Patents

Literature

442results about How to "Improve the baking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

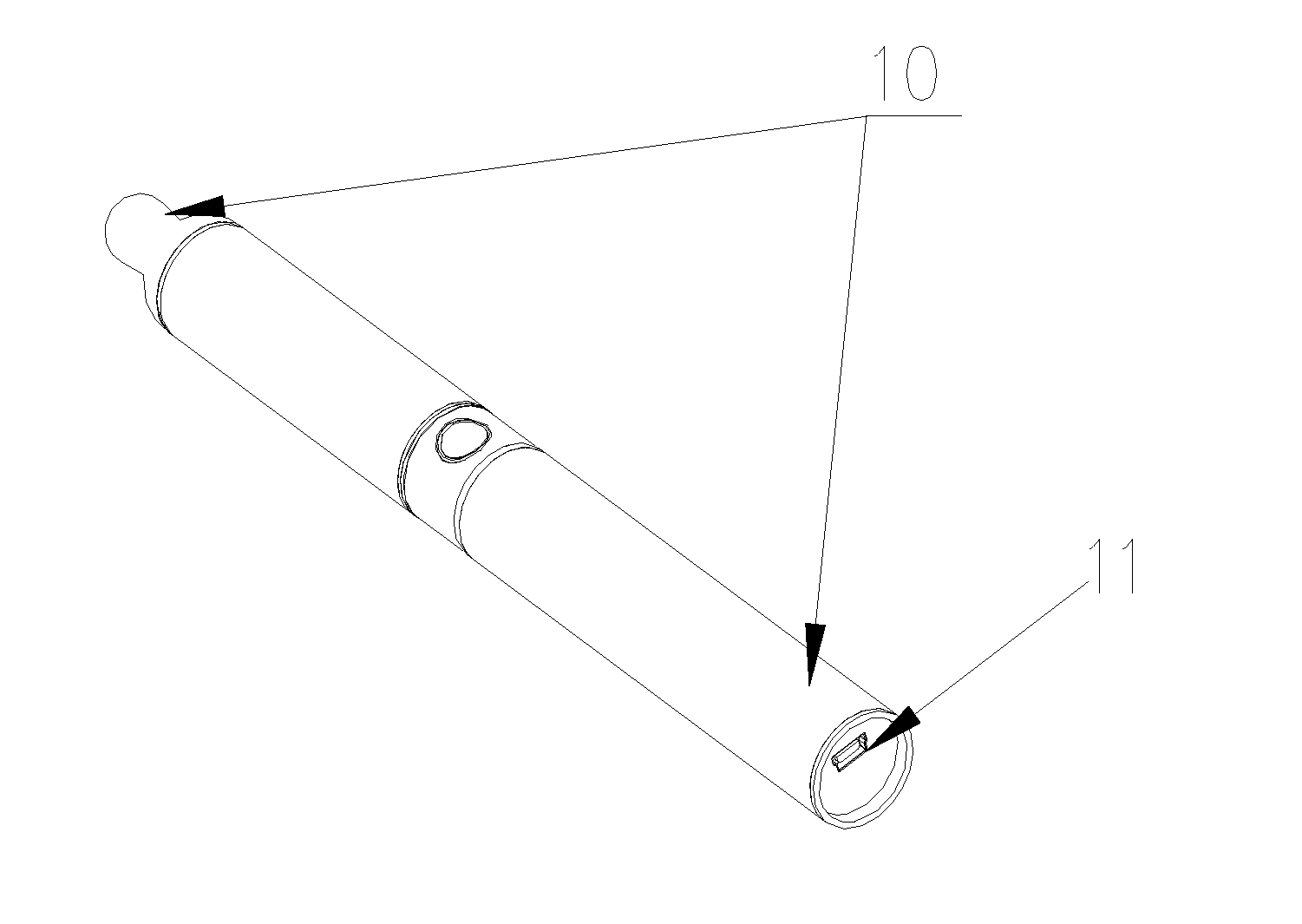

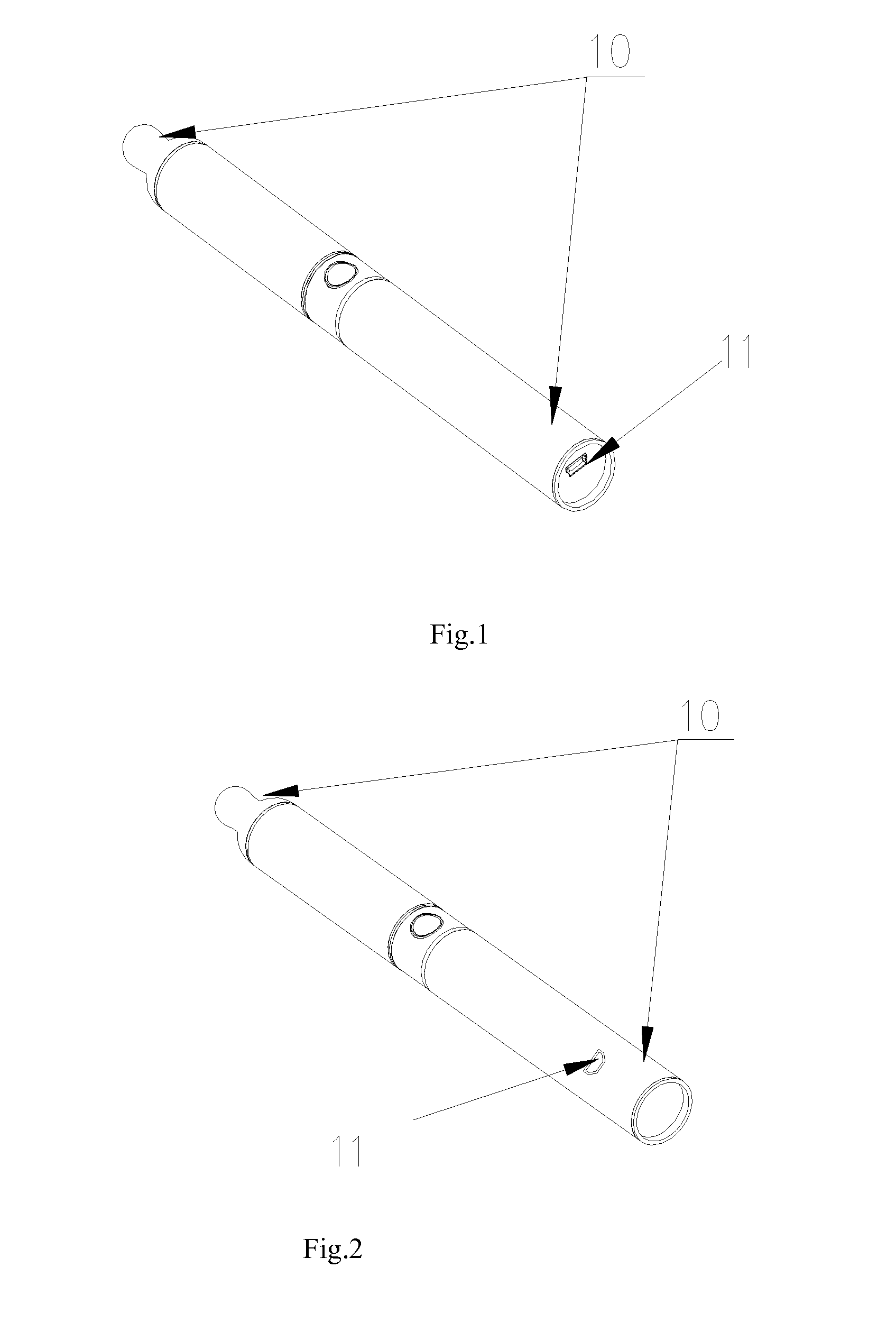

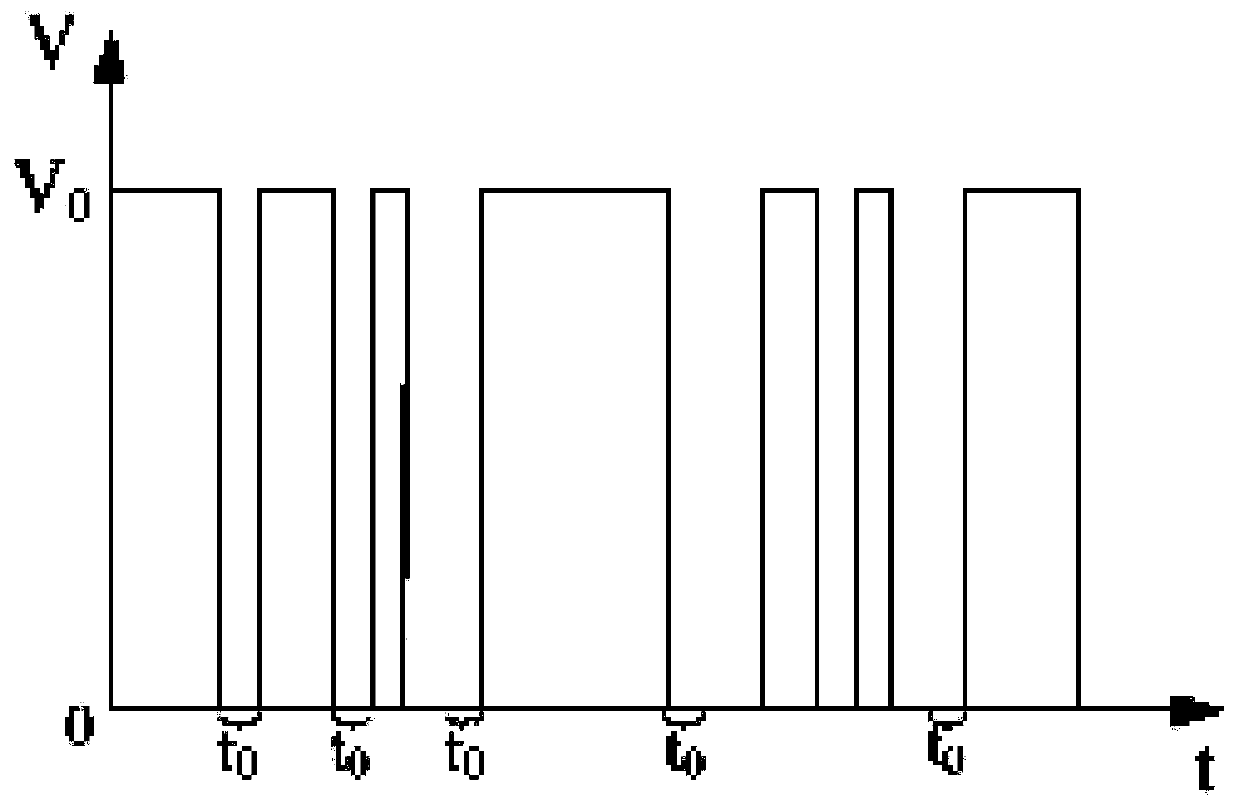

Electronic smoking device

InactiveUS20150189916A1Convenient operationConveniently chargeTobacco devicesMachines/enginesVoltage regulationElectrical battery

This invention discloses an electronic smoking device. The device comprises a shell containing a tobacco container. A heating circuit is configured to heat the tobacco container. At least one energy storage battery placed in the shell and a charging circuit configured to charge the energy storage battery, characterized in that, the electronic smoking device further comprises a general interface set on the shell and a voltage regulation circuit connected between the charging circuit and the energy storage battery. The charging circuit connected to the general interface. By implementing the invention, it can achieve both charging the device with normal voltage and outputting higher baking voltage. The device also can achieve both charging and baking simultaneously, and regulate the output power of baking.

Owner:WU CHANGMING +1

Hybrid enzymes

InactiveUS20060147581A1Less riskImprove the baking effectDough treatmentBacteriaHybrid enzymeBiochemistry

Owner:NOVOZYMES AS

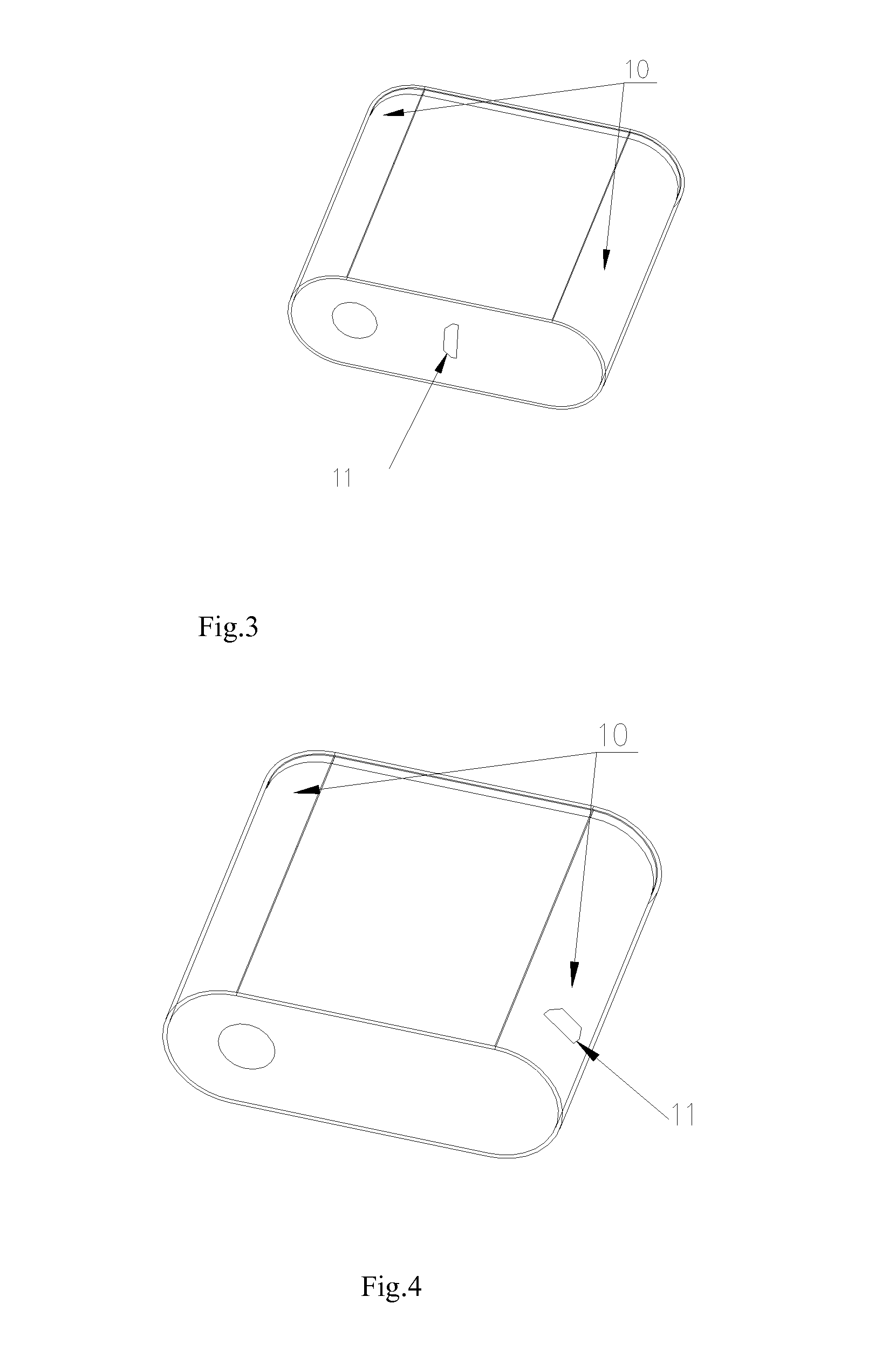

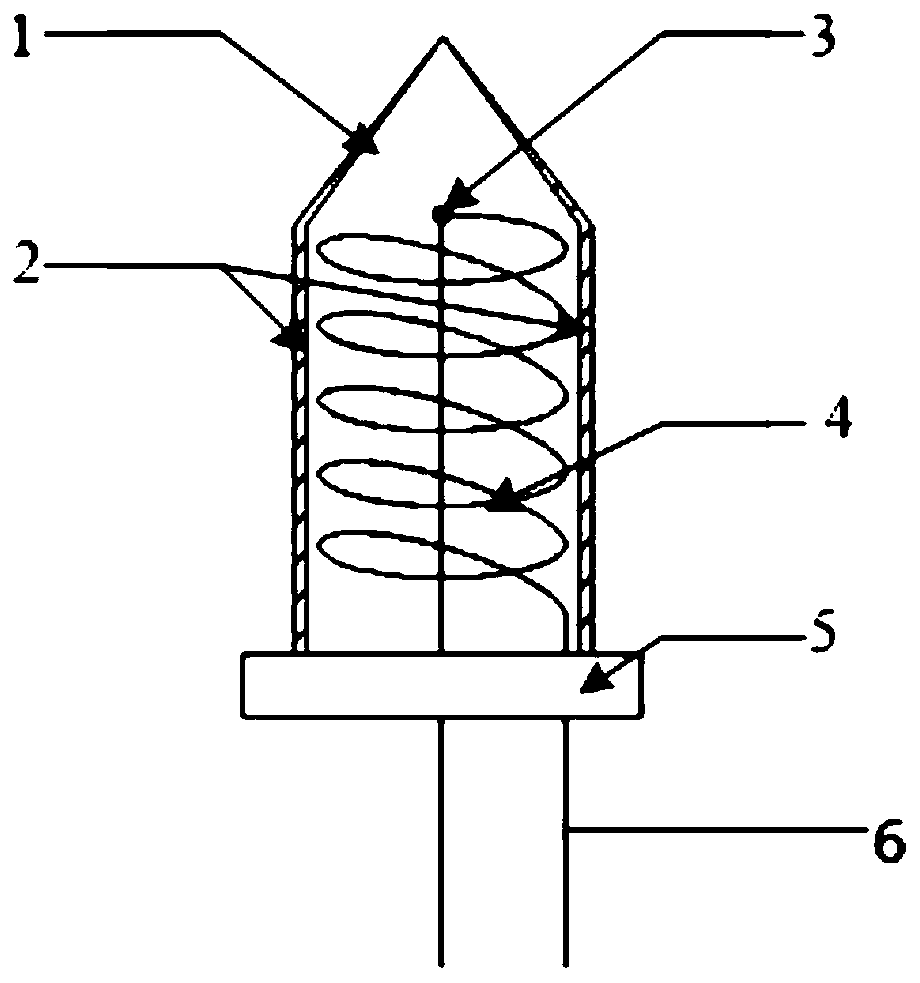

Composite temperature rising and controlling integrated heating element and temperature control method

PendingCN111150109ASimple manufacturing processImprove performanceSoldering apparatusHeating element materialsTemperature controlEngineering

The invention belongs to the technical field of novel smoking set heating elements, and particularly relates to a composite temperature rising and controlling integrated heating element and a temperature control method. A heating element (1) comprises a heating body (4) which is welded into a whole at a welding point (3) through two different conductive materials, and a temperature measuring element except the heating body (4) is not arranged on the heating element (1). The temperature rising and controlling integrated heating element is designed for the first time, the heating body is formedby welding two kinds of conductive materials, and when high voltage is applied, the two kinds of conductive materials serve as the heating body for heating; when voltage supply is stopped, the two conductive materials are used as thermocouple temperature measurement sensors to measure the temperature of the heating element. Compared with an existing heating element, a temperature measuring sensoris omitted, the manufacturing process of the heating element is simplified, the performance of the heating element is improved, the cigarette baking effect is improved, the production cost is reduced,and better use experience is brought to consumers.

Owner:SHENZHEN BUDDY TECH DEV CO LTD

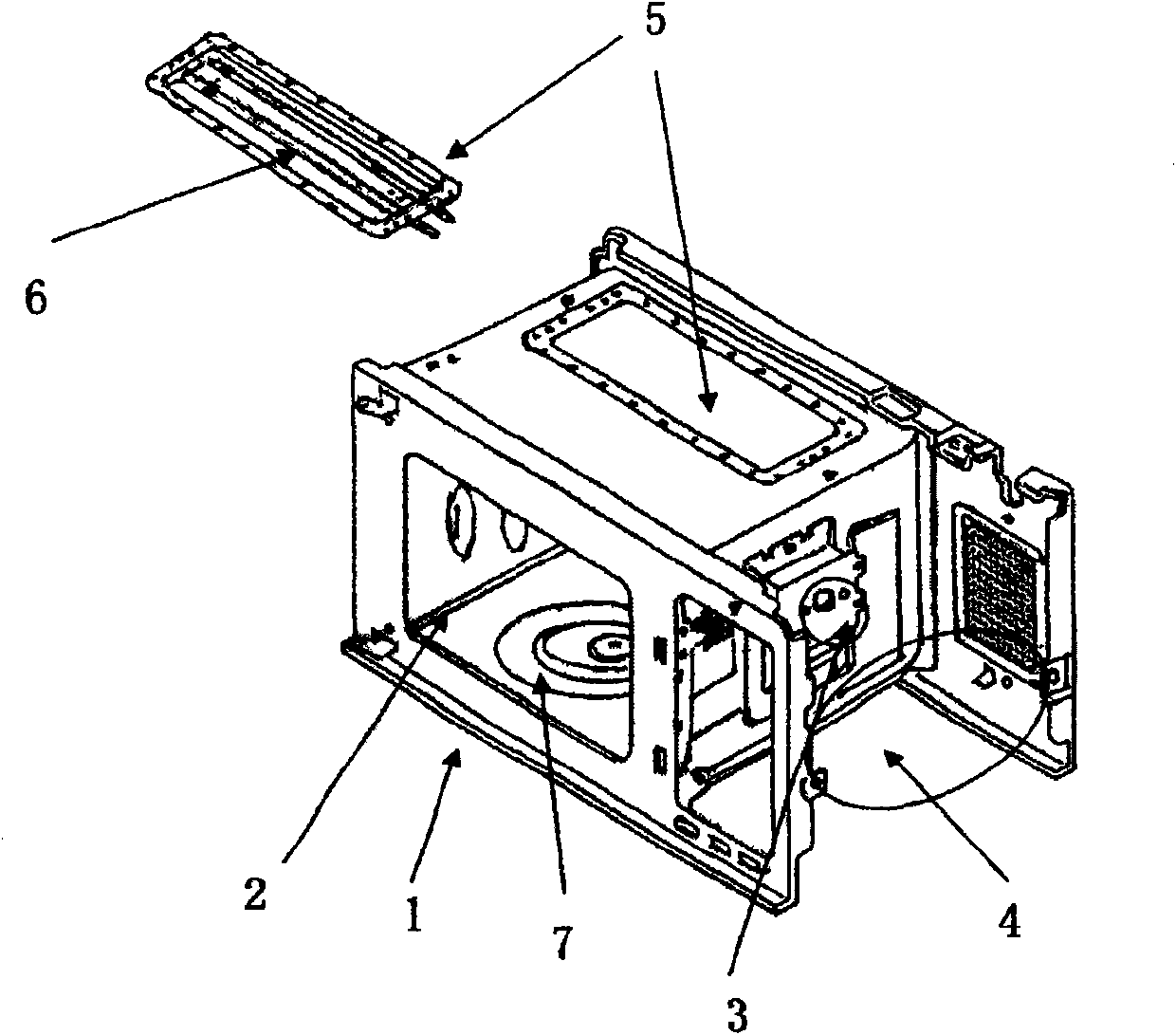

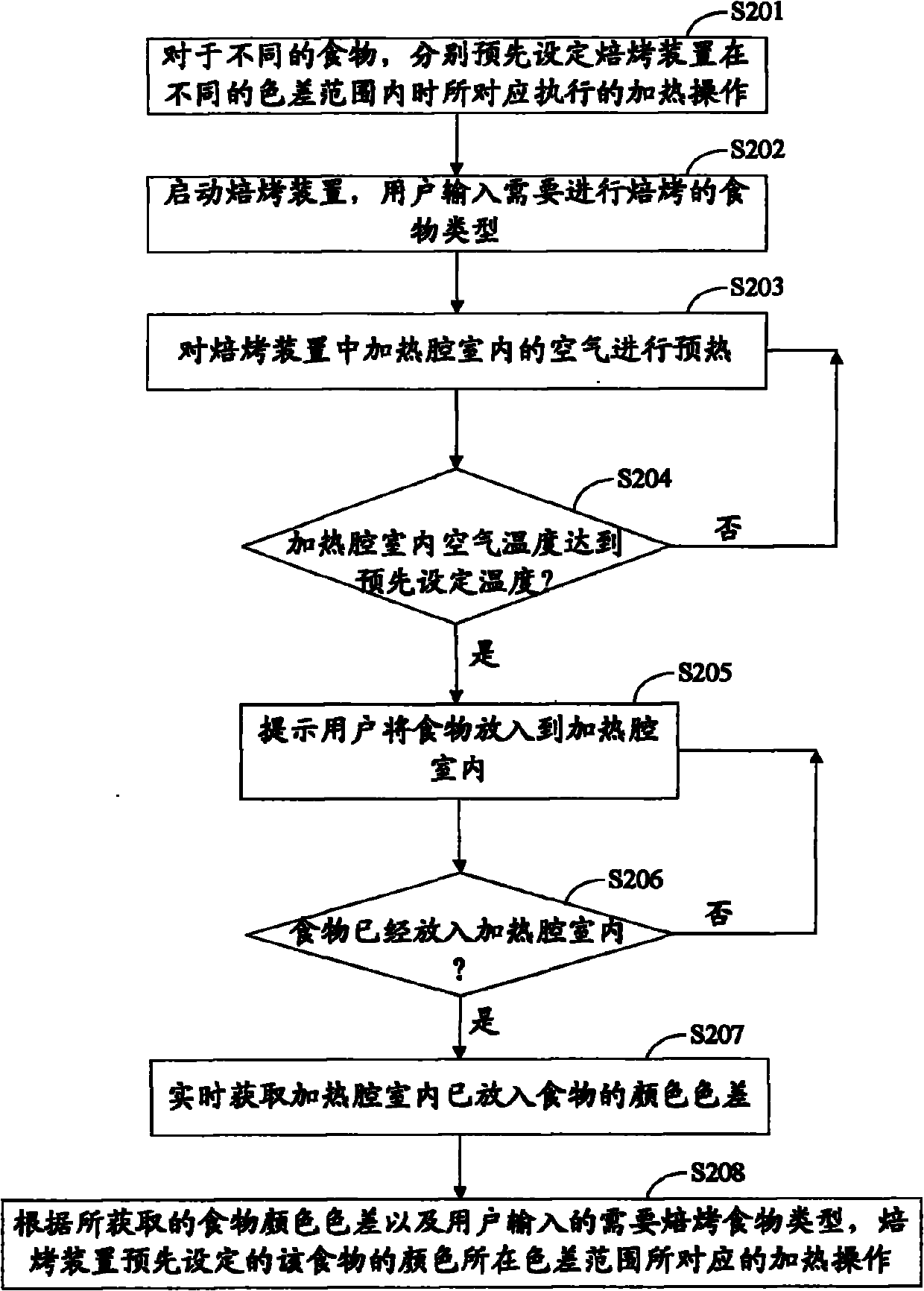

New method for controlling cooling degree of baked products

InactiveCN102022762AImprove the baking effectShorten the timeDomestic stoves or rangesLighting and heating apparatusCooking & bakingMicrowave oven

