Temperature and humidity control algorithm for intensive curing barn controller

A technology of temperature and humidity control and dense curing barn, applied in the direction of adaptive control, general control system, non-electric variable control, etc., can solve the problems of low control precision, difficult to guarantee the quality of tobacco leaf curing, extensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

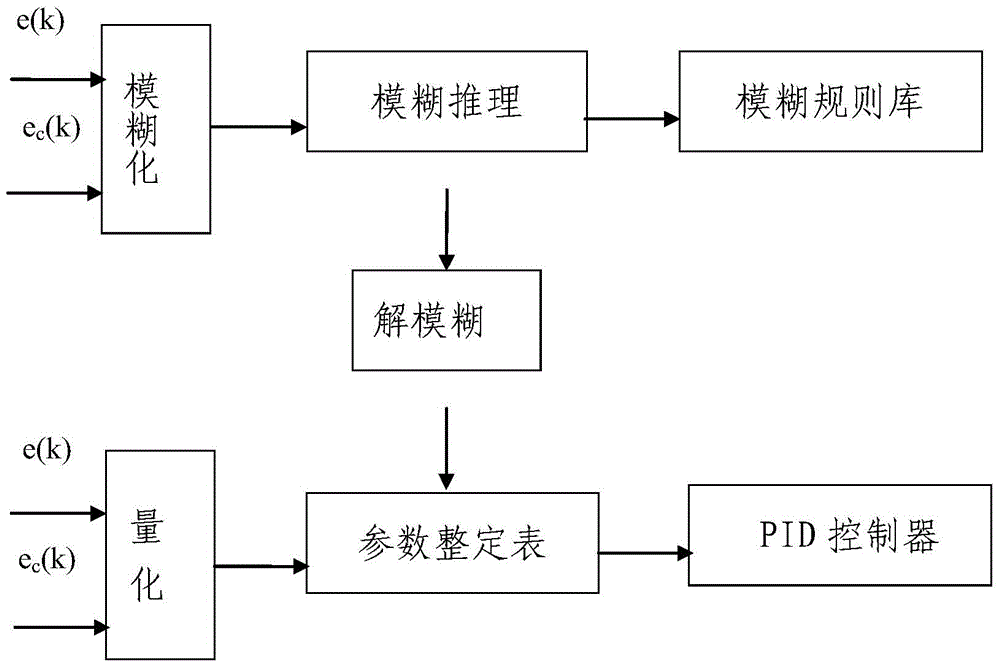

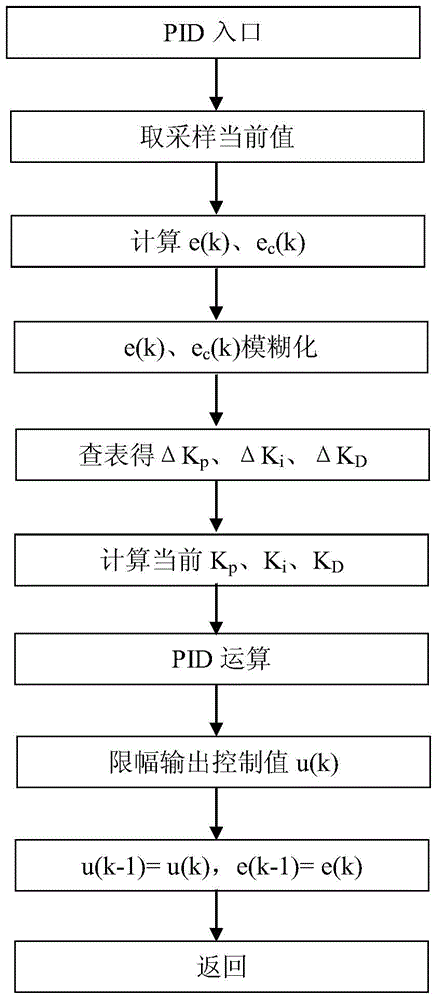

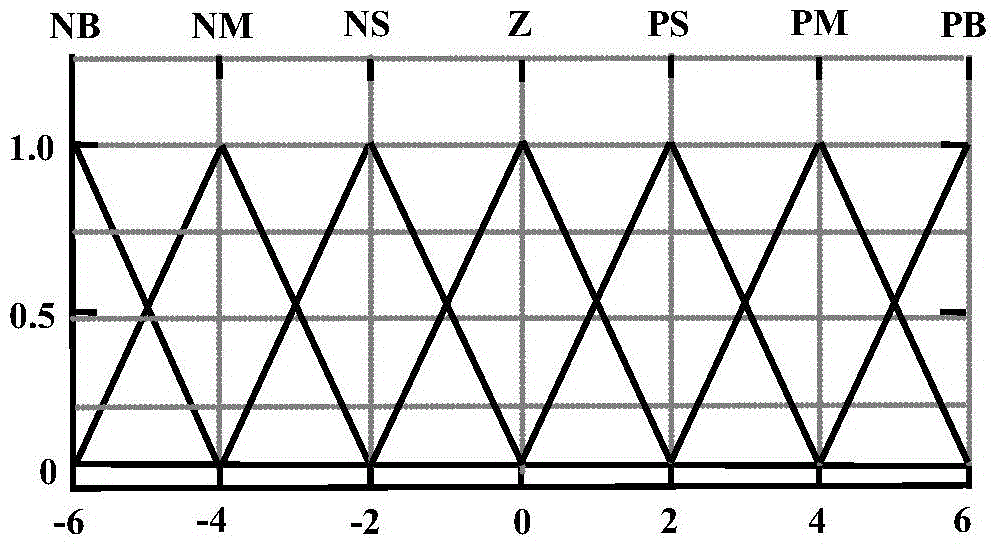

[0050] The temperature and humidity control algorithm of the dense barn controller of this embodiment adopts an optimized PID algorithm, and the precise control of temperature and humidity is realized by the controller; its controller includes a PID controller, a relay link and a fuzzy control for correcting PID parameters Three parts of the controller, among which: the PID controller completes the control algorithm and calculates the output control quantity; the relay link realizes the initial parameters of the PID controller; the fuzzy controller according to the deviation e and the deviation change rate e c , online real-time adjustment of PID parameter K P 、K i and K D , so that the PID controller has the ability of sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com