Efficient simplified wheat flour milling technology and efficient simplified wheat flour milling device

A high-efficiency, high-efficiency technology, applied in grain processing and other fields, can solve the problems of material temperature rise and sharp reduction of use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

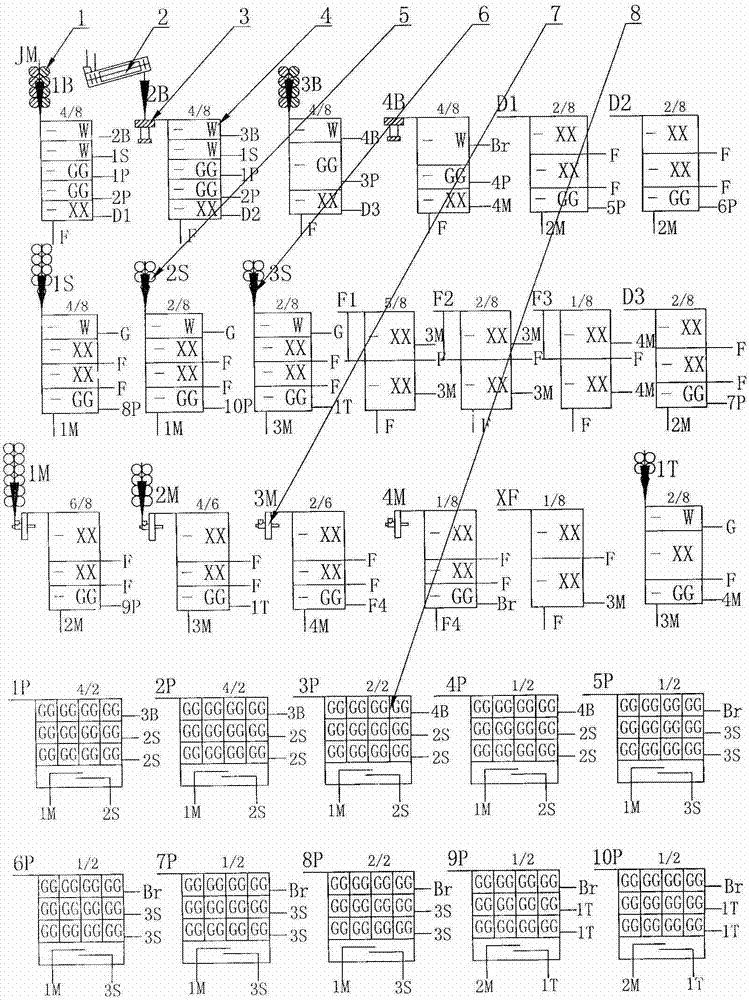

[0033] The invention provides an efficient and simplified wheat flour milling process, which includes a skin grinding process, a slag grinding process, a core grinding process, a tail grinding process and a powder cleaning process, and the skin grinding process is provided with 4 skin mills.

[0034] The second skin of the skin milling process adopts a crushing and cutting pulverizer; the minimum gap between the rotor pin and the stator pin of the squeezing and pulverizing machine is 1 to 2mm. The speed is 30m / s~70m / s.

[0035]The 2 skins of the skin milling process are provided with a water wetting process before crushing and processing by a crushing machine, the amount of water added is 0.5% to 2% (weight ratio, that is, the ratio of the amount of water added to the weight of the incoming material), and the water temperature is 0 ° C ~ 60°C, the wetting time is 1 minute to 5 minutes, and the operator controls the peeling and scraping rate of 2 skins after processing with a 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com