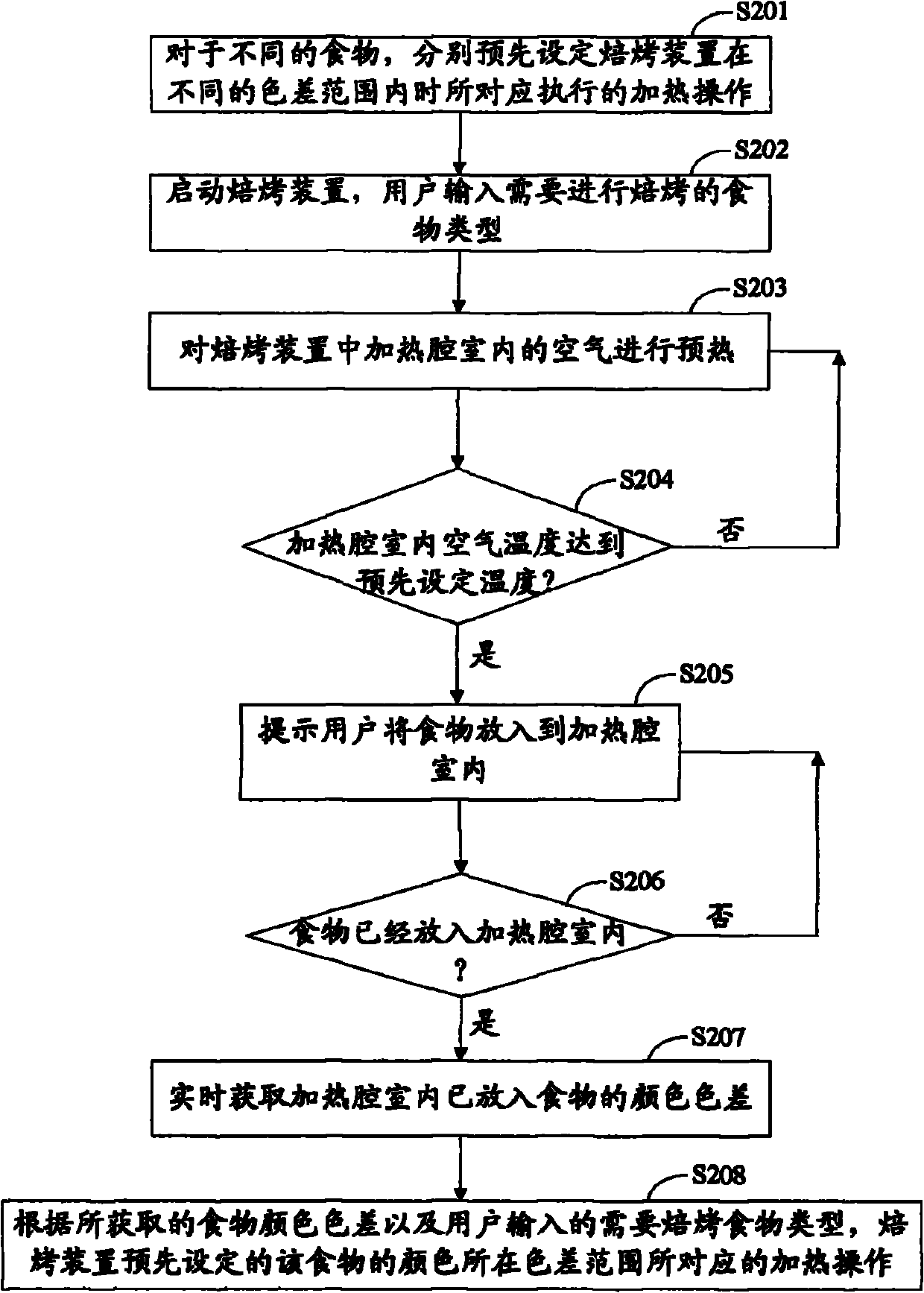

The invention discloses a new method for controlling the cooling degree of baked food. In the method, the cooling degree of food to be baked can be controlled automatically by combining a color sensor for achieving the optimal baking effect on the food, and the method is simple and accurate, is convenient and easy to operate, can save a large amount of time for a user and improve the product use experience of the user of an oven or microwave oven, and therefore has a great production and practice significance. In the new method for controlling the cooling degree of the baked food, the user can allow a baking device to bake the food automatically according to the preset heating operation scheme only by putting the food to be baked into the baking device such as the oven or the microwave oven and selecting and inputting the type of the food to be baked without determining the cooling degree of the food artificially by means of the conventional baking experience, so that the food has excellent color and luster and offers a good mouthfeel, the observation time of the users is saved greatly, a great convenience is brought to the user, and the product use experience of the users is enhanced .

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

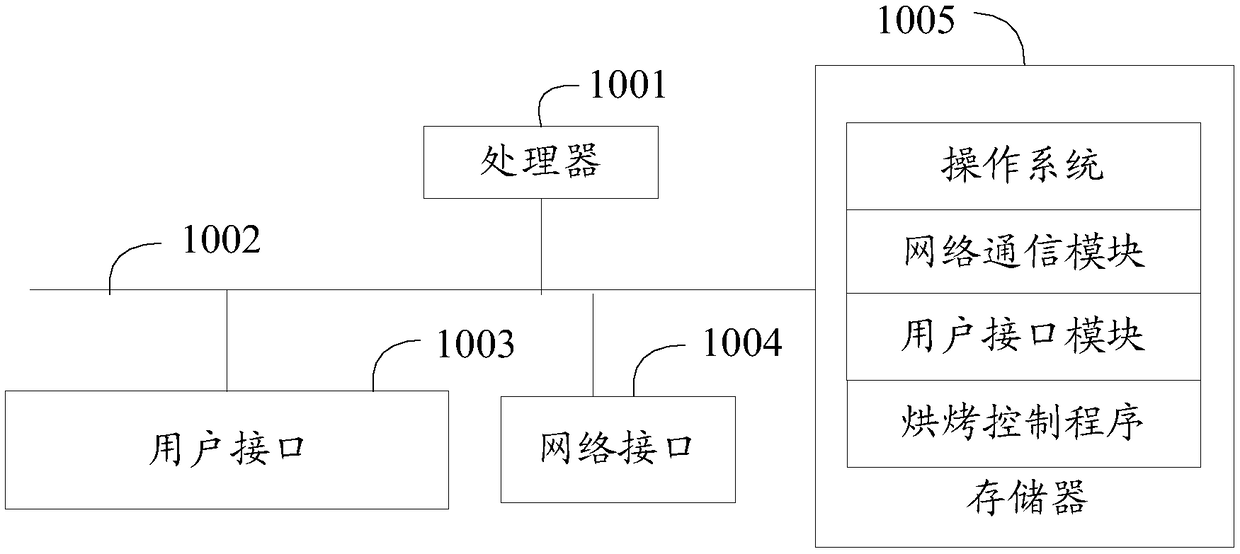

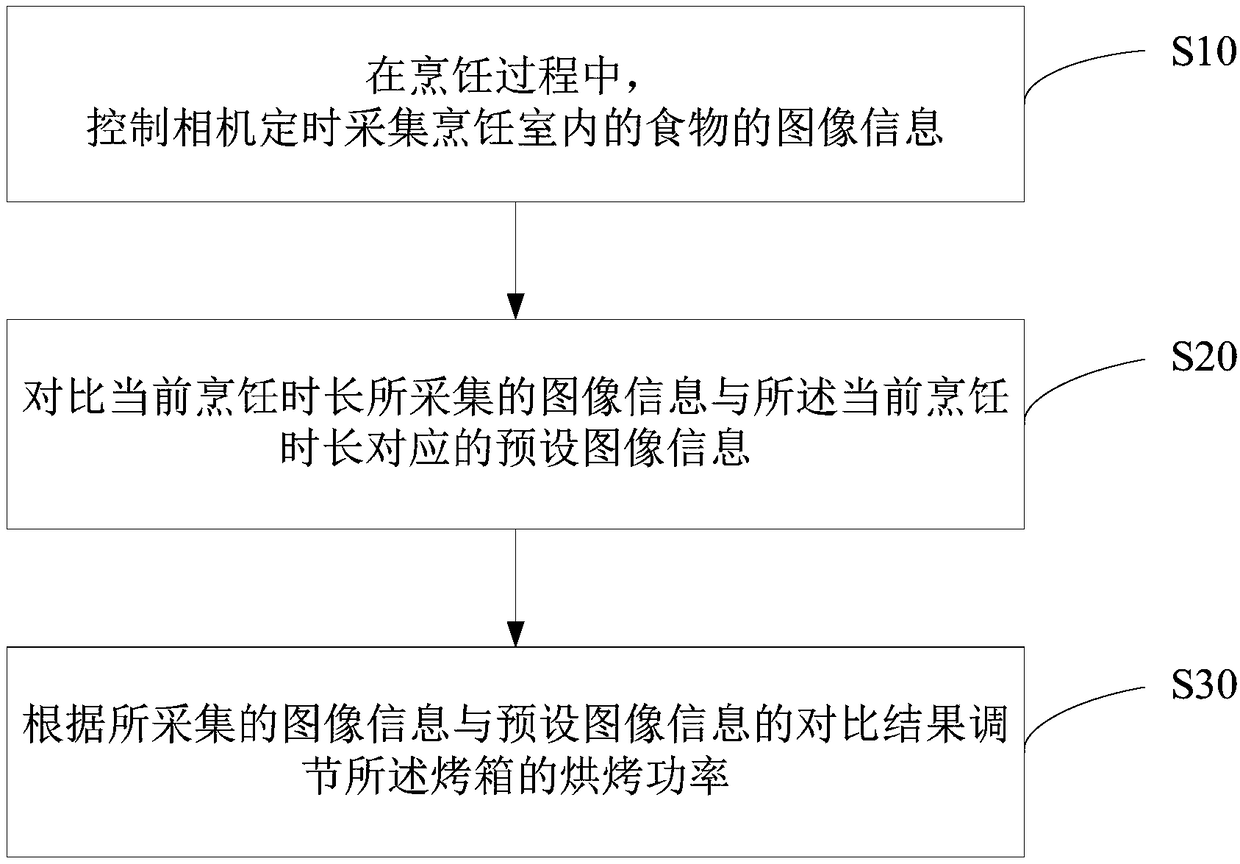

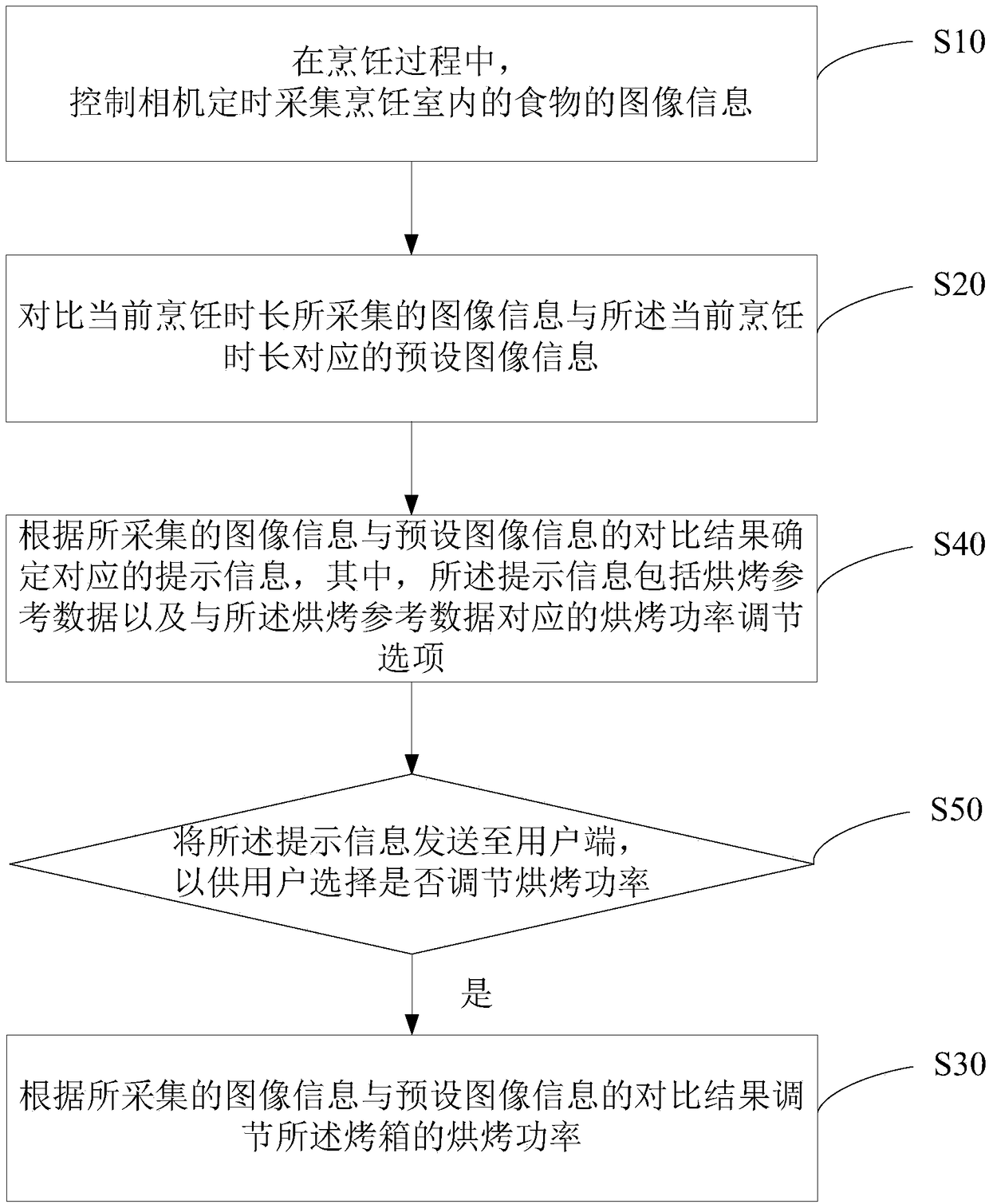

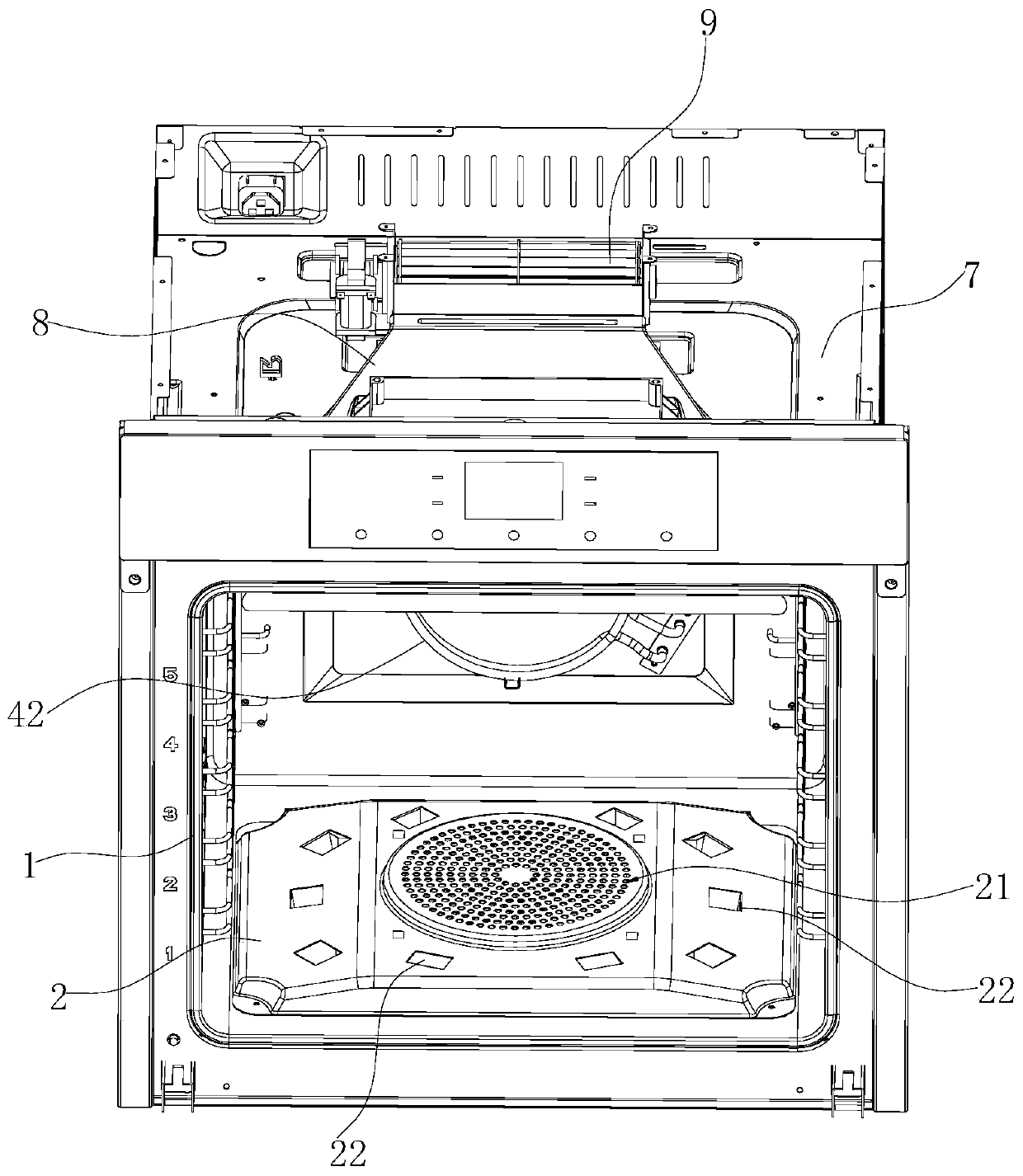

Oven baking control method and device and computer readable storage medium

InactiveCN108646625ABakedImprove the baking effectProgramme controlComputer controlProcess engineeringCooking process

The invention discloses an oven baking control method. An oven comprises a main body, a cooking chamber and a camera, the cooking chamber is arranged in the main body, and the camera is arranged on the upper portion of the cooking chamber so as to capture the interior of the cooking chamber; the method comprises the following steps that in the cooking process, the camera is controlled to collect image information of food in the cooking chamber regularly; the image information collected for current cooking time is compared with preset image information corresponding to the current cooking time;according to the comparison result of the collected image information and the preset image information, the baking power of the oven is adjusted. The invention further discloses an oven baking control device and a computer readable storage medium. Accordingly, by arranging the camera on the upper portion of the cooking chamber of the oven, controlling the camera to collect the image information of the food in the cooking chamber regularly, monitoring the oven baking process regularly, and adjusting the baking power properly, it is guaranteed that the food is braked at the best baking power, and the food achieves the best baking effect.

