Patents

Literature

54results about How to "Guaranteed baking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

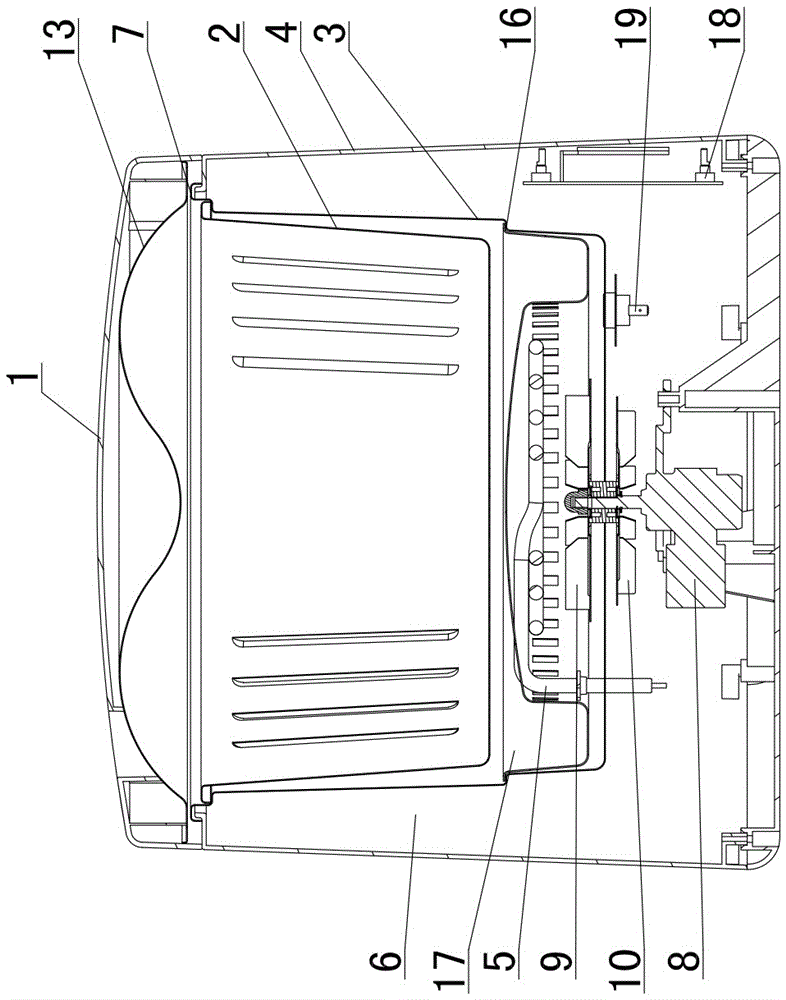

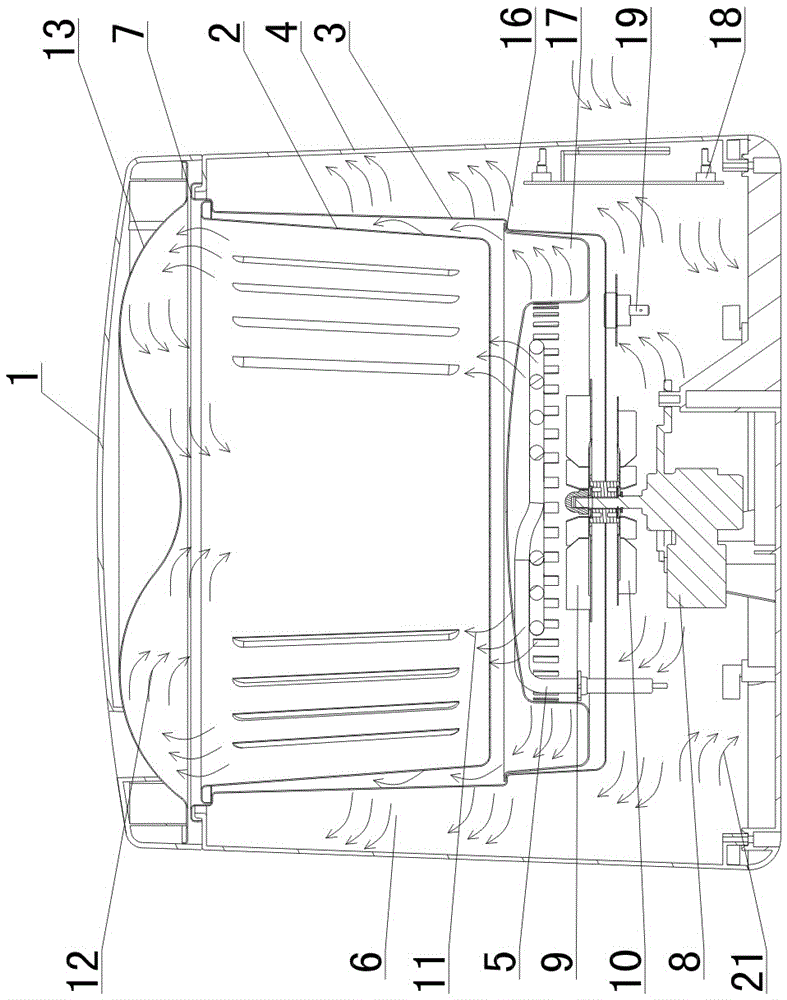

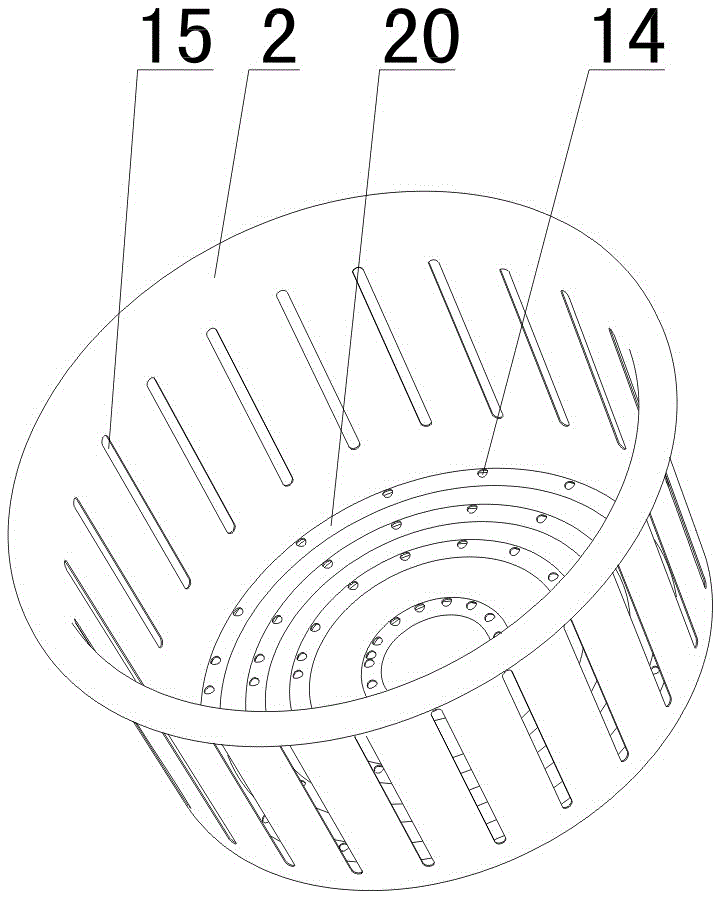

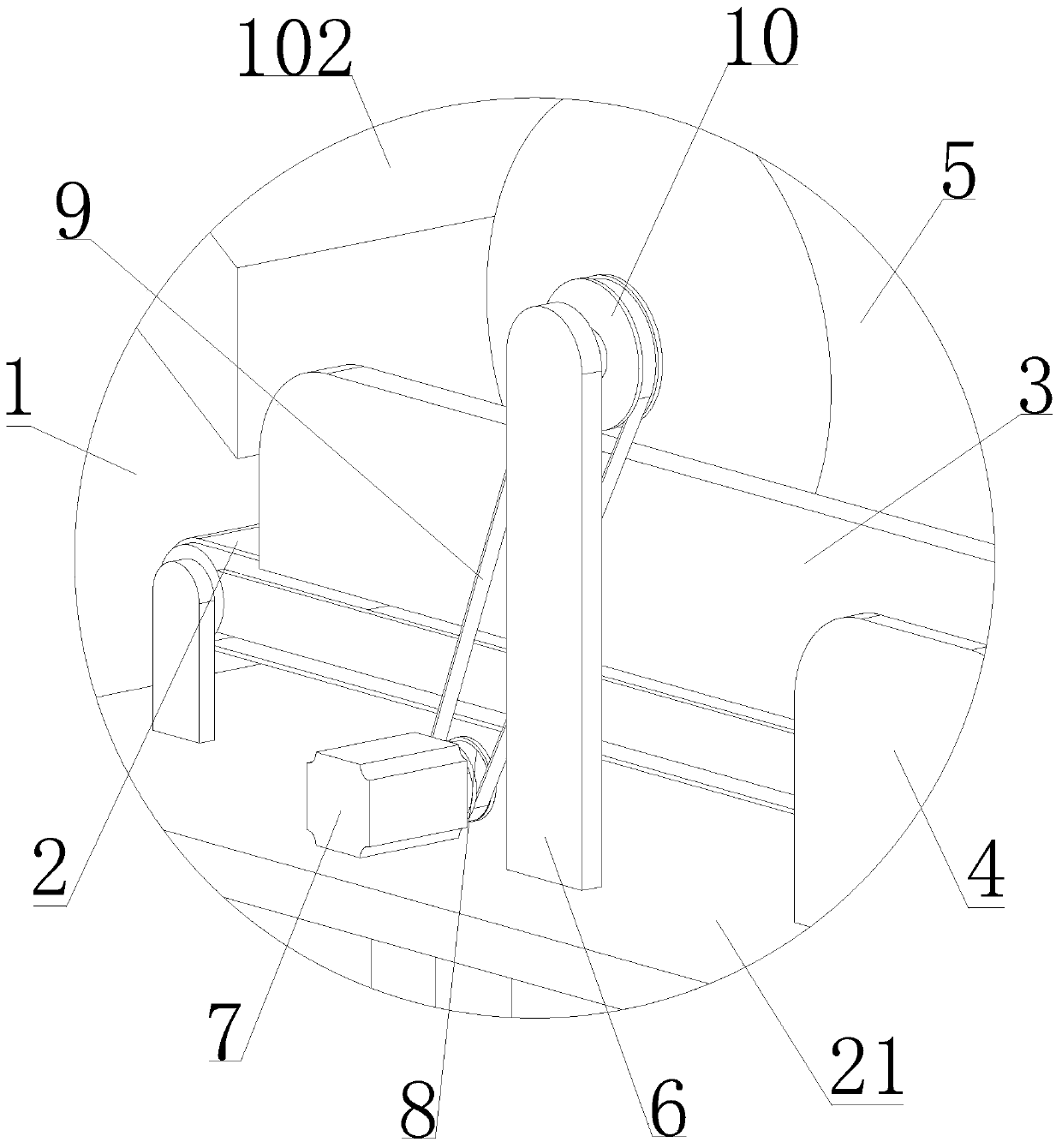

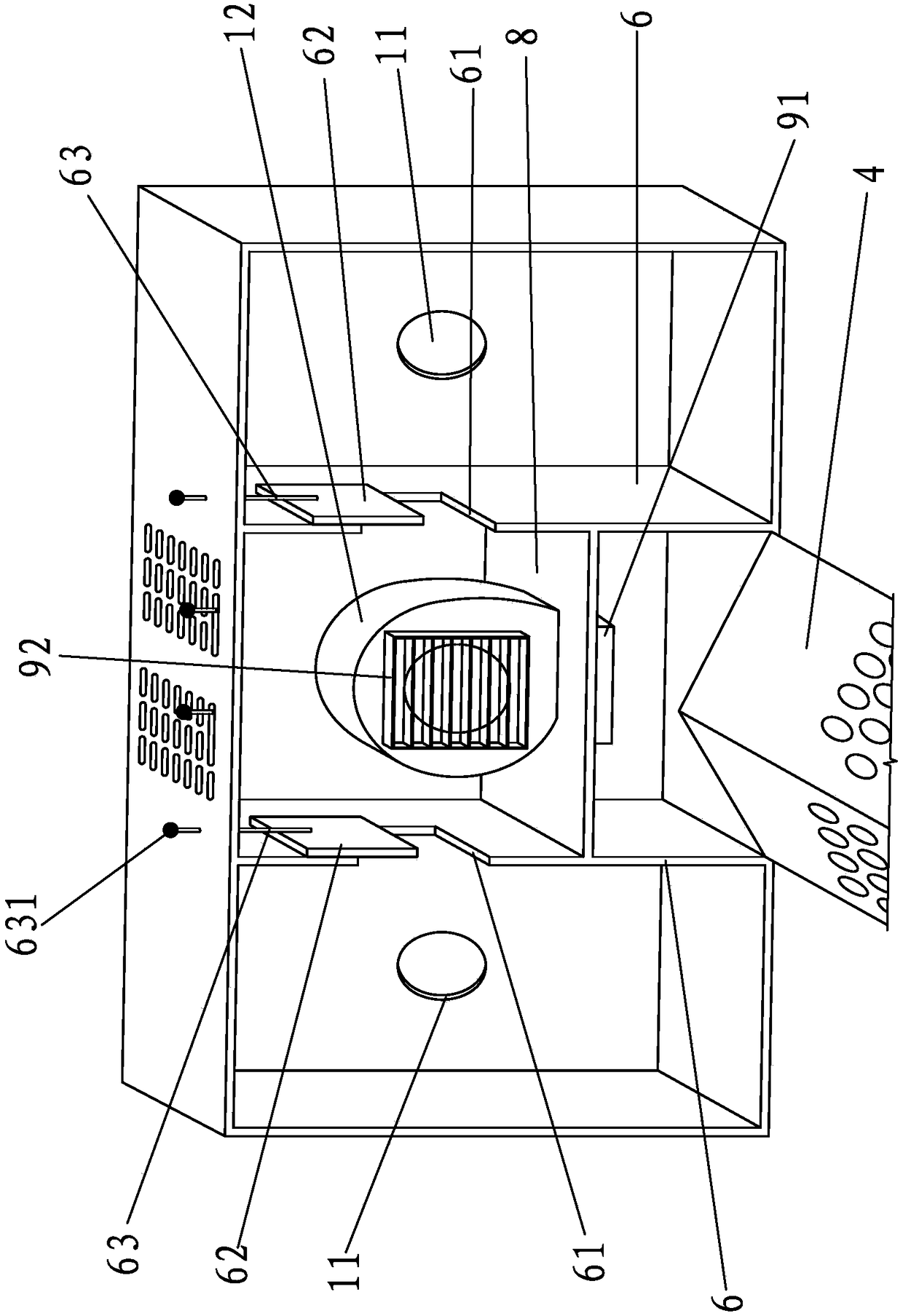

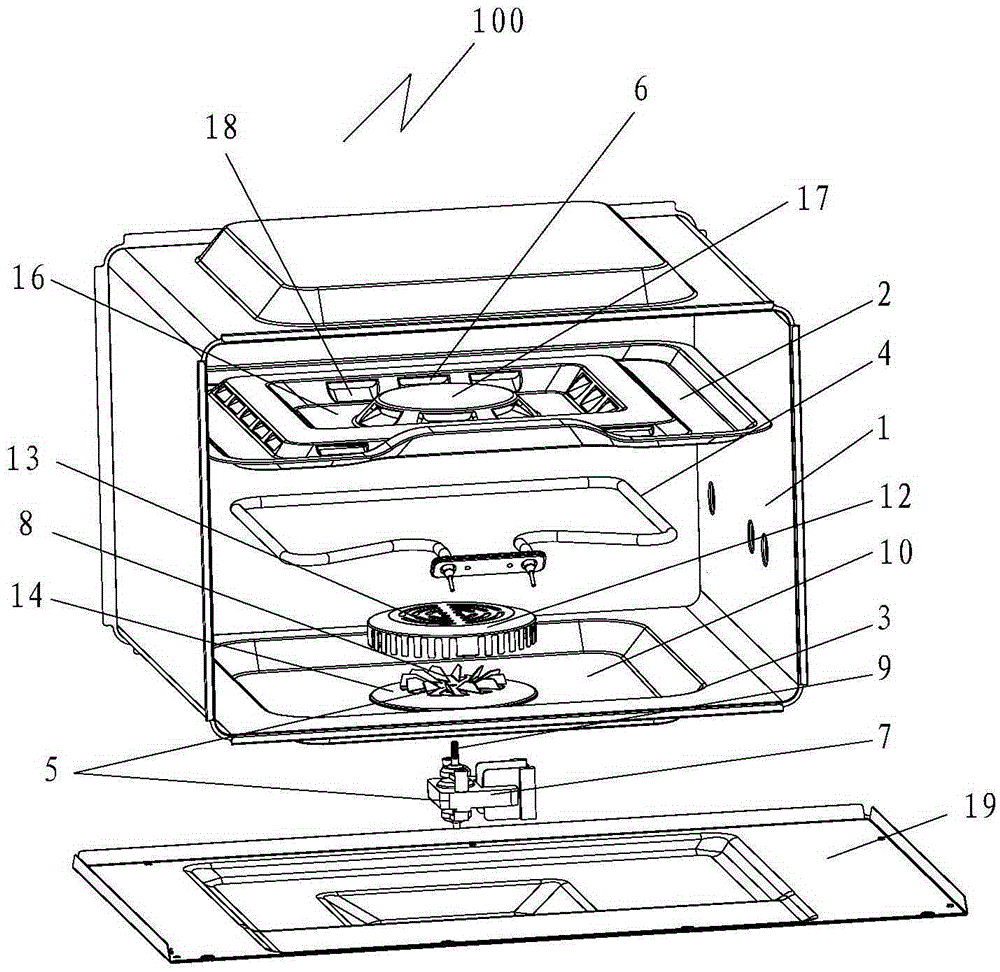

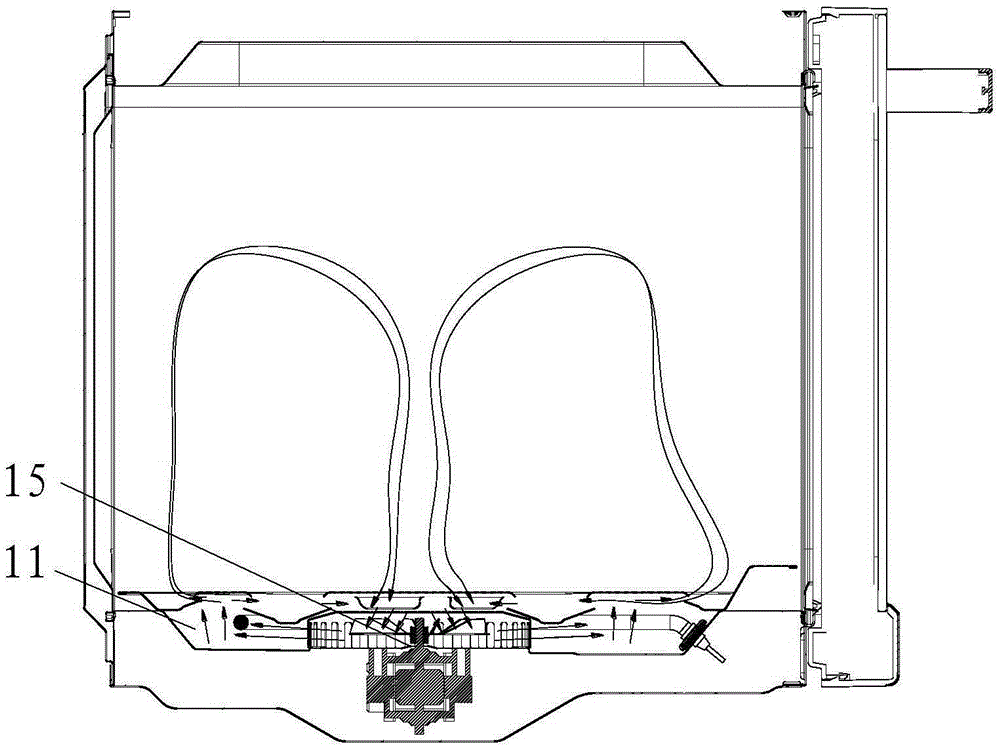

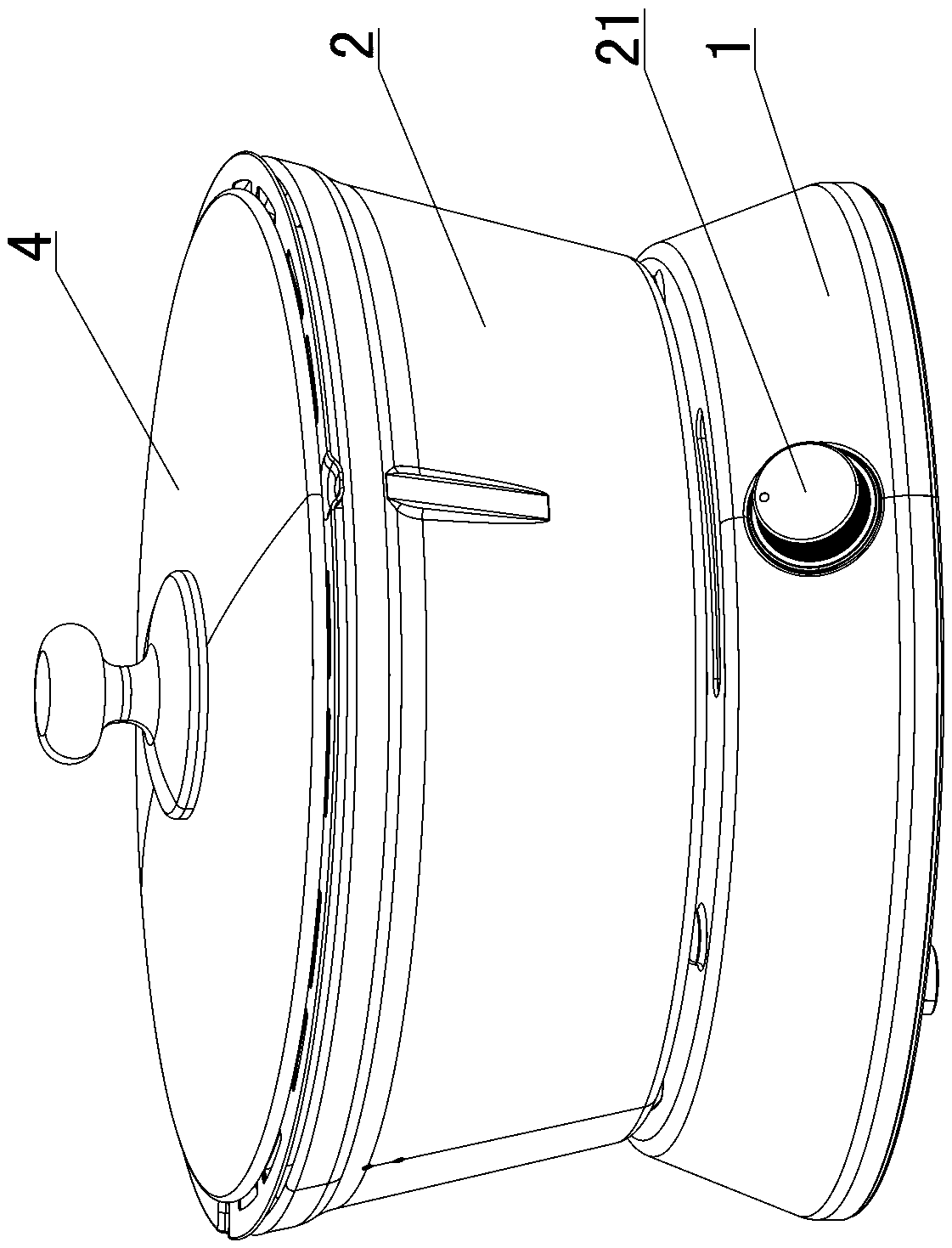

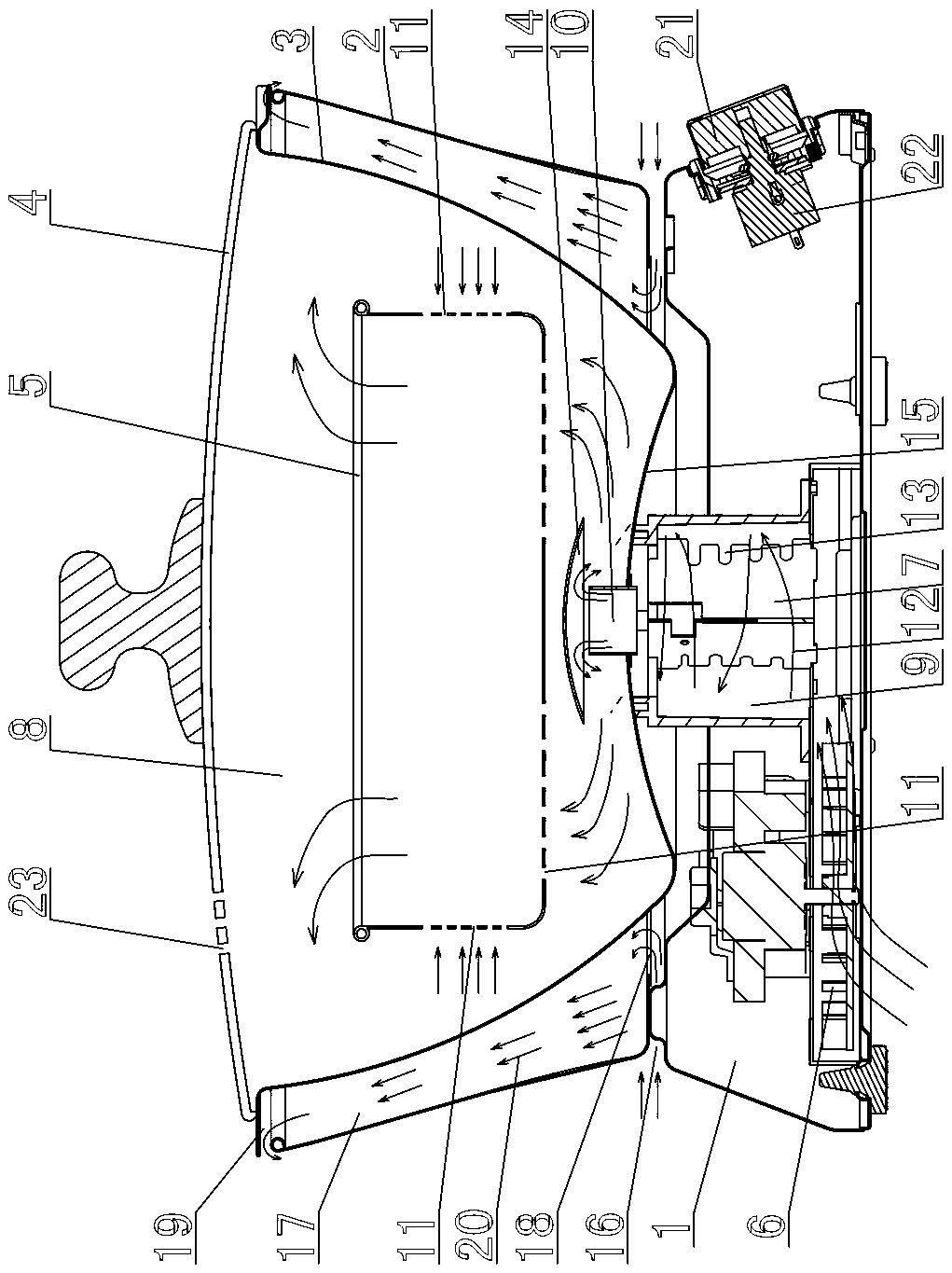

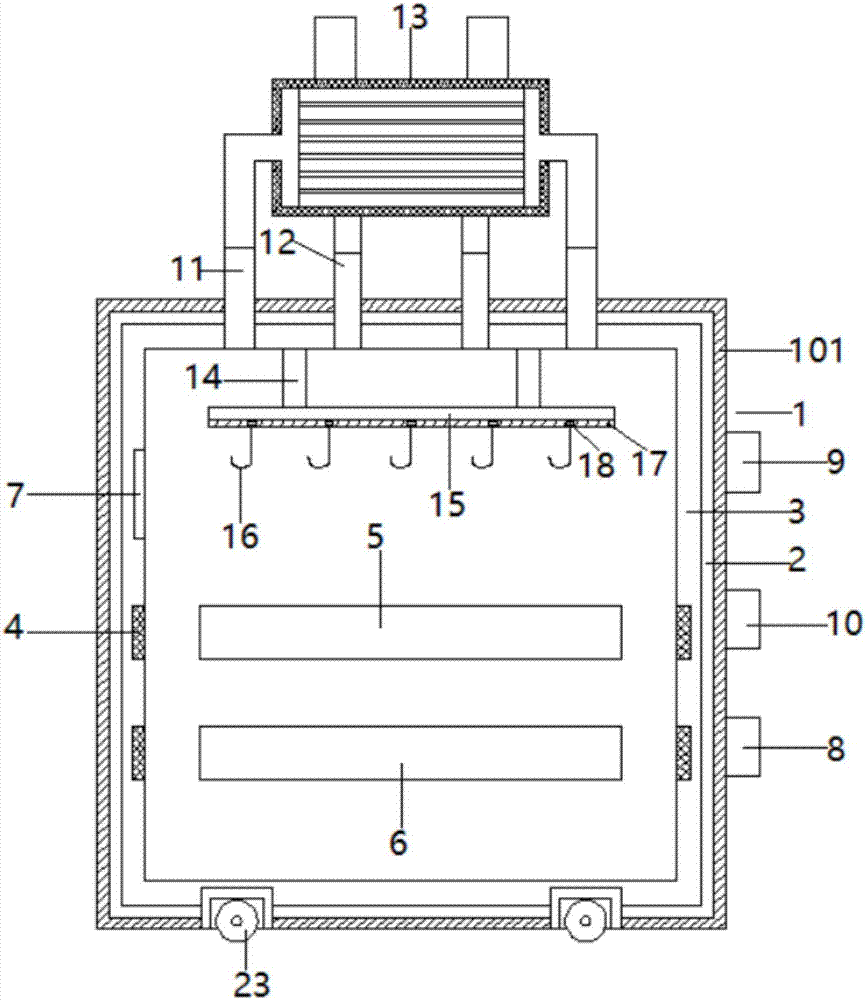

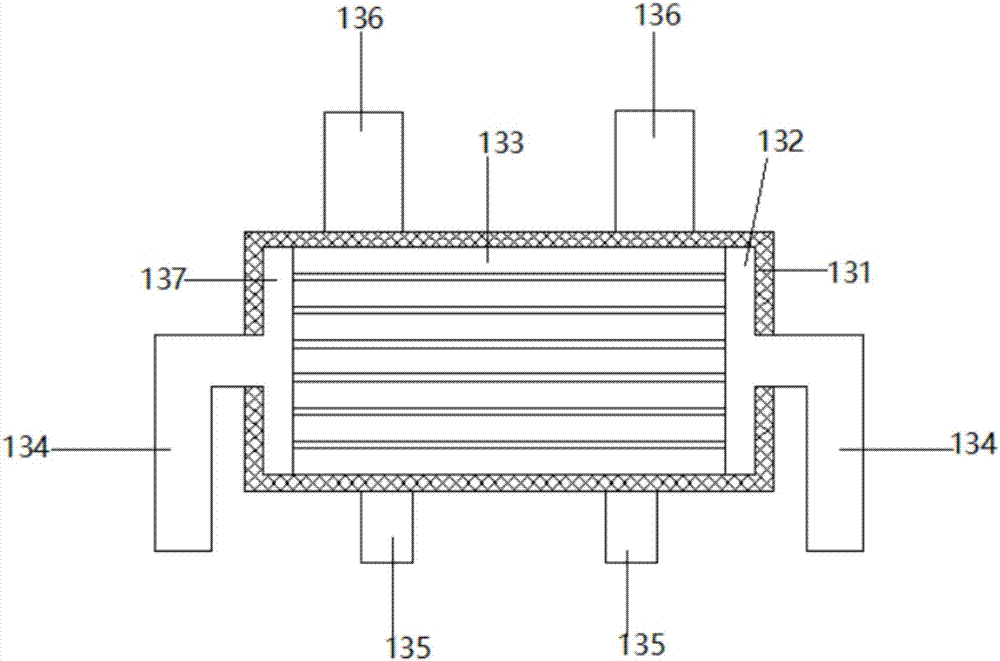

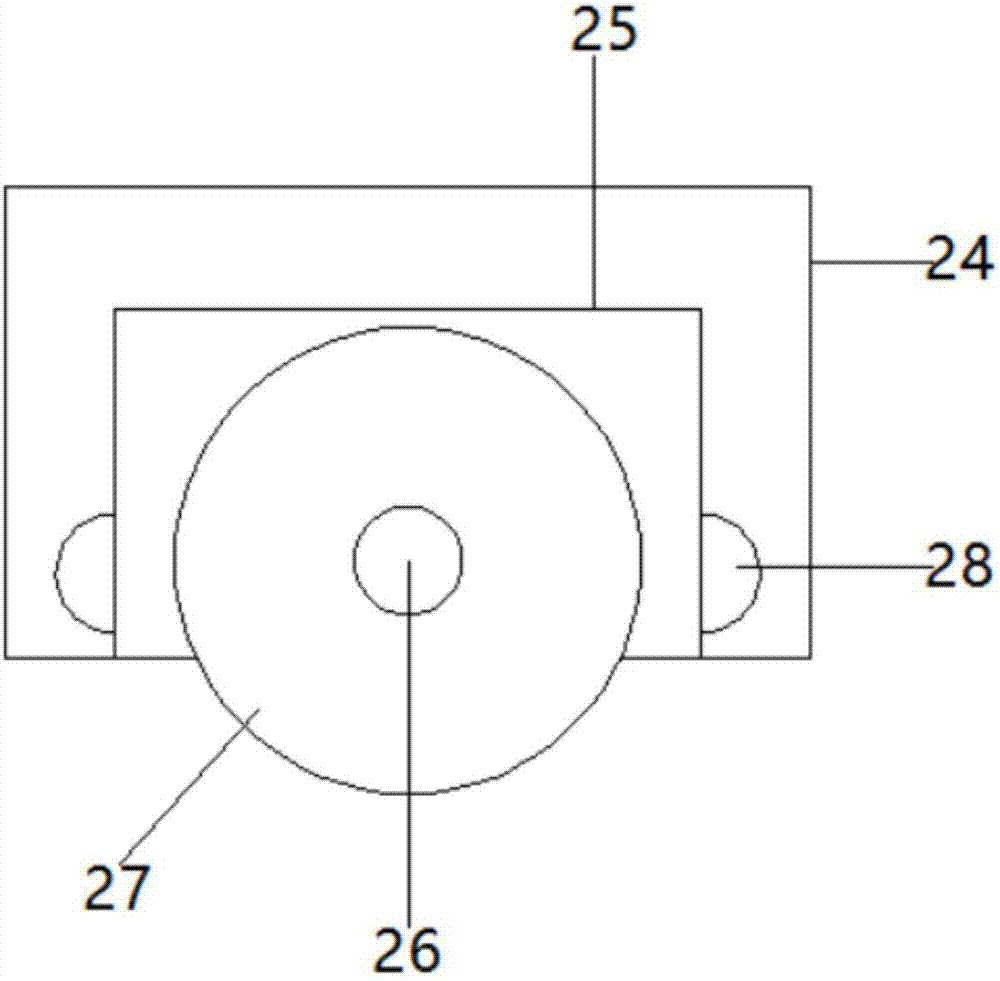

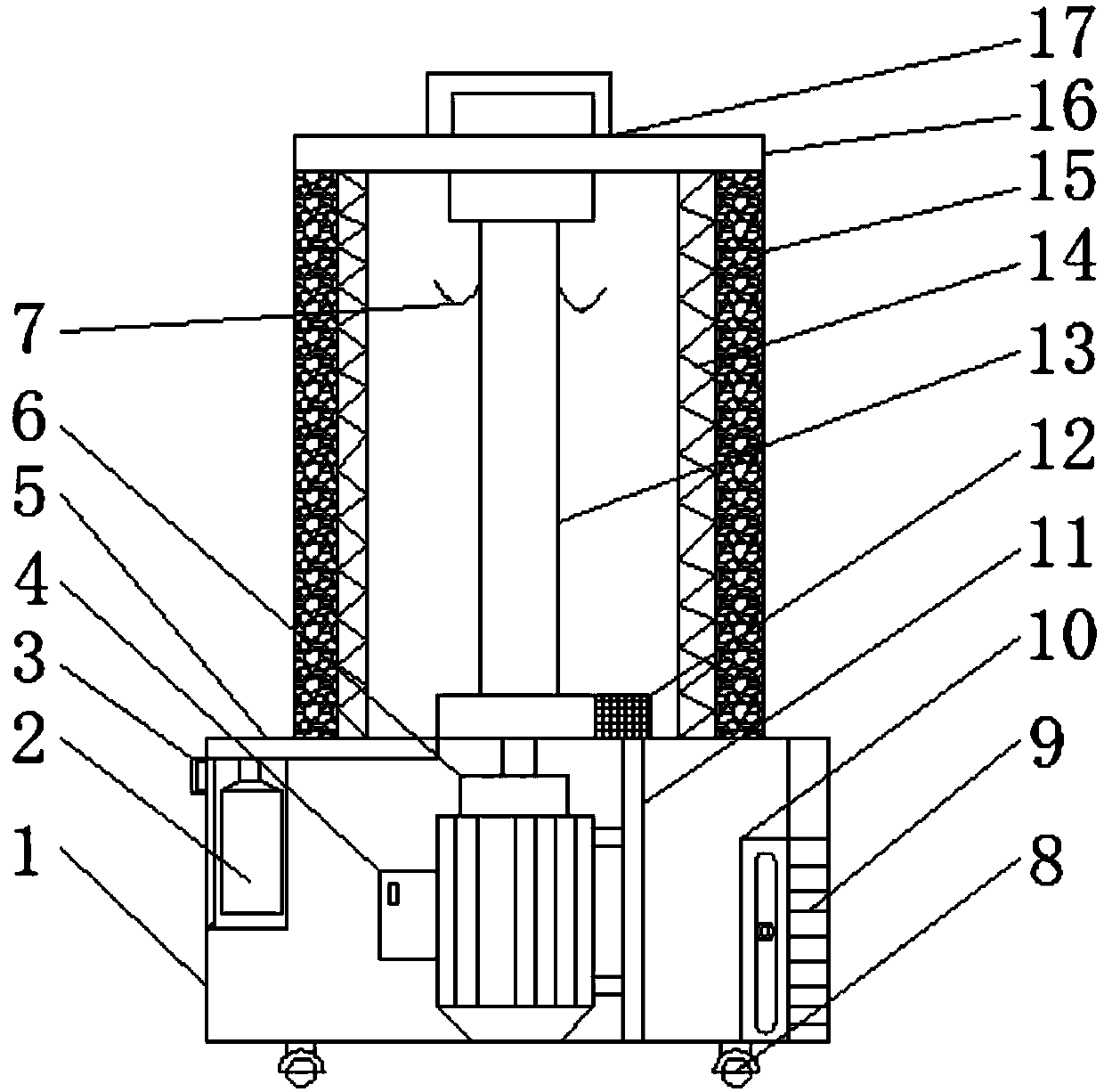

Multifunctional household air energy pot

InactiveCN105996809AHeating evenlyGuaranteed baking effectCooking utensils shields/jacketsRoasters/grillsCold airElectric machine

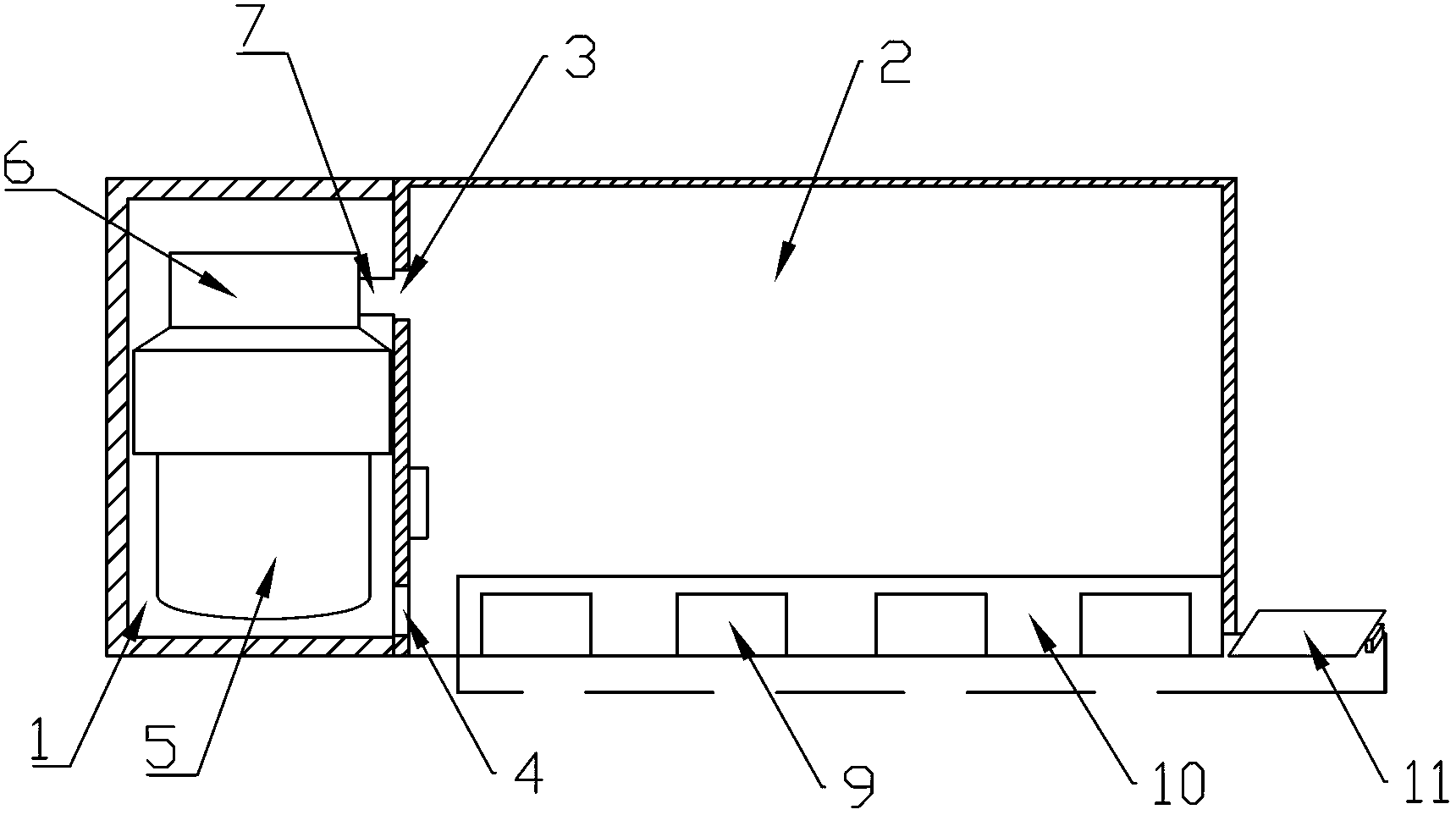

The invention provides a multifunctional household air energy pot which comprises an upper cover, an inner container, a heat insulating cover and a shell; a fan drive component and an electric heating pipe are arranged at the bottom of the heat insulating cover, the fan drive component comprises a drive motor, an upper fan blade and a lower fan blade, the upper fan blade and the lower fan blade are respectively adaptively mounted on a middle shaft of the drive motor, the drive motor drives the upper fan blade to rotate to form a hot air circulation path for heating the inner container, so that the air heat of a heat source is ensured, food is quickly and uniformly heated, and the food baking effect is ensured; meanwhile, the drive motor drives the lower fan blade to form a cold air circulation path for cooling the shell and drive motor, so that the use quality of products is ensured; as the heat insulation cover has an upper placing level convenient for installation of the inner container, the inner container can be replaced according to the type of the food to be processed, so that the food baking function and the food cooking function in the same equipment are achieved; the multifunctional household air energy pot is convenient to use and strong in adaptability.

