Patents

Literature

37results about How to "Improve ripening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

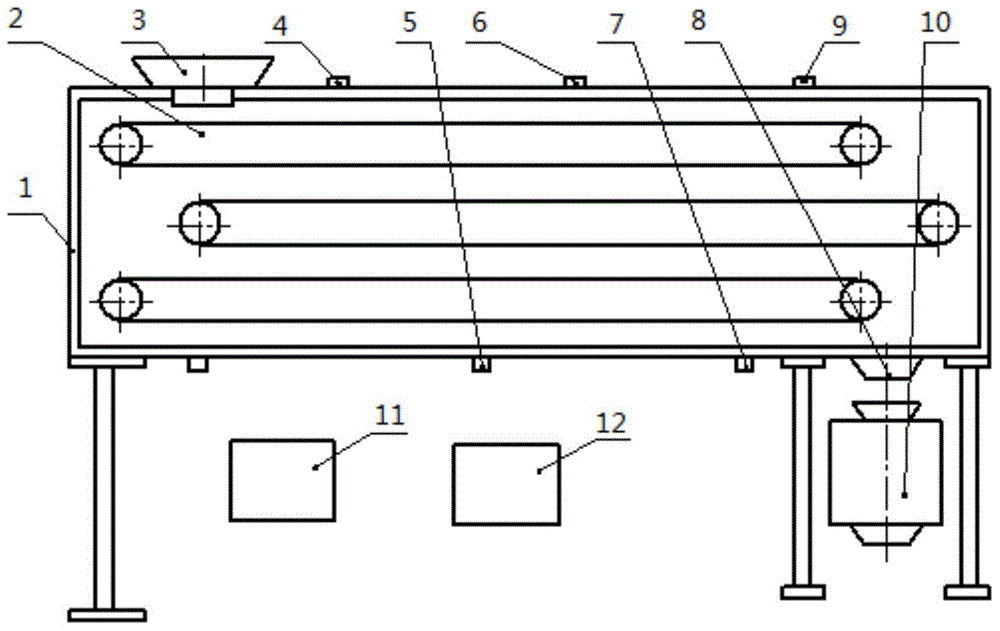

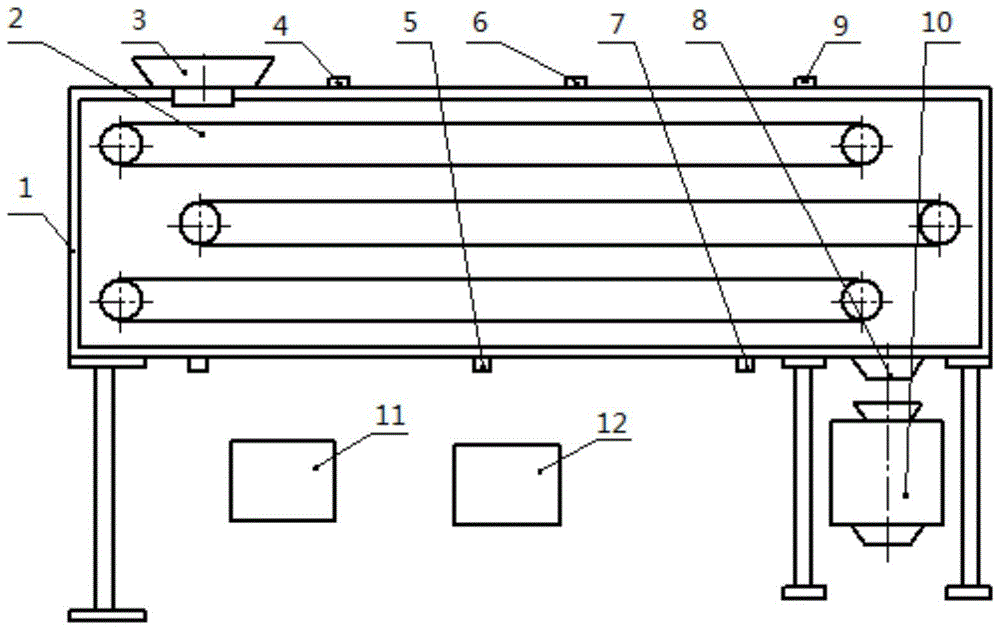

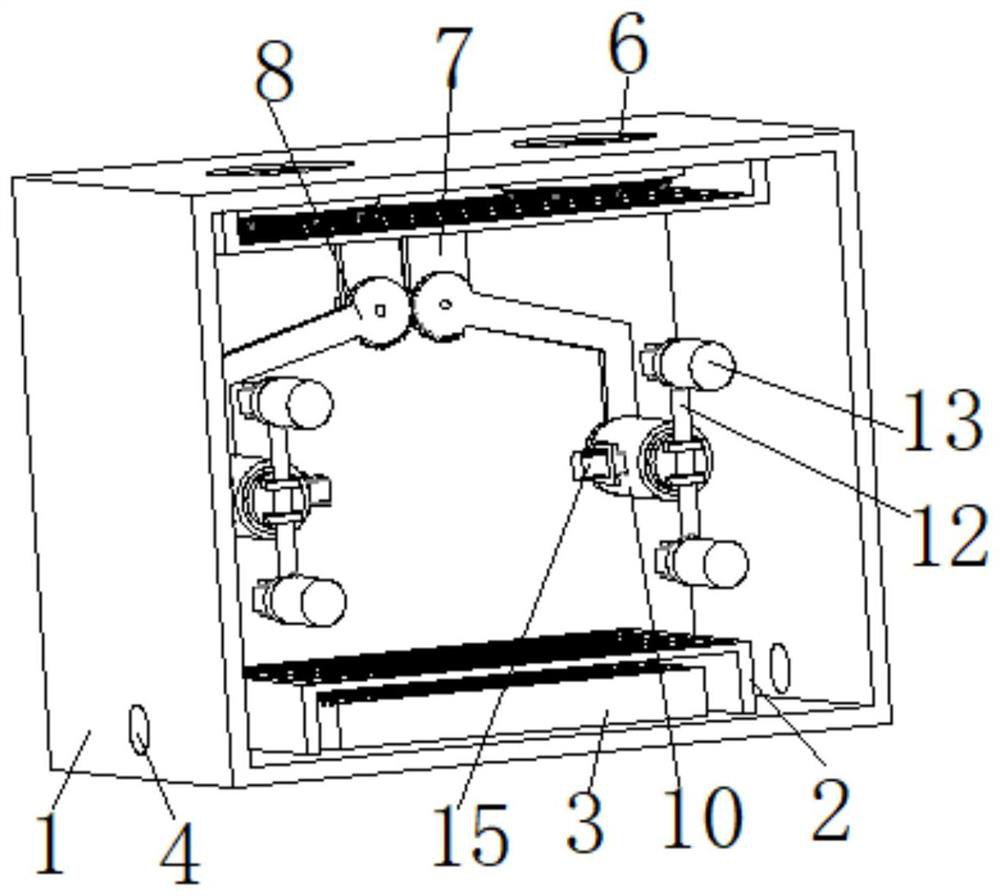

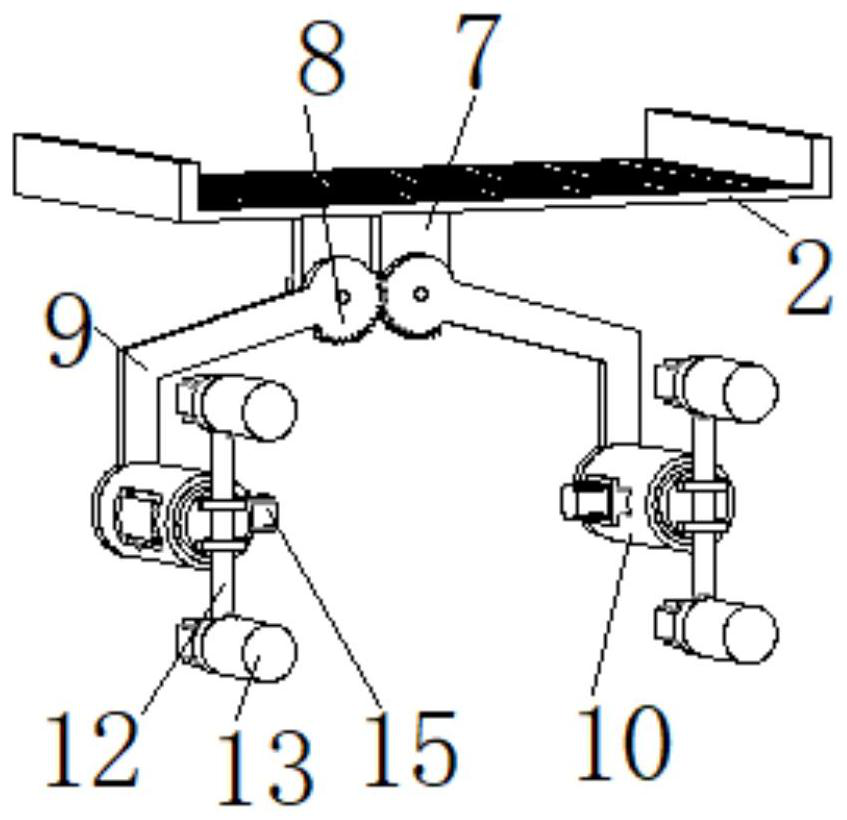

System and method of removing green peels of walnuts through ethylene gas ripening

ActiveCN104544491AReduce moisture contentThe amount of liquid squeezed out is reducedHuskingHullingRipeningBreakage rate

The invention discloses a system and a method of removing green peels of walnuts through ethylene gas ripening. Green-peeled walnuts are poured into a box from a feeder and dropped onto a top wire mesh conveying belt in the box, the green-peeled walnuts are slowly conveyed from an entry of the box to an exit of the box, and a gas ethylene generator enters the box during conveying and performs ethylene gas ripening to the green peels of the walnuts; after the green peels are ripened, the walnuts directly fall into a rubbing stripping unit from the tail end of a bottom wire mesh conveying belt, and the green peels and inner hard shells of the walnuts are separated. Gas ethylene is used to ripen the green peels o the walnuts and remove the green peels; removal rate of the green peels is high; breakage rate is low; yield of commercial walnuts is high; efficiency is high; the use of the gas ethylene in ripening the green peels prevents kernels from being contaminated, resulting in food contamination; meanwhile, the processing process is green.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method for AKD (Alkyl Ketene Dimer) emulsion and water-resistant treatment method for paper sheets

InactiveCN105421145AReduce the degree of hydrolysisGuaranteed water resistanceWater-repelling agents additionStarch gelatinizationCreaming

The invention discloses a preparation method for an AKD (Alkyl Ketene Dimer) emulsion and a water-resistant treatment method for paper sheets. The preparation method comprises the following steps of firstly, gelatinizing cationic starch, melting AKD wax powder at the temperature of 70 DEG C, then, pouring the gelatinized starch into the melted AKD wax powder, adding a stabilizer into the melted AKD wax powder, turning on an emulsifying machine to carry out emulsification, carrying out homogenization treatment on the solution, and carrying out rapid cooling, thereby obtaining the AKD emulsion. According to the preparation method for the AKD emulsion, disclosed by the invention, on the premise of guaranteeing the water resistance of the AKD emulsion, no starch etherifying process is carried out, and the gelatinized starch is directly used for emulsifying AKD after the starch is gelatinized, so that the equipment and labor investment of AKD emulsion manufacturers can be reduced, the aging efficiency of the AKD emulsion is high, the degree of hydrolysis of the AKD is greatly lowered, the water resisting effect is effectively guaranteed, and the economic benefit is obvious.

Owner:广东志广生物科技有限公司

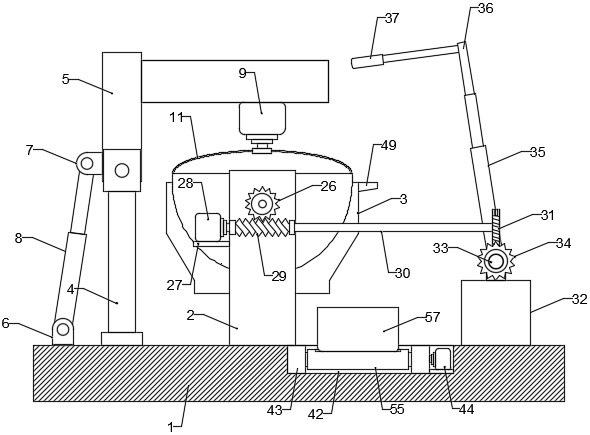

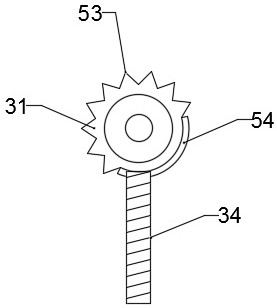

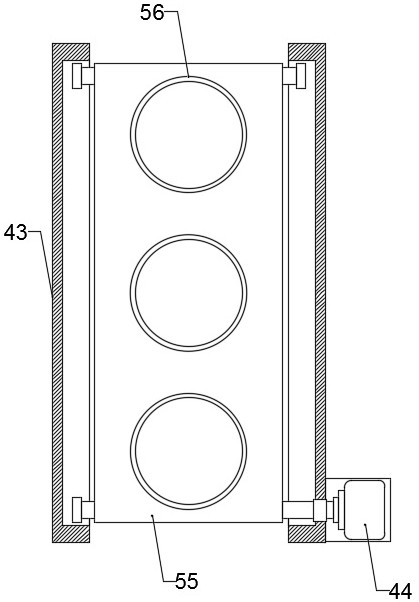

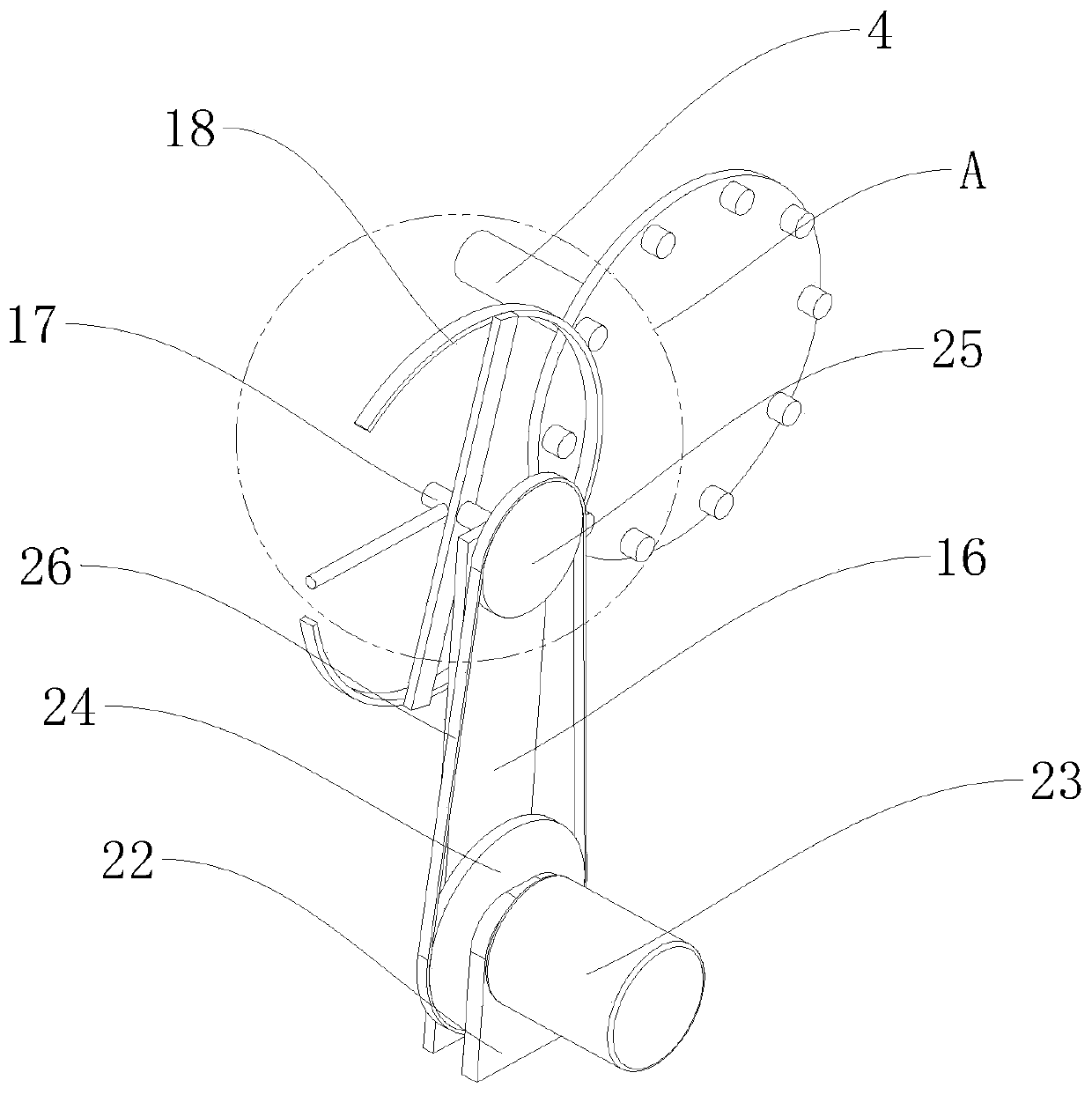

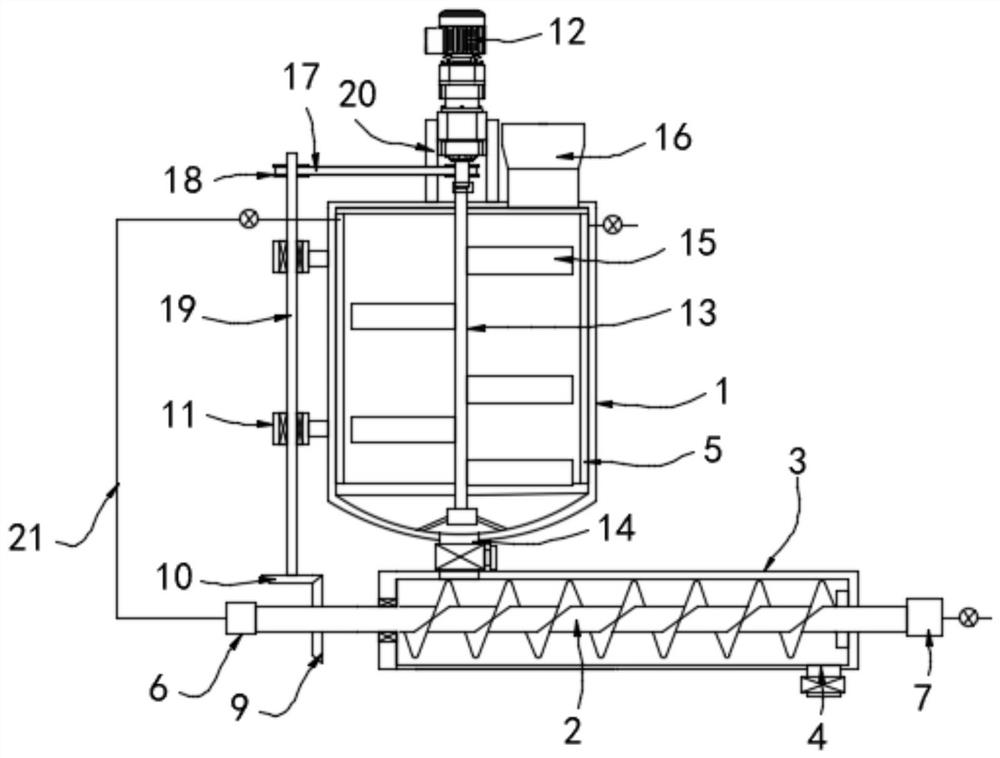

Beef cooking device in production process of bottled beef sauce

PendingCN111789212APrevent incomplete ripeningImprove ripening efficiencyFood shapingProcess engineeringConveyor belt

The invention discloses a beef cooking device in the production process of bottled beef sauce. The beef cooking device comprises a mounting base and a pair of opposite flip mounting seats fixedly mounted on the mounting base, a jacketed pot is movably installed on the flip mounting seats, the jacketed pot is provided a stirring mechanism, and a scraping mechanism is arranged on one side of the jacketed pot. The beef cooking device has the beneficial effects that beef in the jacketed pot can be effectively stirred through the stirring mechanism located on the jacketed pot, a circular meat pressing plate can press the cooked beef to prevent the beef from being cooked incompletely, scum generated during beef cooking can be filtered through a scum filter net, the scum filter net is a of detachable structure, impurities in the scum filter net can be conveniently cleaned, the scraping mechanism can automatically scrap beef broth remained in the pot after the jacketed pot pours materials, thelabor of manual scraping is reduced, a cleaning head can automatically clean the jacketed pot, a conveyor belt can convey the cooked beef to a next production line, and the beef cooking efficiency iseffectively improved.

