Efficient desulfuration digesting device

A digester and high-efficiency technology, applied in chemical instruments and methods, dissolving, mixers, etc., can solve problems such as affecting the work effect of subsequent processes and poor lime slaking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

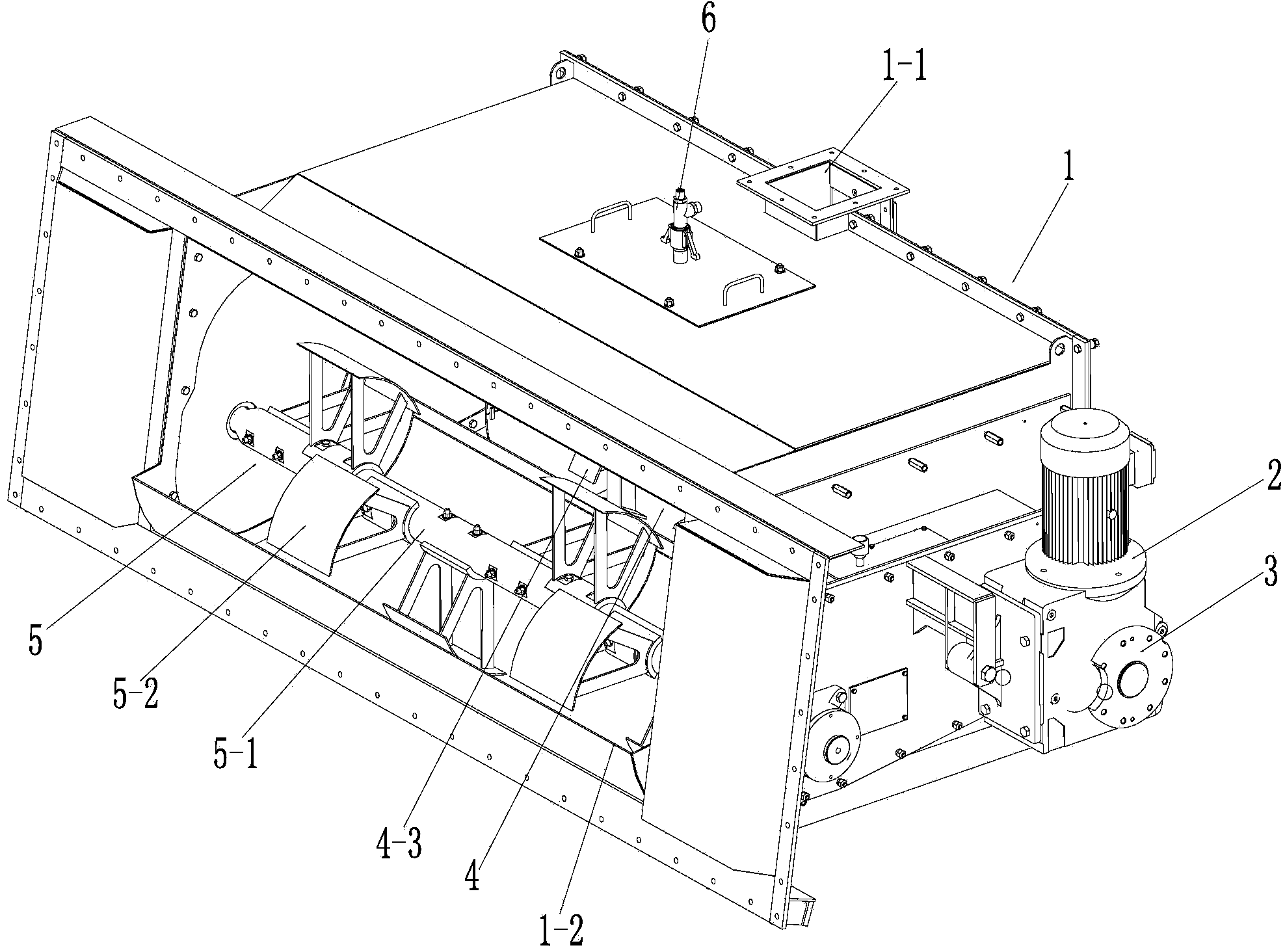

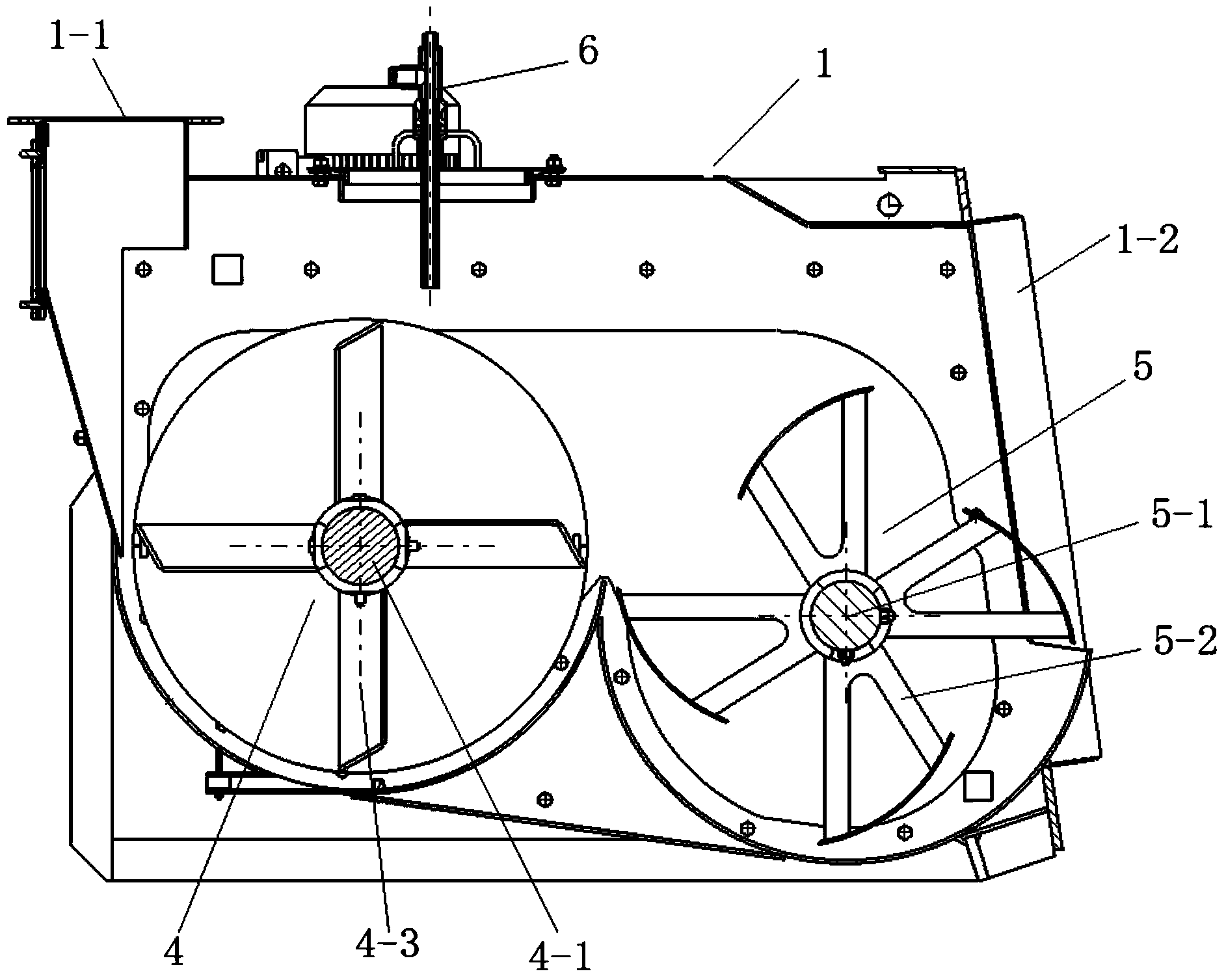

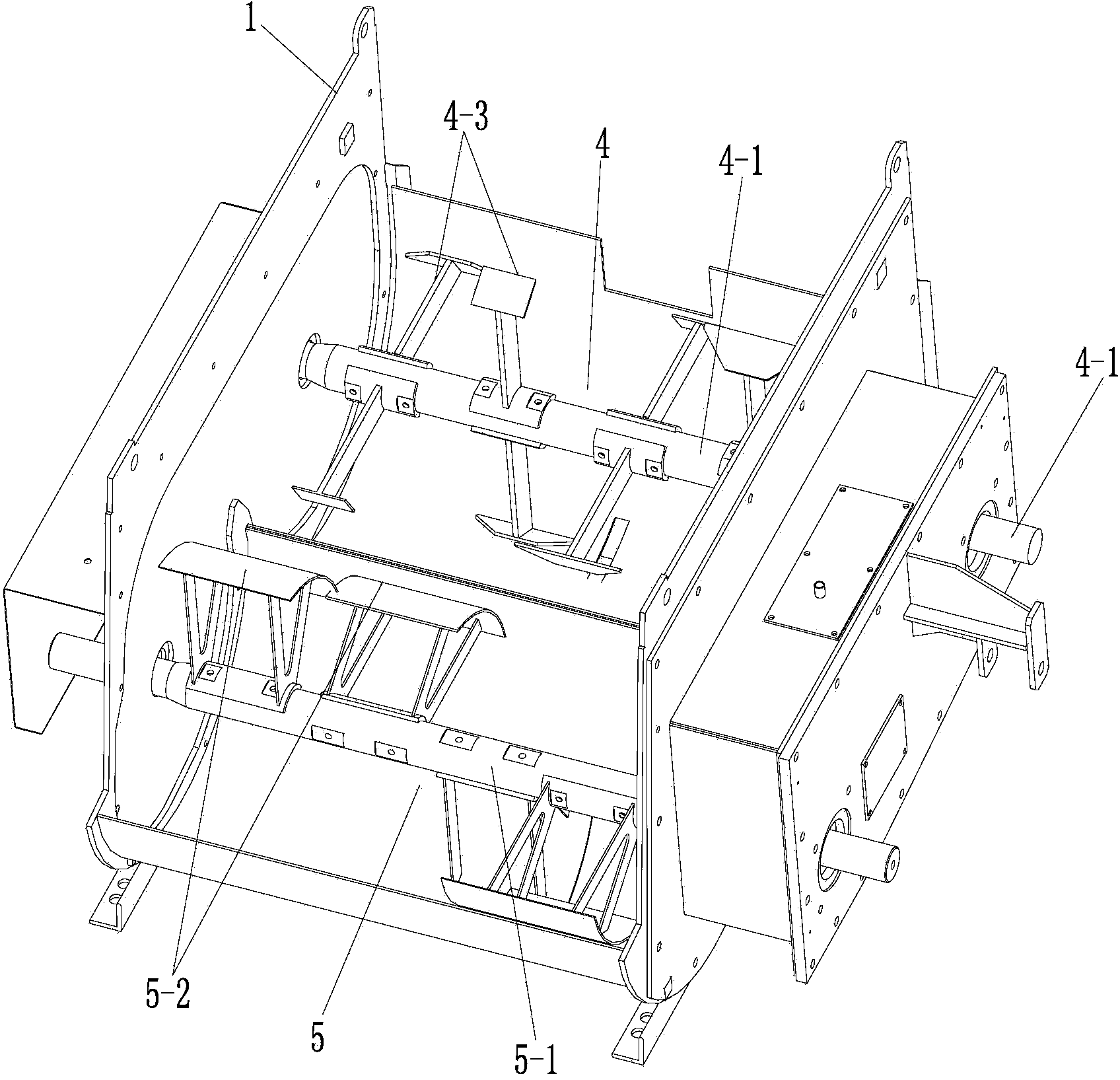

[0019] like Figure 1-3 As shown, a high-efficiency desulfurization digester according to the present invention includes a shell 1, the top surface of the shell 1 is provided with a feed port 1-1 and a spray gun 6, and the spray end of the spray gun 6 extends into the shell 1 in the inner cavity; the water inlet end of the spray gun 6 is connected with the water source.

[0020] The front surface of the housing 1 is provided with a discharge port 1-2 for connecting the mixer, the right surface of the housing 1 is provided with a motor 2 and a reduction box 3, and the rotating shaft of the motor 2 is connected to the transmission input shaft of the reduction box 3. Fixed connection; the inner cavity of the housing 1 is provided with a first stirring chamber and a second stirring chamber, the cross sections of the first stirring chamber and the second stirring chamber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com