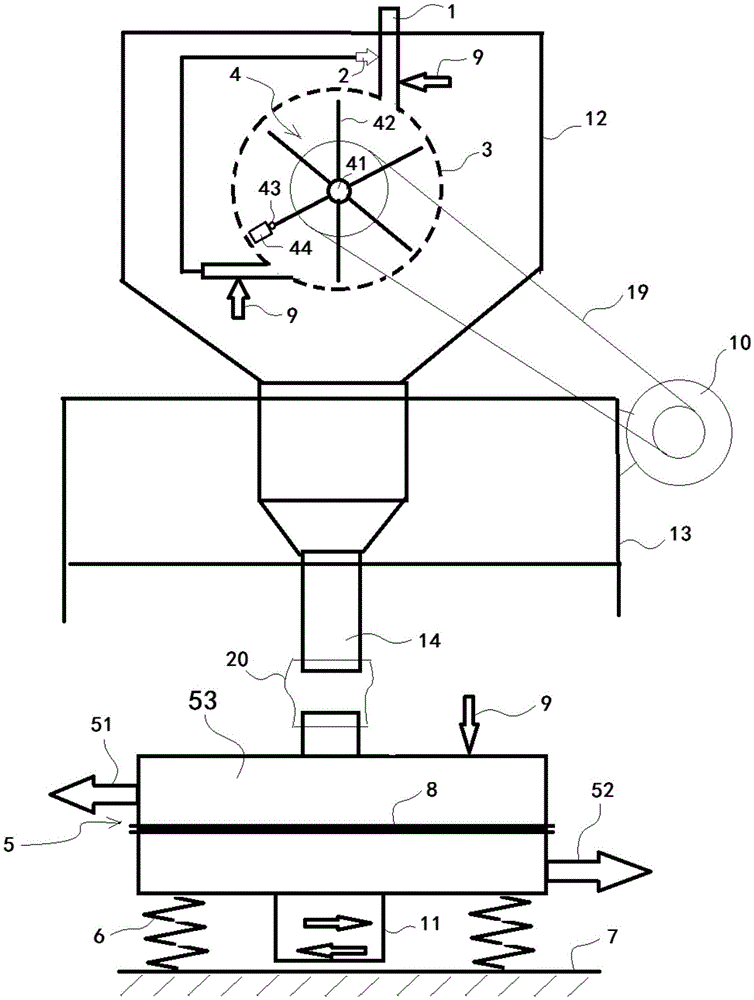

Crushing and screening device for materials

InactiveCN105521863AGuaranteed high speed operationSmooth speed regulationSievingScreeningFrequency conversionElectric machinery

The invention discloses a crushing and screening device for materials. The crushing and screening device is characterized by comprising a charge device, a crushing device and a screening device, wherein the charge device is communicated with a shell; the crushing device is arranged in the shell, and provided with a filter screen at the periphery; and the screening device is located below the crushing device. Preferably, the materials are alloy sheets; the charge device comprises a charge nozzle and a loop from the filter screen to the charge nozzle; an inert gas inlet is arranged in the top of the charge nozzle and the bottom of a stainless steel elbow pipe respectively; the crushing device is provided with a drive motor; the screening device is provided with a vibration motor; the drive motor is a special frequency conversion motor; and the special frequency conversion motor is controlled by a frequency converter. The crushing and screening device disclosed by the invention is simple in structure, simple and convenient to operate overall, stable and reliable in running, low in noise, less in raising dust, good in field environment, and capable of effectively preventing frictional sparking generated by ultrafine powder grains with a pipe wall during a high-speed rotation process, thus safety performance is greatly improved.