Owner:河北世轩科技有限公司

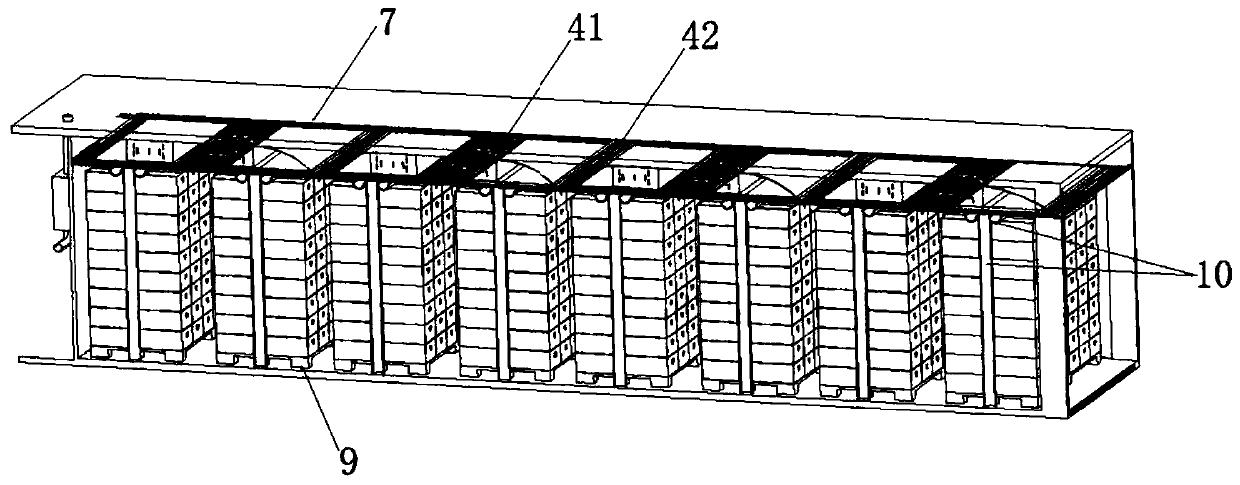

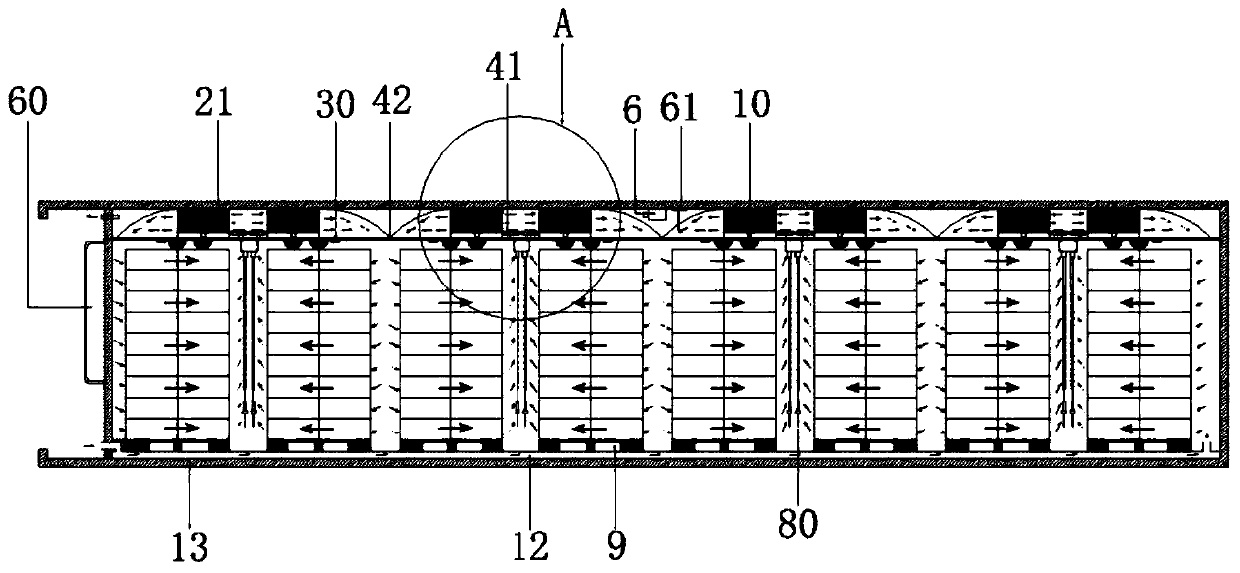

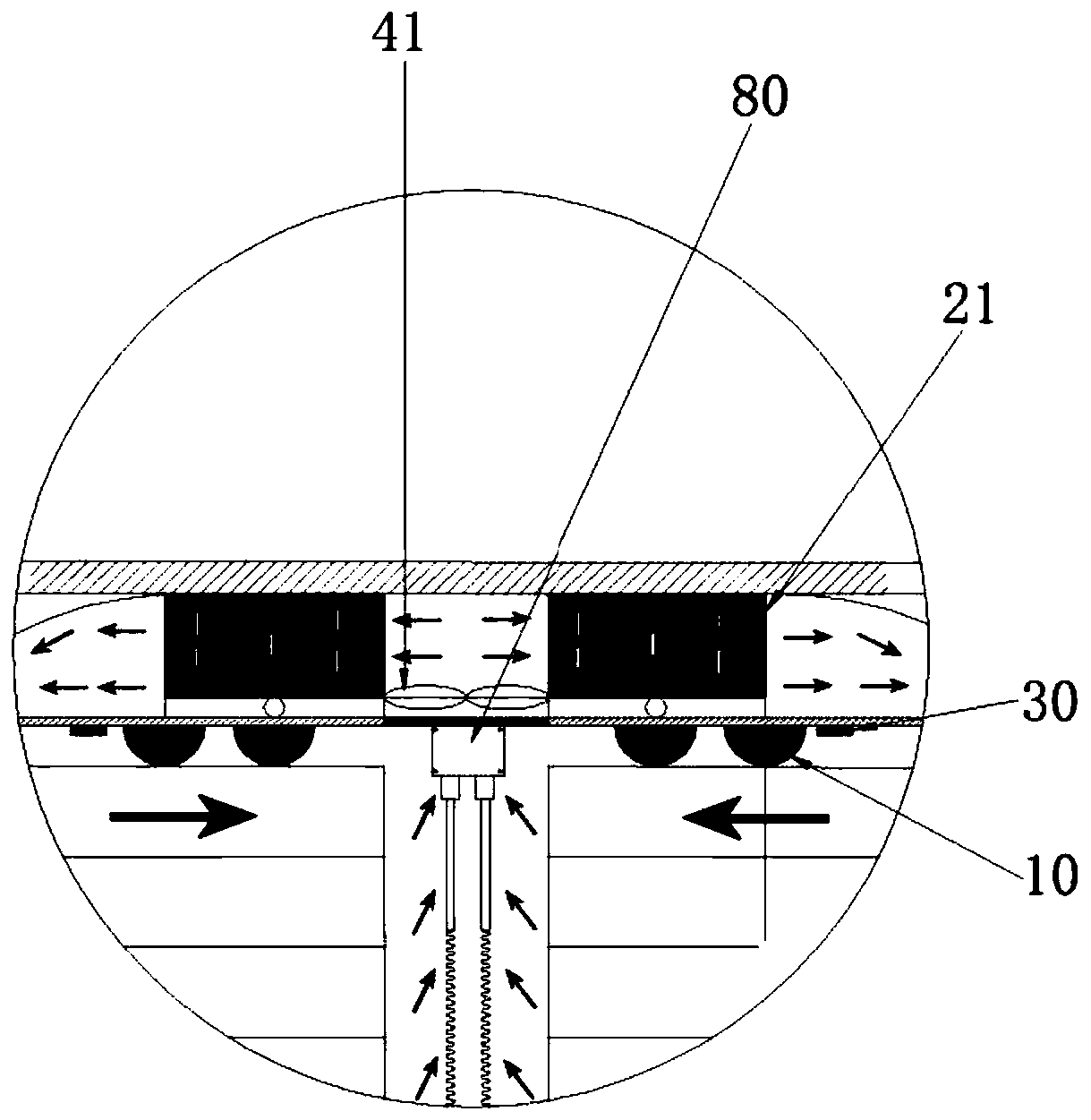

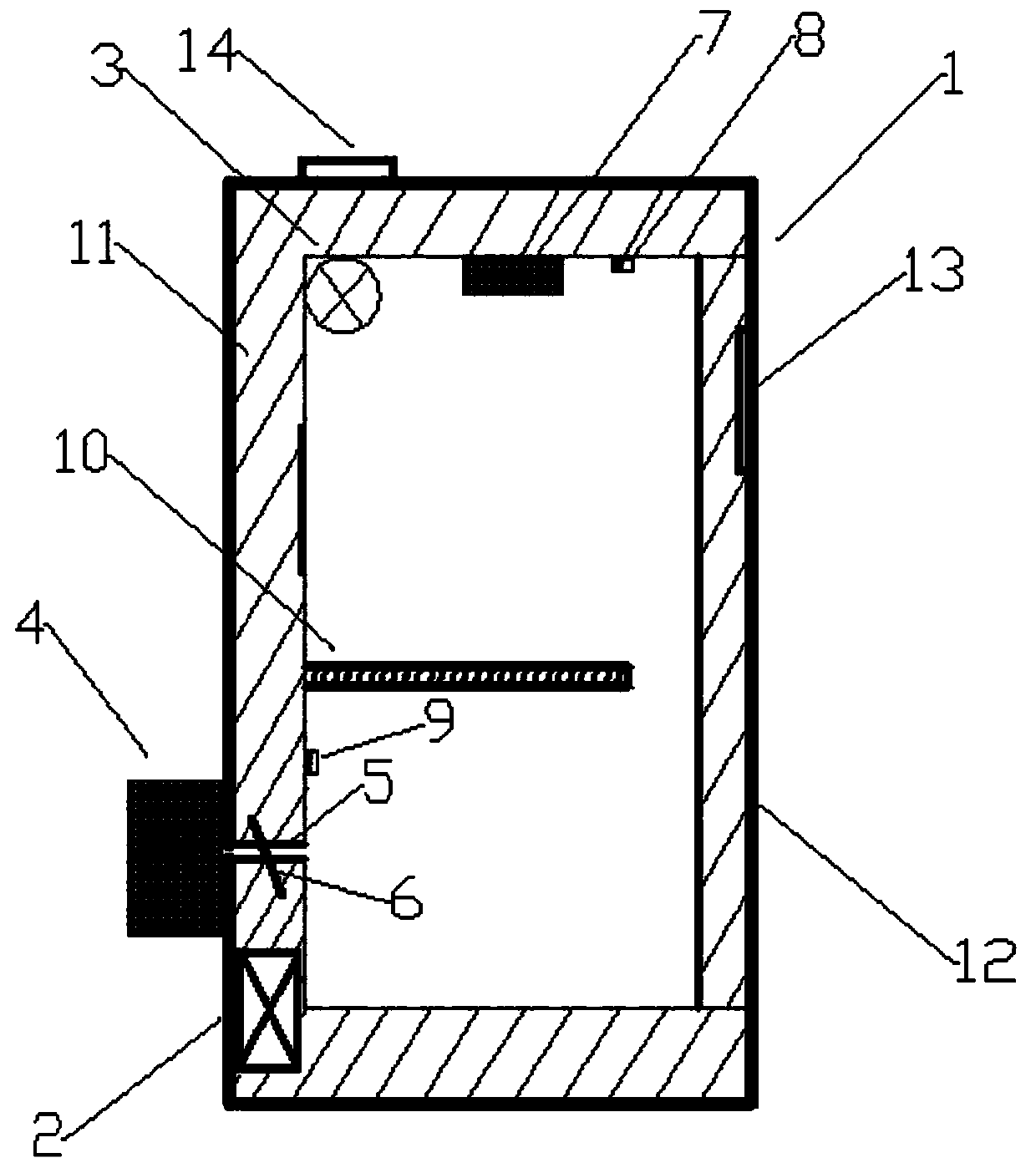

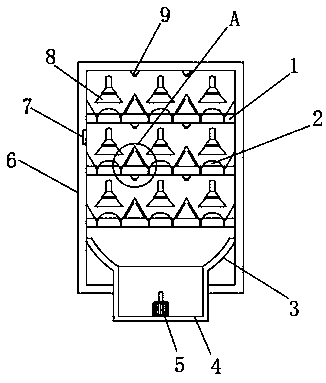

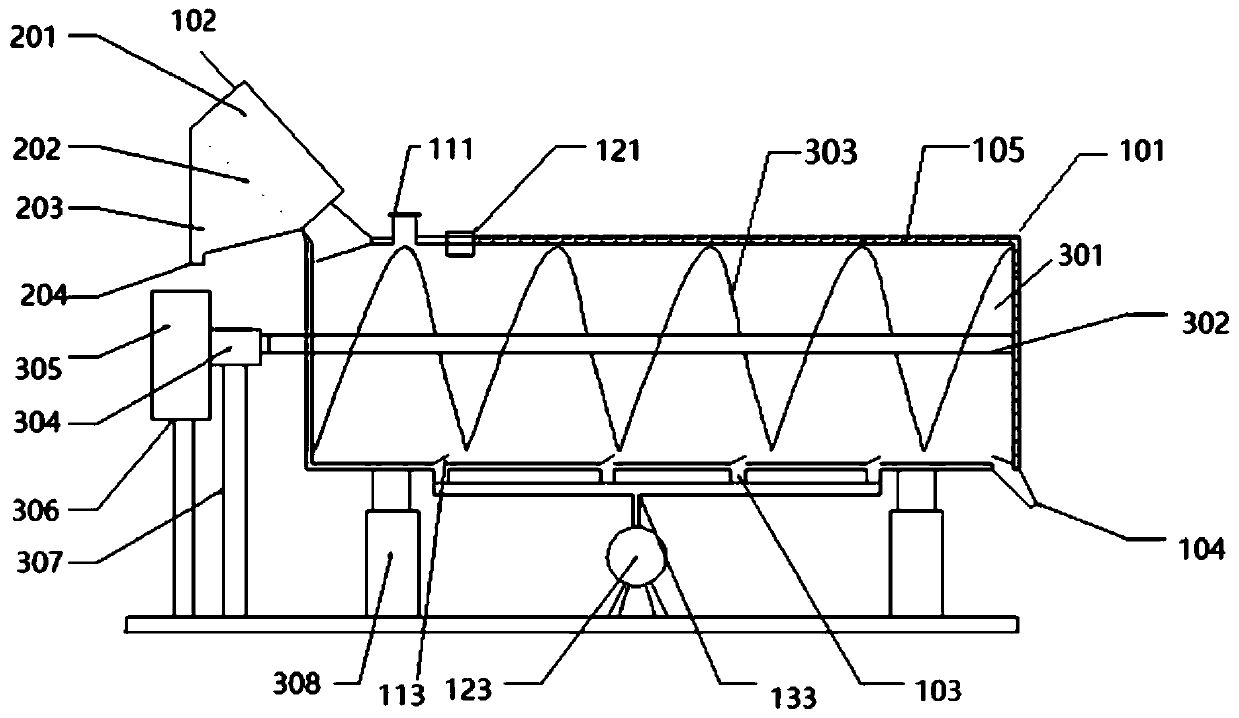

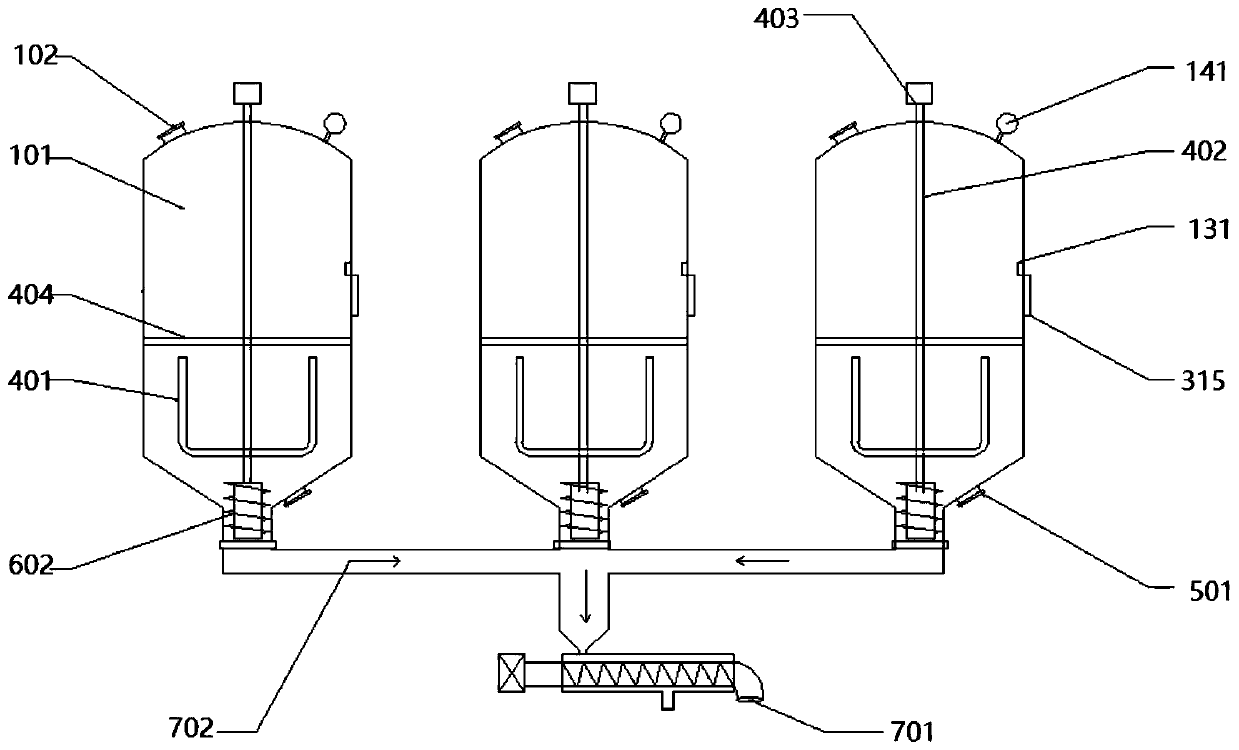

Container-type fruit and vegetable ripening device

PendingCN111357806AHigh degree of automationVersatileFruit and vegetables preservationGaseous substancesHorticultureEnvironmental geology

The invention relates to a container-type fruit and vegetable ripening device. The device comprises a ripening warehouse made of containers; a plurality of fruit and vegetable boxes are arranged in rows; the ripening warehouse is divided into a plurality of sections by the rows of fruit and vegetable boxes; the sections are arranged to be air inlet channels and air outlet channels in a staggered mode; a circulating fan is arranged above each air outlet channel; and a sealing filling piece is packed in a gap between the fruit and vegetable boxes and the inner wall surface of the ripening warehouse. Each group of the air inlet channel and the air outlet channel form a flow circulating channel with a circulating chamber through one corresponding circulating fan, and after the circulating fanis started, air in the air outlet channel below the circulating fan is pumped out to generate negative pressure in the air outlet channel, then circulating air enters the air inlet channel through thecirculating chamber, and positive pressure is generated in the air inlet channel. A pressure difference is formed between two sides of each row of fruit and vegetable boxes, heat and gas generated byfruits and vegetables in the fruit and vegetable boxes are brought out by the pressure difference, and cold quantity or heat quantity during refrigeration by a refrigeration coil or heating by a heater is quickly led out.

Owner:广东企鹅冷链技术有限公司

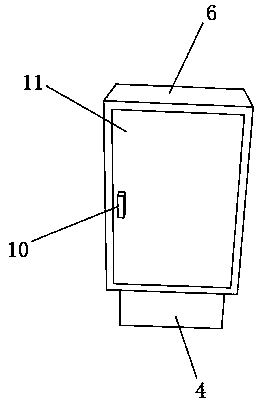

Ripening box and control method thereof

PendingCN110393304AImprove ripening efficiencySolve the problem of long-term storage before eatingFood treatmentTemperature controlInsulation layer

The invention discloses a ripening box and a control method thereof, and relates to the technical field of ripening boxes. The ripening box includes a box body, a door body is hinged to one side of the box body, and the box body is mainly composed of a box tank, a shell and an insulation layer filling between the box tank and the shell; and the box body is provided with s temperature control system, an ethylene control system and a control end, and the door body is provided with a display end. According to the ripening box and the control method thereof, the ripening box is provided to improvethe efficiency of fruit ripening and solve the problem that fruits need to be stored for a long time before the fruits can be eaten after purchase, and accelerated ripening of the fruits is realizedby controlling the content of ripening gas and controlling the temperature of ripening.

Owner:CHANGHONG MEILING CO LTD

Grain cooking and processing quick cooling device for white spirit production

ActiveCN109943433AImprove ripening efficiencyAccelerate heat dissipationBiofuelsAlcoholic beverage preparationEngineeringWhite spirit