Owner:FOSHAN SHUNDE HUIERJIA HOUSEHOLD ELECTRICAL

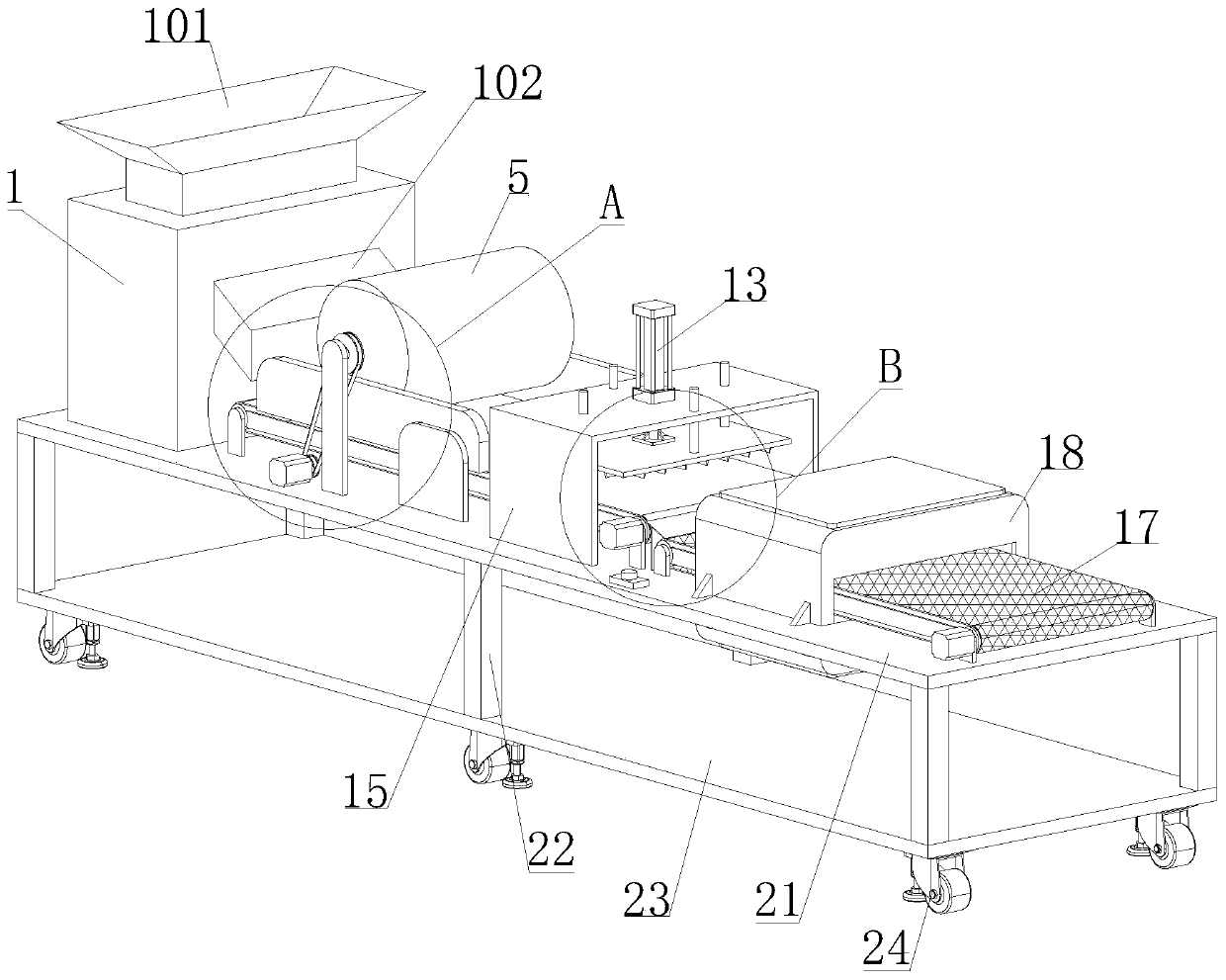

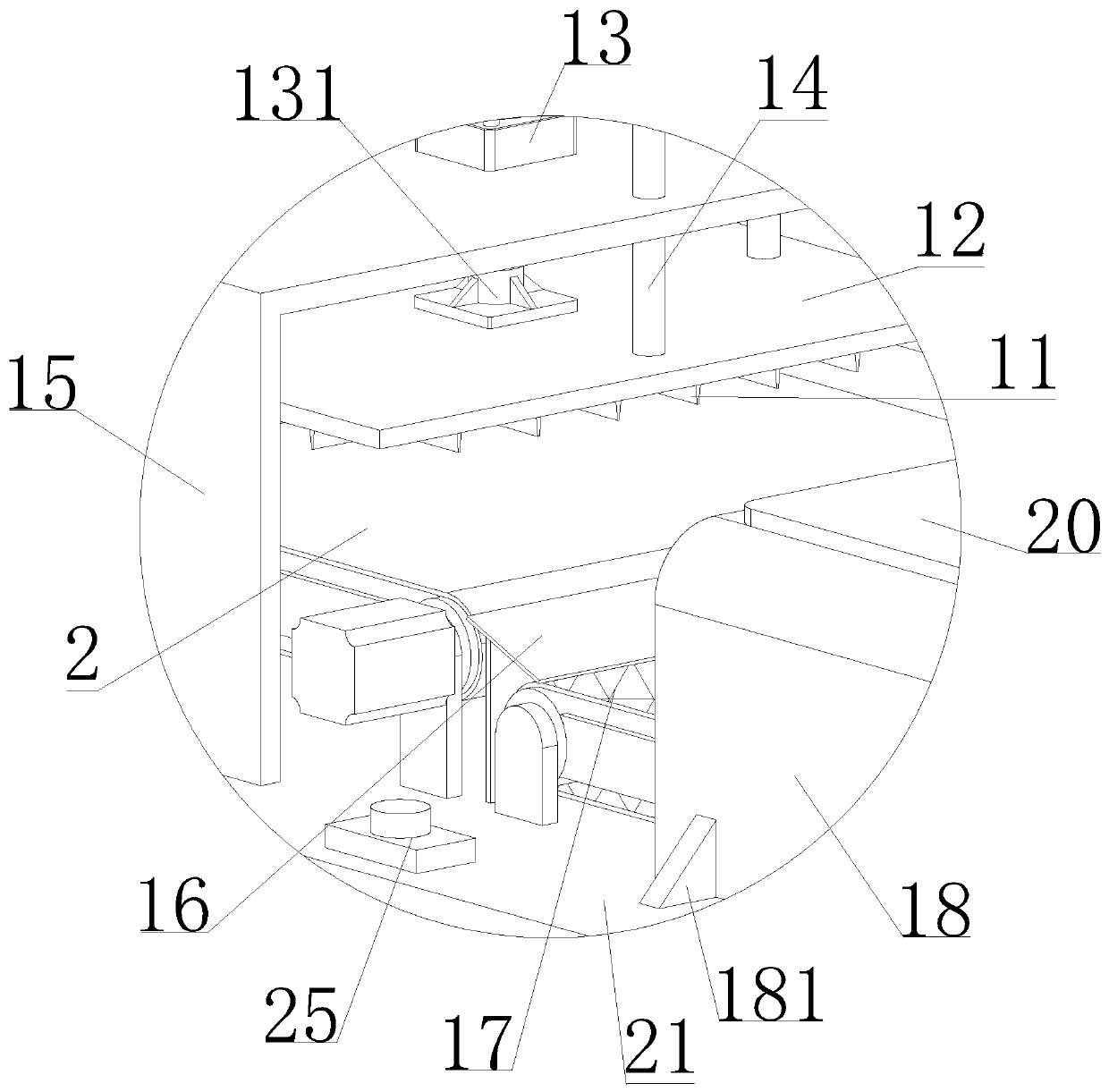

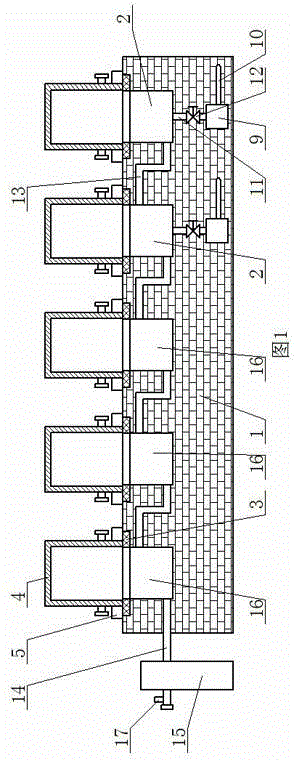

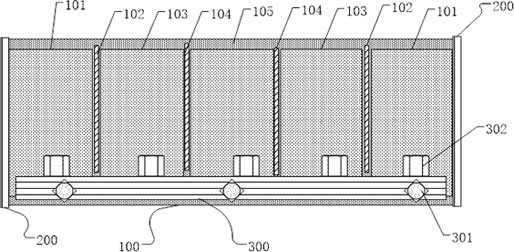

Leavened cake production device and preparation method thereof

InactiveCN110973179AImprove production efficiencyFully bakedDough-sheeters/rolling-machines/rolling-pinsDough dividingEngineeringControl switch

The invention discloses a leavened cake production device and a preparation method thereof. The leavened cake production device comprises a conveying belt conveying mechanism, baffles, a connecting plate, a dough rolling roller, a forming grid plate, a first mounting plate, a supporting frame, a mesh belt conveying mechanism, a baking cover, a baking device, a processing table, supporting legs anda control switch. The two baffles are located at the top of a conveying belt, arranged side by side in the longitudinal direction and connected with the connecting plate. The connecting plate is arranged on the processing table; a driving mechanism for driving the dough rolling roller to rotate is arranged on the processing table; the forming grid plate is arranged at the bottom of the first mounting plate; the supporting frame is arranged on the processing table, and an electric push rod used for driving the first mounting plate to move in the vertical direction is arranged on the supportingframe; the baking cover is arranged on the processing table; the baking device is arranged on the baking cover; the control switch is in respective control connection with the conveying belt conveying mechanism, the mesh belt conveying mechanism, the driving mechanism, the electric push rod and the baking device. According to the invention, automatic production can be achieved, and the leavened cake production efficiency is improved.