Owner:江西江钨稀有金属新材料股份有限公司

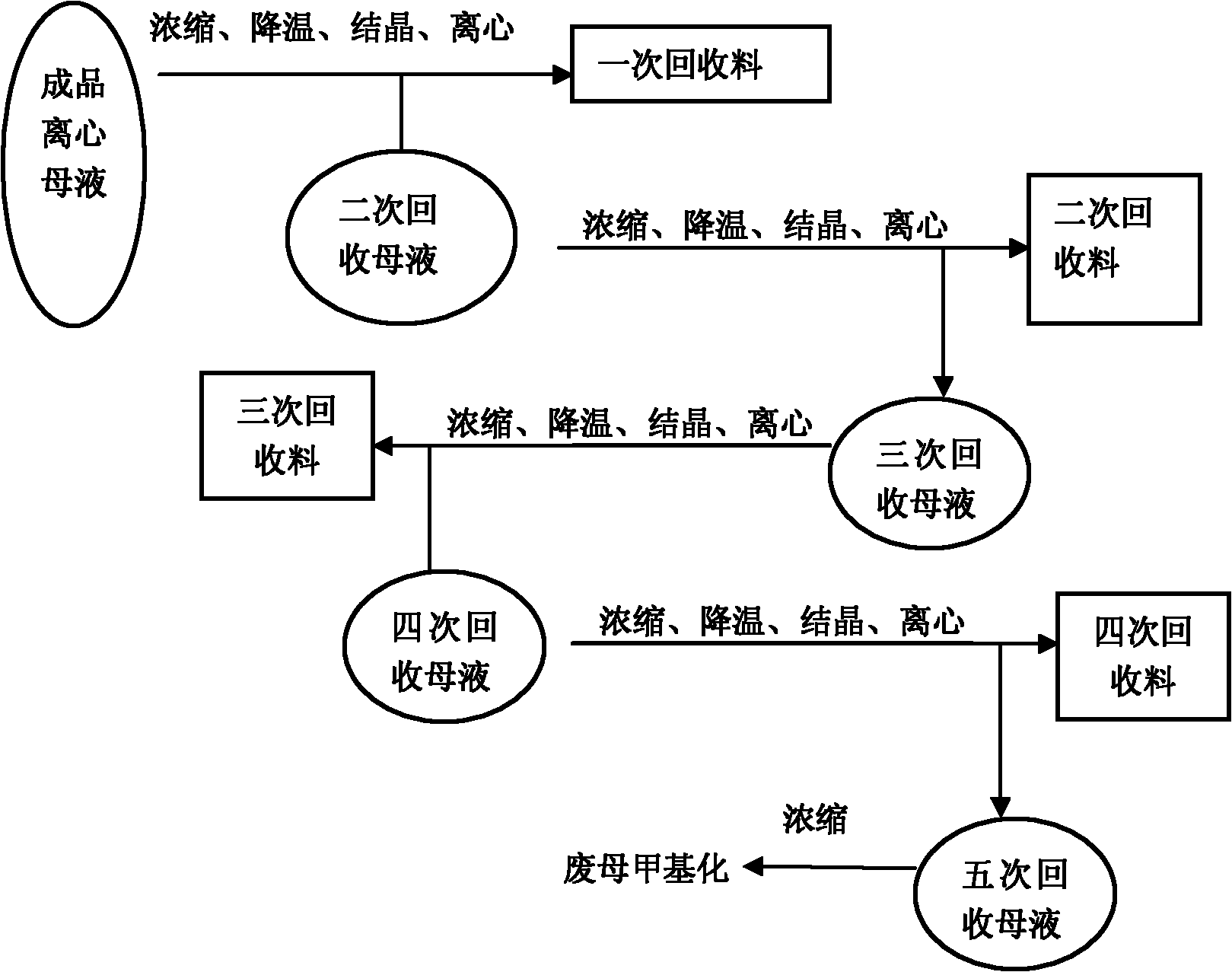

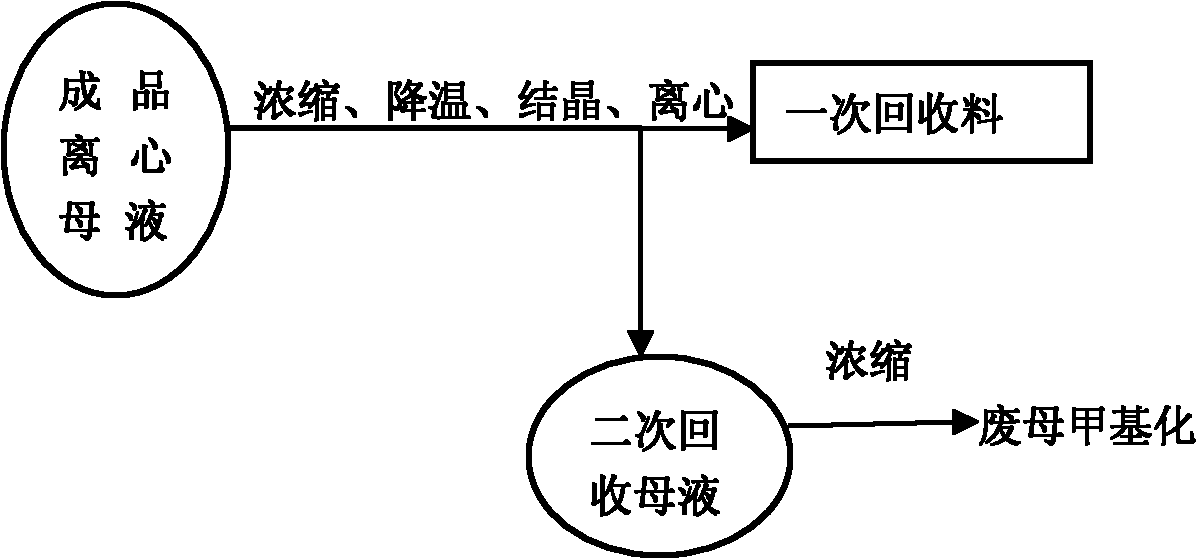

Recovery process of analginum finished product centrifugal mother liquid

ActiveCN102584706ASimple processIncrease crystallization rateOrganic chemistryOrganic solventCentrifugation

The invention belongs to the field of medicine chemical and particularly relates to a recovery process of analginum finished product centrifugal mother liquid. Firstly, the analginum finished product centrifugal mother liquid is concentrated, then, organic solvents are added into concretes for dissolution, and analginum primary recovery materials and secondary recovery mother liquid are prepared through temperature reduction, crystallization and centrifugation. The recovery process provided by the invention has the advantages that the process is simple, the content in the analginum primary recovery materials can reach 77 to 80 percent, and the crystallization rate of the finished product centrifugation mother liquid reaches 84 to 92 percent. The centrifugation rate is improved, the analginum content in the secondary recovery mother liquid only accounts for 3 to 5 percent of the total theoretical quantity of the analginum, and the secondary recovery mother liquid can be directly delivered to aminopyrine waste mother liquid methylation posts. The recovery temperature reduction problem of secondary recovery mother liquid to quartic recovery mother liquid is avoided. An open type stainless steel groove can be directly removed, the in-site environment is obviously improved, and the recovery process more perfectly conforms to the environment-protection and audit requirement. The analginum recovery purity is high, the crystallization rate is high, the pollution is avoided, and the industrial production is easily realized.