Owner:SHENZHEN LINGDU INTELLIGENT CONTROL TECH CO LTD

Aluminum alloy and preparation method thereof

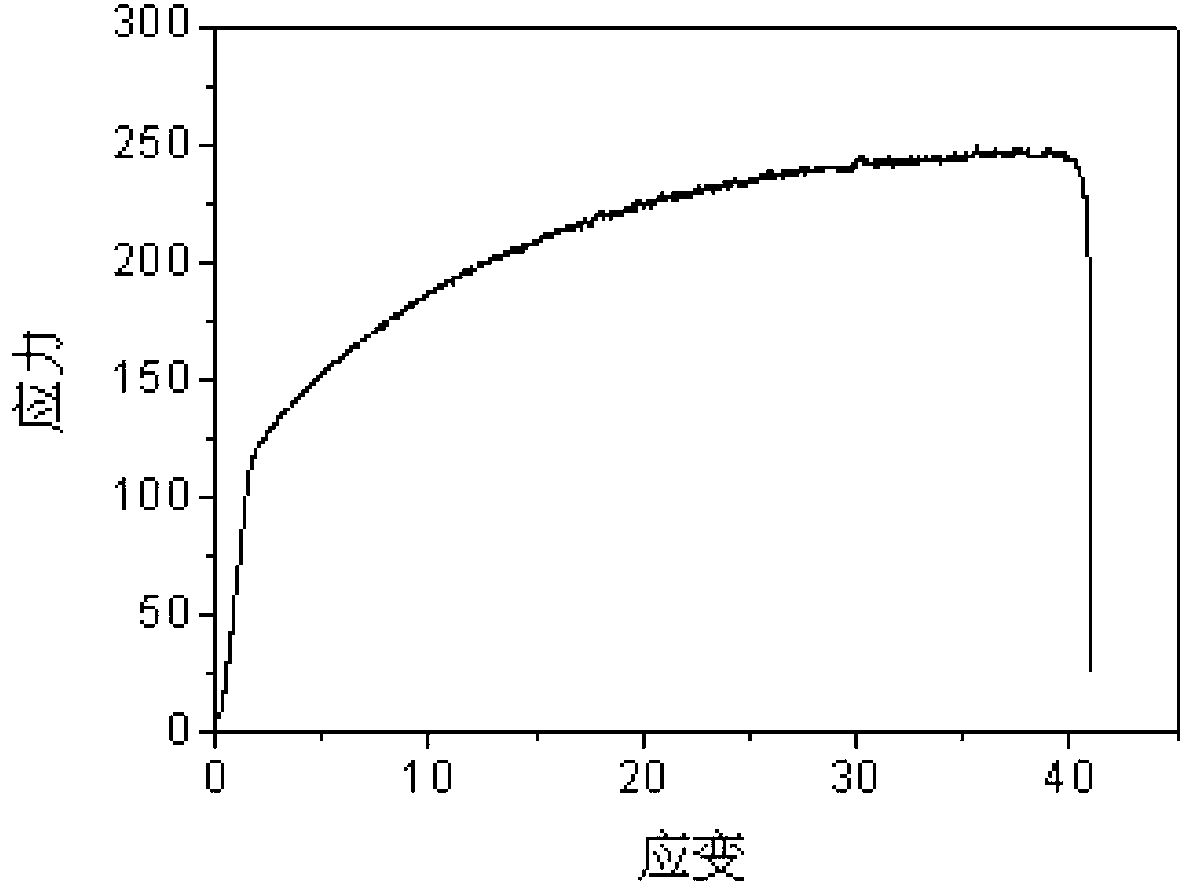

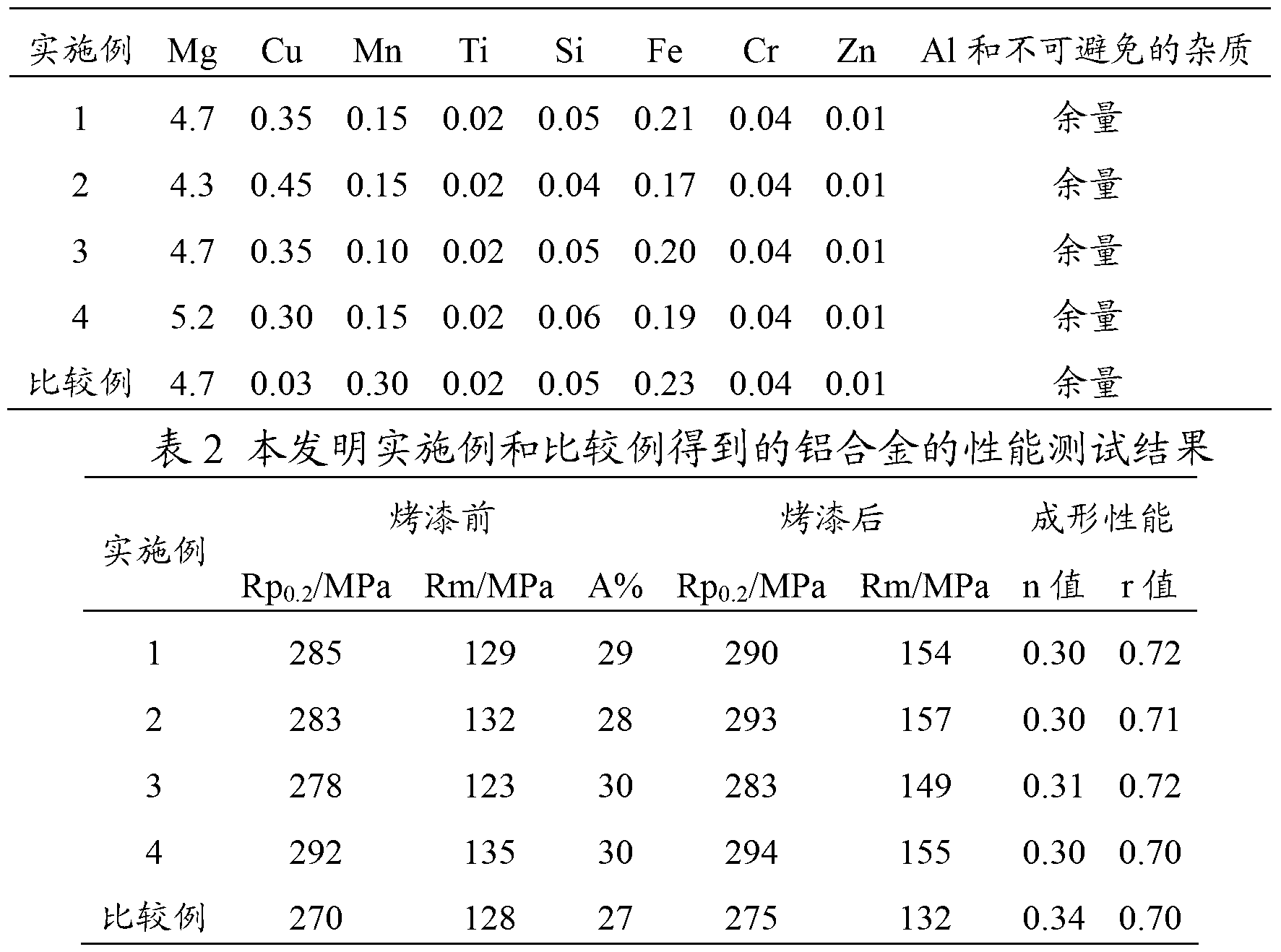

The invention provides aluminum alloy, which comprises the following components: 4.0-6.0wt% of Mg, 0.20-0.50wt% of Cu, 0.05-0.30wt% of Mn, 0.05-0.30wt% of Fe, 0.03-0.15wt% of Si, less than or equal to 0.10wt% of Cr, less than or equal to 0.10wt% of Zn, 0.01-0.10wt% of Ti and balance of Al and inevitable impurities. In the aluminum alloy, the Mg not only guarantees the strength of the aluminum, but also meets the requirements on plasticity and corrosion resistance when the aluminum alloy is used for making automobile body plates; and the Cu can further improve the strength of the prepared aluminum alloy and can enable the aluminum alloy to have better baking softening resistance and forming performance. Therefore, the aluminum alloy provided by the invention has good baking performance and forming performance.

Owner:ZHEJIANG GKO ALUMINUM

Automatic baking control method for baking oven

ActiveCN103349032AGood baking effectImprove the baking effectBaking ovenHeating timeProcess engineering

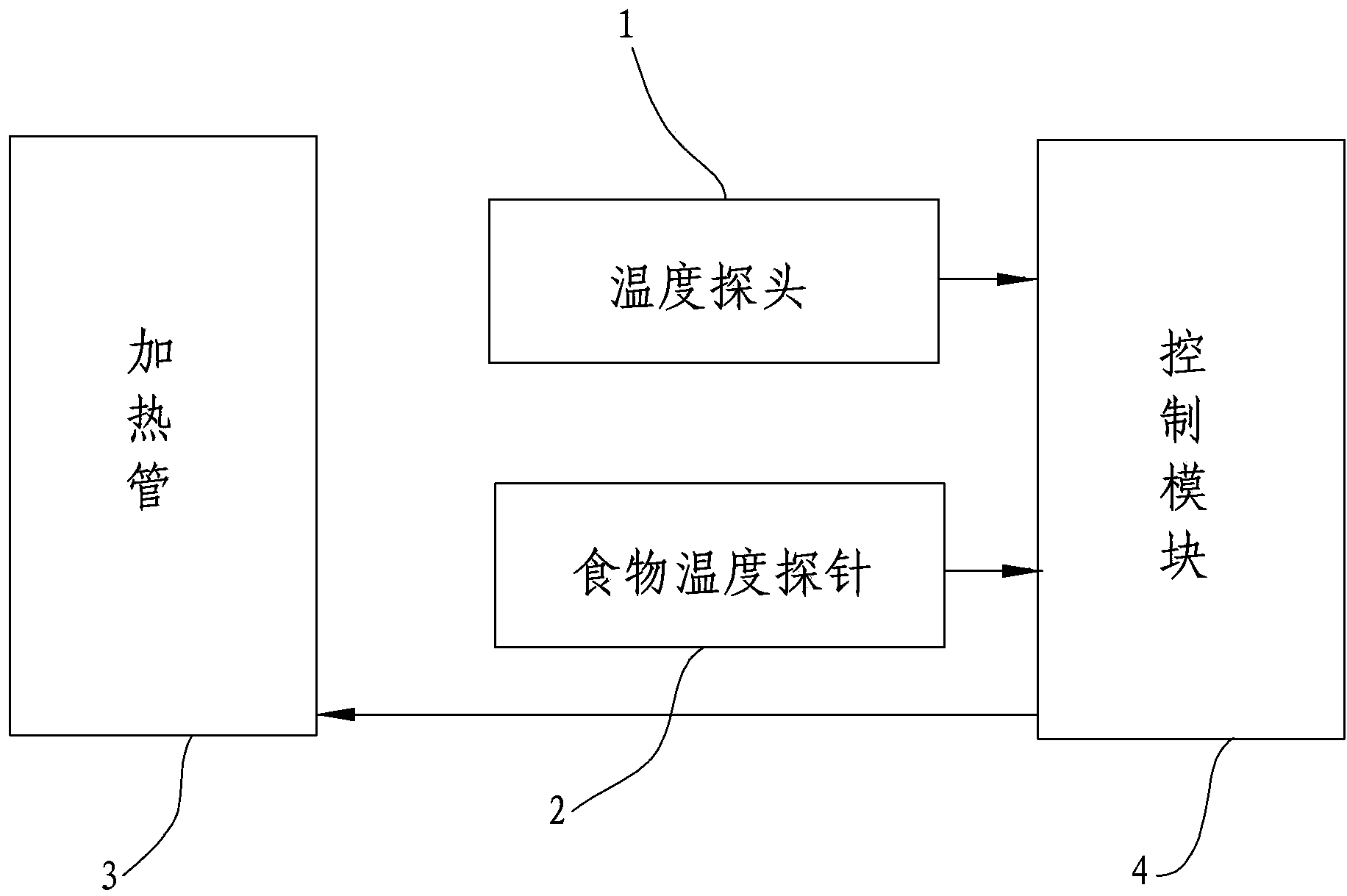

The invention discloses an automatic baking control method for a baking oven, which comprises the following steps: placing food to-be-baked into the baking oven, inserting a food temperature probe into the food, and starting a baking program corresponding to the food in the baking oven; (2), when a first baking stage set by the baking program is started, calculating the first real-time temperature change rate Delta T1 in a first time stage with a control module, and comparing the first real-time temperature change rate Delta T1 with a corresponding first predetermined temperature change rate Delta T1' in the baking program, so as to judge whether continuing heating is required or not; (3), when continuing heating is required and a second baking stage set by the baking program is started, calculating the second real-time temperature change rate Delta T2 in a second time stage with the control module, and comparing the second real-time temperature change rate Delta T2 with a corresponding second predetermined temperature change rate Delta T2' in the baking program, so as to judge whether continuing heating is required or not; the steps circulate till baking is fulfilled. As inner temperature change rates of food in specified time and final temperature value are adopted for adjusting total heating time, best baking time is selected, which ensures that meat foods of different initial attributes can be well baked.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

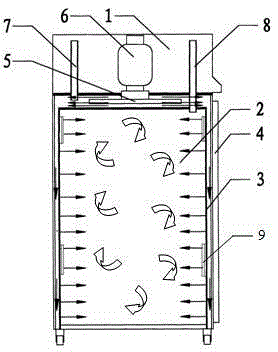

Efficient energy-saving electric oven for roast ducks

ActiveCN107212760AEvenly heatedImprove the baking effectBaking ovenRoasting apparatusActive carbonEfficient energy use

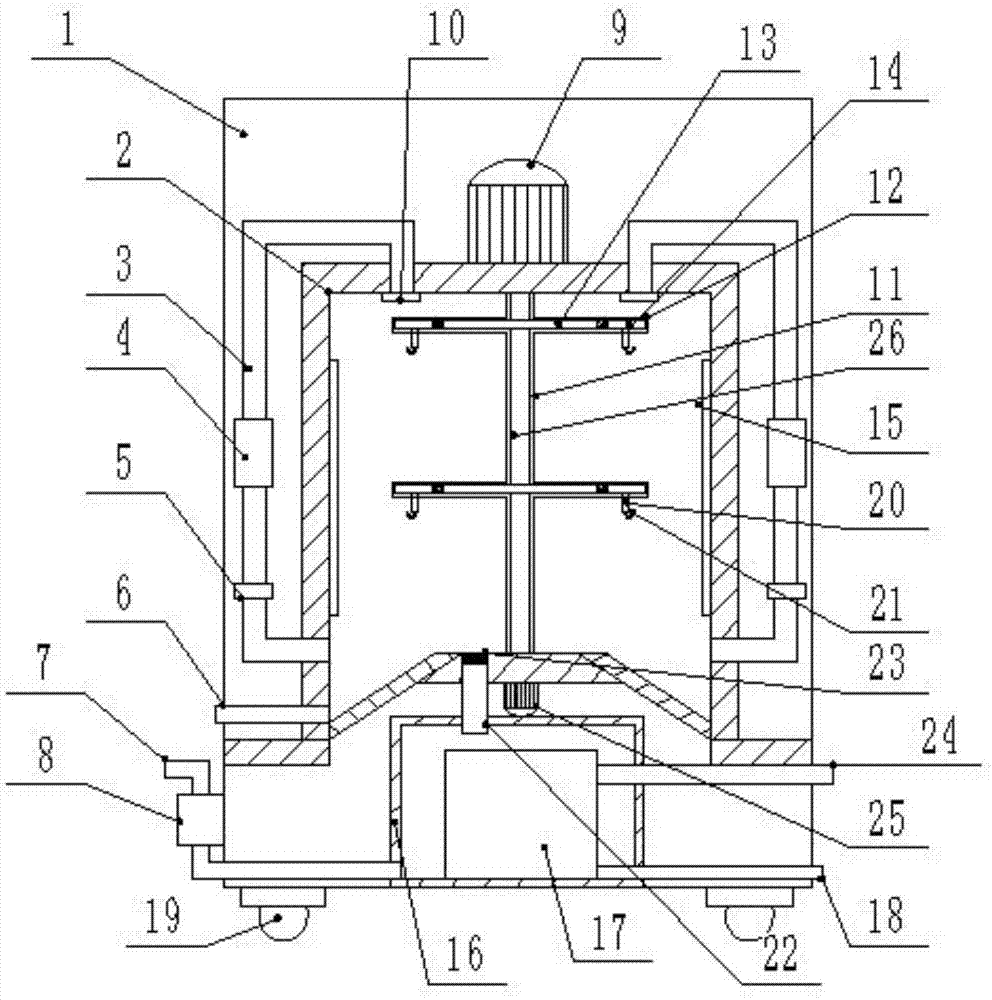

The invention discloses an efficient energy-saving electric oven for roast ducks. The oven comprises a shell, a roasting chamber and a seal cover; the oven is characterized in that the roasting chamber is formed in the shell, and a rotating motor is arranged at the upper end of the roasting chamber; a reversal motor is arranged at the lower end of the roasting chamber, and an output end of the reversal motor is fixedly connected with a third rotating shaft; heating pipes are arranged on the periphery of the roasting chamber; circulating mechanisms are symmetrically arranged on the left side and the right side of the roasting chamber in sequence, and the circulating mechanisms are composed of circulating air pipes, circulating pumps, active carbon adsorption layers and air nozzles; the seal cover is arranged at the lower end of the roasting chamber, and a water tank is arranged in the seal cover; an air outlet pipe is arranged on the left side of the seal cover, and a cooling pump is arranged on the air outlet pipe. The efficient energy-saving electric oven for the roast ducks is simple in structure and convenient to operate, the ducks conduct orbit motion and autorotation in the roasting process, so that the ducks are evenly heated, and the roasting effect is good; a hot wind current is formed in the roasting chamber by the circulating mechanisms, the roasting efficiency is improved, surplus hot gas is reused, and the resources are saved.

Owner:佛山市将轩金属制品有限公司

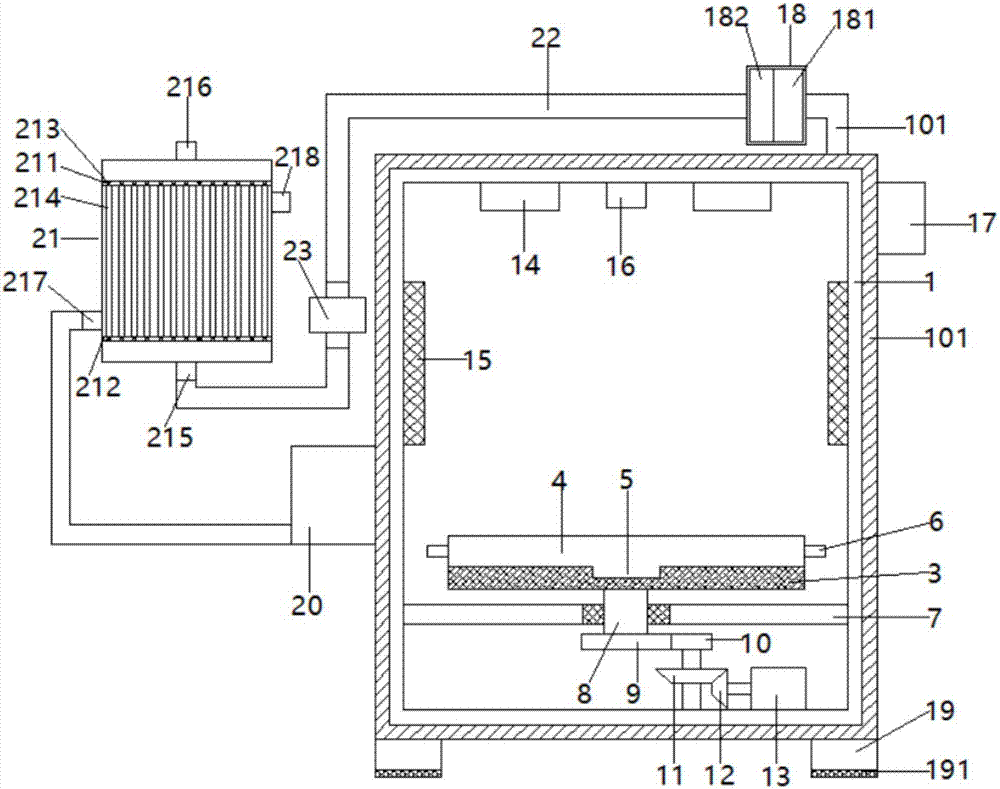

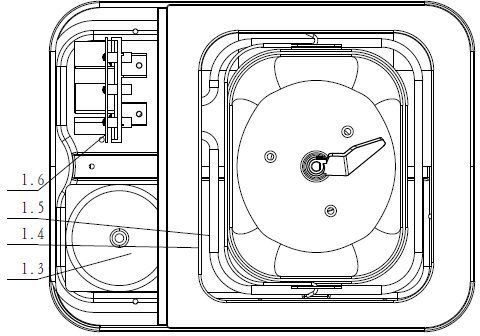

Domestic intelligent electric oven

InactiveCN106943034AImprove the baking effectImprove job stabilityRoasters/grillsAutomatic controlEngineering

The invention discloses a household intelligent electric oven, which comprises a box body, an insulation layer is arranged on the outer wall of the box body, and a partition board is horizontally arranged on the lower side inside the box body, and the partition board divides the box body into a baking cavity on the upper side and a baking chamber on the upper side. In the installation cavity on the lower side, a turntable is horizontally arranged at the center of the lower side of the box body, and a circular groove is opened at the center of the upper surface of the turntable. The limiting protrusion of the household electric oven of the present invention can effectively eliminate oil fume and reduce pollution during the baking process, can automatically control the baking temperature, improve the baking effect, and drive the food to rotate at a uniform speed during baking, so that The food is baked more evenly. Infrared heating and hot air are used for baking, which improves the baking efficiency, effectively reduces shock, improves stability, and improves the efficiency of heat use, avoids heat loss, and saves energy.