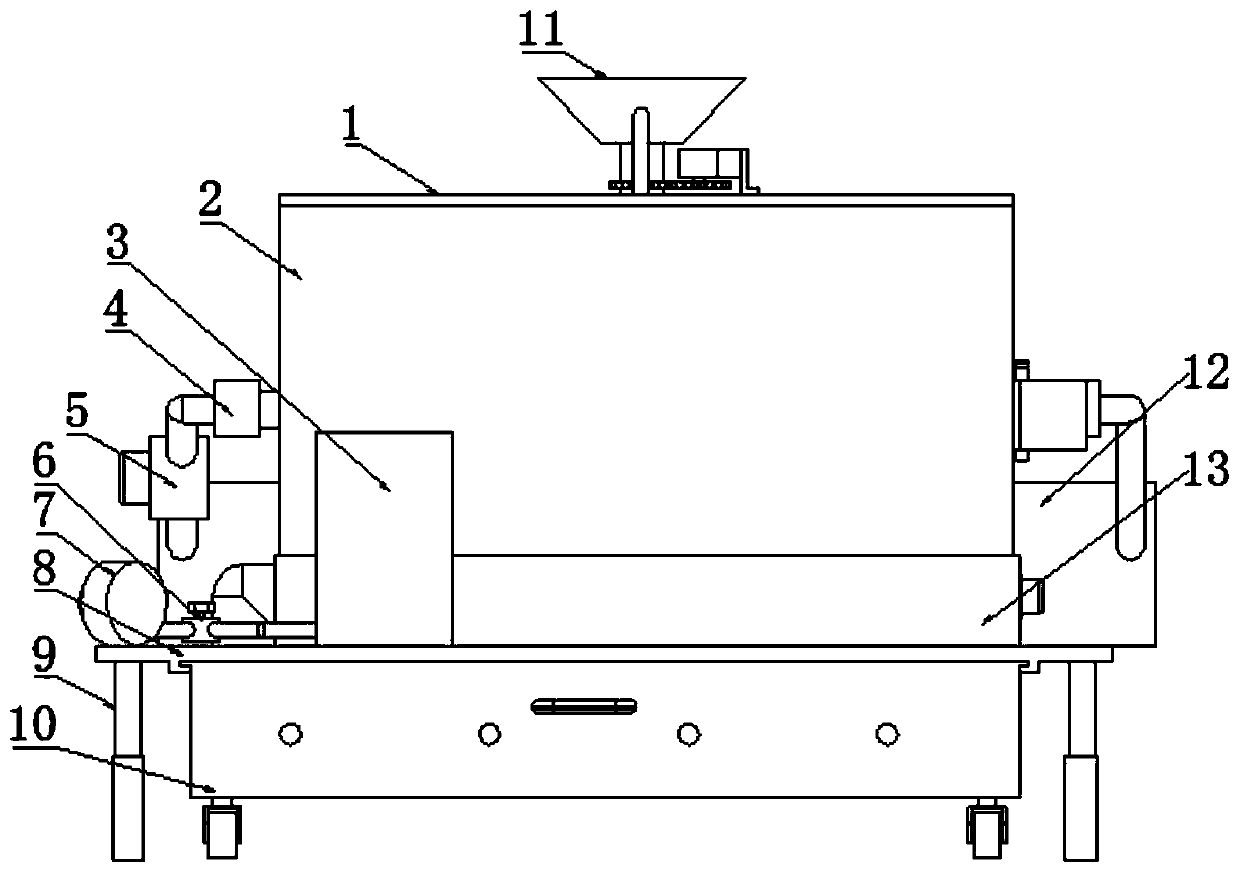

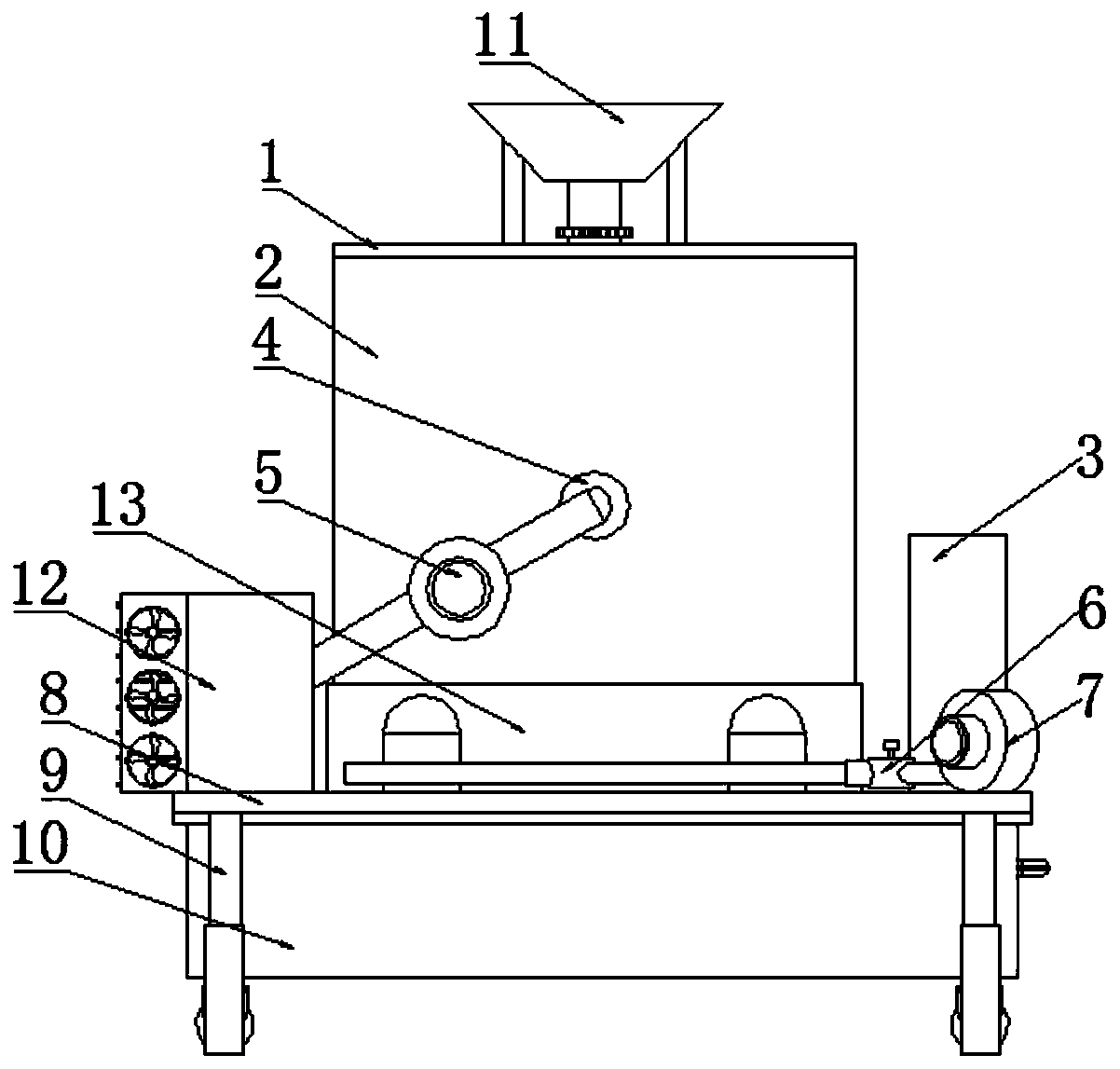

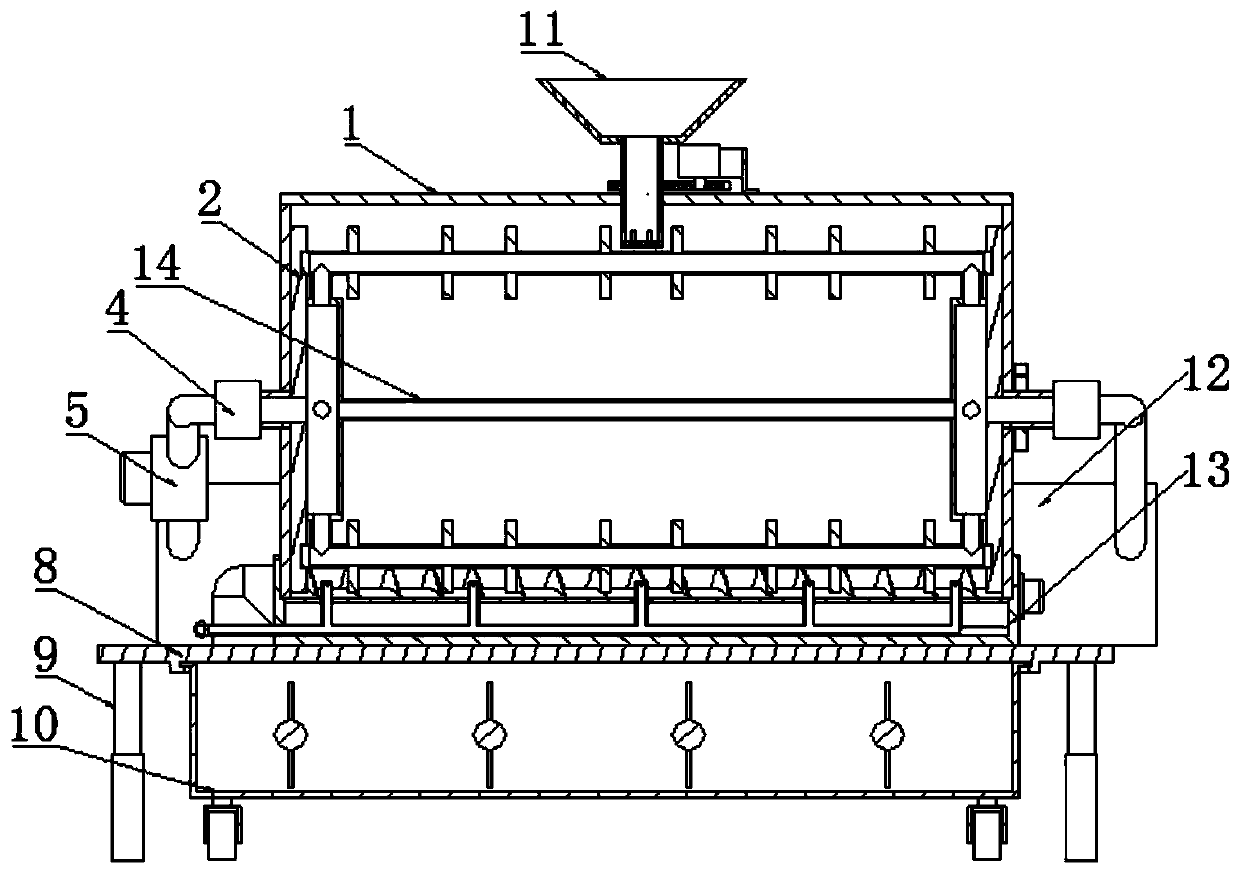

The invention discloses a grain cooking and processing quick cooling device for white spirit production, which comprises a stirring box, a fermentation mechanism, a radiating mechanism and a cooling mechanism, wherein a box cover is arranged on a mask at the upper end of the stirring box; a powder spreading mechanism is fixedly arranged on the upper end surface of the box cover; a discharging endat the lower end of the powder spreading mechanism is communicated with the stirring box; a base is arranged at the lower end of the stirring box; the lower end of the stirring box is inserted into anupper port of the base; a bottom plate is arranged at the lower end of the base; lifting rods are arranged at four corners close to the lower end surface of the bottom plate; and a fermentation mechanism is arranged at the lower end surface of the bottom plate. Through the structure of the simple device, the integration of ripening, cooling and stirring of grains in the production and processingof white spirit is realized, the input cost of equipment and the production and processing cost of white spirit are greatly reduced, the turntable in the cooling mechanism is driven by the motor to rotate to drive the plurality of cooling pipes to simultaneously stir the grains, and the cooling efficiency of ripened grains is greatly improved.

Owner:贵州金沙窖酒酒业有限公司

fast pulping method

ActiveCN102273596AAvoid the "paste tube" problemOmit boil structureFood preparationPulp and paper industryComposite material

The invention relates to a rapid pulping method. The rapid pulping method comprises a preheating stage for heating water and / or materials, and a crushing and curing stage for crushing and curing the materials; in the crushing and curing stage, a crushing cutting tool and a container are provided; when the materials and water are mixed in the container and is crushed into pulp / paste by the crushing cutting tool, heat is generated by the mutual friction among the pulp / paste, the crushing cutting tool, and the container, which heats the pulp / paste till the pulp / paste is cured. The rapid pulping method of the invention overcomes the prejudice that a boiling way is necessary for pulp / paste preparation in the industry, and saves the soybean milk boiling stage; the pulp or paste is cured by means of heating through friction among the pulp / paste, the crushing cutting tool, and the container; because material crushing and pulp or paste curing are performed simultaneously in the crushing and curing stage, the pulp or paste boiling time is saved, and thus the total pulping time is greatly shortened.

Owner:JOYOUNG CO LTD

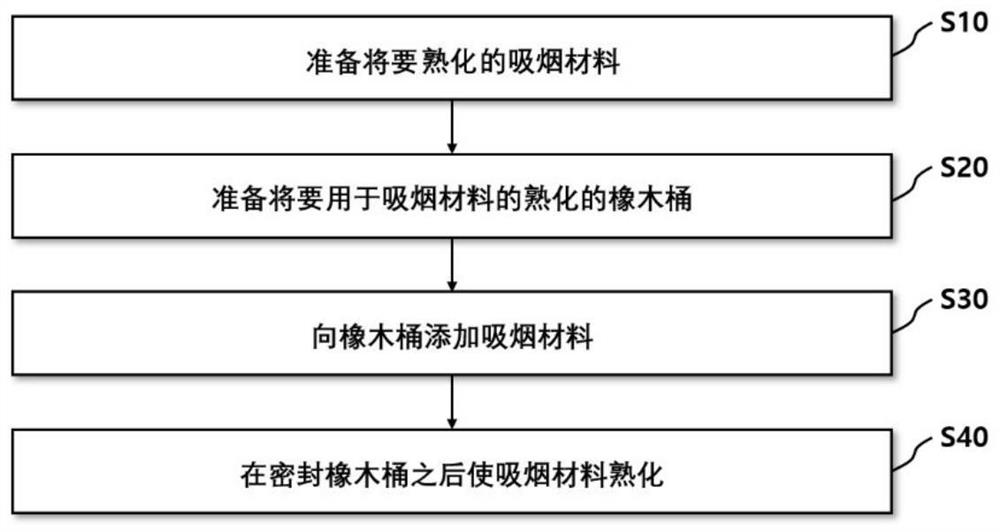

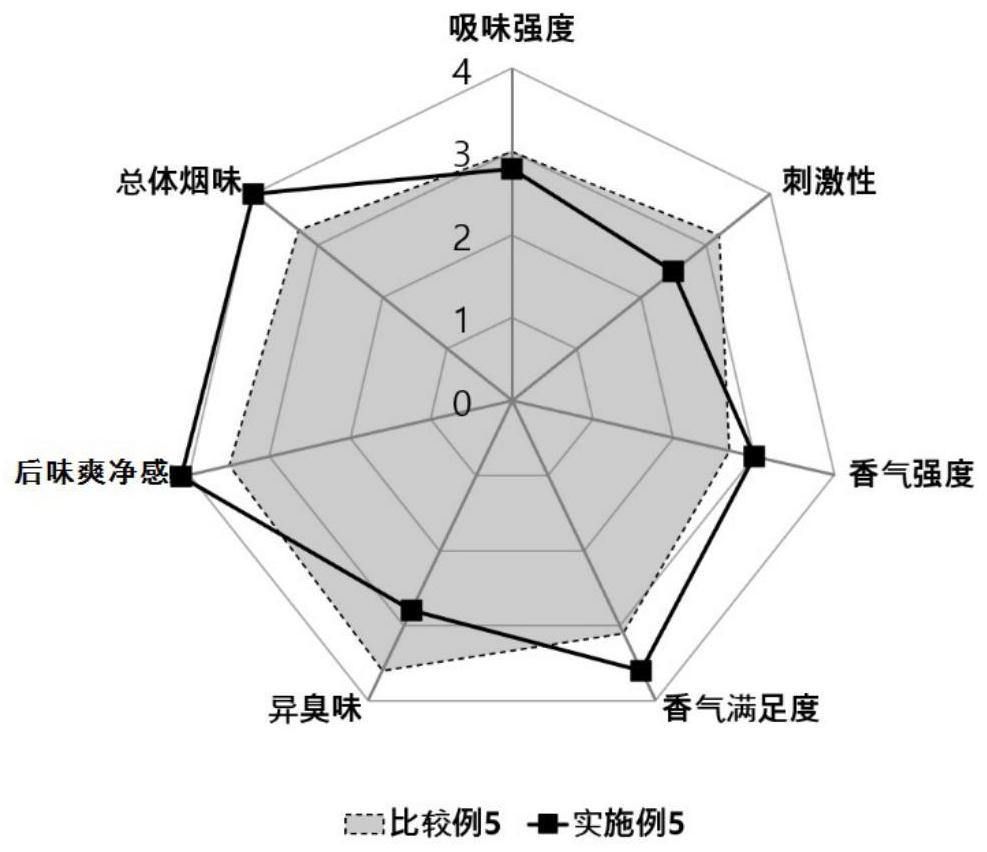

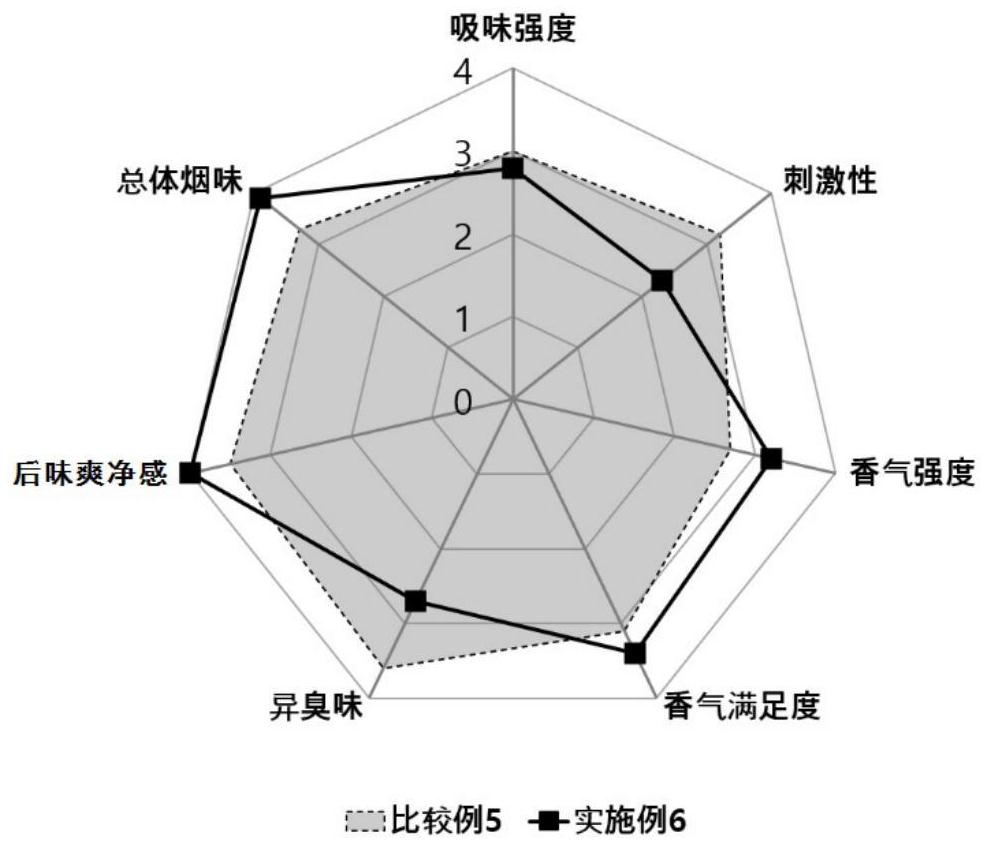

Method for aging smoking material by using oak barrel, and smoking article manufactured using same

ActiveCN113556946AImprove aroma componentsShorten the timeTobacco preparationTobacco treatmentInterior spaceChemistry

According to an embodiment of the present invention, provided is a method for aging a smoking material for forming at least a portion of a smoking material part of a smoking article, the method comprising the steps of: preparing an oak barrel and a smoking material; adding the smoking material to the internal space of the oak barrel; and sealing the oak barrel, and then aging the smoking material.