Owner:九江市金樱食品发展有限公司

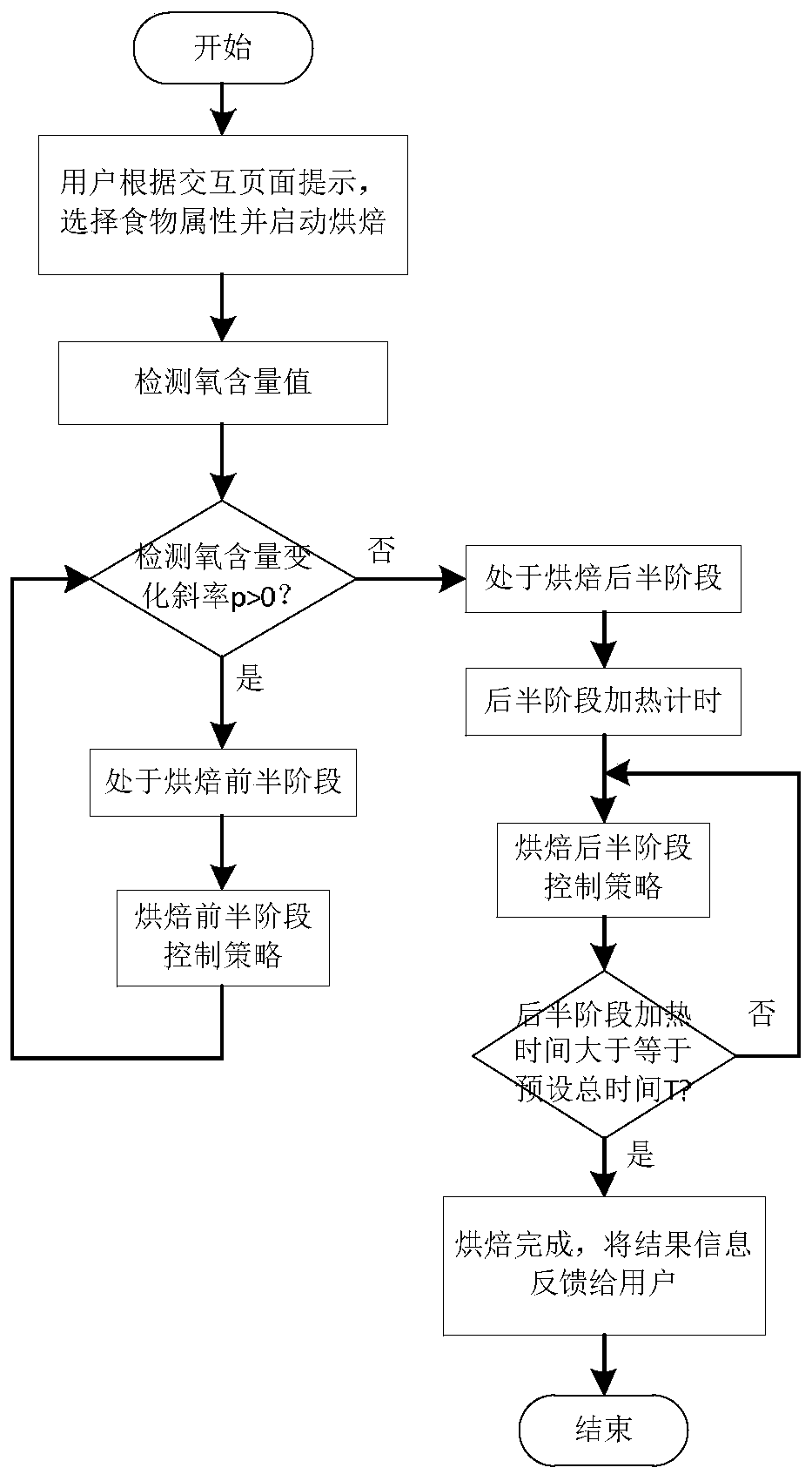

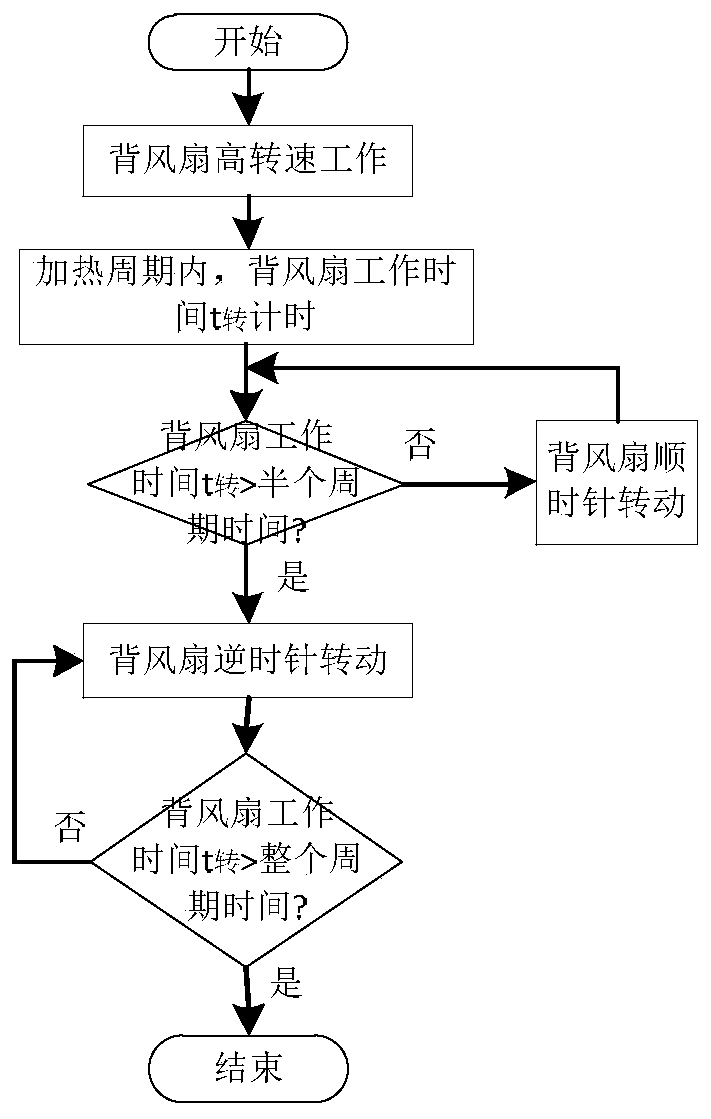

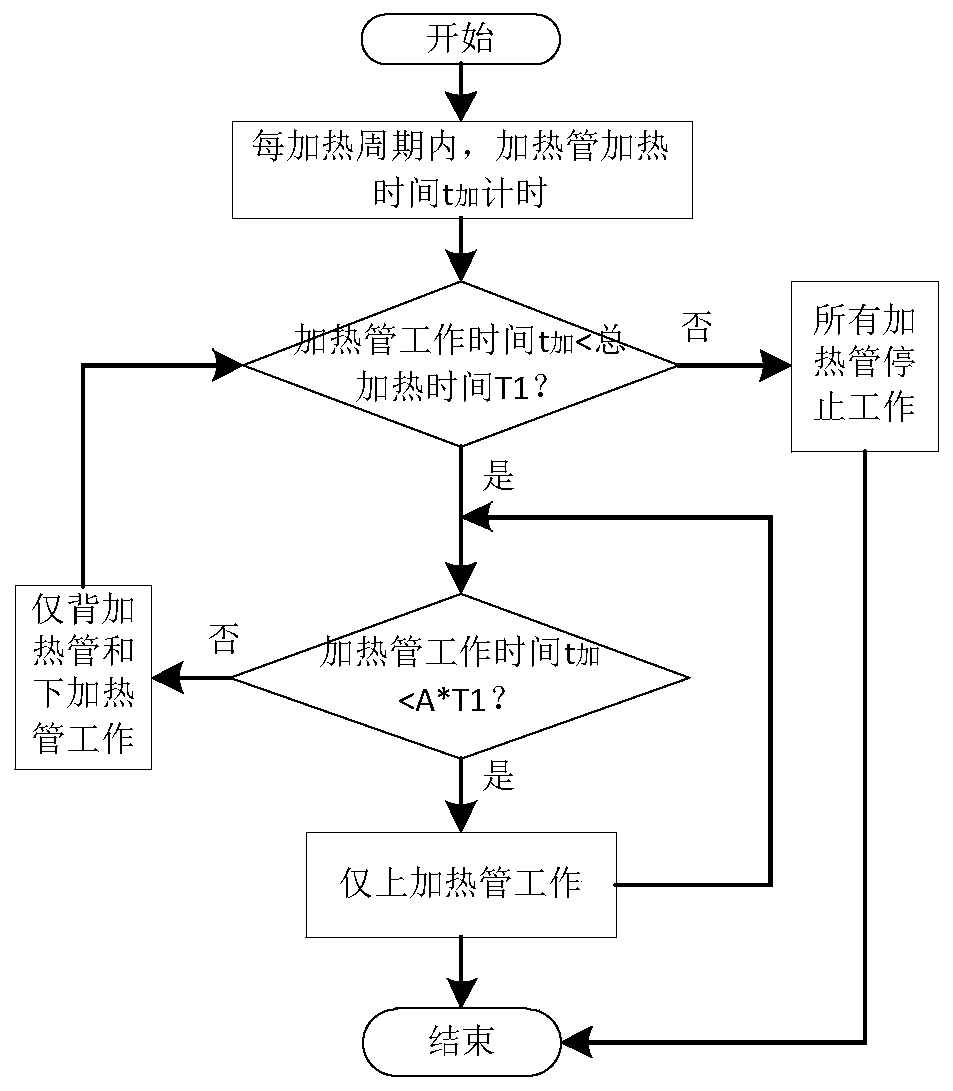

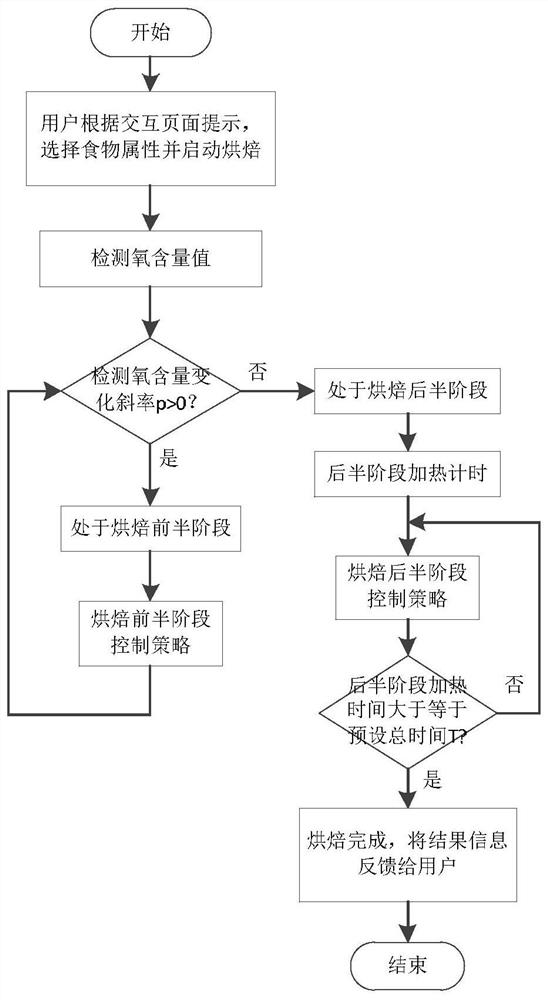

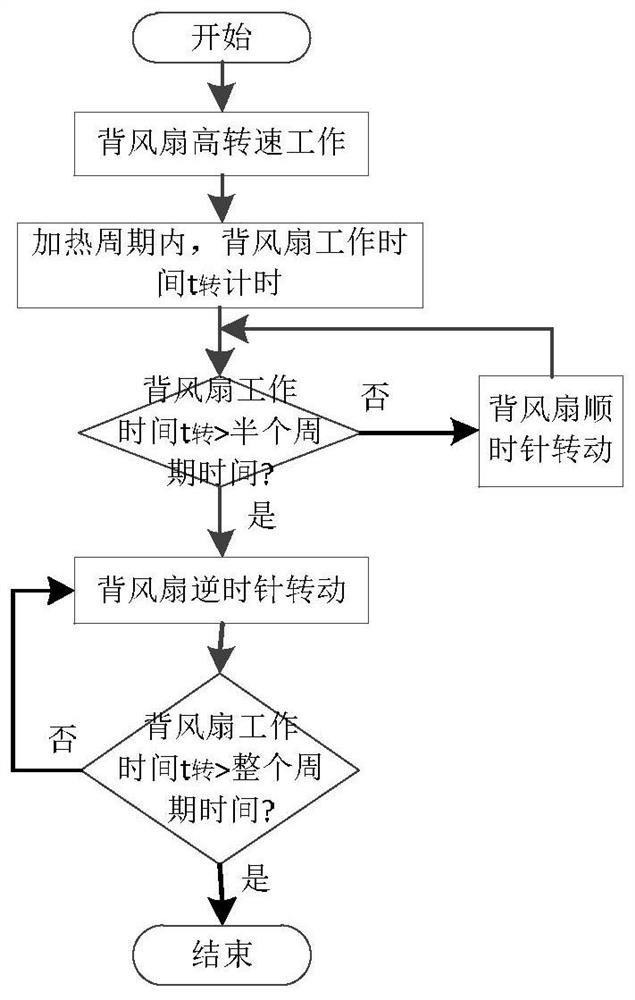

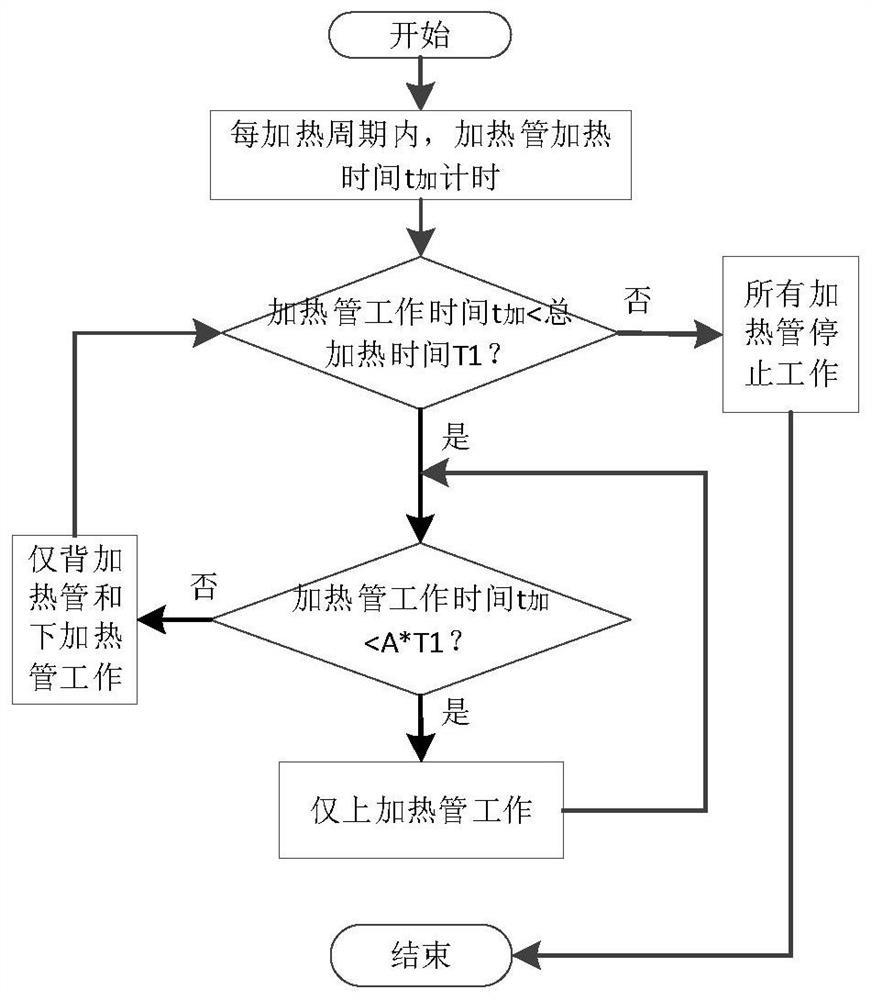

Cooking control method of electric oven

ActiveCN110584501AImprove baked tasteEnhanced convectionRoasters/grillsHeating timeProcess engineering

The invention discloses a cooking control method of an electric oven. The method comprises the steps that firstly, food properties are selected; secondly, an oxygen content value is detected; thirdly,whether the change slope of the oxygen content value is greater than 0 or not is judged, if yes, food is at the first half stage of baking, and the next step is executed, or otherwise the food is atthe second half stage of baking, and the fifth step is executed; fourthly, a control strategy for the first half stage of baking is adopted, and the third step is returned to; fifthly, heating time tat the second half stage is counted; sixthly, a control strategy for the second half stage of baking is adopted, and the next step is executed; seventhly, whether t is greater than or equal to T or not is judged, if yes, the next step is executed, or otherwise the sixth step is executed; and eighthly, baking is completed. The method has the advantages that the current baking stage of the food is judged according to the change trend of the oxygen content value, then different baking strategies are adopted respectively to control the baking process, therefore, air convection and circulation efficiency in a cavity is higher, heat distribution is more uniform, and accordingly the baking effect is guaranteed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

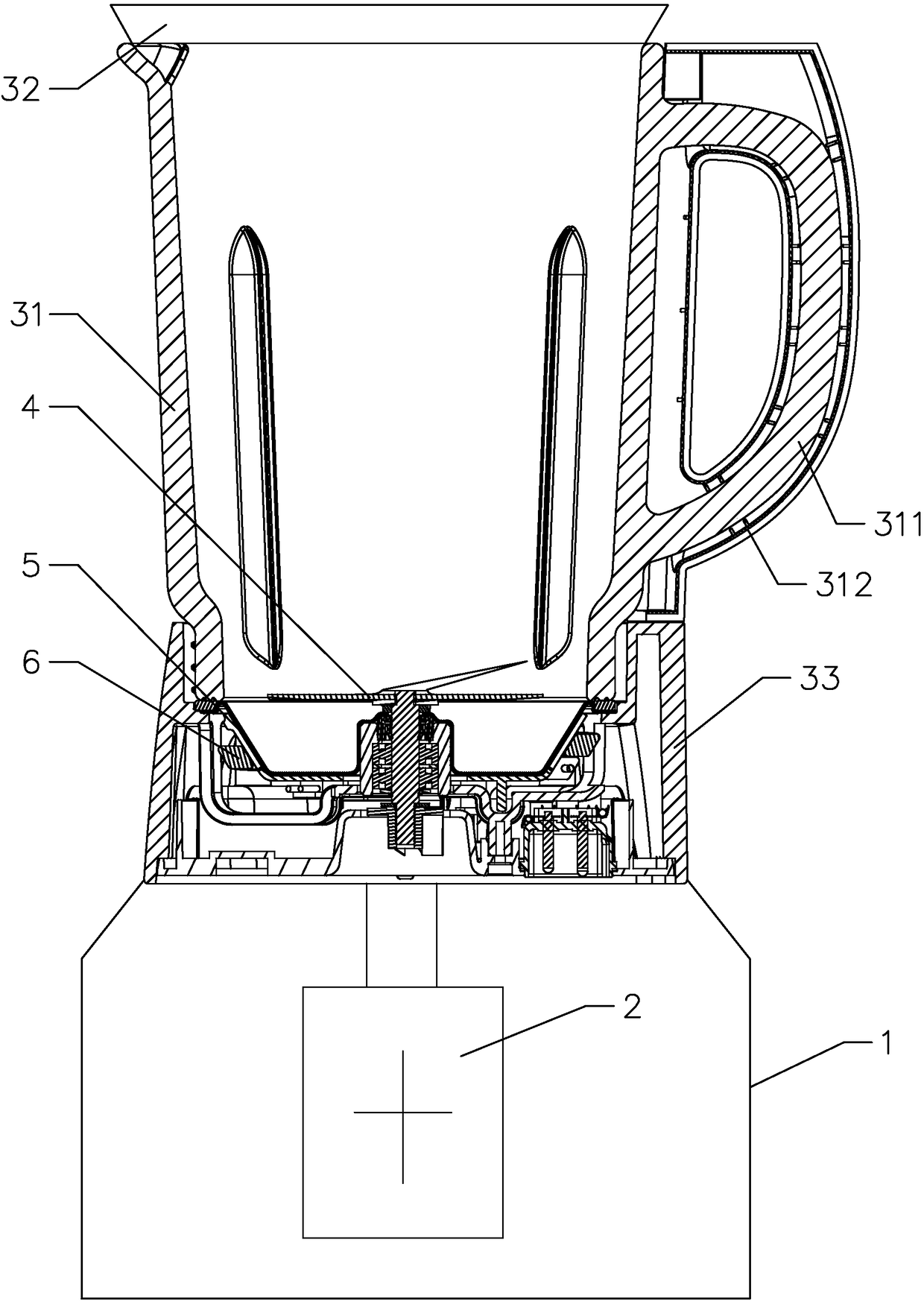

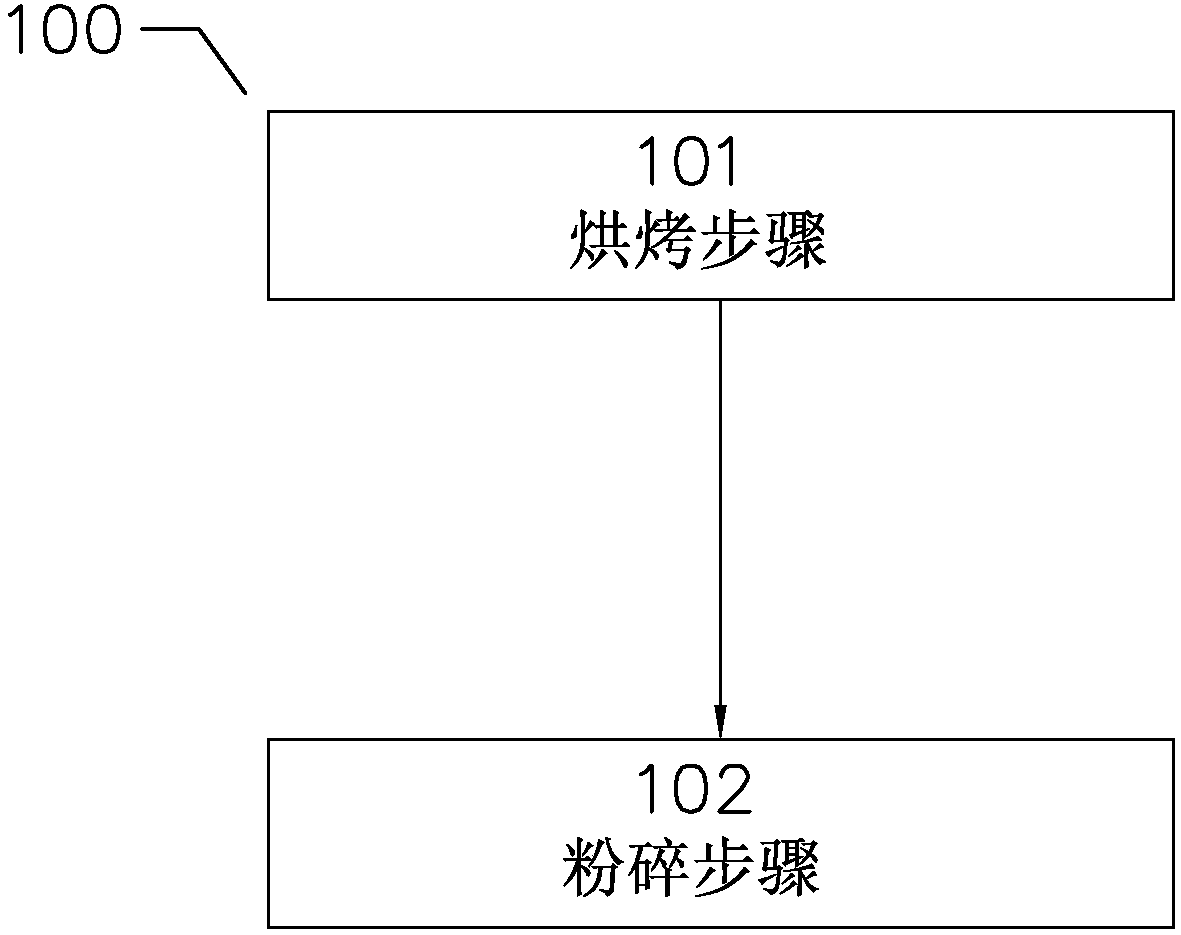

Nut paste processing method of food processer

The invention provides a nut paste processing method of a food processer. The method includes the following steps of braking and crushing, wherein in the braking step, a heating plate is used for heating nuts in a cup body until the nuts are cooked, and in the crushing step, a motor drives a crushing blade to rotate so as to crush the nuts in the cup body. The food processor is used for preparingnut paste, compared with a traditional household making method, the method is more convenient and faster, preparation steps are few, required utensils are few, the preparation process is pleasant, pleasure obtained by users in the preparation process is greatly increased, and the DIY fun of the users is increased. Meanwhile the heating plate is arranged at the lower end of the cup body, the heating plate includes a heating plate body and a heating pipe arranged on the side wall of the heating plate body, in this way, the nuts on the bottom are not burnt, the nuts are heated from the side face,the nuts can thus be heated more uniformly, it is ensured that the nuts are cooked, have no scorched flavor and also can produce strong nut fragrance, and therefore the made nut paste is more delicious and mellow.

Owner:JOYOUNG CO LTD

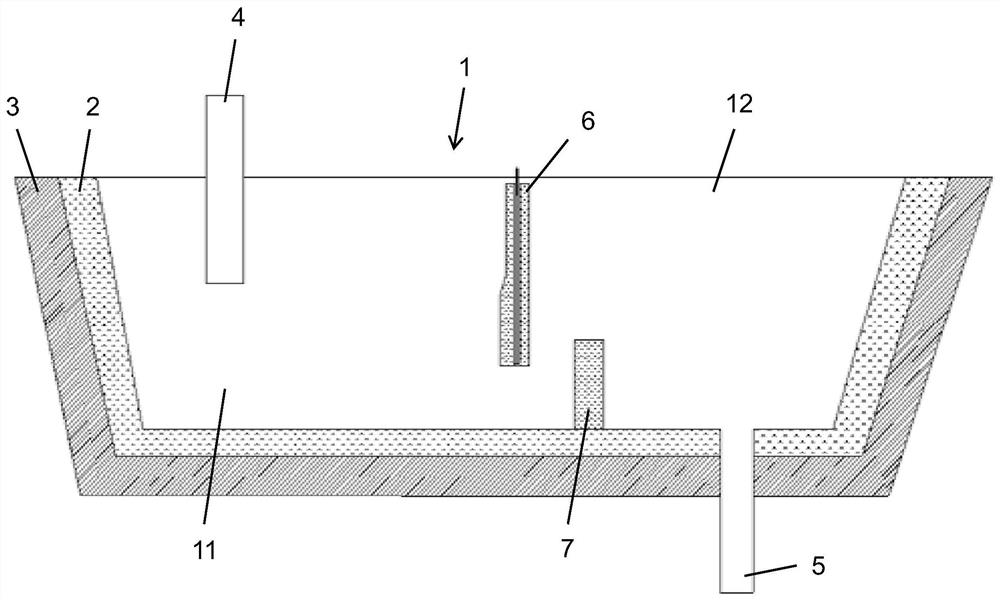

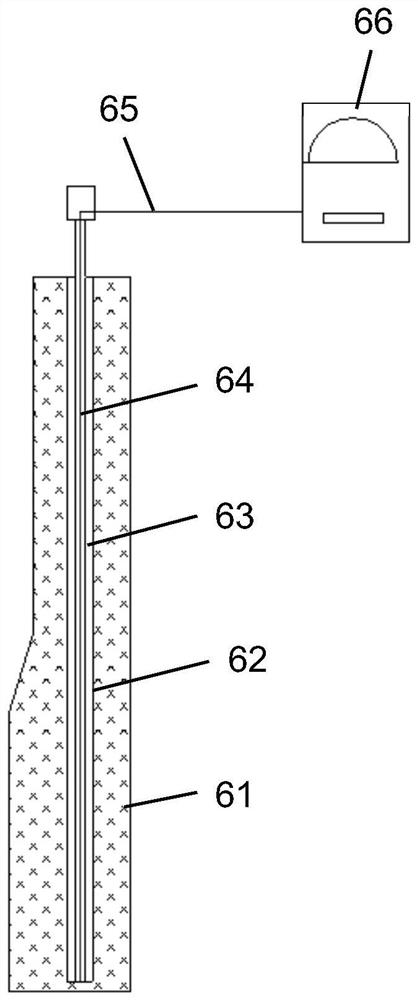

Continuous temperature measuring device for tundish molten steel

InactiveCN112059127AContinuous and accurate temperature detectionPrevent melt lossMelt-holding vesselsCasting parameters measurement/indication devicesRefractoryThermocouple

The invention discloses a continuous temperature measuring device for a tundish molten steel. The device comprises a tundish, a long nozzle connected to the top of the tundish, a submersed nozzle connected to the bottom of the middle of the tundish and a temperature measuring weir plate arranged in the tundish, the tundish is divided into a mixing area and a casting area by the temperature measuring weir plate, the long nozzle is arranged in the mixing area, and the submersed nozzle is arranged in the casting area; the temperature measurement weir plate comprises a weir plate refractory material body, a temperature measurement hole is formed in the weir plate refractory material body, a temperature measurement refractory material protection sleeve is arranged in the temperature measurementhole, a temperature measurement thermocouple is arranged in the temperature measurement refractory material protection sleeve, and the temperature measurement thermocouple is connected with a temperature signal acquisition device through a temperature signal line. According to the continuous temperature measuring device, the problem that a temperature measuring probe cannot continuously detect the temperature of molten steel is solved, and meanwhile the problems that the temperature measuring probe is short in service life and high in temperature measuring cost are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

