Stirring device for feed processing

A stirring device and feed processing technology, which is applied to heating devices, mixers with rotating stirring devices, feed, etc., can solve the problems of poor mixing effect, small stirring volume, and low stirring efficiency, so as to improve uniformity and improve Efficiency, good use of the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

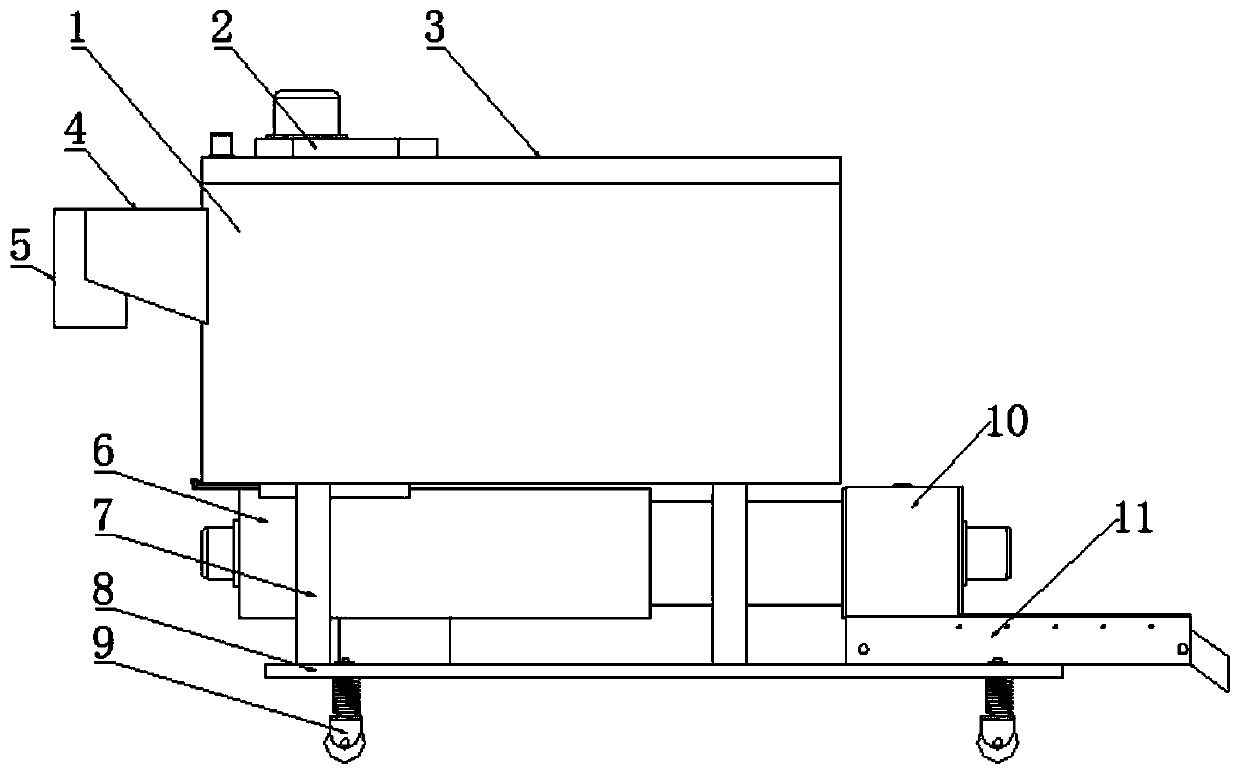

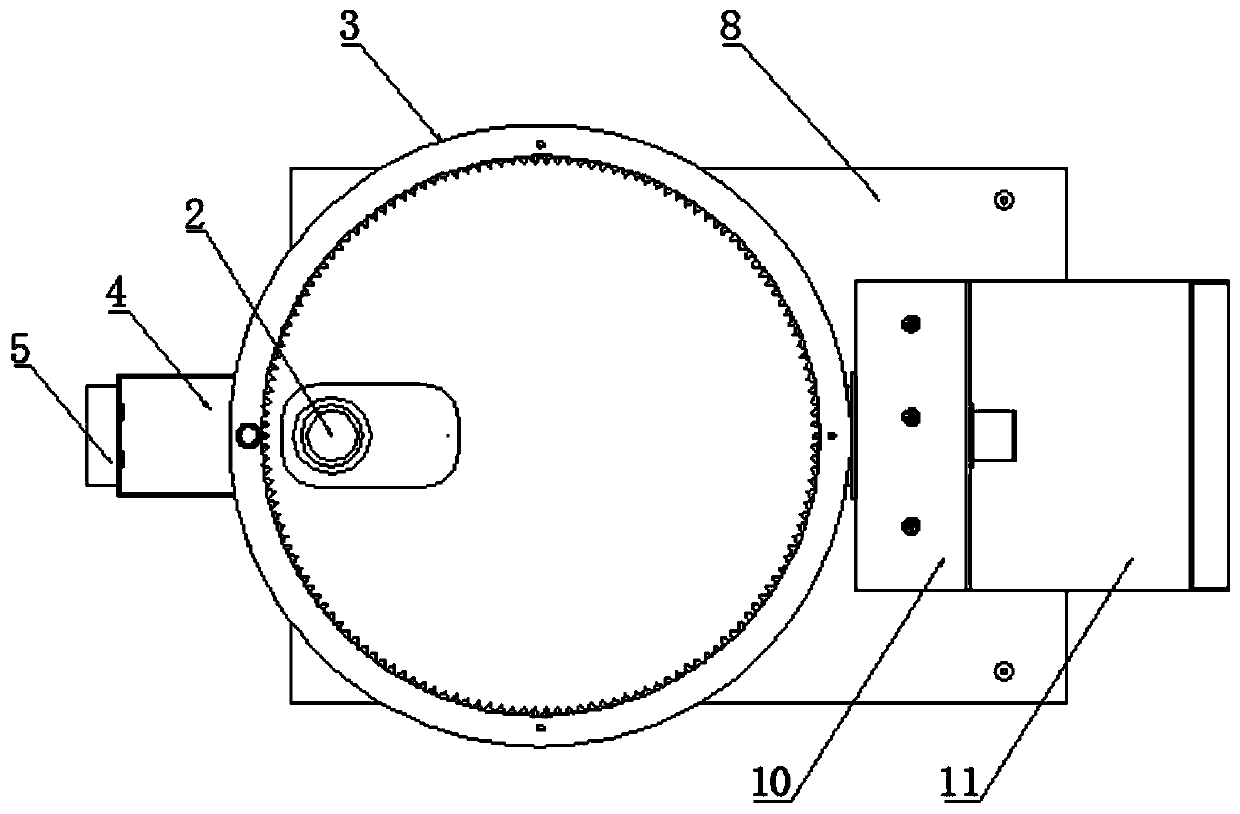

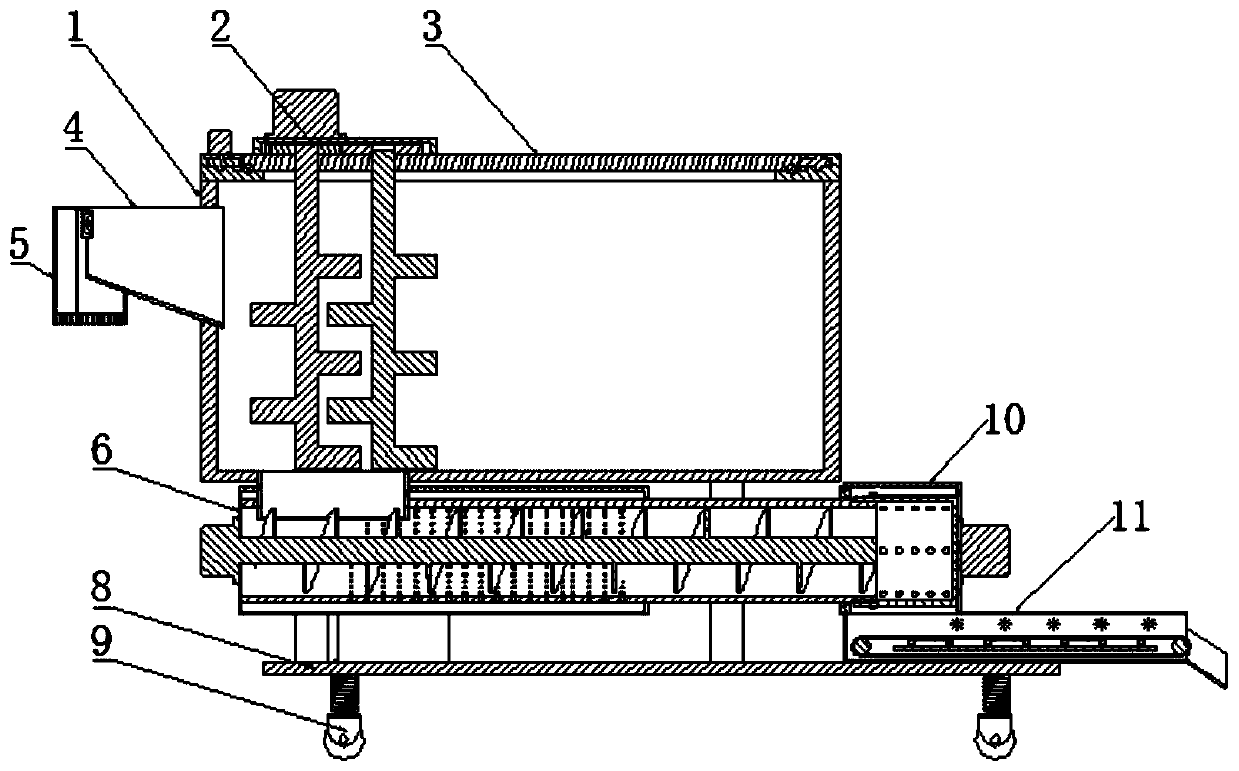

[0033] Example 1, please refer to figure 1 , figure 2 , image 3 with Figure 4 , a stirring device for feed processing, comprising a tank body 1 and a tank cover 3, the tank cover 3 is set on the upper port of the tank body 1, and the left end of the tank body 1 is fixedly provided with a hopper 4 near the upper end, and the hopper 4 is used for Add raw materials, the right end of the hopper 4 is connected with the tank body 1, the left end of the hopper 4 is provided with a fan, the fan sends the dust generated by adding raw materials to the dust removal mechanism 5, and the left end of the hopper 4 is fixedly provided with the dust removal mechanism 5, the dust removal mechanism The right end of 5 is provided with opening, and the right end cover of dedusting mechanism 5 is arranged on the position that fan is set in hopper 4, and dedusting mechanism 5 realizes the filtering collection of dust, avoids dust diffusion, and the inner side of tank body 1 is provided with agi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com