Grain cooking and processing quick cooling device for white spirit production

A rapid cooling and grain technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of high production input costs and low grain cooling efficiency, improve cooling efficiency, reduce equipment input costs and liquor production and processing costs, and simple devices structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

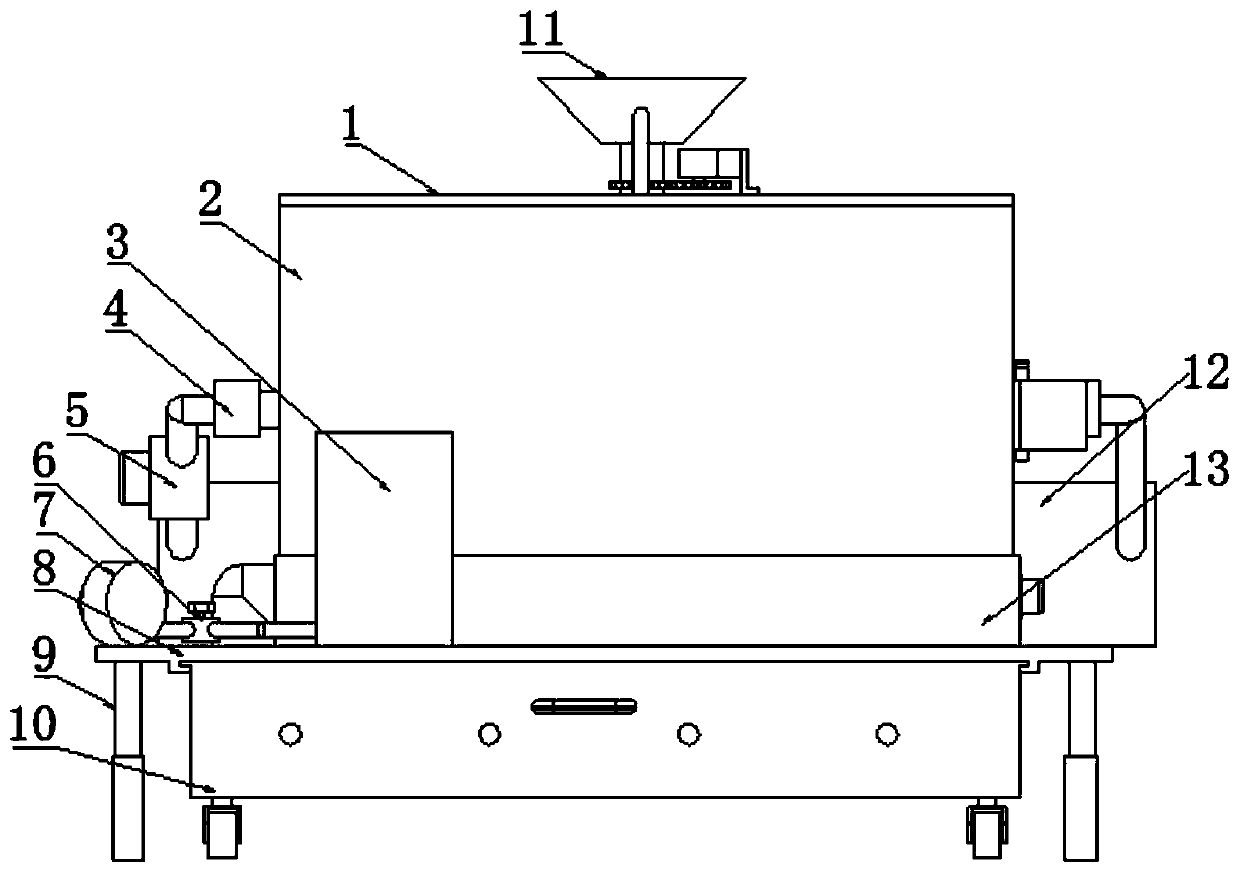

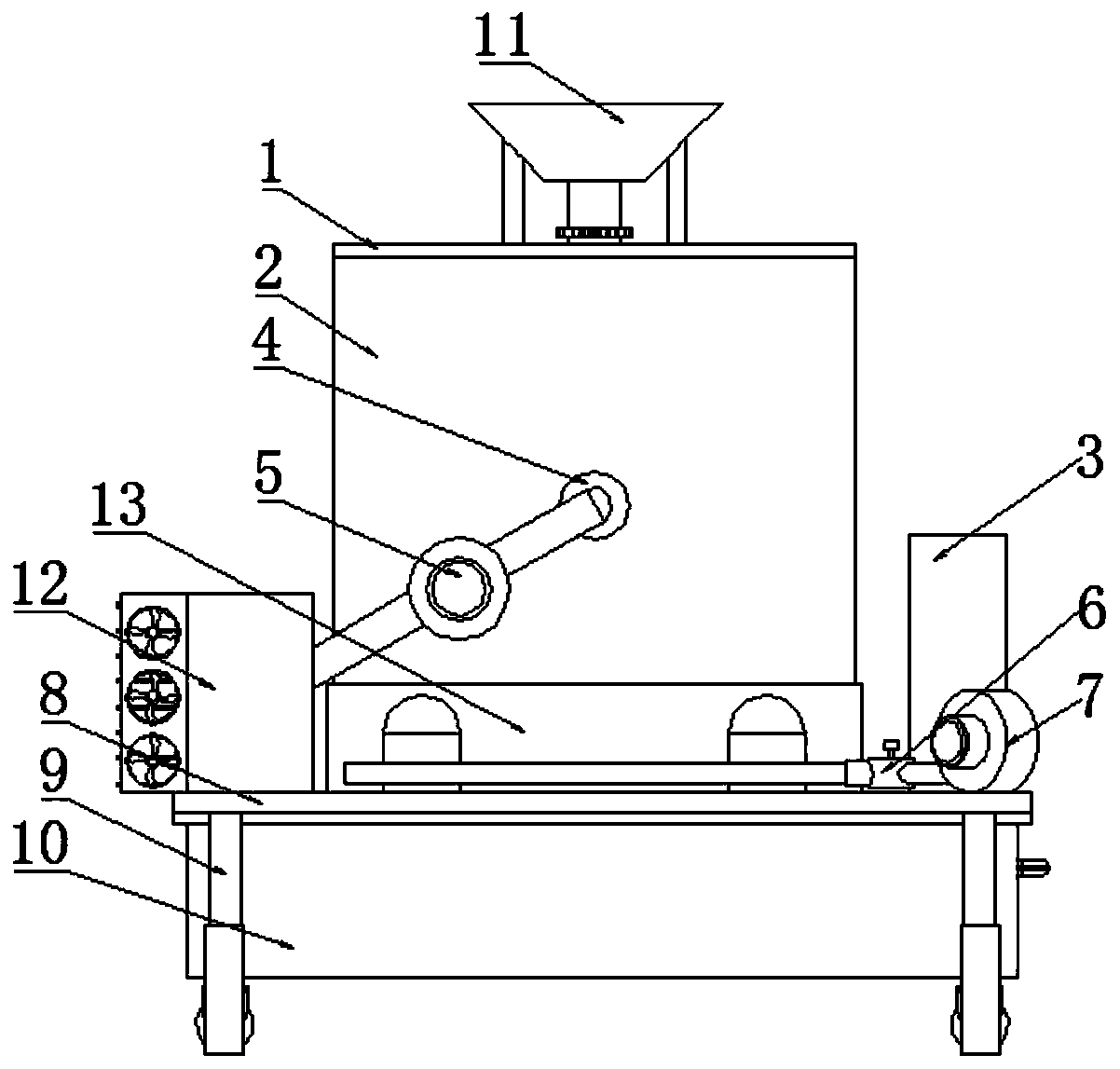

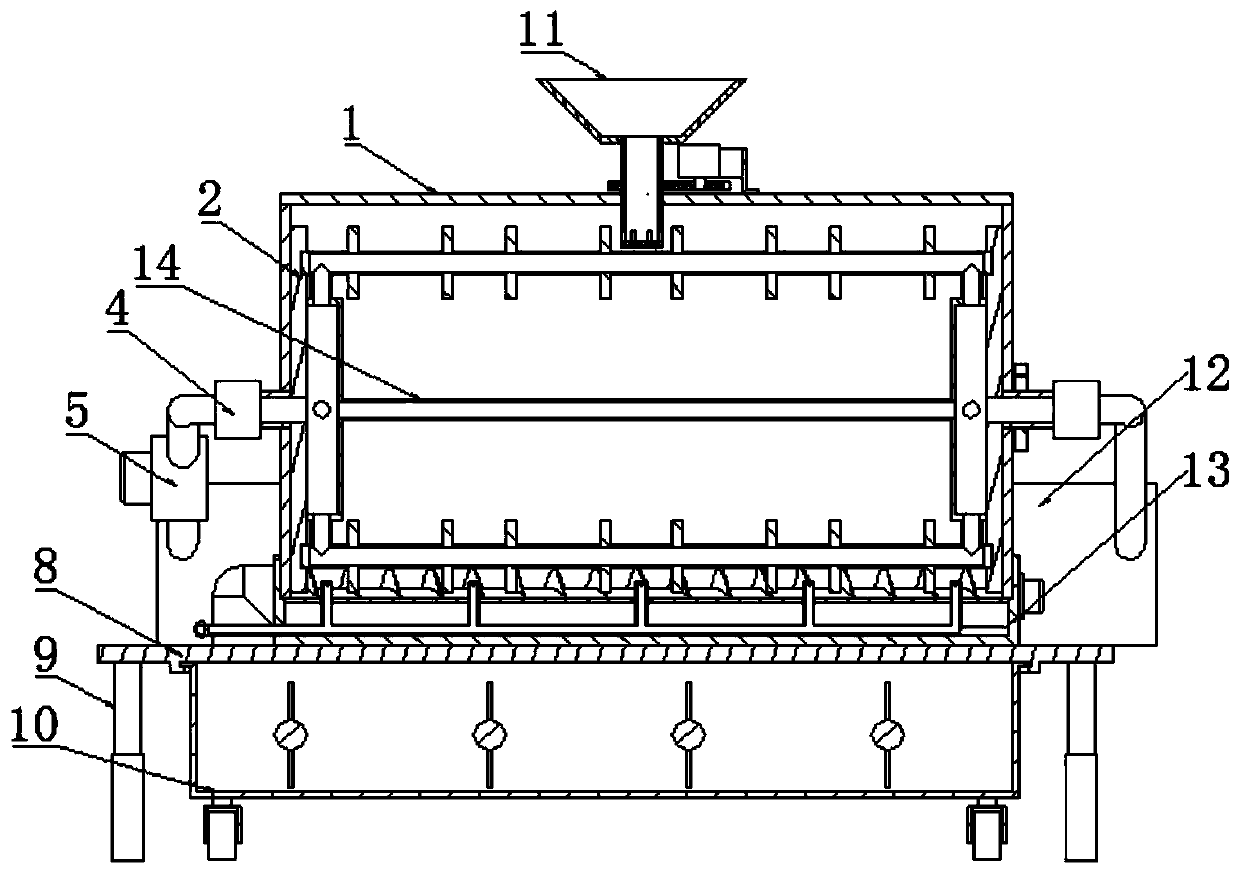

[0028] Example 1, please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a fast cooling device for grain cooking and processing for liquor production, comprising a stirring box 2, a fermentation mechanism 10, a heat dissipation mechanism 11 and a cooling mechanism 14, the upper end mask of the stirring box 2 is provided with a box cover 1, and the upper end surface of the box cover 1 is fixed A powder spreading mechanism 11 is provided, and the discharge end of the lower end of the powder spreading mechanism 11 is connected with the mixing box 2, and the distiller's yeast powder is evenly spread in the mixing box 2 by the powder spreading mechanism 11, which is conducive to the uniform mixing of the subsequent sequence, and the stirring box The lower end of 2 is provided with base 13, and the lower end of stirring tank 2 is inserted in the upper port of base 13 to facilitate the separation of base 13 and stirring tank 2 to facilitate follow-up maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com