Yarn drying oven

An oven and yarn technology, applied in the field of yarn ovens and yarn drying equipment, can solve the problems of uncontrollable air dispersion and flow, and achieve convenient baking time, high pass rate, and good baking uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

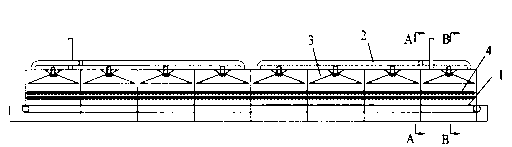

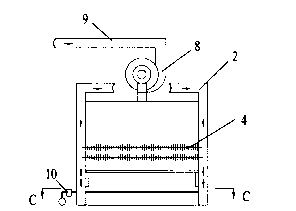

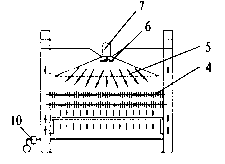

[0018] like Figure 1 to Figure 4 Shown, a kind of yarn oven comprises drying chamber 3, conveyer belt 1, heat exchanger 4, air collecting pipe 2, blower fan 8 and exhaust pipe 9, and drying chamber 3 is composed of a plurality of connected drying chambers Unit 3-1 is composed. The heat exchanger 4 is a finned heat exchanger, and steam is used as a heat source during operation. The conveyor belt 1 is located at the lower part of the yarn oven and passes through the drying chamber 3 , and the heat exchanger 4 is arranged at the upper part of the conveyor belt 1 and is located in the drying chamber 3 . The air collecting pipe 2 is located at both sides of the drying chamber 3, and the air collecting pipe 2 is connected with the exhaust pipe 9 through the fan 8 on the top of the drying chamber 3, and the outlet of the fan 8 is connected with the exhaust pipe 9. The blower fan 8 can be turned on according to actual needs, so as to facilitate the control of the drying effect. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com