Owner:KT&G CO LTD

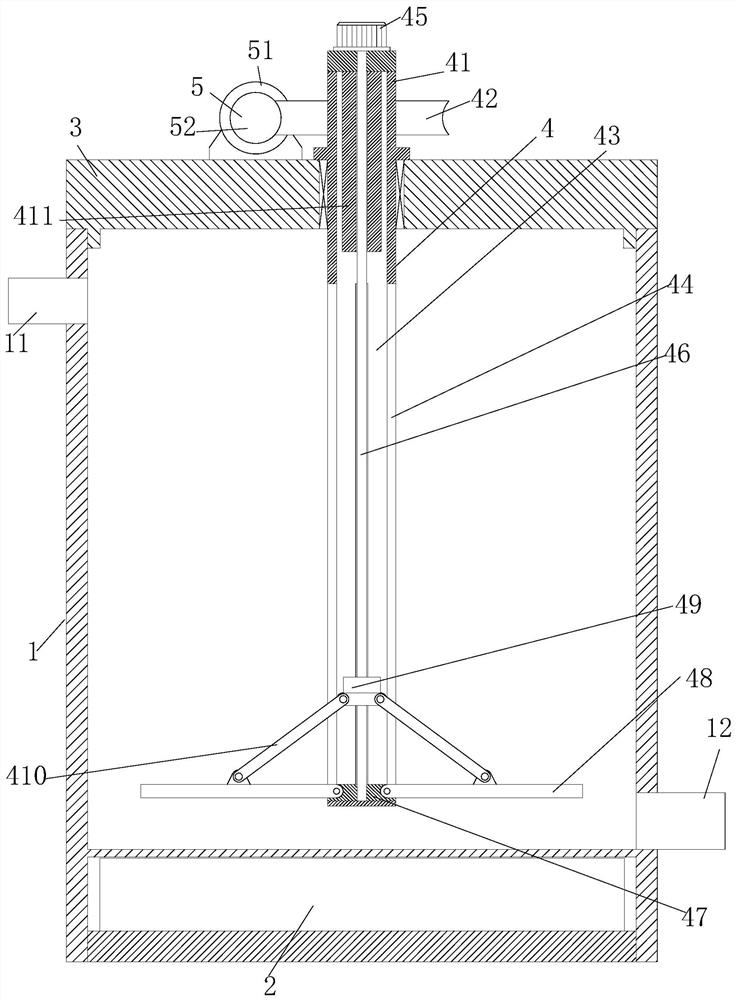

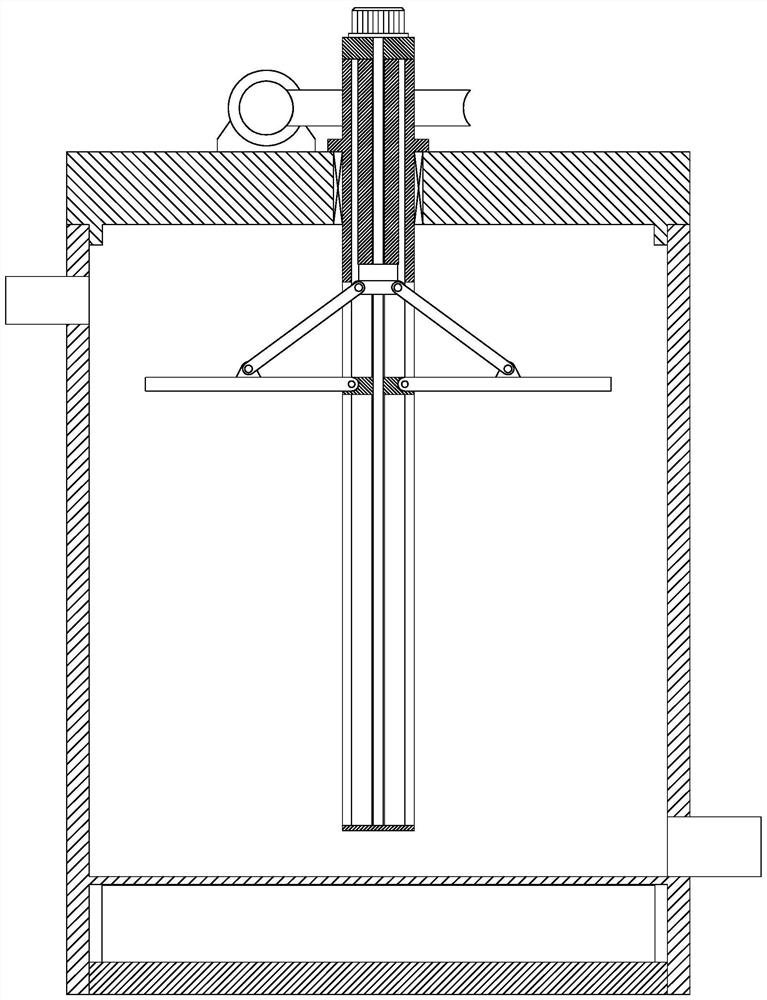

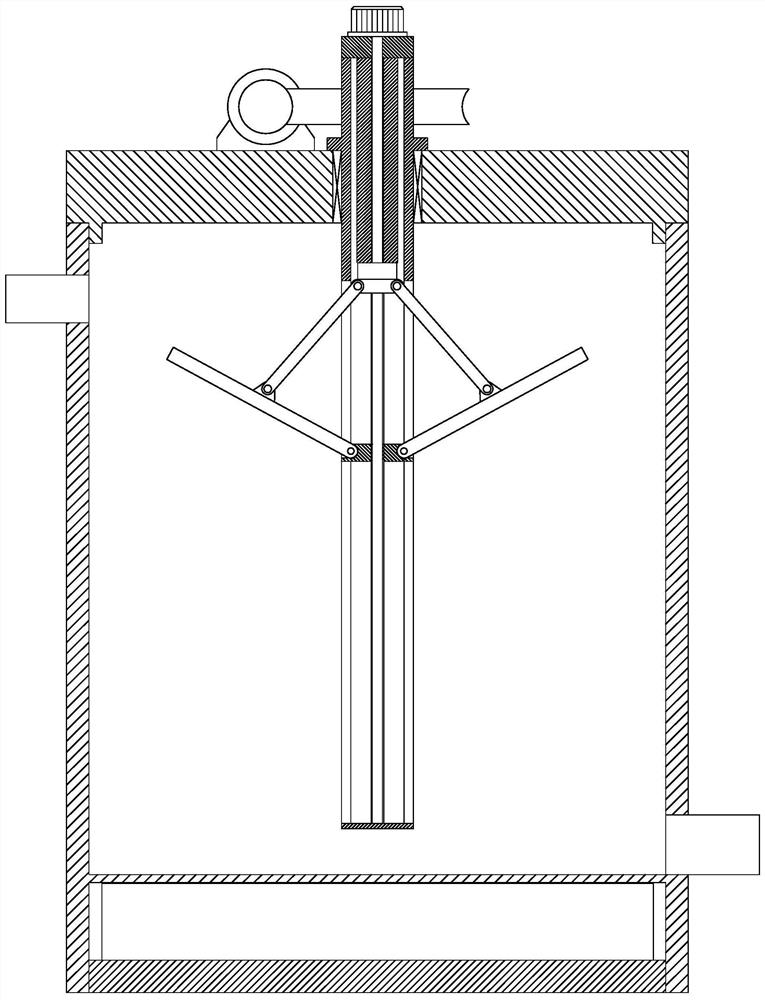

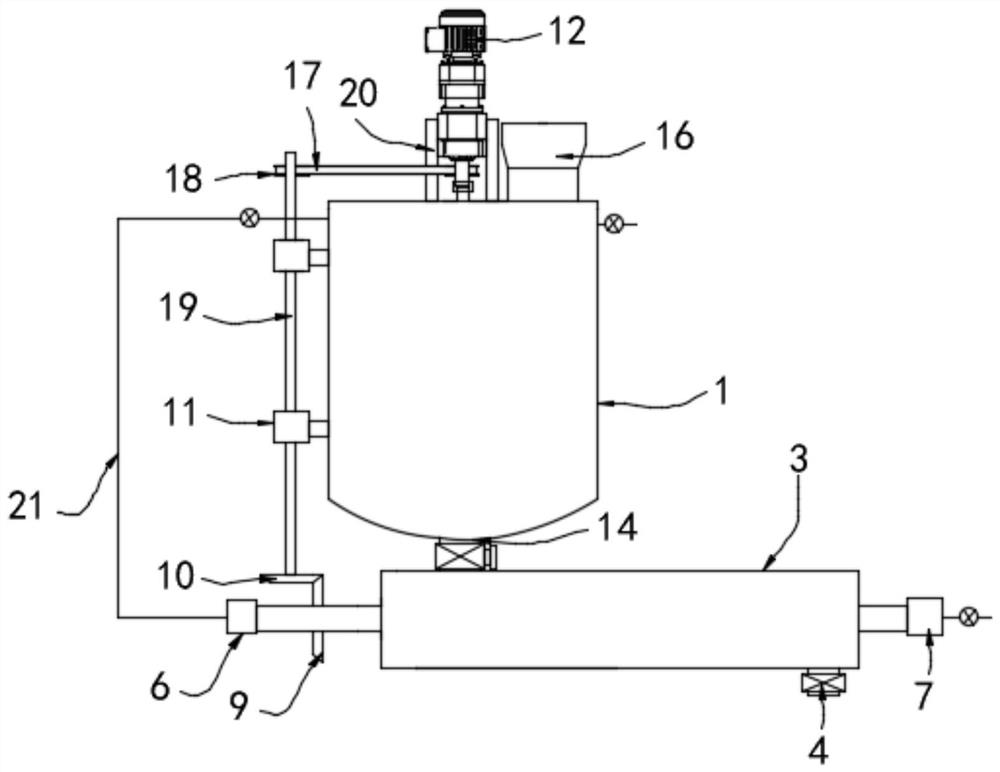

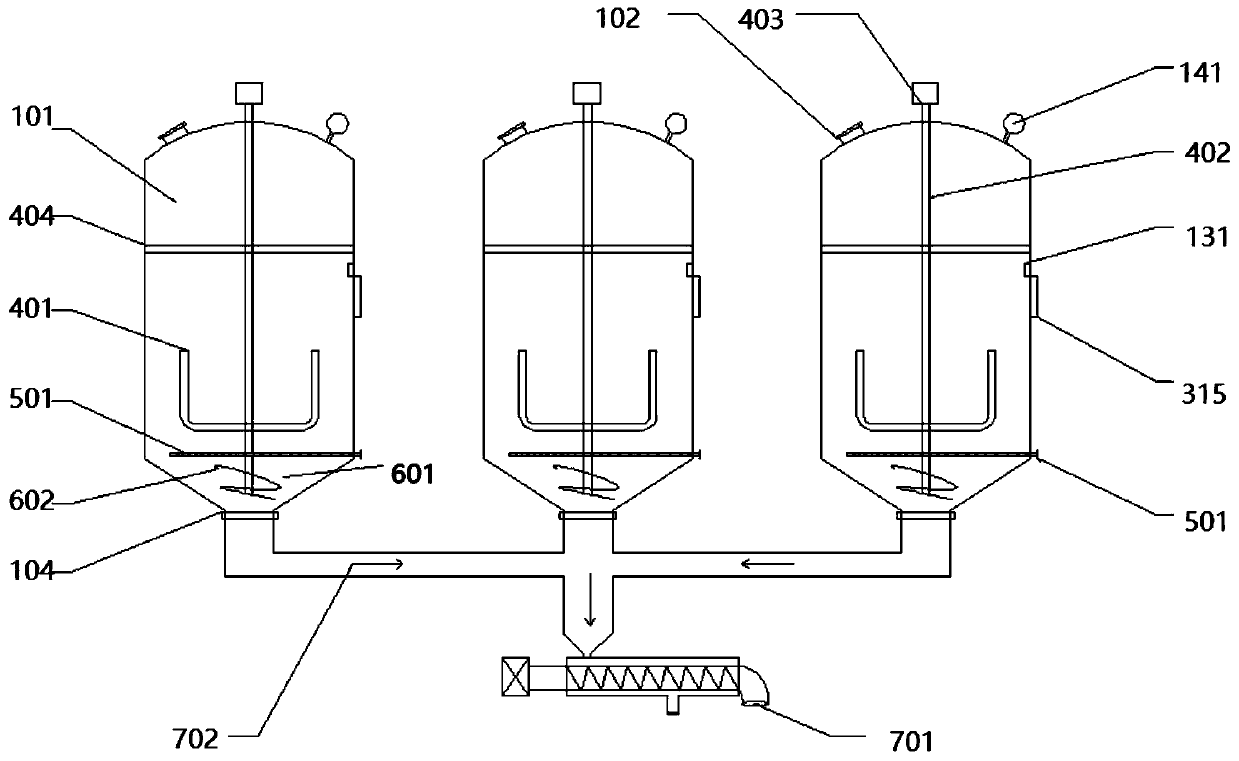

White spirit ripening device for white spirit production

PendingCN111979080AImprove ripening effectImprove ripening efficiencyAlcoholic beverage preparationMechanical engineeringWhite spirit

One or more embodiments of the invention provide a white spirit ripening device for white spirit production. The white spirit ripening device comprises a tank body, wherein a feeding port is formed inthe upper part of one side of the tank body; a discharging port is formed in the lower part of the other side of the tank body; an ultrasonic assembly is mounted at the bottom of the tank body; a cover body is mounted at the upper part of the tank body; a stirring assembly is rotationally mounted in the middle of the cover body; and a driving assembly for driving the stirring assembly to work ismounted on the cover body. The ultrasonic assembly and the stirring assembly are combined, so that the white spirit ripening effect during white spirit production is improved, and the ripening efficiency is improved.

Owner:ANHUI SHUANLUN VINO

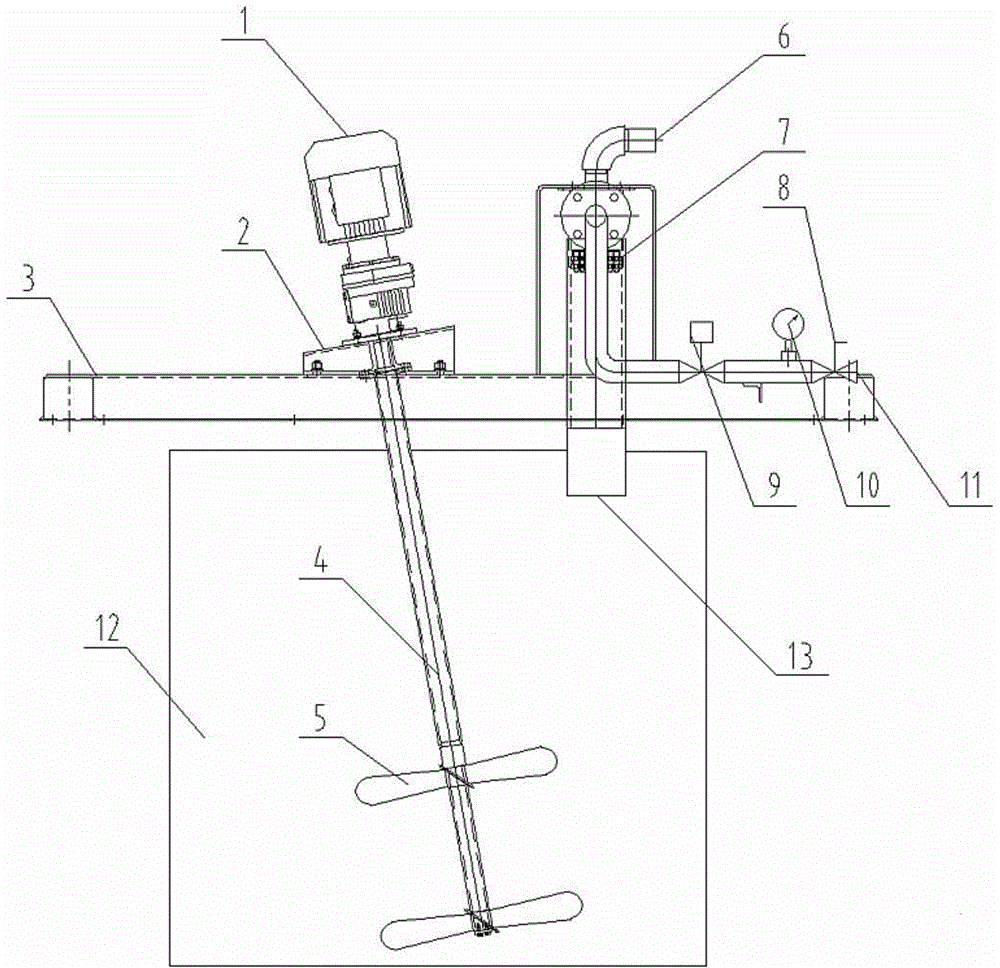

Novel automatic agitating device

The invention provides a novel automatic agitating device which comprises an agitating mechanism frame and an agitating barrel arranged below the agitating mechanism frame, wherein a motor installing frame and a water medicine premixer are welded and connected to the agitating mechanism frame, a speed reducing motor is arranged on the motor installing frame, and is connected with an agitating shaft, the agitating shaft penetrates through the agitating mechanism frame and extends into the bottom of the agitating barrel, an agitating paddle blade is arranged on the agitating shaft, one side of the water medicine premixer is connected with a medicine powder channel, a medicine powder inlet is formed in the medicine powder channel, the other side of the water medicine premixer is connected with a water inlet channel, a water inlet is formed in the water inlet channel, the water inlet channel is connected with a pressure meter, a discharging channel is arranged at the bottom of the water medicine premixer, the discharging channel penetrates through the agitating mechanism frame and extends into the agitating barrel, and a discharging hole is formed in the discharging channel. The novel automatic agitating device has the beneficial effects of improving the mixing effect of water and medicine powder by arranging the water medicine premixer, further improving the curing efficiency, prolonging the service life of a machine, saving the production cost and ensuring the product quality.

Owner:TIANJIN DUOLEPENG TECH

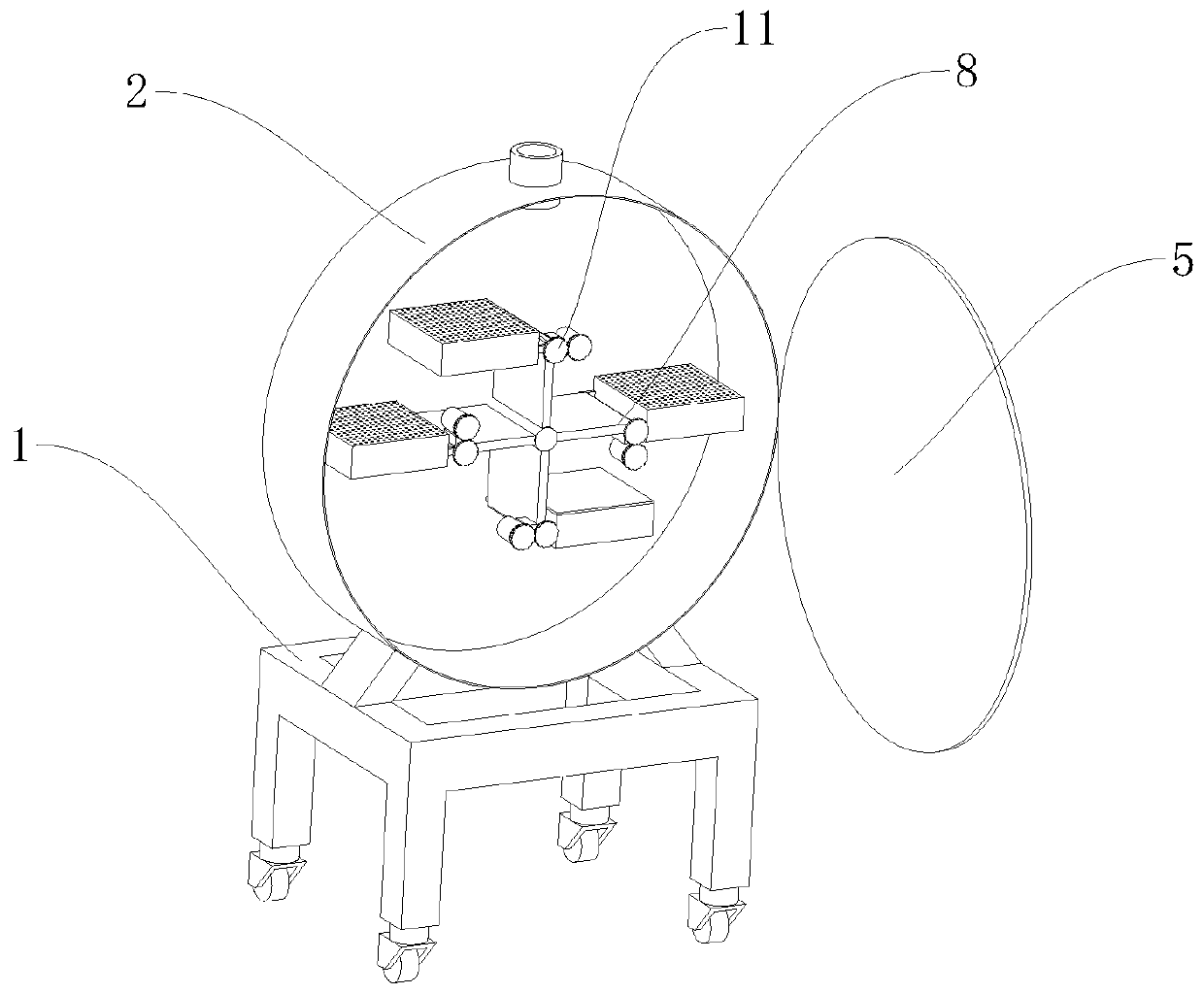

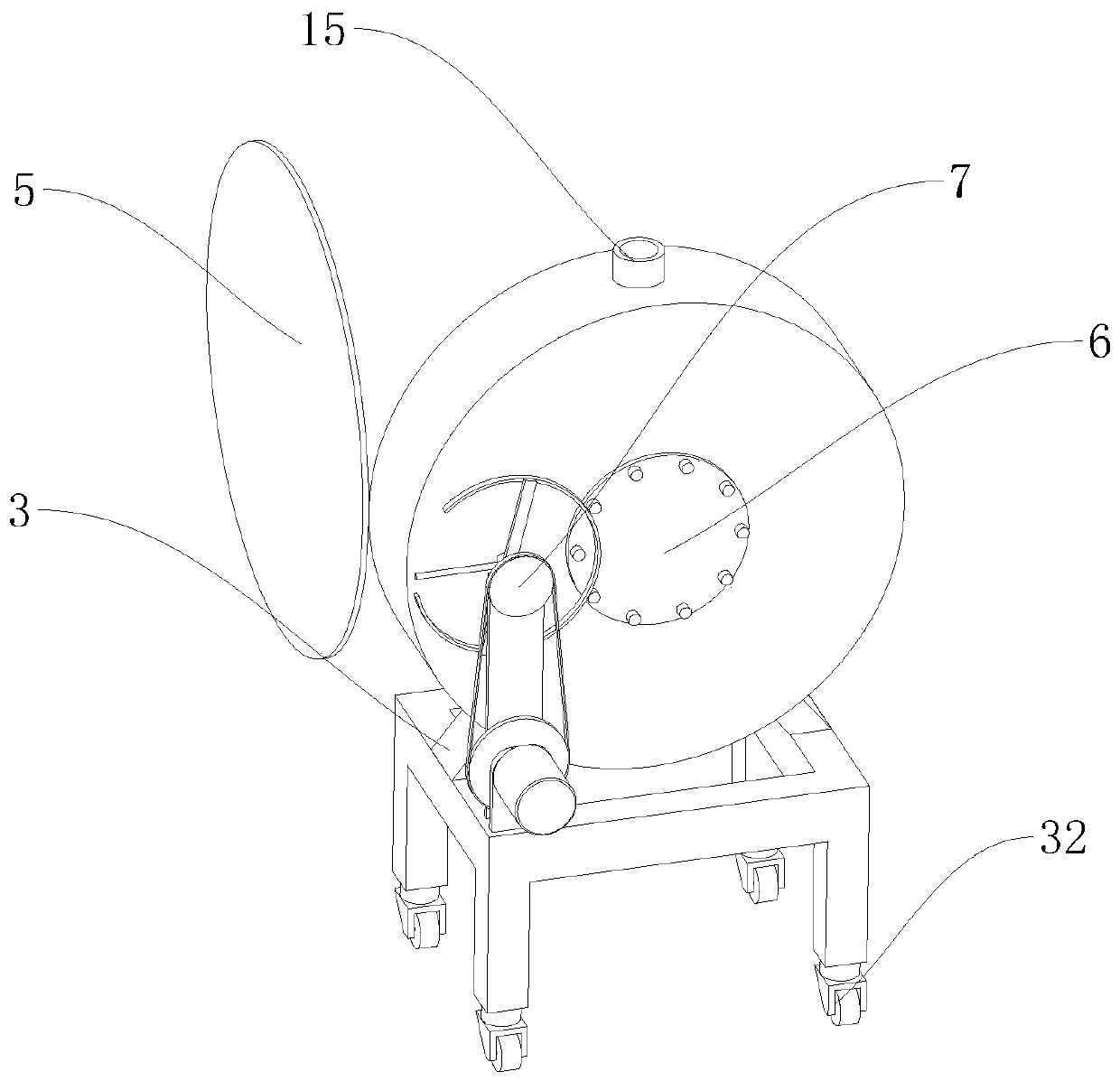

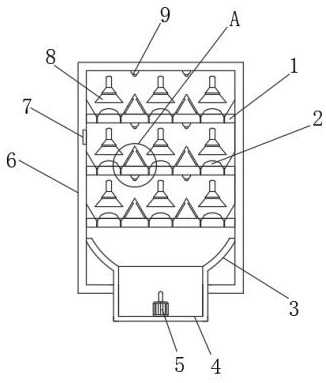

Fruit quick ripening device

InactiveCN109699740AUniform ripeningImprove ripening efficiencyFruit and vegetables preservationCircular discFixed frame

The invention relates to the technical field of agricultural machinery, in particular to a fruit rapid ripening device, which comprises a base, a sealing disc, a placing device and a rotating device for driving the rotation of the placing device, the sealing disc is fixedly mounted on the base, a middle horizontal shaft of the sealing disc is connected with a rotating shaft extending into the sealing disc, a sealing cover is hinged at the front end of the sealing disc, the rotating device comprises a rotating plate fixedly mounted at an end of the rotating shaft and a driving assembly for driving the rotating plate to rotate regularly, the placing device comprises a plurality of holding components uniformly mounted on the rotating shaft in the sealing disc, the loading component comprisesa mounting plate, a loading box and a rotating mechanism for driving the loading box. The mounting plate is arranged on the rotating shaft, and the end of the mounting plate is connected with a firstrotating shaft. A storage box is connected to the first rotating shaft through a fixing frame, and the rotating mechanism is mounted on the mounting plate, and the device improves the ripening efficiency of the fruit.

Owner:叶锋

Efficent curing process of polyurethane material for automotive trim

PendingCN112745523AImprove ripening efficiencyThe curing process is simpleCoatingsAnti bacteriaWear resistance

The invention discloses an efficient curing process of a polyurethane material for automotive trim. The efficient curing process comprises the following steps: S1, coating the surface of a polyurethane foaming material for the automotive trim with a wear-resistant coating; and S2, then feeding the material into a drying oven for curing. Curing is carried out in three stages, in the first stage, the curing temperature is 75-95 DEG C, and the curing time is 13-15 hours; in the second stage, the curing temperature is 103-117 DEG C, and the curing time is 5-7 hours; and in the third stage, the curing temperature is 85-95 DEG C, and the curing time is 8-12 hours. The efficient curing process of the polyurethane material for the automotive trim is simple in procedure, high in curing efficiency and good in curing effect, and the obtained product is excellent in wear resistance; there is little ordor, and body health is facilitated; and the foaming effect is good, foam holes are uniform, the elasticity is good, the mechanical property is high, the sound absorption and insulation effects are good, and the antibacterial effect is good.