Owner:湖南鸣腾智能科技有限公司

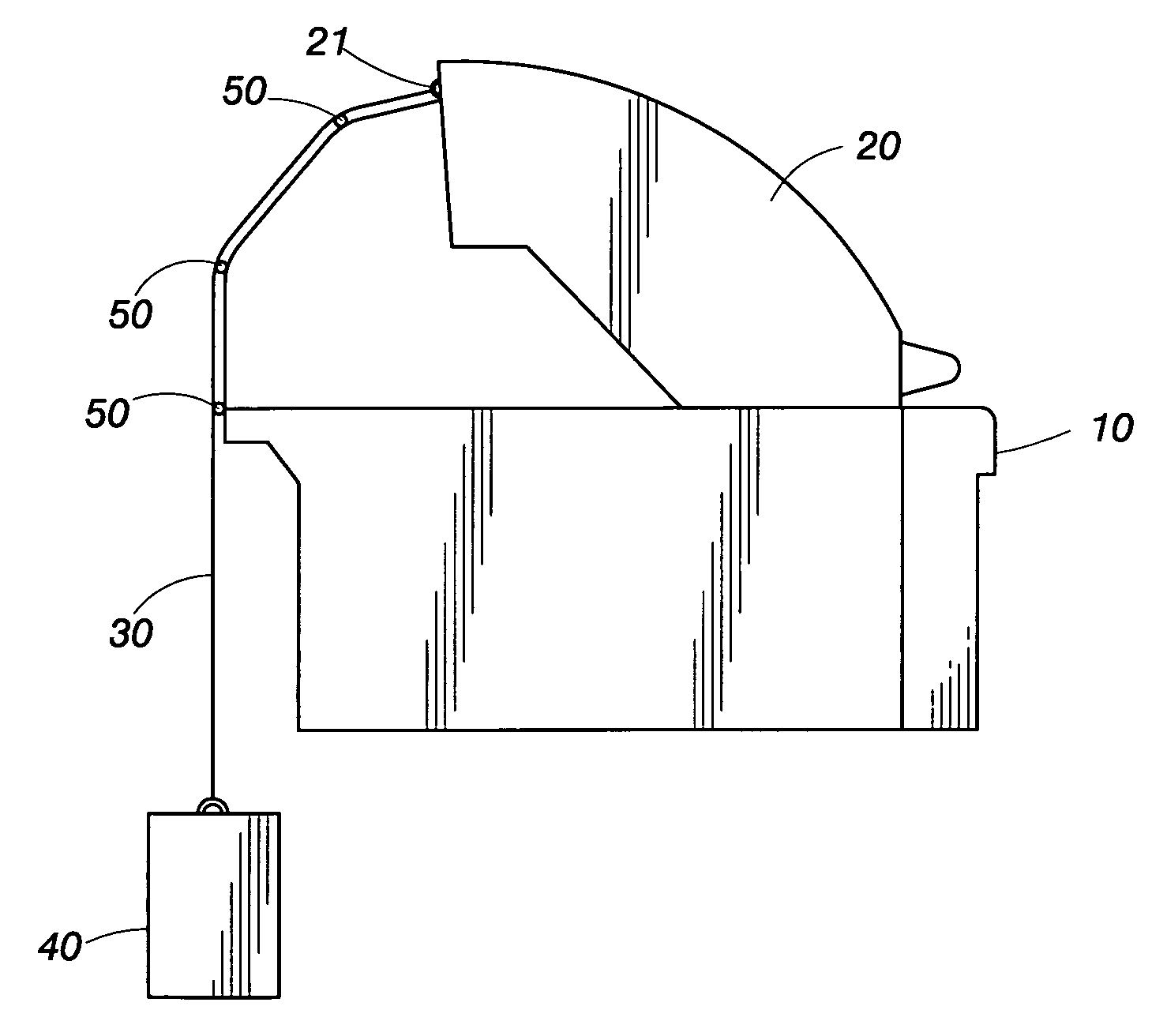

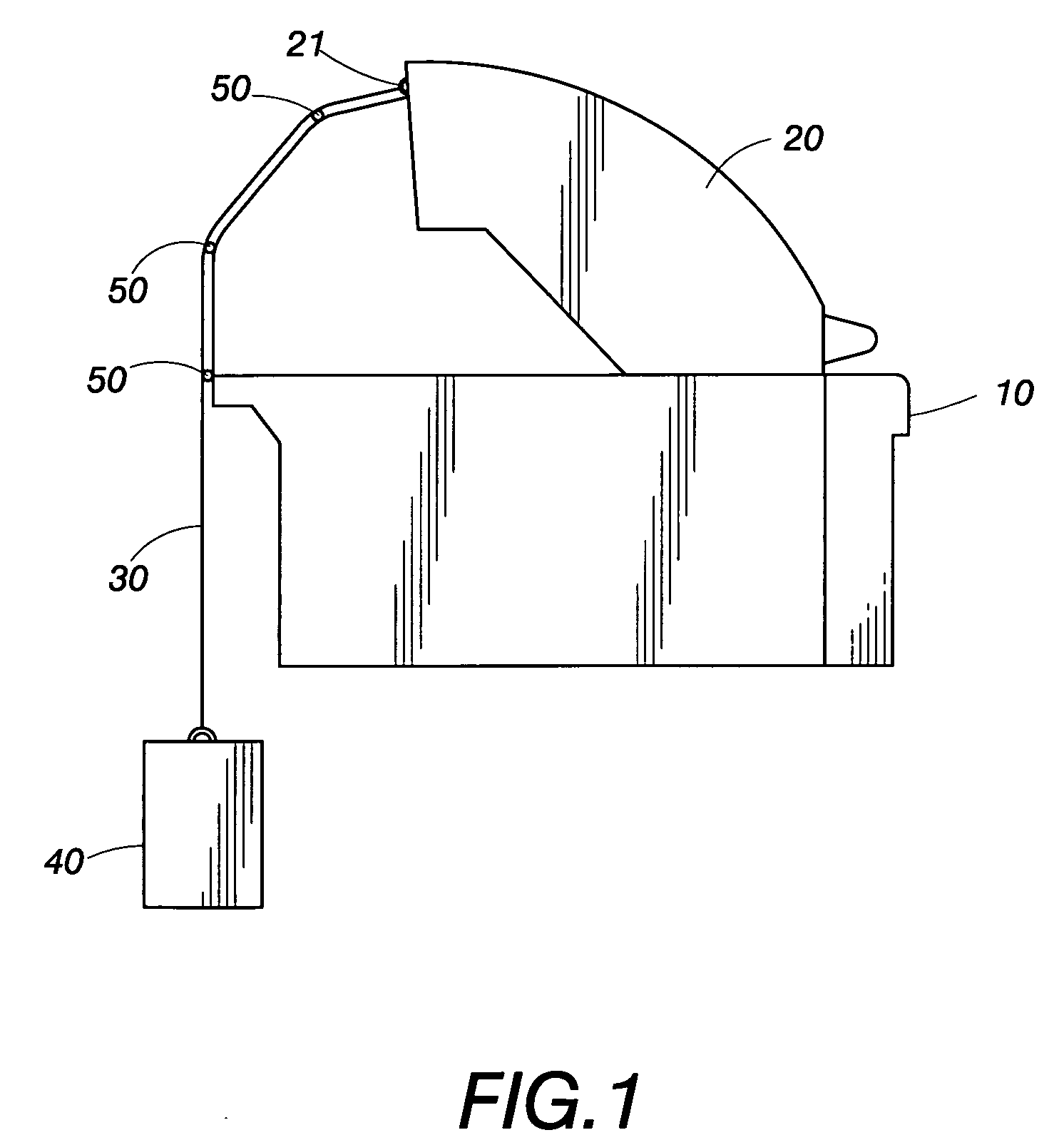

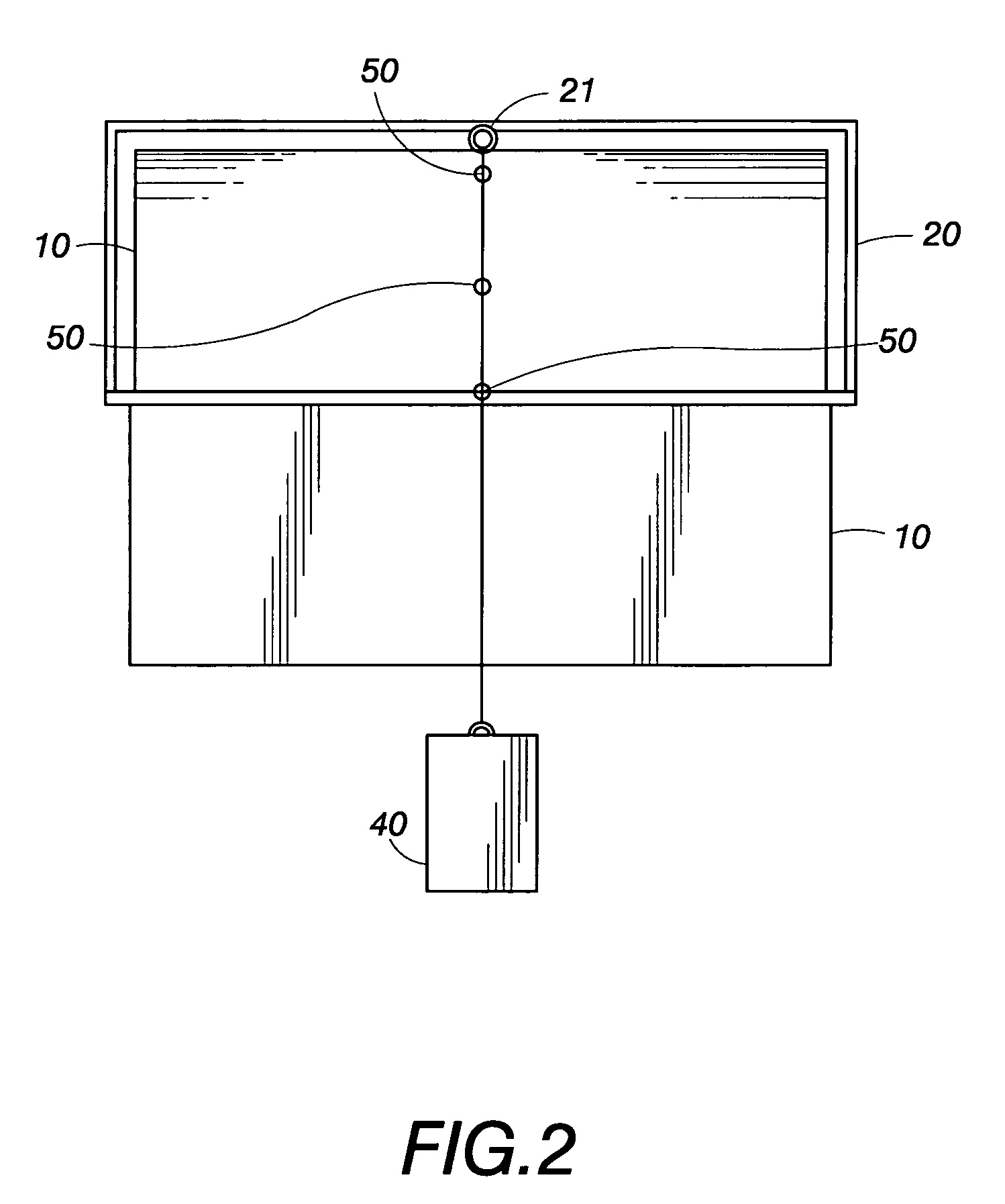

Auxiliary opening/closing mechanism for a cover of a roasting stove

InactiveUS20100024797A1High strengthReduce the overall diameterDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

An auxiliary opening / closing mechanism for a cover of a roasting stove, the mechanism can improve the roasting stove to eliminate the defect resided in using a thick and heavy metallic roasting stove cover which makes uneasy for opening and closing the auxiliary mechanism is connected with a rope on the rear of it, the rope extends down along the back of the roasting stove, and one end of the rope has a pending counterbalance weight, the weight of the counterbalance weight pulls the roasting stove cover to help to open it, thereby the roasting stove cover gets rid of the trouble of being uneasy for opening and closing being due to its thickness and heaviness.

Owner:TSUNG KAO HSUNG

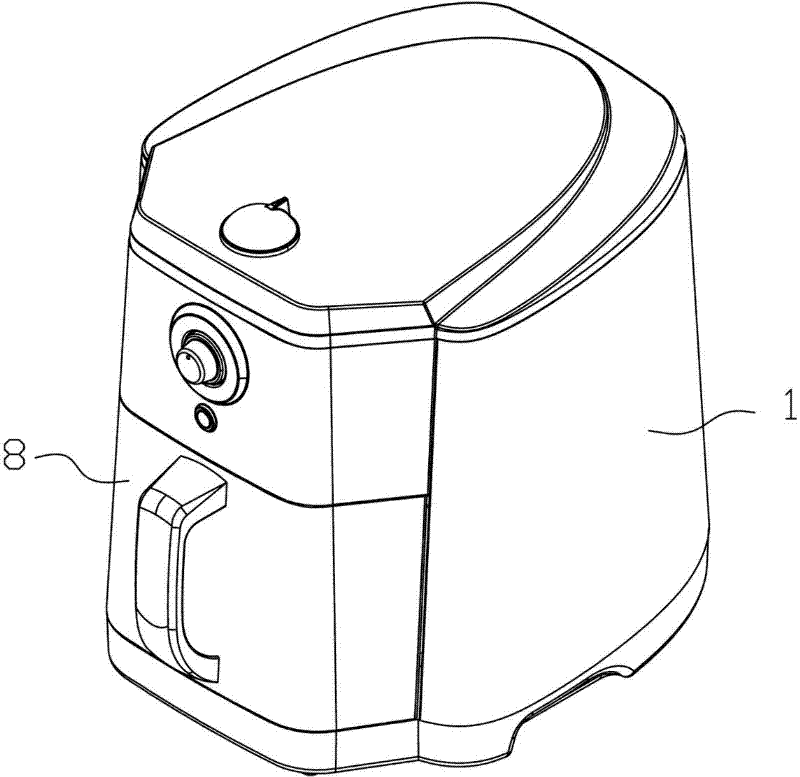

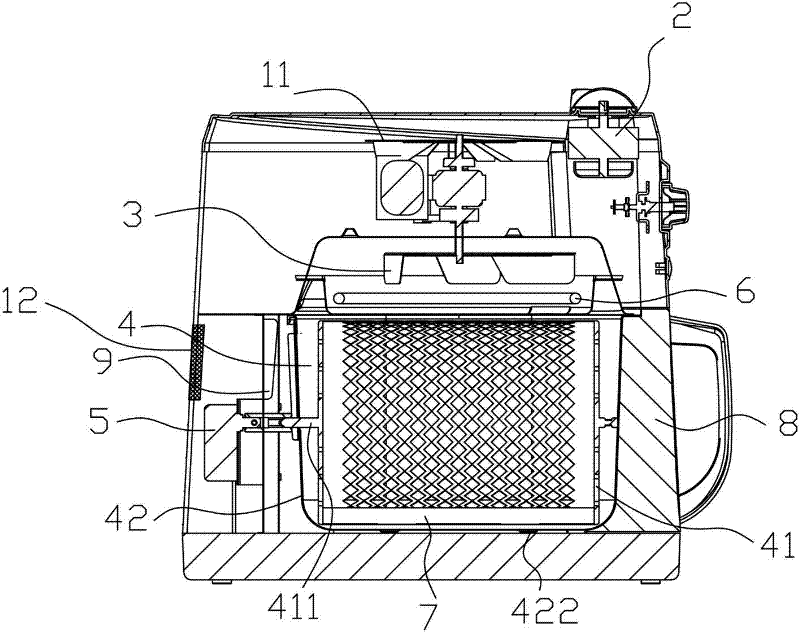

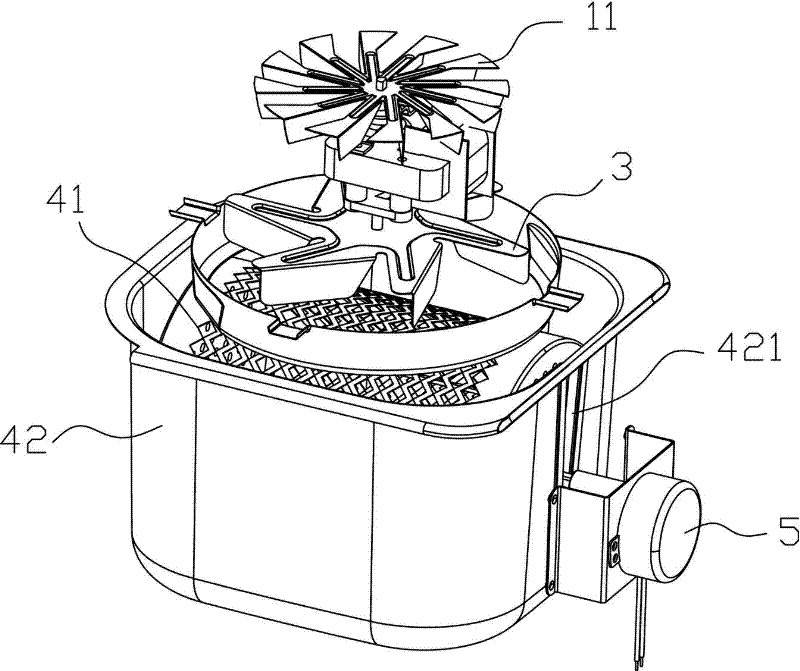

Hot whirlwind type multifunctional cooker

InactiveCN102342761AAvoid Process Safety IssuesImprove the heating effectRoasters/grillsDeep fat fryersBiochemical engineeringHeating effect

The invention discloses a hot whirlwind type multifunctional cooker. The hot whirlwind type multifunctional cooker comprises a main body, a control assembly, a heating assembly, an air blowing assembly and a containing assembly, wherein the containing assembly comprises a rotating type containing basket, a motor assembly is arranged on the main body, the air blowing assembly is arranged above the containing basket, and is used for blowing air towards the top of the containing basket, and the heating assembly comprises a plurality of heating pieces which are arranged between the air blowing assembly and the containing basket. In the invention, heat produced by the heating pieces can be driven by cyclonic eddy to flow into the whole heating space, so that a good and uniform heating effect can be achieved; and food to be processed can be overturned at the same time to achieve a good and uniform baking effect, so that the problem on the safety of food processing due to the excessive application and recycling of oil caused by immersing and frying the food in oil is solved. When an oil scoop is further provided to pour shoveled oil above the food, the oil can rotate together with the food, and can be uniformly mixed with the food, so that fried food is more uniform and healthy after being heated by high-temperature cyclonic eddy.

Owner:黄朝龙

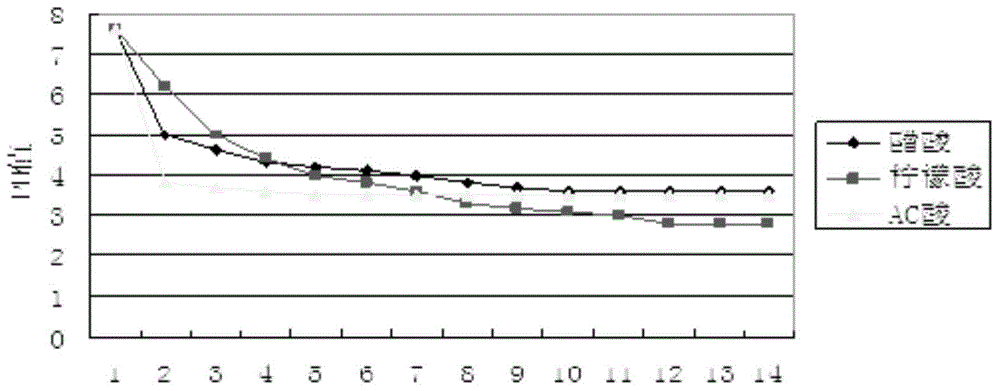

Intensive curing barn baking process for airflow alternate-operation flue-cured tobacco

ActiveCN102068028AReduce the plane temperature differenceReduce vertical temperature differenceTobacco preparationTobacco treatmentEcological environmentOperation mode

The invention relates to an intensive curing barn baking process for airflow alternate-operation flue-cured tobacco, belonging to the technical field of flue-cured tobacco preparation process. The intensive curing barn baking process for airflow alternate-operation flue-cured tobacco is the improvement on the existing intensive curing barn baking process. The improvement point is characterized inthat interval time for the alternate operation of airflow rise and airflow descending is as follows: in the low-temperature humidifying and yellowing stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the stable-temperature dehumidifying and withering stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the ventilating, dewatering and leaf-drying stage: two airflow operation modes are provided, the time interval is 0.75 hour, and alternation is carried out once; and in the temperature and moisture controlling and tendon drying stage: two airflow operation modes are provided, the time interval is 1.00 hour, and alternation is carried out once. Other baking operation technologies of the process are same with the conventional baking process. The intensive curing barn baking process can obviously improve the baking property of the tobacco loading chamber of the intensive curing barn, improve tobacco leaf baking quality, and improve the safety for baking the tobacco leaf. The intensive curing barn baking process is suitable for intensive baking underdifferent ecological environment conditions in the tobacco area in China.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