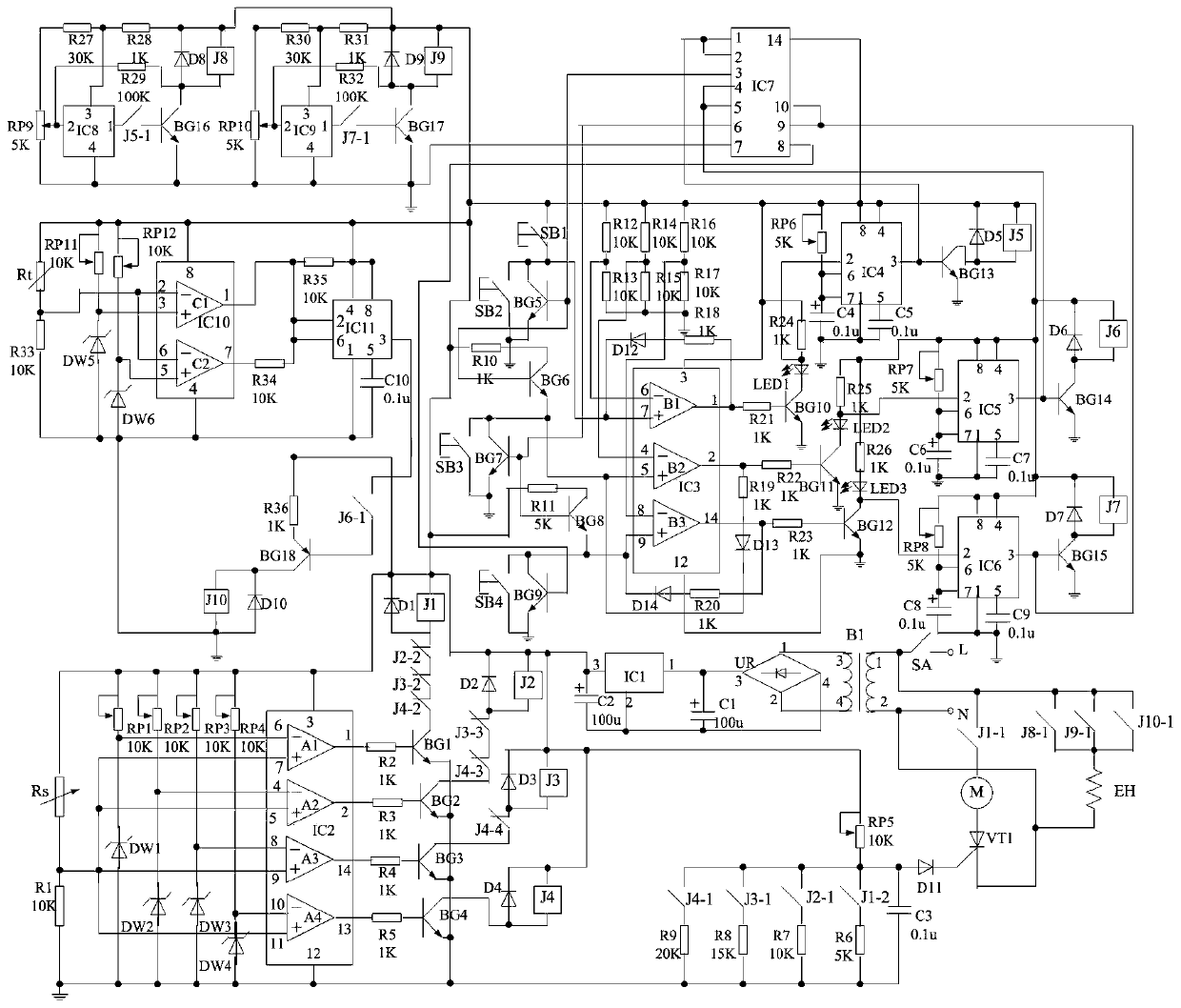

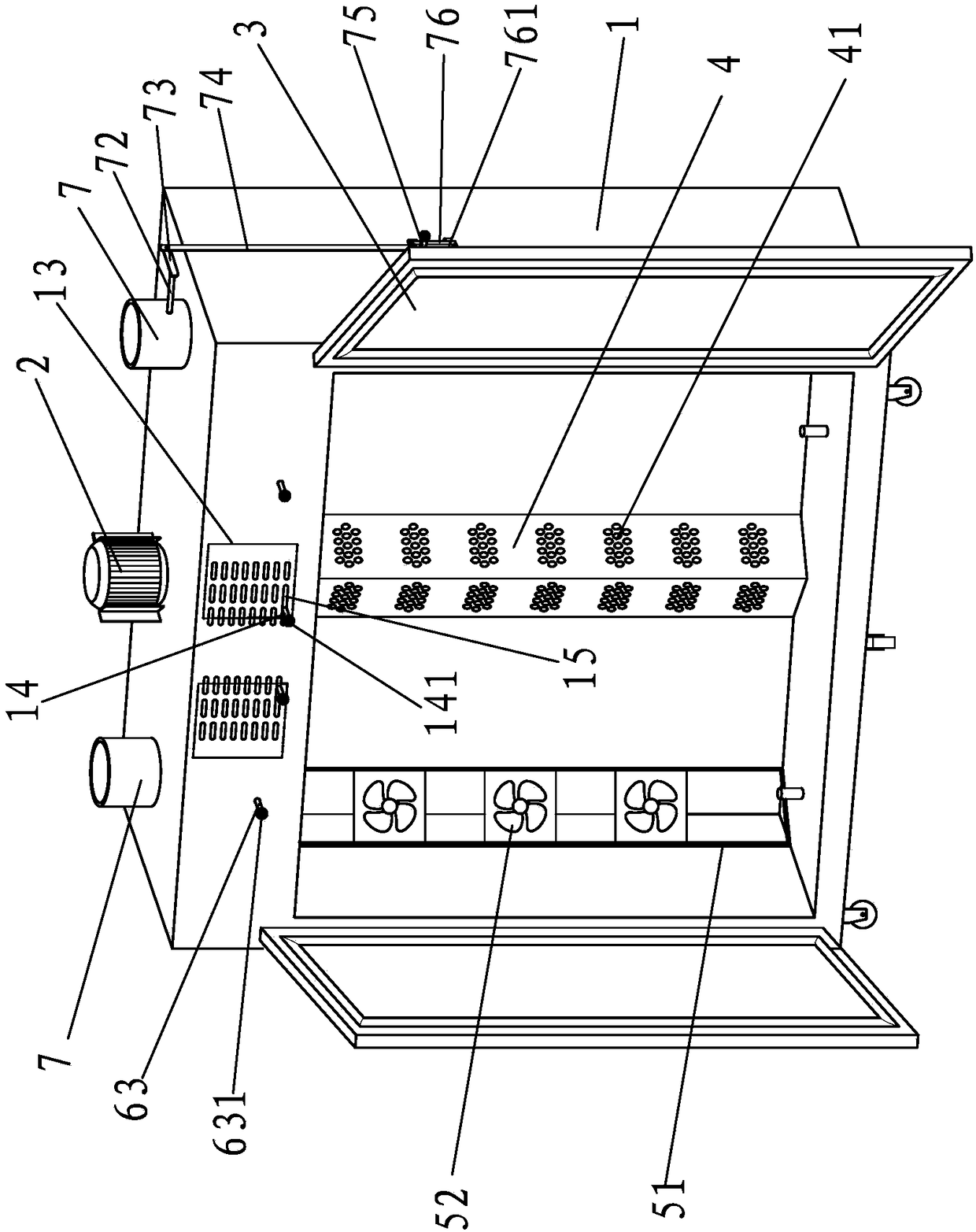

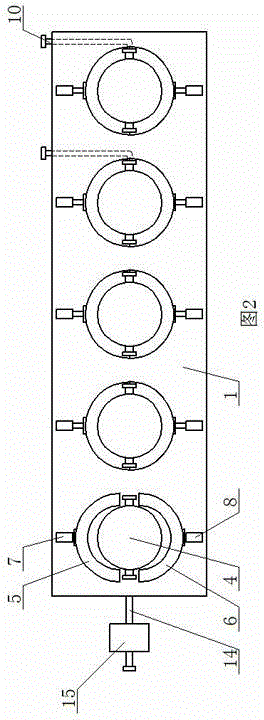

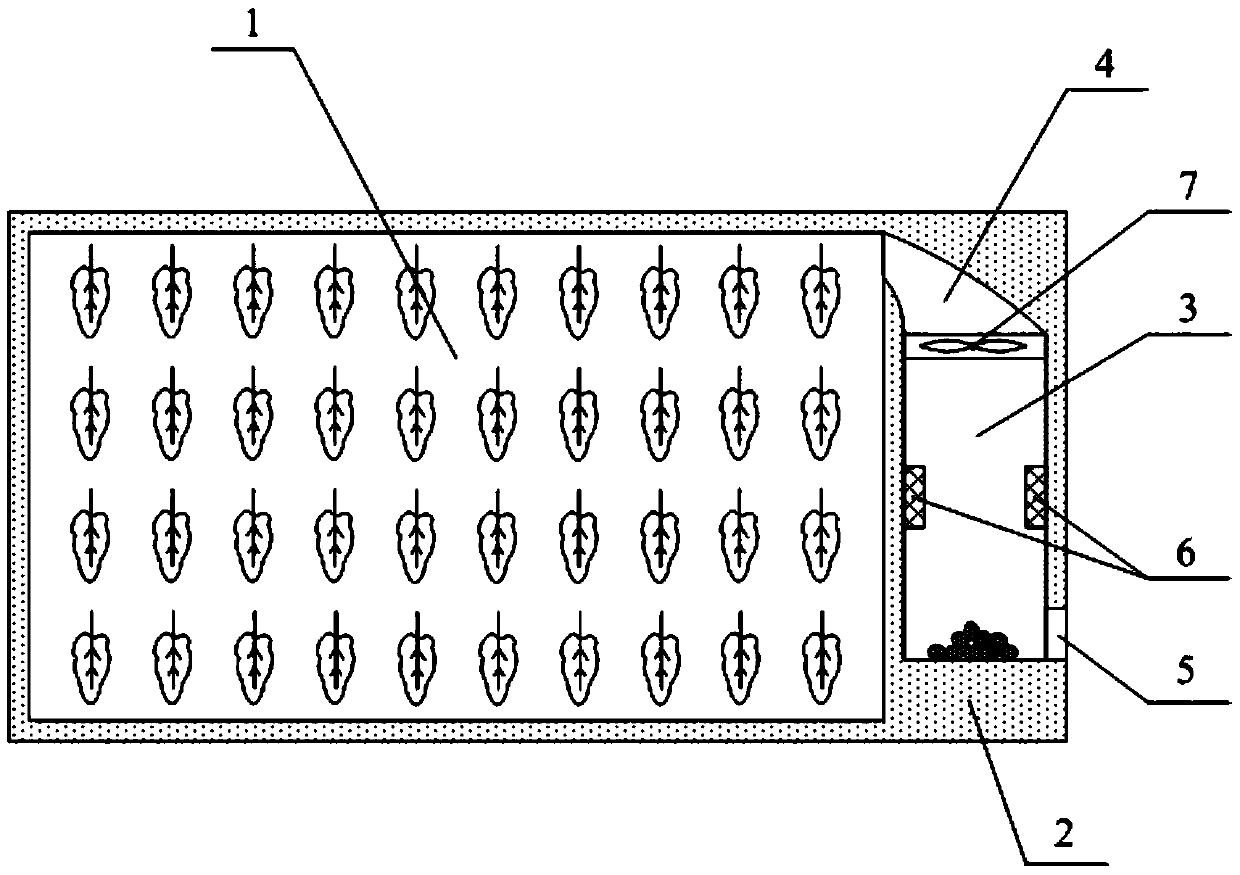

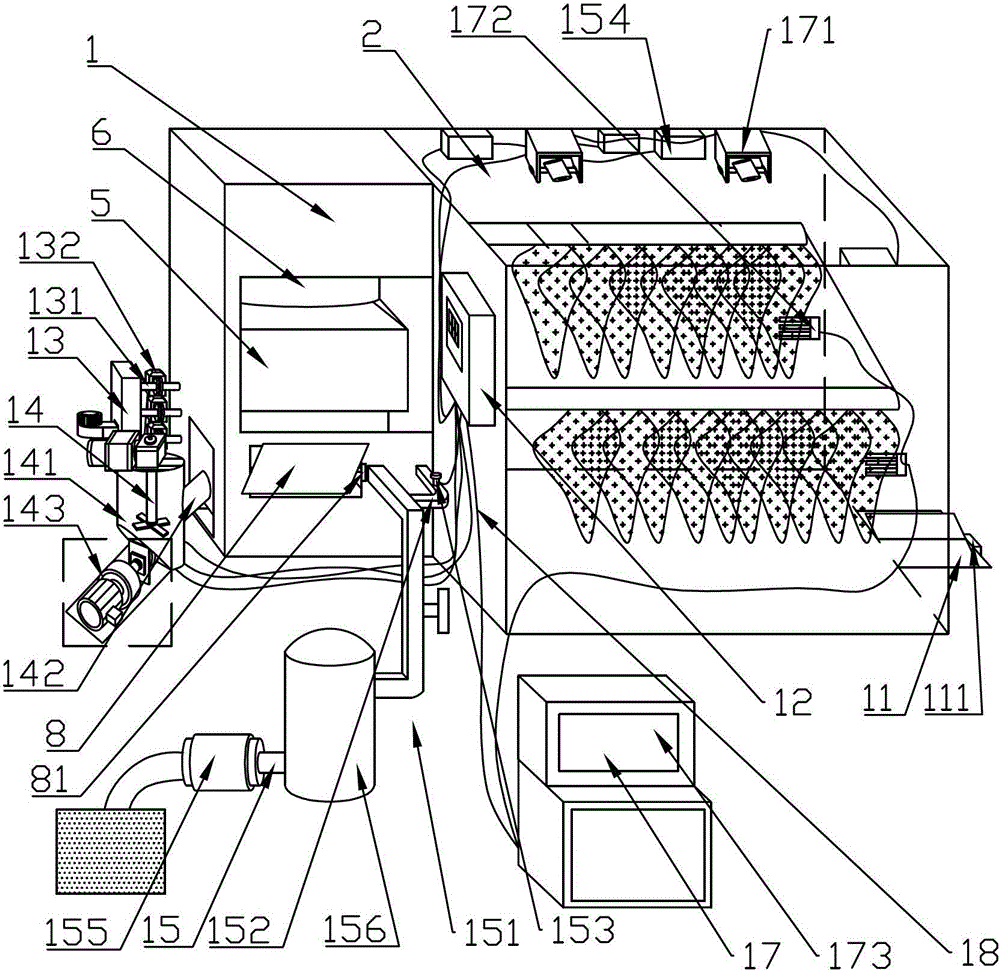

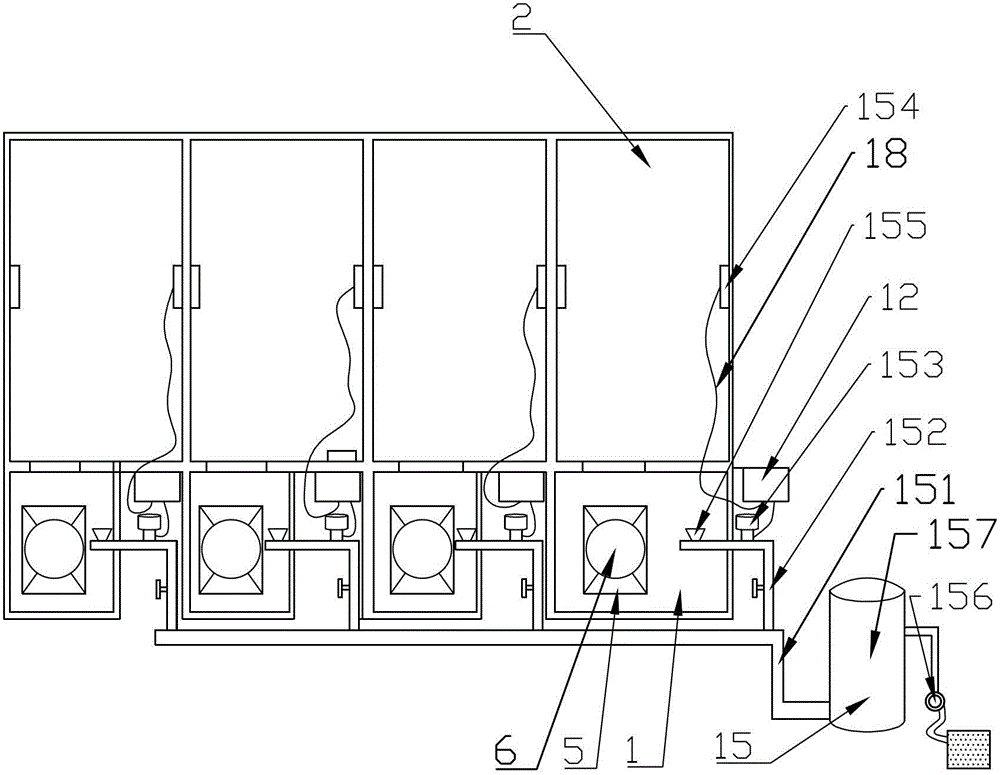

Agaric full-automatic dryer

ActiveCN110187724AGuaranteed baking effectSave electricityHumidity controlFood treatmentTemperature controlAuto regulation

The invention discloses an agaric full-automatic dryer. The agaric full-automatic dryer is composed of a power supply circuit, a humidity automatic control circuit, a timing circuit, a low-temperaturedehumidification temperature control circuit, a high-temperature drying temperature control circuit, and a low-temperature drying temperature control circuit; the power supply circuit supplies powerfor each of the humidity automatic control circuit, the timing circuit, the low-temperature dehumidification temperature control circuit, the high-temperature drying temperature control circuit, and the low-temperature drying temperature control circuit; the drying process is divided into a low-temperature dehumidification stage, a high-temperature drying stage and a low-temperature drying stage;and the drying process can automatically turn to the next stage after each stage is finished. The heating rotating rate of an exhaust fan motor M can be automatically adjusted according to the humidity in a drying oven so as to save the power; the set temperature can be precisely controlled at each stage, thereby guaranteeing the baking effect of the agaric.

Owner:XUZHOU COLLEGE OF INDAL TECH

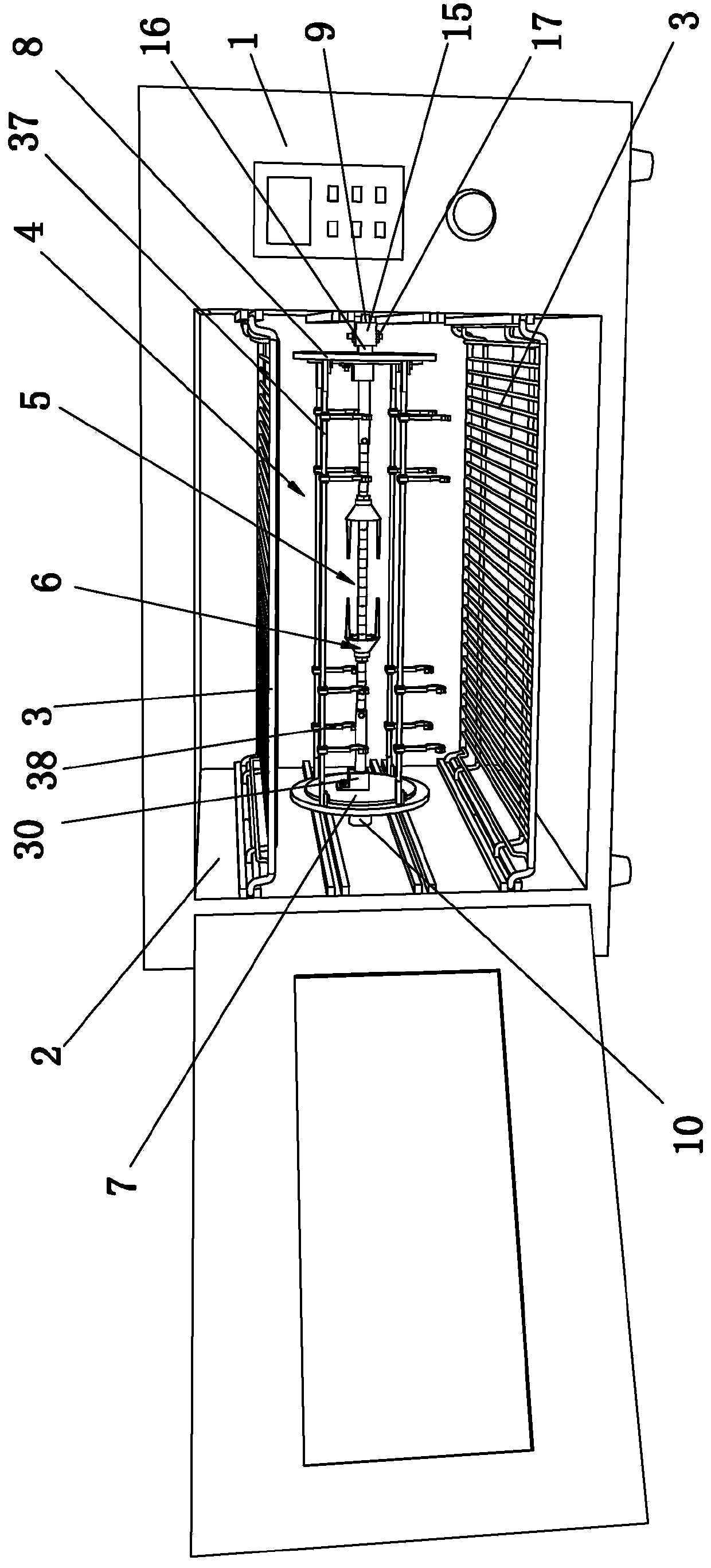

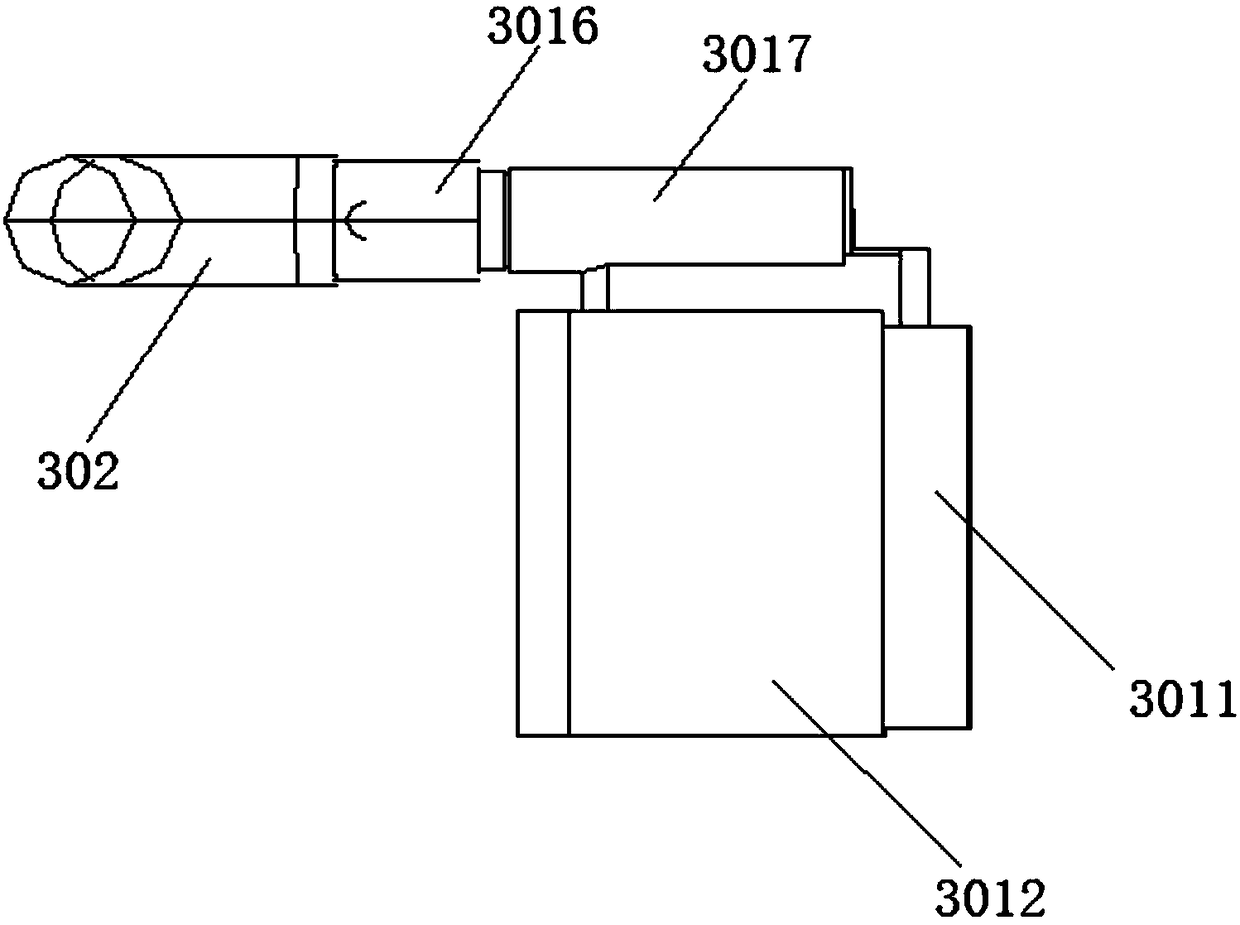

Baking and shaping device based on vacuum switch tube

PendingCN111863487ASmooth rotationAvoid shakingLighting and heating apparatusDispersed particle separationElectric machineVacuum switch

The invention discloses a baking and shaping device based on a vacuum switch tube. The device comprises a baking box, wherein partition plates are welded to an inner wall of the baking box at equal intervals, a slave moving groove is formed in a front surface of an inner wall of the baking box corresponding to a top end edge of the partition plate, heaters are fixedly mounted in positions, corresponding to edges of top ends of the moving grooves, of the front surface of the inner wall of the baking box, and clamping rotating mechanisms are fixedly mounted on two sides of the inner walls of thepartition plates. The device is advantaged in that the structure is scientific and reasonable, safe and convenient use, a positioning gear, a rotating gear, a rotating plate, a groove, a wedging holeand a mold plate are arranged, a mold plate can be conveniently mounted, mounting difficulty of the mold plate is reduced, meanwhile, the position of the mold plate can be limited, a phenomenon thatthe position shakes when the mold plate rotates is prevented, the rotating plate can rotate conveniently through the motor, and therefore a surface of the mold plate can rotate conveniently, and a vacuum switch tube on a surface of the mold plate can be rotated and baked.

Owner:刘丽娟

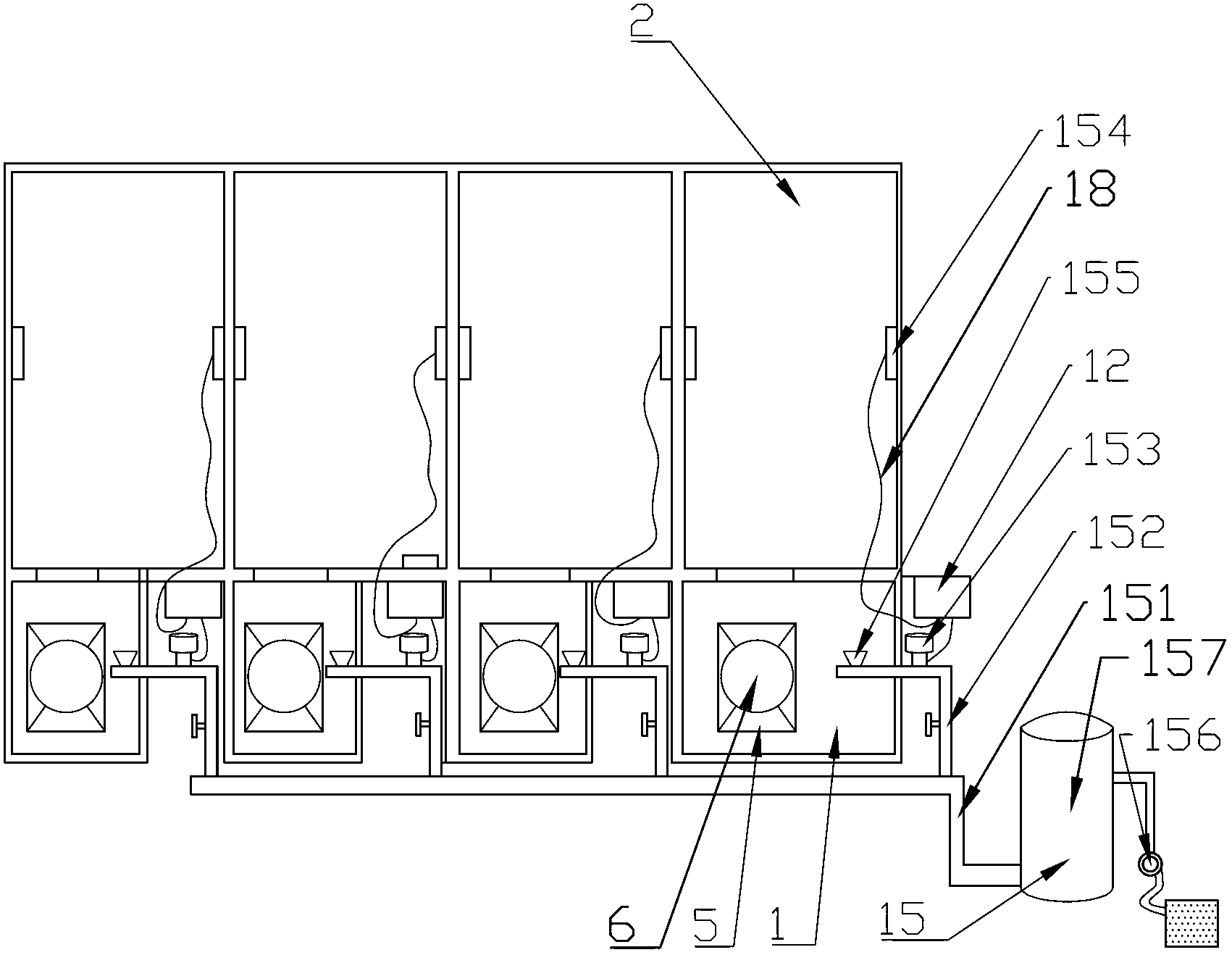

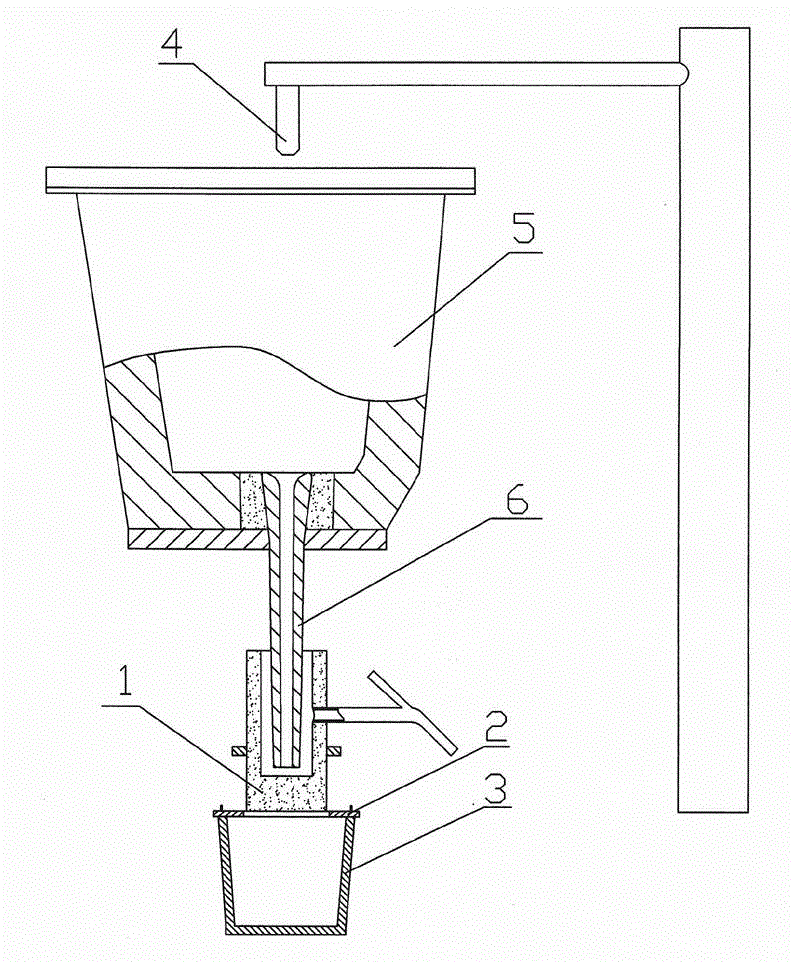

Self-control bulk curing barn capable of accurately baking biomass

InactiveCN103019278AGuaranteed baking effectMonitor the environment in real timeSimultaneous control of multiple variablesCooking & bakingAutomatic control

The invention discloses a self-control bulk curing barn capable of accurately baking biomass, which comprises a heating chamber and a baking chamber, wherein an upper ventilation duct and a lower ventilation duct are correspondingly arranged at the upper end and the lower end of a wall between the heating chamber and the baking chamber; the heating chamber is communicated with the baking chamber through the upper ventilation duct and the lower ventilation duct; a heating furnace is arranged in the heating chamber; a fan is arranged on the upper part of the heating furnace; the fan is connected to the upper ventilation duct through an air outlet of the fan; a cold air valve for controlling an airflow to enter is arranged on the side wall of the heating chamber; a moisture discharging channel with a ventilation hole is arranged at the bottom of the baking chamber; a moisture discharging window is arranged at the tail end of the moisture discharging channel outside the baking chamber. The self-control bulk curing barn is characterized by further comprising a controller, an automatic air inlet control system, an automatic feeding device, an automatic control humidifying system, an automatic control moisture discharging system and an automatic tobacco baking state monitoring device. The self-control bulk curing barn with the accurate baking biomass disclosed by the invention is capable of automatically and precisely controlling the internal environment of the curing barn and has the advantages of good baking effect, high energy utilization rate and the like, and is convenient for operation.

Owner:SHANDONG LINYI TOBACCO

Environment-friendly type agricultural product baking machine

PendingCN108552560ADrain fastMany cyclesFood processingFood treatmentCooking & bakingAgricultural engineering

The invention discloses an environment-friendly type agricultural product baking machine. The environment-friendly type agricultural product baking machine comprises a body and a blower, wherein the body is provided with a baking chamber and a draft chamber; an auxiliary blowing mechanism and a hollow heat supply seat are arranged in the baking chamber; a moisture removal port and a moisture removal cylinder are arranged on the top surface of the body; a moisture removal adjusting device is arranged on the moisture removal cylinder; a side partition plate and a middle partition plate are arranged in the draft chamber; the blower is mounted in a front chamber; a heating element is mounted in a back chamber; the hollow heat supply seat communicates with the back chamber; a side port and a side seal plate are arranged on the side partition plate; a return air control device for controlling the side port to be opened or closed is arranged on the side seal plate; an air inlet and a front seal plate are arranged on the front side surface of the body; and an inlet air control device for controlling the air inlet to be opened or closed is mounted on the front seal plate. Compared with theprior art, by adjusting the air amount of the moisture removal port, the side port and the air inlet, the baking machine disclosed by the invention can adapt to a baking process required by shiitake mushrooms and also adapt to baking processes of different agricultural products, so the baking machine has the advantages of wide application range, energy saving, environmental protection and high baking speed.

