Galvanized bake hardening steel and production method thereof

A technology of bake hardening and production method, which is applied in hot dipping process, metal material coating process, coating and other directions, can solve the problems of not reaching the high strength of bake hardening steel, reducing product strength and increasing production cost. , to achieve the effect of reducing production cost, suitable yield strength and good bake hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

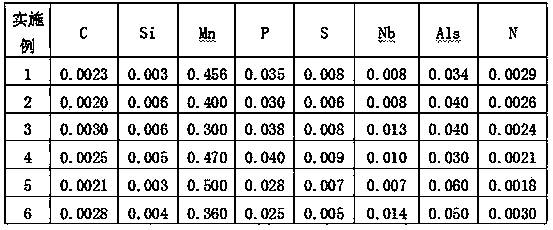

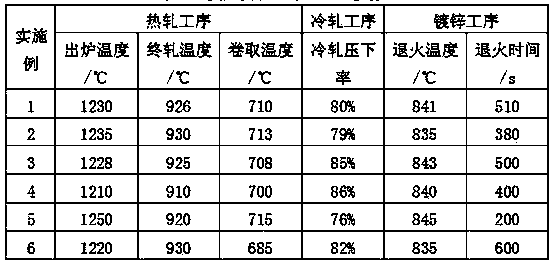

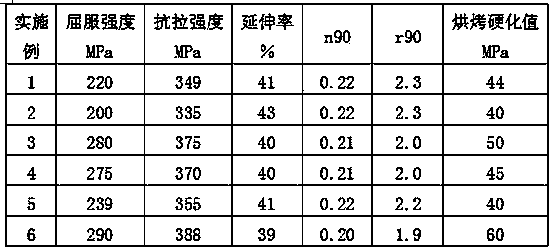

[0013] Embodiment 1-6: The galvanized bake hardened steel adopts the following composition ratio and process steps.

[0014] (1) Substrate component distribution ratio:

[0015] The galvanized bake hardening steel strictly controls the carbon and niobium alloy content of the substrate to ensure that the bake hardening value of the final product is between 38 and 60 MPa; and the carbon of the finished product is minimized to ensure deep drawing performance on the one hand, and on the other In terms of reducing the amount of Nb alloy added, reducing production costs. The addition of Si in the substrate can increase the strength of the product, but as its content increases, the surface of the steel sheet after annealing treatment is significantly enriched, the plateability of the steel sheet will decrease, and the surface of the steel sheet is prone to defects in plating. Therefore, the hardened steel substrate requires Si content Strictly control within the range of not more than 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com