Hot air heating bread maker

A technology of hot air heating and bread machine, which is applied in the baking workshop, roaster/barbecue grid, kitchen utensils, etc. It can solve the problems of burning wire, uneven baking color of bread skin, and lack of anti-dry function. To achieve excellent performance, improve the use of safety, ingenious design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

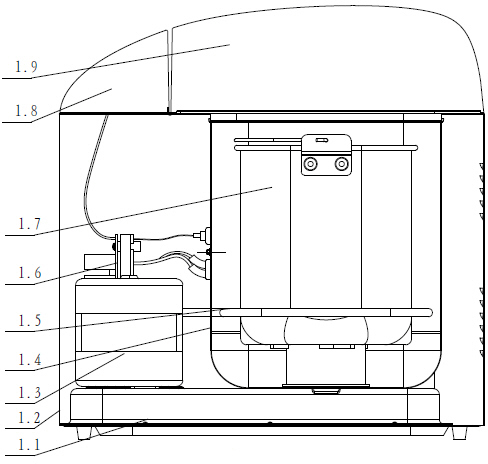

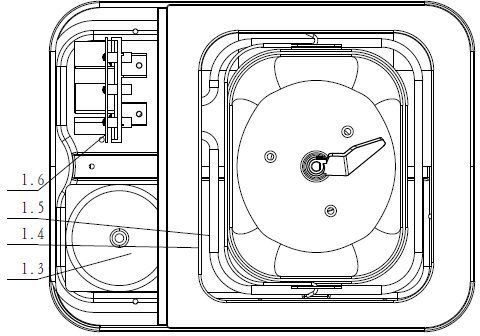

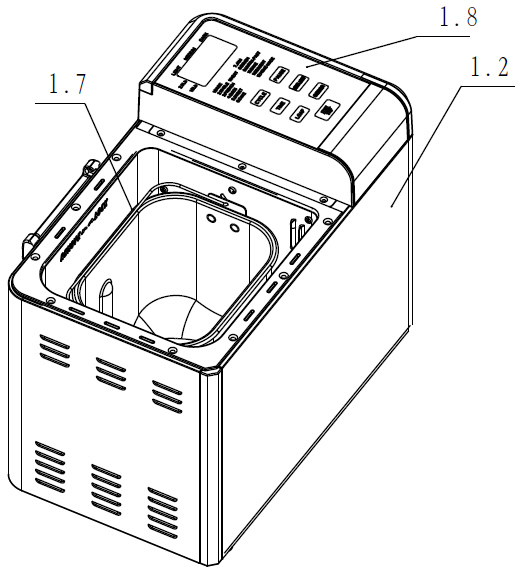

[0029] The structure diagram of the present invention is as image 3 , 4 , 5, and 6, the hot air heating bread machine of the present invention includes a shell 1.2, a baking chamber 1.4, a heating pipe 1.5, a bread barrel 1.7, a controller 1.8, and an upper cover 1.9, wherein the baking chamber 1.4 is arranged on the shell 1.2 In the set hollow cavity, the bread barrel 1.7 is set in the baking chamber 1.4, the top of the bread barrel 1.7 is equipped with a cover 1.9, the controller 1.8 is electrically connected with the heating pipe 1.5, and the outside of the baking chamber 1.4 is provided with a heating Room 2.3, heat pipe 1.5 is placed in the heating chamber 2.3, and the side of the heat pipe 1.5 is equipped with a centrifugal drive fan 2.4, the centrifugal drive fan 2.4 is installed on the output shaft of the drive motor 2.6, the controller 1.8 and the drive The motor 2.6 is electrically connected, and the side wall connecting the baking chamber 1.4 and the heating chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com