Owner:QUANZHOU CHANGSHENG TEA MACHINERY

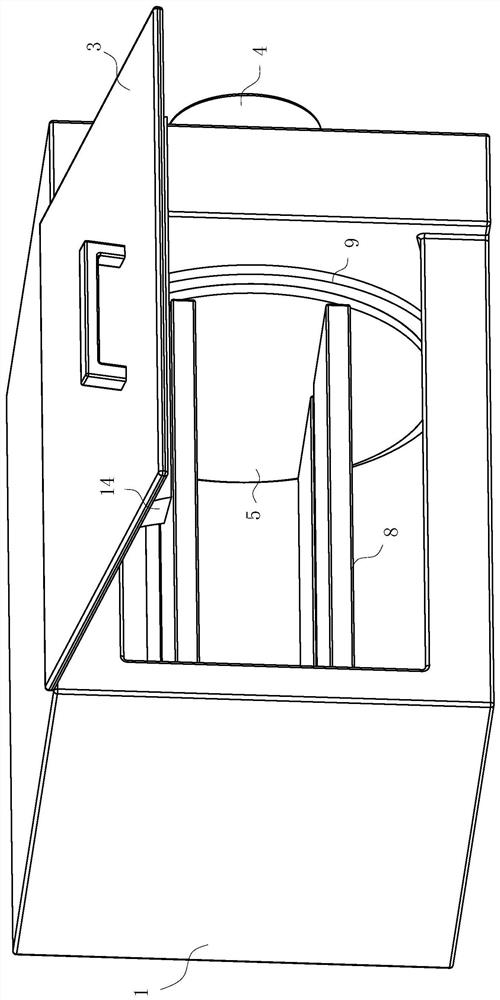

Food steaming oven

InactiveCN111657756AGuaranteed baking effectConsistent toastingSteam cooking vesselsRoasters/grillsElectric machineGear wheel

The invention belongs to the technical field of steaming ovens, in particular to a food steaming oven. The food steam oven comprises a steam oven body, wherein the steaming oven body comprises a shelland an oven cover; a driving motor is arranged on the side wall of the shell; a first disc is fixed to the output shaft end of the driving motor, a second disc is rotationally installed in an inner cavity of the shell, four rotating shafts are rotationally mounted between the first disc and the second disc; a placing plate is fixed to the surfaces of the rotating shafts, the four rotating shaftsare of a square structure, a gear ring is fixed to an inner cavity of the shell, the ends, close to the driving motor, of the rotating shafts extend out of the first disc, and gears are fixed to the ends, close to the driving motor, of the rotating shafts and engaged with the gear ring. The baking degree of the food receiving steaming oven body on the placing plate is changed by changing the position of the placing plate, so that the baking degrees of multiple layers of food receiving steaming oven bodies in the steaming oven body are kept consistent, and the food baking effect is guaranteed.

Owner:张健

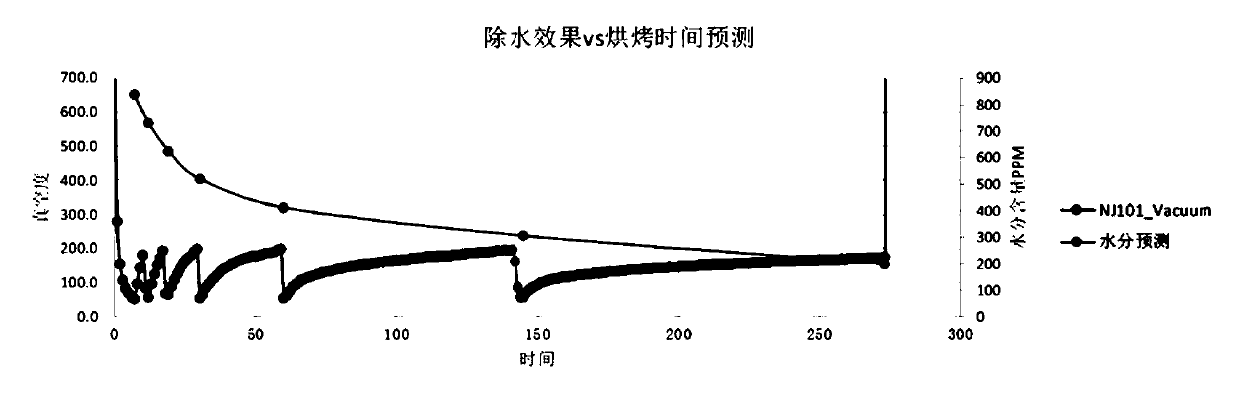

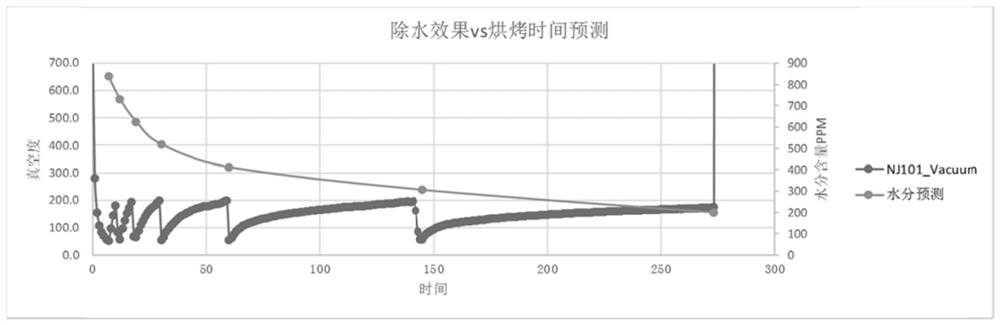

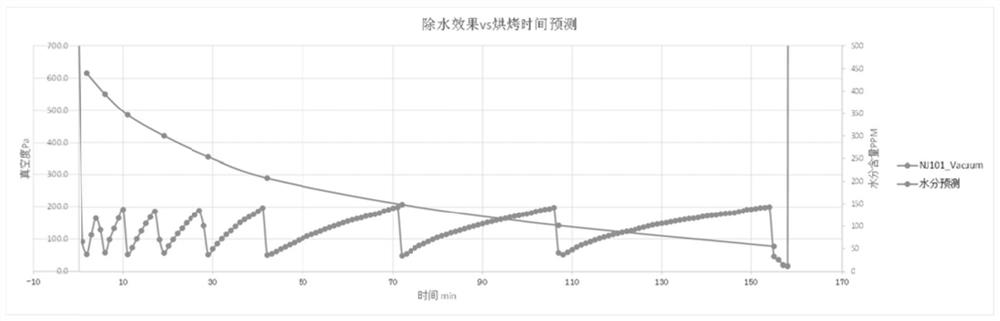

Baking curve construction method and baking method of lithium ion battery pole pieces

ActiveCN111486664AImprove baking efficiencySaves baking timeDrawing from basic elementsDrying solid materials without heatPole pieceLithium-ion battery

The invention belongs to the technical field of lithium ion battery processing and manufacturing, particularly relates to a baking curve construction method based on lithium ion battery pole pieces made of different materials, and further discloses a baking method of the lithium ion battery pole pieces. According to the baking curve construction method and the baking method of the lithium ion battery pole piece, firstly, the baking pressure change rate curves of different material systems are obtained through one-time experiment and data analysis, the water removal rate in the baking process is represented through the pressure change rate, the proper pressure change rate is selected as the baking ending condition, the vacuum baking time is correspondingly and automatically adjusted, the pole piece baking condition of a new material system can be rapidly determined, the method can be used for one-time effective baking of pole pieces with different initial water containing conditions, and the baking efficiency is effectively improved.

Owner:华鼎国联四川动力电池有限公司

Oven

The invention provides an oven. The oven comprises a casing having a bottom board, a slag pan which is arranged in an inner chamber of the casing and is arranged above the bottom board, a heating tube which is arranged on the bottom board and is arranged below the slag pan, and a convection device which is arranged on the bottom board and is arranged below the slag pan, wherein the slag pan is provided with an up-to-down-through ventilation mouth. The oven has an advantage of high baking efficiency.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Ladle preheating kiln

InactiveCN104625037AReduce consumptionImprove heat utilizationMelt-holding vesselsCombustionDirect heating

The invention provides a ladle preheating kiln which comprises a kiln base. At least one direct-heating kiln opening and at least one waste heat kiln opening are formed in the top face of the kiln base. The direct-heating kiln openings and the waste heat kiln openings are sequentially communicated through a smoke channel respectively. The direct-heating kiln openings are located in one side of the gas inlet end of the smoke channel. The waste heat kiln openings are located in one side of the gas outlet end of the smoke channel. The direct-heating kiln openings are communicated with a combustion engine through heat supply pipes. The combustion engine is communicated with a gas inlet pipe. The waste heat kiln opening close to the gas outlet end of the smoke channel is communicated with a waste gas pipe which is provided with an induced draft fan. A stop valve is installed on each heat supply pipe. By means of the ladle preheating kiln, the gas consumed for baking ladles can be effectively reduced for iron and steel enterprises, and meanwhile the gas combustion heat utilization rate is greatly increased.

Owner:马斌

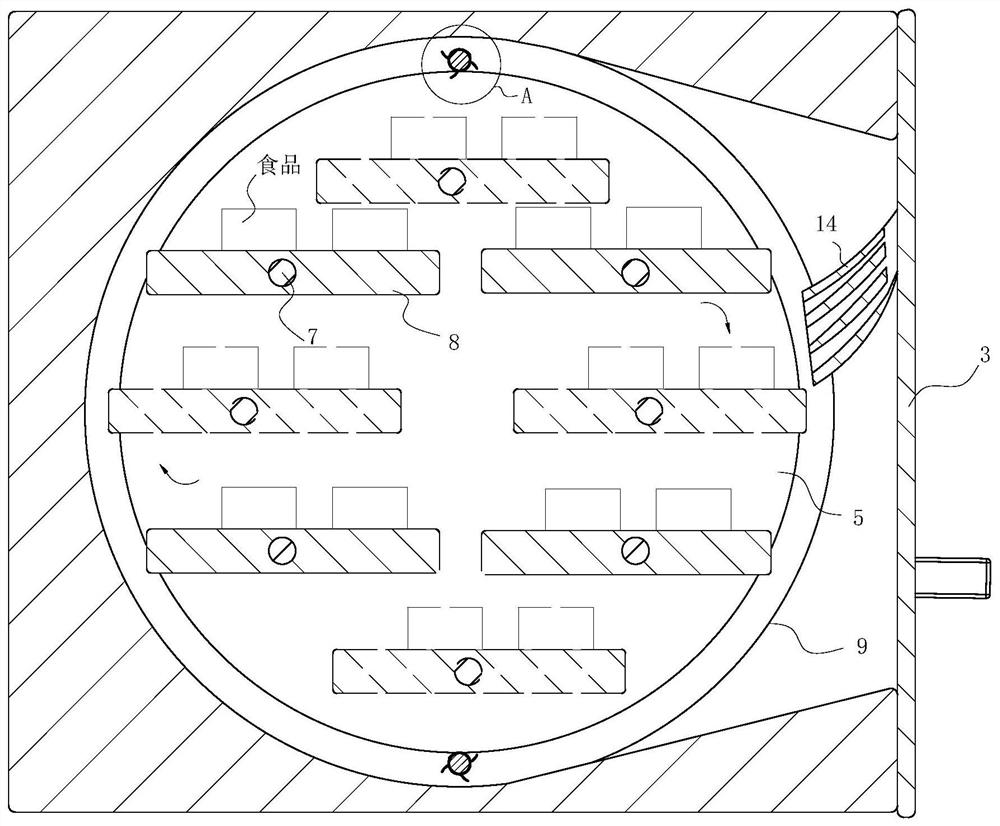

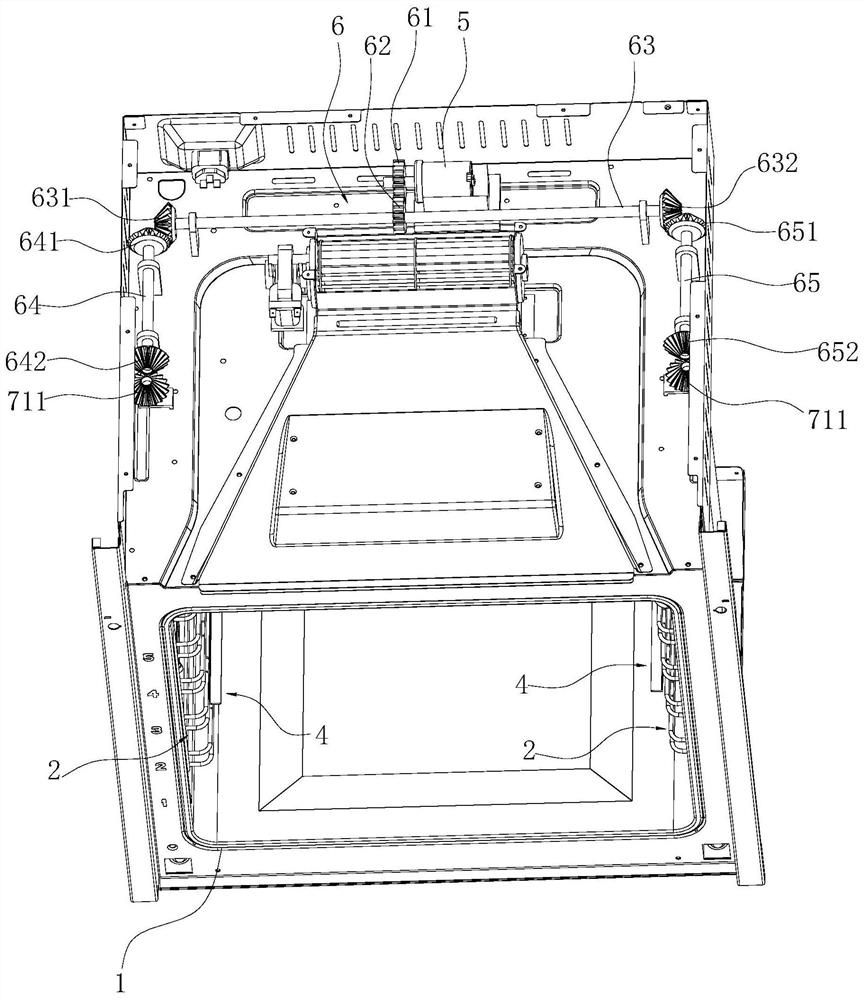

Steaming oven with rotary grill and using method of rotary grill

PendingCN110811308AAchieve rotationRealize synchronized motionSteam cooking vesselsRoasting apparatusEngineeringSteaming

The invention discloses a steaming oven with a rotary grill. The steaming oven comprises an oven body, wherein a horizontal grill and a rotary grill are placed in a working cavity of the oven body; the rotary grill is detachably connected to the oven body; the rotary grill comprises a rotating disc, a rotating rod and two rotating forks; the rotating disc comprises a left rotating disc and a rightrotating disc; the left rotating disc is movably connected to the left side wall of the oven body in a sleeved manner; and the right rotating disc is connected to a rotating head on the right side wall of the oven body. A using method of the rotary grill comprises the following steps of 1) installation of the right rotating disc; 2) installation of the left rotating disc; 3) placement of food onthe rotating rod; 4) placement of food on an auxiliary rod; and 5) baking operation. The food is subjected to rotary baking through the design of the rotary grill, so that the baking of the food is more evenly heated, and thus a good food effect is achieved; and furthermore, a detachable structure is adopted between the rotary grill and the oven body, so that the assembly or disassembly of the rotary grill is selected according to actual requirements, and thus the steaming oven is more convenient to use.

Owner:浙江蓝炬星电器有限公司

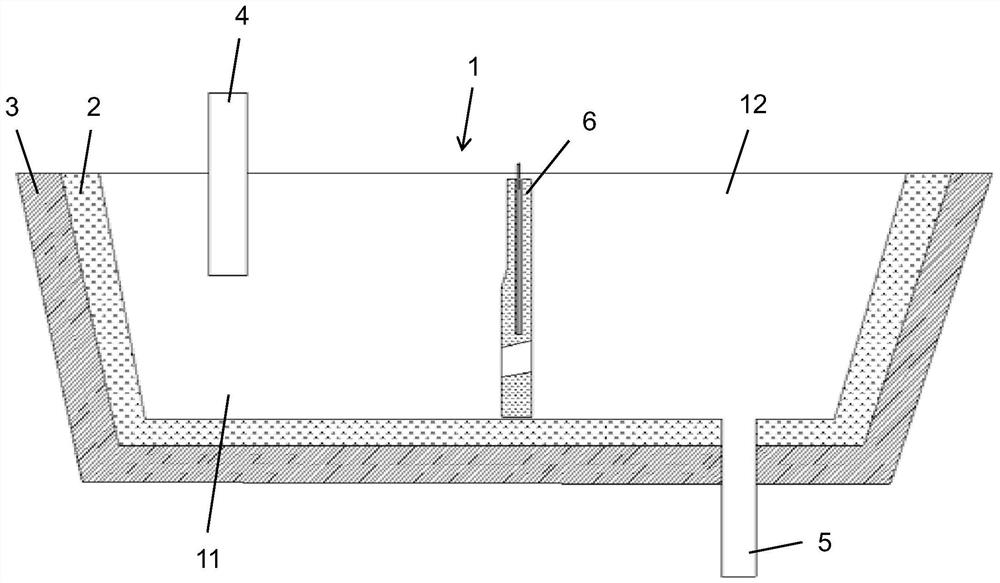

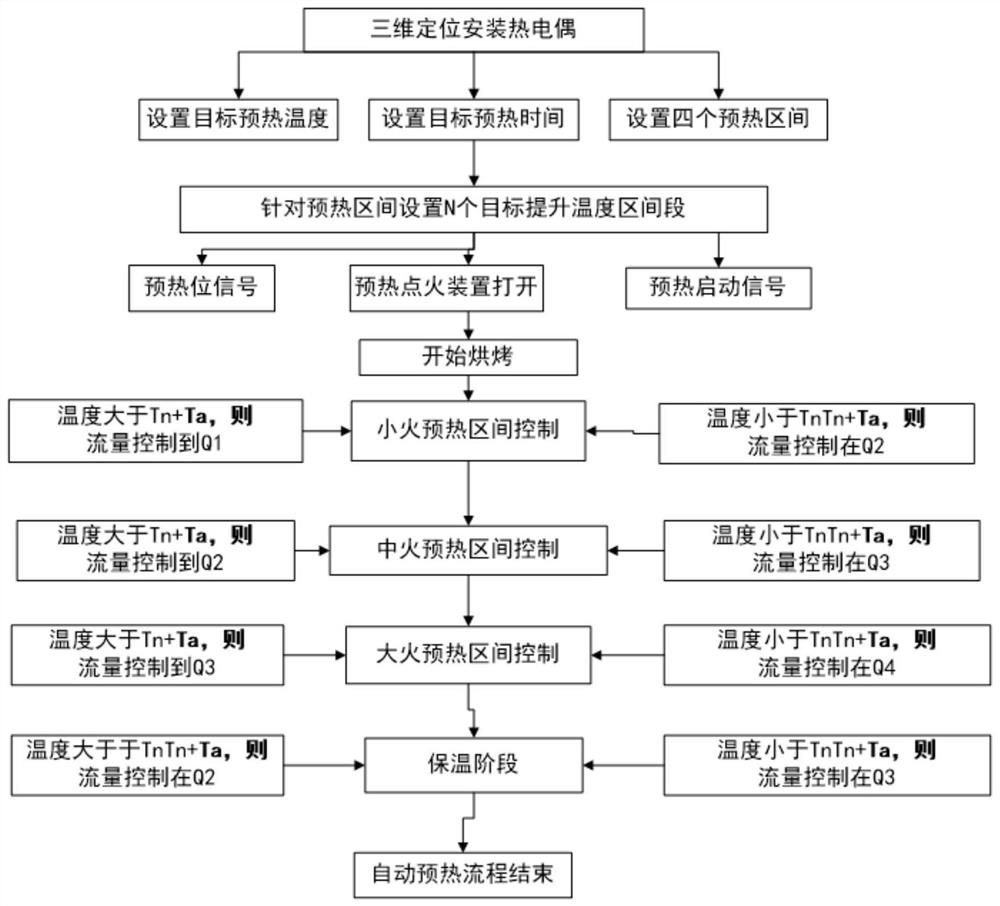

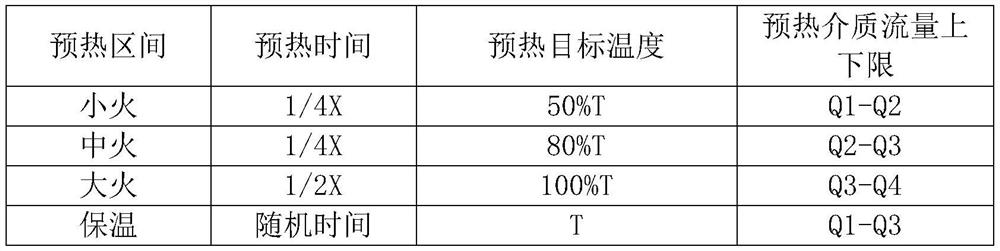

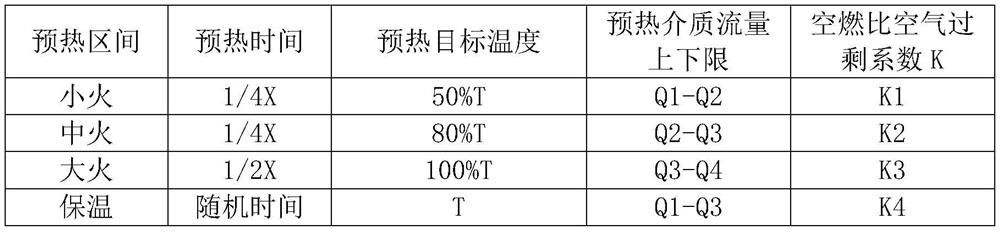

Tundish preheating automatic control method based on continuous temperature measurement

ActiveCN112808960AGuaranteed baking effectImprove the baking effectMelt-holding vesselsTemperature controlAutomatic control

The invention relates to a tundish preheating automatic control method based on continuous temperature measurement. The method is mainly characterized in that an online temperature measurement thermocouple is pre-buried in a tundish through a three-dimensional positioning method, and preheating temperature of the tundish is detected in real time; four preheating intervals including small fire, medium fire, big fire and heat preservation are divided according to target preheating temperature (1100 DEG C to 1300 DEG C) of the tundish and preheating time requirement of the tundish; and the temperature rise speed of a tundish refractory is controlled, target interval temperature is set for the corresponding preheating intervals to achieve normal preheating temperature rise, the air excess coefficient range of the air-fuel ratio is set to control the combustion flame length and the baking effect, and then control according to the target temperature is realized. According to the method, the defect that the baking effect is judged according to manual experience is avoided, meanwhile, due to real-time feedback control in the preheating process, the baking efficiency is guaranteed, in addition, the hidden danger including over-baking and fire deficiency of the baking refractory is avoided, therefore, the baking energy consumption is saved to a certain degree, and the energy-saving effect is remarkable.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A cooking control method for an electric oven

ActiveCN110584501BImprove baked tasteEnhanced convectionRoasters/grillsProcess engineeringOxygen content

A cooking control method for an electric oven, comprising the following steps: 1. Selecting food attributes; 2. Detecting the oxygen content value; 3. Judging whether the change slope of the oxygen content value is greater than 0, if it is the first half stage of baking, the next step; if not, after baking Half stage, go to step 5; 4. Control strategy in the first half stage of baking, return to step 3; 5. Timing of heating time t in the second half stage; 6. Control strategy in the second half stage of baking, next step; , if it is the next step; if no step six; eight, the baking is completed. The present invention has the advantages of: judging the current baking stage of the food through the change trend of the oxygen content value, and then adopting different baking strategies to control the baking process, so that the air convection and circulation efficiency in the cavity is higher, and the heat distribution is more uniform. So as to ensure the baking effect.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

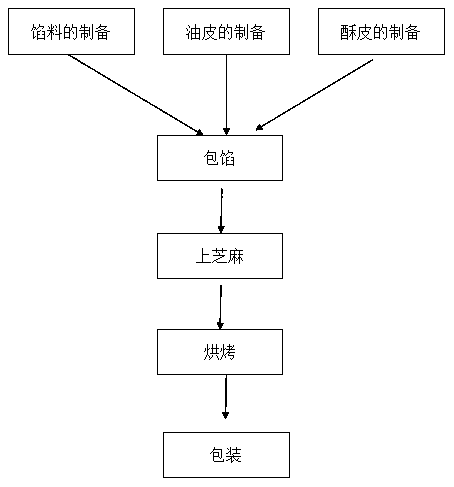

Processing and manufacturing method of crispy and thin wrapper mooncake

InactiveCN110742113AReduce generationReduce the impactModified nutritive productsWarm waterPreservative

The invention provides a processing and manufacturing method of crispy and thin wrapper mooncake. The method comprises the following steps of 1, preparing stuffing; 2, preparing oil wrappers: puttingplain flour and tea oil into a stirring machine, simultaneously adding warm water slowly and performing uniform stirring to form the oil wrappers, and kneading the materials into a smooth dough by hand after the uniform stirring; 3, preparing crispy wrappers: then, taking the plain flour and the tea oil, directly mixing and uniformly stirring the plain flour and the tea oil, performing still standing for 20 to 40 minutes after stirring, and making a pastry dough for use; 4, filling the stuffing; 5, adhering sesame; 6, performing baking; and 7, performing packaging: adding a preservative or a deoxidizing agent, and performing sterilization, packaging and opening sealing. The processing and manufacturing method of the crispy and thin wrapper mooncake has the advantages that the healthy effect of the crispy and thin wrapper mooncake is effectively improved; the baking temperature is effectively raised; the quality and the mouthfeel of the crispy and thin wrapper mooncake are convenientlyimproved; the generation of harmful substances is effectively reduced; and the human body health is facilitated.