Owner:平湖华申汽车内饰件有限公司

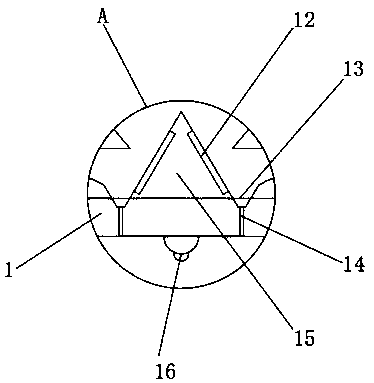

Spray ripening device for banana production and use method thereof

ActiveCN111387533AImprove ripening qualityGuaranteed uniformityFruit and vegetables preservationFood processingRipeningMechanical engineering

The invention belongs to the technical field of banana ripening, and in particular relates to a spray ripening device for banana production and a use method thereof. The device comprises a ripening box; the outer wall of the bottom of the ripening box is provided with a mounting hole; the inner wall of the mounting hole is in inserted connection with an ethylene box; the inner wall of the bottom of the ethylene box is provided with a liquid pump; the output end of the liquid pump is in sleeved connection with a water pipe; the end, far away from the liquid pump, of the water pipe is in sleevedconnection with an infusion tub; the outer wall of the infusion tube is provided with a through hole; the inner wall of the through hole is in inserted connection with a circular-truncated-cone-shaped spray disc; the inner walls of the periphery of the circular-truncated-cone-shaped spray disc are provided with spray holes; the inner wall of the top of the circular-truncated-cone-shaped spray disc is provided with a mounting opening; and the inner wall of the mounting opening is in inserted connection with a connecting pipe. The device ensures the spray uniformity of ethylene liquid; and a flow guide block can gather the ethylene liquid to a banana ring, so that on one hand, the time of contact between bananas with the ethylene liquid can be prolonged, and on the other hand, the waste caused by deposition of the ethylene liquid in the ripening box is avoided and the ripening quality of the bananas is improved.

Owner:邳州市景鹏创业投资有限公司

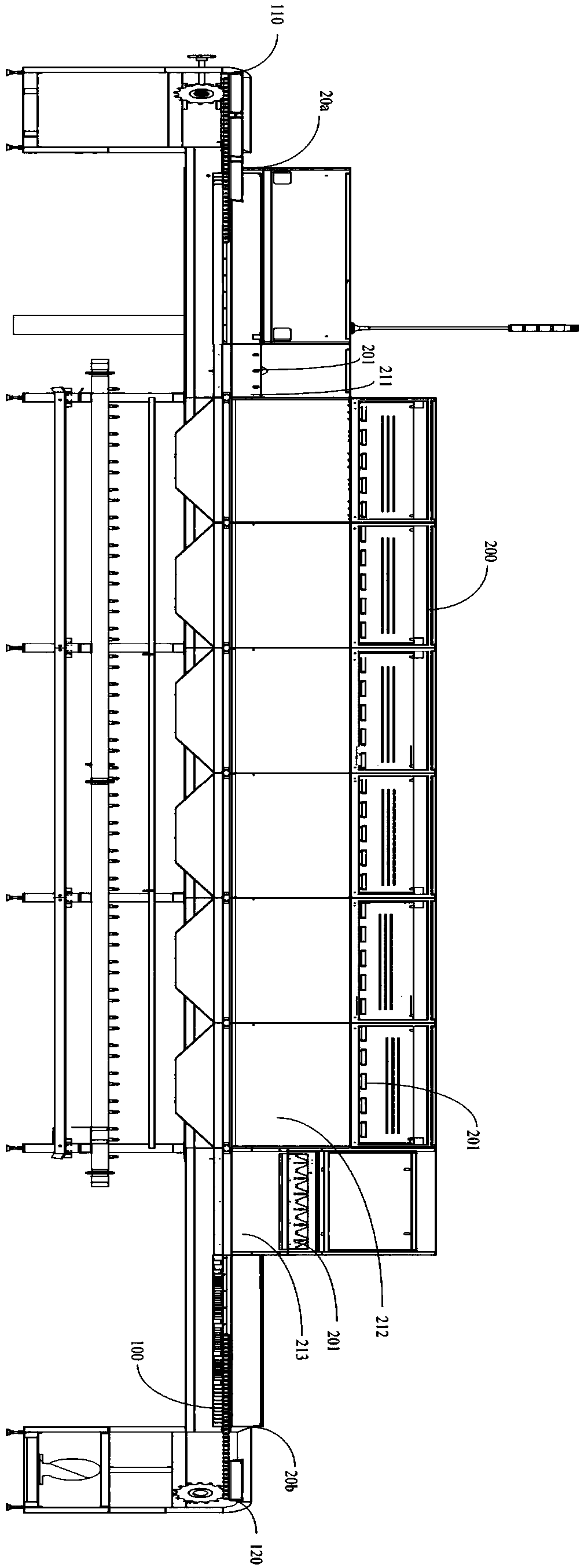

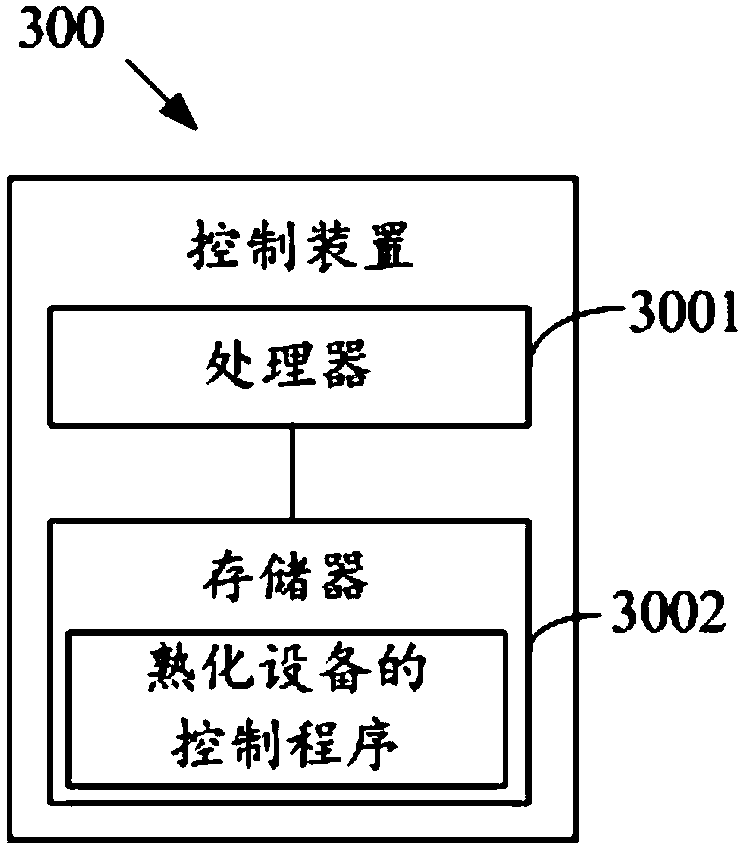

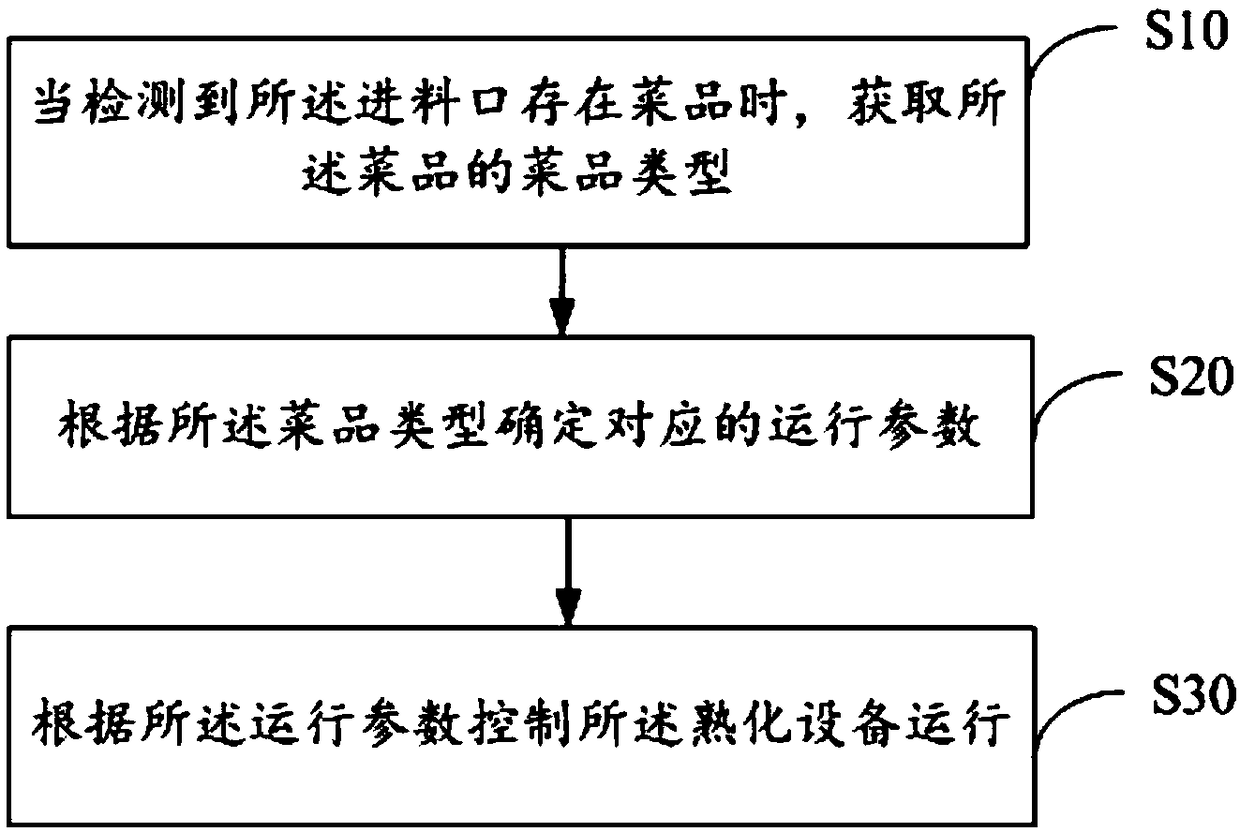

Ageing equipment and control method of ageing equipment

ActiveCN109463612AImprove ripening efficiencyReduce dependenceFood shapingParameter controlEmbedded system

The invention discloses a control method of ageing equipment. The control method comprises the following steps of when the situation that a dish exists in a feeding opening is detected, obtaining thedish type of the dish; according to the dish type, determining corresponding operation parameters; and according to the operation parameters, controlling the ageing equipment to operate. The inventionalso discloses the ageing equipment. Through the adoption of the control method disclosed by the invention, dishes are automatically aged, so that the ageing efficiency of the dishes is improved, andthe dependence of professional cooking workers is reduced.

Owner:佛山倍翔自动化科技有限公司

A spray ripening device for banana production and its application method

ActiveCN111387533BImprove ripening qualityGuaranteed uniformityFruit and vegetables preservationFood processingRipeningEngineering

The invention belongs to the technical field of banana ripening, in particular to a spray ripening device for banana production and its use method. A vinyl box is plugged in, and a liquid pump is provided on the inner wall of the bottom of the vinyl box, and a water pipe is sleeved on the output end of the liquid pump. A through hole, the inner wall of the through hole is inserted with a conical spray plate, and the inner wall around the conical spray plate is provided with spray holes, the top inner wall of the conical spray plate is provided with a mounting hole, and the inner wall of the mounting hole There is a connecting pipe plugged in. The invention ensures the uniformity of the ethylene liquid spraying, and the guide block can gather the ethylene liquid to the direction of the banana ring, on the one hand, it can increase the contact time between the banana and the ethylene liquid, and on the other hand, it can prevent the ethylene liquid from depositing in the ripening box waste, improving the ripening quality of bananas.

Owner:邳州市景鹏创业投资有限公司

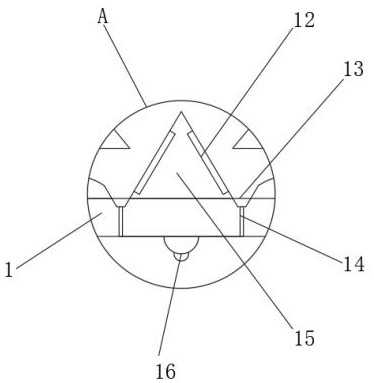

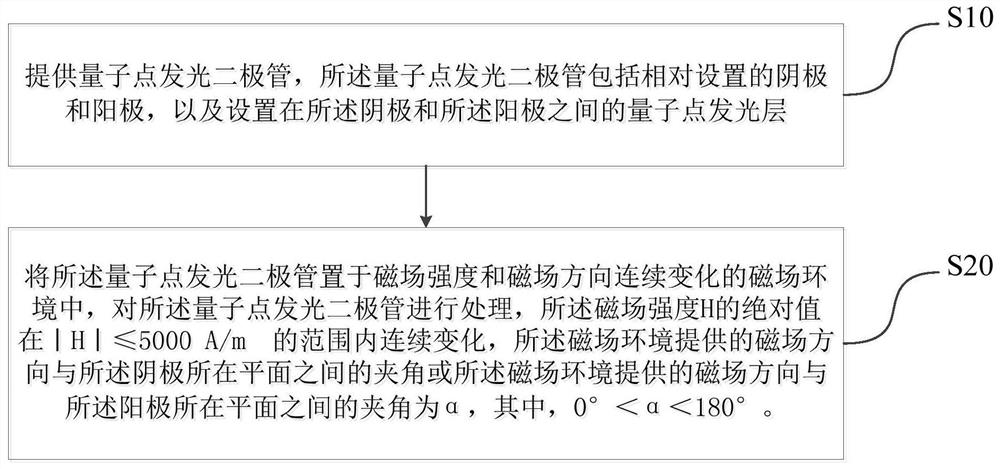

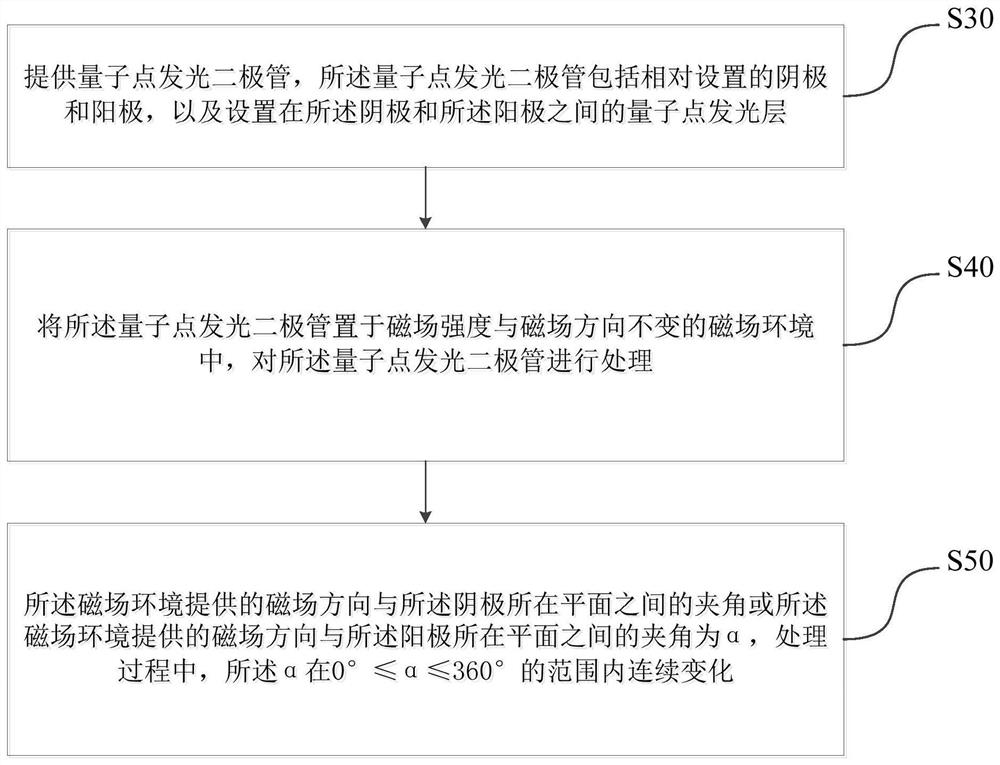

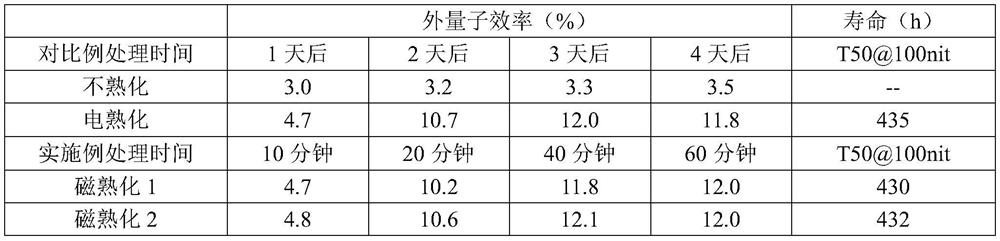

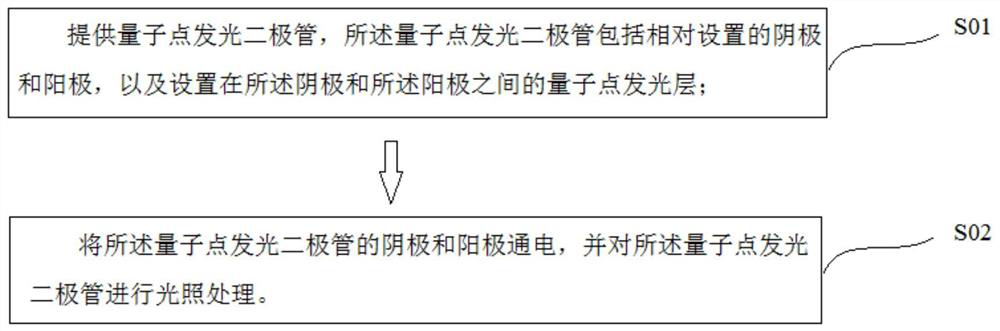

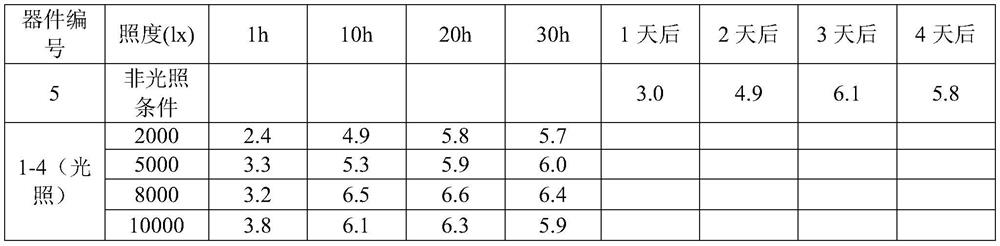

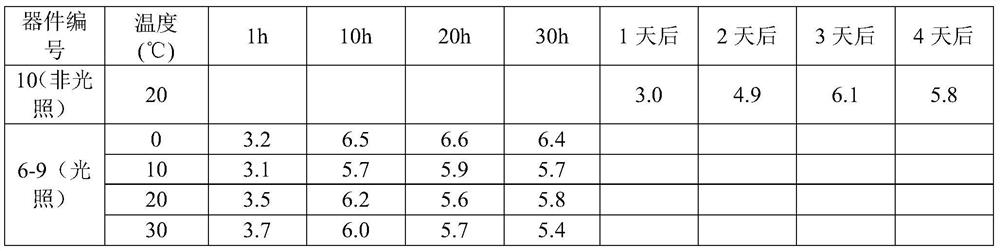

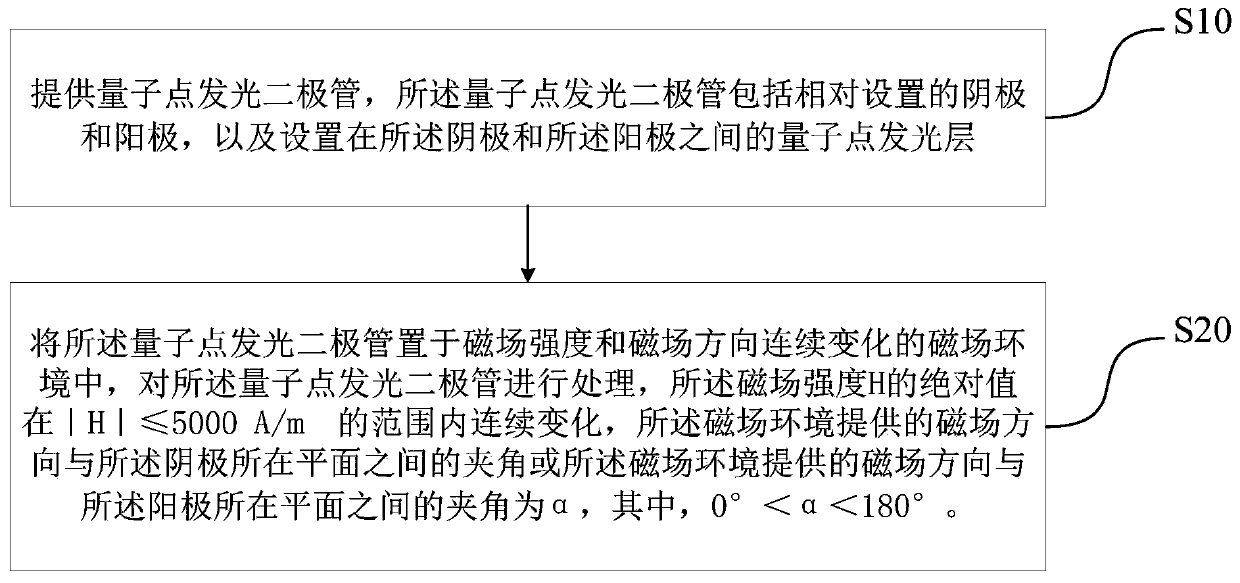

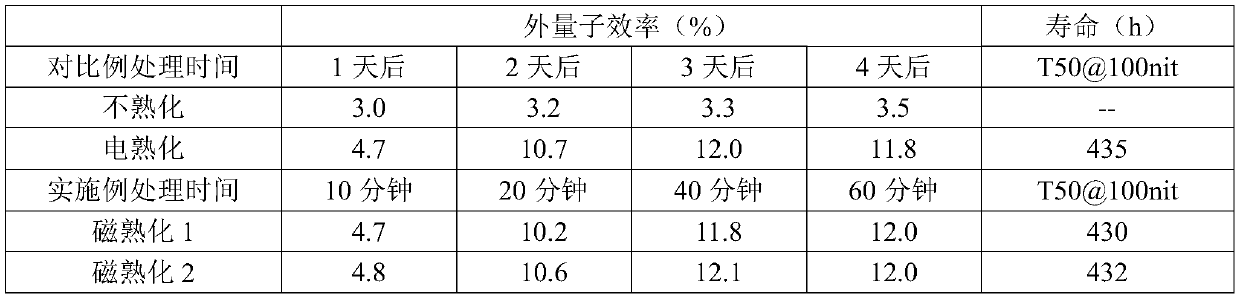

Post-processing method of quantum dot light-emitting diode

ActiveCN111384305BShort manufacturing cycleImprove external quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotParticle physics

The invention provides a post-processing method of a quantum dot light-emitting diode, comprising the following steps: providing a quantum dot light-emitting diode, the quantum dot light-emitting diode includes a cathode and an anode oppositely arranged, and an anode arranged between the cathode and the anode The quantum dot light-emitting layer between them; the quantum dot light-emitting diode is placed in a magnetic field environment where the magnetic field strength and the direction of the magnetic field change continuously, and the absolute value of the magnetic field strength H is continuous within the range of 0A / m≤H≤5000A / m Change, the angle between the magnetic field direction provided by the magnetic field environment and the plane where the cathode is located or the angle between the magnetic field direction provided by the magnetic field environment and the plane where the anode is located is α, where 0°<α <180°, the quantum dot light-emitting diode is processed.

