System and method of removing green peels of walnuts through ethylene gas ripening

A technology for walnut green peel and green peel, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of poor on-site environment of processing equipment, large investment in freezing, low commodity rate, etc., and achieves good processing equipment and on-site environment. The effect of improving ripening efficiency and reducing crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in combination with specific embodiments and accompanying drawings.

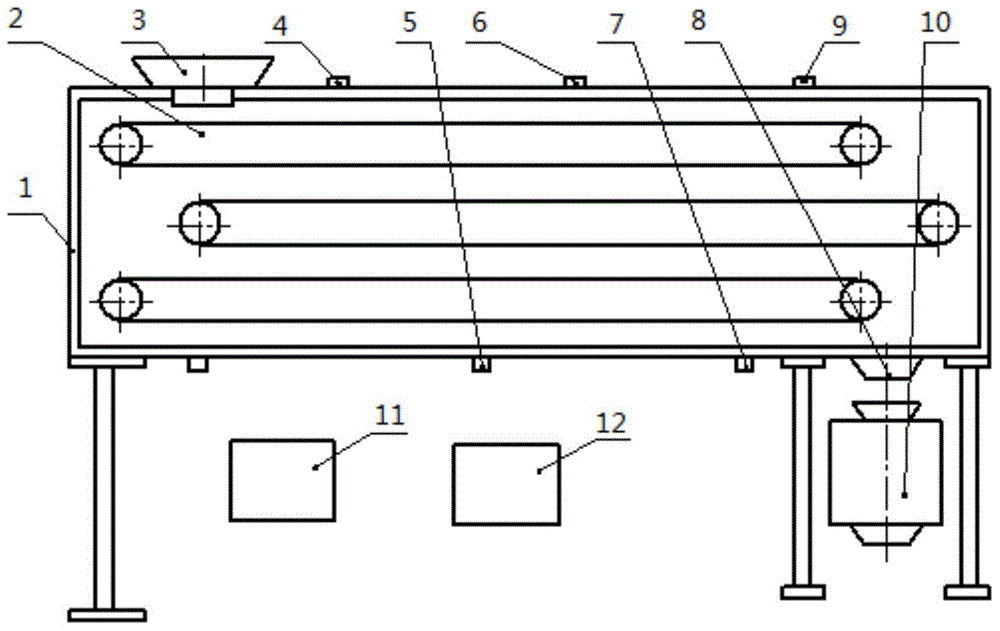

[0031] like figure 1 As shown, a system for ethylene gas ripening and stripping walnut green peels includes a closed box body 1 and a multi-layer wire mesh conveyor belt 2 arranged in the box body 1, and the transmission direction of two adjacent layers of wire mesh conveyor belts 2 On the contrary, and in the adjacent two layers of wire mesh conveyor belts 2, the starting end of the lower floor wire mesh conveyor belt 2 protrudes from the end of the upper floor wire mesh conveyor belt 2; Feeder 3, the lower opening of the feeder 3 corresponds to the starting end of the top-layer wire mesh conveyor belt 2, and a discharge port 8 is provided on the bottom surface of the box body 1, and the position of the discharge port 8 corresponds to the end of the bottom wire mesh conveyor belt 2. A rubbing and peeling device 10 for separating the gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com