Owner:衡阳市南北特食品有限公司

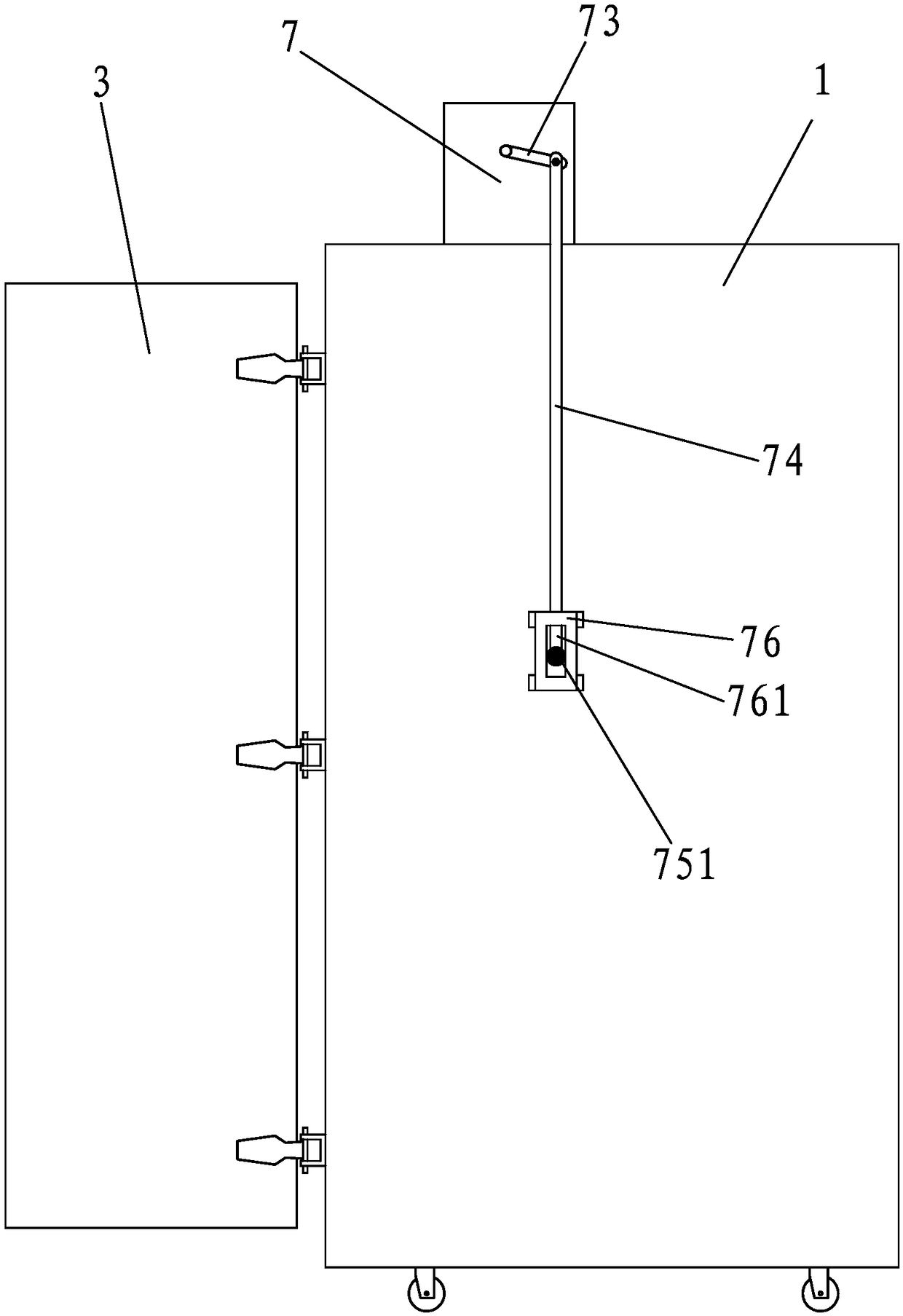

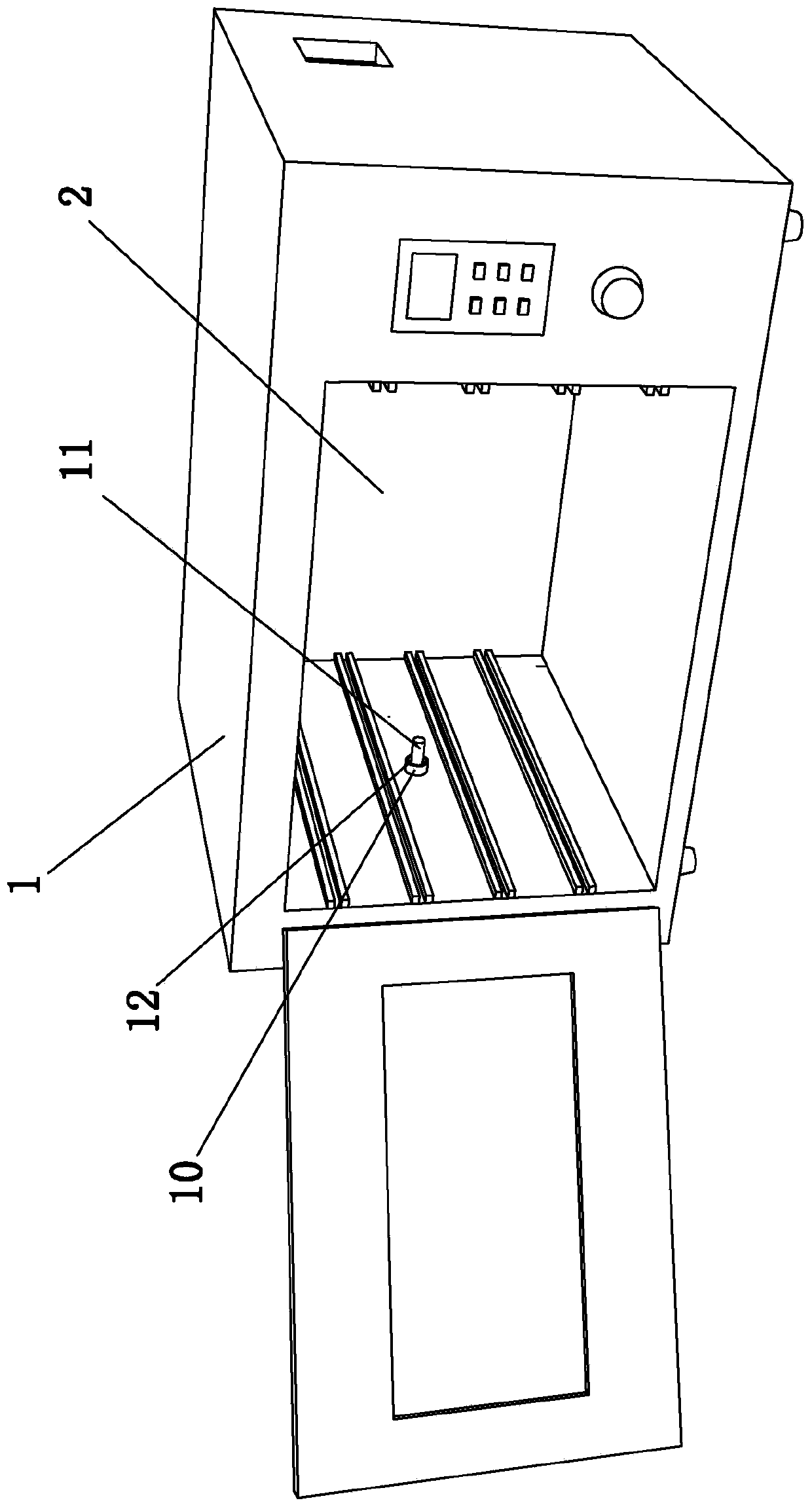

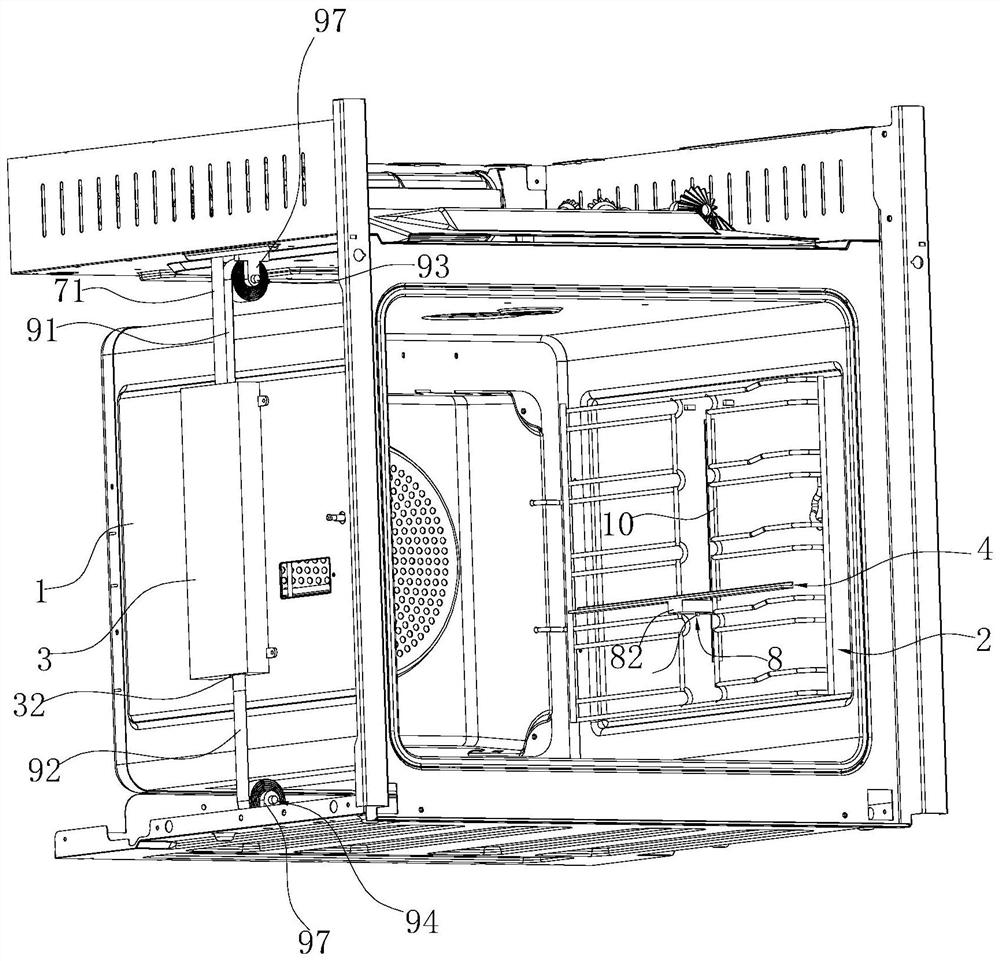

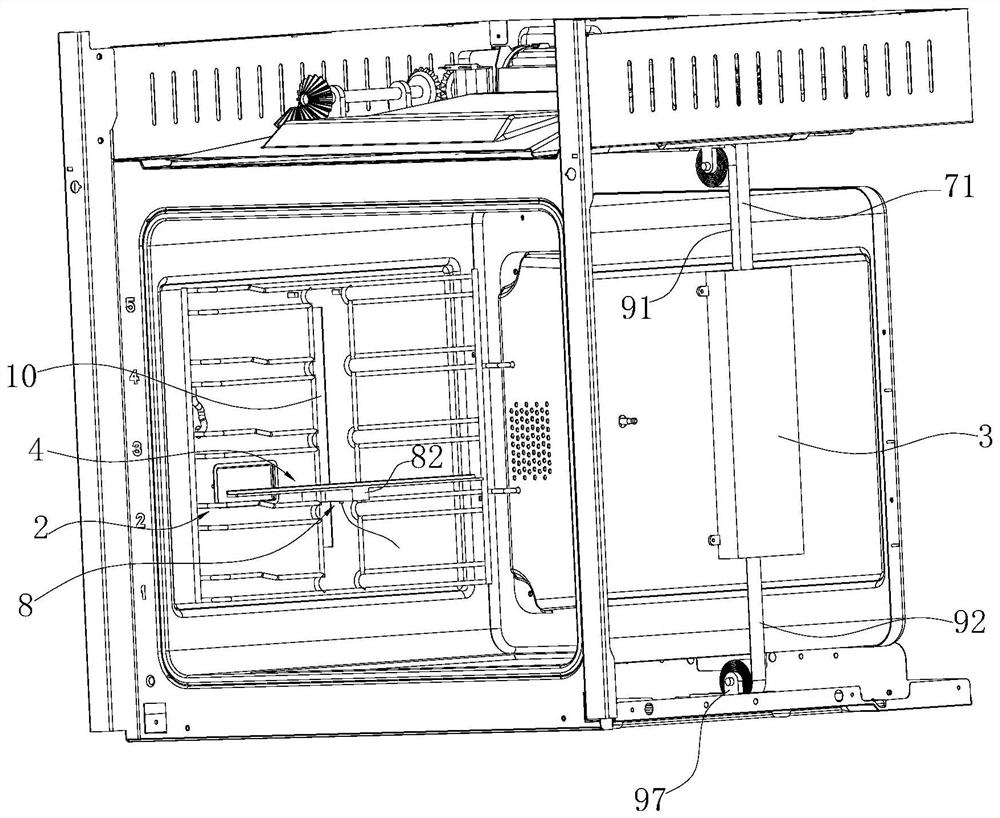

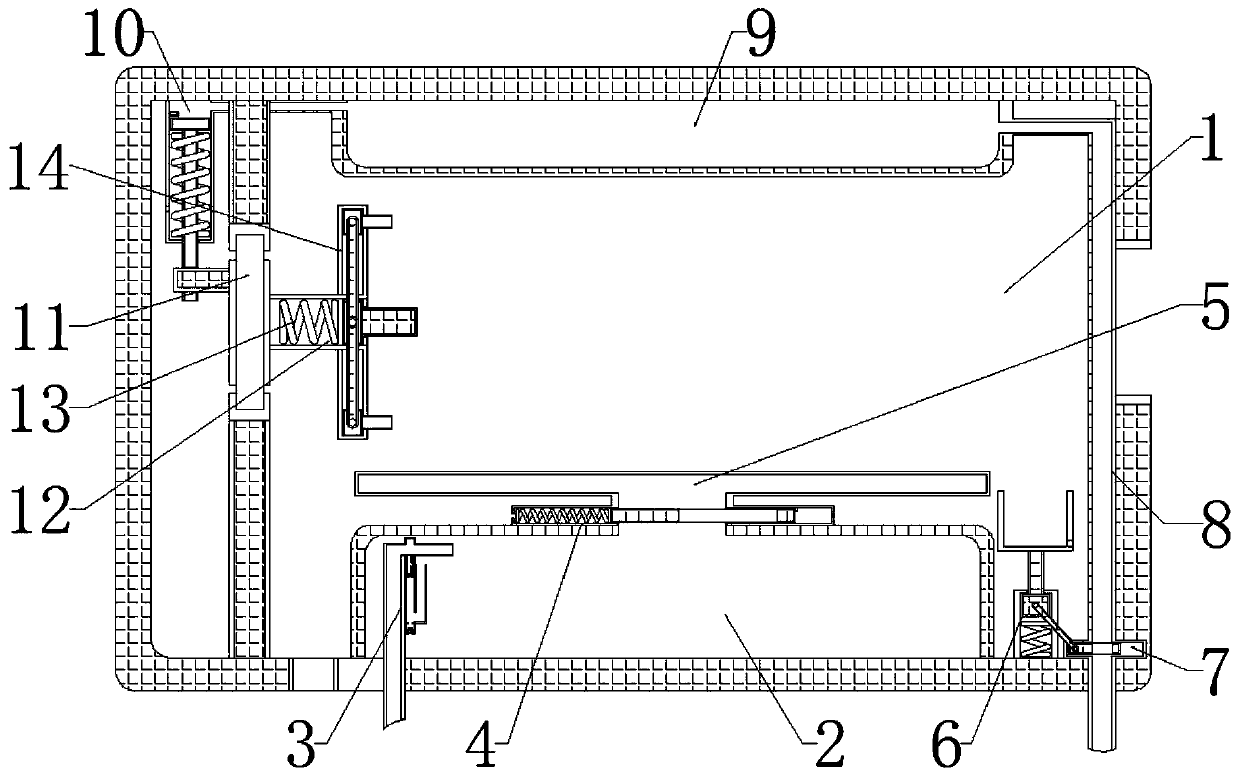

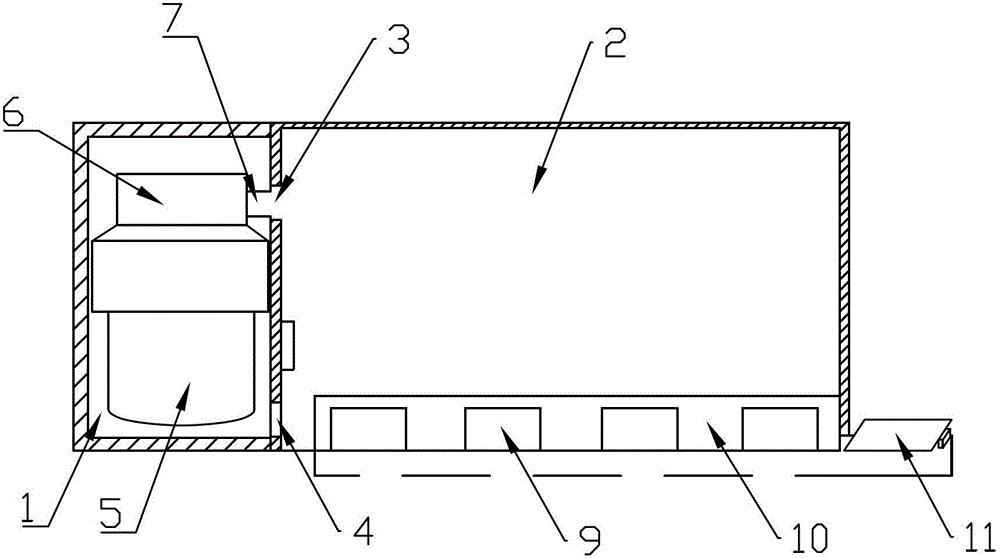

Oven with liftable baking tray

ActiveCN113116171AGuaranteed baking effectImprove user experienceRoasting apparatusRoasters/grillsEngineeringStructural engineering

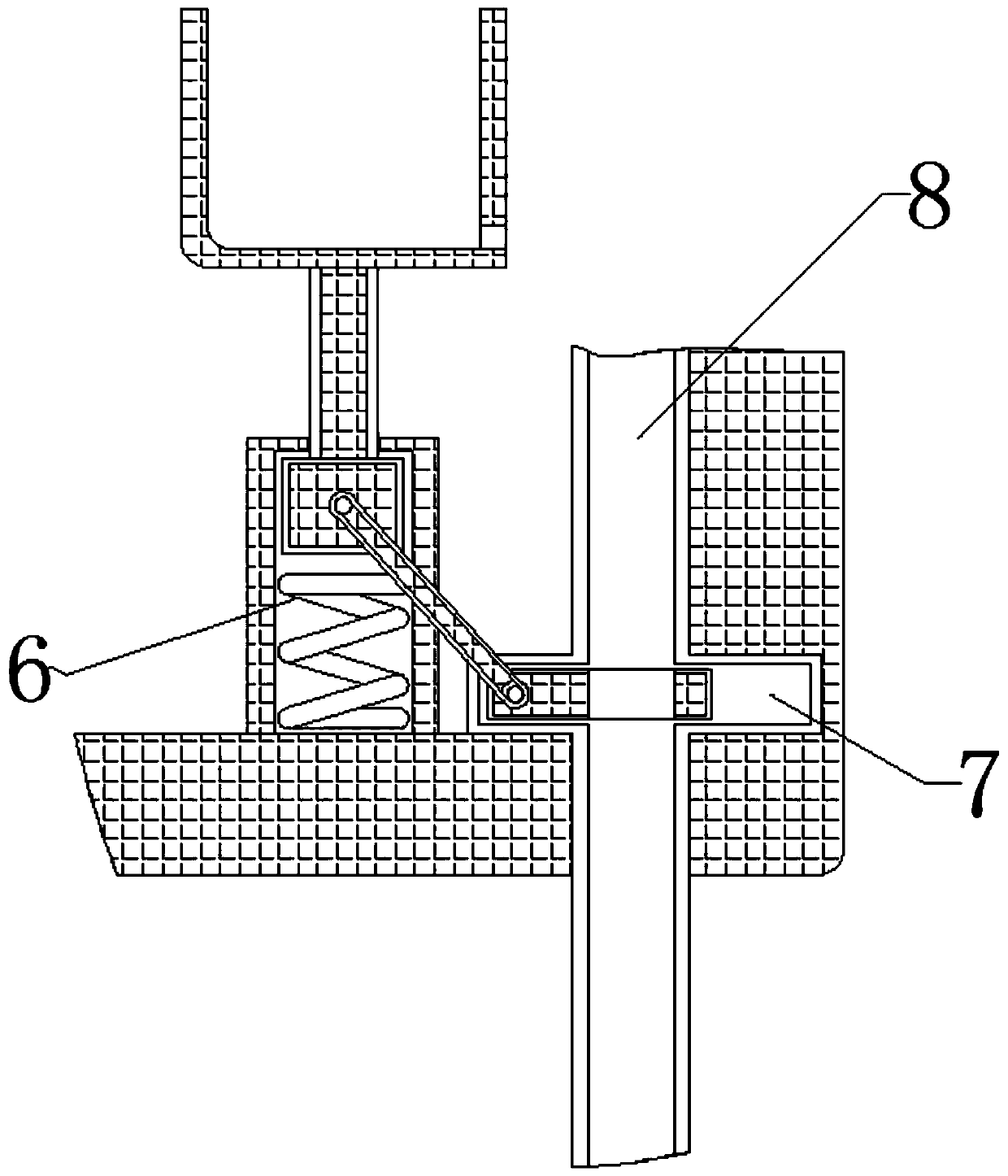

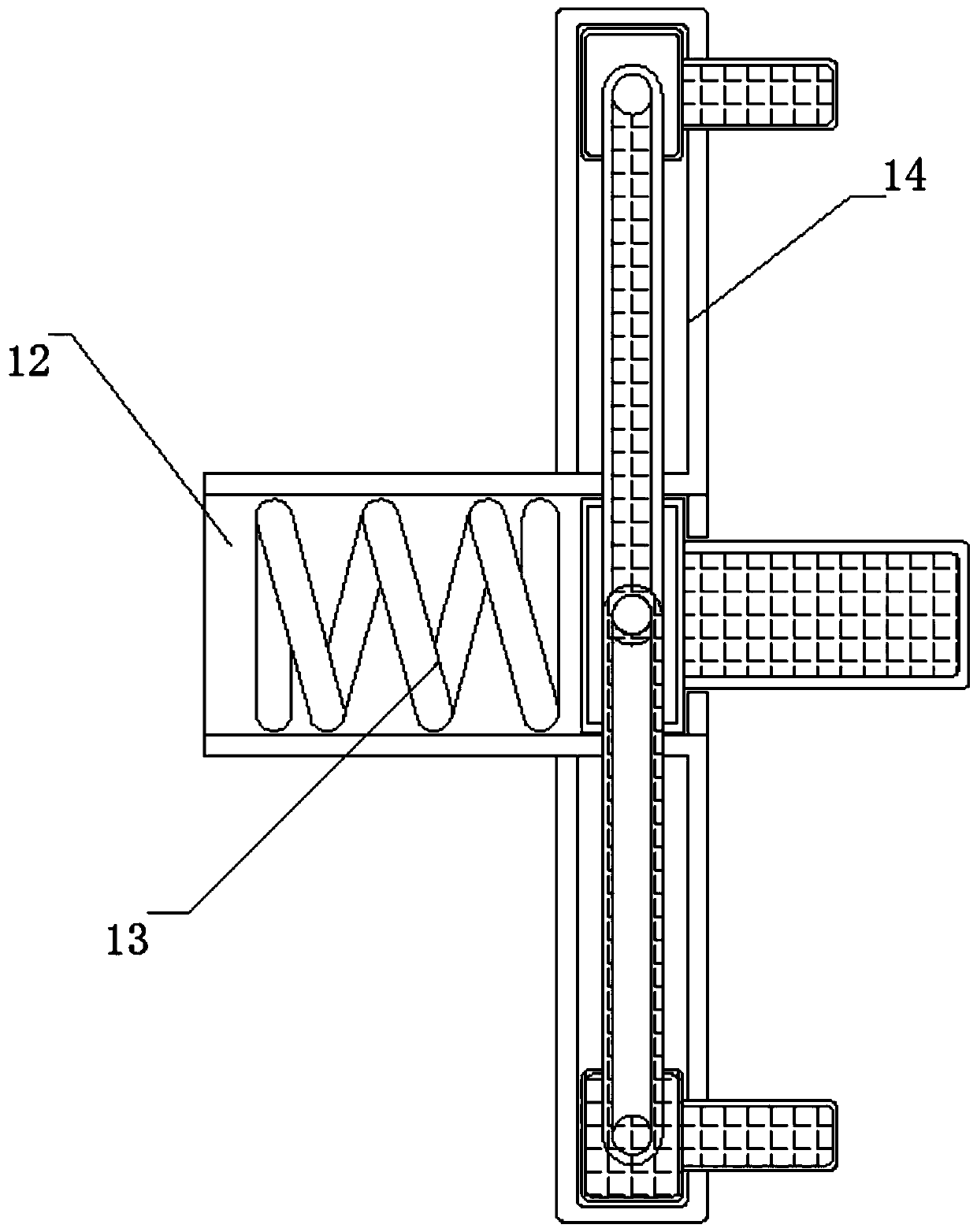

The invention relates to an oven with a liftable baking tray. The oven comprises an inner container, movable side supports are arranged on the left inner side surface and the right inner side surface of the inner container respectively, a driving device, a synchronous transmission mechanism and lifting mechanisms corresponding to the movable side supports respectively are arranged on the outer side of the inner container, and the lifting mechanisms are in linkage with the driving device through the synchronous transmission mechanism. The lifting mechanisms are connected with the corresponding movable side supports through connecting structures respectively, vertical holes allowing the corresponding connecting structures to move up and down are formed in the left side wall and the right side wall of the inner container respectively, and protective covers cover the positions, corresponding to the vertical holes, of the left outer side surface and the right outer side surface of the inner container respectively. The vertical holes are sealed through the protective covers so that the inner container can be sealed at the vertical holes, heat in the inner container can be prevented from leaking out through the vertical holes in the baking process, the baking effect is guaranteed, meanwhile, oil dirt in the inner container can be prevented from leaking out through the vertical holes in the baking process, and the use experience of a user is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Furniture material taking device capable of quickly controlling baking temperature and automatically turning over for antique finish

ActiveCN111590705AImprove processing efficiencyProtect woodWood treatment detailsThermal wood treatmentWater storage tankManufacturing engineering

The invention relates to the technical field of furniture taking and processing, and discloses a furniture material taking device capable of rapidly controlling the baking temperature and automatically turning over for antique finish. The device comprises a processing machine, the bottom in the processing machine is movably connected with a water storage tank, a water inlet pipe is movably connected into the water storage tank, a temperature control rail is movably connected to the upper portion of the water storage tank, an atomization rail is movably connected to the upper portion of the water storage tank, a fixed rail is movably connected to the right side of the water storage tank, a control valve is movably connected to the right side of the fixed rail, and a gas pipe is movably connected to the right side of the interior of the processing machine. A rotating plate is driven to rotate, and after a power rod is located at the position of a through hole formed in a sliding rail power rail, the power rod is reset and reciprocates under the elastic force effect of a power spring, so that the effect of uniformly baking the surface of the furniture raw material is achieved, the effect of rapidly baking the surface of the furniture raw material for antique finish is achieved, and the machining efficiency is improved.