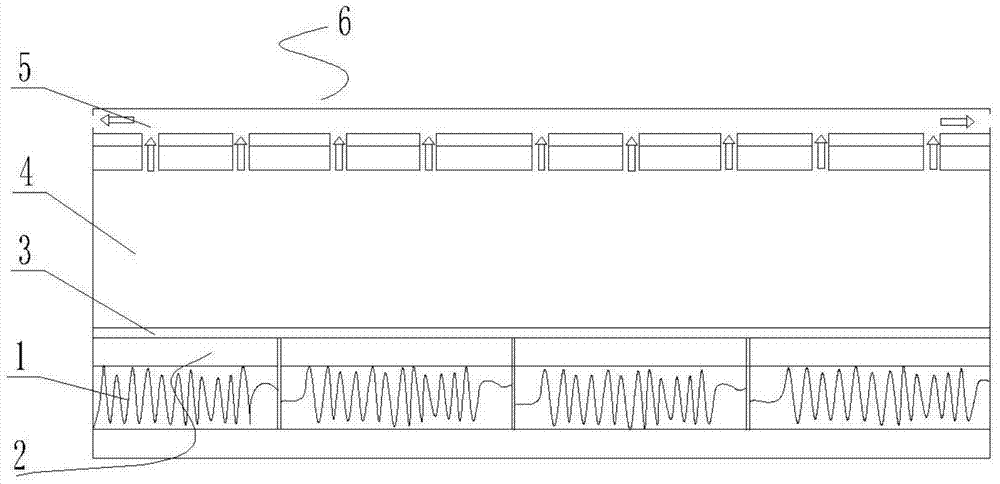

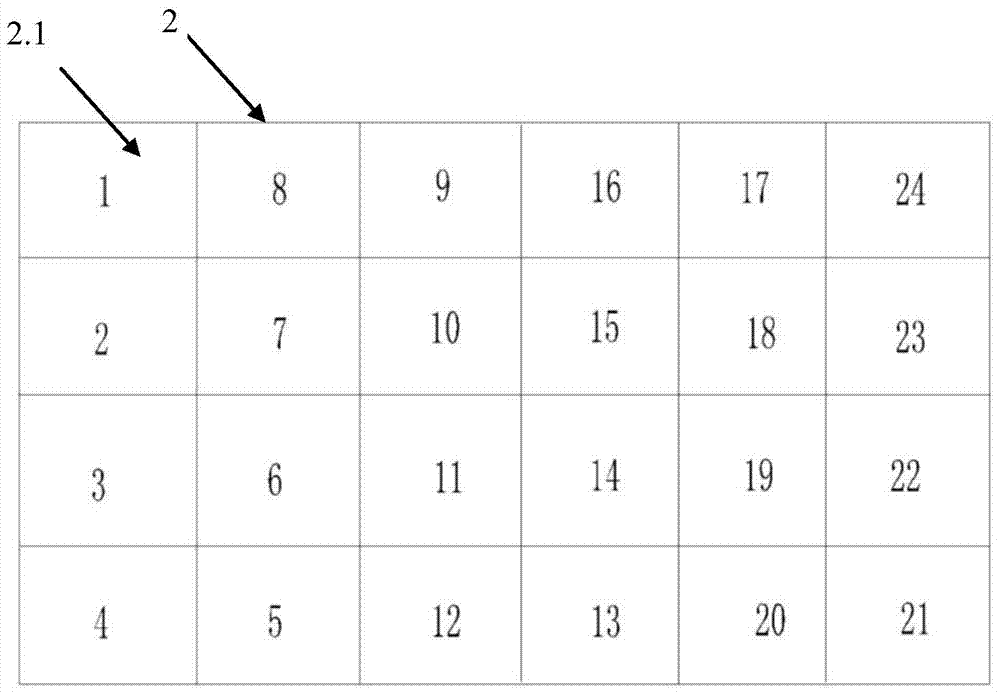

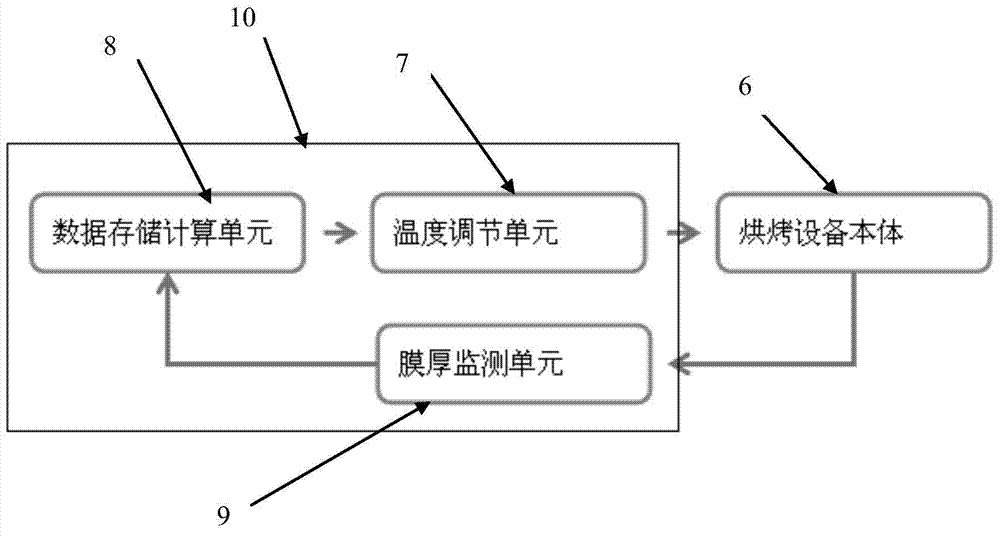

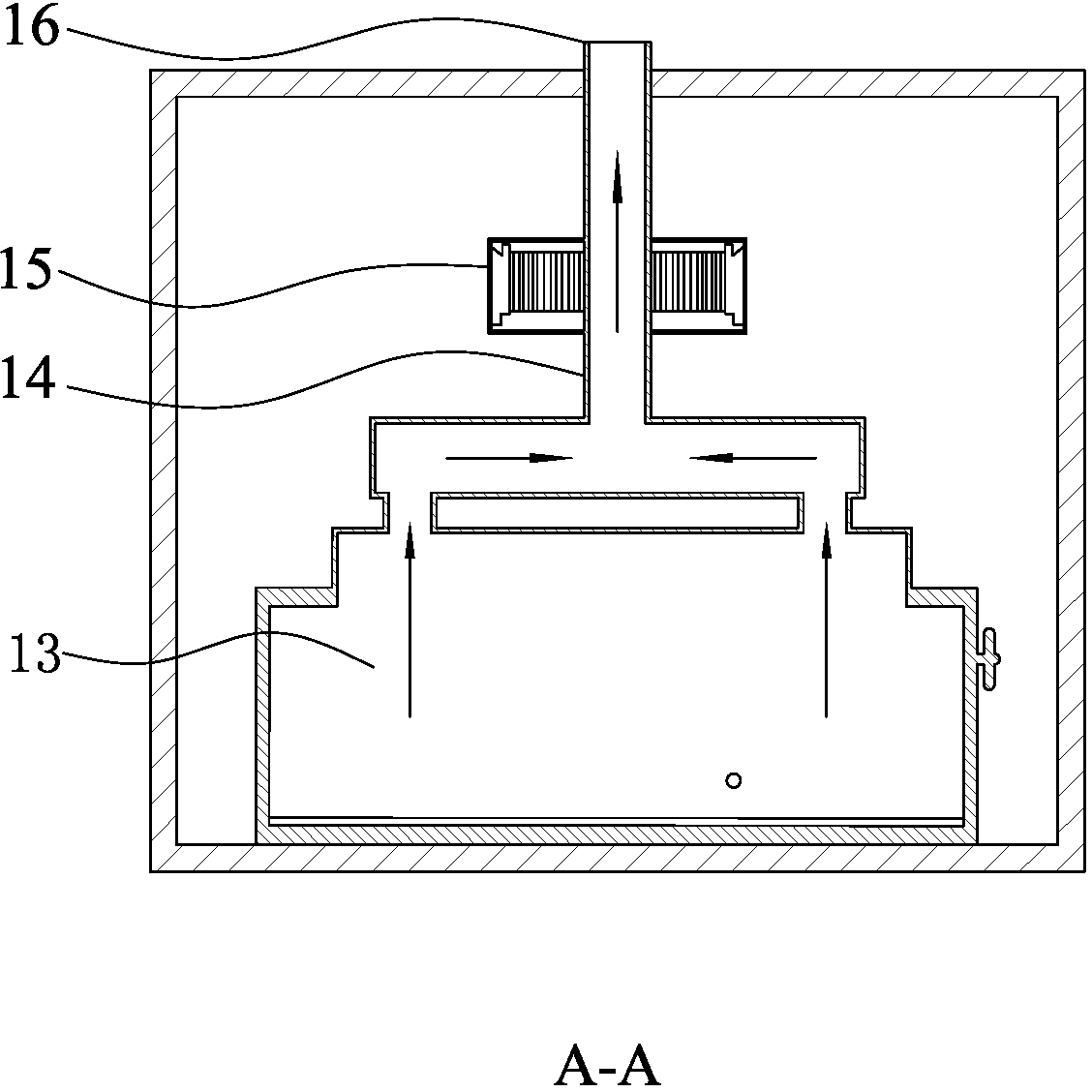

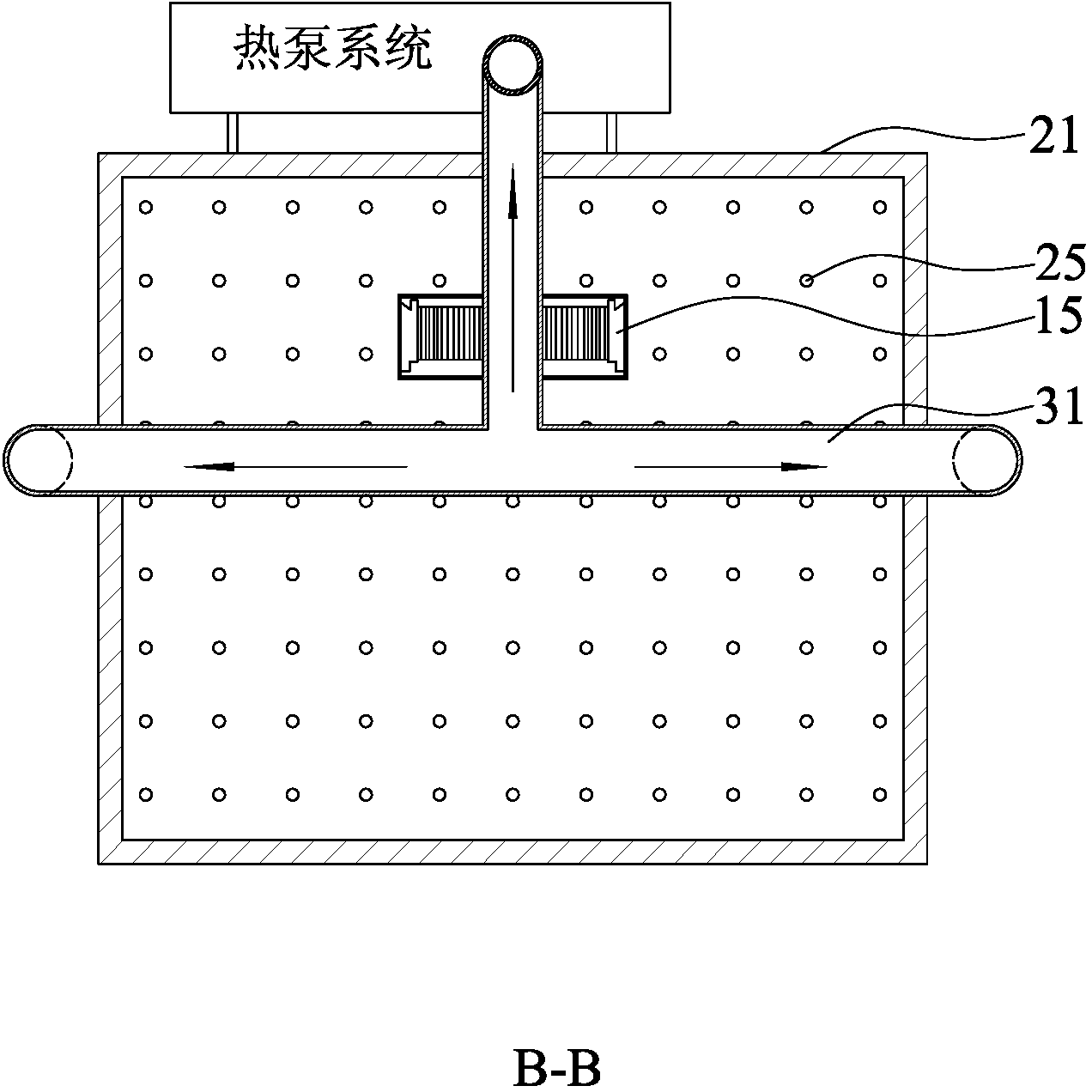

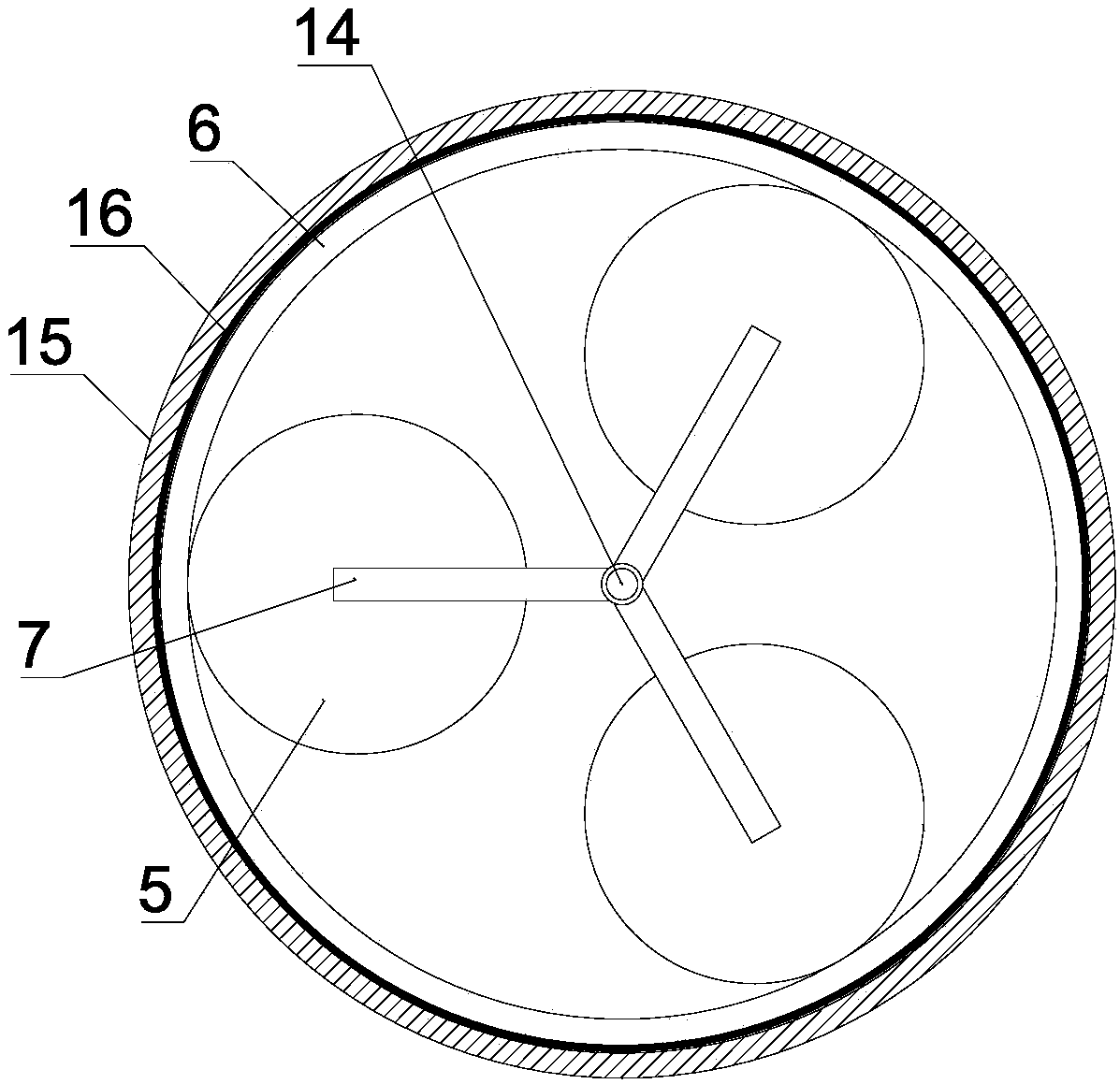

Substrate roasting device and temperature adjustment method thereof

ActiveCN103760753AImprove film thickness uniformityPlay a more uniform role in heat conductionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingHeat conductingHeating temperature

The invention discloses a substrate roasting device and a temperature adjustment method thereof. The substrate roasting device comprises a roasting device main body which is used for roasting the substrate, wherein the roasting device body comprises a heating plate formed by a plurality of sub heating plates, and a temperature adjusting mechanism which is used for adjusting the heating temperature of each sub heating plate of the roasting device main body. A heat conducting layer is arranged on the heating plate, and the heat conducting layer covers each sub heating plates. Due to the adoption of the substrate roasting device, the film thickness evenness of the substrate can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

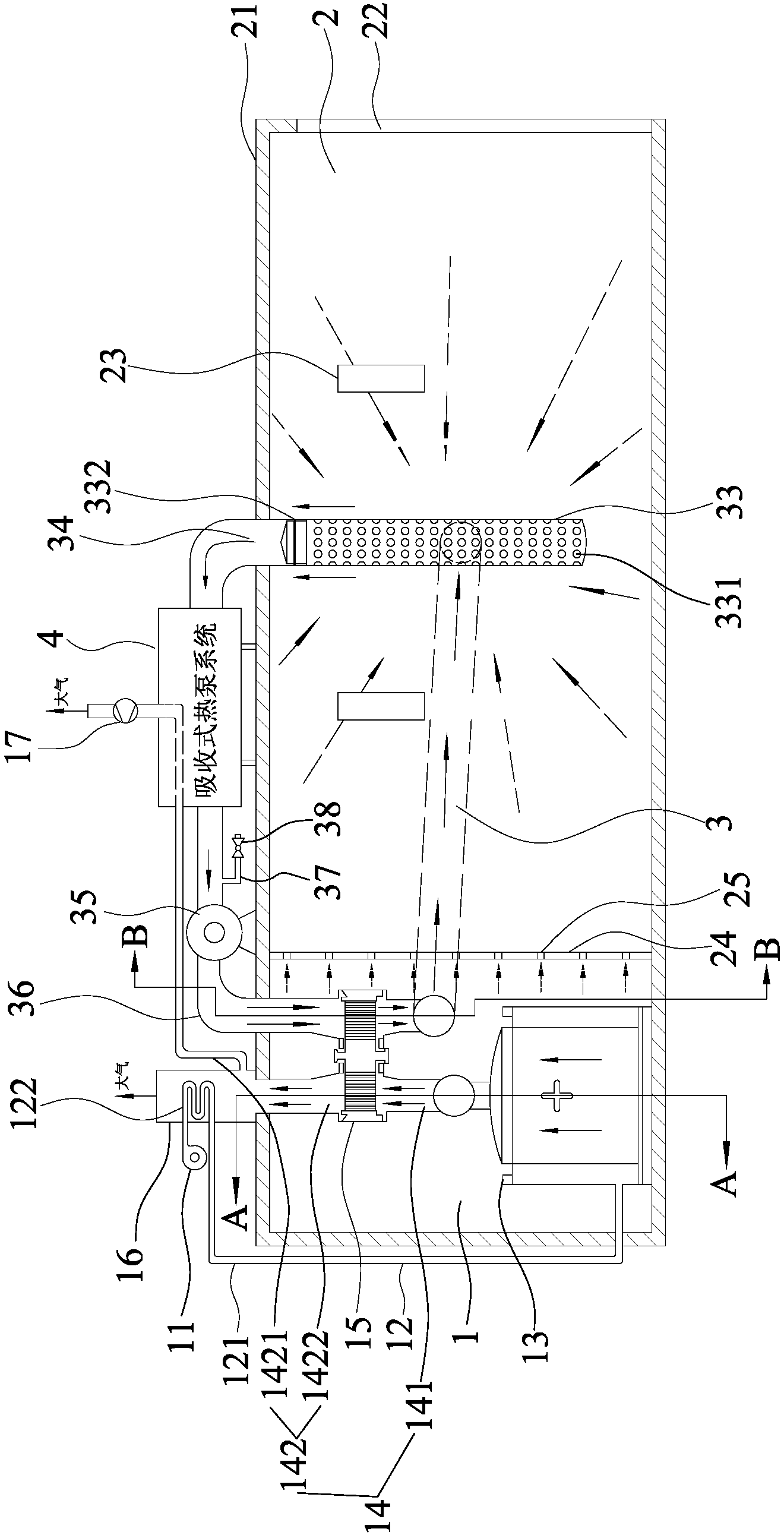

High-efficiency and energy-saving intensive tobacco flue-curing house

ActiveCN102697157AImprove combustion efficiencyImprove energy utilizationTobacco preparationFinal product manufactureHigh energyAbsorption heat pump

The invention discloses a high-efficiency and energy-saving intensive tobacco flue-curing house, which comprises a heat supply chamber, a baking chamber, a hot air circulating system and an absorption type heat pump system, wherein the hot air circulating system is connected with the heat supply chamber, the baking chamber and the absorption type heat pump system sequentially by a pipeline; and the absorption type heat pump system is arranged on the top of the baking chamber. According to the high-efficiency and energy-saving intensive tobacco flue-curing house, the heat exchange efficiency and energy utilization rate are improved by utilizing a technology of performing heat exchange by a rotary air heat exchanger, a technology of preheating air required by the combustion of a hearth by recovered smoke waste heat, a technology that the recycled smoke waste heat is used as a heat source of the absorption type heat pump system and the like; a baking effect of the tobacco flue-curing house is improved by utilizing technologies of supplying air from two sides of a side wall air distribution board and exhausting the air from the center of a central air draft pipe; and a humidity-discharging effect and an energy-saving effect are improved by utilizing a technology of performing deep dehumidification and recovering humidity-discharging waste heat by the heat pump system. Therefore, the high-efficiency and energy-saving intensive tobacco flue-curing house has the characteristics of high heat exchange efficiency, high energy utilization rate, good baking effect and good humidity-discharging effect, is particularly suitable for low-cost and large-scale production, and can be widely applied to the technical field of tobacco flue-curing.

Owner:JIMEI UNIV

Aluminum alloy substrate for high-cap bottle cap and production method thereof

The invention discloses an aluminum alloy substrate for a high-cap bottle cap. The aluminum alloy substrate comprises, by weight, 0.4 percent to 0.8 percent of Si, 0.6 percent to 0.9 percent of Fe, 0.02 percent to 0.04 percent of Cu, no larger than 0.1 percent of Mn, no larger than 0.05 percent of Mg, no larger than 0.1 percent of Zn, no larger than 0.05 percent of Cr, 0.01 percent to 0.03 percent of Ti, no larger than 0.15 percent of impurities and the balance Al. The invention further discloses a production method of the aluminum alloy substrate for the high-cap bottle cap. The production procedure comprises batching, casting, homogenization treatment, hot continuous rolling, cold rolling, heat treatment, cold rolling, stretching bending and straightening and cropping. In the procedure of homogenization treatment, the temperature of homogenization treatment is 550 DEG C to 600 DEGC, and heat preservation time is 6 h to 10 h; in the procedure of cold rolling, cold rolling is carried out on blanks obtained through the hot continuous rolling procedure till the blanks are 0.4 mm to 0.5 mm, then heat treatment is carried out, the temperature of heat treatment ranges from 300 DEG C to 330 DEG C, heat preservation time ranges from 5 h to 9 h, and discharging cooling is carried out. Finally, cold rolling is carried out the blanks till the designed thickness is achieved.

Owner:CHINALCO SWA COLD ROLLING

Efficient simplified wheat flour milling technology and efficient simplified wheat flour milling device

InactiveCN103894260ADoes not destroy nutrientsKeep the scentGrain treatmentsProcess engineeringIndustrial engineering

The invention relates to an efficient simplified wheat flour milling technology comprising the working procedures of shelling, residue grinding, core grinding, tailing grinding and flour clearing, and an efficient simplified wheat flour milling device. In the shelling working procedure, an extrusion cutting grinder with a superior stripping and scraping function is used for replacing the existing tooth roller flour mill and is taken as a main residue making device; in the core grinding working procedure, an efficient impact flour mill is used for replacing a smooth roll flour mill and is taken as a main flour making device, and the grinding function of the efficient impact flour mill is more than twice as high as that of the prior art; two wraps are wetted by water, residue grinding is carried out for three times, and germ extraction is carried out during residue grinding; after the core 1 and the core 2 are slightly ground by a roller mill, the aim of rapidly and efficiently producing the high-quality flour at low temperature with low consumption can be achieved by virtue of a strong impact method of a water cooling efficient impact grinder and the like. The wheat flour milling production line extrusion process designed by the invention is simple in process, low in civil engineering equipment investment, high in production efficiency, simple in operation and management and low in energy consumption; the produced high precision flour is large in proportion; the produced flour is good in edible quality and food production performance; the produced flour has the advantages that the original fragrance of the wheat is maintained by the flour, and the like.

