Processing method for chemical-preventing fabric

A technology of anti-chemical and processing method, which is applied in the field of textile industry, can solve the problem of poor air permeability and moisture permeability, and cannot be processed to produce air-permeable anti-acid, anti-alkali, anti-solvent, anti-oil, waterproof, anti-chemical, which cannot be realized. Pure cotton or cotton fabric processing and other issues, to achieve the effect of improving color fastness, improving thickness and continuity, excellent air permeability and anti-chemical penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Preparation of 20 / 2×20 / 2 72×48 58 / 59 cotton canvas

[0044] A method for processing chemical-resistant fabrics, the method is carried out on the basis of gray fabrics woven with pure cotton yarns or polyester-cotton yarns, including blank inspection, seam turning, singeing, cold stacking, short steam washing, and dyeing Operation, also includes the following steps in the described method:

[0045] A. Open width washing

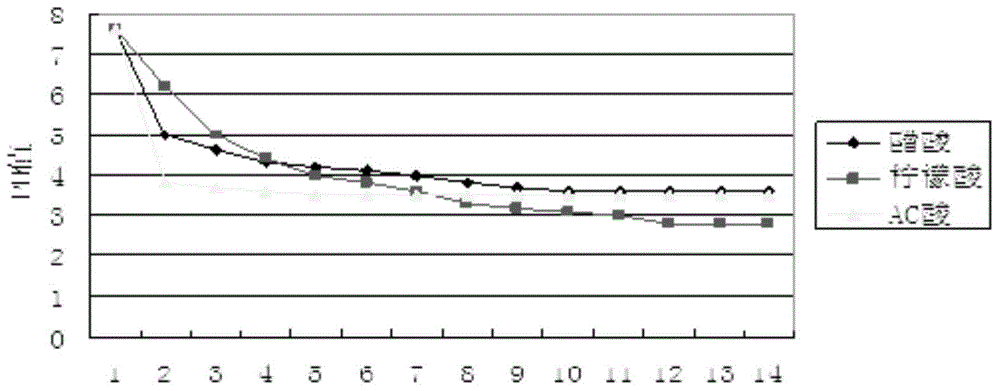

[0046] Arrange the dyed blanks on the open-width desizing machine for water washing. During the washing process, add cleaning agent KST 10g / L, control the speed of the machine at 60m / min, the excess rate of 60%, and control the washing temperature at 90°C. The temperature of the tank is normal temperature, and AC acid 3g / L is added when washing the last two washing tanks, so that the pH value of the washed cloth surface reaches 5.6, and the capillary effect is ≥9.7cm / min;

[0047] B. Anti-chemical finishing

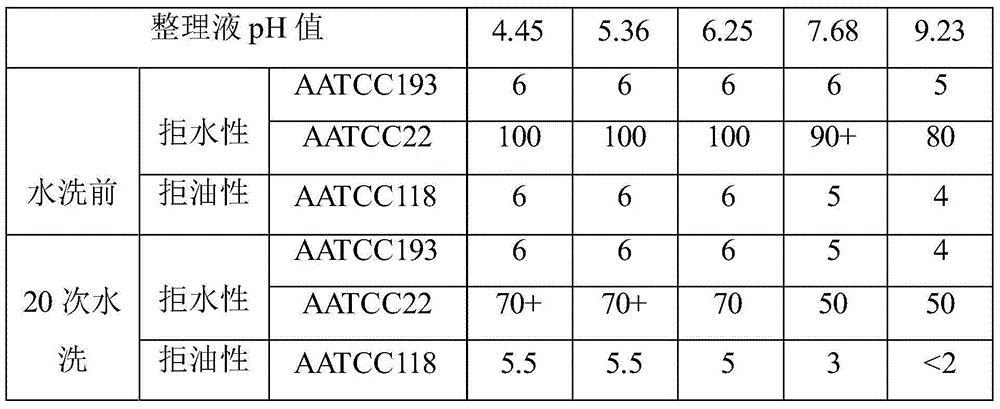

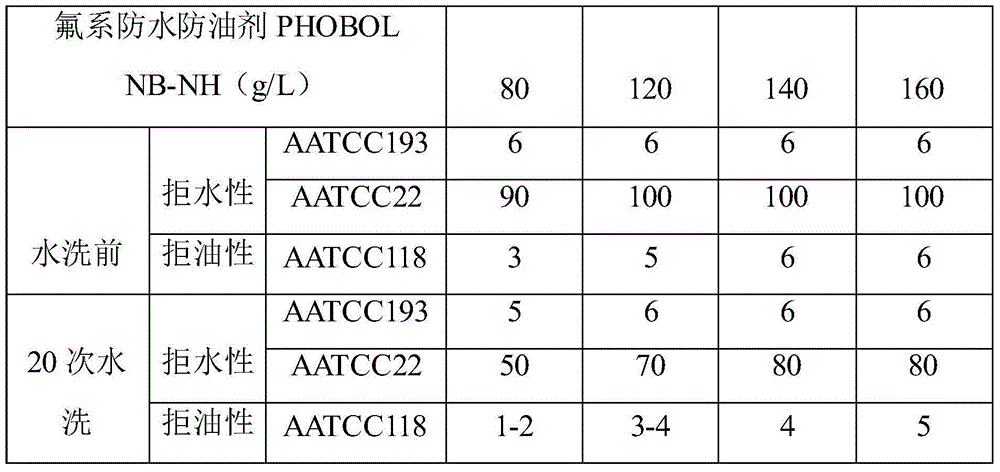

[0048] First, prepare a chemic...

Embodiment 2

[0054] Example 2: Preparation of T / C60 / 4032 / 2+A×32 / 2+A 100×53 58 / 59 CVC anti-static twill

[0055] A method for processing chemical-resistant fabrics, the method is carried out on the basis of gray fabrics woven with pure cotton yarns or polyester-cotton yarns, including blank inspection, seam turning, singeing, cold stacking, short steam washing, and dyeing Operation, also includes the following steps in the described method:

[0056] A. Open width washing

[0057] Arrange the dyed blanks on the open-width desizing machine for water washing. During the washing process, add cleaning agent KST 10g / L, control the speed of the machine to 70m / min, the excess rate of 67%, and control the washing temperature to 86°C. The temperature of the tank is normal temperature, and AC acid 2g / L is added when washing in the last two washing tanks, so that the pH value of the washed cloth surface reaches 5.8, and the capillary effect is ≥10.8cm / min;

[0058] B. Anti-chemical finishing

[0059...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com