Owner:HEBEI JIRONG FURNITURE

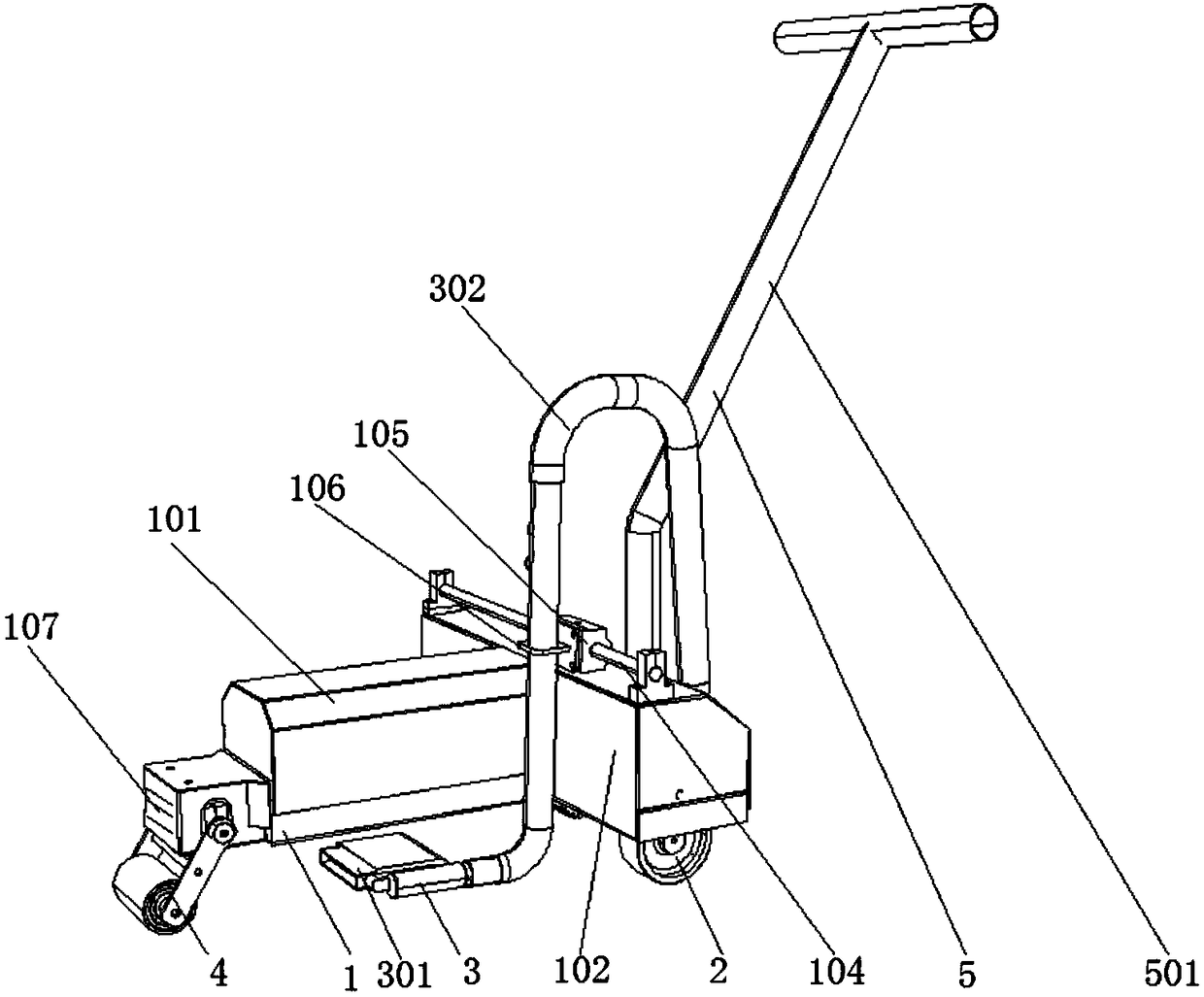

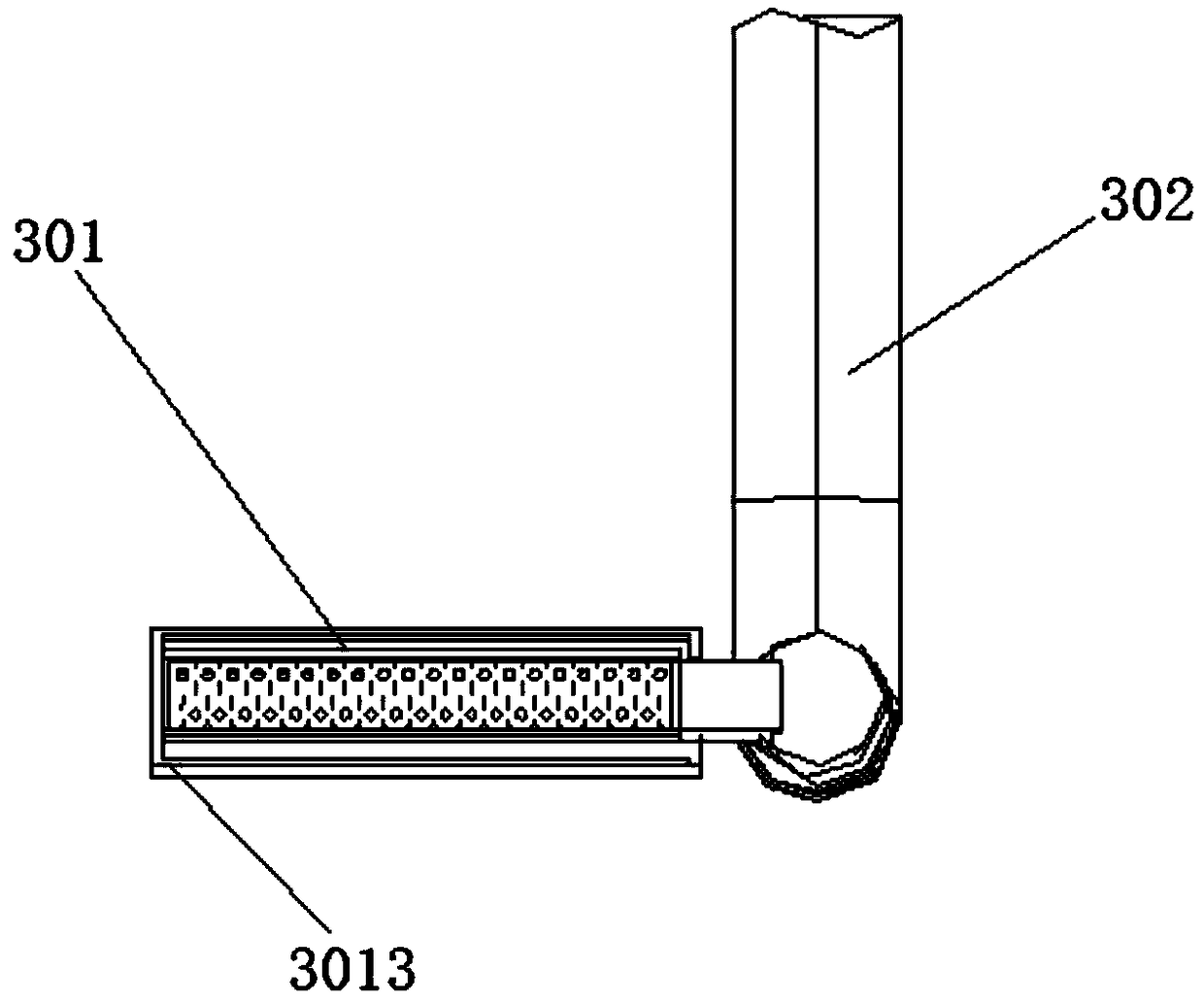

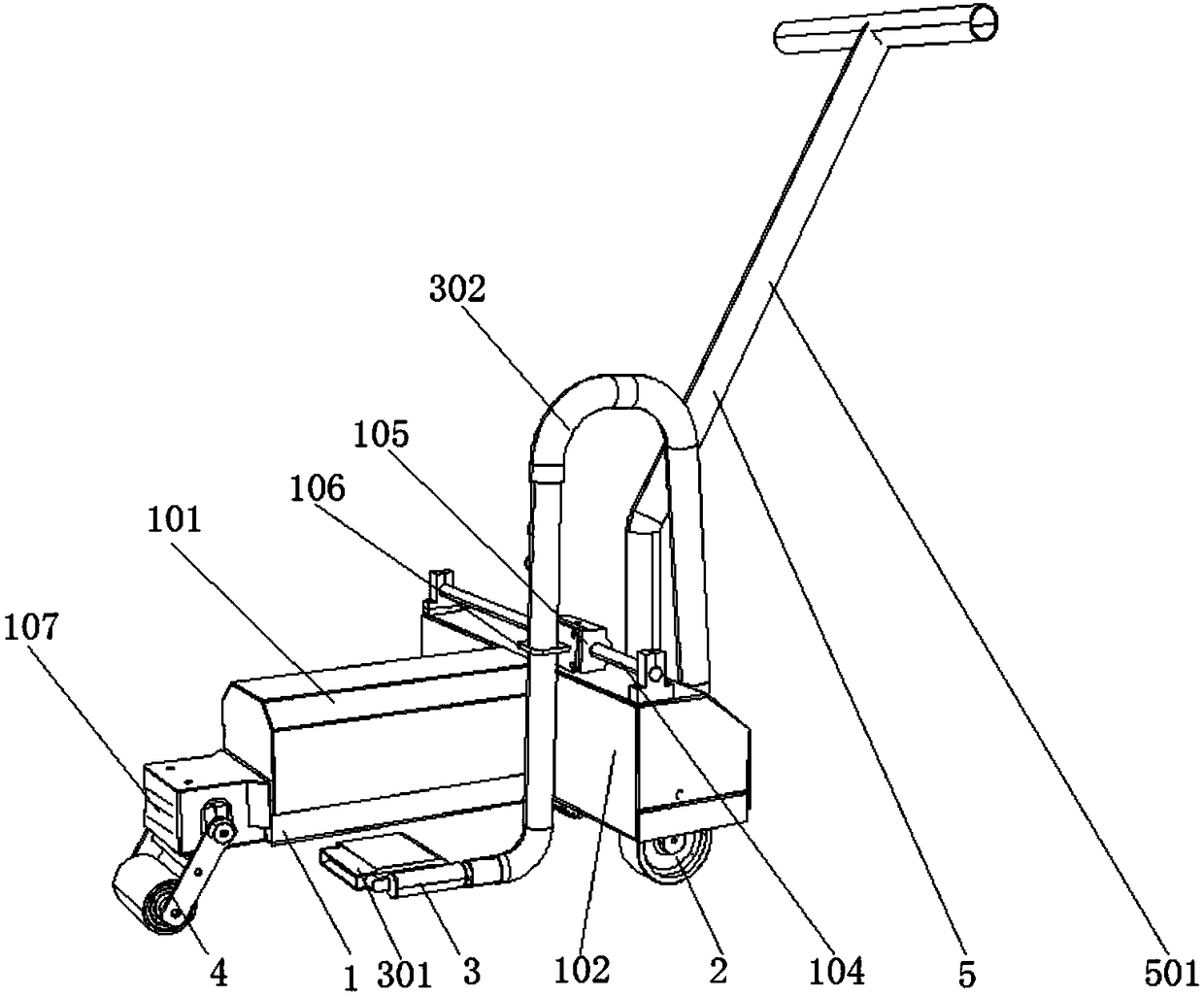

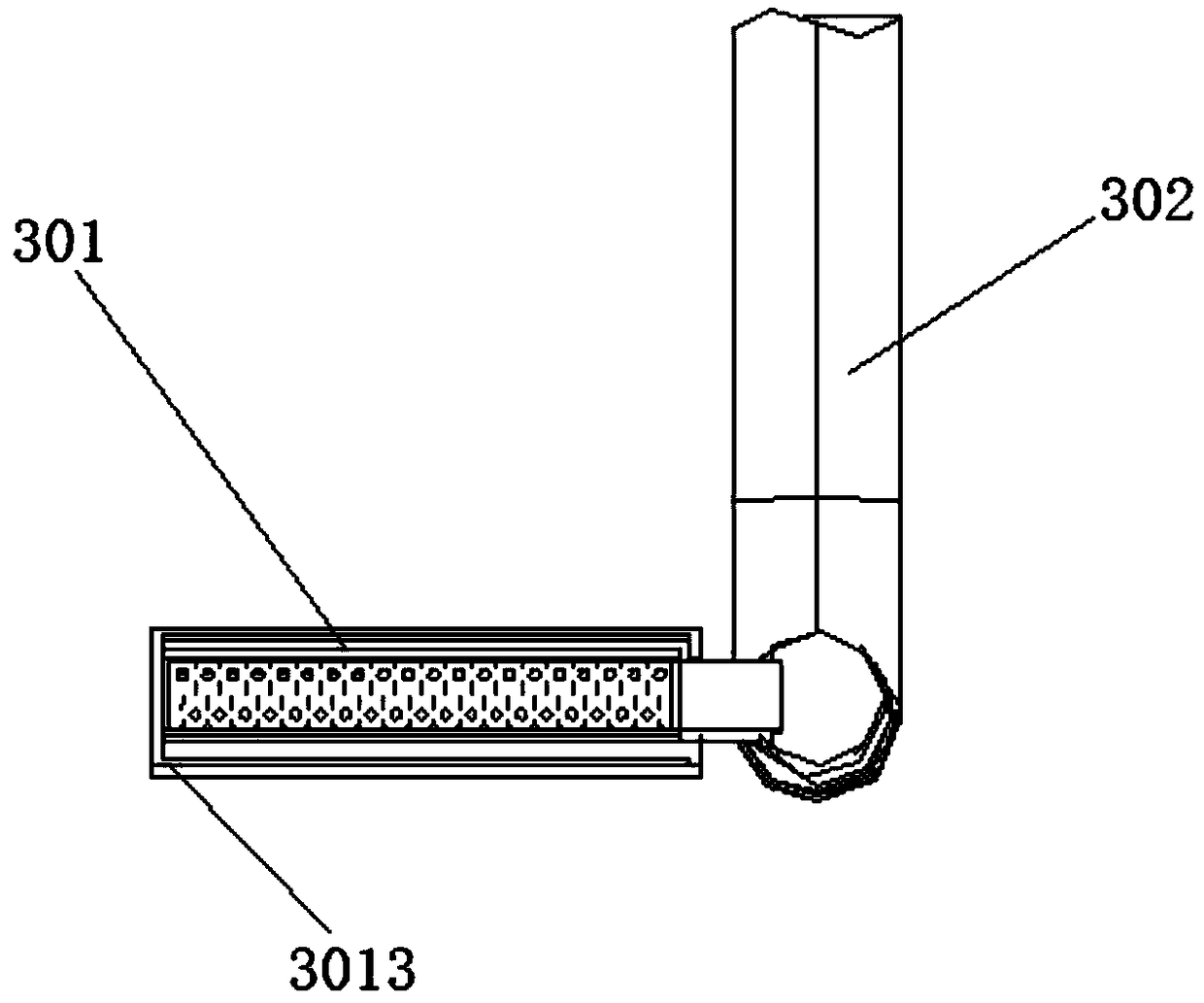

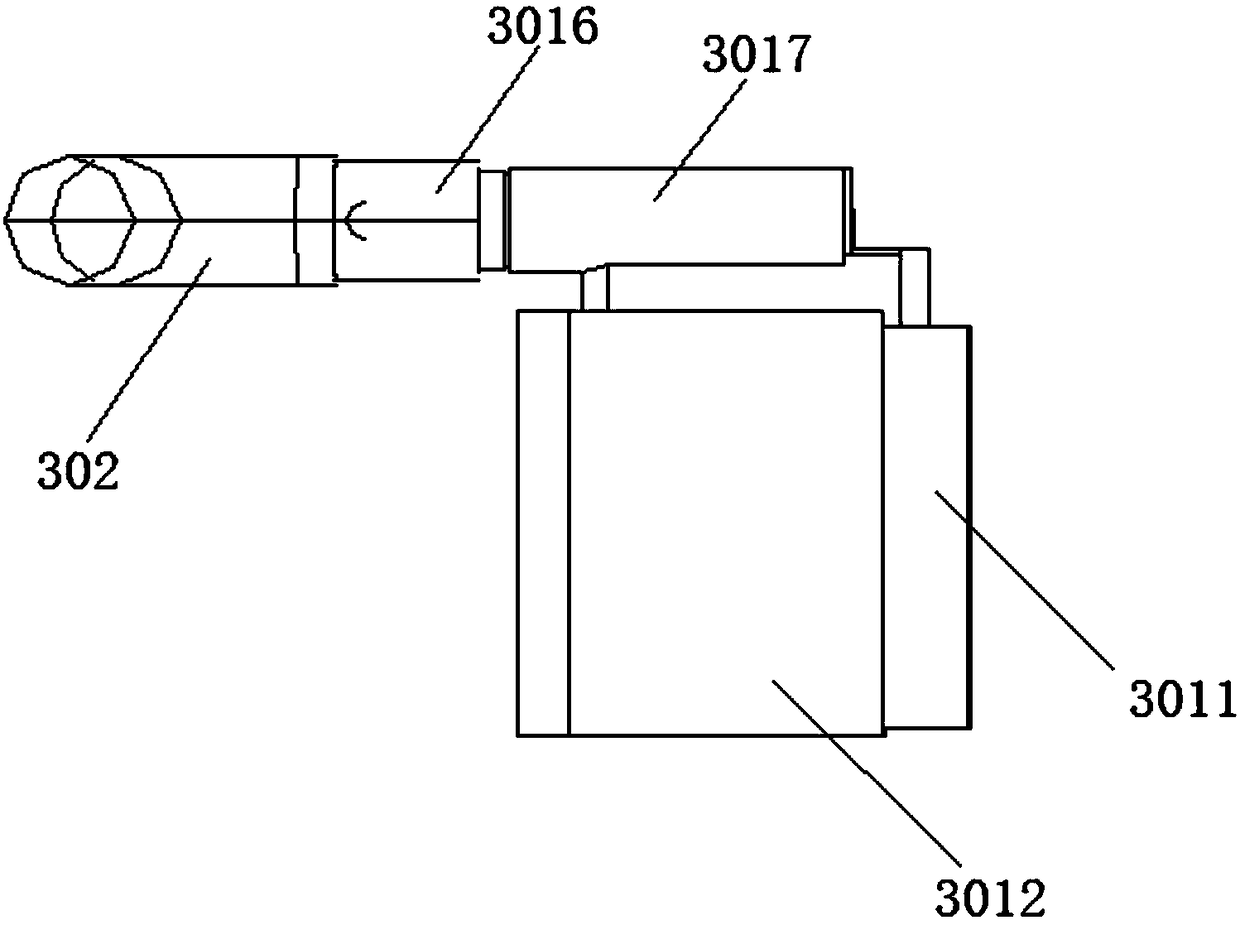

Hot-molten coiled material overlap edge welding machine with explosion-proof function

The invention provides a hot-molten coiled material overlap edge welding machine with an explosion-proof function. The hot-molten coiled material overlap edge welding machine comprises a frame, a power supply unit, a combustor and an induced draft fan, wherein a driving wheel is arranged at one end of the bottom of the frame, and a compaction roller is arranged at the other end; the power supply unit is arranged on the frame; a thermal insulation channel is formed between the power supply unit and the frame; the combustor comprises a combustion head, and a mixing pipe connected with the combustion head; the combustion head is arranged below the frame, and is positioned between the driving wheel and the compaction roller; the induced draft fan is arranged on the frame; an air outlet of theinduced draft fan is connected to the mixing pipe through a connecting pipe; and an air sucking port of the induced draft fan is towards the thermal insulation channel. The hot-molten coiled materialoverlap edge welding machine can improve the effect of a waterproof coiled material overlap edge welding machine, and meanwhile, achieves the explosion-proof function.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

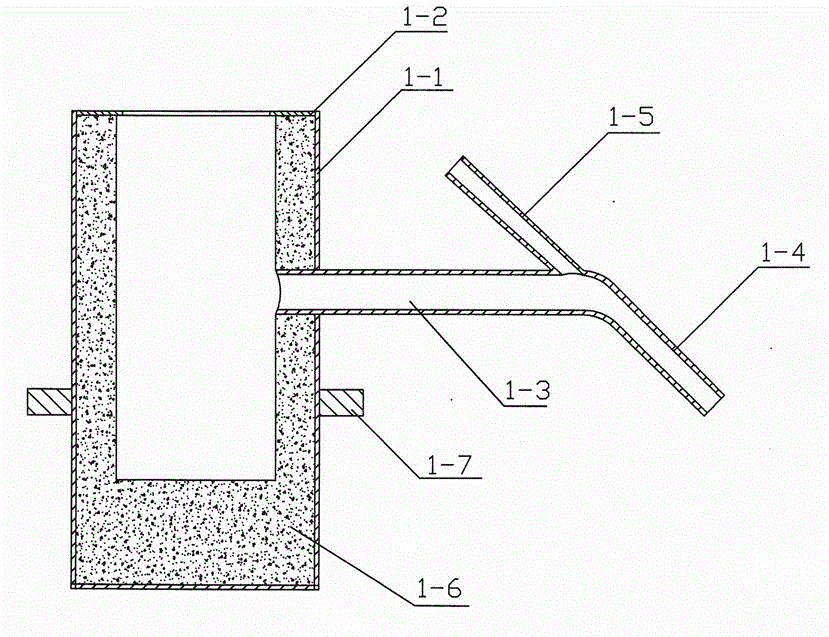

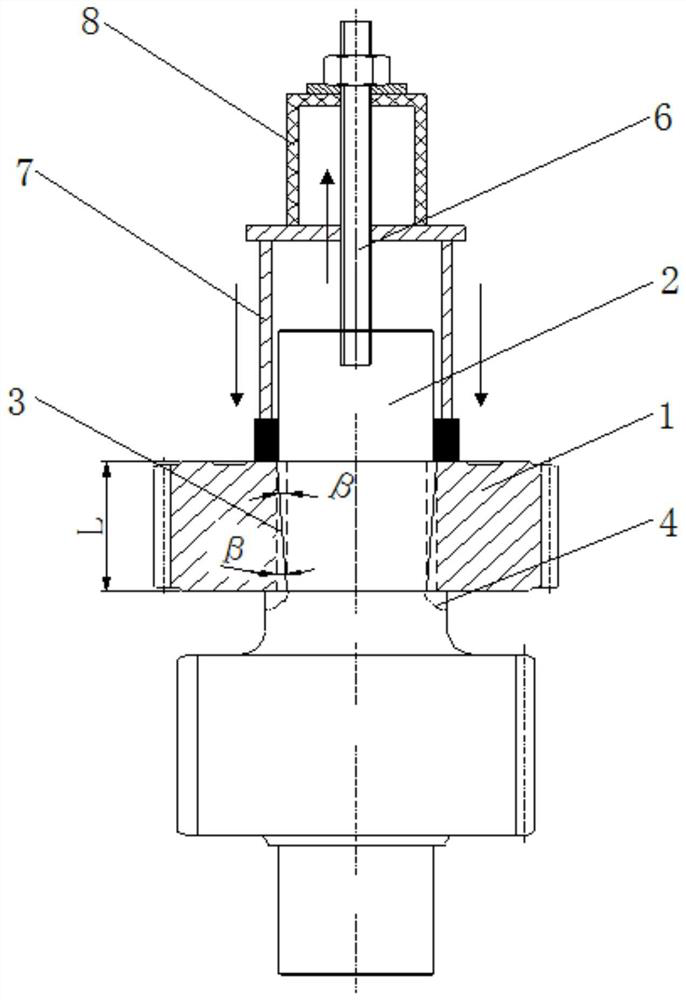

Baking device and method for integral water gap of continuous casting tundish

The invention discloses a baking device and method for an integral water gap of a continuous casting tundish. The baking device comprises a cylindrical baking barrel, wherein the inner wall and the bottom of the baking barrel are respectively provided with a refractory material layer, two symmetrical supports are welded on the outer wall of the baking barrel, an air duct is arranged on the barrel wall of the baking barrel, one end of the air duct is welded on the outer wall of the baking barrel, an exhaust pipe joint and a blowing pipe joint are welded at the other end of the air duct, and a cover plate is further welded at the opening end of the baking barrel. The baking method comprises the steps of: during baking, inserting the integral water gap into the baking device, tightly binding up the outer wall of the integral water gap and a combination part at the upper port of the baking device with asbestos cloth, then igniting to bake the tundish for 1.5-2 hours, opening a compressed air valve when the temperature inside the tundish reaches 700-800 DEG C, blowing compressed air into the blowing pipe joint, introducing smoke in the tundish to be exhausted from the exhaust pipe joint, and baking the integral water gap of the tundish.

Owner:HENGYANG VALIN STEEL TUBE

Welding machine for overlap edge of hot-melt coiled material

The invention provides a welding machine for the overlap edge of a hot-melt coiled material. The welding machine for the overlap edge of the hot-melt coiled material comprises a vehicle frame, a combustor and an adjustment unit, wherein a drive wheel is arranged at one end of the bottom of the vehicle frame, and a compaction roll is arranged at the other end of the bottom of the vehicle frame; andthe adjustment unit comprises a transversal slide way, a slide block and a clamping buckle, the transversal slide way is arranged at the top of the vehicle frame; the slide block is arranged on the transversal slide way; the clamping buckle is arranged on the slide block; and a mixing pipe is capable of being clamped to the slide block through the clamping buckle. The welding machine for the overlap edge of the hot-melt coiled material is capable of improving the welding effect for the overlap edge of the coiled material, realizing mechanical welding for the overlap edge of the coiled material, and guaranteeing uniform roasting for the overlap edge of the coiled material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

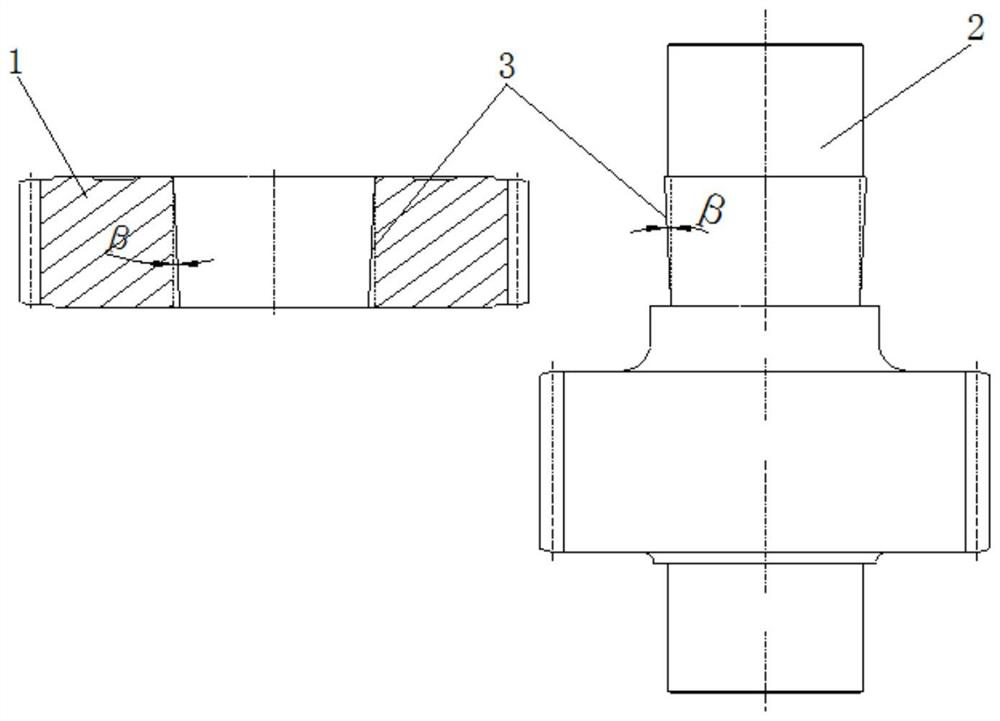

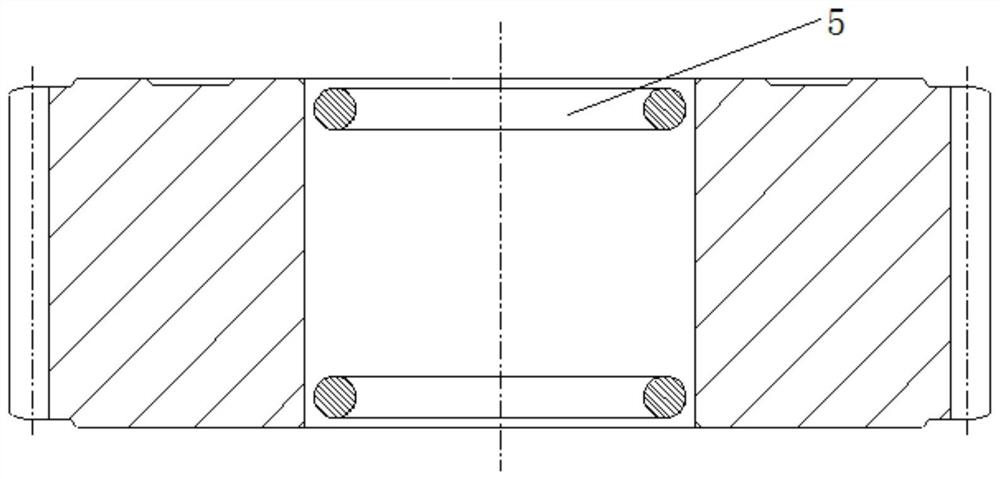

Drying structure, drying tool and drying method

PendingCN113305539AAchieve fitHardness does not decreaseMetal working apparatusInterference fitEngineering

The invention belongs to the technical field of drying, and particularly relates to a drying structure, a drying tool and a drying method. The drying structure comprises a containing body and a contained body which are in interference fit, wherein a taper directional sliding structure is arranged between the containing body and the contained body, a gas escape structure communicating with an interlayer between the containing body and the contained body is arranged on a shaft shoulder of the contained body, the taper directional sliding structure comprises inclined conical surfaces which are arranged on an inner hole of the containing body and the outer circle of the contained body correspondingly and are matched with each other, the inclined conical surfaces are arranged in an inclined mode from top to bottom, the gas escape structure comprises a plurality of exhaust grooves which are uniformly distributed in the circumferential direction of the shaft shoulder of the contained body, one ends of the exhaust grooves are located on the inner side of the minimum diameter end of the inner hole of the containing body, and the other ends of the exhaust grooves communicate with the outside of the shaft shoulder of the contained body. According to the drying structure, the drying tool and the drying method, through the design of the taper directional sliding structure, the gas escape structure, a double-side induction coil and a three-point uniform pressure structure, the drying gap can be less than or equal to 0.03mm, and even complete fit without gaps can be realized.

Owner:CHANGZHOU TIANSHAN HEAVY IND MACHINERY

An electric coal mixed flue-cured tobacco heating device

The invention relates to the technical field of tobacco processing, and discloses a method and device for heating electric coal mixed flue-cured tobacco. The heating device includes a tobacco flue-curing room and a heating room, the interior of the heating room is provided with a coal-fired furnace cavity and an air duct connected to the tobacco-cure room at the top of the coal-fired furnace cavity; the bottom of the cavity wall of the coal-fired furnace cavity There is a coal inlet, and several groups of electric heaters connected in parallel on the same horizontal line are installed at the waist of the coal-fired furnace cavity. The heating device has the characteristics of easy power adjustment by means of electric heating, and can stably heat the air through electric heating or electric coal mixed heating, and precisely control the temperature rise or temperature stabilization process of the flue-curing room, thereby ensuring the tobacco curing effect As well as the quality of finished cigarettes, it can reduce the generation of toxic gases, avoid deteriorating the health of smokers, and reduce energy costs and labor costs to meet the development needs of the tobacco processing industry for low-carbon environmental protection, labor and cost reduction.

Owner:重庆和创简一科技有限公司 +1

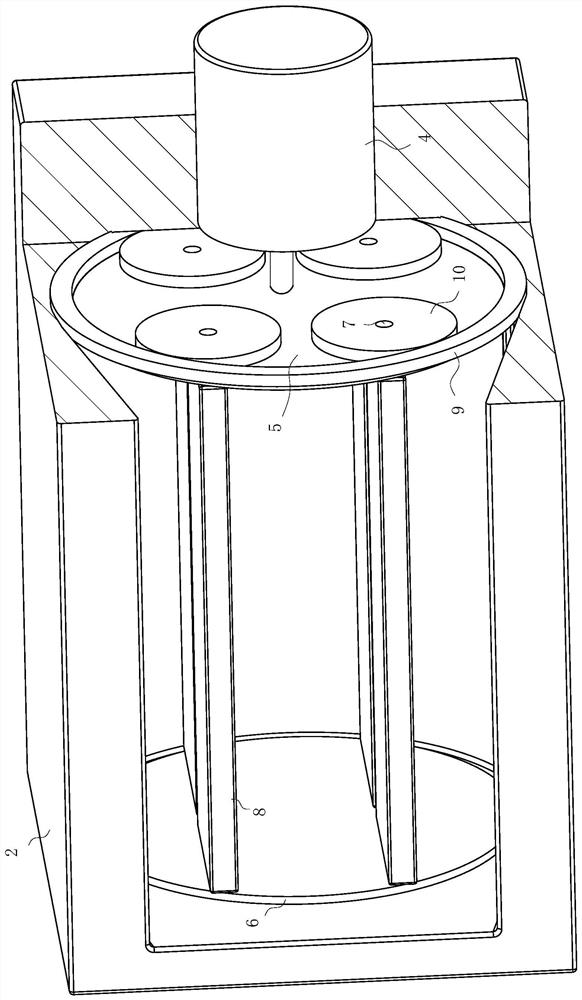

An air oven for preparing food

The invention provides an air baking oven for making food. Wind flow is driven through a fan to flow to a heat source piece and form heat source wind flow, and a guiding cylinder, a wind guiding pipe, a baking cavity and an air inlet form a heat source wind flow path; asymmetrical guiding grooves which enable the heat source wind flow to be spirally guided into the wind guiding pipe inside the guiding cylinder are formed in the heat source piece, heat of the heat source wind flow is ensured, food can be rapidly and uniformly heated, and the food baking effect is ensured; on the basis of the cold wind circulation path structure, cold air enters the cold wind circulation structure, the cooling effect is achieved, and the product using quality is ensured; on the basis of a rotary knob and a temperature controller for adjusting and controlling temperature, operation is easy and flexible, and the market requirement is met.

Owner:FOSHAN SHUNDE HUIERJIA HOUSEHOLD ELECTRICAL

Precise roasting biomass self-control dense barn

InactiveCN103019278BGuaranteed baking effectMonitor the environment in real timeSimultaneous control of multiple variablesCold airAutomatic control

The invention discloses a self-control bulk curing barn capable of accurately baking biomass, which comprises a heating chamber and a baking chamber, wherein an upper ventilation duct and a lower ventilation duct are correspondingly arranged at the upper end and the lower end of a wall between the heating chamber and the baking chamber; the heating chamber is communicated with the baking chamber through the upper ventilation duct and the lower ventilation duct; a heating furnace is arranged in the heating chamber; a fan is arranged on the upper part of the heating furnace; the fan is connected to the upper ventilation duct through an air outlet of the fan; a cold air valve for controlling an airflow to enter is arranged on the side wall of the heating chamber; a moisture discharging channel with a ventilation hole is arranged at the bottom of the baking chamber; a moisture discharging window is arranged at the tail end of the moisture discharging channel outside the baking chamber. The self-control bulk curing barn is characterized by further comprising a controller, an automatic air inlet control system, an automatic feeding device, an automatic control humidifying system, an automatic control moisture discharging system and an automatic tobacco baking state monitoring device. The self-control bulk curing barn with the accurate baking biomass disclosed by the invention is capable of automatically and precisely controlling the internal environment of the curing barn and has the advantages of good baking effect, high energy utilization rate and the like, and is convenient for operation.