Owner:TCL CORPORATION

Banana ripening acceleration device

InactiveCN112401271AEvenly distributedImprove product qualityFruit and vegetables preservationFood treatmentRipeningEngineering

The invention belongs to the technical field of fruit ripening acceleration, and particularly relates to a banana ripening acceleration device. To solve the problems of slow ripening acceleration andnon-uniform ripening acceleration of bananas, the following scheme is provided: the banana ripening acceleration device comprises a workbench, a ripening acceleration cylinder is fixed to the outer wall of the top of the workbench, two containing trays with the same size are arranged on the circumferential inner wall of the ripening acceleration cylinder, bulges which are evenly distributed are arranged on the outer walls of the tops of the containing trays, air outlet holes which are evenly distributed are formed in the outer walls of the bulges, an outer barrel is fixed to the circumferential inner walls of the containing trays, and an inner barrel is fixedly installed on the inner wall of the outer barrel. Bananas are placed on the bulges, an air inlet mechanism blows air upwards, the air enters a first reducing pipe, a ripening accelerator generated by apples in the inner barrel is blown away outwards, part of the ripening accelerator is diffused into the first reducing pipe and blown out upwards from air outlet holes, the bananas obtain the ripening accelerator uniformly, the ripening accelerator rushes into all parts of the bananas, the ripening accelerator is evenly distributed, the bananas are ripe simultaneously, and the product quality is high.

Owner:林美云

Stirring device for feed processing

InactiveCN110193311AImprove uniformityImprove ripening efficiencyFeeding-stuffRotary stirring mixersFeed processingCircular motion

The invention discloses a stirring device for feed processing. The device includes a tank body and a tank cover, the tank cover is arranged at the upper port of the tank body, a hopper is fixedly disposed on the left end of the tank body close to the upper end, the right end of the hopper is communicated with the tank body, the left end face of the hopper is equipped with a fan, a dedusting mechanism is fixedly disposed at the left end of the hopper, the right end of the dedusting mechanism is equipped with an opening, and the right end of the dedusting mechanism covers the fan's position where the hopper is disposed, the tank body is internally equipped with a stirring mechanism, the upper end of which is fixed on the tank cover. Two stirring rods are utilized to stir the feed in the tankbody simultaneously, a constantly rotating fluted disc disposed on the tank cover drives the stirring rods to do circular motion in the tank body, thus realizing stirring at multiple positions in thetank body, ensuring stirring of feed at all positions, greatly improving the stirring uniformity and the feed stirring efficiency, and also meeting mass feed stirring.

Owner:倪黄女

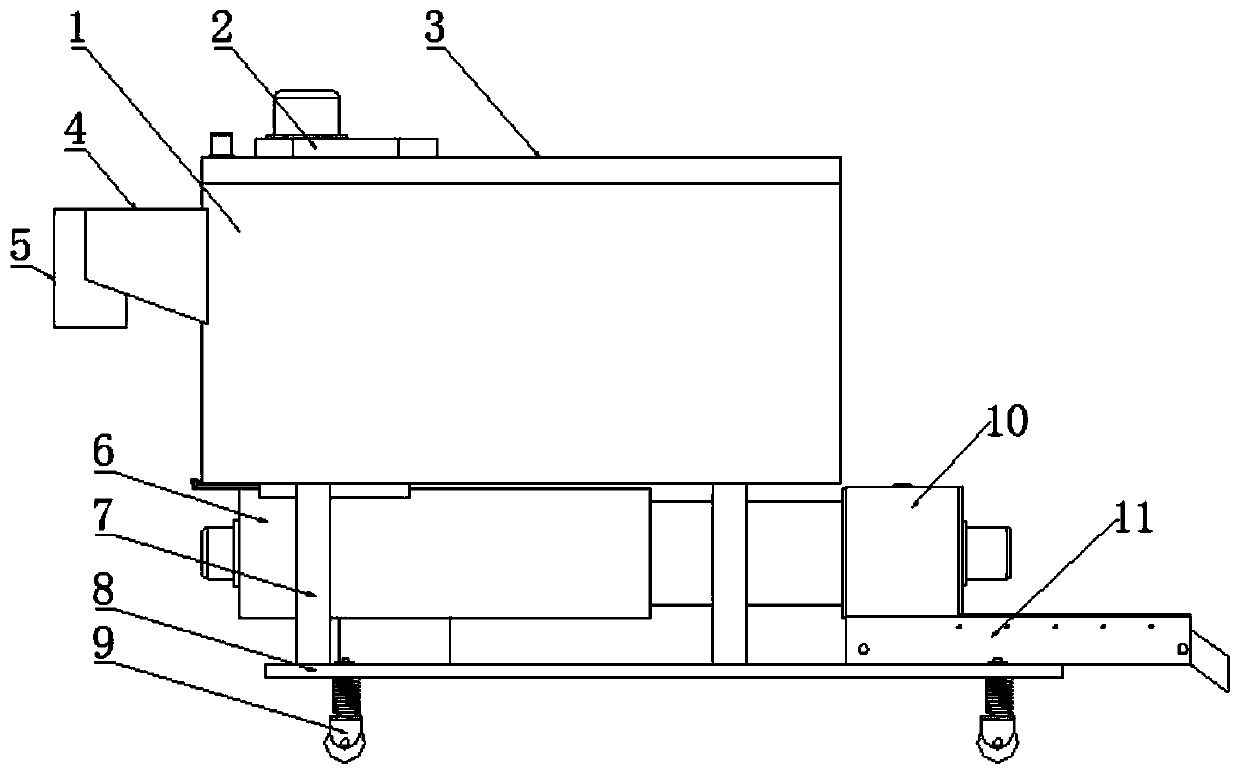

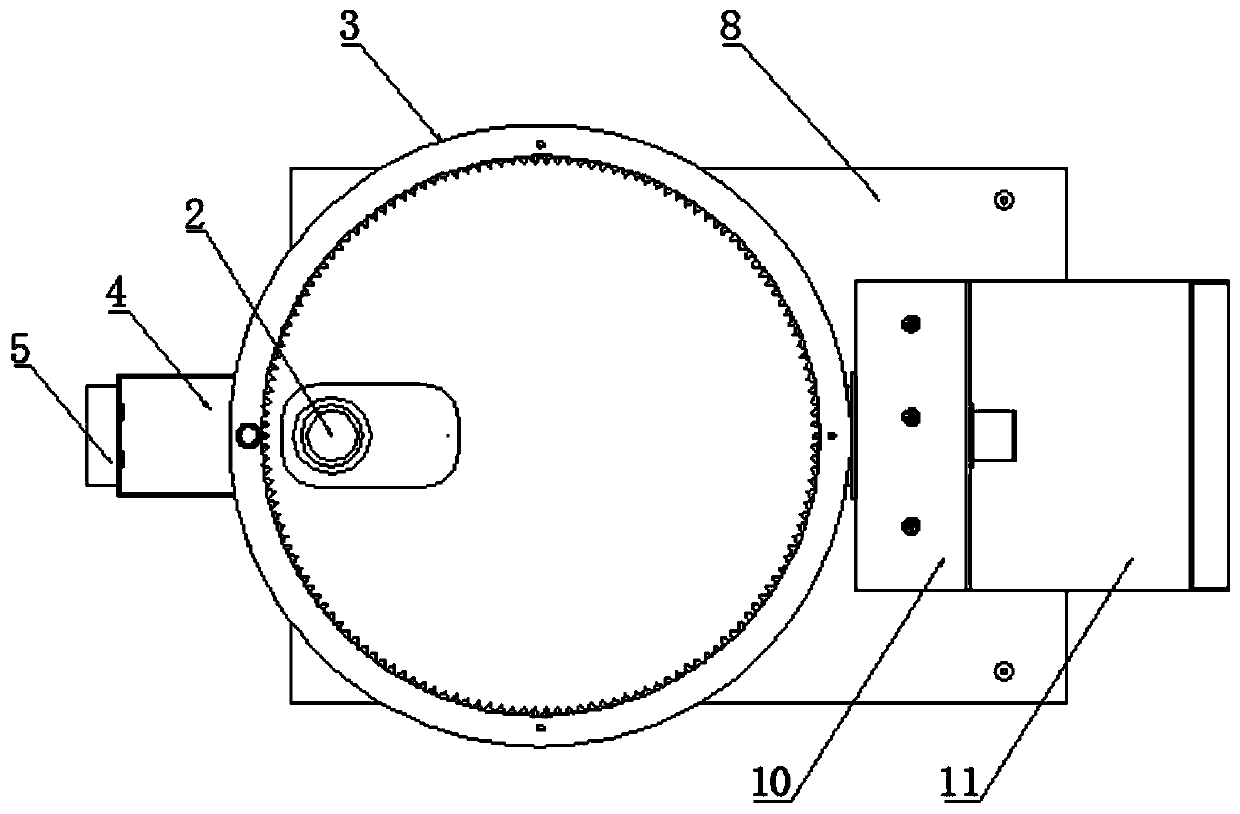

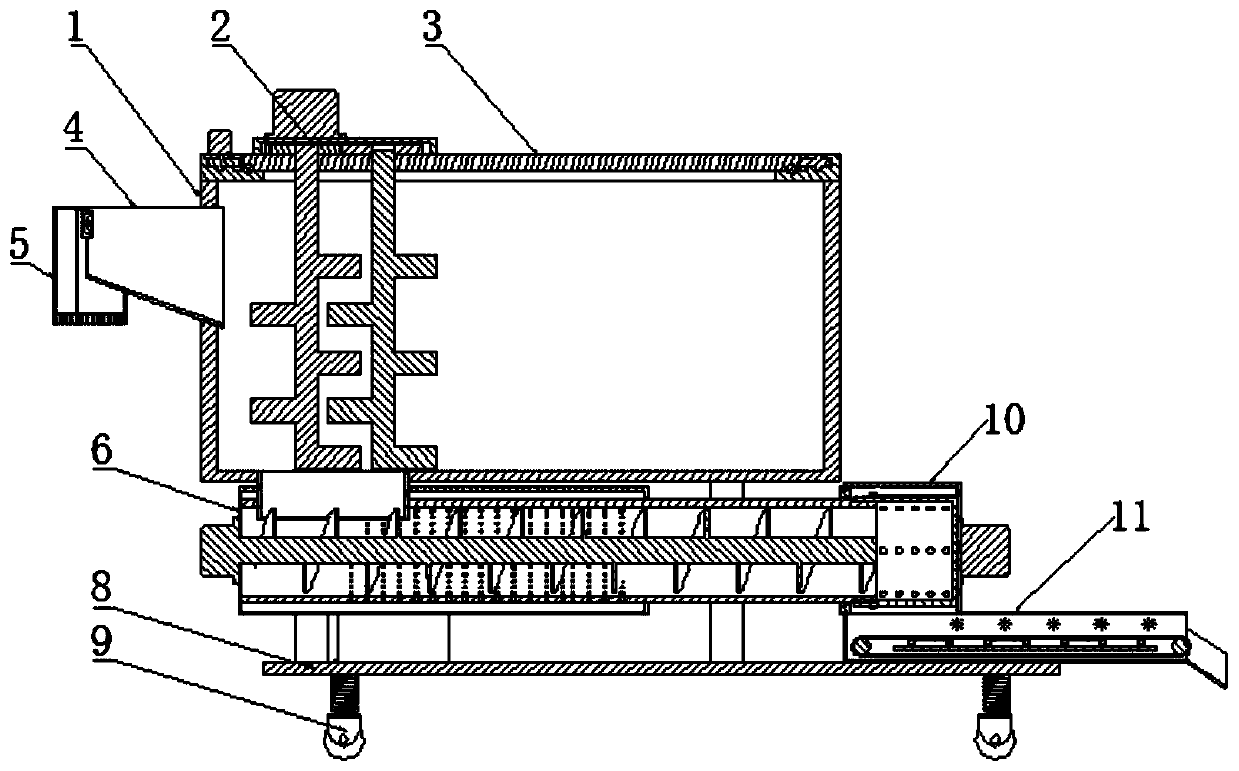

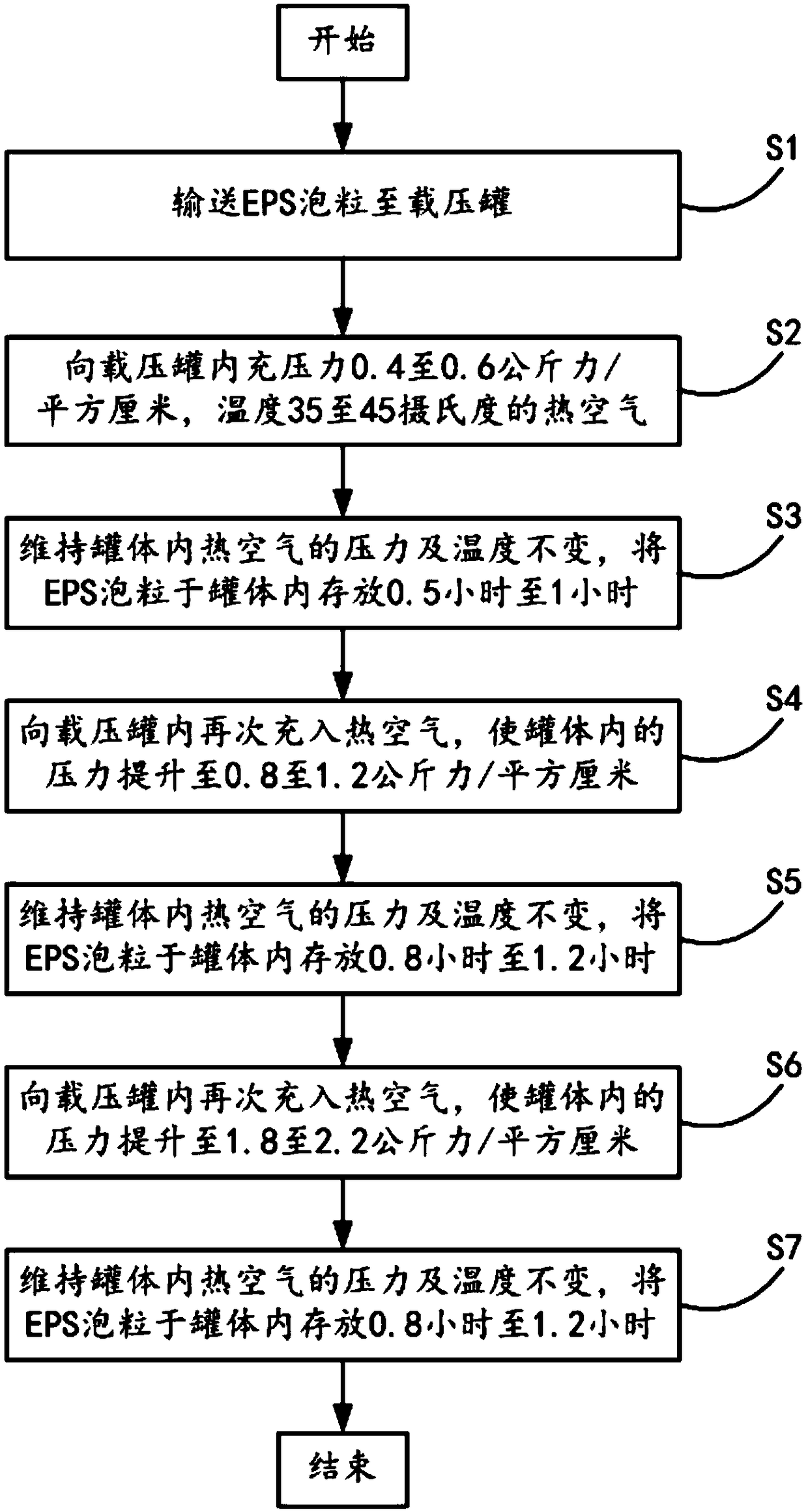

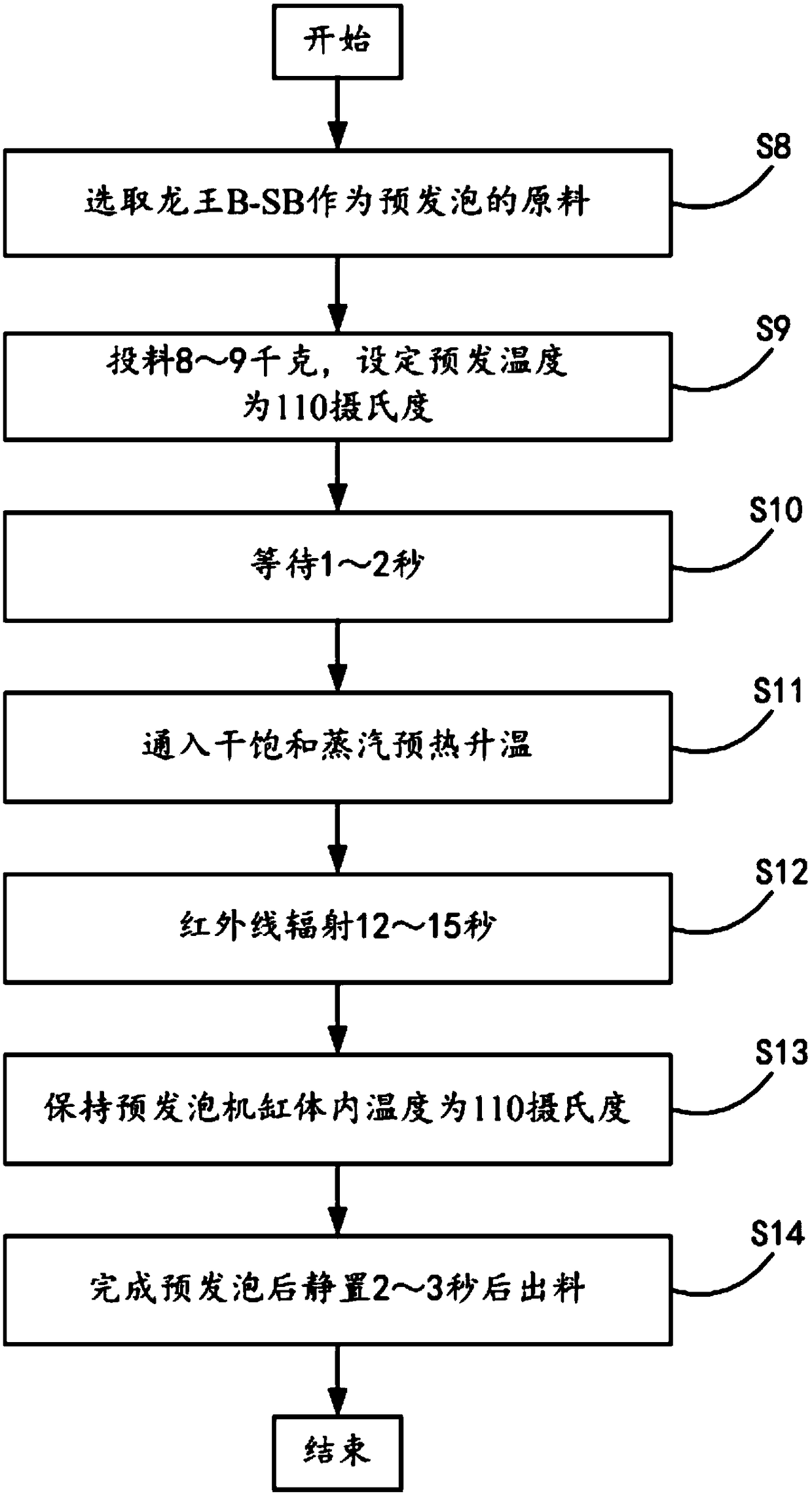

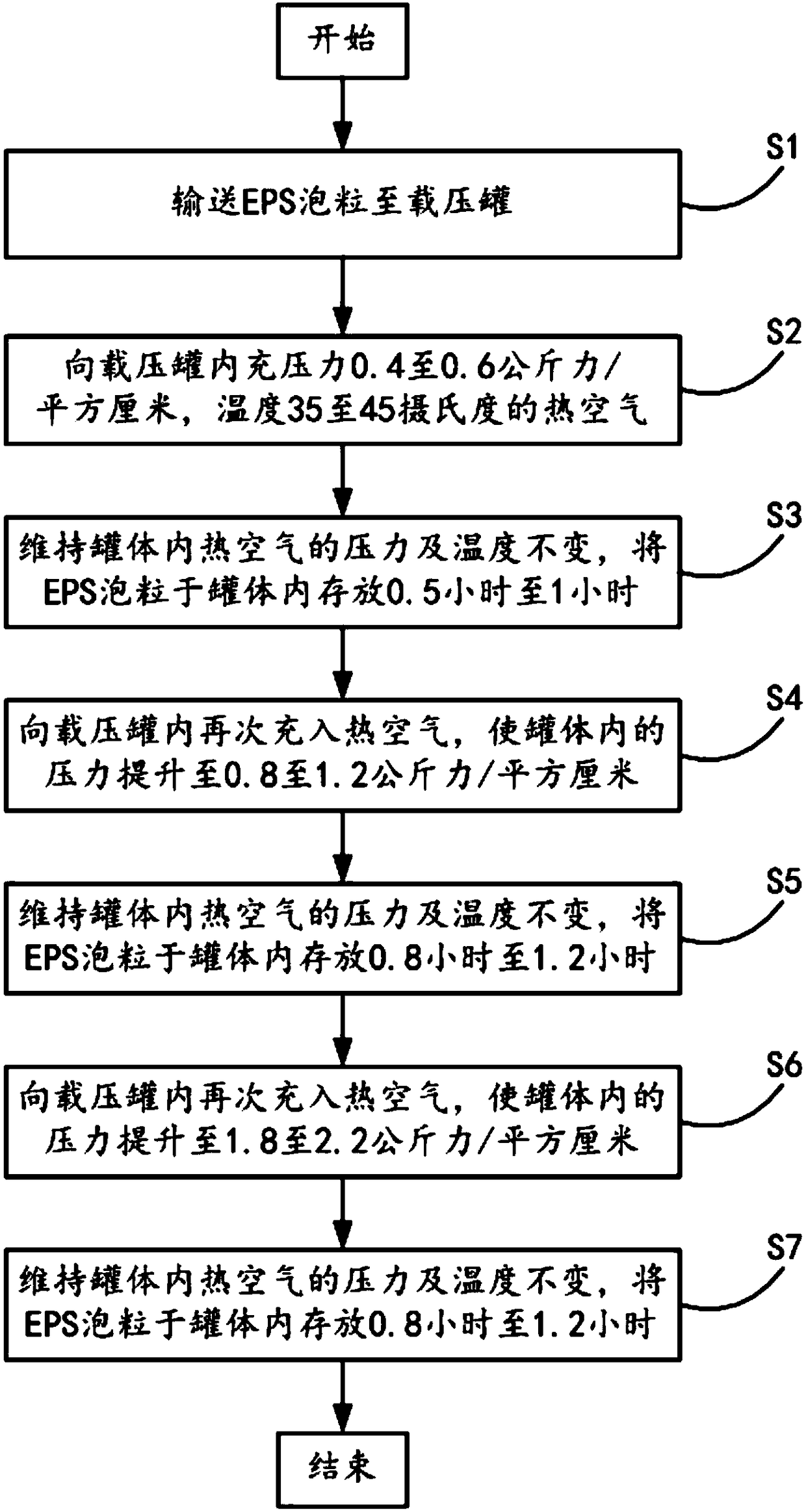

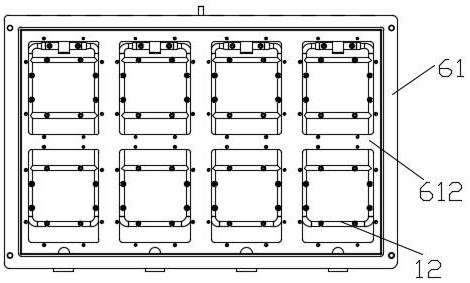

A production process of eps foam packaging box

The invention discloses an EPS foam packing box production process. The EPS foam packing box production process comprises pre-foaming, curing and forming procedures, wherein in the curing procedure, EPS foam particles are conveyed to a pressure-loading tank; hot air of which the pressure is 0.4-0.6 kilogram force per square centimeter and the temperature is 35-45 DEG C is injected into the tank body of the pressure-loading tank; the pressure and the temperature of hot air in the tank body are kept unchanged, and the EPS foam particles are stored for 0.5-1 hour; hot air is injected into the tank body again, thereby increasing the internal pressure of tank body to 0.8-1.2 kilogram force per square centimeter; the internal pressure and temperature of the tank body are kept unchanged, and the EPS foam particles are stored for 0.8-1.2 hours; hot air is injected into the tank body for the third time, thereby increasing the internal pressure of tank body to 1.8-2.2 kilogram force per square centimeter; and the internal pressure and temperature of the tank body are kept unchanged, the EPS foam particles are stored for 0.8-1.2 hours, and then the curing treatment is completed. According to the EPS foam packing box production process, a pressurizing and warming mode is adopted for the curing treatment, the curing effect is good, and the cell internal negative pressure recovery rate reaches 99%.