Owner:SHANDONG XINHUA PHARMA CO LTD

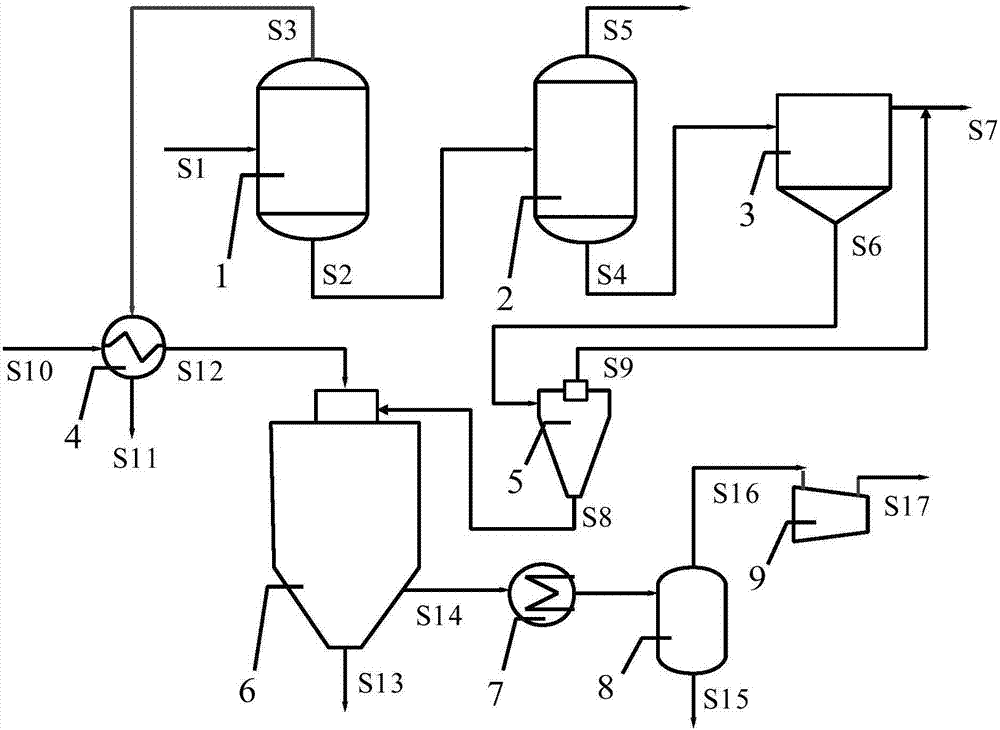

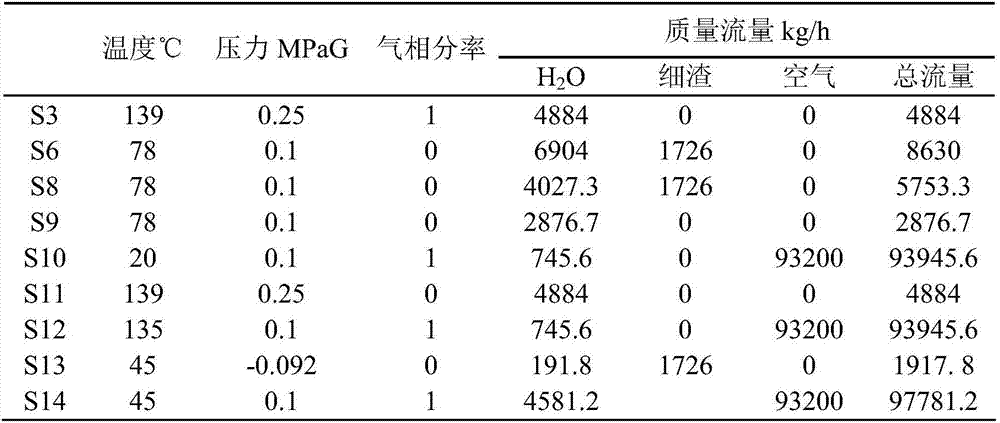

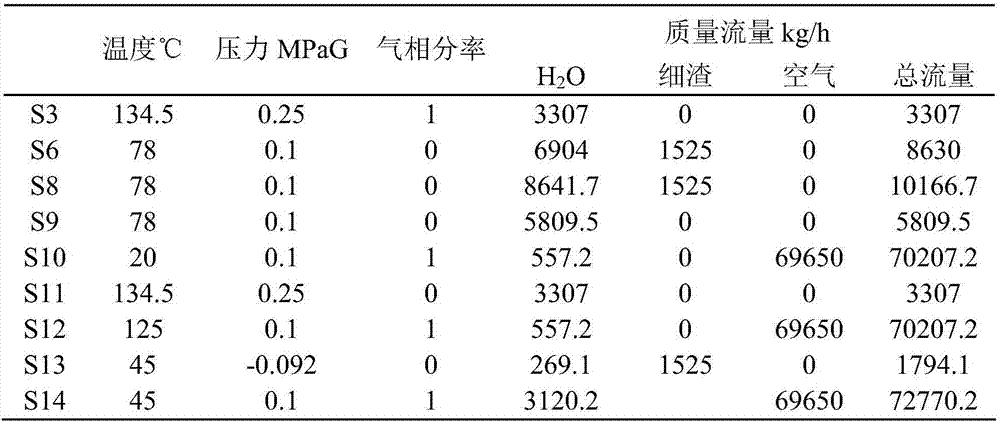

Dewatering drying method for fine slag slurry in coal gasification system and dewatering drying system used by dewatering drying method

InactiveCN107162102ATake advantage ofImprove utilization efficiencyGas treatmentSpecific water treatment objectivesSlagSpray dried

The invention discloses a dewatering drying method for fine slag slurry in coal gasification system, which comprises the following steps that (a) the fine slag slurry produced by the coal gasification system is pre-dewatered by a pre-dehydration and concentration device to obtain the concentrated fine slag slurry; (b) a waste heat resource produced by the coal gasification system exchanges heat with air for heating the air into hot air; (c) the concentrated fine slag slurry and the hot air are fed into a spray dryer at the same time, so that heat and mass transfer is carried out by the direct contact between the concentrated fine slag slurry and the hot air in the spray dryer, and after most of the water is removed, the concentrated fine slag slurry flows out at the bottom and becomes dry fine slag. The invention also discloses a dewatering drying system used by the method. According to the method, the waste heat resource produced by the coal gasification system is used for heating the air, and then the heated hot air is used for drying the concentrated fine slag slurry by a spray dewatering drying technology, so that the waste heat resource can be fully utilized, the equipment cost and the influence on the site environment can be reduced, and the discharged dry fine slag can be further utilized directly.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com