Owner:王洪福

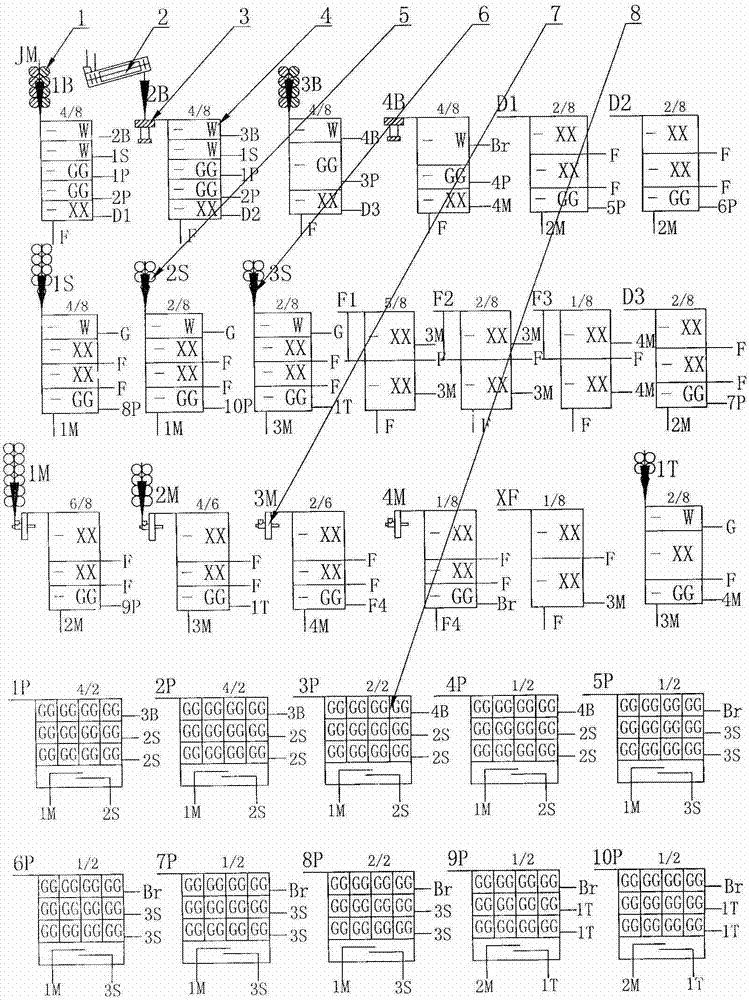

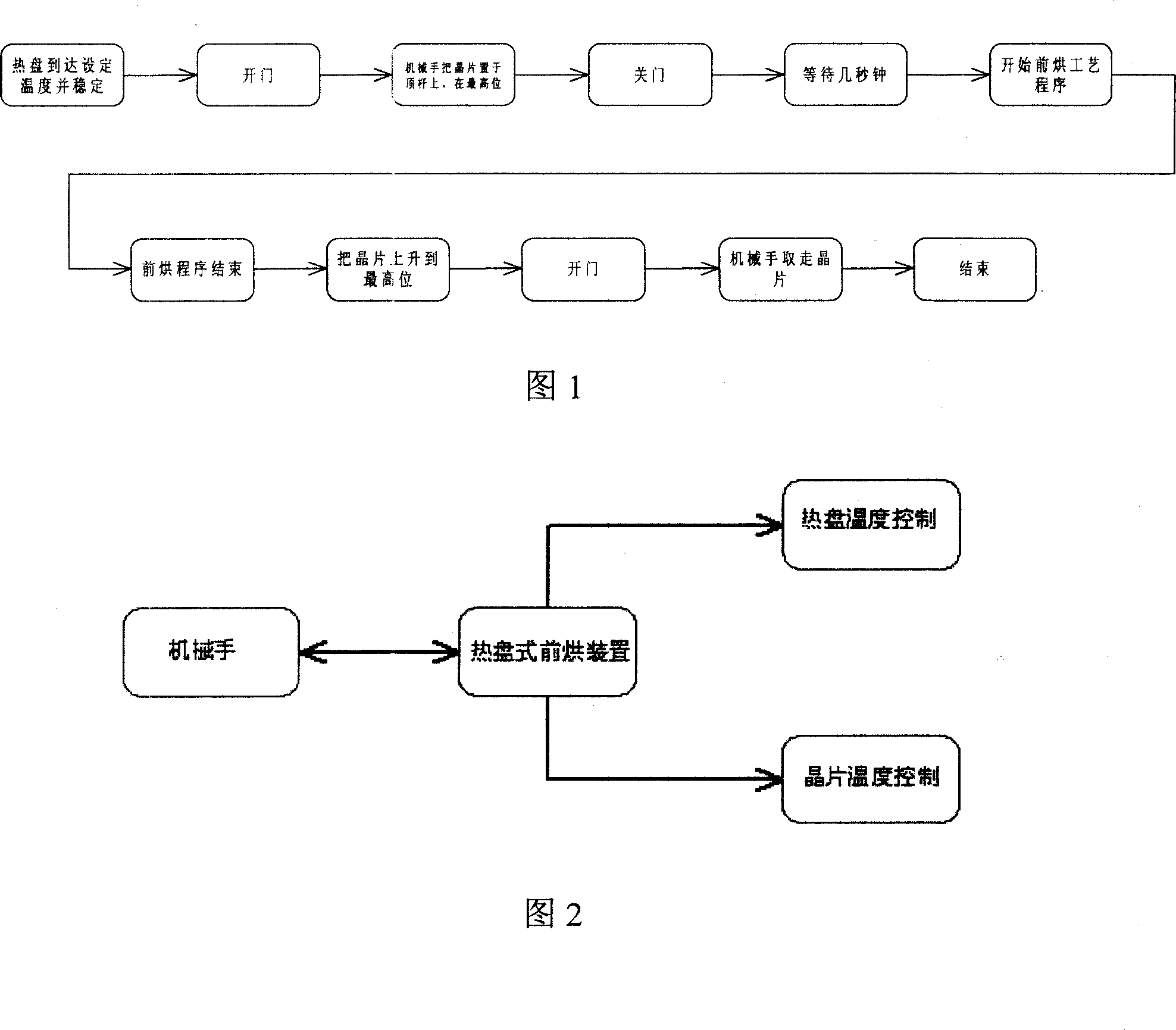

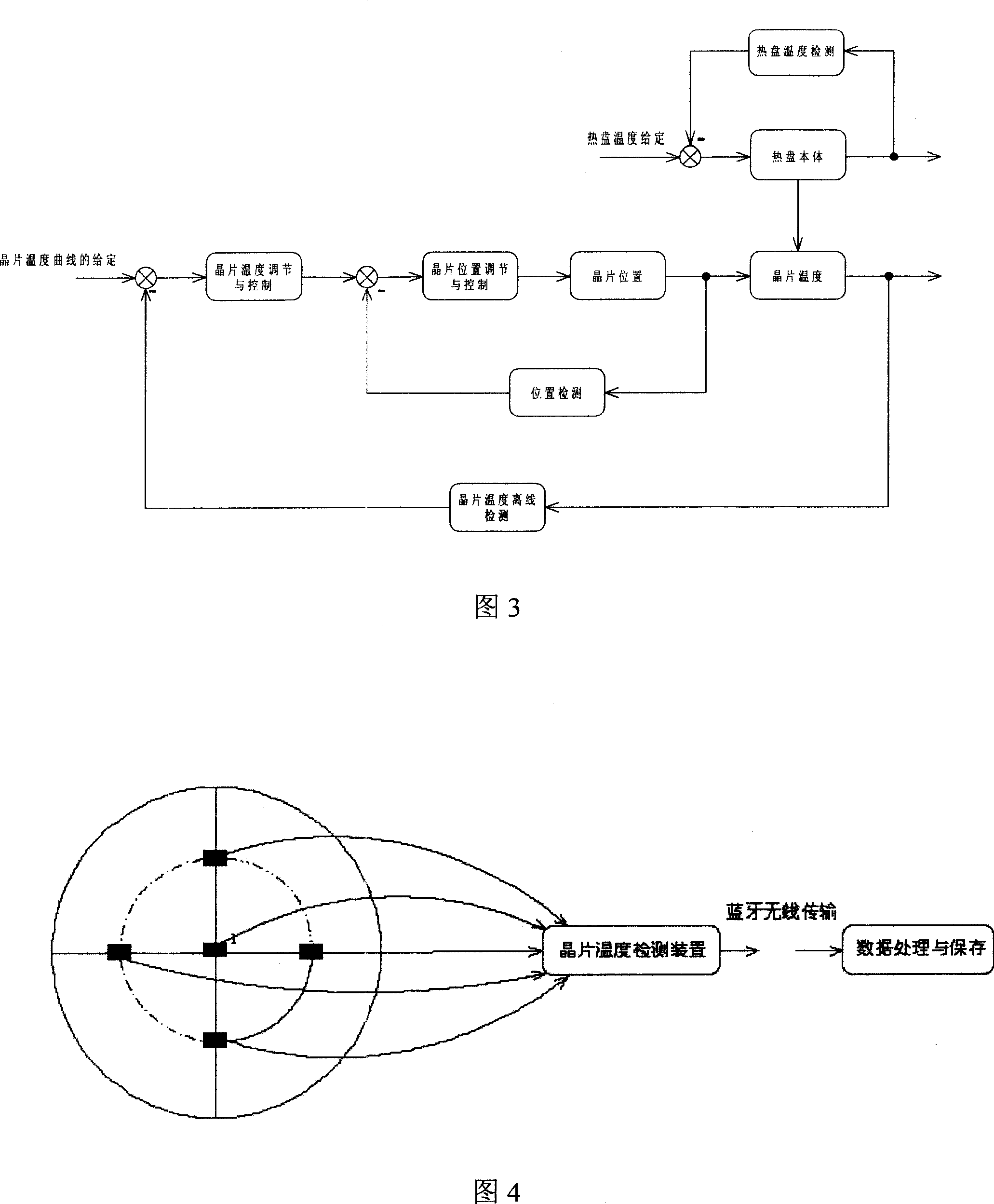

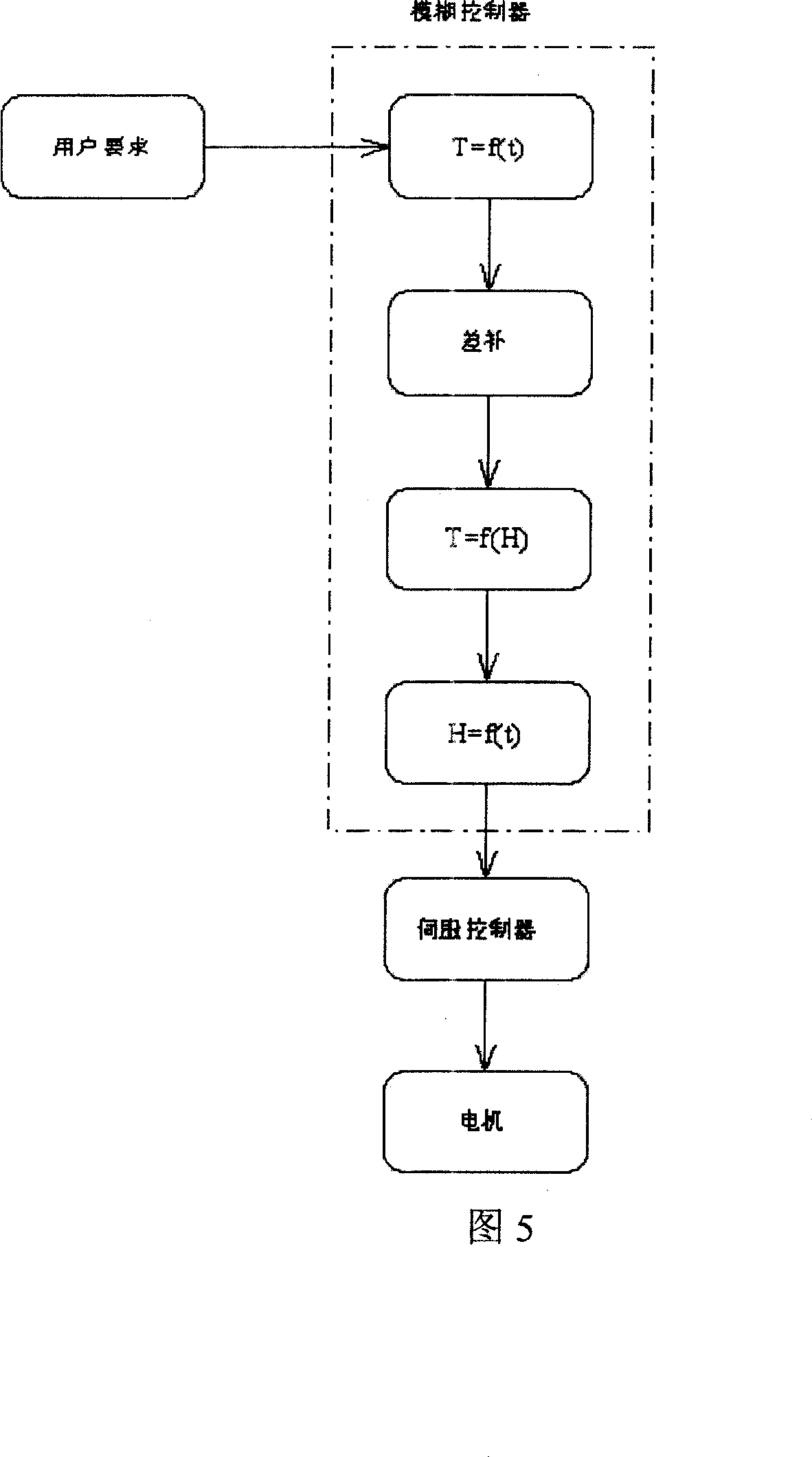

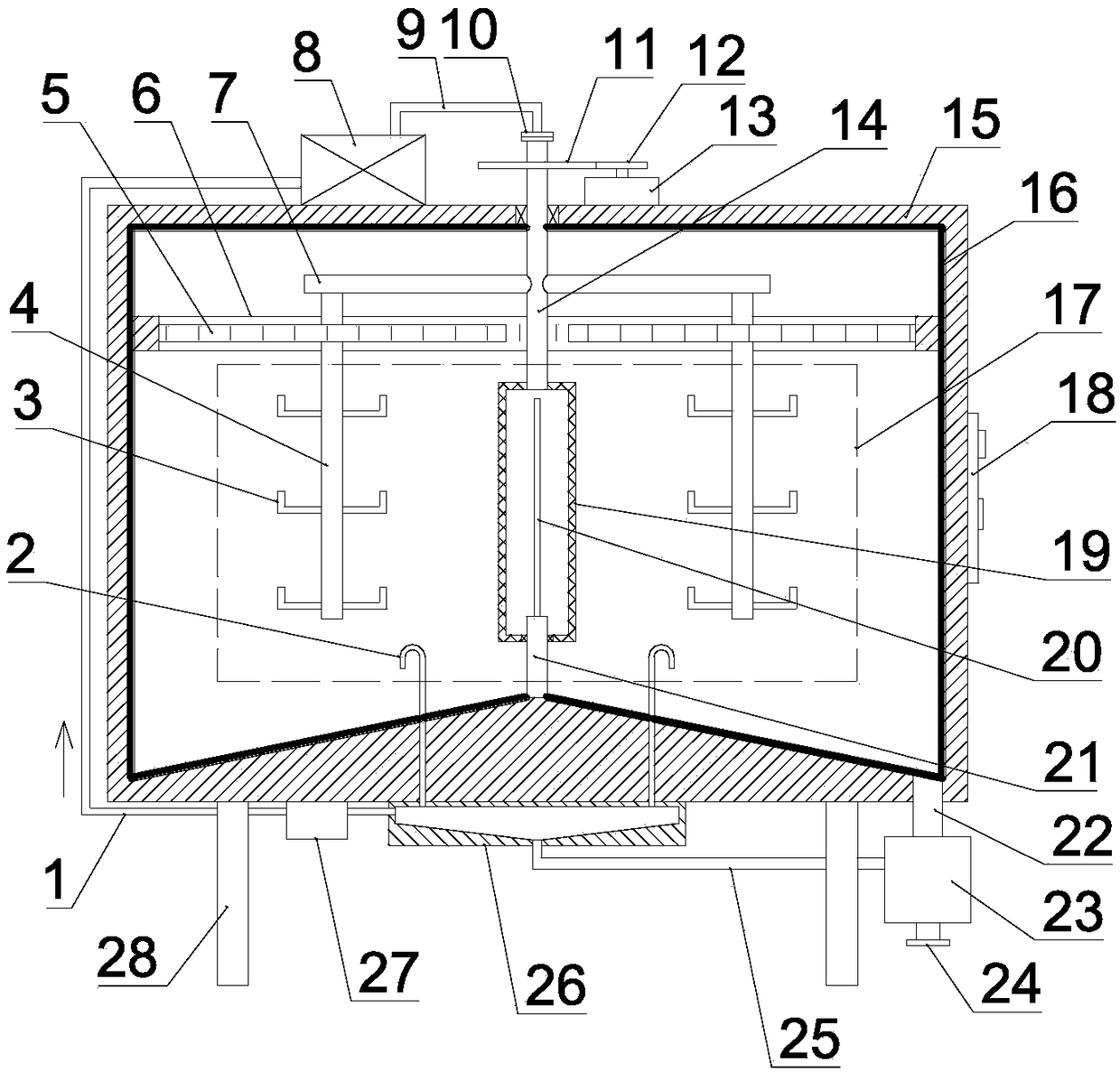

Temperature gradient controllable wafer front-drying method and its hot plate type front drying device

InactiveCN101144988AImprove the baking effectHighly integratedSemiconductor/solid-state device manufacturingPhotosensitive material processingPhotolithographyElectricity

The present invention relates to a prebaking method and a hot disk-type prebaking device for chips, the temperature gradient of the present invention is controllable; the method is through adopting fuzzy control theory and three closed-loop approach of the temperature of a hot disk, the position and temperature of a chip, the position changing of the chip in the hot disk can be accurately traced and the temperature gradient and changing process of a glue film on the chip can be controlled; the device comprises a furnace body, a hot disk body, a heater and a temperature detection device, a chip top rod, a lifting mechanism; the furnace body has an upper cover with an extracting opening and a door for the chip accessing; the hot disk body is arranged in the furnace body; a heater and a temperature detection device are arranged in the hot disk body and connected electrically with the hot-disk temperature controller; the chip top rod is arranged on the hot disk body and the bottom of the chip top rod goes through the hot disk body and to connect the lifting mechanism; the output shaft of the lifting mechanism which is connected with a servo controller by a motor is provided with a coder which is connected with the bottom of the top rod by a leadscrew; the present invention can strictly control temperature, time and warming speed, and can gain the best characteristics of glue film and best lithography effects and finally can produce semiconductor devices with high integration level and high reliability.

Owner:SHENYANG KINGSEMI CO LTD

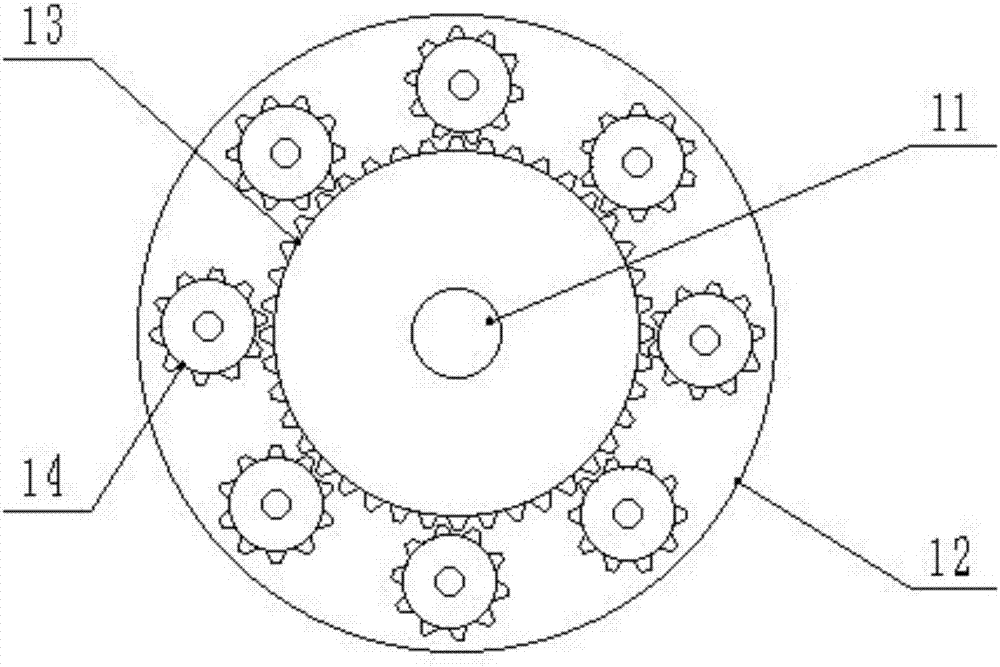

Circulating air oven for food processing

InactiveCN108185833AImprove insulation effectImprove heat utilizationRoasters/grillsCooking & bakingEngineering

The invention discloses a circulating air oven for food processing. The circulating air oven comprises an oven main body, a main rotating pipe is arranged in the middle of the inner side of the oven main body, cross bars are installed on the upper portion of the main rotating pipe, auxiliary rotating rods are installed on the lower sides of the outer ends of the cross bars, gears are installed onthe upper portions of the auxiliary rotating rods, inner gear rings meshed with the gears are correspondingly mounted on the inner wall of the oven main body, and a plurality of hooks are mounted on each auxiliary rotating rod. The upper end of the main rotating pipe is connected with a ventilation pipe through a rotary connector, the other end of the ventilation pipe is connected with a circulating fan, an air inlet of the circulating fan is connected with an air return pipe, and the other end of the air return pipe is connected with the upper portion of the side surface of a sedimentation tank. A uniform air net cylinder is fixedly installed at the lower end of the main rotating pipe, a support rod is mounted at the lower end of the uniform air net cylinder, and a heating rod is mountedat the upper end of the support rod. According to the circulating air oven for food processing, circulating ventilation is achieved, the baking effect is good, energy is saved, the environment is protected, and popularization is facilitated.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Temperature and humidity control algorithm for intensive curing barn controller

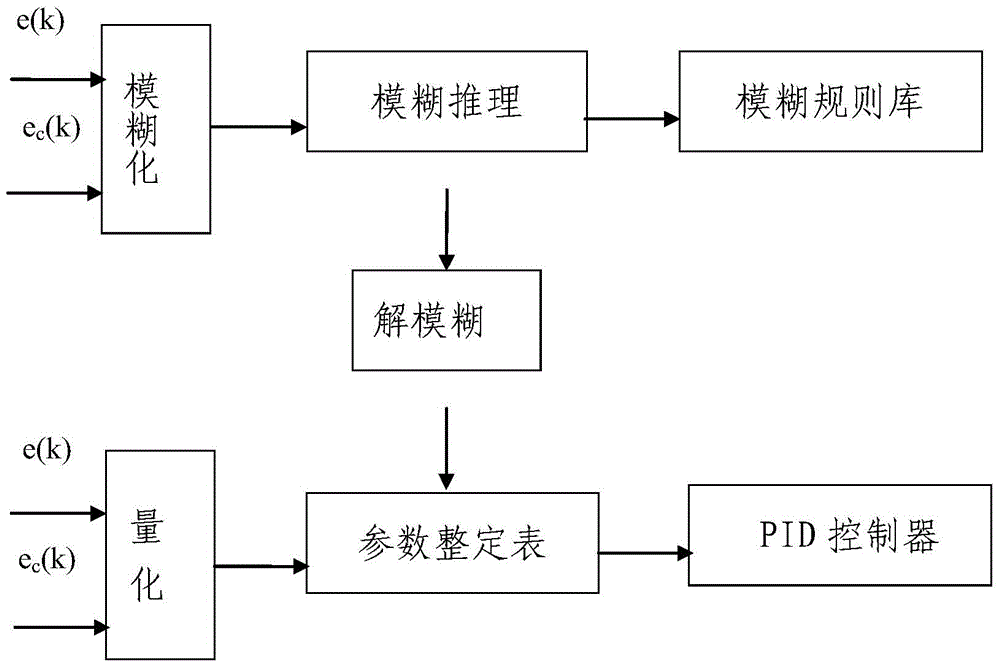

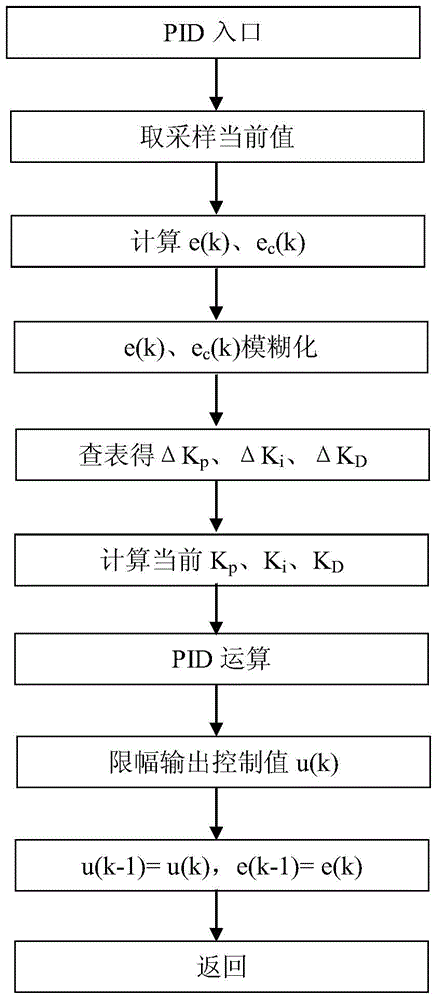

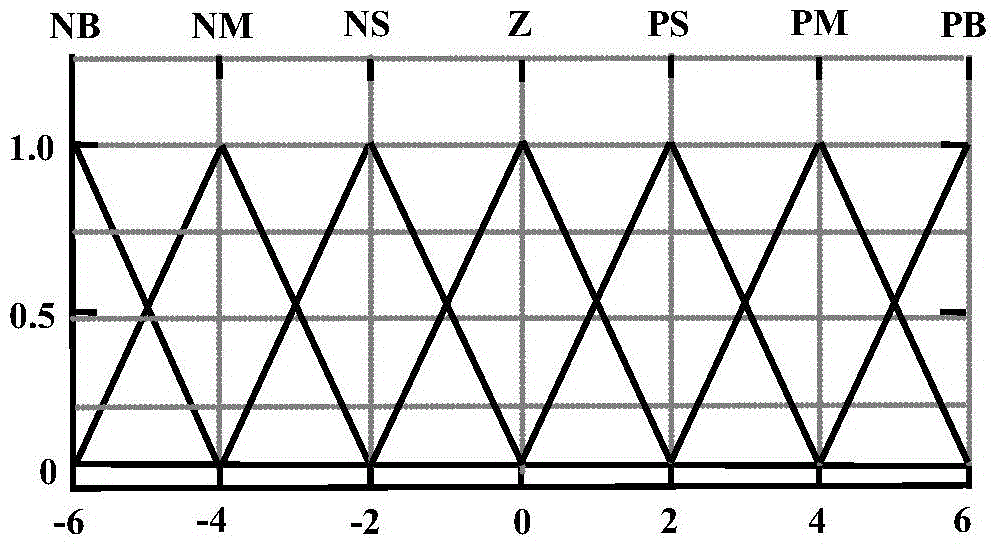

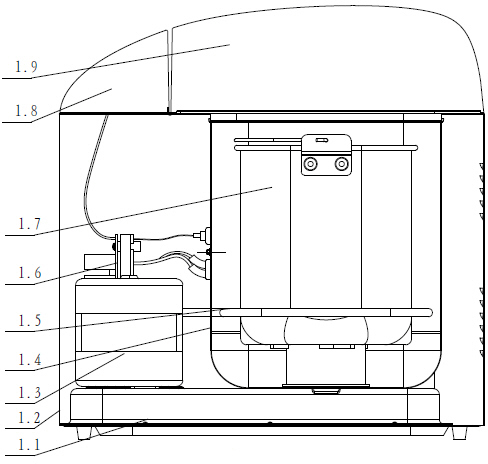

InactiveCN104375415AImprove the baking effectExtended opening timeSimultaneous control of multiple variablesAdaptive controlProportion integration differentiationOptimal control

The invention discloses a temperature and humidity control algorithm for an intensive curing barn controller and relates to the technical field of environmental control in facility agriculture. Optimized PID (proportion integration differentiation) algorithm is used, and accurate control of temperature and humidity is realized by a controller. The controller comprises a PID controller, a relay link and a fuzzy controller for calibrating PID parameters; the PID controller completes control algorithm and calculates the control amount of output; initial parameters of the PID controller are achieved through the relay link; the fuzzy controller conducts online and real-time adjustments of the PID parameters of KP, Ki and KD according to deviation e and deviation rate of change ec so that the PID controller has adaptive capacity, and the system is always in an optimal control state. The temperature and humidity control algorithm for the intensive curing barn controller has the advantages of calculating parameters and variation amount of various environmental conditions in a curing barn, realizing accurate control of the temperature and humidity of the curing barn, and the like. Furthermore, the temperature and humidity control algorithm for the intensive curing barn controller can be used as a temperature and humidity controller in an intensive curing barn in domestic regions of any different latitude to conduct algorithm.

Owner:长沙瑞和数码科技有限公司

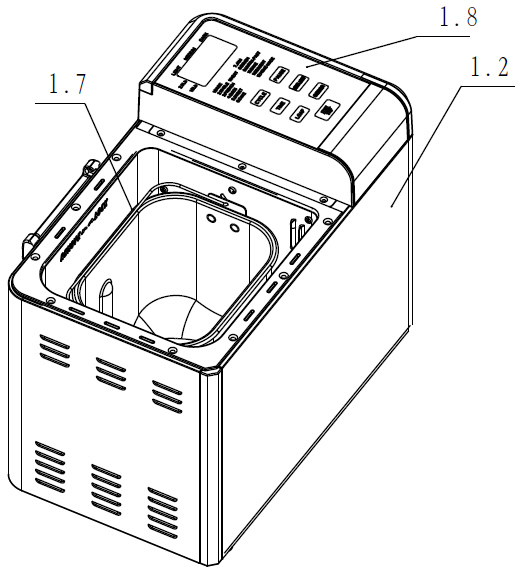

Hot air heating bread maker

InactiveCN102068210AImprove securityImprove the safety of useRoasters/grillsBaking plantsCooking & bakingProcess engineering

The invention discloses a hot air heating bread maker, which comprises a shell, a baking chamber, a heating tube, a bread barrel, a controller and an upper cover, wherein the baking chamber is formed in a hollow cavity formed on the shell; the bread barrel is arranged in the baking chamber; the upper cover is arranged at the top of the bread barrel; the controller is electrically connected with the heating tube; a heating chamber is formed outside the baking chamber; the heating tube is arranged in the heating chamber; a centrifugal drive fan is arranged on one side of the heating tube and on an output shaft of a drive motor; the controller is electrically connected with the drive motor; and the sidewall, connected with the heating chamber, of the baking chamber is provided with heating chamber air inlets and heating chamber air outlets which are communicated with one another. The heating tube in the baking chamber of the bread maker cannot be seen by a user, so that the user is ensured not to contact a heating body in the process of operating the bread barrel, the utilization safety of the bread maker is improved and a better bread baking effect can be achieved. Bread baked by the hot air heating bread maker has thin crust, and the surface of the bread is uniformly colored.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Efficient tea parching machine

InactiveCN104824185AImprove baking effect and work efficiencyEvenly heatedPre-extraction tea treatmentElectric heatingElectricity

The invention discloses an efficient tea parching machine comprising a main part, a screw stirrer and a sprayer. The main unit is internally provided with an electric heating layer; the electric heating layer evenly covers the inner wall of the main part; the upper left of the main part is provided with a feed hopper; a connection of the feed hopper and the main part is provided with an electromagnetic valve; the internal axial position of the main part is provided with the screw stirrer. The efficient tea parching machine allows tea leaves to be well parched, allows the tea leaves to be evenly heated during parching, is good in parching effect and high in operating efficiency, allows the quality of the tea leaves to be protected from decline caused by excess heating of the tea leaves during parching, allows good moisture and dust removal, is higher in parching effect, protects the environment and allows automatic discharging, thus greatly reducing labor intensity and improving work efficiency.