Owner:福建南安艺洋泡沫制品有限公司

Rapid pulping method

ActiveCN102273596BAvoid the "paste tube" problemOmit boil structureFood preparationPulp and paper industryComposite material

The invention relates to a rapid pulping method. The rapid pulping method comprises a preheating stage for heating water and / or materials, and a crushing and curing stage for crushing and curing the materials; in the crushing and curing stage, a crushing cutting tool and a container are provided; when the materials and water are mixed in the container and is crushed into pulp / paste by the crushing cutting tool, heat is generated by the mutual friction among the pulp / paste, the crushing cutting tool, and the container, which heats the pulp / paste till the pulp / paste is cured. The rapid pulping method of the invention overcomes the prejudice that a boiling way is necessary for pulp / paste preparation in the industry, and saves the soybean milk boiling stage; the pulp or paste is cured by means of heating through friction among the pulp / paste, the crushing cutting tool, and the container; because material crushing and pulp or paste curing are performed simultaneously in the crushing and curing stage, the pulp or paste boiling time is saved, and thus the total pulping time is greatly shortened.

Owner:JOYOUNG CO LTD

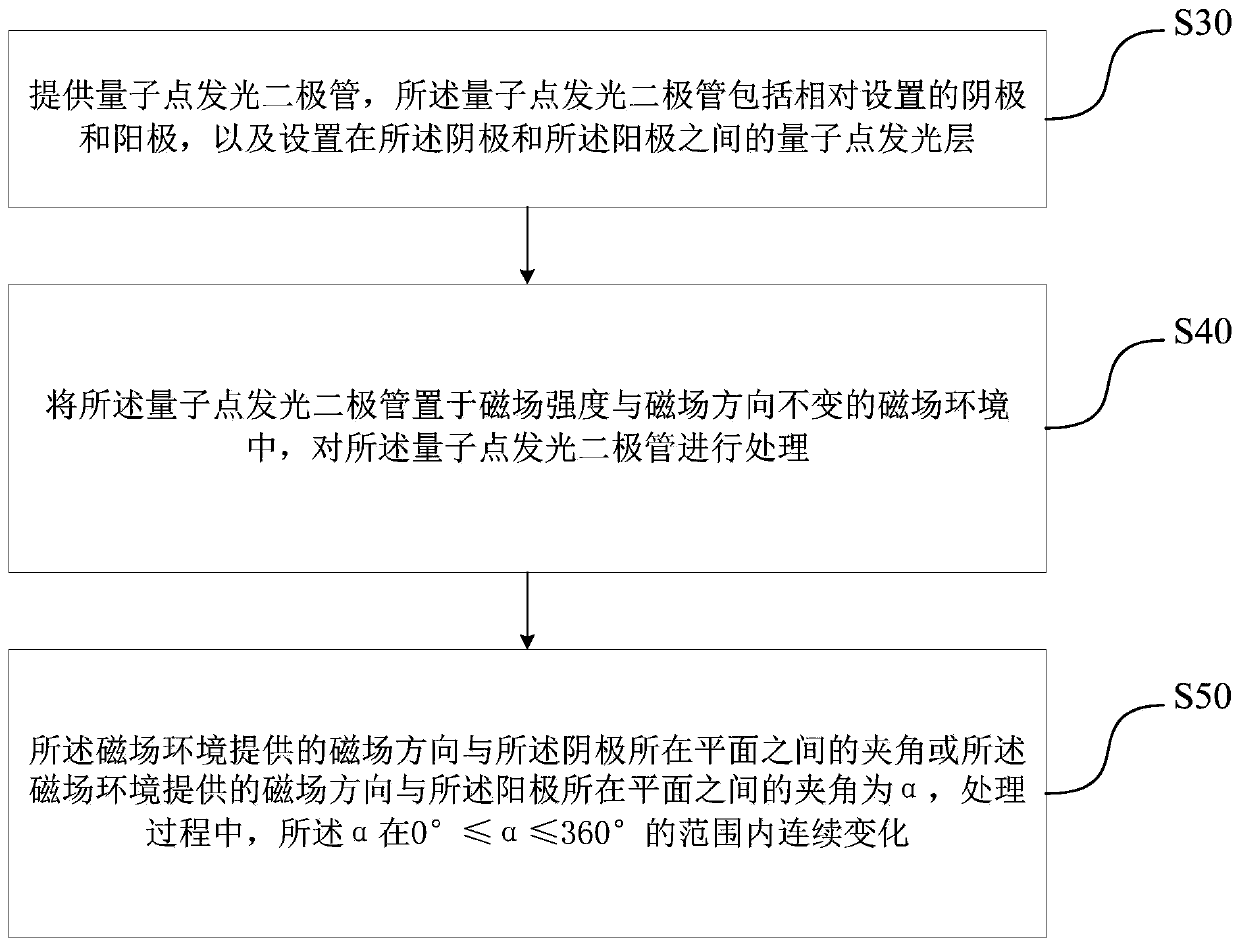

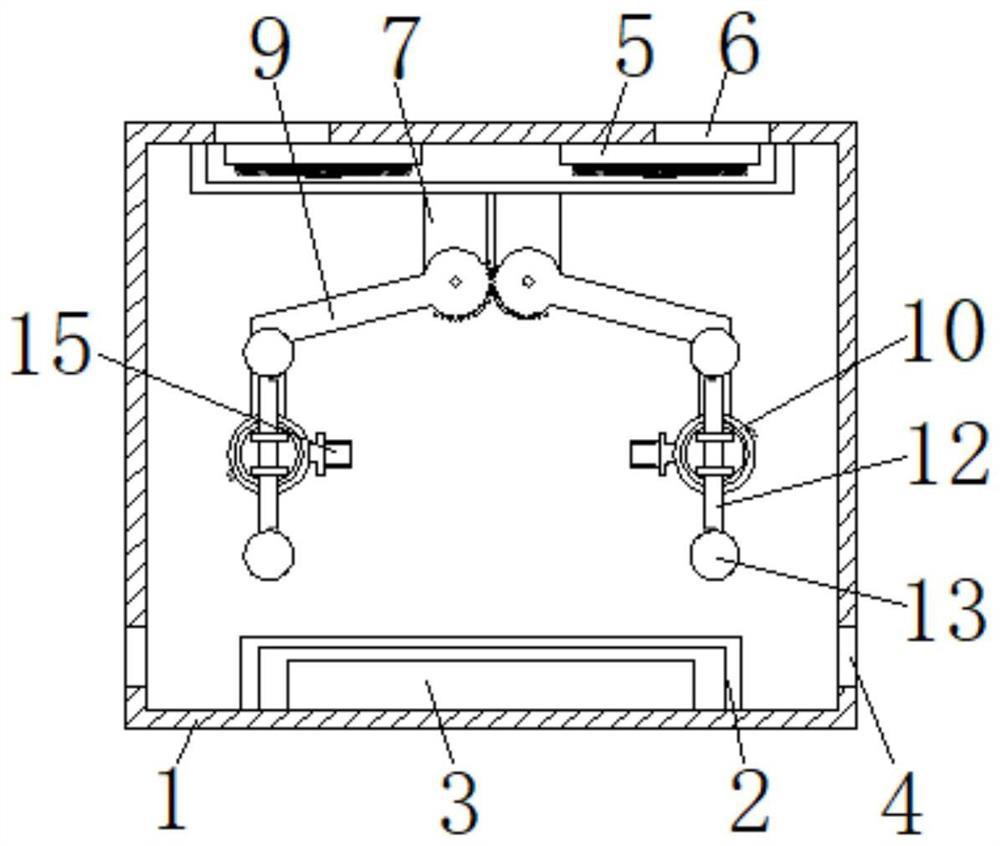

Post-processing method of quantum dot light-emitting diode

ActiveCN111384304BImprove ripening efficiencyShort manufacturing cycleSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotParticle physics

The invention provides a post-processing method of a quantum dot light-emitting diode, comprising the following steps: providing a quantum dot light-emitting diode, the quantum dot light-emitting diode includes a cathode and an anode oppositely arranged, and an anode arranged between the cathode and the anode The quantum dot light-emitting layer between; the cathode and the anode of the quantum dot light-emitting diode are energized, and the quantum dot light-emitting diode is subjected to light treatment.

Owner:TCL CORPORATION

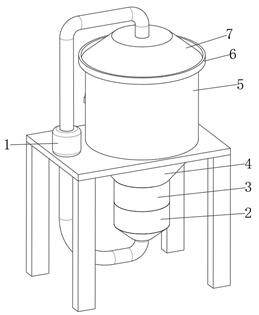

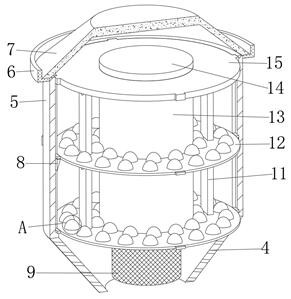

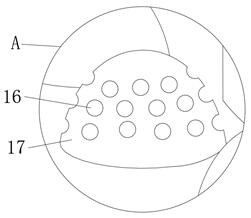

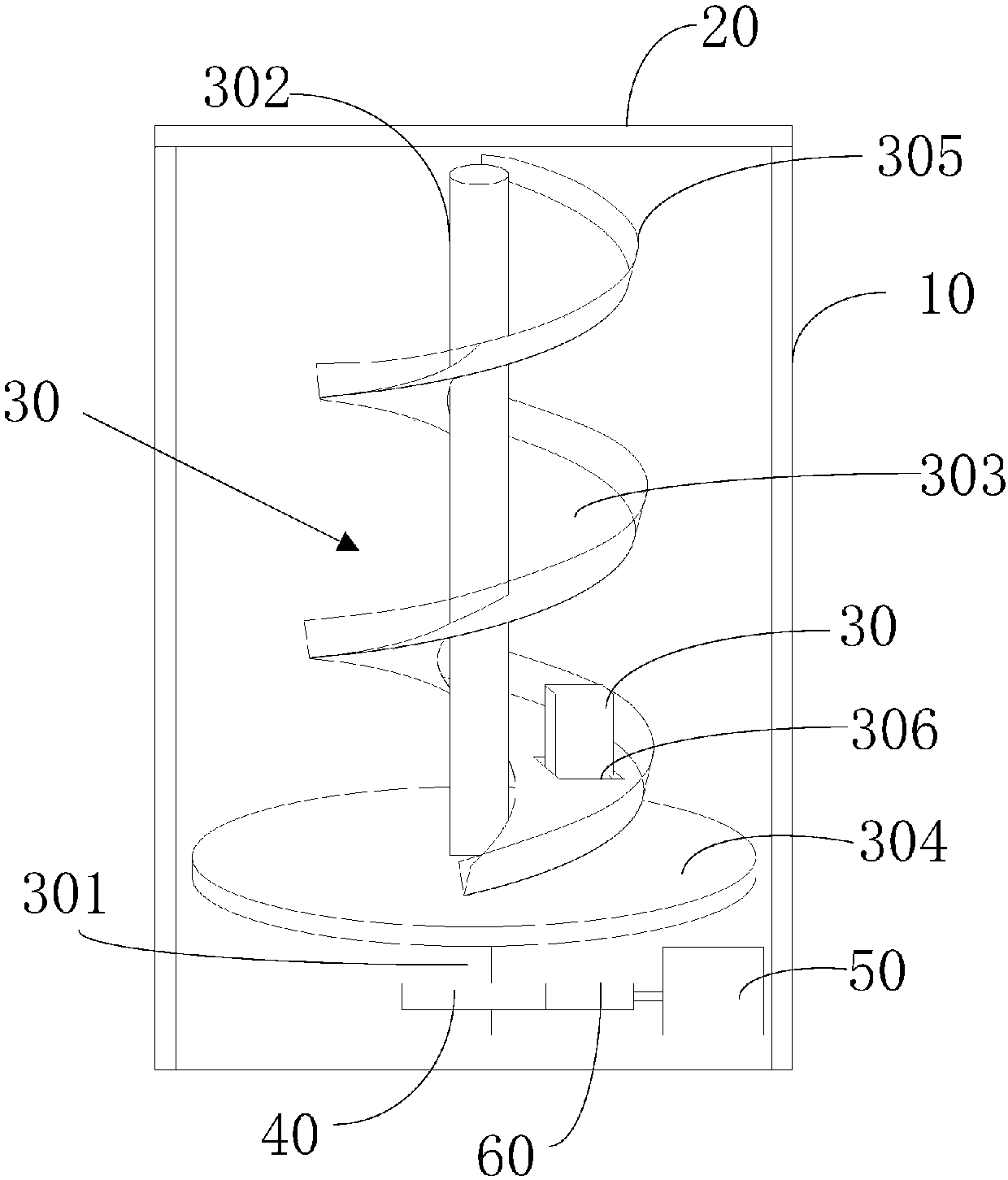

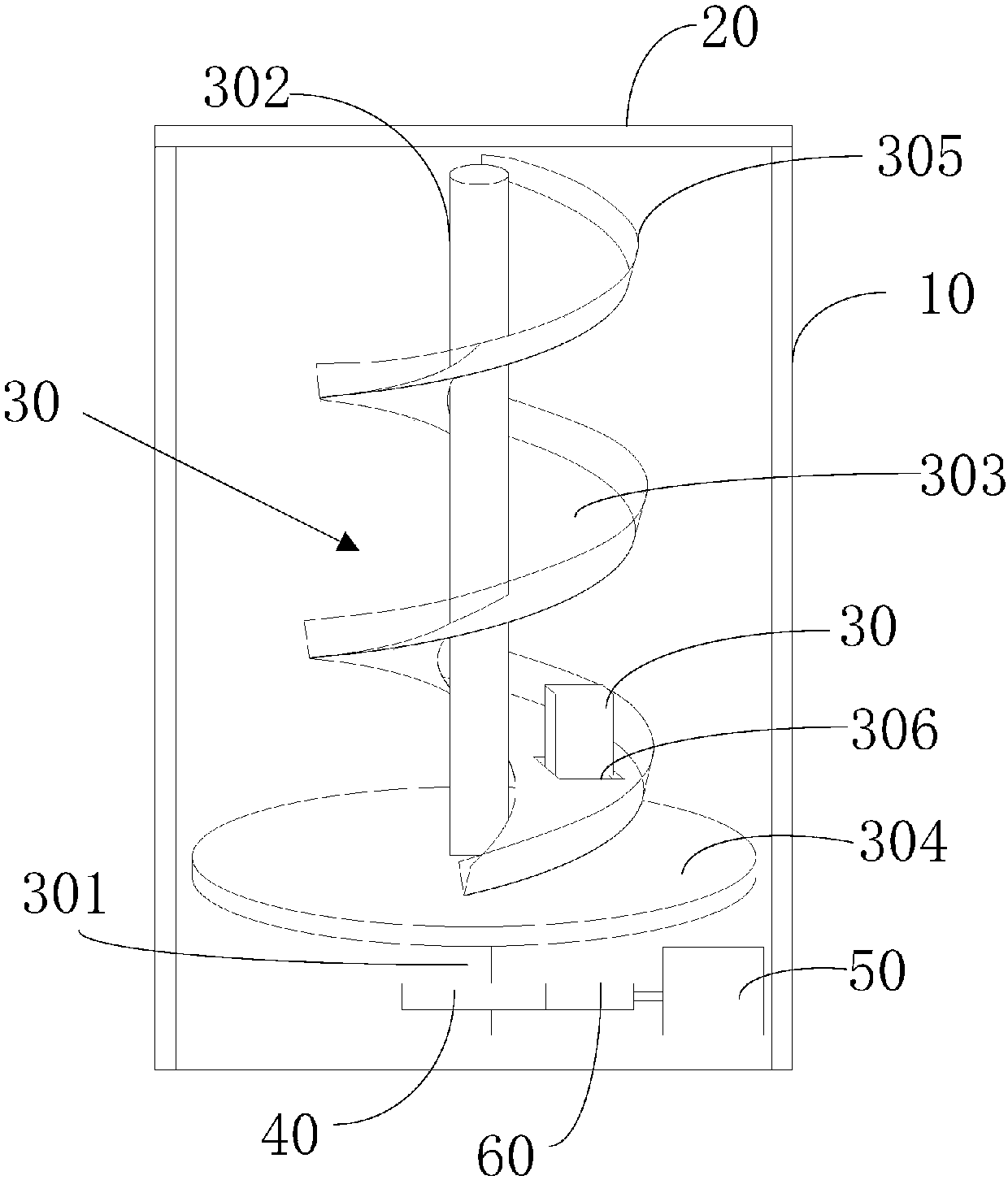

Simple material aging accelerating device

InactiveCN109957489AImprove stabilityImprove reliabilityAlcoholic beverage preparationSteering wheelEngineering

The present invention discloses a simple material aging accelerating device. The simple material aging accelerating device comprises a large barrel, a wine storing device arranged in the large barreland a pot cover covering the large barrel, the wine storing device comprises an automatic shaft, a safe barrel arranged on the automatic shaft and in thread engagement with the automatic shaft, a spirally wound direction plate arranged on the safe barrel and along an axis, a placing plate arranged on a bottom part of the automatic shaft, a starter arranged at a bottom part of the placing plate anda cup arranged on the direction plate, baijiu is filled in the cup, the automatic shaft and the placing plate are integrally arranged, a sliding wheel is arranged at a bottom part of the placing plate, the starter is meshed with the sliding wheel to drive the placing plate and the automatic shaft to rotate at the same time, an edge of the direction plate is provided with a screen arranged upward,and a circular groove used for positioning the cup is arranged in surface of the direction plate. The simple material aging accelerating device is good in stability, excellent in reliability, convenient for operation and use, novel in design, strong in practicability and easy for promotion and application.

Owner:西安琦瑶智能科技有限公司

Energy-saving and emission-reducing curing equipment

The invention belongs to the technical field of curing equipment, in particular to energy-saving and emission-reducing curing equipment. The energy-saving and emission-reducing curing equipment comprises a curing tank and a curing cylinder. An unloading pipe is fixedly connected to one side of an inner bottom wall of the curing cylinder, a hollow conveying shaft and an auger blade are arranged in the curing cylinder, the left end of the hollow conveying shaft extends outside the curing cylinder and is provided with a mounting groove, a driving motor is arranged above the curing tank, an output shaft of the driving motor is connected to a stirring mechanism, the stirring mechanism is located in the curing tank, a discharge pipe is fixedly connected to an inner bottom wall of the curing tank, and the curing tank is connected to the curing cylinder through the discharge pipe. By connecting an external hot oil pipeline to a second rotary joint, hot oil is introduced into the external hot oil pipeline, the hot oil heats the hollow conveying shaft and then heats a clamping sleeve, and plastic particles heated and cured in the curing tank enter the curing cylinder to be further cured, so that the curing efficiency is improved, the energy source can be saved effectively, and the energy-saving and emission-reducing curing equipment is suitable for promotion and application.

Owner:江西捷美软包装有限公司

Post-processing method of quantum dot light emitting diode

ActiveCN111384305AShort manufacturing cycleImprove external quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotParticle physics

The invention provides a post-processing method for a quantum dot light emitting diode. The method comprises the following steps: providing the quantum dot light emitting diode which comprises a cathode and an anode, which are opposite to each other, and a quantum dot light emitting layer disposed between the cathode and the anode; placing the quantum dot light emitting diode in a magnetic field environment with continuously changed magnetic field intensity and magnetic field direction, wherein the absolute value of the magnetic field intensity H is continuously changed in a range of 0 A / m <=H <= 5000A / m, the included angle between the magnetic field direction provided by the magnetic field environment and the plane where the cathode is located or the included angle between the magnetic field direction provided by the magnetic field environment and the plane where the anode is located is alpha, and the inequation of 0<alpha<180(degrees) is satisfied; and performing treatment on the quantum dot light-emitting diode.

