An eps heating and pressurized curing process

A process and curing technology, applied in the field of expandable polystyrene curing, can solve the problems of unfavorable production planning, prolonging the production cycle, high investment cost, etc., and achieve the effects of easy adjustment of production plan, reduction of investment cost and improvement of curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

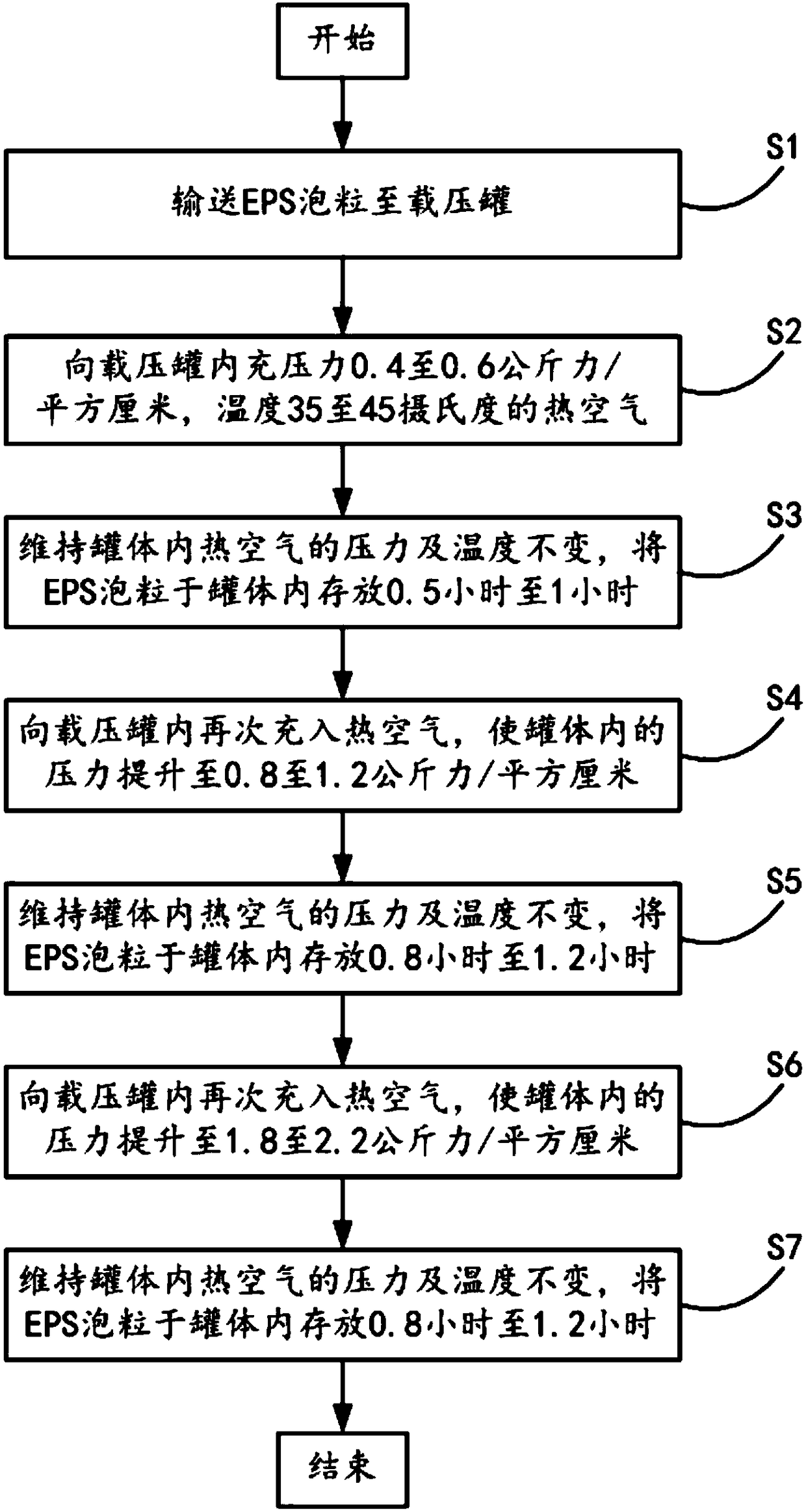

[0044] The pre-released EPS foam particles are transported to the tank body of the pressure tank through the feeder and the delivery pipe, and the pressure is 0.4 kgf / cm2, and the temperature is 35 degrees Celsius. Hot air, keep the pressure (0.4 kgf / cm2) and temperature (35 degrees Celsius) of the hot air in the tank unchanged, store the EPS foam in the tank for 0.5 hours, and then fill it again into the tank of the pressure tank The temperature is the hot air of 35 degrees Celsius, so that the pressure in the tank is increased to 0.8 kgf / cm2, and the pressure (0.8 kgf / cm2) and temperature (35 degrees Celsius) of the hot air in the tank are maintained at this time. The foam particles are stored in the tank for 0.8 hours, after which, the hot air with a temperature of 35 degrees Celsius is filled into the tank body of the pressure tank again, so that the pressure in the tank is increased to 1.8 kgf / cm2, and the hot air in the tank is maintained at this time The pressure (1.8 k...

Embodiment 2

[0047]The pre-released EPS foam particles are transported to the tank body of the pressure tank through the feeder and the delivery pipe, and the pressure is 0.5 kgf / cm2 and the temperature is 40 degrees Celsius. Hot air, keep the pressure (0.5 kgf / cm2) and temperature (40 degrees Celsius) of the hot air in the tank unchanged, store the EPS foam in the tank for 0.8 hours, and then fill it again into the tank of the pressure tank The temperature is the hot air of 40 degrees Celsius, so that the pressure in the tank is increased to 1 kgf / cm2, and the pressure (1 kgf / cm2) and temperature (40 degrees Celsius) of the hot air in the tank are maintained at this time. Bubbles are stored in the tank for 1 hour, and then, fill the tank with hot air at a temperature of 40 degrees Celsius again to increase the pressure in the tank to 2 kgf / cm2, and maintain the hot air in the tank at this time The pressure (2 kgf / cm2) and temperature (40 degrees Celsius) remain unchanged, and the EPS foam...

Embodiment 3

[0050] The pre-released EPS foam particles are transported to the tank body of the pressure tank through the feeder and the delivery pipe, and the pressure is 0.6 kgf / cm2 and the temperature is 45 degrees Celsius. Hot air, keep the pressure (0.6 kgf / cm2) and temperature (45 degrees Celsius) of the hot air in the tank unchanged, store the EPS foam in the tank for 1 hour, and then fill it again into the tank of the pressure tank The temperature is the hot air of 45 degrees Celsius, so that the pressure in the tank is increased to 1.2 kgf / cm2, and the pressure (1.2 kgf / cm2) and temperature (45 degrees Celsius) of the hot air in the tank are maintained at this time. The foam particles are stored in the tank for 1.2 hours. After that, the hot air with a temperature of 45 degrees Celsius is filled into the pressure tank again, so that the pressure in the tank is increased to 2.2 kgf / cm2, and the hot air in the tank is maintained at this time. The pressure (2.2 kgf / cm2) and temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com