Owner:SHANDONG LINYI TOBACCO

Domestic energy-saving electric oven

The invention discloses a household energy-saving electric oven, which comprises a box body. The box body is a layered structure including an outer shell, a middle partition and an inner container arranged from the outside to the inside. A box door is hinged on the front side of the box body. There are electric heating elements inside, and the electric heating elements include four far-infrared tubes on the left and right sides, a quartz heating tube and an ultraviolet heating tube on the rear side. The temperature control device includes a temperature sensor installed inside the inner tank on the left side and a controller installed on the outer wall on the right side of the casing. The household energy-saving electric oven of the present invention has fast heating and heating up, improves baking efficiency, and can realize high-temperature sterilization. The role of the oven is to ensure the baking effect, and it can be remotely controlled by mobile devices. It is easy to use, and the energy-saving device is used to recycle the heat energy discharged from the oven, which reduces energy consumption and greatly saves electric energy. In addition, it is easy to move and Fixed, convenient and practical.

Owner:湖南鸣腾智能科技有限公司

A method for constructing a baking curve of a lithium-ion battery pole piece and a baking method thereof

ActiveCN111486664BImprove baking efficiencyGuaranteed performanceDrawing from basic elementsDrying solid materials without heatElectrical batteryProcess engineering

The invention belongs to the technical field of lithium-ion battery processing and manufacturing, and in particular relates to a method for constructing a baking curve based on different materials for lithium-ion battery pole pieces, and further discloses a baking method for lithium-ion battery pole pieces. The baking curve construction method and baking method of the lithium ion battery pole piece of the present invention, first obtain the baking pressure change rate curves of different material systems through an experiment and data analysis, and characterize the removal process during the baking process through the pressure change rate. Water rate, select the appropriate pressure change rate as the baking end condition, and automatically adjust the vacuum baking time correspondingly, which can quickly determine the baking conditions of the pole pieces of the new material system, and can be used for one-time effective baking of pole pieces with different initial water content conditions Baking, effectively improve the baking efficiency.

Owner:华鼎国联四川动力电池有限公司

Baking device with guaranteed functions

InactiveCN109875411AMaximize UtilizationMaximize performanceRoasting apparatusRoasters/grillsSurface mountingEngineering

The invention discloses a baking device with guaranteed functions. The baking device comprises a core appearance, a rotating device, a rotating column and an LCD screen device, wherein the rotating device is arranged in the core appearance, and a rotating device fixing frame is arranged on the right side of the rotating device; a waste storage position is arranged on the left side in the core appearance, and an outer end cover is arranged on the left side of the waste storage position; the rotating column is arranged above the rotating device, and a waste oil recycling pipe is arranged on theleft side of the rotating column; the right side of the rotating column is provided with a hook, the right side of the rotating column is provided with a heating sheet, and the right side of the heating sheet is provided with a slow-down temperature reducing device; an upper end cover is arranged above the rotating column, a handheld part is installed on the upper portion of the upper end cover, and a control panel is arranged on the surface of the core appearance. According to the baking device, cooling equipment is added, so that the heat energy consumption and the instrument external consumption inside the equipment are reduced, the energy utilization rate and the performance maximization are improved, and the loss is reduced.

Owner:吴雨桐

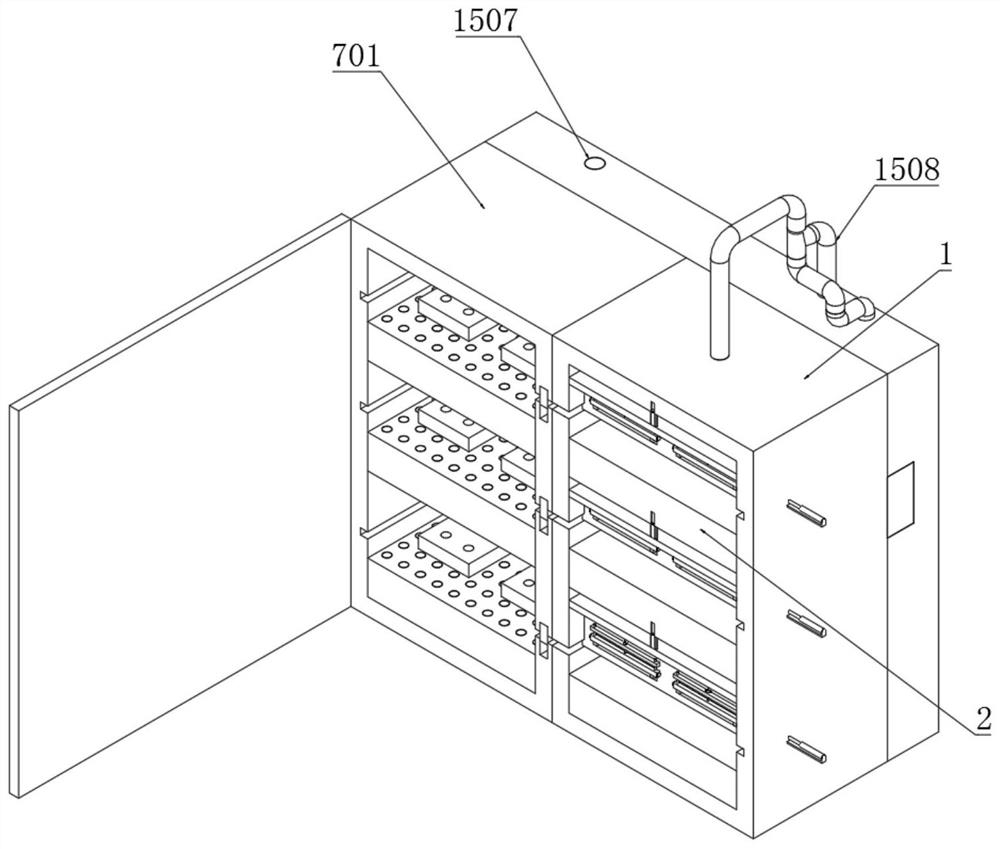

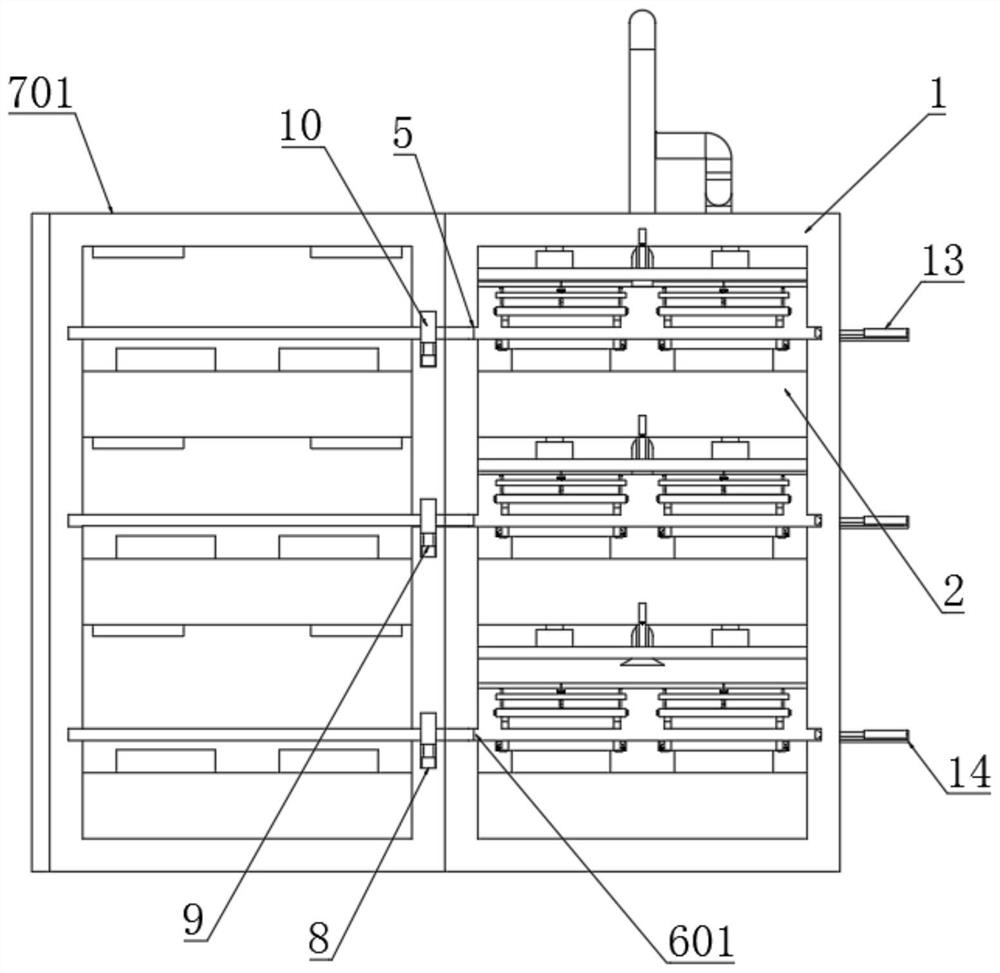

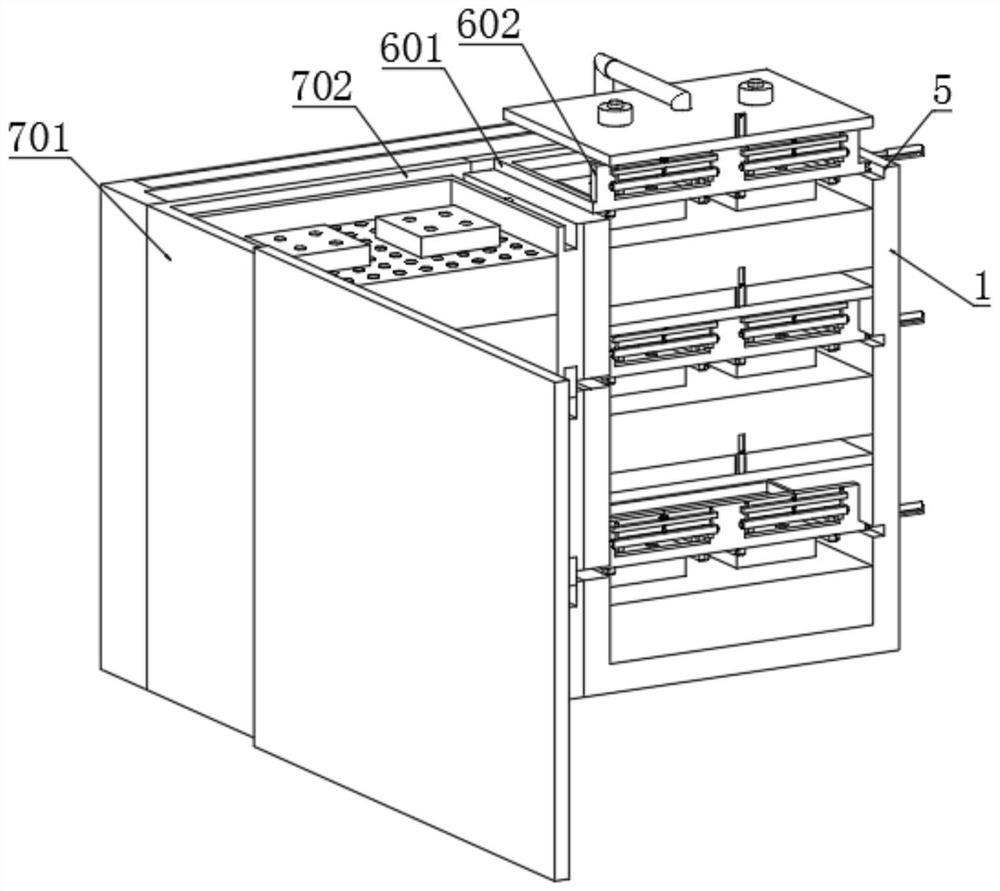

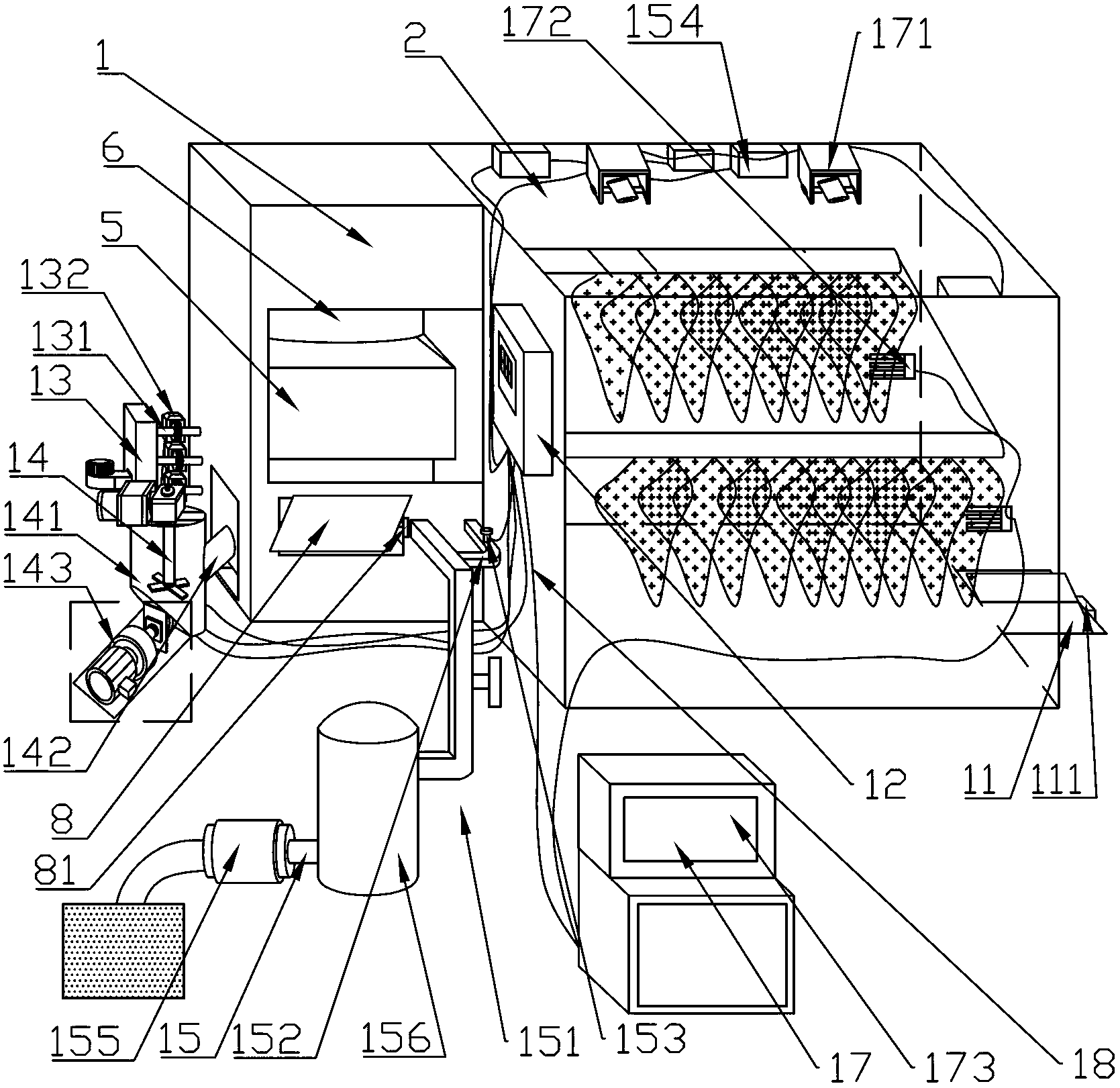

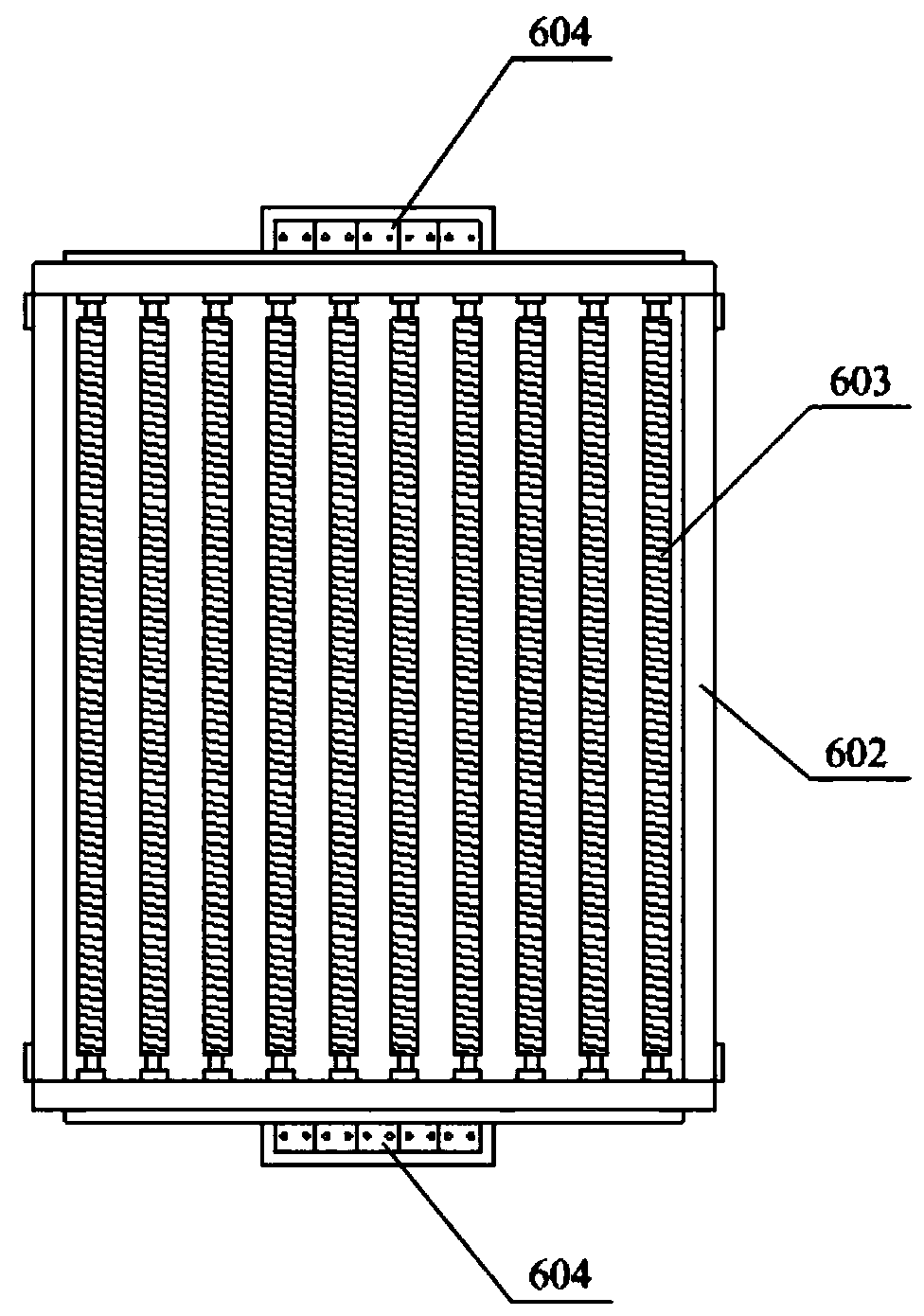

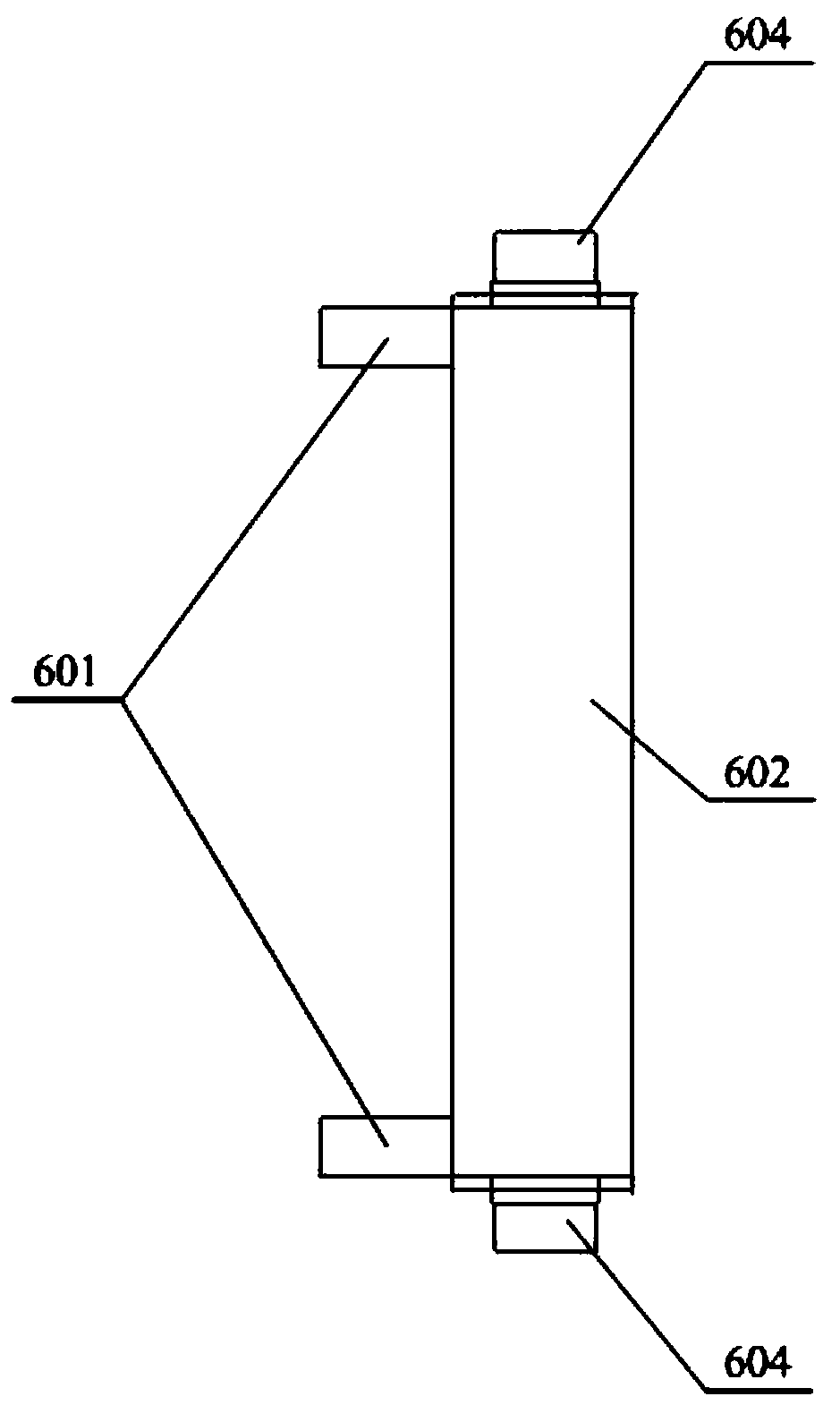

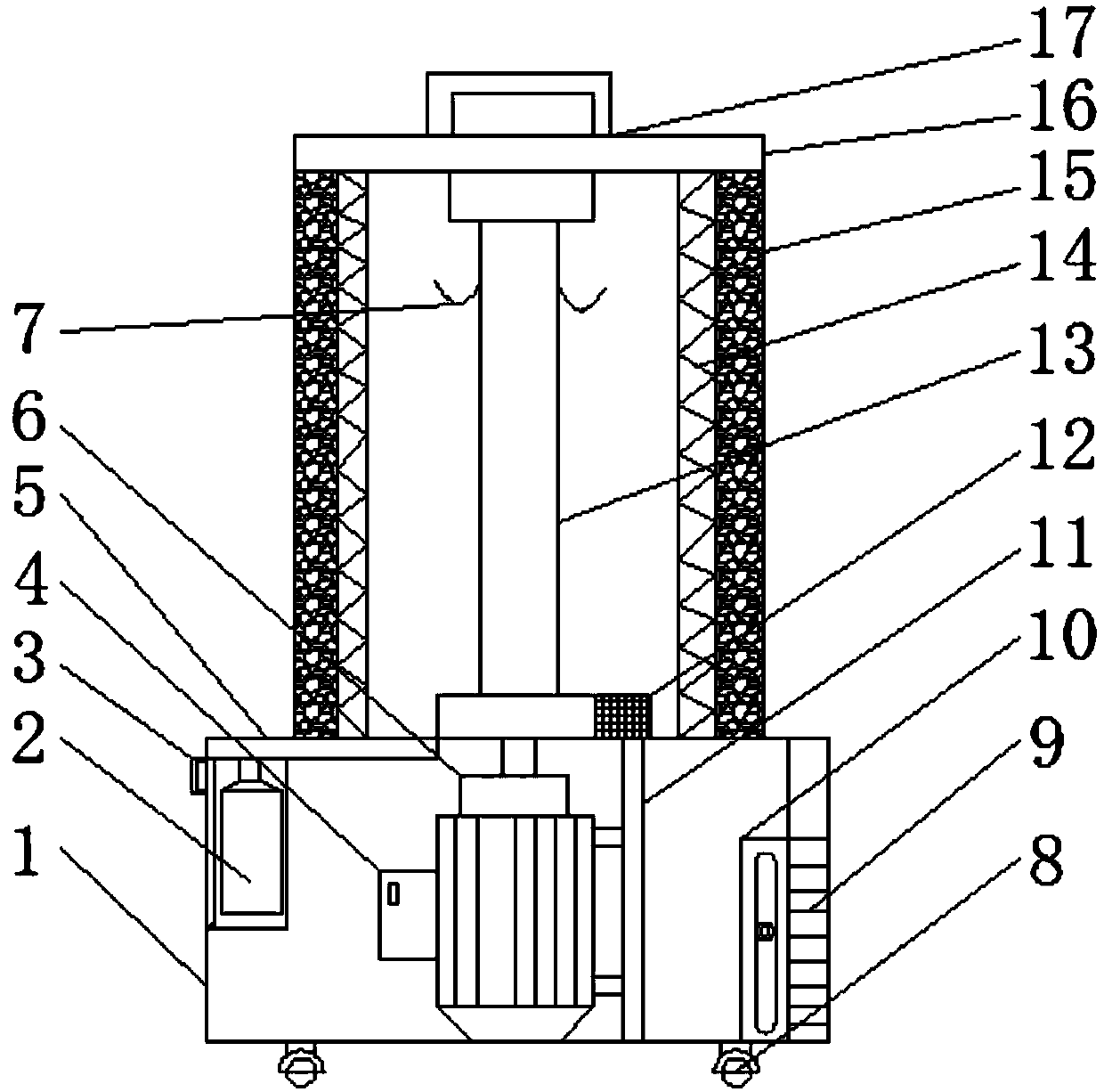

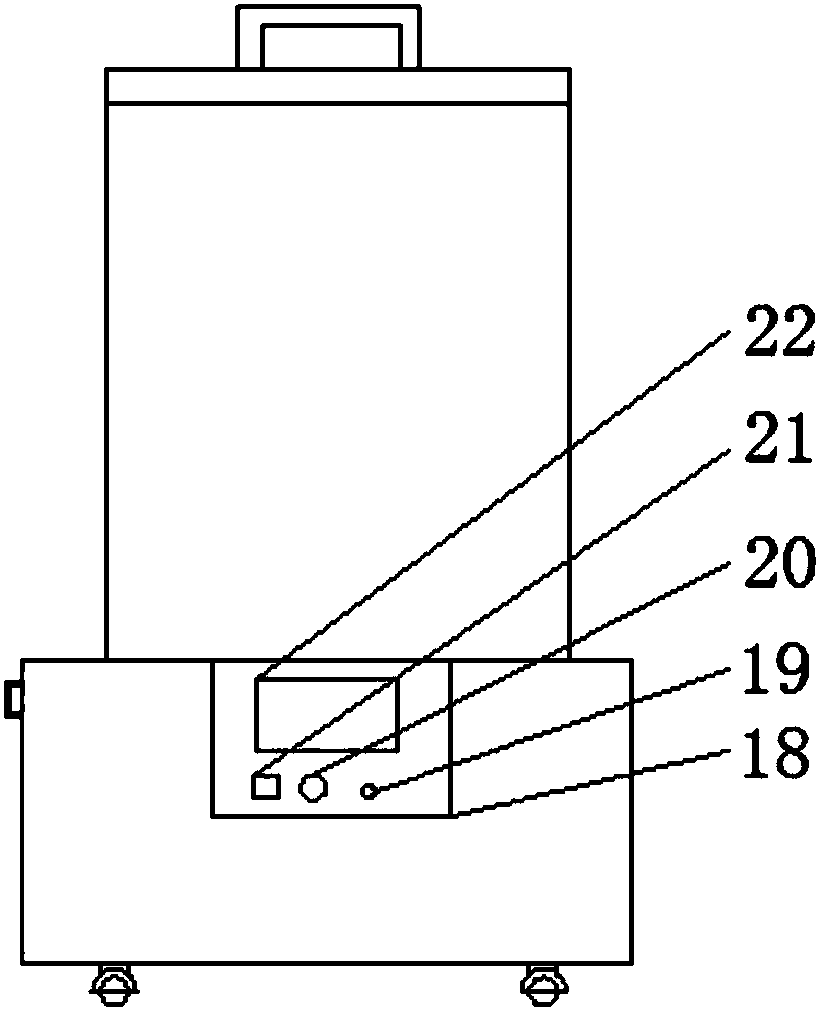

Lithium ion battery pole piece baking device and baking method

PendingCN113418368AAvoid direct thermal convectionReduce lossDrying gas arrangementsDrying chambers/containersEngineeringLithium-ion battery

The invention discloses a lithium ion battery pole piece baking device and baking method. The device comprises a box body and box doors and is characterized in that a convection type cavity is formed in the box body, and the box doors are arranged at the two ends of the convection type cavity; and a high-temperature baking area is arranged in the middle of the convection type cavity, medium-temperature baking areas are arranged at the two ends of the high-temperature baking area, and a low-temperature baking area is arranged at the other end of a transition baking area. The device and the method have the characteristics of low energy consumption cost, good baking effect, short baking time and high equipment utilization rate.

Owner:SHENZHEN HONCELL ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com