Owner:TCL CORPORATION

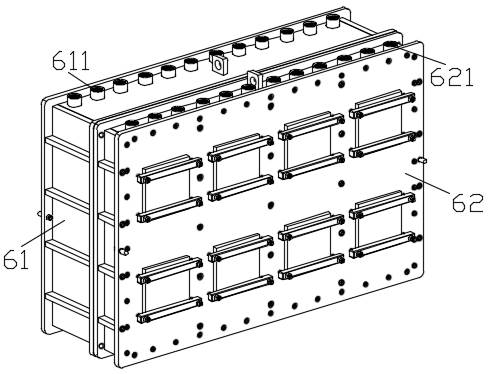

An eps heating and pressurized curing process

The invention discloses an EPS temperature-increasing pressurizing curing process. The EPS temperature-increasing pressurizing curing process comprises the steps that EPS particles are conveyed to a pressure-loading tank; hot air of which the pressure ranges from 0.4 kgf / cm<2> to 0.6 kgf / cm<2> and the temperature ranges from 35 DEG C to 45 DEG C is injected into the pressure-loading tank; the pressure and temperature of the hot air in a tank body remain unchanged, and the EPS particles are stored for 0.5 h to 1 h; the hot air is injected into the pressure-loading tank again, and the pressure in the tank body is increased to 0.8 kgf / cm<2> to 1.2 kgf / cm<2>; the pressure and temperature in the tank body remain unchanged, and the EPS particles are stored for 0.8 h to 1.2 h; the hot air is injected into the pressure-loading tank again, and the pressure in the tank body is increased to 1.8 kgf / cm<2> to 2.2 kgf / cm<2>; the pressure and temperature in the tank body remain unchanged, the EPS particles are stored for 0.8 h to 1.2 h, and curing of the EPS particles is completed. Curing treatment is conducted on EPS in a temperature-increasing pressurizing mode, the curing effect is good, and the negative pressure recovery rate in cell reaches 99%.

Owner:承德鸿城节能科技有限公司

A system and method for ethylene gas ripening and stripping walnut green peel

ActiveCN104544491BReduce moisture contentThe amount of liquid squeezed out is reducedHuskingHullingRipeningBreakage rate

The invention discloses a system and a method of removing green peels of walnuts through ethylene gas ripening. Green-peeled walnuts are poured into a box from a feeder and dropped onto a top wire mesh conveying belt in the box, the green-peeled walnuts are slowly conveyed from an entry of the box to an exit of the box, and a gas ethylene generator enters the box during conveying and performs ethylene gas ripening to the green peels of the walnuts; after the green peels are ripened, the walnuts directly fall into a rubbing stripping unit from the tail end of a bottom wire mesh conveying belt, and the green peels and inner hard shells of the walnuts are separated. Gas ethylene is used to ripen the green peels o the walnuts and remove the green peels; removal rate of the green peels is high; breakage rate is low; yield of commercial walnuts is high; efficiency is high; the use of the gas ethylene in ripening the green peels prevents kernels from being contaminated, resulting in food contamination; meanwhile, the processing process is green.

Owner:SHAANXI UNIV OF SCI & TECH

Packaging composite curing method and system

Owner:湖南泽坤包装科技有限公司

Soybean milk cooking technology, whole soybean milk manufacturing technology and cooking device

PendingCN110432331AIncrease nutritionGreat tasteMilk substitutesManufacturing technologySteam cooking

The present invention discloses a soybean milk cooking technology, a manufacturing technology and a cooking device, and belongs to the field of food processing. The soybean milk cooking technology comprises conducting water steam cooking of raw materials containing soybeans under high pressure conditions. High pressure water steam is used for cooking, cooking time is short, a protein denaturationrate of the soybeans is low, and the obtained soybean milk has high nutrition and good mouthfeel. The manufacturing technology of the whole soybean milk comprises conducting soybean washing of the rawmaterials containing the soybeans, soybean soaking, cooking, slurry grinding and slurry boiling. The manufacturing technology of the whole soybean milk does not remove soybean hulls and soybean dregsof the soybeans, can retain all nutrition of the soybeans, also enables the manufactured soybean milk to be good in mouthfeel, and is high in efficiency for preparing the soybean milk. The cooking device is suitable for the cooking of the raw materials of the soybean milk, also high in the cooking efficiency, uniform in the cooking of the raw materials, and not liable to clog, and easily controlswater content in the raw materials.

Owner:豆源和(山东)食品饮料有限公司

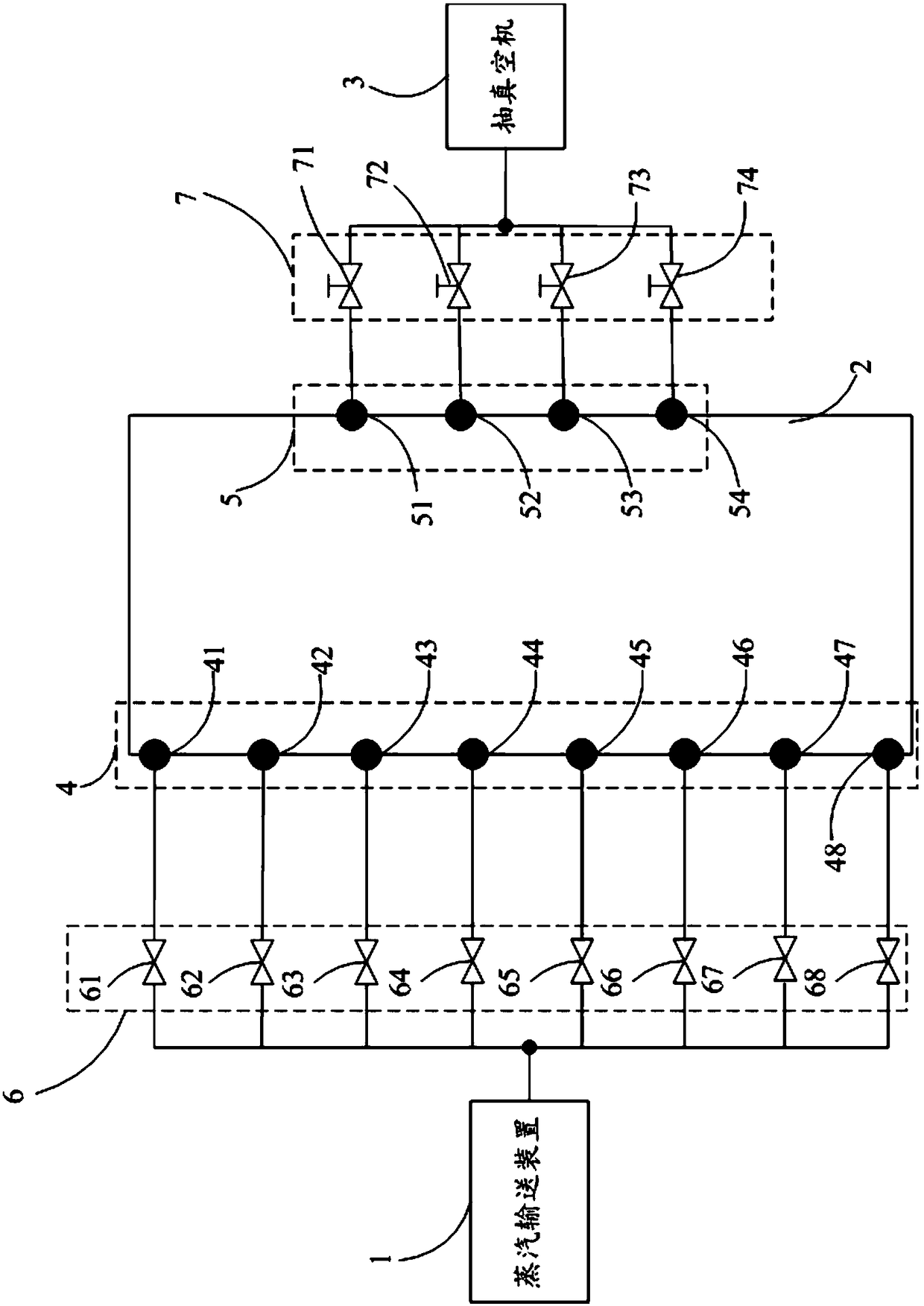

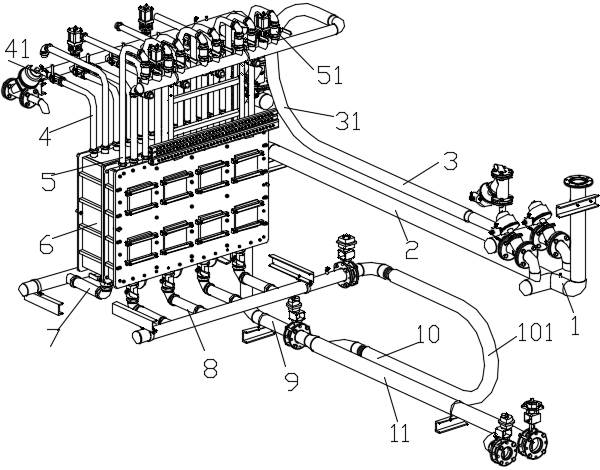

Curing device for accelerating steam penetration through multi-pipeline steam inlet and curing method thereof

The invention relates to a curing device for accelerating steam penetration through multi-pipeline steam inlet and a curing method of the curing device, and aims to solve the problems of relatively slow steam inflow and non-uniform curing of a curing device in the prior art. According to the technical scheme, the curing device comprises a steam inlet header pipe, a fixed die steam inlet header pipe, a movable die steam inlet header pipe, a fixed die steam inlet pipe, a movable die steam inlet pipe, a die frame, a fixed die steam exhaust pipe, a movable die steam exhaust pipe, a fixed die steam exhaust header pipe, a movable die steam exhaust header pipe, a steam exhaust header pipe and a steam inlet distributor; the fixed die steam inlet header pipe and the movable die steam inlet header pipe are both connected with the steam inlet header pipe; the fixed die steam exhaust header pipe and the movable die steam exhaust header pipe are both connected with the steam exhaust header pipe; the die frame comprises a fixed die frame and a movable die frame; a fixed die steam inlet is formed in the upper end of the fixed die frame; a fixed die plate for mounting a die is also arranged on the fixed die frame; and a movable die steam inlet is formed in the upper end of the movable die frame. The curing device is rapid in steam inlet and uniform in curing.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

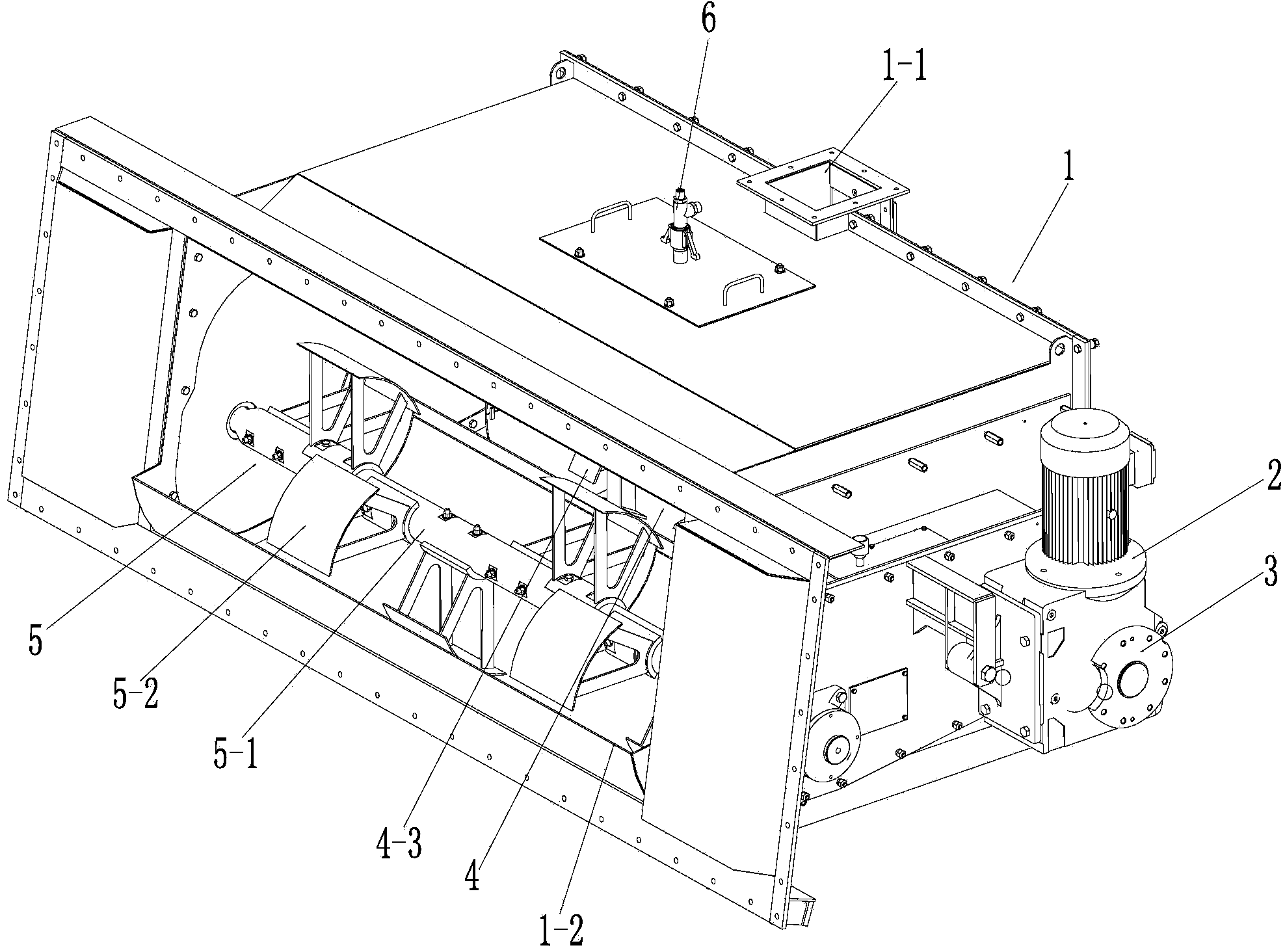

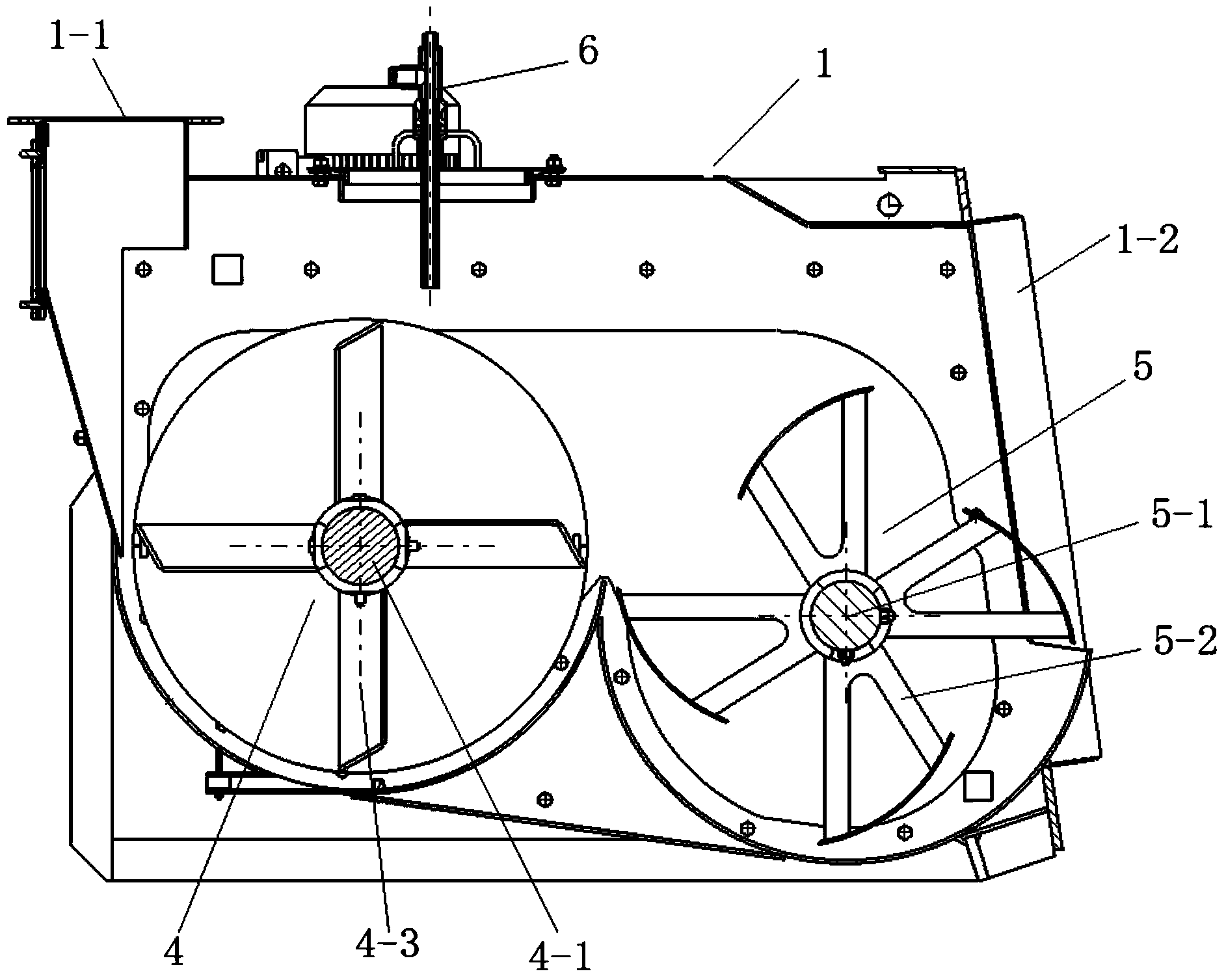

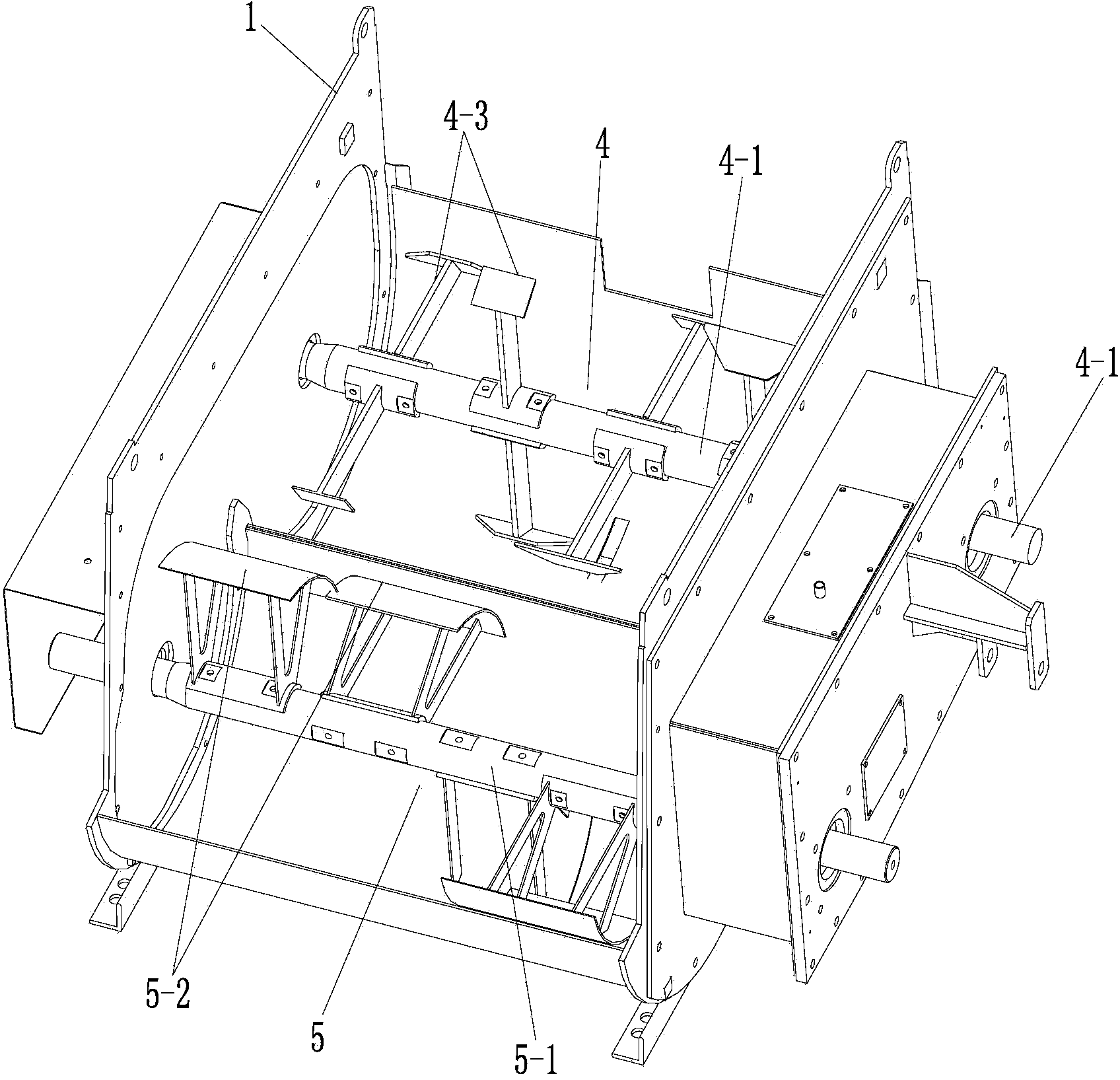

Efficient desulfuration digesting device

InactiveCN104056570AImprove ripening efficiencyGood aging effectDispersed particle separationMixersEngineering

The invention relates to the technical field of the environmental friendliness industry, in particular to an efficient desulfuration digesting device which comprises a shell. The top end face of the shell is provided with a feeding port and a spray gun. The front surface of the shell is provided with a discharging port, and the right surface of the shell is provided with a motor and a reduction box. A rotating shaft of the motor is fixedly connected with a transmission input shaft of the reduction box. A first stirring cavity and a second stirring cavity are formed in an inner cavity of the shell, the first stirring cavity is provided with a first stirring device, and the second stirring cavity is provided with a second stirring device. The spraying end of the spray gun is located over the first stirring device, and the second stirring device is close to the discharging port. A chain wheel of the first stirring device is connected with a chain wheel of the second stirring device through a chain, and the first stirring device is fixedly connected with a transmission output shaft of the reduction box. When the efficient desulfuration digesting device is used, the lime curing efficiency is improved, the lime curing effect is improved, and lime blocks are prevented from being mixed into a mixer. The efficient desulfuration digesting device has the advantages of being simple in structure, reasonable in arrangement, low in manufacturing cost and the like.

Owner:ZHANGJIAGANG JINMING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com