Owner:江苏安特佳信息科技有限公司

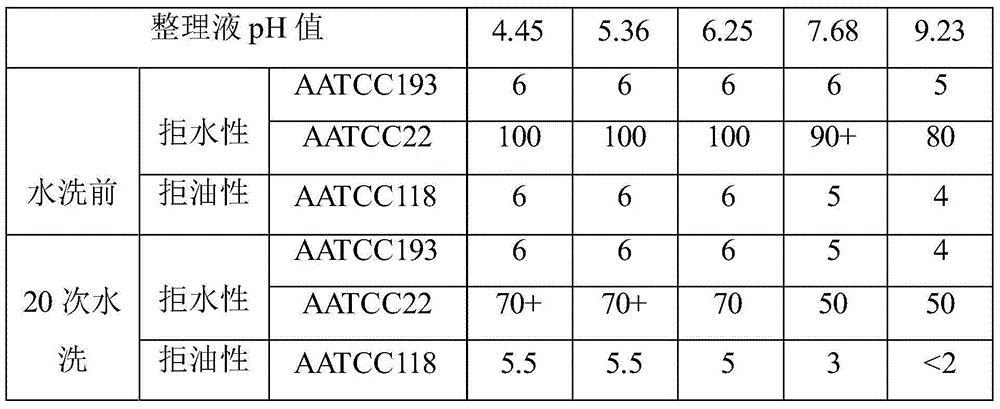

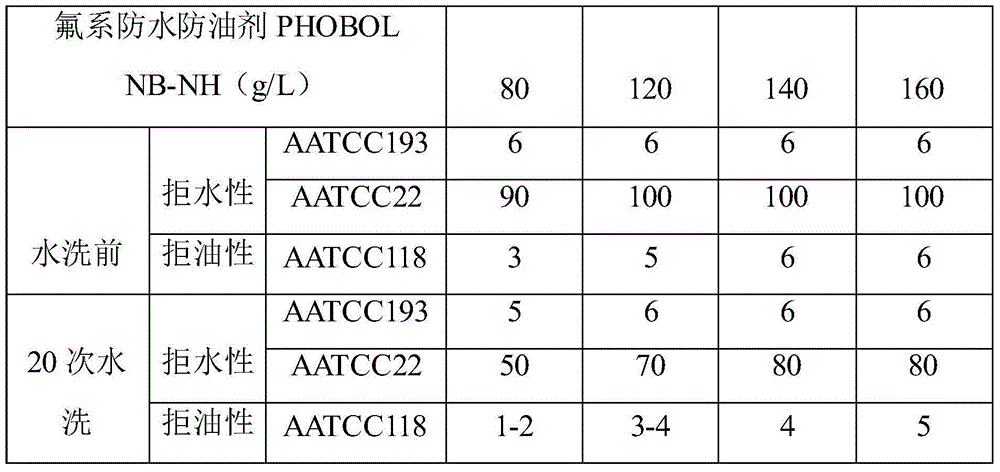

Processing method for chemical-preventing fabric

ActiveCN104963188AImprove permeabilityImprove breathabilityShrinkingLiquid/gas/vapor removalCooking & bakingYarn

The invention discloses a processing method for chemical-preventing fabric, and belongs to the technical field of textile industry. The method is carried out on the basis of gray fabric woven from pure cotton yarns or polyester cotton yarns, and comprises the processes of blank inspection, seam overturning, singeing, cold batching, short steaming, washing and dyeing. The method is characterized by also comprising the steps of A, open-width washing, B, chemical-preventing arrangement, C, preshrinking treatment, and D, baking. The chemical-preventing fabric processed by the method has a function of preventing sulfuric acid, hydrochloric acid, nitric acid and caustic soda, has a good function of preventing chemical solvents such as o-xylene, methyl alcohol and acetone, and meets an EN14325 chemical-preventing standard.

Owner:HEBEI NINGFANG GRP

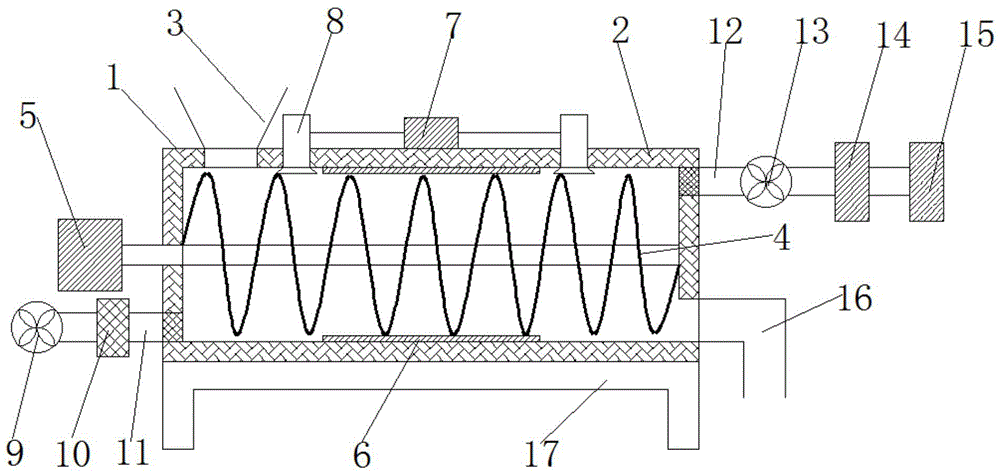

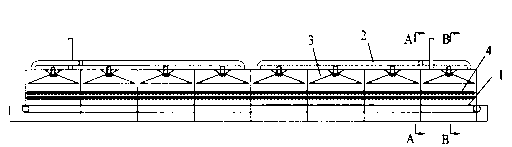

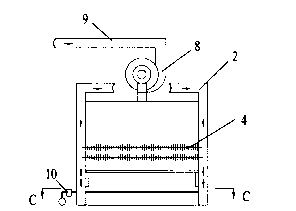

Yarn drying oven

InactiveCN102865726ADry evenlyAvoid wet and dry situationsDrying gas arrangementsLiquid/gas/vapor removalYarnCooking & baking

The invention relates to yarn drying equipment, in particular to a yarn drying oven. The yarn drying oven comprises a drying chamber (3), a conveying belt (1), a heat exchanger (4), an air collection pipe (2), a fan (8) and an air exhaust pipe (9), wherein the conveying belt (1) is positioned at the lower part of the yarn drying oven and penetrates through the drying chamber (3); the heat exchanger (4) is arranged at the upper part of the conveying belt (1) and is positioned in the drying chamber (3); the air collection pipe (2) is positioned at the two sides of the drying chamber (3) and is connected with the air exhaust pipe (9) through the fan (8) at the upper part of the drying chamber (3); a dispersion cover (5), an impeller (6) and a motor (7) which is used for driving the impeller (6) are arranged at the upper part of the drying chamber (3); and the impeller (6) is positioned below the dispersion cover (5) and the motor (7) is positioned above the dispersion cover (5). The yarn drying oven is simple in structure, can uniformly distribute dry air and has good yarn baking effect, good yarn baking uniformity and good quality of baked yarns.

Owner:CHANGZHOU POLYACE TEXTILE & YARN

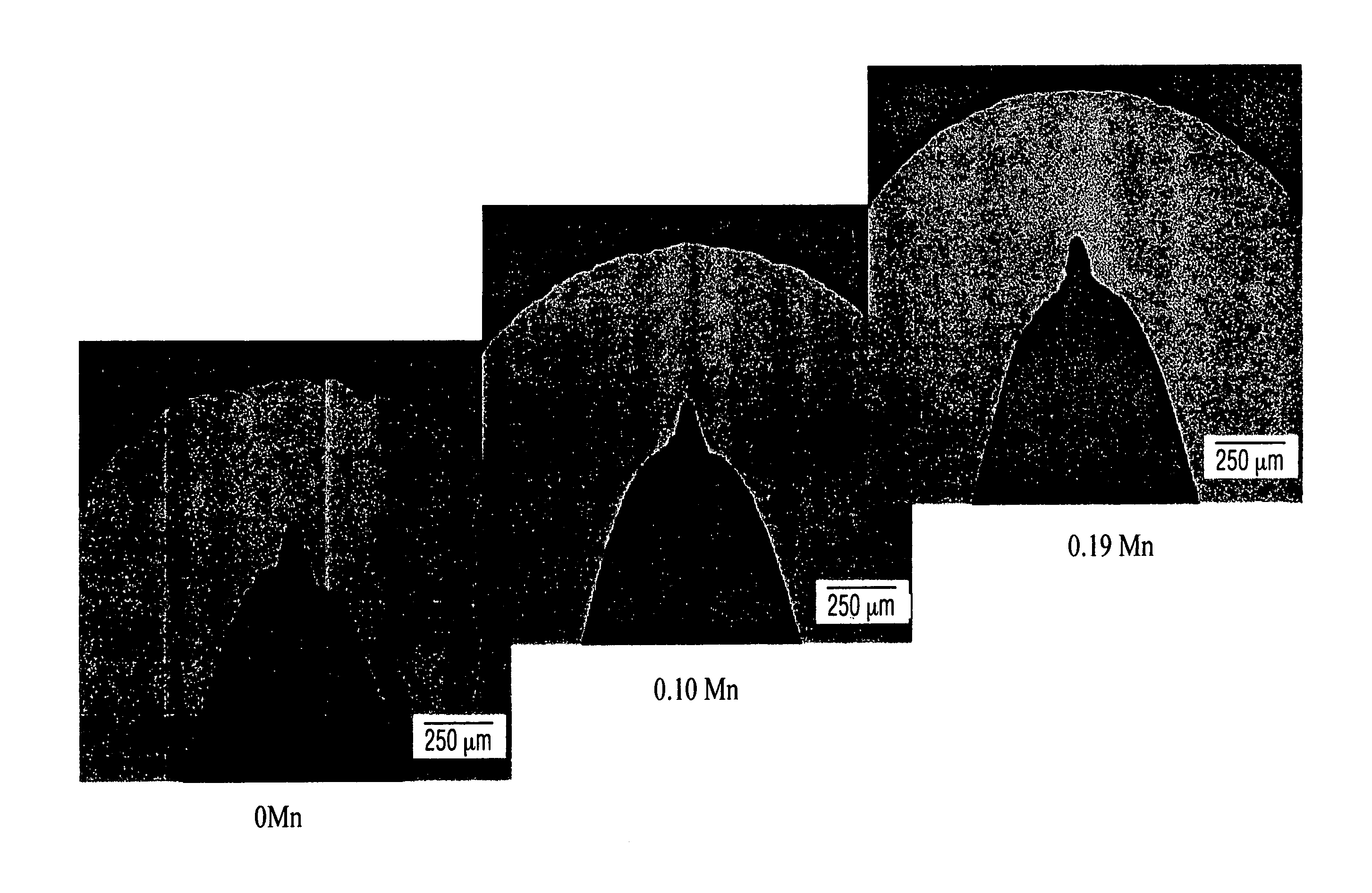

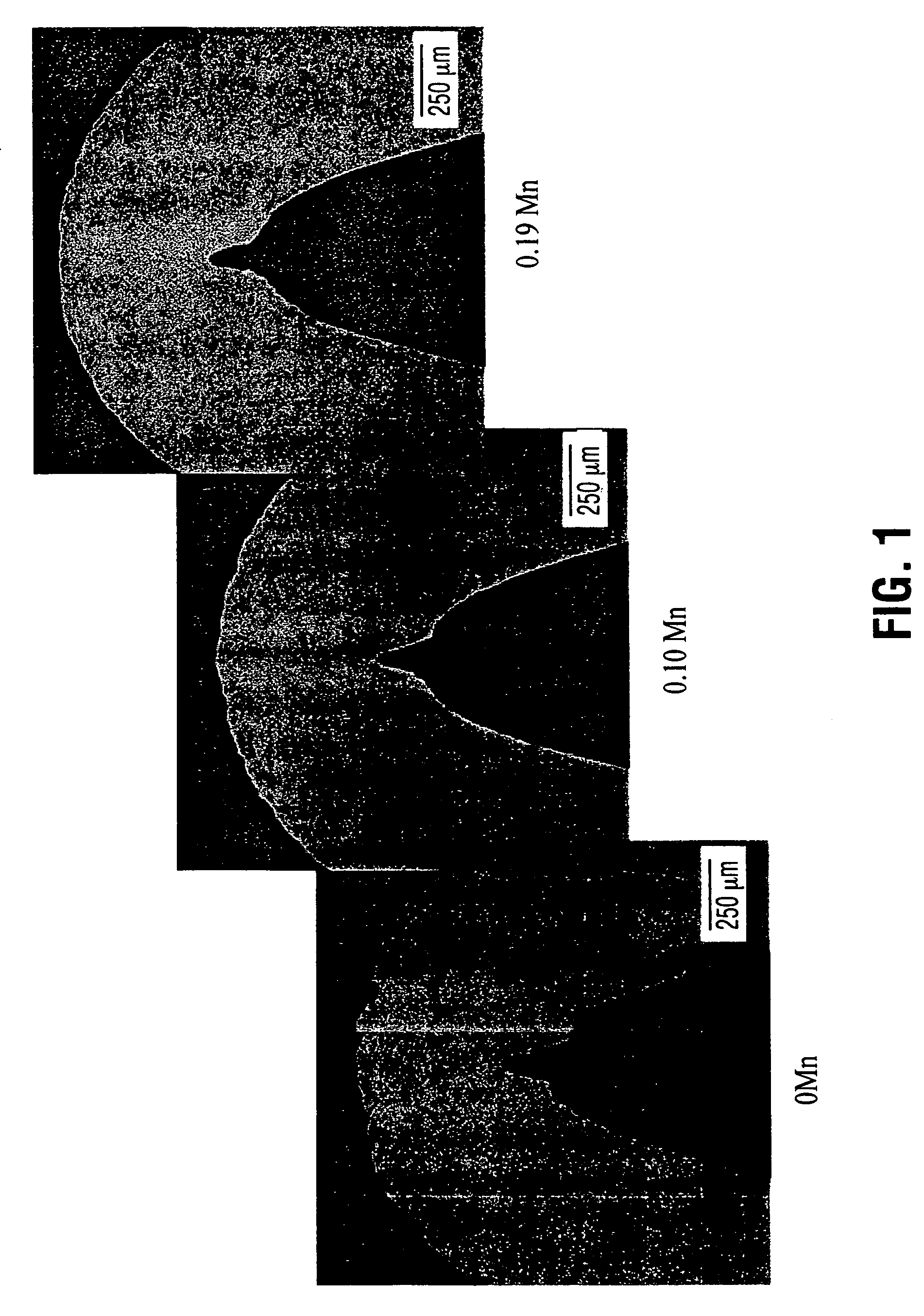

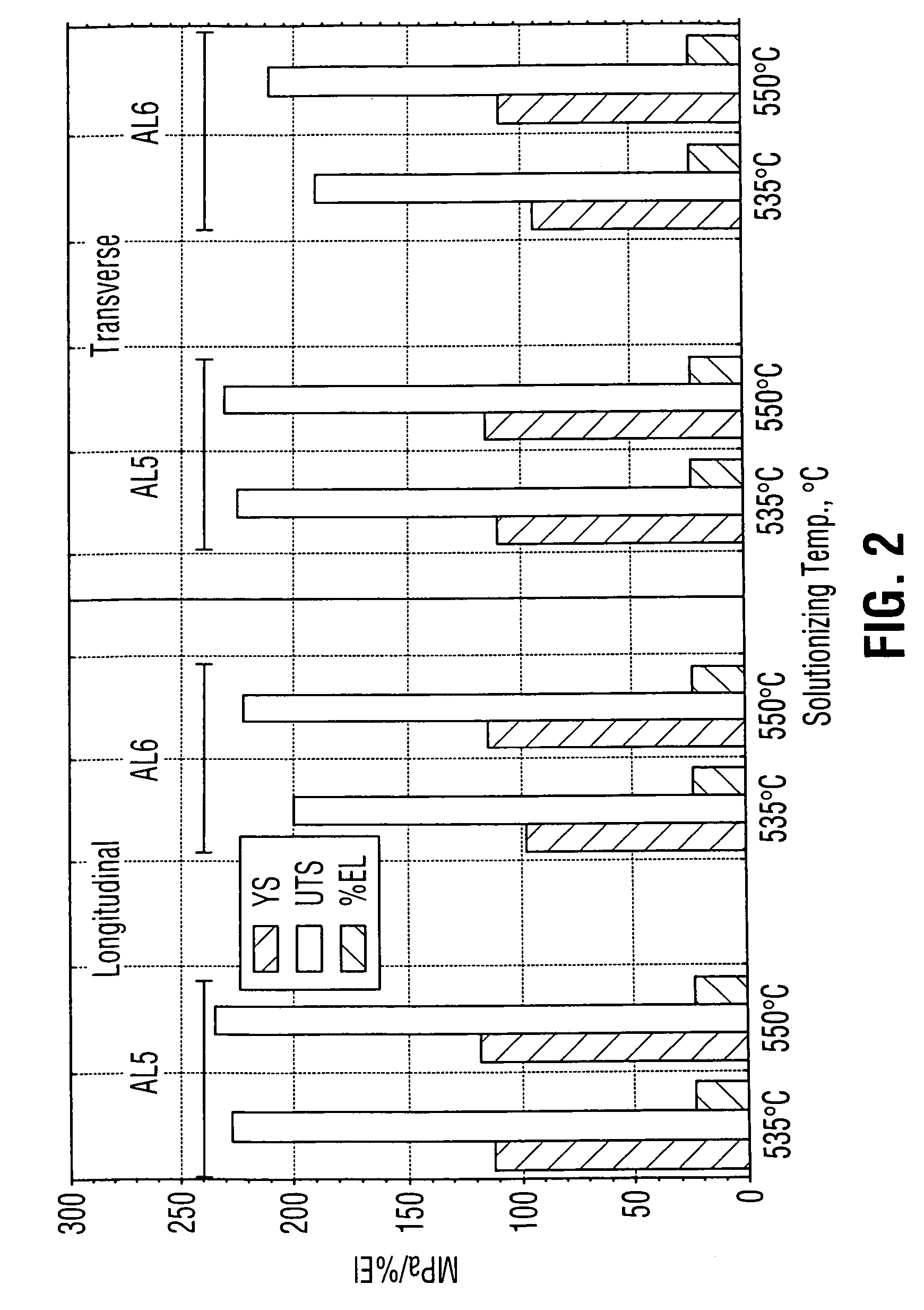

Process for making aluminum alloy sheet having excellent bendability

A process is described for producing an aluminum alloy sheet having excellent bendability for use in forming panels for automobiles. An aluminum alloy containing 0.50 to 0.75 by weight Mg, 0.7 to 0.85% by weight Si, 0.1 to 0.3% by weight Fe, 0.15 to 0.35% by weight Mn, and the balance Al and incidental impurities, is used and is semi-continuously cast into ingot. The cast alloy ingot is subjected to hot rolling and cold rolling, followed by solution heat treatment of the formed sheet. The heat treated sheet is quenched to a temperature of about 60–120° C. and the sheet is then coiled. This coil is then pre-aged by slowly cooling the coil from an initial temperature of about 60–120° C. to room temperature at a cooling rate of less than 10° C. / hr.

Owner:NOVELIS INC

Lithium battery baking oven

InactiveCN106813464AReduction of blocked surfacesStable hot air circulationFinal product manufactureDrying gas arrangementsFiberTemperature control

The invention discloses a lithium battery round baking oven, which comprises a case and an oven body arranged in the case, wherein the oven body uses a round structure; a heater and a heat insulation layer are arranged on the inner wall of the case; an air inlet opening and an air outlet opening are formed in the top of the case; a blower device positioned on the top of the oven body is arranged in the case, and is connected with a motor; when the blower device is driven by the motor, eddy current is generated between the case and the oven body; after a plurality of exhaust holes are formed in the oven body, high-speed flowing hot air is formed in the oven body, so that each corner in the oven body can receive heat radiation; in addition, the heated condition is uniform; the baking effect is greatly improved. A certain number of adsorbent fiber materials are arranged on the inner wall of the oven body. The lithium battery round baking oven has the characteristics that the battery temperature can fast reach the process baking temperature; drying and dewatering are performed; the cost is lower; the humidity and temperature control on the external environment is not needed; the equipment and the energy sources are saved; the baking cost is reduced.

Owner:陕西融泰企业管理咨询有限公司

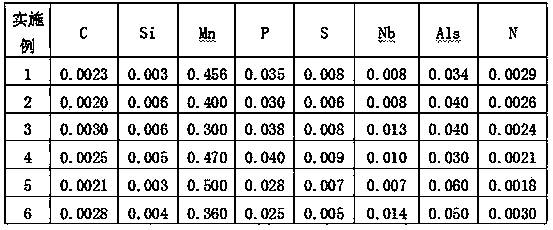

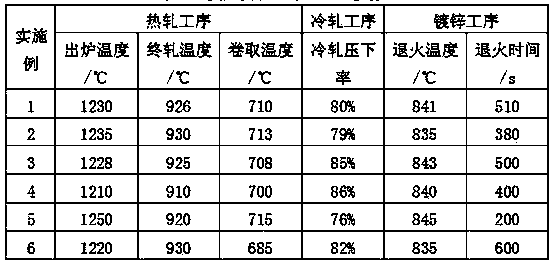

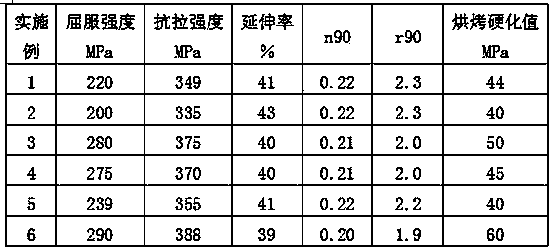

Galvanized bake hardening steel and production method thereof

InactiveCN104213020AImprove stamping effectImprove the baking effectHot-dipping/immersion processesChemical compositionEconomic benefits

The invention discloses galvanized bake hardening steel and a production method thereof. The production method comprises procedures of hot rolling, cold rolling and galvanizing; a substrate comprises the following chemical components in percentage by weight: 0.002-0.003% of C, Si not higher than 0.006%, 0.3-0.5% of Mn, 0.025-0.040% of P, S not higher than 0.009%, 0.007-0.014% of Nb, 0.030-0.060% of Als, N not higher than 0.0030%, and the balance of Fe. The chemical components are designed, and the technological parameters of the hot rolling, cold rolling and galvanizing procedures are adjusted and optimized, so that the Nb-contained bake hardening steel for deep drawing with excellent comprehensive performance can be successfully produced without adding other alloy elements; the substrate produced by the method is easily galvanized; and the galvanized bake hardening steel with excellent surface quality can be produced. A galvanized plate produced by the method has such characteristics as proper yield strength, high n value (strain hardening index) and r value (plastic strain ratio) and good bake hardenability; and meanwhile, the alloy content is reasonably matched, the production cost is reduced, and the considerable economic benefit is brought to enterprises.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Oven with drying function

ActiveCN110840279AAvoid the influence of windBlock downward movementRoasters/grillsThermodynamicsEngineering

The invention relates to an oven with a drying function. The oven with the drying function comprises an inner liner, wherein an exhaust opening is formed in a top plate of the inner liner; the exhaustopening is in fluid communication with an exhaust passage with an exhaust fan; a hot air baffle plate with a first air inlet and first air outlets is arranged at the lower part of the inner liner; alower hot air chamber is defined by the hot air baffle plate and the bottom plate of the inner liner; a centrifugal fan blade is arranged in the hot air chamber; a lower heating pipe is arranged on the outer periphery of the centrifugal fan blade; an air flow cover with second air inlets and second air outlets is arranged on the first air inlet of the hot air baffle plate in a covering way; an axial flow fan blade is arranged in a flow dividing space defined by the air flow cover and the hot air baffle plate; and the axial flow fan blade and the centrifugal fan blade are in coaxial arrangement. The hot air circulation in the vertical direction is formed in the inner liner; the treatment efficiency on water vapor in the inner liner is improved; further, the oven provided by the invention can achieve a better baking effect when being used for cooking food with a high moisture content; and meanwhile, the oven can fast discharge the water vapor in the inner liner, so that the oven is alsosuitable for being used for baking dry food.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

