Lithium ion battery pole piece baking device and baking method

A lithium-ion battery and baking device technology, which is applied in the direction of heating devices, drying, drying machines, etc., can solve the problems of prolonging the time occupied by the pole piece in the oven, high energy consumption costs, and occupying a large workshop area. Achieve the effect of improving heat utilization rate, reducing baking time and high equipment utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

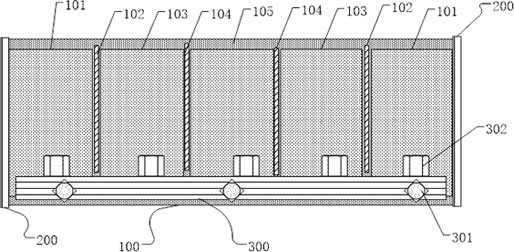

[0030] Such as figure 1 As shown, the present invention discloses a lithium-ion battery pole piece baking device, which includes a box body 100 and a box door 200. The box body 100 is provided with a convection cavity, and both ends of the convection cavity are provided with a box door. 200; a high-temperature baking zone 105 is set in the middle of the convection cavity, a medium-temperature baking zone 103 is set at both ends of the high-temperature baking zone 105, and a low-temperature baking zone 101 is set at the other end of the transitional baking zone.

[0031] In this embodiment, the bottom of the box is provided with a material moving track 300 that runs through the high-temperature baking zone 105, the medium-temperature baking zone 103, and the low-temperature baking zone 101, and pole piece trays corresponding to different temperature zones are movable on the moving track 300 302. Generally speaking, the moving track is built in the bottom of the box, and the mo...

Embodiment 2

[0038] Another aspect of the present invention is to protect the baking method of the lithium-ion battery pole pieces of the above-mentioned baking device, comprising the following steps:

[0039] S1. Initial baking: Load the lithium-ion battery pole pieces that need to be baked on the three pole piece trays, and then place the adjacent ones on the moving track respectively in the high-temperature baking area, medium-temperature baking area, and low-temperature baking area. position, close the doors at both ends, set the heating tube in the starting box to work and start the initial baking;

[0040] S2. The first shift baking: After the initial baking is completed, the three electrode trays move forward synchronously, and the electrode trays in the previous high-temperature baking area are moved to the opposite medium-temperature baking area. The electrode tray in the low-temperature baking area is moved to the high-temperature baking area, and the electrode tray in the original...

Embodiment 3

[0045] In the present invention, in order to ensure the full use of heat and reduce the loss of heat, the pole piece trays adjacent to each other are arranged on the moving track in gaps. The positions are corresponding. After the sequence-changing baking is completed, the door at the feed end, the first isolation plate, and the second isolation plate are all closed, and then the door at the output end is opened to take out the pole piece tray in the low-temperature baking area; then close the output end. The box door at the material end, open the first isolation plate and the second isolation plate, and move the pole piece tray in the box forward along the moving track to realize the temperature zone change; then close the first isolation plate and the second isolation plate, and open the feeding Put the new electrode tray in the low-temperature baking area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com