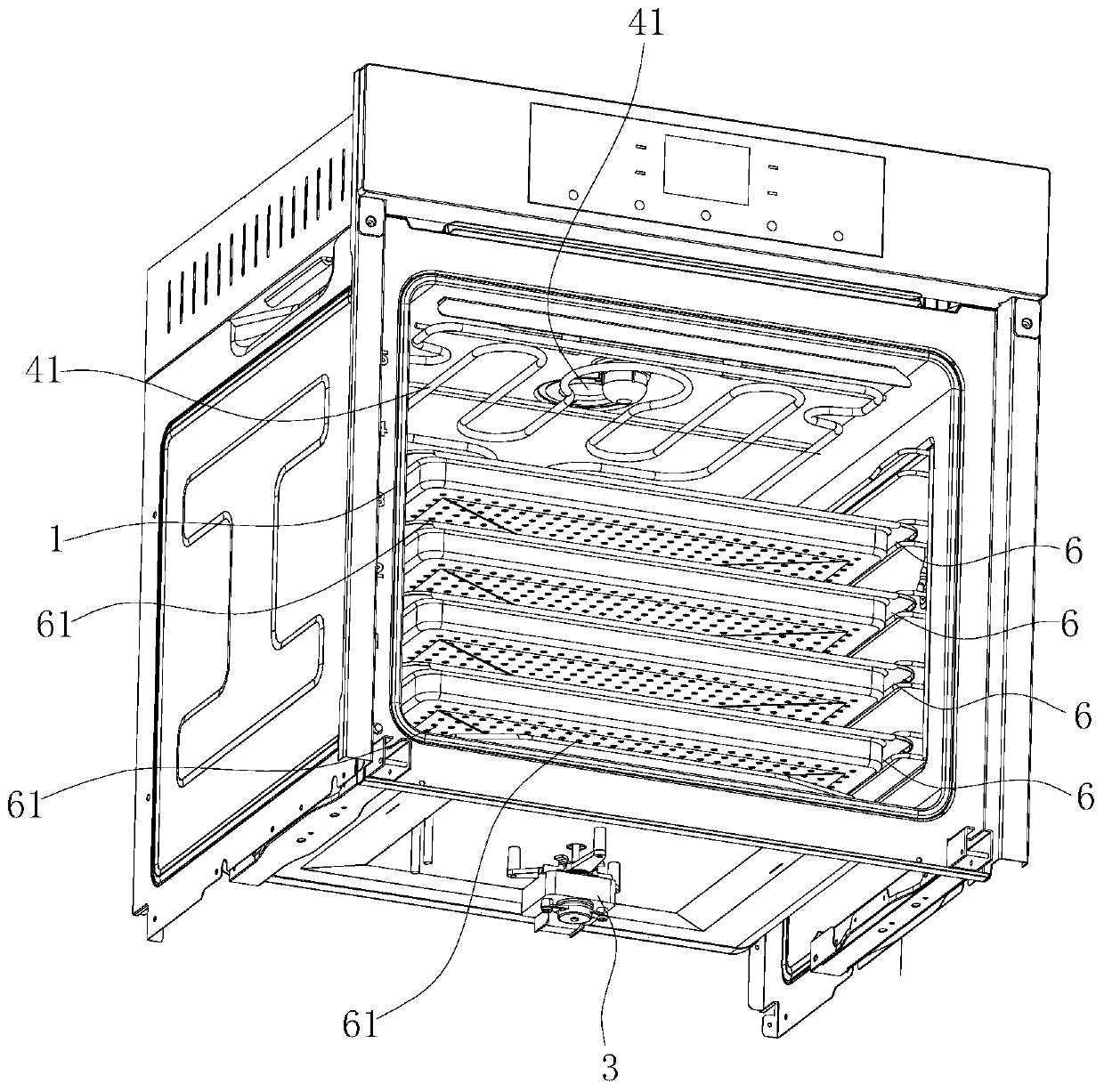

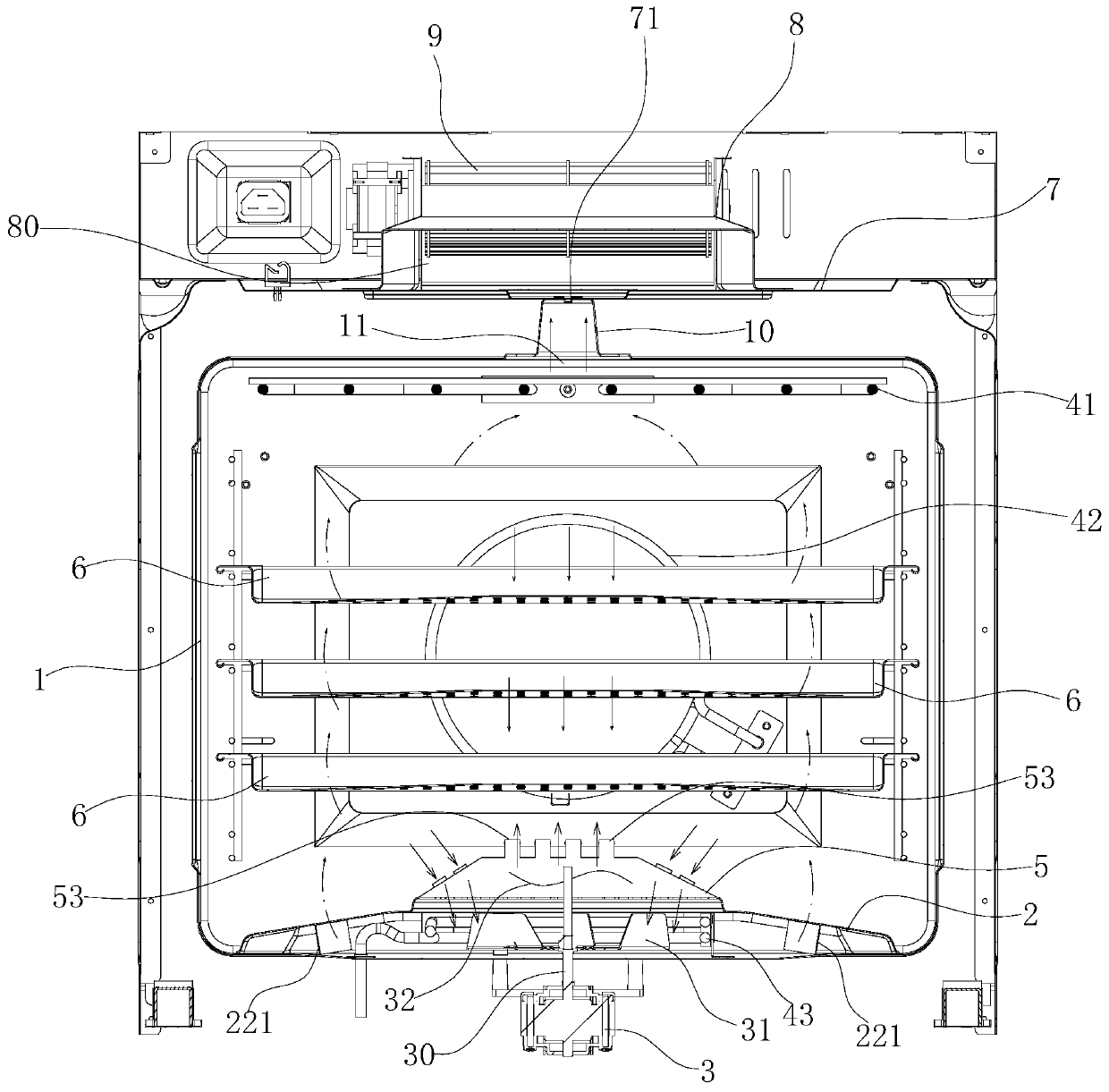

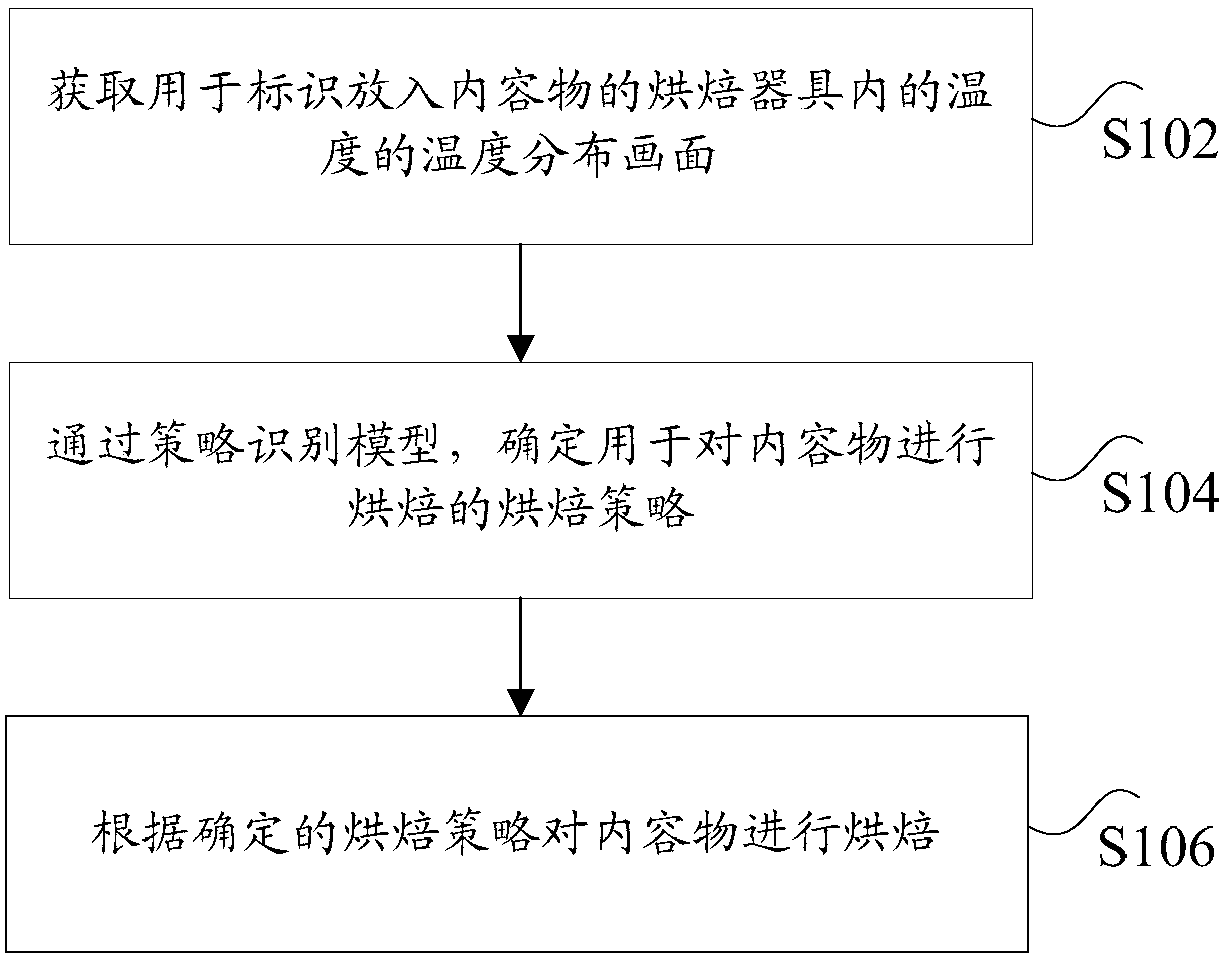

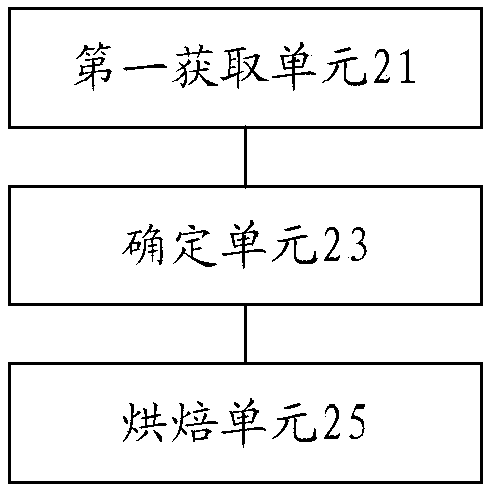

Baking method and device

ActiveCN107752794AEffective closed-loop controlPrecise closed-loop controlCharacter and pattern recognitionRoasters/grillsProcess engineeringComputer science

The invention discloses a baking method and device. The baking method comprises the steps of obtaining a temperature distribution picture used for identifying the temperature of the interior of a baking utensil in which content is put; determining a baking strategy used for baking the content through a strategy identifying model, wherein the strategy identifying model is obtained by using multiplesets of data to conduct machine learning and training, and each set of data of the multiple sets of data comprises the corresponding temperature distribution picture and the corresponding baking strategy for baking the content corresponding to the temperature distribution picture; baking the content according to the determined baking strategy. The technical problem in the related art that bakingequipment is not intelligent enough is solved.

Owner:GREE ELECTRIC APPLIANCES INC

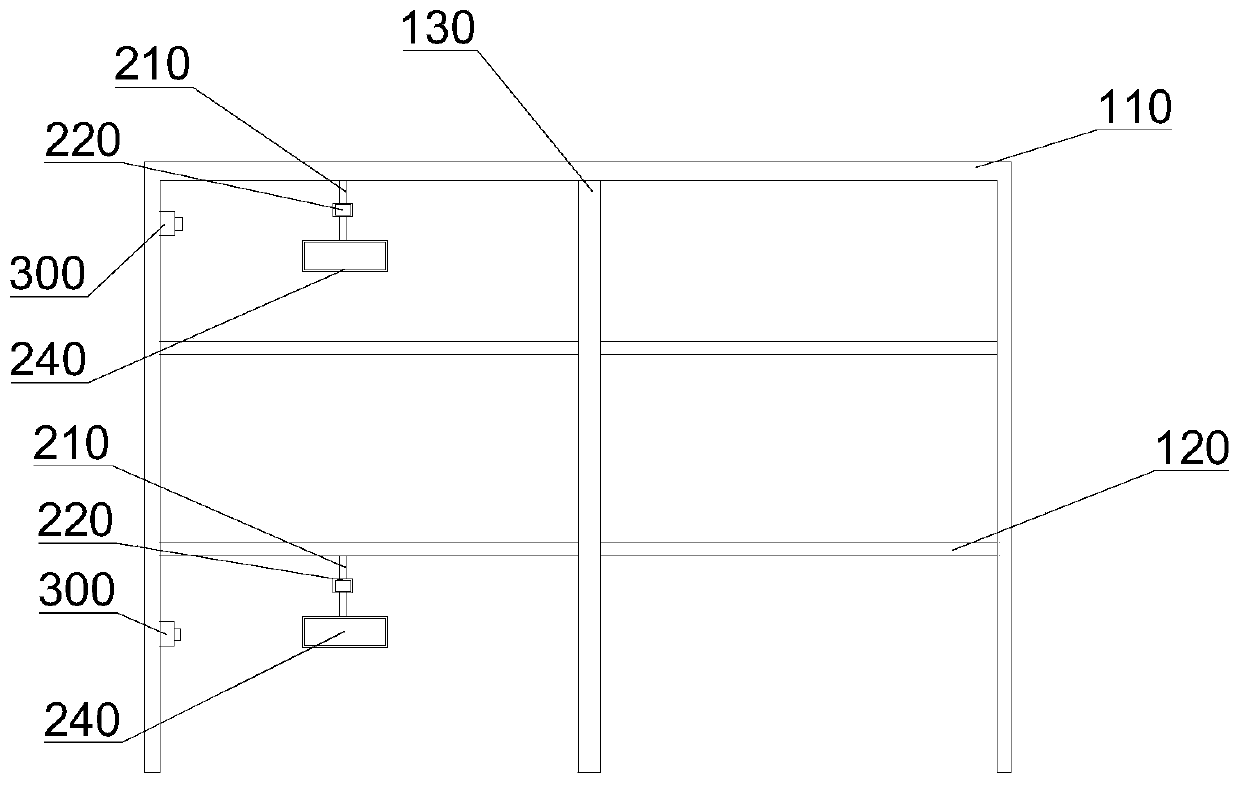

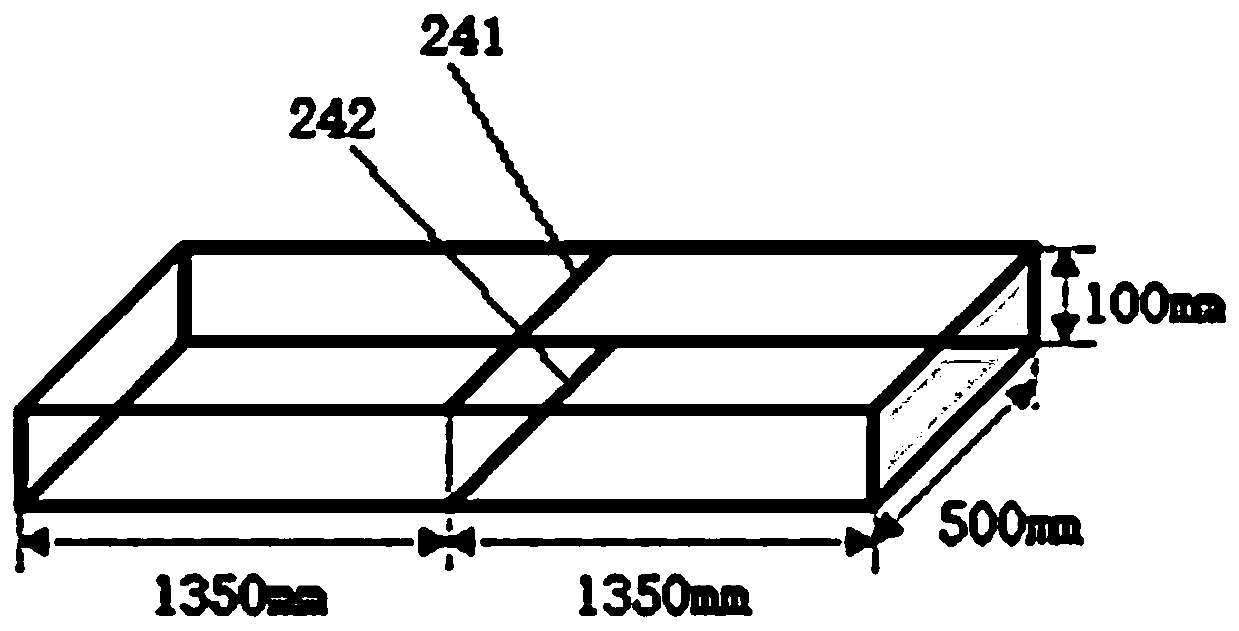

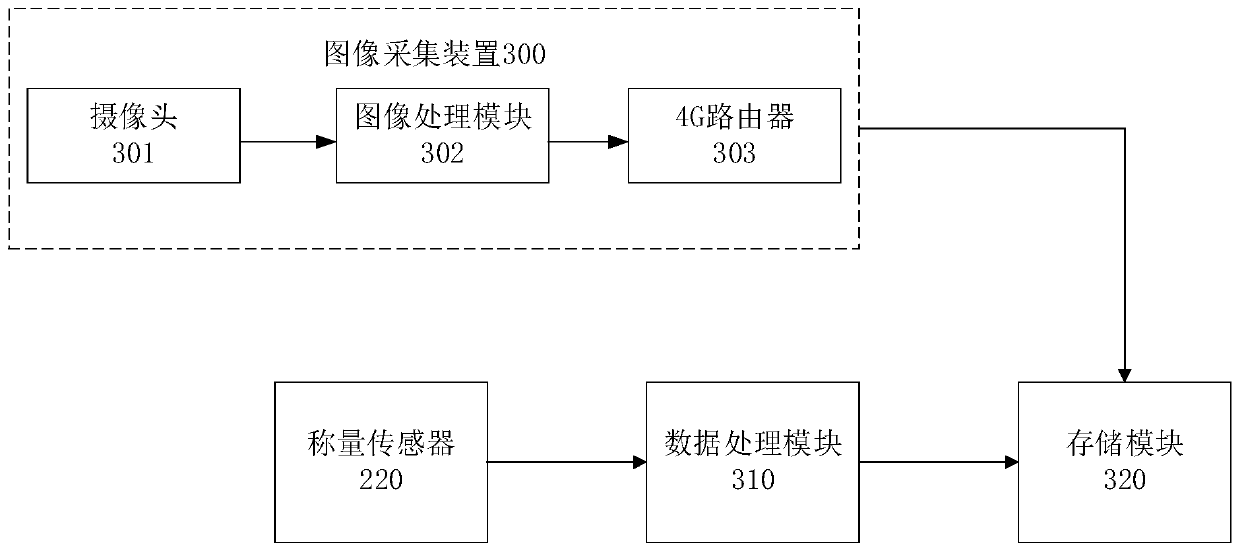

Tobacco leaf curing method based on image acquisition and moisture change

ActiveCN111406968AReduce baking laborImprove the baking effectWeighing by removing componentTobacco preparationCuring of tobaccoTobacco water

The invention discloses a tobacco leaf curing method based on image acquisition and moisture change, which comprises the following steps: S100, respectively installing image acquisition devices on theside walls of a ceiling and a bottom shed of a curing barn, respectively hanging a tobacco leaf water loss rate measuring device on a ceiling cross rod and a bottom shed cross rod, and hanging a plurality of rods of tobacco leaves to be cured in a tobacco leaf hanging frame; S200, enabling the weighing sensor to obtain the mass of the tobacco leaves to be baked every 30 minutes, calculating the water loss rate of the tobacco leaves according to the obtained real-time mass of the tobacco leaves, enabling the image collecting device to obtain images of the tobacco leaves to be baked every 1 hour and correspondingly store the images and the water loss rate of the tobacco leaves according to the obtaining time sequence, and obtaining tobacco leaf image-tobacco leaf water loss rate data; and S300, obtaining the tobacco curing process according to the tobacco image-tobacco water loss rate data. The tobacco flue-curing process with a good overall flue-curing effect is obtained by accuratelymeasuring the change of the moisture content of tobacco leaves in a flue-curing barn, matching with a real-time image acquisition device and integrating image information and water loss rate information.

Owner:YUNNAN TOBACCO CORP QUJING BRANCH

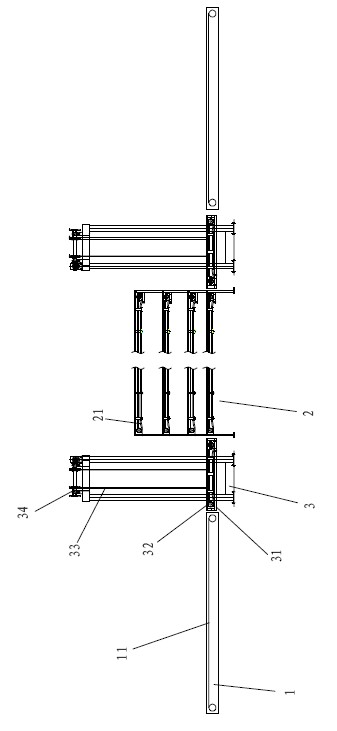

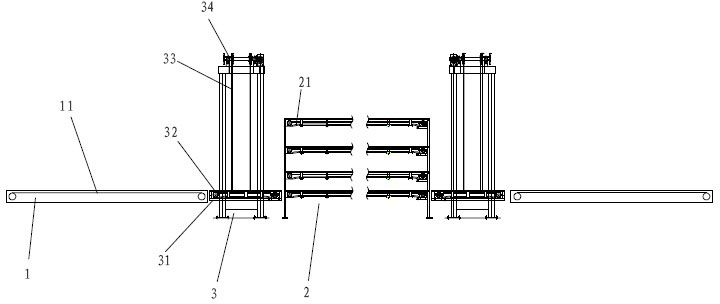

Multilayered baking oven system

ActiveCN102589264AImprove baking efficiencyImprove feeding efficiencyDrying chambers/containersDrying machines with progressive movementsProcess engineeringEngineering

A multilayered baking oven system comprises a conveying portion and a baking oven communicated with the conveying portion. At least two layers are arranged inside the baking oven from top to bottom, and the conveying portion is connected with the baking oven by a lifting system. The multiple layers of the baking oven can run simultaneously, a plurality of workpieces are baked at the same time, and baking efficiency of the baking oven is effectively improved; the conveying portion conveys the workpieces into the baking oven, manual intervention of operators is omitted, conveying efficiency is improved, and labor cost is also lowered; and heating temperature inside the baking oven is uniform, and a baking effect is good.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com